Effect of Magnesium Powder Application on the Microstructure and Properties of Rods Extruded by the Forward-Backward Rotating Die Extrusion Method

Abstract

:1. Introduction

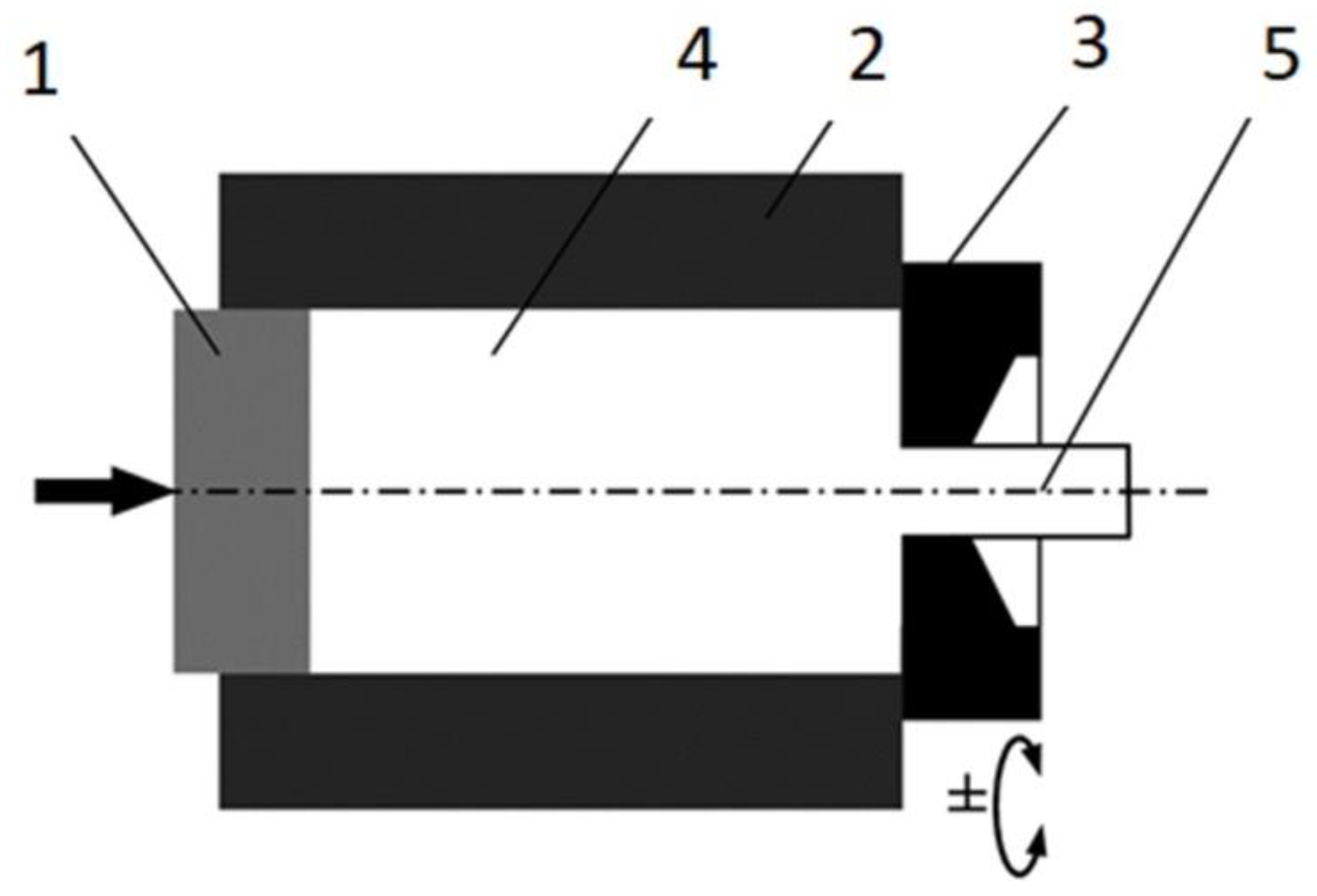

