Ultra-High-Performance Concrete (UHPC): A State-of-the-Art Review

Abstract

:1. Introduction

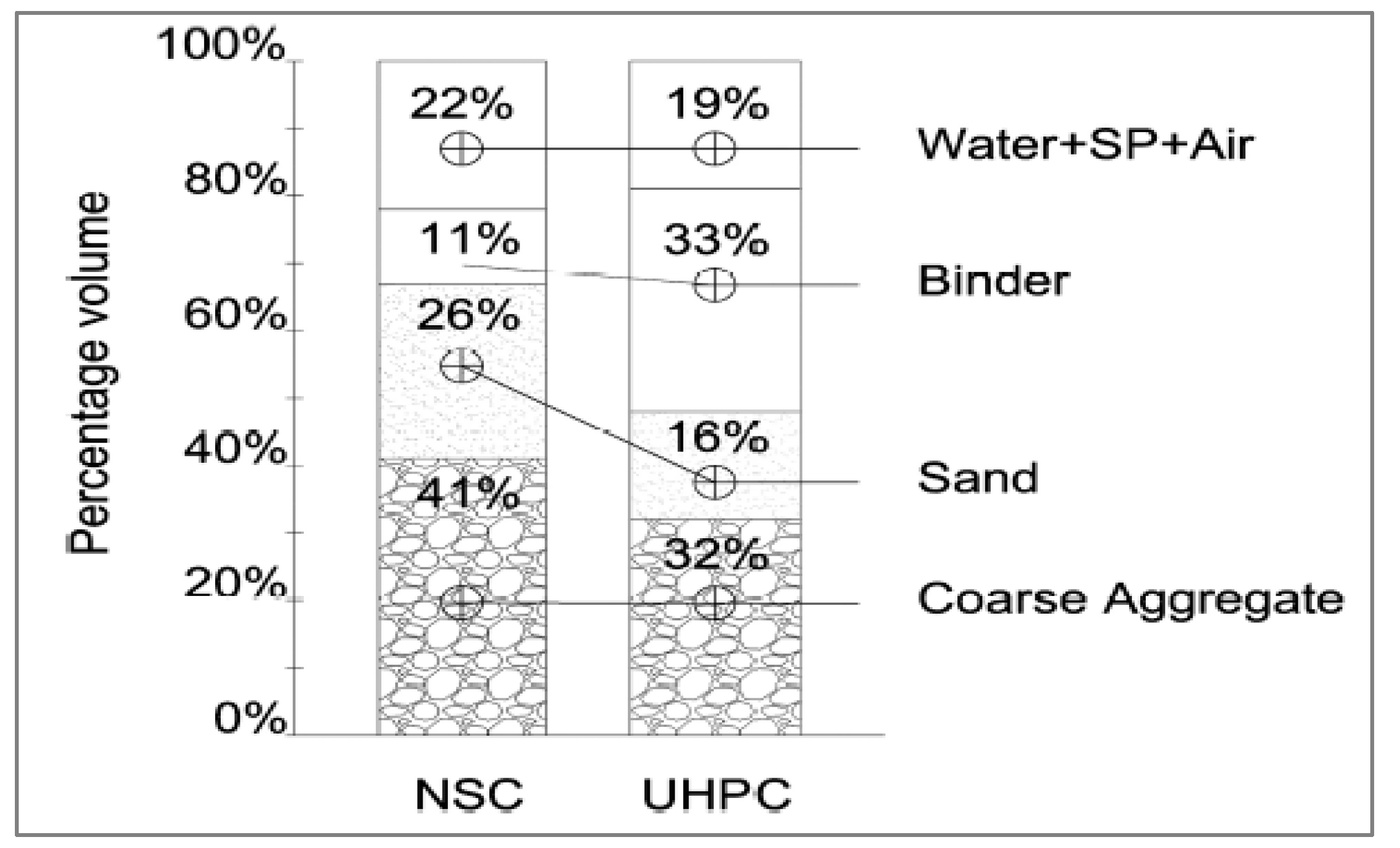

2. Materials

2.1. Cement

2.2. Chemical Admixture

2.3. Aggregates

2.3.1. Coarse Aggregate

2.3.2. Fine Aggregate

2.4. Micro Silica/Silica Fume

2.5. Steel Fibers

2.6. Mix Design

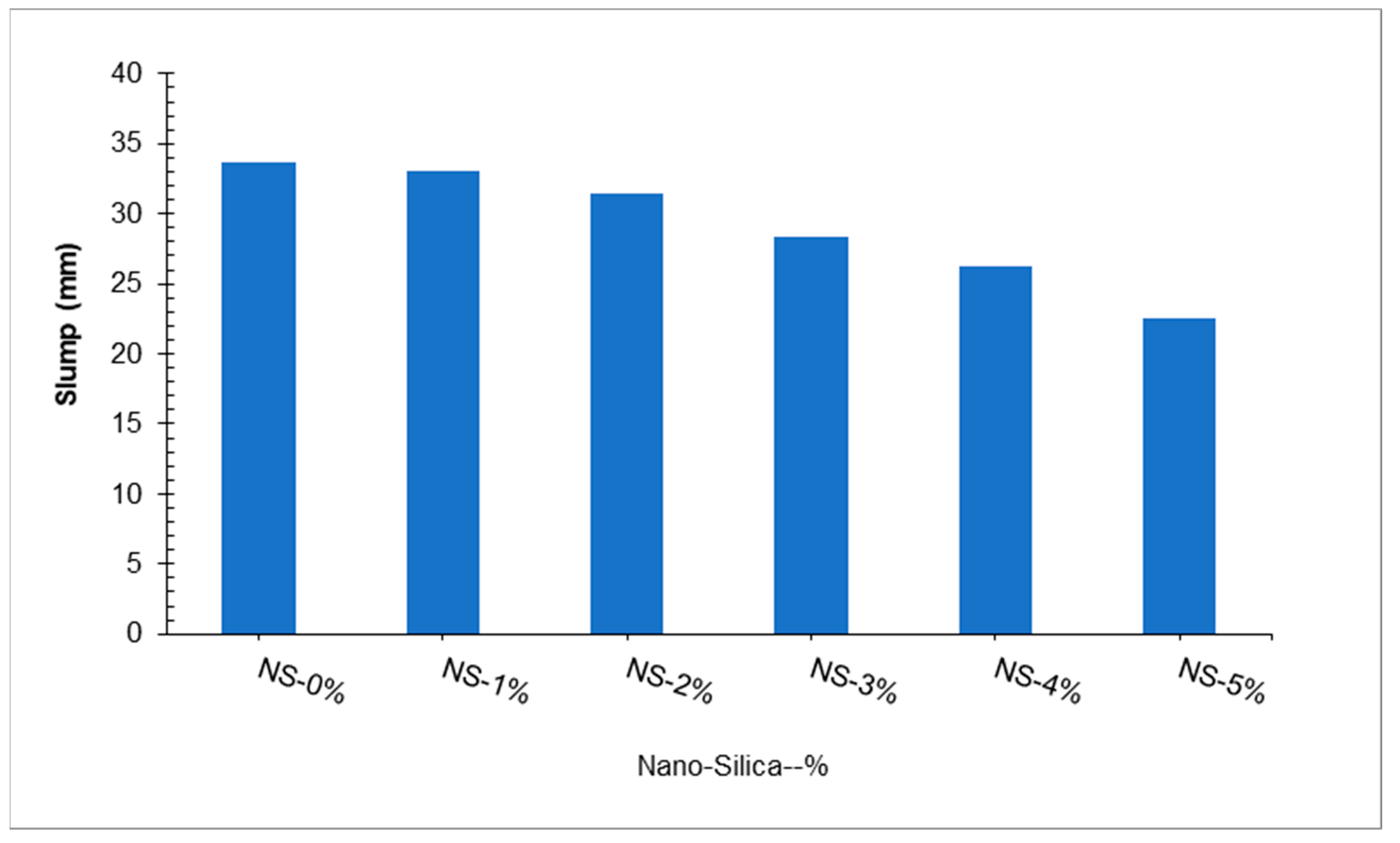

3. Fresh Properties

4. Mechanical Properties

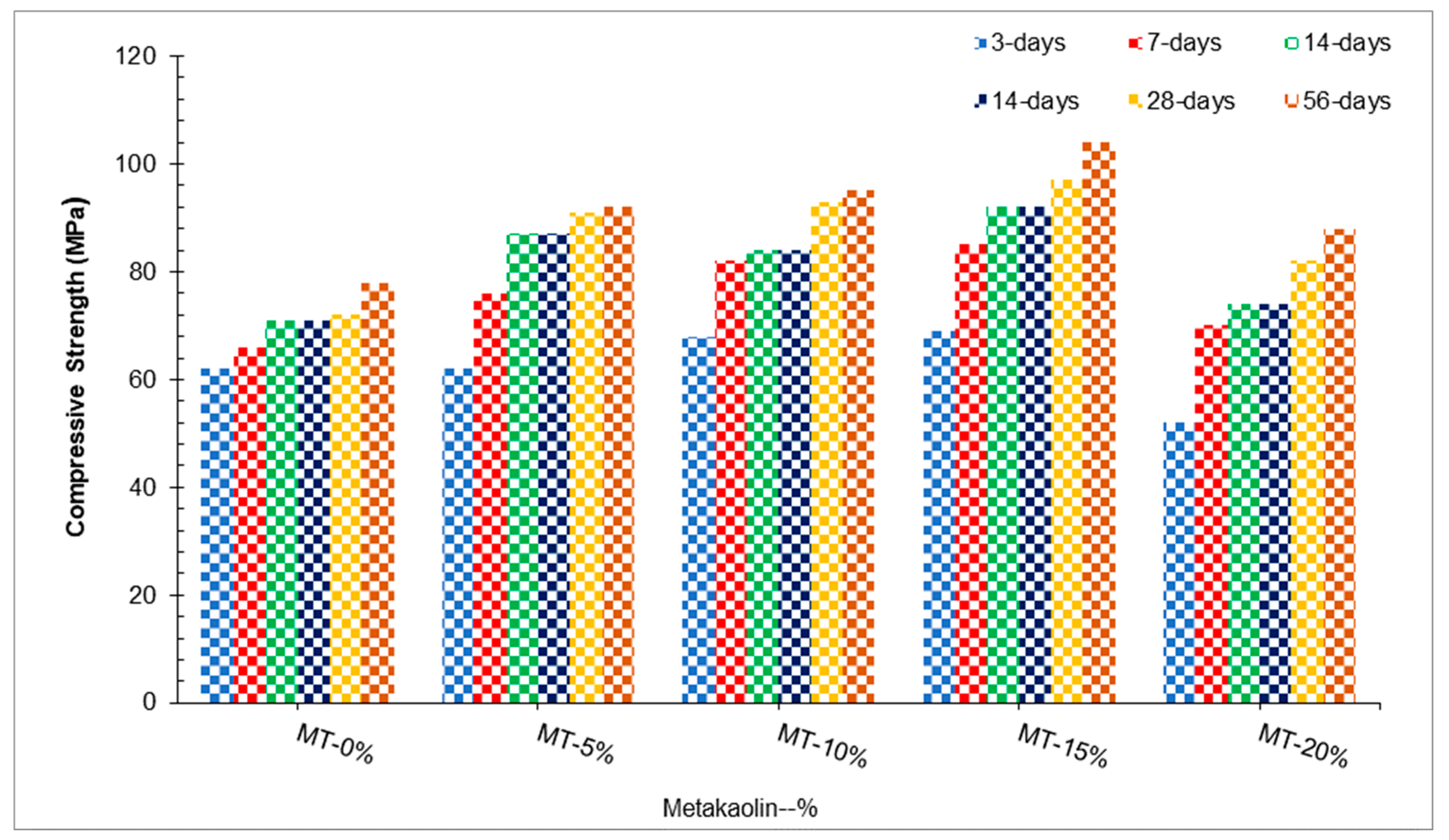

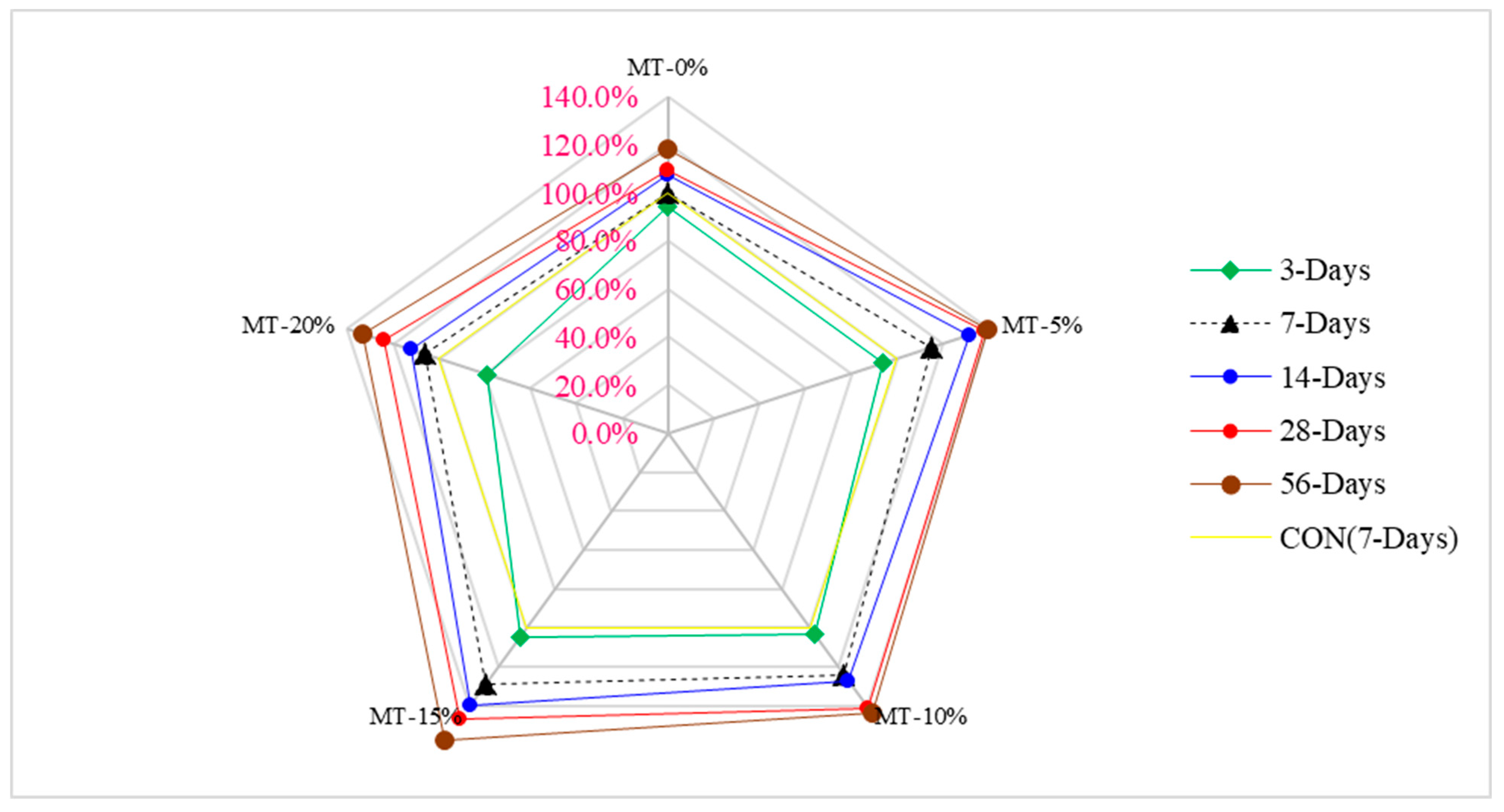

4.1. Compressive Strength

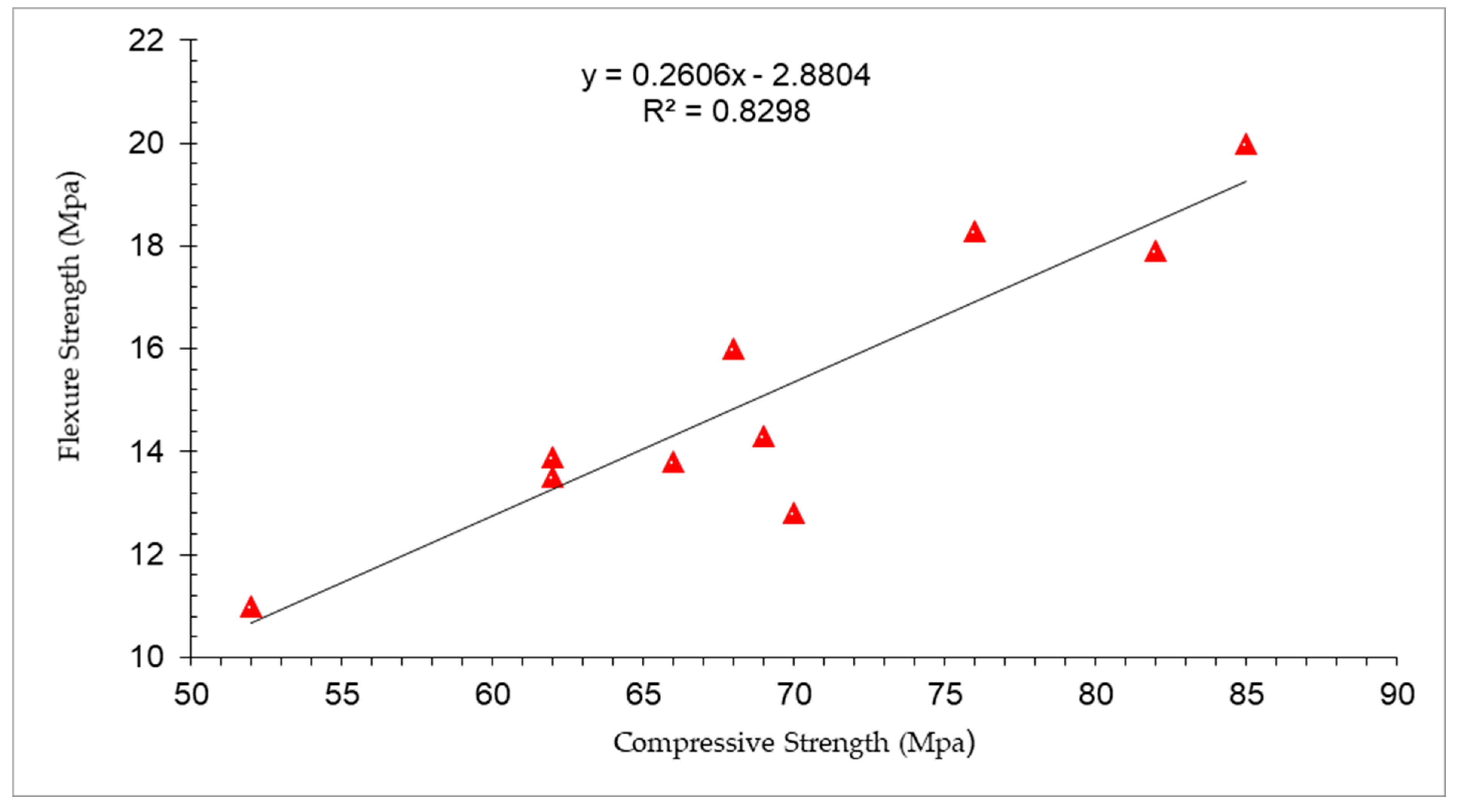

4.2. Flexure Strength

| Authors/ Reference | Material | W/C | Fiber Type % | Compressive Strength (MPa) | Flexural Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|

| Wu et al. [27] | Silica fume | 0.18 | Straight 0 1 2 3 Corrugated 1 2 3 Hooked 1 2 3 | ----- 110 125 145 150 ------- 135 145 155 ------ 140 155 165 | ---- 18 20 25 35 ---- 23 28 37 ---- 25 32 40 | ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ------- ------- |

