The Effect of Grain Orientation of β-Sn on Copper Pillar Solder Joints during Electromigration

Abstract

:1. Introduction

2. Experiment

3. Results

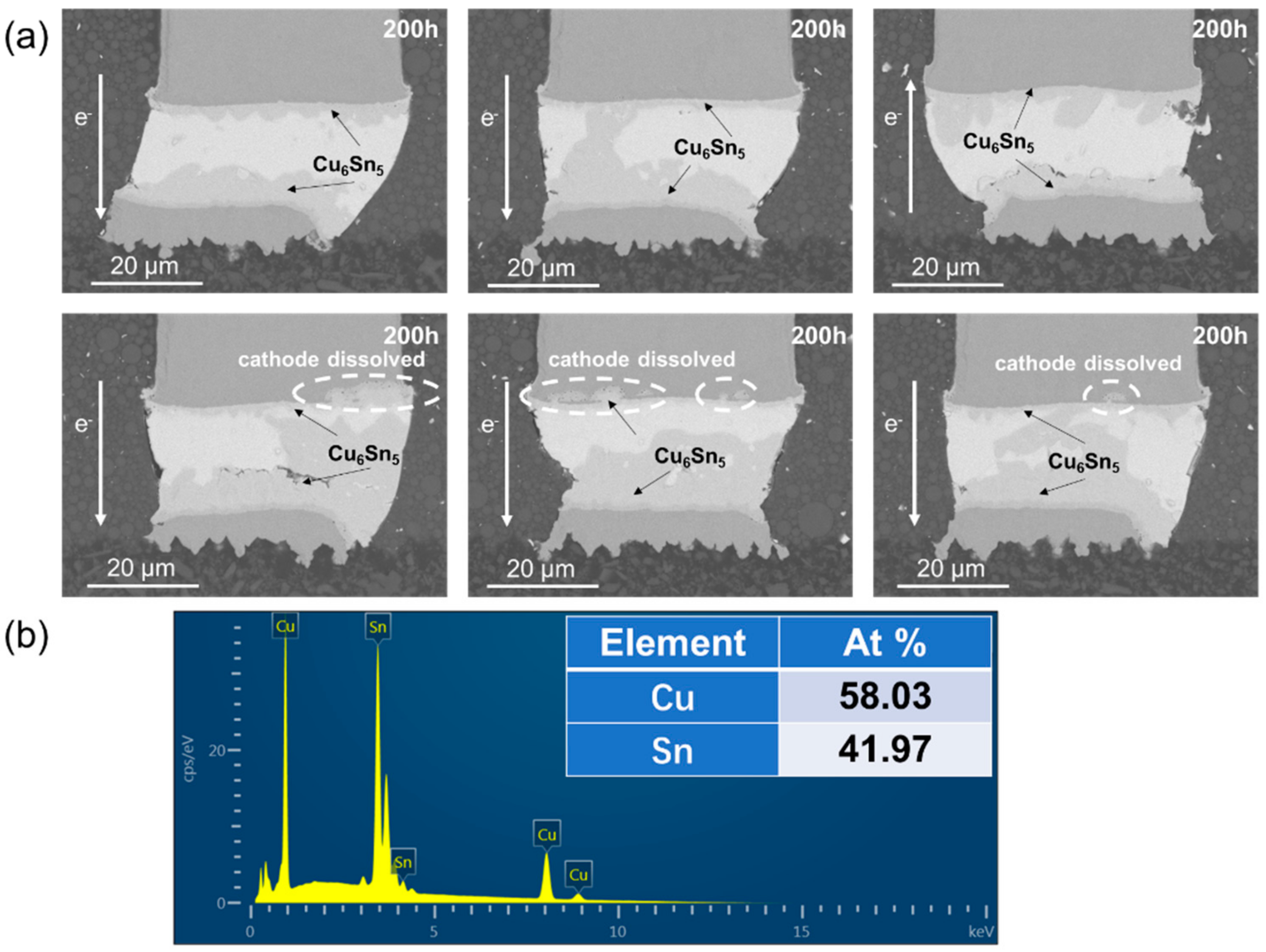

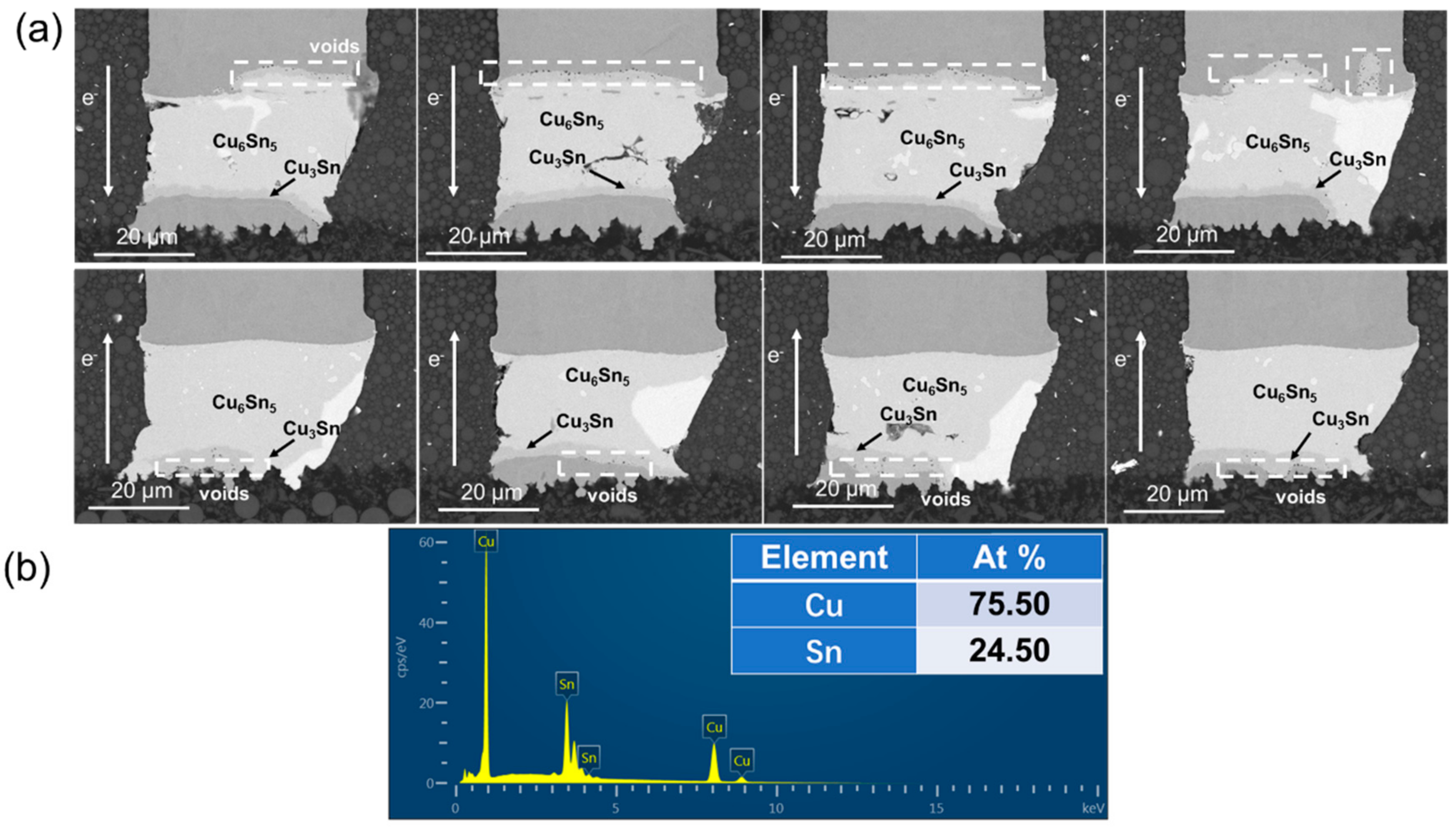

3.1. Microstructure Evolution of Cu Pillar after Electromigration Test

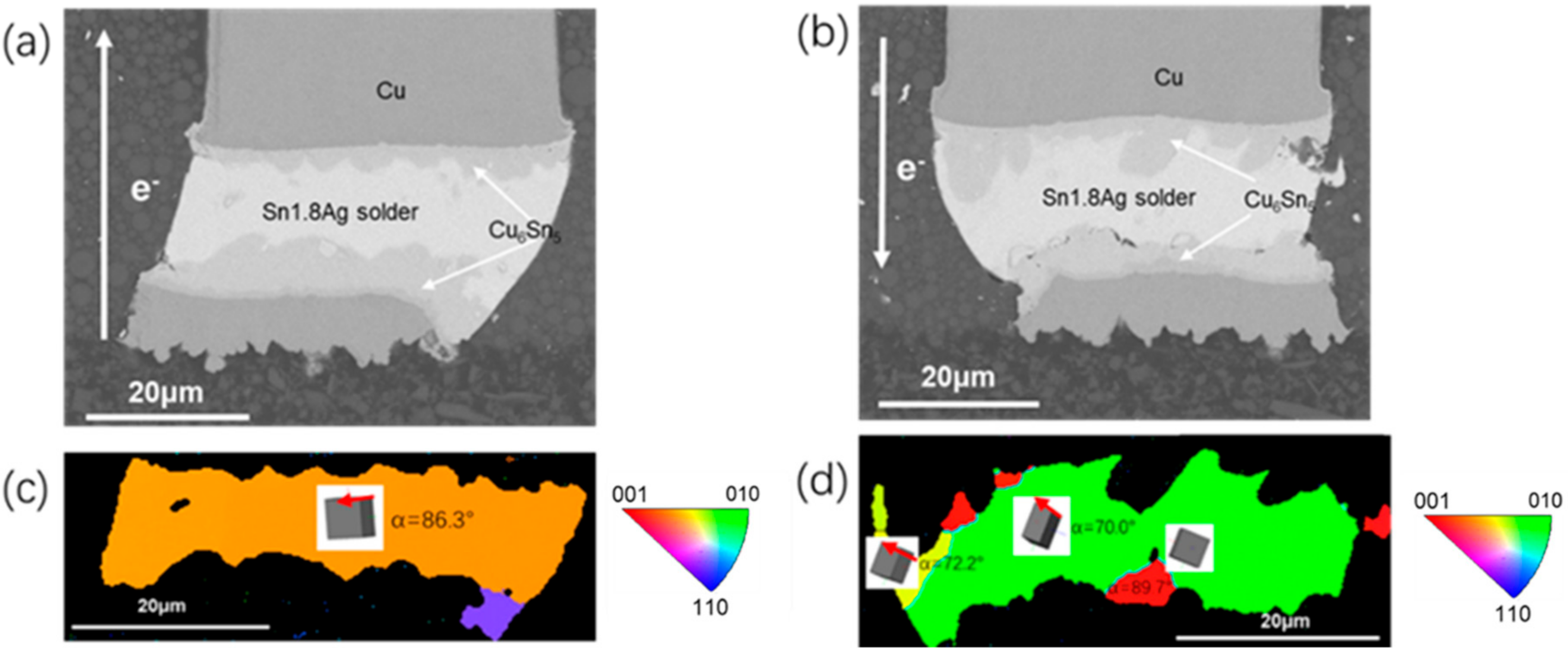

3.2. The Effect of Grain Orientation on Electromigration Damage