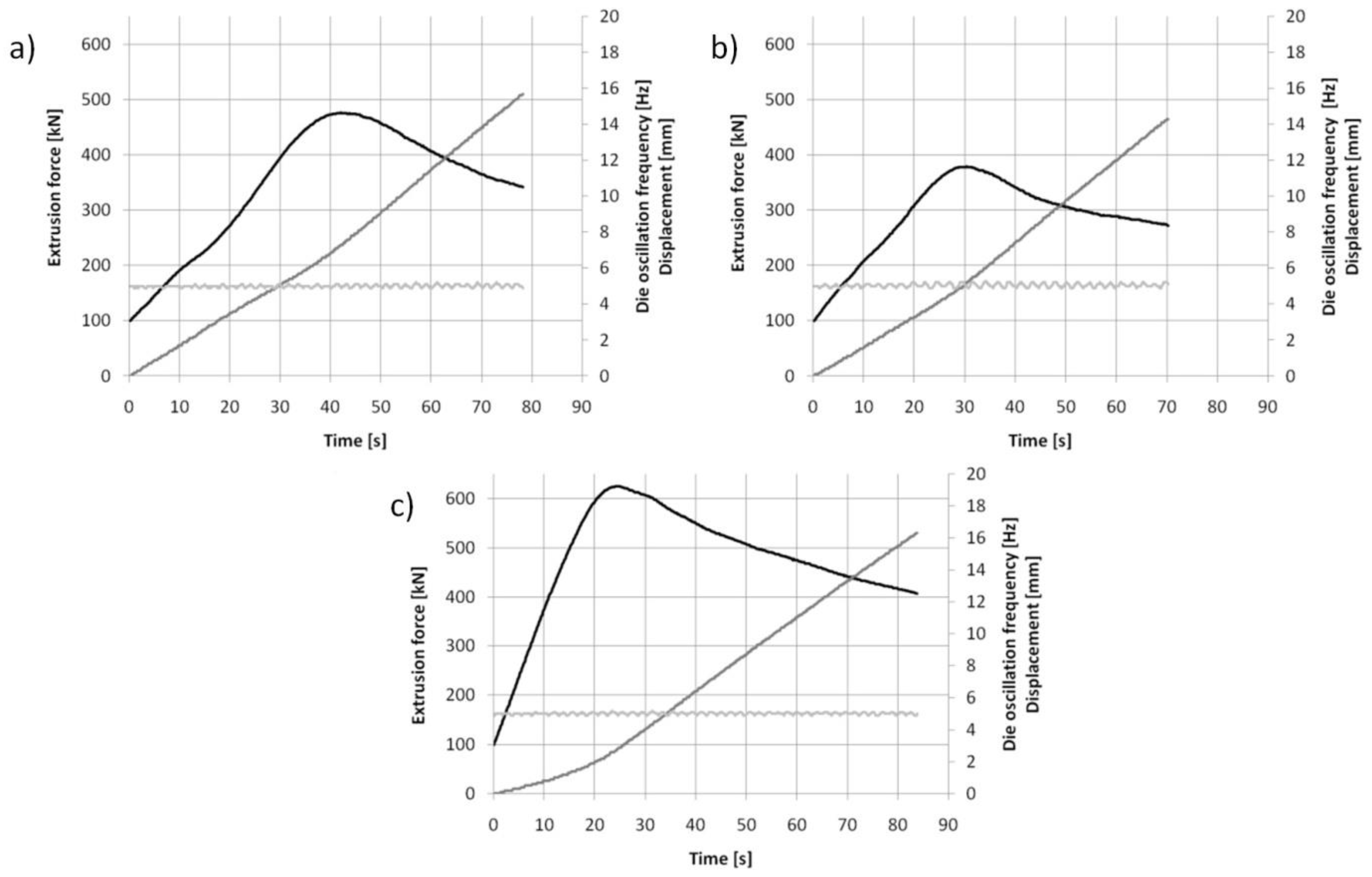

2. Materials and Methods

3. Results and Discussion

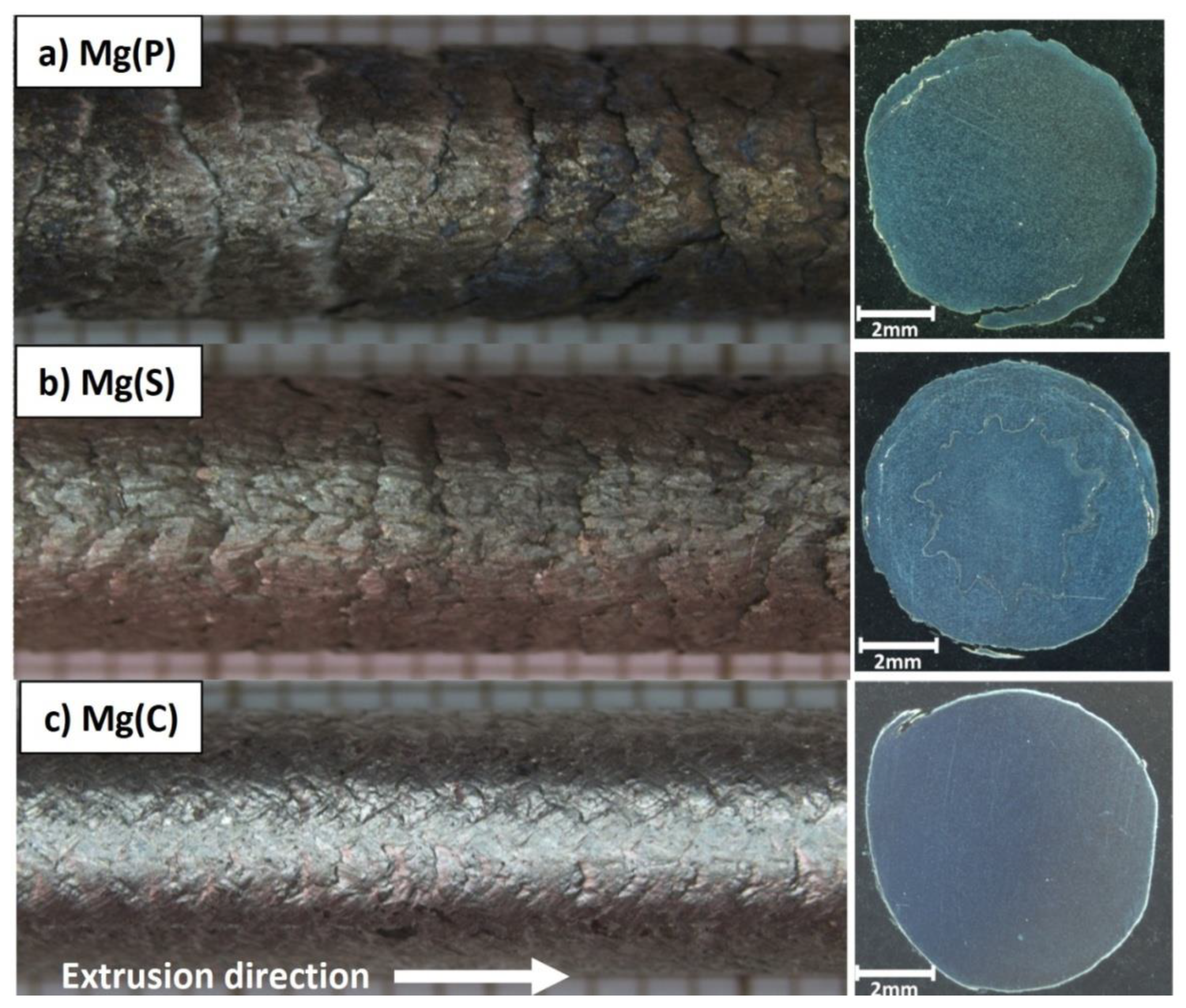

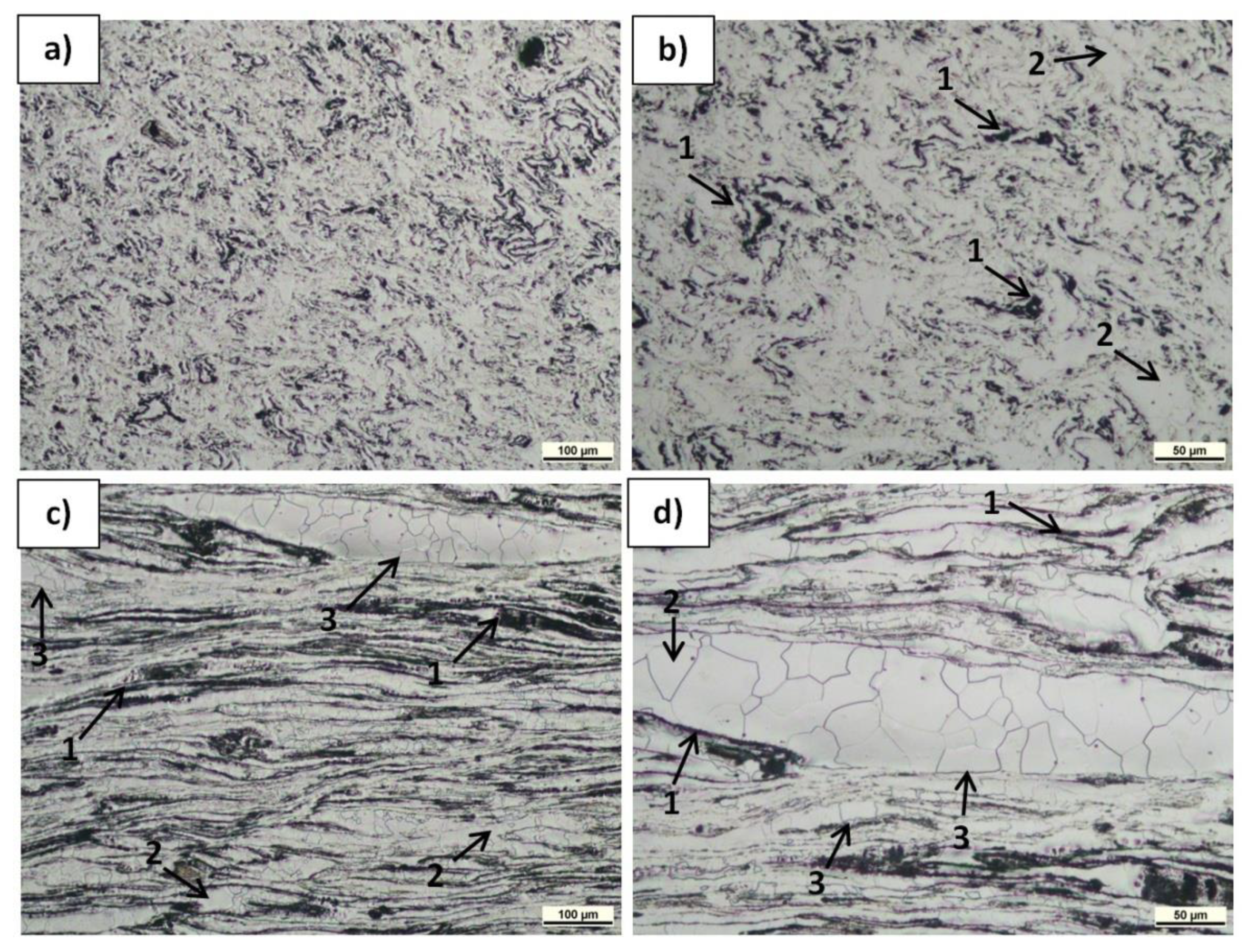

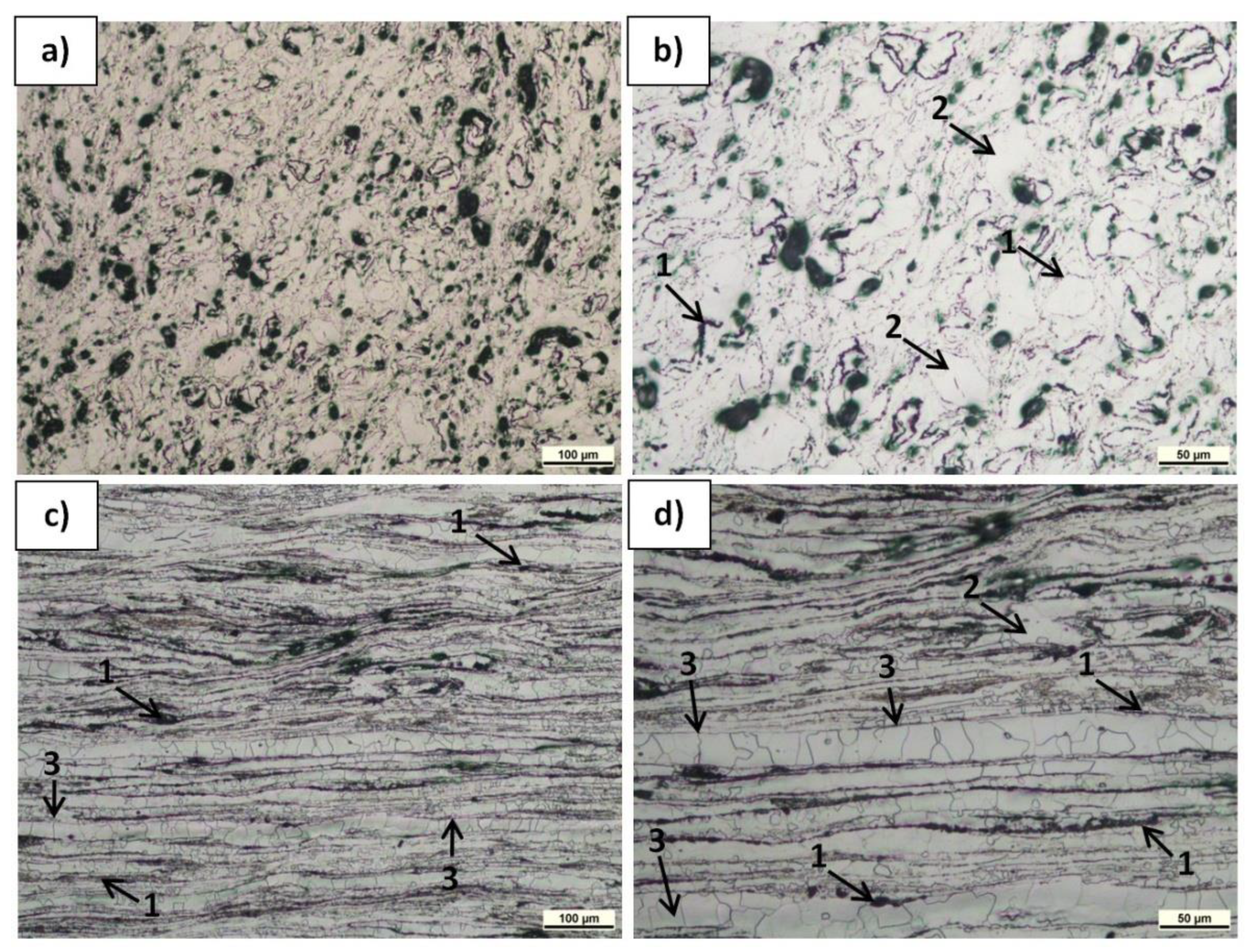