| Shafieifar et al. (2017) [28] | Premix-ductal | 0.15 | Straight 0% 2% | ----- 40.4 138 | 8.3 37.6 | 4.9 21.9 |

| Zemei et al. [29] | Silica fume 0 5 10 15 20 25 | 0.18 | 2% | ----- 81 98 112 115 113 110 | ------ 13.06 14.38 17.23 14.63 15.15 13.84 | ------ 4.53 5.23 7.87 7.65 6.01 5.76 |

| Wang et al. [53] | SF 10% GGBS 0 20 40 LP 0 20 40 | 0.18 | NA | 138 122 110 142 150 130 | --- --- --- --- --- --- | --- --- --- --- --- --- |

| W. Meng et al. [30] | GNPs SF FA | 0.2 | %GNPs/%CN’s 0/0 0.05/0.05 0.1/0.1 0.15/0.15 0.2/0.2 0.3/0.3 | GNPs/CNFs 174/174 174.5/16 177/177 180/178 182/181 184/184 | GNPs/CNFs 7.73/7.73 8.17/8.49 8.28/8.94 10.7/9.53 11.12/10.1 11.26/10.7 | GNPs/CNFs 5.84/5.84 7.01/6.49 7.65/6.99 7.97/7.32 8.36/7.67 9.09/8.17 |

| P. R. Prem et al. [44] | SF QP | 0.2 | SF 0 2 2.5 | ----- 132 175.28 171.35 | ----- 16 43 33.35 | ----- 11.3 23.2 19.1 |

| Mo et al. [55] | LS 30% MK 0 5 10 15 20 | 0.2 | NA | ---- ---- 72 91 93 97 82 | ---- ---- 11.5 18.3 17.8 16.3 17.8 | ---- ---- ---- ---- ---- ---- ---- |

| C.C. Hung et al. [54] | SF + QP | 0.135 | Macro-steel fiber 0 1 2 | ---- 150 126 132 | --- --- --- --- | --- 5.9 6.1 6.6 |

| Aziz and Ahmed [28] | SF | 0.16/0.62 0.62 0.16 0.16 0.2 | SF 0 0 0.12 0.26 | ---- 38.8 131.4 125.2 126.8 | ---- 3.95 22.24 18.45 19.63 | --- 2.97 11.03 8.91 13.76 |

| M.A. Ibrahim et al. [46] | SF (10%, 20%, 30%) GGBS (10%, 20%) FA (10%, 20%) GS (0%, 5%, 10%, 15%, 20%, 25%) | 0.18 to 0.24 | SF + GS | 159 139 146 158 ----- 144 152 154 155 160 161 | 104 132 144 160 159 160 144 154 147 ---- ---- | ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ ------ |

| SF0 SF10 SF20 SF30 GS 0% 5% 10% 15% 20% 25% | ||||||

| H.J. Chen et al. [49] | Silica fume-SF Ultra-fine silicon powder-SFP | 0.195 | St. fiber | (St.F + PPF + SF + SFP)% | 90 128.1 127 ------ 121.6 123.6 125.8 | 12.7 6.6 12.6 ------ 14.7 12.2 12.7 |

| 0.5 0.75 1 PP-fibers 0.03 0.06 0.09 | 0 + 0 + 0 + 0 0.5 + 0.03 + 17.4 + 2.2 1 + 0.06 + 18.7 + 2.2 ----------------- 0.75 + 0.03 + 18.7 + 3.2 0.75 + 0.09 + 20 + 2.2 1 + 0.03 + 20 + 2.7 | |||||

| Yu et al. [51] | Nano-silica 0 1 2 3 4 5 ---- 0 1 2 3 4 5 | 0.4 | Macro-steel fiber 0% 2.5% | ---- --- 78 79.9 81.5 89.2 91.3 86.9 ----- 113 120 129 136 138.4 136.4 | --- --- 10.4 11.9 12.8 13.4 14 13.2 ------ 18 21.2 22.5 24.4 25 24.1 | --- --- |

| Teng et al. [45] | Welan Gun Powder-WG (0%, 0.18%, 0.22%, 0.27%) Class-c fly ash- 40% Silica fume 5% Air-detraining admixture, polyether, 0.8% | 0.2 | Straight steel fibers 0% | 115 112 110 105 --- 120 119.8 119.5 117 --- 128 127 125 121 --- 133 132 131.2 130 | 9 9 8 7 -- 15 17 16 15 --- 16 19 21 20 --- 20 23 26 27 | |

| WG–0% WG–0.18% WG–0.22% WG–0.27% | ||||||

| 1% | ||||||

| WG–0% WG–0.18% WG–0.22% WG–0.27% | ||||||

| 2% | ||||||

| WG–0% WG–0.18% WG–0.22% WG–0.27% | ||||||

| 3% | ||||||

| WG–0% WG–0.18% WG–0.22% WG–0.27% | ||||||

| Azmee et al. [32] | SF%–FA% 0–0 0–30 0–40 0–50 10–30 10–40 10–50 | 0.16 | Steel fiber = 1% | 120 127 120 9898 128 130 117 | ------ ------ ------ ------ ------ ------ ------ | ------ ------ ------ ------ ------ ------ ------ |

| Kwon et al. [69] | SF Anti-foaming agent | 0.22 | Micro SF (const)-straight = 1% Macro SF (varying) 0.5 1 1.5 2 | 28-day avg compressive strength = 182 MPa | 11.9 12.4 16.1 20.1 | ------ ------ ------ ------ |

5. Durability

5.1. Water Absorption and Porosity

5.2. Chloride Penetration

5.3. Freezing and Thawing

5.4. Dry Shrinkage

5.5. Creep of UHPC

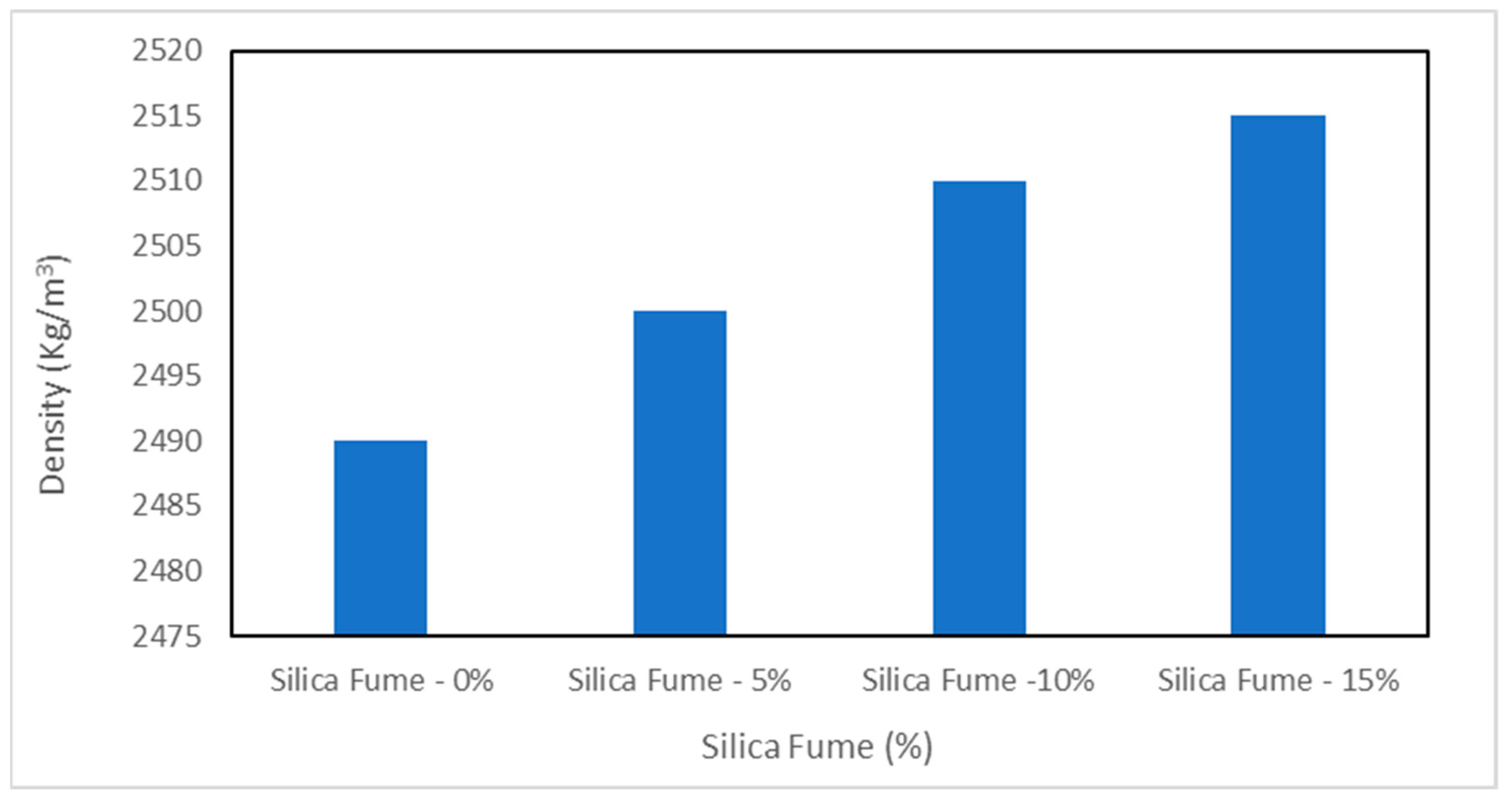

5.6. Density

6. Thermal Properties of UHPC

| Authors/ Reference | Material | W/C | Fiber Type (%) | Water Absorption (%) | Chloride Penetration (Coulombs) | Freezing and Thawing- 28-Cycle (g/m2) | Porosity (%) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Alkaysi et al. [110] | SF = 25% White cement 0 15 25 Silica powder 0 15 25 GGBS 0 15 25 | 0.22 | 1.5% | ----- | 637 295 89 --- 57 488.5 939.5 ----- 137.5 229 137.5 | 17.7 20.7 98.8 ---- 42.2 18 18.2 ---- 44.7 24.2 20.5 | ----- | ||||

| Ghafari et al. [111] | SF = 27% Nano-silica 0% 1% 2% 3% 4% | 0.2 | NA | 1.2 1.1 0.95 0.80 0.85 | 6.35 4.74 4.66 4.30 4.80 | ----- | 6.35 4.74 4.66 4.30 4.80 | ||||

| Abbas et al. [73] | Silica fume Quartz sand Quartz powder | 0.23 | Steel fibers 8 mm 1% 3% 6% 12 mm 1% 3% 6% | 0.0589 0.0540 0.0477 -------- 0.0591 0.0544 0.0479 | 71 60 45 ---- 60 47 38 | 3.7 3.3 3 1.4 ---- 3.4 3.1 3.5 | |||||

| Scheydt et al. [112] | Silica fume quartz sand Quartz powder Basalt | 0.21 | SF = 2% 0 2%-(N-Tem) 2%-(90 °C) | 8.9 10.9 5.4 | |||||||

| Teichmann et al. [113] | Silica fume Quartz powder Quartz sand | 0.5 0.33 0.24 0.17 | SF % | OPC-kg/m3 | 15 8.3 6.2 2 | ||||||

| 0 0 0 2 | 350 450 733 1000 | ||||||||||

| Piérard et al. [114] | Q-Powder SF-kg/m3 100 166 156 | 0.23 | Steel fiber 0 1 0 | 0 6 5 | |||||||

| Huang et al. [115] | SF Kg/m3 | RHA Kg/m3 | 0.2 | NA | 18 8 3.7 6 6.8 7.5 | ----- ----- ----- | 3.75 ---- 3.55 ----- 3.41 3.61 | ||||

| 276 230 184 138 92 46 0 | 0 46 92 138 184 230 276 | ||||||||||

| Coutinho et al. [116] | Silica fume 0% 10% Rice husk ash 10% 15% 20% | 0.43 | NA | 2349.3 464.3 ------ 435 322 260 | |||||||

| Valipour et al. [117] | -Lightweight sand-(LWS) -CaO-based expansive agent (EXC) - MgO-based expansive agent (EXM) shrinkage reducing agent-SRA GGBS-50% LWS-50% EXC-7.5% EXC7.5%LWS25% EXC7.5%LWS40% EXC7.5%LWS60% EXC5%LWS60% EXC10%LWS60% EXM5%LWS60% EXM7%LWS60% SRA1.5%LWS60% SRA3%LWS60% | 0.4 | SF = 2% | Total shrinkage under initially air dried (AD), 3-day moist curing (3MC), and 7-day moist curing conditions (− reduction and + increased) | |||||||

| 28 days | 91 days | ||||||||||

| AD | 3MC | 7MC | AD | 3MC | 7MC | ||||||

| −782 −780 −517 −623 −430 −513 −570 −94 −730 −690 −565 −318 | −780 −698 −413 −519 −333 −400 −500 −26 −690 −528 −550 −280 | −728 −580 −350 −460 −289 −273 −371 +254 −560 −480 −468 −250 | −810 −830 −580 −680 −465 −535 −600 −110 −815 −756 −680 −455 | −820 −750 −465 −575 −370 −453 −551 −30 −750 −610 −750 −366 | −730 −630 −410 −470 −350 −321 −415 +105 −600 −520 −550 −310 | ||||||

7. Environmental and Cost Estimations of UHPC

8. Conclusions

- UHPC should contain only fine aggregates like natural sand, silica sand, recycled glass cullet, quartz sand, etc., and not coarse aggregates because they will weaken the ITZ.

- UHPC normally exhibits lower workability as compared to normal strength concrete. UHPC normally contains fiber, increasing the internal friction between concrete ingredients, leading to lower workability.

- The best mechanical characteristics were obtained for UHPFRC mixtures when the water-to-binder ratio was less than 0.20.

- Maximum mechanical and durability performance was achieved at 2.0% addition of steel fiber by volume and hook-type fiber, further enhancing the performance of UHPC.

- Low water absorption, porosity, carbonation depth, freezing and thawing action, and dry shrinkage of UHPC make it usable in all types of aggressive environments.

- Thermal conductivity of UHPC is higher than that of conventional concrete due to higher density.

- UHPC is not recommended for use in high-temperature applications due to its low heat absorption capacity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Russell, H.G.; Graybeal, B.A.; Russell, H.G. Ultra-High Performance Concrete: A State-of-the-Art Report for the Bridge Community; Federal Highway Administration Office of Infrastructure Research and Development: McLean, VA, USA, 2013. Available online: https://scholar.google.com/scholar?hl=en&as_sdt=0%2C5&q=1.%09Russell%2C+H.G.%3B+Graybeal%2C+B.A.%3B+Russell%2C+H.G.+Ultra-High+Performance+Concrete%3A+A+State-of-the-Art+Report+for+the+Bridge+Community%3B+United+States%2C+Federal+Highway+Administration.+Office+of+Infrastructure+Research+and+Development+%3A+2013.&btnG= (accessed on 17 March 2022).

- Meng, W.; Valipour, M.; Khayat, K.H. Optimization and Performance of Cost-Effective Ultra-High Performance Concrete. Mater. Struct. 2017, 50, 29. [Google Scholar] [CrossRef]

- Graybeal, B.; Crane, C.K.; Perry, V.; Corvez, D.; Ahlborn, T.M. Advancing Ultra-High-Performance Concrete. Concr. Int. 2019, 41, 41–45. [Google Scholar]

- Kusumawardaningsih, Y.; Fehling, E.; Ismail, M.; Aboubakr, A.A.M. Tensile Strength Behavior of UHPC and UHPFRC. Procedia Eng. 2015, 125, 1081–1086. [Google Scholar] [CrossRef] [Green Version]

- de Larrard, F.; Sedran, T. Optimization of Ultra-High-Performance Concrete by the Use of a Packing Model. Cem. Concr. Res. 1994, 24, 997–1009. [Google Scholar] [CrossRef]

- Graybeal, B. Ultra-High Performance Concrete (FHWA-HRT-11-038); Federal Highway Administration: Washington, DC, USA, 2011.

- Wille, K.; Naaman, A.E.; El-Tawil, S.; Parra-Montesinos, G.J. Ultra-High Performance Concrete and Fiber Reinforced Concrete: Achieving Strength and Ductility without Heat Curing. Mater. Struct. 2012, 45, 309–324. [Google Scholar] [CrossRef]

- Wang, D.; Shi, C.; Wu, Z.; Xiao, J.; Huang, Z.; Fang, Z. A Review on Ultra High Performance Concrete: Part II. Hydration, Microstructure and Properties. Constr. Build. Mater. 2015, 96, 368–377. [Google Scholar] [CrossRef]

- Zollo, R.F. Fiber-Reinforced Concrete: An Overview after 30 Years of Development. Cem. Concr. Compos. 1997, 19, 107–122. [Google Scholar] [CrossRef]

- Chan, Y.-W.; Chu, S.-H. Effect of Silica Fume on Steel Fiber Bond Characteristics in Reactive Powder Concrete. Cem. Concr. Res. 2004, 34, 1167–1172. [Google Scholar] [CrossRef]

- Kang, S.T.; Lee, B.Y.; Kim, J.-K.; Kim, Y.Y. The Effect of Fibre Distribution Characteristics on the Flexural Strength of Steel Fibre-Reinforced Ultra High Strength Concrete. Constr. Build. Mater. 2011, 25, 2450–2457. [Google Scholar] [CrossRef]

- Sbia, L.A.; Peyvandi, A.; Soroushian, P.; Lu, J.; Balachandra, A.M. Enhancement of Ultrahigh Performance Concrete Material Properties with Carbon Nanofiber. Adv. Civ. Eng. 2014, 2014, 854729. [Google Scholar]

- Ahmad, J.; Manan, A.; Ali, A.; Khan, M.W.; Asim, M.; Zaid, O. A Study on Mechanical and Durability Aspects of Concrete Modified with Steel Fibers (SFs). Civ. Eng. Archit. 2020, 8, 814–823. [Google Scholar] [CrossRef]

- Rao, G.A. Investigations on the Performance of Silica Fume-Incorporated Cement Pastes and Mortars. Cem. Concr. Res. 2003, 33, 1765–1770. [Google Scholar] [CrossRef]

- Vikan, H.; Justnes, H. Rheology of Cementitious Paste with Silica Fume or Limestone. Cem. Concr. Res. 2007, 37, 1512–1517. [Google Scholar] [CrossRef]

- Yan, H.; Sun, W.; Chen, H. The Effect of Silica Fume and Steel Fiber on the Dynamic Mechanical Performance of High-Strength Concrete. Cem. Concr. Res. 1999, 29, 423–426. [Google Scholar] [CrossRef]

- Si, R.; Dai, Q.; Guo, S.; Wang, J. Mechanical Property, Nanopore Structure and Drying Shrinkage of Metakaolin-Based Geopolymer with Waste Glass Powder. J. Clean. Prod. 2020, 242, 118502. [Google Scholar] [CrossRef]

- Williams, E.M.; Graham, S.S.; Reed, P.A.; Rushing, T.S. Laboratory Characterization of Cor-Tuf Concrete with and without Steel Fibers; Engineer Research and Development Center Vicksburg Ms Geotechnical and Structures Lab.: Vicksburg, MS, USA, 2009; Available online: https://scholar.google.com/scholar?hl=en&as_sdt=0%2C5&q=18.%09Williams%2C+E.M.%3B+Graham%2C+S.S.%3B+Reed%2C+P.A.%3B+Rushing%2C+T.S.+Laboratory+Characterization+of+Cor-Tuf+Concrete+with+and+without+Steel+Fibers%3B+Engineer+Research+and+Development+Center+Vicksburg+Ms+Geotechnical+and+Structures+Lab+.%3A+2009.&btnG= (accessed on 17 March 2022).

- Zhang, D.; Dasari, A.; Tan, K.H. On the Mechanism of Prevention of Explosive Spalling in Ultra-High Performance Concrete with Polymer Fibers. Cem. Concr. Res. 2018, 113, 169–177. [Google Scholar] [CrossRef]

- Ahmad, J.; Zaid, O.; Shahzaib, M.; Abdullah, M.U.; Ullah, A.; Ullah, R. Mechanical Properties of Sustainable Concrete Modified by Adding Marble Slurry as Cement Substitution. AIMS Mater. Sci. 2021, 8, 343–358. [Google Scholar] [CrossRef]

- IS 383. Specification for Coarse and Fine Aggregates from Natural Sources for Concrete. Bureau for Indian Standards: New Delhi, India, 1970.

- Rajput, S.P.S.; Chauhan, M.S. Suitability of Crushed Stone Dust as Fine Aggregate in Mortars. Micron 2014, 89, 35–59. [Google Scholar]

- Sidodikromo, E.P.; Chen, Z.; Habib, M. Review of the Cement-Based Composite Ultra-High-Performance Concrete (UHPC). Open Civ. Eng. J. 2019, 13, 147–162. [Google Scholar] [CrossRef] [Green Version]

- C 1240-2005. Standard Specification for Silica Fume Used in Cementitious Mixtures. ASTM International: West Conshohocken, PA, USA, 2005.

- Harrison, T. Standards for Fresh Concrete; BSI British Standards Institution: London, UK, 2004; ISBN 0580421155. [Google Scholar]

- Ahmad, J.; Zaid, O.; Siddique, M.S.; Aslam, F.; Alabduljabbar, H.; Khedher, K.M. Mechanical and Durability Characteristics of Sustainable Coconut Fibers Reinforced Concrete with Incorporation of Marble Powder. Mater. Res. Express 2021, 8, 075505. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W.; Wu, L. Effects of Steel Fiber Content and Shape on Mechanical Properties of Ultra High Performance Concrete. Constr. Build. Mater. 2016, 103, 8–14. [Google Scholar] [CrossRef]

- Shafieifar, M.; Farzad, M.; Azizinamini, A. Experimental and Numerical Study on Mechanical Properties of Ultra High Performance Concrete (UHPC). Constr. Build. Mater. 2017, 156, 402–411. [Google Scholar] [CrossRef]

- Wu, Z.; Khayat, K.H.; Shi, C. Changes in Rheology and Mechanical Properties of Ultra-High Performance Concrete with Silica Fume Content. Cem. Concr. Res. 2019, 123, 105786. [Google Scholar] [CrossRef]

- Meng, W.; Khayat, K.H. Mechanical Properties of Ultra-High-Performance Concrete Enhanced with Graphite Nanoplatelets and Carbon Nanofibers. Compos. Part B Eng. 2016, 107, 113–122. [Google Scholar] [CrossRef]

- Kim, H.; Koh, T.; Pyo, S. Enhancing Flowability and Sustainability of Ultra High Performance Concrete Incorporating High Replacement Levels of Industrial Slags. Constr. Build. Mater. 2016, 123, 153–160. [Google Scholar] [CrossRef]

- Azmee, N.M.; Nuruddin, M.F. Impact Performance of Low Cement Ultra-High-Performance Concrete. WIT Trans. Ecol. Environ. 2017, 223, 481–488. [Google Scholar]

- Park, S.H.; Kim, D.J.; Ryu, G.S.; Koh, K.T. Tensile Behavior of Ultra High Performance Hybrid Fiber Reinforced Concrete. Cem. Concr. Compos. 2012, 34, 172–184. [Google Scholar] [CrossRef]

- Mészöly, T.; Ofner, S.; Randl, N. Effect of Combining Fiber and Textile Reinforcement on the Flexural Behavior of UHPC Plates. Adv. Mater. Sci. Eng. 2020, 2020, 9891619. [Google Scholar] [CrossRef]

- Christ, R.; Pacheco, F.; Ehrenbring, H.; Quinino, U.; Mancio, M.; Muñoz, Y.; Tutikian, B. Study of Mechanical Behavior of Ultra-High Performance Concrete (UHPC) Reinforced with Hybrid Fibers and with Reduced Cement Consumption. Rev. Ing. Construcción 2019, 34. [Google Scholar] [CrossRef] [Green Version]

- Abbas, S.; Nehdi, M.L.; Saleem, M.A. Ultra-High Performance Concrete: Mechanical Performance, Durability, Sustainability and Implementation Challenges. Int. J. Concr. Struct. Mater. 2016, 10, 271–295. [Google Scholar] [CrossRef] [Green Version]

- Fennis, S.A.A.M.; Walraven, J.C.; Den Uijl, J.A. The Use of Particle Packing Models to Design Ecological Concrete. Heron 2009, 54, 185–204. [Google Scholar]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Mix Design and Properties Assessment of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Taghaddos, H.; Mahmoudzadeh, F.; Pourmoghaddam, A.; Shekarchizadeh, M. Prediction of Compressive Strength Behaviour in RPC with Applying an Adaptive Network-Based Fuzzy Interface System. In Proceedings of the International Symposium on Ultra High Performance Concrete, Kassel, Germany, 13–15 September 2004; pp. 273–284. [Google Scholar]

- Ghafari, E.; Costa, H.; Júlio, E. RSM-Based Model to Predict the Performance of Self-Compacting UHPC Reinforced with Hybrid Steel Micro-Fibers. Constr. Build. Mater. 2014, 66, 375–383. [Google Scholar] [CrossRef]

- Ahmad, J.; Aslam, F.; Martinez-Garcia, R.; De-Prado-Gil, J.; Qaidi, S.M.A.; Brahmia, A. Effects of Waste Glass and Waste Marble on Mechanical and Durability Performance of Concrete. Sci. Rep. 2021, 11, 21525. [Google Scholar] [CrossRef]

- Ahmad, J.; Zaid, O.; Aslam, F.; Shahzaib, M.; Ullah, R.; Alabduljabbar, H.; Khedher, K.M. A Study on the Mechanical Characteristics of Glass and Nylon Fiber Reinforced Peach Shell Lightweight Concrete. Materials 2021, 14, 4488. [Google Scholar] [CrossRef]

- Ahmad, J.; Tufail, R.F.; Aslam, F.; Mosavi, A.; Alyousef, R.; Faisal Javed, M.; Zaid, O.; Khan Niazi, M.S. A Step towards Sustainable Self-Compacting Concrete by Using Partial Substitution of Wheat Straw Ash and Bentonite Clay Instead of Cement. Sustainability 2021, 13, 824. [Google Scholar] [CrossRef]

- Prem, P.R.; Bharatkumar, B.H.; Iyer, N.R. Mechanical Properties of Ultra High Performance Concrete. World Acad. Sci. Eng. Technol. 2012, 68, 1969–1978. [Google Scholar]

- Teng, L.; Meng, W.; Khayat, K.H. Rheology Control of Ultra-High-Performance Concrete Made with Different Fiber Contents. Cem. Concr. Res. 2020, 138, 106222. [Google Scholar] [CrossRef]

- Ibrahim, M.A.; Farhat, M.; Issa, M.A.; Hasse, J.A. Effect of Material Constituents on Mechanical and Fracture Mechanics Properties of Ultra-High-Performance Concrete. ACI Mater. J. 2017, 114, 453. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Development of an Eco-Friendly Ultra-High Performance Concrete (UHPC) with Efficient Cement and Mineral Admixtures Uses. Cem. Concr. Compos. 2015, 55, 383–394. [Google Scholar] [CrossRef] [Green Version]

- He, J.; Chen, W.; Zhang, B.; Yu, J.; Liu, H. The Mechanical Properties and Damage Evolution of UHPC Reinforced with Glass Fibers and High-Performance Polypropylene Fibers. Materials 2021, 14, 2455. [Google Scholar] [CrossRef]

- Chen, H.-J.; Yu, Y.-L.; Tang, C.-W. Mechanical Properties of Ultra-High Performance Concrete before and after Exposure to High Temperatures. Materials 2020, 13, 770. [Google Scholar] [CrossRef] [Green Version]

- Fadzil, A.M.; Norhasri, M.; Hamidah, M.S.; Zaidi, M.R.; Mohd Faizal, J. Alteration of Nano Metakaolin for Ultra High Performance Concrete. In InCIEC 2013; Springer: Singapore, 2014; pp. 887–894. [Google Scholar]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Effect of Nano-Silica on the Hydration and Microstructure Development of Ultra-High Performance Concrete (UHPC) with a Low Binder Amount. Constr. Build. Mater. 2014, 65, 140–150. [Google Scholar] [CrossRef] [Green Version]

- Rezania, M.; Panahandeh, M.; Razavi, S.M.J.; Berto, F. Experimental Study of the Simultaneous Effect of Nano-Silica and Nano-Carbon Black on Permeability and Mechanical Properties of the Concrete. Theor. Appl. Fract. Mech. 2019, 104, 102391. [Google Scholar] [CrossRef]

- Wang, C.; Yang, C.; Liu, F.; Wan, C.; