Fundamental Studies on CO2 Sequestration of Concrete Slurry Water Using Supercritical CO2

Abstract

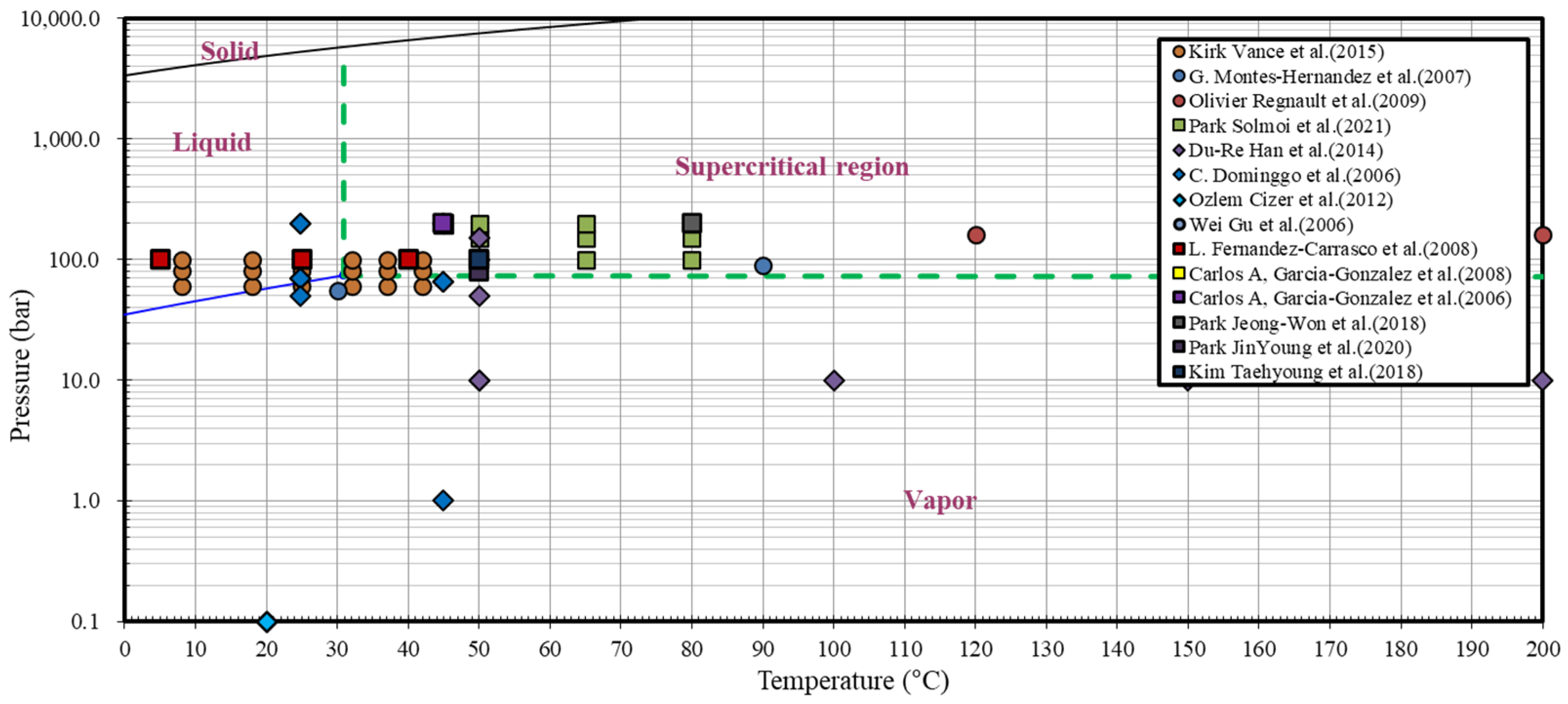

:1. Introduction

2. Experimental

2.1. Materials

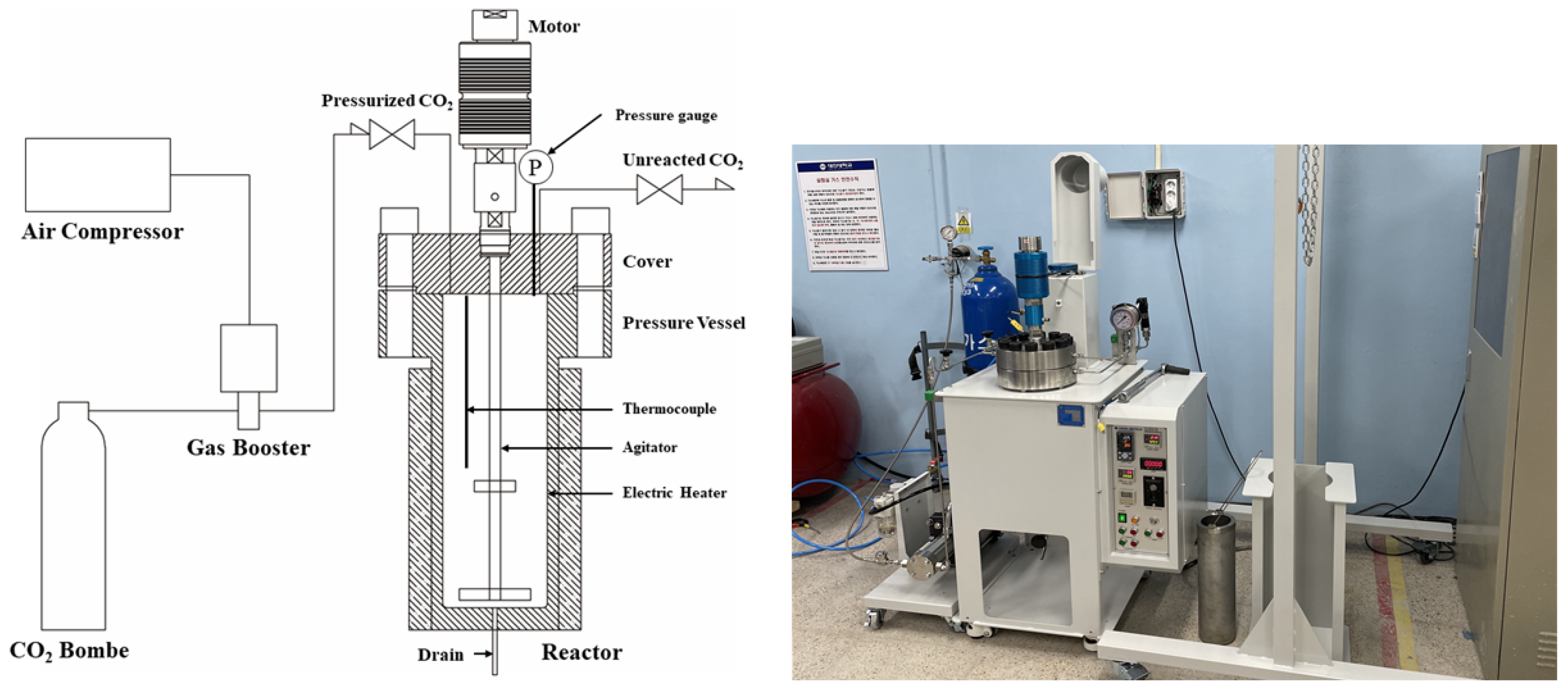

2.2. Supercritical CO2 Reactor

2.3. Supercritical CO2 Carbonation

- The sample diluted with supernatant water and concrete slurry waste is added to the reactor, which is then assembled. The concrete slurry water used in this study is shown in Figure 4.

- The electric heater is powered on. Once the reactor vessel reaches the target temperature, CO2 is injected until the desired pressure is achieved.

- Once the CO2 inside the vessel reaches the target pressure, the agitator is operated at 200 rpm to perform accelerated carbonation over the specified reaction time, while maintaining the temperature and pressure.

- After the specified reaction time has elapsed, CO2 is released, the reactor is disassembled, and the sample is retrieved.

- The supernatant water and concrete slurry waste are separated from the sample. The concrete slurry waste is dried at 105 °C until it reaches a constant weight.

- SEM (Philips XL30 ESEM, Eindhoven, The Netherlands), XRD (Rigaku D/max 2200+ Ultima, Tokyo, Japan), and TG–DTA (Hitachi STA 7300, Tokyo, Japan) characterizations and pH (Hanna Instruments HI2215, Woonsocket, RI, USA) measurements are conducted on the dehydrated concrete slurry waste to determine the degree of carbonation reaction.

2.4. Chemical Analysis

3. Results

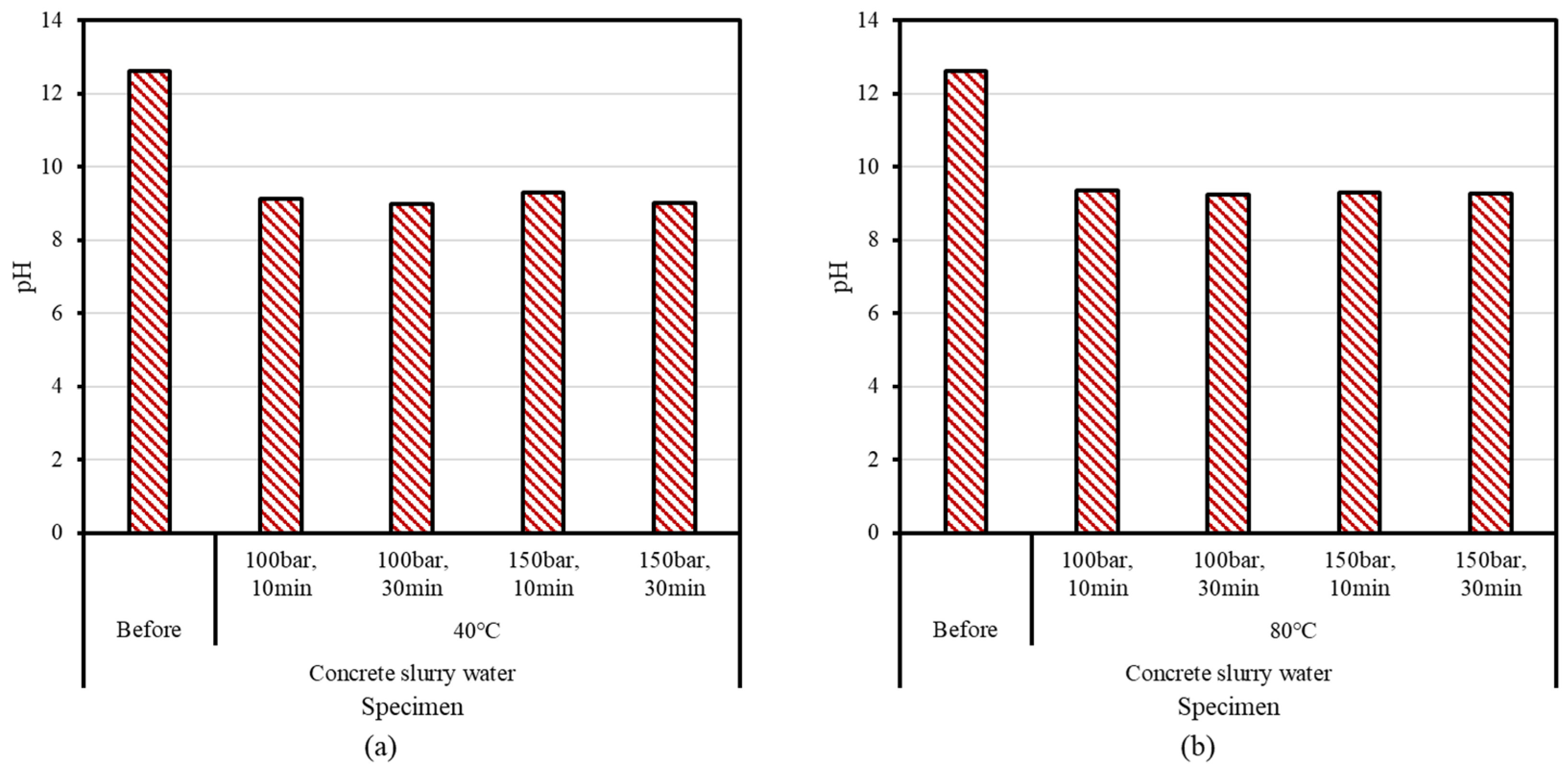

3.1. PH Measurement

3.2. SEM

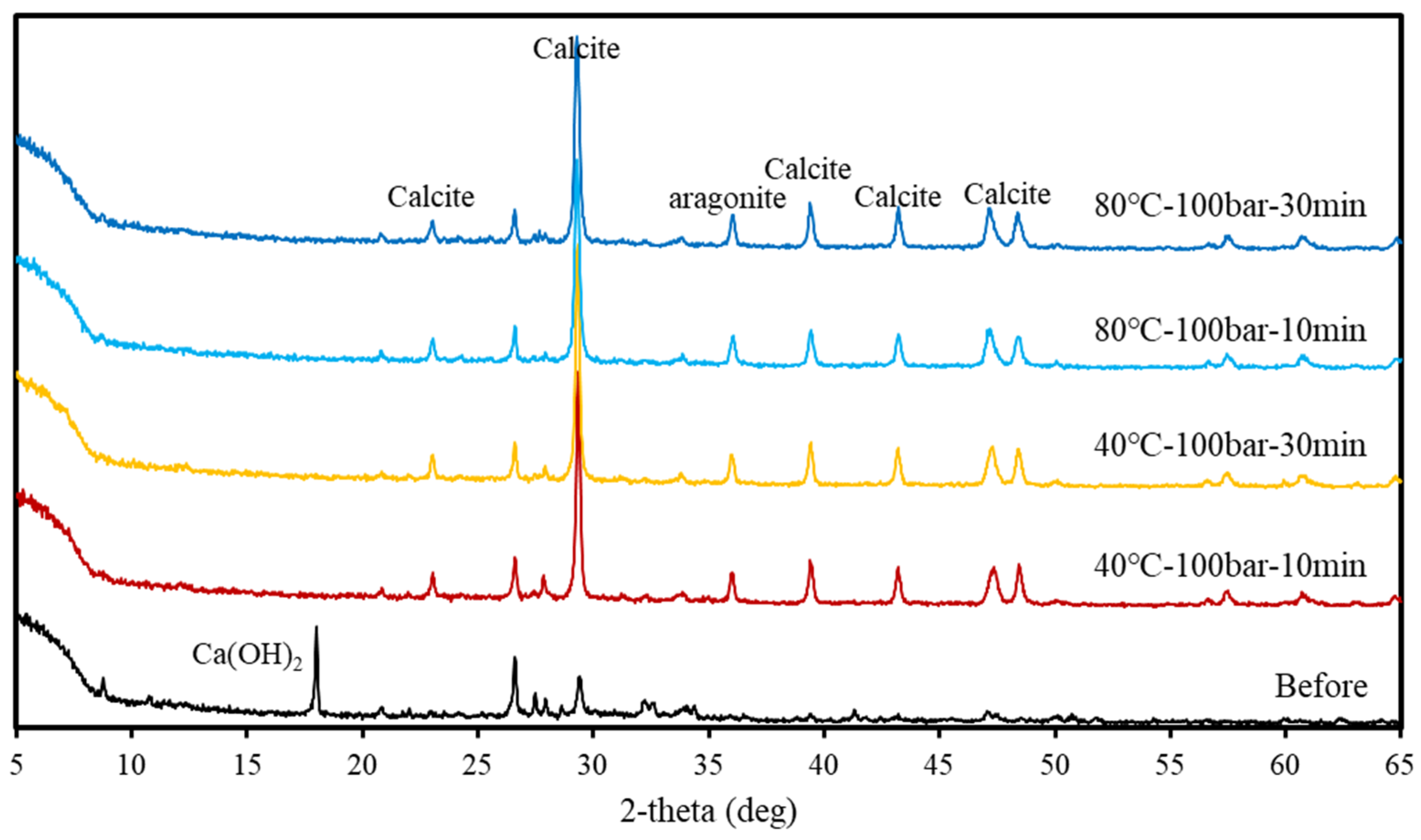

3.3. XRD Measurement Results

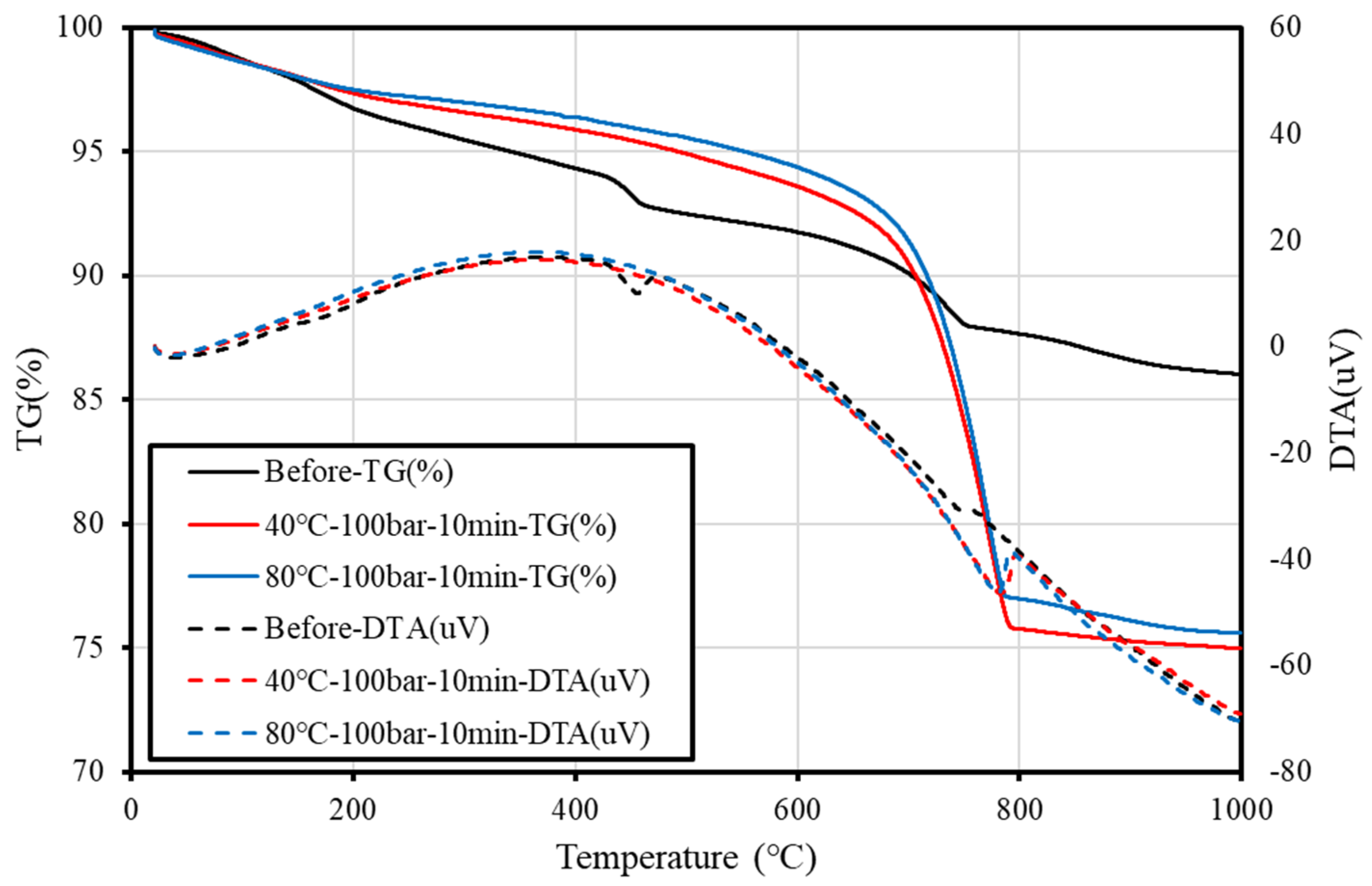

3.4. TG–DTA Measurement Results

4. Conclusions

- For supernatant water under supercritical CO2 conditions, reaction products could not be confirmed due to Ca(HCO3)2 existing as an aqueous solution in the presence of an excess amount of injected CO2. However, since the reaction is reversible, CaCO3 can precipitate from aqueous Ca(HCO3)2 over time at room temperature, along with the release of CO2 gas; hence, further research is necessary.

- Mineral carbonation of concrete slurry water by supercritical CO2 demonstrated that complete carbonation can be achieved in only 10 min of reaction at a sludge solids content of 5%. However, the reaction seemed to be independent of the supercritical CO2 temperature and pressure at 5% sludge solids content. Further investigation on the change in the reaction with respect to sludge solids content is to be performed.

- In future studies, quantitative analyses on supercritical CO2 carbonation (optimal temperature, pressure, and reaction time) and CO2 storage capacity with respect to sludge solids content will be conducted.

- Collating the results, it is possible to fix CO2 via supercritical CO2 carbonation, and the implementation of a new CO2 fixation source with concrete slurry water is considered viable. The implementation of supercritical CO2 mineral carbonation technology using concrete slurry water will enable carbon-neutrality to be achieved by reducing greenhouse gas emissions from not only cement industries, but all industrial sectors.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Behera, M.; Bhattacharyya, S.K.; Minocha, A.K.; Deoliya, R.; Maiti, S. Recycled aggregate from C&D waste & its use in concrete—A breakthrough towards sustainability in construction sector: A review. Constr. Build. Mater. 2014, 56, 501–516. [Google Scholar]

- Xuan, D.; Zhan, B.; Poon, C.S.; Zheng, W. Innovative reuse of concrete slurry waste from ready-mixed concrete plants in construction products. J. Hazard. Mater. 2016, 312, 65–72. [Google Scholar] [CrossRef] [PubMed]

- Cement Production in the United States and Worldwide from 2010 to 2020. Available online: https://www.statista.com/statistics/219343/cement-production-worldwide/ (accessed on 1 September 2021).

- United Nations. World Population Prospects 2019; United Nations: New York, NY, USA, 2019. [Google Scholar]

- Haas, W.; Krausmann, F.; Wiedenhofer, D.; Heinz, M. How circular is the global economy? An assessment of material flows, waste production, and recycling in the European Union and the world in 2005. J. Ind. Ecol. 2015, 19, 765–777. [Google Scholar] [CrossRef]

- Papi, J.A.F. Recycling of fresh concrete exceeding and wash water in concrete mixing plants. Mater. Constr. 2014, 64, 004. [Google Scholar]

- Andersson, R.; Stripple, H.; Gustafsson, T.; Ljungkrantz, C. Carbonation as a method to improve climate performance for cement based material. Cem. Concr. Res. 2019, 124, 105819. [Google Scholar] [CrossRef]

- Izumi, Y.; Lizuka, A.; Ho, H.J. Calculation of greenhouse gas emissions for a carbon recycling system using mineral carbon capture and utilization technology in the cement industry. J. Clean. Prod. 2021, 312, 127618. [Google Scholar] [CrossRef]

- Miler, S.A.; Habert, G.; Myers, R.J.; Harver, J.T. Achieving net zero greenhouse gas emission in the cement industry via value chain mitigation strategies. One Earth 2021, 4, 1398–1411. [Google Scholar] [CrossRef]

- IPCC. Climate Change 2007: The Physical Science Basis. In Fourth Assessment Report; IPCC Secretariat: Geneva, Switzerland, 2007. [Google Scholar]

- Alcalde, J.; Stephanie, S.; Wilkinson, M.; Johnson, G.; Edlmann, K.; Bond, C.E.; Scott, V.; Gilfillan, S.M.V.; Ogaya, X.; Haszeldin, R.S. Estimating geological CO2 storage security to deliver on climate mitigation. Nat. Commun. 2018, 9, 2201. [Google Scholar] [CrossRef] [PubMed]

- Han, D.R.; Namkung, H.; Lee, H.M.; Huh, D.G.; Kim, H.T. CO2 sequestration by aqueous mineral carbonation of limestone in a supercritical reactor. J. Ind. Eng. Chem. 2015, 21, 792–796. [Google Scholar] [CrossRef]

- Vance, K.; Falzone, G.; Pignatelli, I.; Bauchy, M.; Balonis, M.; Sant, G. Direct Carbonation of Ca(OH)2 Using Liquid and Supercritical CO2: Implications for Carbon-Neutral Cementation. Ind. Eng. Chem. Res. 2015, 51, 8908–8918. [Google Scholar] [CrossRef]

- Montes-Hernandez, G.; Renard, F.; Geoffroy, N.; Charlet, L.; Pironon, J. Calcite precipitation from CO2-H2O-Ca(OH)2 slurry under high pressure of CO2. J. Cryst. Growth 2007, 308, 228–236. [Google Scholar] [CrossRef] [Green Version]

- Regnault, O.; Lagneau, V.; Schneider, H. Experimental measurement of portlandite carbonation kinetics with supercritical CO2. Chem. Geol. 2009, 265, 113–121. [Google Scholar] [CrossRef]

- Gu, W.; Bousfield, D.W.; Tripp, C.P. Formation of calcium carbonate particles by direct contact of Ca(OH)2 powders with supercritical CO2. J. Mater. Chem. 2006, 16, 3312–3317. [Google Scholar] [CrossRef]

- Park, S.M.; Moon, H.; Kim, J.H.; Lee, M.H.; Chung, C.W. Reaction of hydrated cement paste with supercritical carbon dioxide. Constr. Build. Mater. 2021, 281, 122615–122622. [Google Scholar] [CrossRef]

- Fernandez-Carrasco, L.; Rius, J.; Miravitlles, C. Supercritical carbonation of calcium aluminate cement. Cem. Concr. Res. 2008, 38, 1033–1037. [Google Scholar] [CrossRef]

- Garcia-Gonzalez, C.A.; Hidalgo, A.; Andrade, C.; Alonso, M.C.; Frail, J.; Lopez-Periago, A.M.; Domingo, C. Modification of Composition and Microstructure of Portland Cement Pastes as a Result of Natural and Supercritical Carbonation Procedures. Ind. Eng. Chem. Res. 2006, 45, 4985–4992. [Google Scholar] [CrossRef]

- Garcia-Gonzalez, C.A.; Grouh, N.E.; Hidalgo, A.; Fraile, J.; Lopez-Periago, A.M.; Andrade, C.; Dominggo, C. New insights on the use of supercritical carbon dioxide for the accelerated carbonation of cement pastes. J. Supercrit. Fluids 2008, 43, 500–509. [Google Scholar] [CrossRef]

- Domingo, C.; Loste, E.; Gomez-Morales, J.; Garcia-Carmona, J.; Fraile, J. Calcite precipitation by a high-pressure CO2 carbonation route. J. Supercrit. Fluids 2006, 36, 202–215. [Google Scholar] [CrossRef]

- Lizuka, A.; Sasaki, T.; Honma, M.; Yoshida, H.; Hayakawa, Y.; Yanagisawa, Y.; Yamasaki, A. Pilot-scale operation of a concrete sludge recycling plant and simultaneous production of calcium carbonate. Chem. Eng. Commun. 2017, 204, 79–85. [Google Scholar]