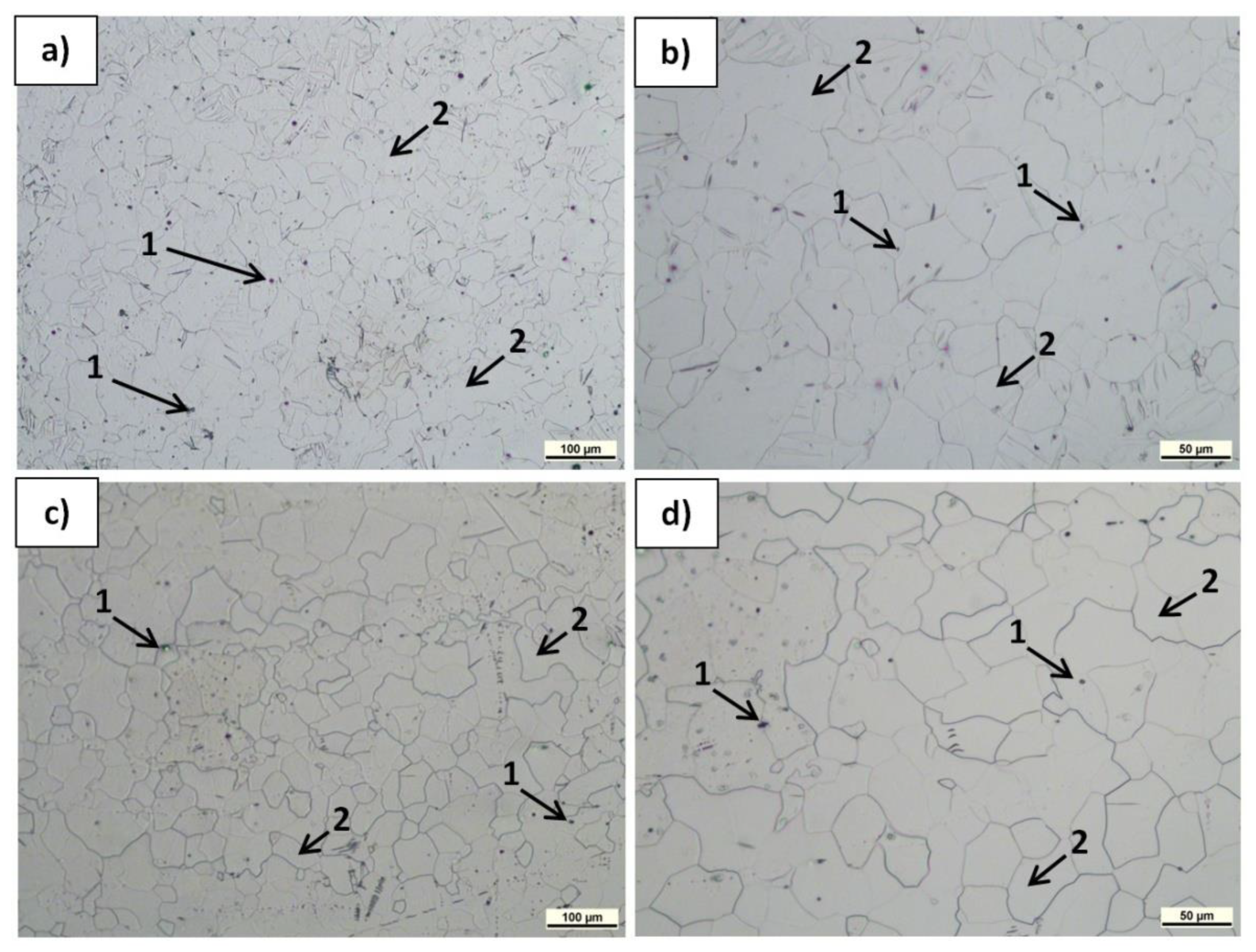

3.1. Macrostructure and Microstructure

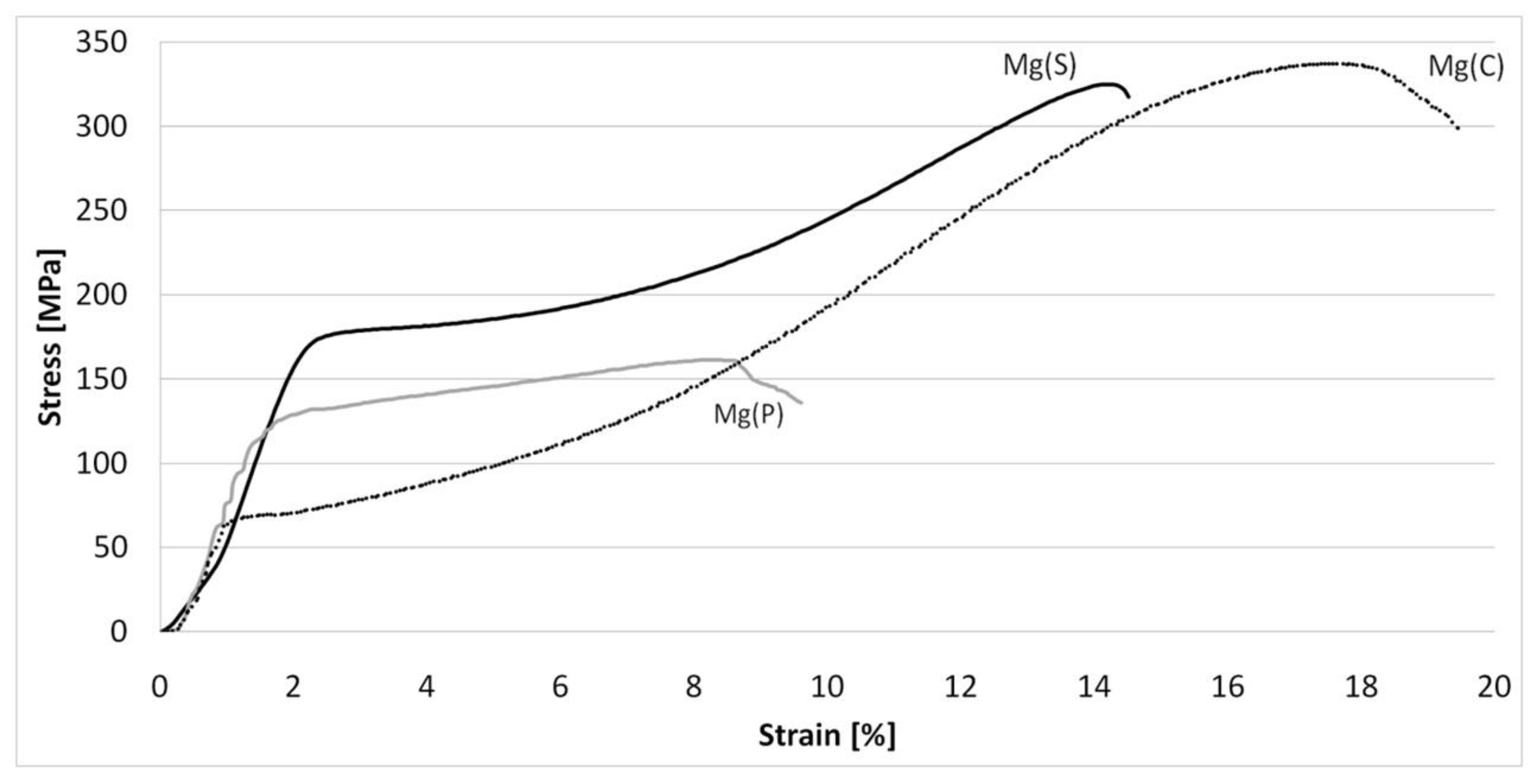

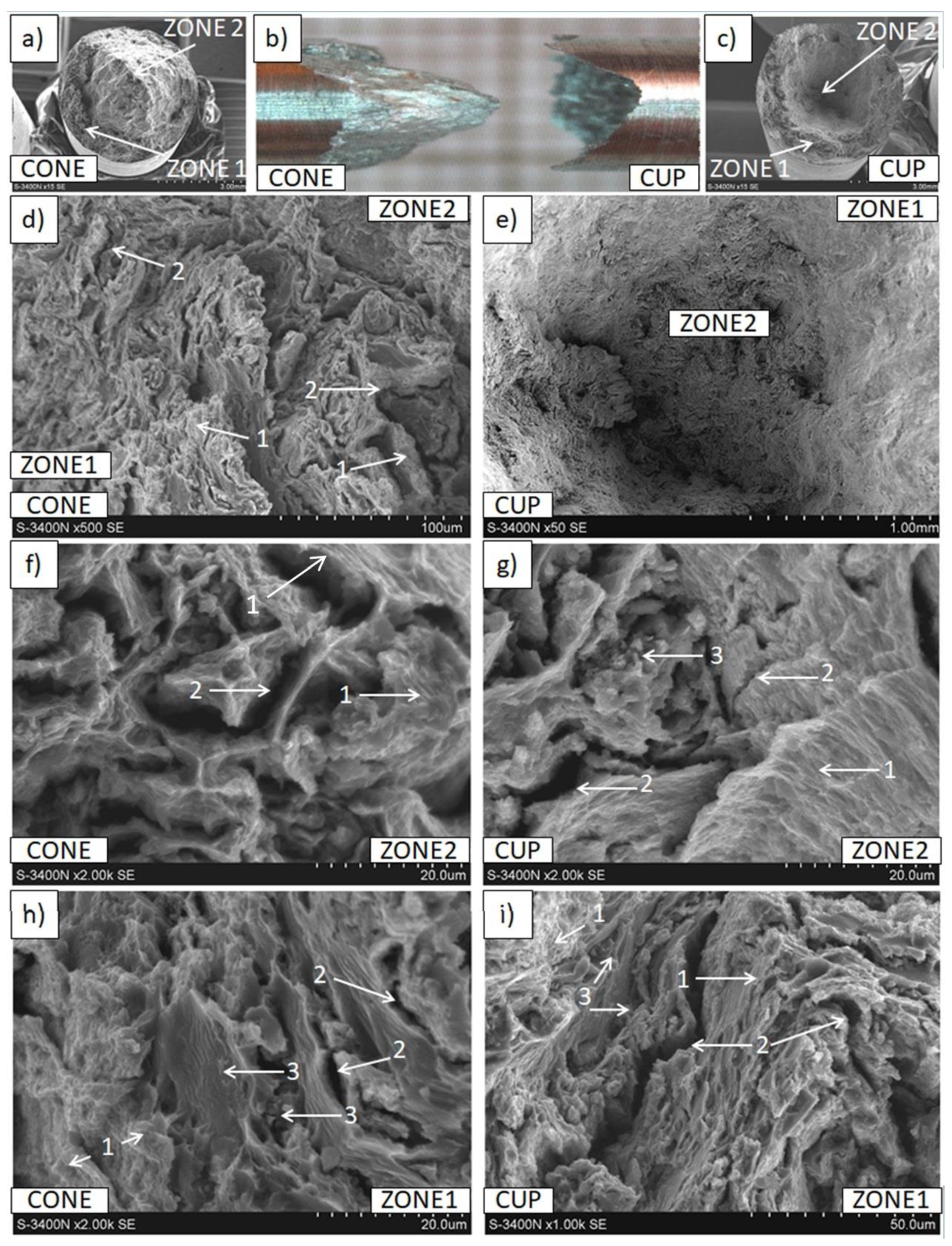

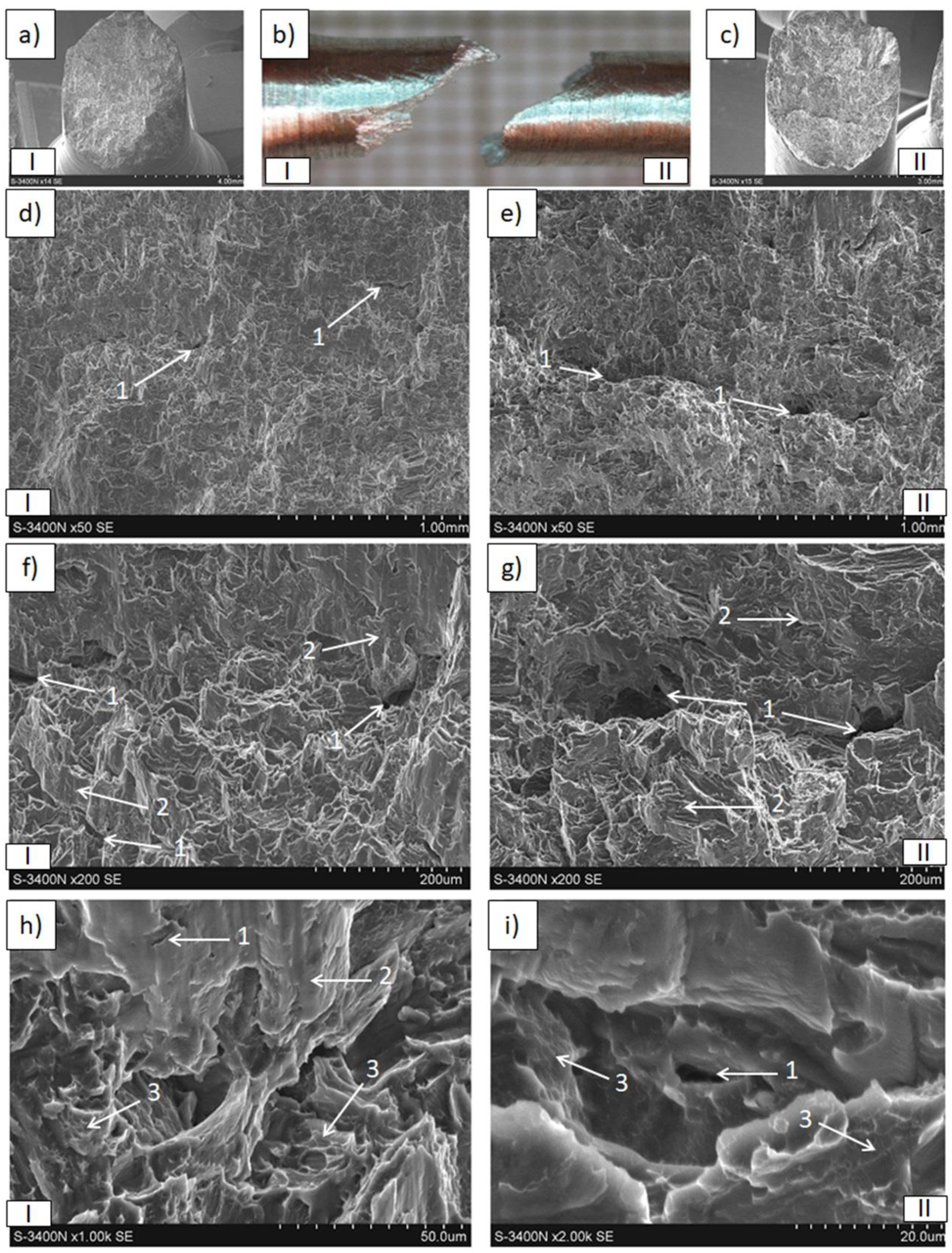

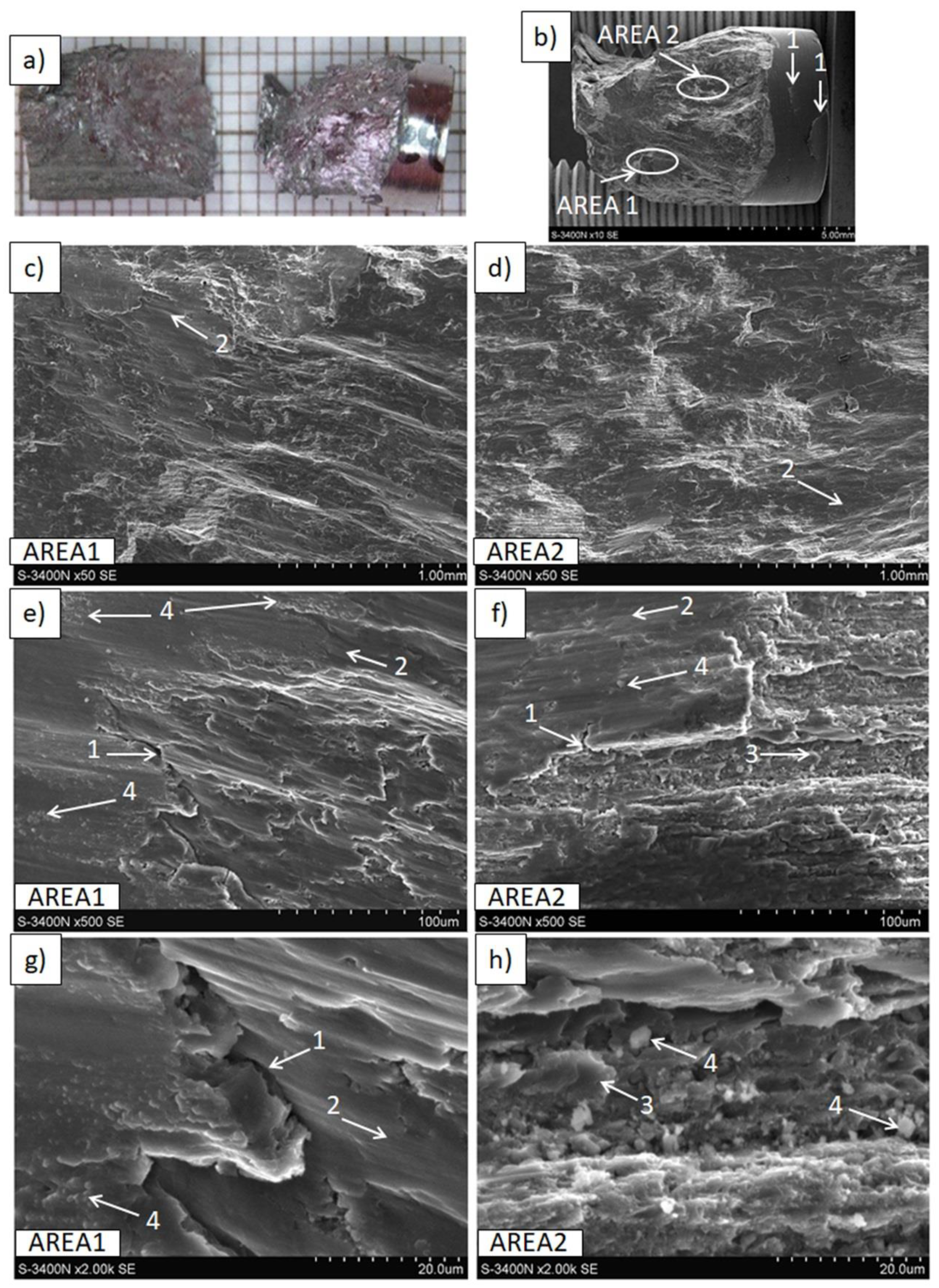

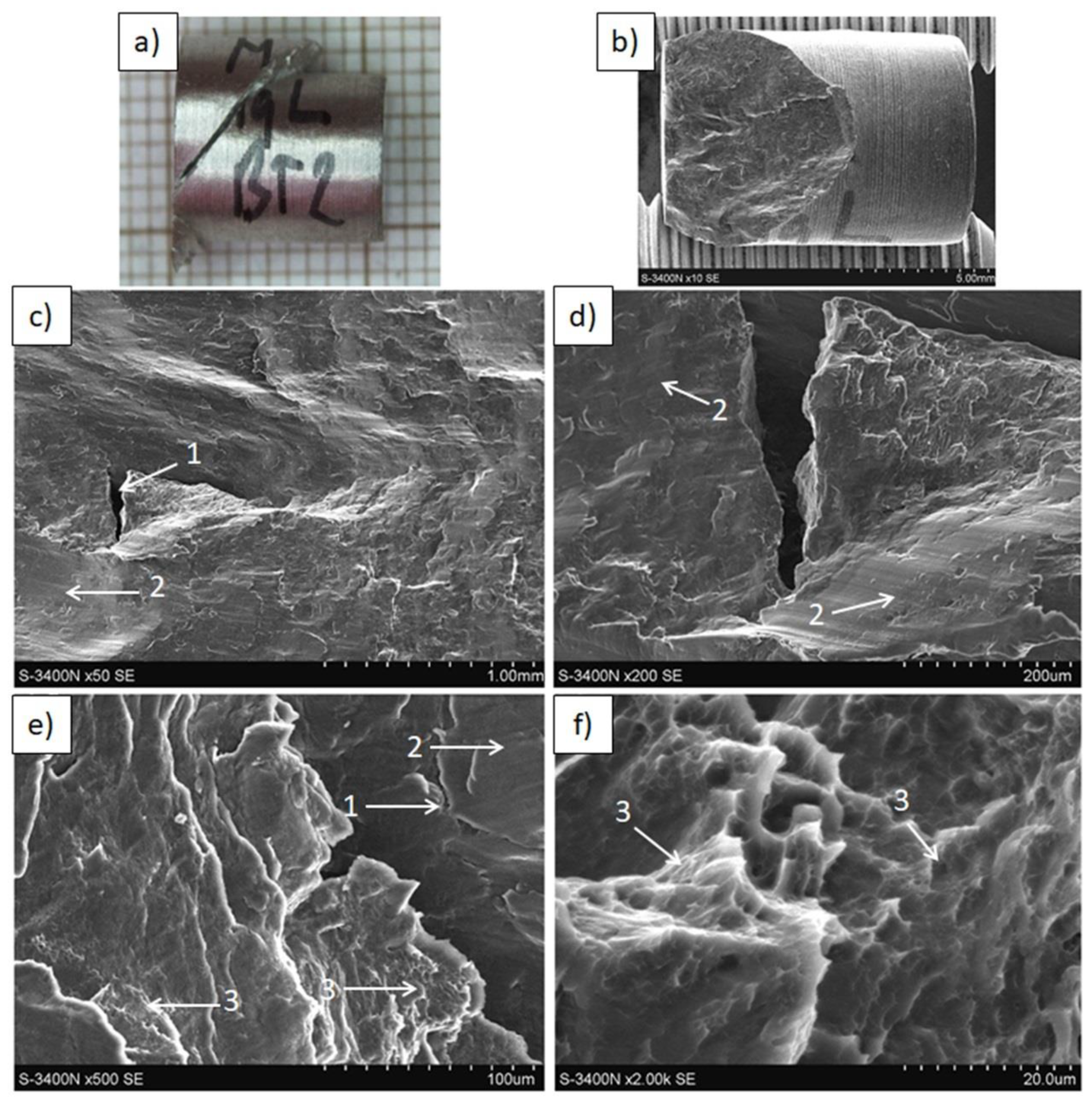

3.2. Mechanical Properties and Decohesion Effects

- The selection of optimum extrusion parameters with respect to the properties of the final products,

- An explanation for the formation of different zones in the cross sections of the processed rods and their influence on the bulk properties,

- characterization of the influence on the magnesium refining processes of the oxide from the magnesium powder surface.

4. Conclusions

- The application of magnesium powder in KOBO cold extrusion, both cold compacted and sintered under pressure, gave rods of diameter 8 mm with shiny scales at the surface oriented with the extrusion direction.

- The sintering of powders under a protective atmosphere prior to the application of the sintered material is recommended for KOBO extrusion. This type of raw material ensures that rods with less porosity, better compaction, higher hardness, and higher tensile and compressive strength parameters are obtained.

- A comparison of rods fabricated from magnesium powder with respect to those produced from cast magnesium showed an increase in hardness, Young’s modulus, and yield strength, but a decrease in UTS and 0.2% OYS.

- The applied parameters of KOBO extrusion induced the formation of submicrosized and elongated α-Mg crystallites in powder-based rods. They were similar in size and degree of elongation, but the rods obtained from previously sintered powder clearly had superior properties, due to better material consolidation. The grains in extruded cast material were regular, but less refined, due to more intense dynamic recovery and recrystallization.

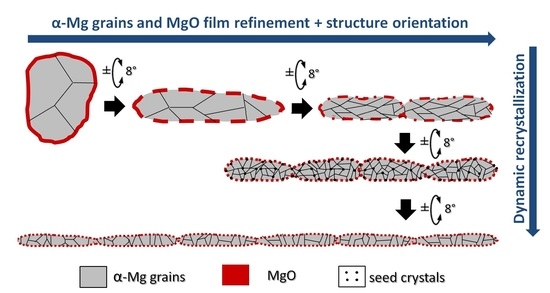

- The presence of oxide film on the surface of the employed powder played a crucial role in the formation of rod microstructure and in the examined decohesion mechanisms. In KOBO extrusion, the MgO film was refined into very fine regular submicro and smaller particles. They were well connected with the strongly refined α-Mg grains and formed bands of oxide-Mg mixture, which were oriented with the extrusion direction but curved in the perpendicular plane, forming a 3D network in the matrix of refined α-Mg crystals.

- The dynamic recovery and recrystallization of α-Mg deformed by extrusion was limited, because of metal microareas closing in the oxide-α-Mg network, which influenced not only the α-Mg grain size but also the shape and orientation of the boundaries.

- The oxide–α-Mg network strongly changed the decohesion processes and fracture morphology, because it formed a preferential path for crack propagation. However, in the case of well-compacted material (e.g., Mg(S)), this skeleton caused a significant increase in hardness and elastic properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Doege, E.; Dröder, K. Sheet metal forming of magnesium wrought alloys—Formability and process technology. J. Mater. Process. Technol. 2001, 115, 14–19. [Google Scholar] [CrossRef]

- Dziubińska, A.; Gontarz, A.; Dziedzic, K. Qualitative Research of AZ31 Magnesium Alloy Aircraft Brackets Produced by a New Forging Method. Arch. Metall. Mater. 2016, 61, 1003–1008. [Google Scholar] [CrossRef] [Green Version]

- Śliwa, R.E.; Balawender, T.; Hadasik, E.; Kuc, D.; Gontarz, A.; Korbel, A.; Bochniak, W. Metal Forming of Lightweight Magnesium Alloys for Aviation Applications. Arch. Metall. Mater. 2017, 62, 1559–1566. [Google Scholar] [CrossRef] [Green Version]

- Bednarczyk, I.; Kuc, D.; Mikuszewski, T. The Microstructure and Mechanical Properties of Magnesium Alloys Mg-Li-RE after the Process of Casting and Extrusion. Arch. Metall. Mater. 2018, 63, 35–38. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Oleksik, V.; Pepelnjak, T.; Najm, S.M.; Paniti, I.; Maji, K. Emerging Trends in Single Point Incremental Sheet Forming of Lightweight Metals. Metals 2021, 11, 1188. [Google Scholar] [CrossRef]

- Luo, A.A.; Shi, R.; Miao, J. Review: Magnesium Sheet Alloy Development for Room Temperature Forming. JOM 2021, 73, 1403–1418. [Google Scholar] [CrossRef]

- Wolff, M.; Schaper, J.G.; Suckert, M.R.; Dahms, M.; Feyerabend, F.; Ebel, T.; Willumeit-Römer, R.; Klassen, T. Metal Injection Molding (MIM) of Magnesium and Its Alloys. Metals 2016, 6, 118. [Google Scholar] [CrossRef] [Green Version]

- Nienaber, M.; Yi, S.; Kainer, K.U.; Letzig, D.; Bohlen, J. On the Direct Extrusion of Magnesium Wires from Mg-Al-Zn Series Alloys. Metals 2020, 10, 1208. [Google Scholar] [CrossRef]

- Junak, G. Fatigue Properties of AZ31 and WE43 Magnesium Alloys. Arch. Metall. Mater. 2020, 65, 721–726. [Google Scholar] [CrossRef]

- Malaki, M.; Xu, W.; Kasar, A.K.; Menezes, P.L.; Dieringa, H.; Varma, R.S.; Gupta, M. Advanced Metal Matrix Nanocomposites. Metals 2019, 9, 330. [Google Scholar] [CrossRef] [Green Version]

- Selva Kumar, M.; Chandrasekar, P.; Chandramohan, P.; Mohanraj, M. Characterisation of titanium–titanium boride composites processed by powder metallurgy techniques. Mater. Charact. 2012, 73, 43–51. [Google Scholar] [CrossRef]

- Bian, Y.; Ni, J.; Wang, C.; Zhen, J.; Hao, H.; Kong, X.; Chen, H.; Li, J.; Li, X.; Jia, Z.; et al. Microstructure and wear characteristics of in-situ micro/nanoscale niobium carbide reinforced copper composites fabricated through powder metallurgy. Mater. Charact. 2021, 172, 110847. [Google Scholar] [CrossRef]

- Chen, J.K.; Huang, I.S. Thermal properties of aluminum–graphite composites by powder metallurgy. Compos. Part B Eng. 2013, 44, 698–703. [Google Scholar] [CrossRef]

- Abdizadeh, H.; Ebrahimifard, R.; Baghchesara, M.A. Investigation of microstructure and mechanical properties of nano MgO reinforced Al composites manufactured by stir casting and powder metallurgy methods: A comparative study. Compos. Part B Eng. 2014, 56, 217–221. [Google Scholar] [CrossRef]

- Dutkiewicz, J.; Kalita, D.; Maziarz, W.; Tański, T.; Borek, W.; Ostachowski, P.; Faryna, M. Efect of KOBO extrusion and following cyclic forging on grain refinement of Mg–9Li–2Al–0.5Sc Alloy. Met. Mater. Int. 2020, 26, 1004–1014. [Google Scholar] [CrossRef] [Green Version]

- Bochniak, W.; Korbel, A.; Ostachowski, P.; Ziółkiewicz, S.; Borowski, J. Extrusion of metals and alloys by KOBO method. Obróbka Plast. Met. 2013, 24, 83–97. [Google Scholar]

- Korbel, A.; Bochniak, W.; Borowski, J.; Błaż, L.; Ostachowski, P.; Łagoda, M. Anomalies in precipitation hardening process of 7075 aluminum alloy extruded by KOBO method. J. Mater. Process. Technol. 2015, 216, 160–165. [Google Scholar] [CrossRef]

- Dutkiewicz, J.; Bobrowski, P.; Rusz, S.; Hilser, O.; Tański, T.; Borek, W.; Łagoda, M.; Ostachowski, P.; Pałka, P.; Boczkal, G.; et al. Efect of various SPD techniques on structure and superplastic deformation of two phase MgLiAl Alloy. Met. Mater. Int. 2018, 24, 1077–1089. [Google Scholar] [CrossRef]

- Korbel, A.; Bochniak, W. Method of Plastic Forming of Materials. U.S. Patent No 5,737,959, 1998. European Patent No 0711210, 2000. [Google Scholar]

- Korbel, A.; Bochniak, W.; Ostachowski, P.; Błaż, L. Visco-plastic flow of metal in dynamic conditions of complex strain scheme. Metall. Mater. Trans. A 2011, 42, 2881–2897. [Google Scholar] [CrossRef] [Green Version]

- Korbel, A.; Bochniak, W. Stratified plastic flow in metals. Int. J. Mech. Sci. 2017, 128, 269–276. [Google Scholar] [CrossRef]

- Gholinia, A.; Prangnell, P.B.; Markushev, M.V. The effect of strain path on the development of deformation structures in Neverly deformed aluminium alloys processed by ECAE. Acta Mater. 2000, 48, 1115–1130. [Google Scholar] [CrossRef]

- Sabirov, I.; Kolednik, O.; Valiev, R.Z.; Pippan, R. Equal channel angular pressing of metal matrix composites: Effect on particle distribution and fracture toughness. Acta Mater. 2005, 53, 4919–4930. [Google Scholar] [CrossRef]

- Pantělejev, L.; Štěpánek, R.; Man, O. Thermal stability of bimodal microstructure in magnesium alloy AZ91 processed by ECAP. Mater. Charact. 2015, 107, 167–173. [Google Scholar] [CrossRef]

- Tokunaga, T.; Kaneko, K.; Horita, Z. Production of aluminum-matrix carbon nanotube composite using high pressure torsion. Mater. Sci. Eng. A 2008, 490, 300–304. [Google Scholar] [CrossRef]

- Al-Zubaydi, A.; Zhilyae, A.; Wang, S.; Reed, P. Superplastic behaviour of AZ91 magnesium alloy processed by high-pressure torsion. Mater. Sci. Eng. A 2015, 637, 1–11. [Google Scholar] [CrossRef]

- Bazarnik, P.; Romelczyk, B.; Huang, Y.; Lewandowska, M.; Langdon, T.G. Effect of applied pressure on microstructure development and homogeneity in an aluminium Alloy processed by high-pressure torsion. J. Alloys Compd. 2016, 688, 736–745. [Google Scholar] [CrossRef] [Green Version]

- Ghalehbandi, S.M.; Malaki, M.; Gupta, M. Accumulative Roll Bonding—A Review. Appl. Sci. 2019, 9, 3627. [Google Scholar] [CrossRef] [Green Version]

- Kuśnierz, J. Nanomateriały wytwarzane metodą intensywnych odkształceń plastycznych. Kom. Budowy Masz. PAN—Oddział W Pozn. 2007, 27, 131–142. [Google Scholar]

- Kuśnierz, J.; Bogucka, J. Accumulative Roll-Bonding (ARB) of Al 99.8%. Arch. Metall. Mater. 2005, 50, 219–230. [Google Scholar]

- Siddesha, H.S.; Shantharaja, M. Characterization of mechanical properties of aluminum processed by repetitive corrugation and straightening process using taguchi analysis. JOM 2013, 65, 294–298. [Google Scholar] [CrossRef] [Green Version]

- Huang, J.; Zhu, Y.T.; Alexander, D.J.; Liao, X.; Lowe, T.C.; Asaro, R.J. Development of repetitive corrugation and straightening. Mater. Sci. Eng. A 2004, 371, 35–39. [Google Scholar] [CrossRef]

- Bhovi, P.M.; Patil, D.C.; Kori, S.A.; Venkateswarlud, K.; Huange, Y.; Langdon, T.G. A comparison of repetitive corrugation and straightening and high-pressure torsion using an Al-Mg-Sc Alloy. J. Mater. Res. Technol. 2016, 5, 353–359. [Google Scholar] [CrossRef]

- Pustovoytov, D.; Pesin, A.; Tandon, P. Asymmetric (Hot, Warm, Cold, Cryo) rolling of light alloys: A Review. Metals 2021, 11, 956. [Google Scholar] [CrossRef]

- Biswas, S.; Kimb, D.; Suwas, S. Asymmetric and symmetric rolling of magnesium: Evolution of microstructure, texture and mechanical properties. Mater. Sci. Eng. A 2012, 550, 19–30. [Google Scholar] [CrossRef]

- Fajfar, P.; Lah, A.S.; Kraner, J.; Kugler, G. Asymmetric rolling process. Mater. Geoenviron. 2017, 64, 151–160. [Google Scholar] [CrossRef] [Green Version]

- Deb, S.; Panigrahi, S.K.; Weiss, M. Development of bulk ultrafine grained Al-SiC nano composite sheets by a SPD based hybrid process: Experimental and theoretical studies. Mater. Sci. Eng. A 2018, 738, 323–334. [Google Scholar] [CrossRef]

- Pramono, A.; Dhoska, K.; Alhamidi, A.; Trenggono, A.; Milandia, A. Investigation of mechanical properties on composite materials by several of severe plastic deformation (SPD) methods. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Bali, Indonesia, 7–8 August 2019; Volume 673, p. 012120. [Google Scholar] [CrossRef]

- Aristizabal, K.; Tayrac, A.; Katzensteiner, A.; Bachmaier, A.; Suarez, S. Friction and Tribo-Chemical Behavior of SPD-Processed CNT-Reinforced Composites. Lubricants 2019, 7, 75. [Google Scholar] [CrossRef] [Green Version]

- Zwolak, M.; Śliwa, R.E. Physical modeling of plastic flow in the KOBO extrusion process using dies of different geometry. Obróbka Plast. Met. 2017, 28, 317–330. [Google Scholar]

- Bogucki, R.; Sulikowska, K.; Bieda, M.; Ostachowski, P.; Sztwiertnia, K. Analysis of microstructure and mechanical properties changes in AA1050 aluminum subjected to ECAP and KoBo processes. Arch. Metall. Mater. 2015, 60, 3063–3068. [Google Scholar] [CrossRef] [Green Version]

- Andrzejewski, D.; Borowski, J.; Garbiec, D. Wpływ wyciskania metodą KOBO na wytrzymałość zmęczeniową stopu aluminium 7075. Inżynieria Mater. 2015, 6, 368–371. [Google Scholar] [CrossRef]

- Korbel, A.; Pieła, K.; Ostachowski, P.; Łagoda, M.; Błaż, L.; Bochniak, W.; Pawlyta, M. Structural phenomena induced in the course of and post low-temperature KOBO extrusion of AA6013 aluminum alloy. Mater. Sci. Eng. A 2018, 710, 349–358. [Google Scholar] [CrossRef]

- Ziółkiewicz, S.; Gąsiorkiewicz, M.; Wesołowska, P.; Szczepanik, S.; Szyndler, R. Influence of KOBO treatment on the plastic properties of AM60 magnesium alloy. Obróbka Plast. Met. 2012, 23, 151–158. [Google Scholar]

- Bednarczyk, I.; Kuc, D.; Tomaszewska, A.; Mrugała, A. The influence of extrusion process on the microstructure and mechanical properties of magnesium alloys. Arch. Metall. Mater. 2017, 62, 545–550. [Google Scholar] [CrossRef] [Green Version]

- Bednarczyk, I. Characterization of magnesium LAE442 alloy microstructure after deformation process with the use of KoBo method. Inżynieria Mater. 2018, 2, 56–60. [Google Scholar] [CrossRef]

- Ziółkiewicz, S.; Gąsiorkiewicz, M.; Wesołowska, P.; Szczepanik, S.; Szyndler, R. Effect of KOBO treatment on the plastic properties of the AZ31 magnesium alloy. Obróbka Plast. Met. 2012, 23, 57–67. [Google Scholar]

- Bochniak, W.; Korbel, A.; Ostachowski, P.; Łagoda, M. Plastic flow of metals under cyclic change of deformation path conditions. Arch. Civ. Mech. Eng. 2018, 18, 679–688. [Google Scholar] [CrossRef]

- Długosz, P.; Bochniak, W.; Ostachowski, P.; Molak, R.; Guigou, M.D.; Hebda, M. The influence of conventional or KOBO extrusion process on the properties of AZ91 (MgAl9Zn1) alloy. Materials 2021, 14, 6543. [Google Scholar] [CrossRef]

- Bochniak, W.; Ostachowski, P.; Jagieła, S. Plastic forming of AZ91 alloy using the KOBO method. J. Eng. Mater. Technol. 2016, 138, 041002. [Google Scholar] [CrossRef]

- Rodak, K.; Brzezińska, A.; Sobota, J. Refinement of Al-5%Cu and Al-25%Cu alloys by means of KoBo methods. Arch. Metall. Mater. 2020, 65, 1477–1482. [Google Scholar] [CrossRef]

- Rodak, K.; Kuc, D.; Mikuszewski, T. Superplastic deformation of Al-Cu alloys after grain refinement by extrusion combined with reversible torsion. Materials 2020, 13, 5803. [Google Scholar] [CrossRef]

- Brzezińska, A.; Rodak, K. Refinement of CuCr0.6 alloy by means of KoBo and COT methods. Met. Form. 2018, 29, 369–380. [Google Scholar]

- Korbel, A.; Bochniak, W. Refinement and control of the metal structure elements by plastic deformation. Scr. Mater. 2004, 51, 755–759. [Google Scholar] [CrossRef]

- Ostachowski, P.; Bochniak, W.; Łagoda, M.; Ziółkiewicz, S. Strength properties and structure of CuCrZr alloy subjected to low-temperature KOBO extrusion and heat treatment. Int. J. Adv. Manuf. Technol. 2019, 105, 5023–5044. [Google Scholar] [CrossRef] [Green Version]

- Woźniak, J.; Kostecki, M.; Bochniak, W.; Olszyna, A. Al/SiC composites produced by direct extrusion using the KOBO method. Inżynieria Mater. 2012, 31, 453–456. [Google Scholar]

- Olszówka-Myalska, A.; Kuc, D.; Myalski, J.; Chrapoński, J. Effect of Magnesium Matrix Grain Refinement Induced by Plastic Deformation in a Composite with Short Carbon Fibers. Metals 2019, 9, 724. [Google Scholar] [CrossRef] [Green Version]

- Wieczorek, J.; Oleksiak, B.; Łabaj, J.; Węcki, B.; Mańka, M. Silver matrix composites—Structure and properties. Arch. Metall. Mater. 2016, 61, 323–328. [Google Scholar] [CrossRef]

- Olszówka-Myalska, A.; Wrześniowski, P.; Myalska, H.; Godzierz, M.; Kuc, D. Impact of the Morphology of Micro- and Nanosized Powder Mixtures on the Microstructure of Mg-Mg2Si-CNT Composite Sinters. Materials 2019, 12, 3242. [Google Scholar] [CrossRef] [Green Version]

- Korbel, W.; Bochniak, P.; Ostachowski, A.; Paliborek, M.; Łagoda, A.; Brzostowicz, A. new constitutive approach to large strain plastic deformation. Int. J. Mater. Res. 2016, 107, 44–51. [Google Scholar] [CrossRef]

- Rietveld, H.M. Line profiles of neutron powder-diffraction peaks for structure refinement. Acta Crystallogr. 1967, 22, 151–152. [Google Scholar] [CrossRef]

- Rietveld, H.M. A profile refinement method for nuclear and magnetic structures, Journal of Applied Crystallography. J. Appl. Crystallogr. 1969, 2, 65–71. [Google Scholar] [CrossRef]

- Toby, B.H. R factors in Rietveld analysis: How good is good enough? Powder Diffr. 2006, 21, 67–70. [Google Scholar] [CrossRef] [Green Version]

- Karolus, M.; Łagiewka, E. Crystallite size and lattice strain in nanocrystalline Ni-Mo alloys studied by Rietveld refinement. J. Alloys Compd. 2004, 367, 235–238. [Google Scholar] [CrossRef]

- Wang, Q.J.; Du, Z.Z.; Luo, L.; Wang, W. Fatigue properties of ultra-fine grain Cu–Cr alloy processed by equal-channel angular pressing. J. Alloy. Compd. 2012, 526, 39–44. [Google Scholar] [CrossRef]

- Stolyarov, V.V.; Lapovok, R.; Brodova, I.G.; Thomson, P.F. Ultrafine-grained Al-/5 wt.% Fe alloy processed by ECAP with back pressure. Mater. Sci. Eng. A 2003, 357, 159–167. [Google Scholar] [CrossRef]

- Segal, V.M. Deformation mode and plastic flow in ultra fine grained metals. Mater. Sci. Eng. A 2005, 406, 205–216. [Google Scholar] [CrossRef]

- Jia, H.; Bjørge, R.; Marthinsen, K.; Mathiesen, R.H.; Li, Y. Soft particles assisted grain refinement and strengthening of an Al-Bi-Zn alloy subjected to ECAP. Mater. Sci. Eng. A 2017, 703, 304–313. [Google Scholar] [CrossRef]

| Maximum Extrusion Force [kN] | Time [s] | Displacement [mm] | |

|---|---|---|---|

| Mg(P) 40 × 20 mm | 476 | 42 | 7.3 |

| Mg(S) 40 × 20 mm | 379 | 30.4 | 5.2 |

| Mg(C) 40 × 20 mm | 624 | 24 | 2.7 |

| POROSITY, % | ||||

|---|---|---|---|---|

| Mg(P) after Extrusion | Mg(S) after Sintering | Mg(S) after Extrusion | Mg(C) after Casting | Mg(C) after Extrusion |

| 4.12 | 5.18 | 3.92 | 1.03 | 0.83 |

| Sample | Lattice Parameters, Å | Lattice Strain, % | Crystallite Size, nm |

|---|---|---|---|

| Mg, reference from ICDD 1 | a = 3.2095, c = 5.2104 | - | - |

| Mg, powder 2 | a = 3.211, c = 5.214 | 0.13 ± 0.01 | 161 ± 3 |

| Mg(P) rod, perpendicular | a = 3.211, c = 5.212 | 0.09 ± 0.01 | 232 ± 4 |

| Mg(P) rod, longitudinal | a = 3.212, c = 5.213 | 0.09 ± 0.01 | 271 ± 9 |

| Mg, sintered 2 | a = 3.210, c = 5.211 | 0.08 ± 0.01 | 360 ± 10 |

| Mg(S) rod, perpendicular | a = 3.210, c = 5.211 | 0.11 ± 0.02 | 210 ± 10 |

| Mg(S) rod, longitudinal | a = 3.210, c = 5.211 | 0.11 ± 0.02 | 270 ± 5 |

| cast Mg (2) | a = 3.212, c = 5.212 | 0.07 ± 0.01 | 321 ± 8 |

| Mg(C) rod, perpendicular | a = 3.212, c = 5.213 | 0.14 ± 0.01 | 297 ± 9 |

| Mg(C) rod, longitudinal | a = 3.211, c = 5.213 | 0.04 ± 0.01 | 309 ± 7 |

| Material | Tensile Test | Compressive Test | Hardness HV 0.2 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| UTS | 0.2 % OYS | E | σ max | YS | E | Before | Transverse | Longitudinal | |

| [MPa] | [MPa] | [GPa] | [MPa] | [MPa] | [GPa] | KOBO | |||

| Mg(P) | 108.63 ± 7.23 | 97.48 ± 2.33 | 30.75 ± 0.92 | 183 ± 21.5 | 133.6 ± 3.2 | 11.1 ± 0.2 | 34 ± 3.58 | 46.6 ± 3.4 | 44.5 ± 4.4 |

| Mg(S) | 173.55 ± 1.91 | 114.5 ± 19.66 | 33.95 ± 4.03 | 320.3 ± 10.8 | 171.6 ± 6.4 | 12 ± 0.8 | 33.9 ± 3.7 | 51 ± 2.9 | 50.6 ± 3.3 |

| Mg(C) | 206.19 ± 2.84 | 171.23 ± 4.14 | 22.1 ± 4.1 | 349 ± 22.4 | 68.2 ± 0.2 | 9.4 ± 1.01 | 32 ± 1.21 | 34.4 ± 1.4 | 34.8 ± 3.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olszówka-Myalska, A.; Wrześniowski, P.; Ostachowski, P.; Godzierz, M.; Kuc, D. Effect of Magnesium Powder Application on the Microstructure and Properties of Rods Extruded by the Forward-Backward Rotating Die Extrusion Method. Materials 2022, 15, 4094. https://doi.org/10.3390/ma15124094

Olszówka-Myalska A, Wrześniowski P, Ostachowski P, Godzierz M, Kuc D. Effect of Magnesium Powder Application on the Microstructure and Properties of Rods Extruded by the Forward-Backward Rotating Die Extrusion Method. Materials. 2022; 15(12):4094. https://doi.org/10.3390/ma15124094

Chicago/Turabian StyleOlszówka-Myalska, Anita, Patryk Wrześniowski, Paweł Ostachowski, Marcin Godzierz, and Dariusz Kuc. 2022. "Effect of Magnesium Powder Application on the Microstructure and Properties of Rods Extruded by the Forward-Backward Rotating Die Extrusion Method" Materials 15, no. 12: 4094. https://doi.org/10.3390/ma15124094

APA StyleOlszówka-Myalska, A., Wrześniowski, P., Ostachowski, P., Godzierz, M., & Kuc, D. (2022). Effect of Magnesium Powder Application on the Microstructure and Properties of Rods Extruded by the Forward-Backward Rotating Die Extrusion Method. Materials, 15(12), 4094. https://doi.org/10.3390/ma15124094