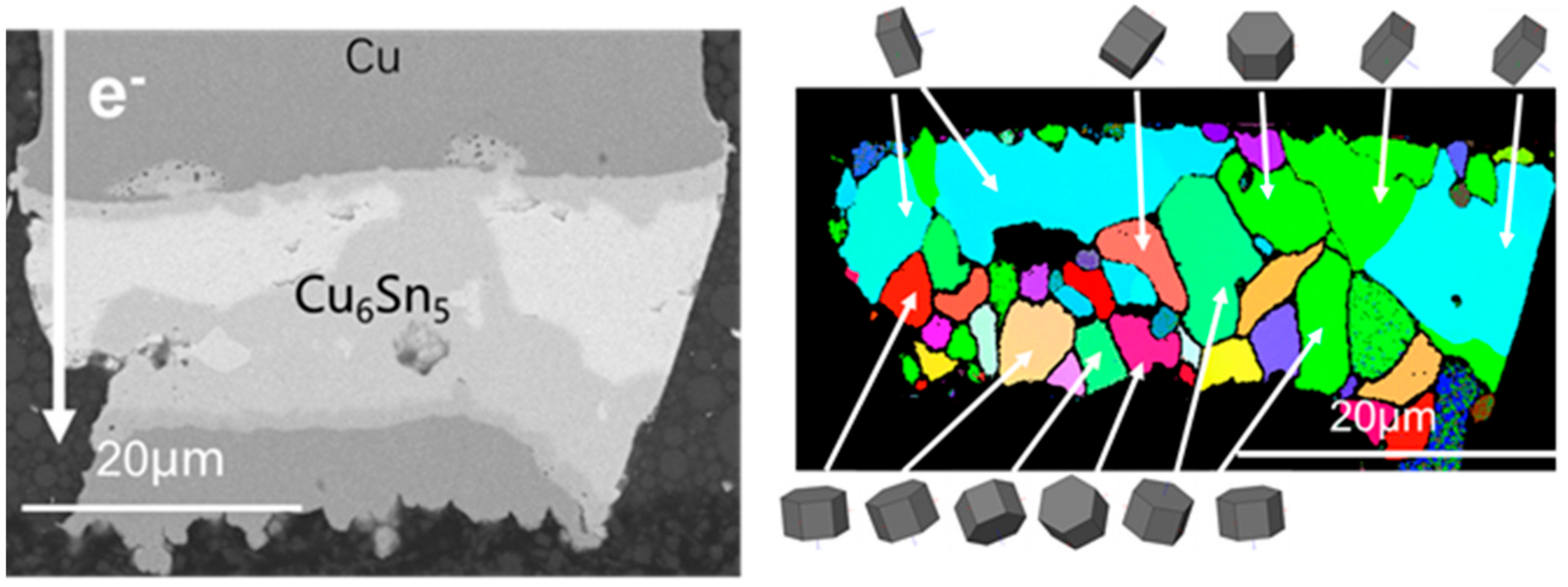

3.3. The Grain Structure of Cu6Sn5 during Electromigration

3.4. Microhardness and Elestic Modulus of IMCs in Copper Pillar Joint after Electromigration Test

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chaware, R.; Nagarajan, K.; Ramalingam, S. Assembly and Reliability Challenges in 3D Integration of 28 nm FPGA Die on a Large High Density 65 nm Passive Interposer. In Proceedings of the 2012 IEEE 62nd Electronic Components and Technology Conference, San Diego, CA, USA, 29 May–1 June 2012; pp. 279–283. [Google Scholar]

- Charbonnier, J.; Assous, M.; Bally, J.-P.; Miyairi, K.; Sunohara, M.; Cuchet, R.; Hida, R. High density 3D silicon interposer technology development and electrical characterization for high end applications. In Proceedings of the 2012 4th Electronic System-Integration Technology Conference, Amsterdam, The Netherlands, 17–20 September 2012; pp. 1–7. [Google Scholar]

- Kim, M.-S.; Kang, M.-S.; Bang, J.-H.; Lee, C.-W.; Kim, M.-S.; Yoo, S. Interfacial reactions of fine-pitch Cu/Sn–3.5Ag pillar joints on Cu/Zn and Cu/Ni under bump metallurgies. J. Alloys Compd. 2014, 616, 394–400. [Google Scholar] [CrossRef]

- Bao, A.; Zhao, L.; Sun, Y.; Han, M.; Yeap, G.; Bezuk, S.; Lee, K. Challenges and opportunities of chip package interaction with fine pitch Cu pillar for 28 nm. In Proceedings of the 2014 IEEE 64th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 27–30 May 2014; pp. 47–49. [Google Scholar]

- Tu, K.-N.; Hsiao, H.Y.; Chen, C. Transition from flip chip solder joint to 3D IC microbump: Its effect on microstructure anisotropy. Microelectron. Reliab. 2013, 53, 2–6. [Google Scholar] [CrossRef]

- Hsu, H.H.; Huang, Y.T.; Huang, S.Y.; Chang, T.C.; Wu, A.T. Evolution of the Intermetallic Compounds in Ni/Sn-2.5Ag/Ni Microbumps for Three-Dimensional Integrated Circuits. J. Electron. Mater. 2015, 44, 3888–3895. [Google Scholar] [CrossRef]

- Liu, Y.; Chu, Y.C.; Tu, K.-N. Scaling effect of interfacial reaction on intermetallic compound formation in Sn/Cu pillar down to 1 μm diameter. Acta Mater. 2016, 117, 146–152. [Google Scholar] [CrossRef]

- Lee, K.; Kim, K.-S.; Tsukada, Y.; Suganuma, K.; Yamanaka, K.; Kuritani, S.; Ueshima, M. Influence of crystallographic orientation of Sn–Ag–Cu on electromigration in flip-chip joint. Microelectron. Reliab. 2011, 51, 2290–2297. [Google Scholar] [CrossRef]

- Li, X.P.; Xia, J.M.; Zhou, M.B.; Ma, X.; Zhang, X.P. Solder Volume Effects on the Microstructure Evolution and Shear Fracture Behavior of Ball Grid Array Structure Sn-3.0Ag-0.5Cu Solder Interconnects. J. Electron. Mater. 2011, 40, 2425–2435. [Google Scholar] [CrossRef]

- Jung, Y.; Yu, J. Electromigration induced Kirkendall void growth in Sn-3.5Ag/Cu solder joints. J. Appl. Phys. 2014, 115, 83708. [Google Scholar] [CrossRef] [Green Version]

- Huang, M.L.; Zhao, J.F.; Zhang, Z.J.; Zhao, N. Role of diffusion anisotropy in β-Sn in microstructural evolution of Sn-3.0Ag-0.5Cu flip chip bumps undergoing electromigration. Acta Mater. 2015, 100, 98–106. [Google Scholar] [CrossRef]

- Suh, D.; Kim, D.W.; Liu, P. Effects of Ag content on fracture resistance of Sn–Ag–Cu lead-free solders under high-strain rate conditions. Mater. Sci. Eng. A 2007, 460, 595–603. [Google Scholar] [CrossRef]

- Anderson, I.E.; Foley, J.C.; Cook, B.A. Alloying effects in near-eutectic Sn-Ag-Cu solder alloys for improved microstructural stability. J. Electron. Mater. 2001, 30, 1050–1059. [Google Scholar] [CrossRef]

- Kim, K.S.; Huh, S.H.; Suganuma, K. Effects of fourth alloying additive on microstructures and tensile properties of Sn–Ag–Cu alloy and joints with Cu. Microelectron. Reliab. 2003, 43, 259–267. [Google Scholar] [CrossRef]

- Chen, H.; Hang, C.; Fu, X.; Li, M. Microstructure and Grain Orientation Evolution in Sn-3.0Ag-0.5Cu Solder Interconnects Under Electrical Current Stressing. J. Electron. Mater. 2015, 44, 3880–3887. [Google Scholar] [CrossRef]

- Fu, X.; Liu, M.; Xu, K.; Chen, S.; Shi, Y.; Fu, Z.; Yao, R. The In-Situ Observation of Grain Rotation and Microstructure Evolution Induced by Electromigration in Sn-3.0Ag-0.5Cu Solder Joints. Materials 2020, 13, 5497. [Google Scholar] [CrossRef] [PubMed]

- Lu, M.; Shih, D.-Y.; Lauro, P.; Goldsmith, C.; Henderson, D.W. Effect of Sn grain orientation on electromigration degradation mechanism in high Sn-based Pb-free solders. Appl. Phys. Lett. 2008, 92, 211909. [Google Scholar] [CrossRef]

- Shen, Y.A.; Chen, C. Effect of Sn grain orientation on formation of Cu6Sn5 intermetallic compounds during electromigration. Scr. Mater. 2017, 128, 6–9. [Google Scholar] [CrossRef]

- Huang, M.L.; Zhao, J.F.; Zhang, Z.J.; Zhao, N. Dominant effect of high anisotropy in β-Sn grain on electromigration-induced failure mechanism in Sn-3.0Ag-0.5Cu interconnect. J. Alloys Compd. 2016, 678, 370–374. [Google Scholar] [CrossRef]

- Han, J.; Guo, F. Nucleation and electromigration-induced grain rotation in an SABI333 solder joint. J. Mater. Sci. 2018, 53, 6230–6238. [Google Scholar] [CrossRef]

- Dyson, B.F.; Anthony, T.R.; Turnbull, D. Interstitial Diffusion of Copper in Tin. J. Appl. Phys. 1967, 38, 3408. [Google Scholar] [CrossRef]

- Tu, K.-N. Interdiffusion and Reaction in Bimetallic Cu-Sn Thin Films. Acta Metall. 1973, 21, 347–354. [Google Scholar] [CrossRef]

- Yeh, D.C.; Huntington, H.B. Extreme Fast-Diffusion System: Nickel in Single-Crystal Tin. Phys. Rev. Lett. 1984, 53, 1469–1472. [Google Scholar] [CrossRef]

- Feng, J.; Hang, C.; Tian, Y.; Wang, C.; Liu, B. Effect of electric current on grain orientation and mechanical properties of Cu-Sn intermetallic compounds joints. J. Alloys Compd. 2018, 753, 203–211. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Deng, X.; Chawla, N.; Chawla, K.K.; Koopman, M. Deformation behavior of (Cu, Ag)–Sn intermetallics by nanoindentation. Acta Mater. 2004, 52, 4291–4303. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, K.; Fu, X.; Wang, X.; Fu, Z.; Yang, X.; Chen, S.; Shi, Y.; Huang, Y.; Chen, H. The Effect of Grain Orientation of β-Sn on Copper Pillar Solder Joints during Electromigration. Materials 2022, 15, 108. https://doi.org/10.3390/ma15010108

Xu K, Fu X, Wang X, Fu Z, Yang X, Chen S, Shi Y, Huang Y, Chen H. The Effect of Grain Orientation of β-Sn on Copper Pillar Solder Joints during Electromigration. Materials. 2022; 15(1):108. https://doi.org/10.3390/ma15010108

Chicago/Turabian StyleXu, Kexin, Xing Fu, Xinjie Wang, Zhiwei Fu, Xiaofeng Yang, Si Chen, Yijun Shi, Yun Huang, and Hongtao Chen. 2022. "The Effect of Grain Orientation of β-Sn on Copper Pillar Solder Joints during Electromigration" Materials 15, no. 1: 108. https://doi.org/10.3390/ma15010108

APA StyleXu, K., Fu, X., Wang, X., Fu, Z., Yang, X., Chen, S., Shi, Y., Huang, Y., & Chen, H. (2022). The Effect of Grain Orientation of β-Sn on Copper Pillar Solder Joints during Electromigration. Materials, 15(1), 108. https://doi.org/10.3390/ma15010108