- Lagrega, M.D.; Buckingham, P.L.; Evans, J.C.; McGraw, H. Hazardous Waste Management, 2nd ed.; Waveland Press: Long Grove, IL, USA, 2010. [Google Scholar]

- Tsimas, S.; Zervaki, M. Reuse of waste water from ready-mixed concrete plants. Manag. Environ. Qual. Int. J. 2011, 22, 7–17. [Google Scholar] [CrossRef]

- Sandrolini, F.; Franzoni, E. Waste wash water recycling in ready-mixed concrete plants. Cem. Concr. Res. 2001, 31, 485–489. [Google Scholar] [CrossRef]

- Charveera, B.; Lertwattanaruk, P.; Makul, N. Effect of sludge water from ready-mixed concrete plant on properties and durability of concrete. Cem. Concr. Compos. 2006, 28, 441–450. [Google Scholar] [CrossRef]

- Korea Concrete Institute. New Concrete Engineering; Kimoondang: Seoul, Korea, 2005. [Google Scholar]

- Zhao, D.F.; Buchholz, A.; Mentel, T.F.; Muller, K.P.; Borchardt, J.; Kiendler-Scharr, A.; Spindler, C.; Tillmann, R.; Trimborn, A.; Zhu, T.; et al. Novel method of generation of Ca(HCO3)2 and CaCO3 aerosols and first determination of hygroscopic and cloud condensation nuclei activation properties. Atmos. Chem. Phys. 2010, 10, 8009–8049. [Google Scholar] [CrossRef] [Green Version]

- Fairchild, I.J.; Smith, C.L.; Baker, A.; Fuller, L.; Spötl, C.; Mattey, D.; McDermott, F. Modification and preservation of environmental signals in speleothems. Earth-Sci. Rev. 2006, 75, 105–153. [Google Scholar] [CrossRef] [Green Version]

- Saulat, H.; Cao, M.; Khan, M.M.; Khan, M.; Khan, M.M.; Rehman, A. Preparation and applications of calcium carbonate whisker with a special focus on construction materials. Constr. Build. Mater. 2020, 236, 117613. [Google Scholar] [CrossRef]

| Chemical Composition (mg/L) | ||||

|---|---|---|---|---|

| Ca | Mg | Na | Fe | K |

| 812 | 0 | 242 | 0 | 711 |

| Chemical Composition (wt.%) | |||||||

|---|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | SO3 | MgO | Fe2O3 | K2O | TiO2 |

| 29.69 | 23.82 | 5.15 | 2.11 | 1.94 | 2.58 | 0.93 | 0.39 |

| Specimens | Amount of Ca(OH)2 (%) | Amount of CaCO3 (%) |

|---|---|---|

| Before | 1.11 | 2.79 |

| 40 °C-100 bar-10 min | 0 | 15.94 |

| 80 °C-100 bar-10 min | 0 | 15.55 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sim, S.-R.; Ryu, D.-W. Fundamental Studies on CO2 Sequestration of Concrete Slurry Water Using Supercritical CO2. Materials 2022, 15, 94. https://doi.org/10.3390/ma15010094

Sim S-R, Ryu D-W. Fundamental Studies on CO2 Sequestration of Concrete Slurry Water Using Supercritical CO2. Materials. 2022; 15(1):94. https://doi.org/10.3390/ma15010094

Chicago/Turabian StyleSim, Sang-Rak, and Dong-Woo Ryu. 2022. "Fundamental Studies on CO2 Sequestration of Concrete Slurry Water Using Supercritical CO2" Materials 15, no. 1: 94. https://doi.org/10.3390/ma15010094

APA StyleSim, S.-R., & Ryu, D.-W. (2022). Fundamental Studies on CO2 Sequestration of Concrete Slurry Water Using Supercritical CO2. Materials, 15(1), 94. https://doi.org/10.3390/ma15010094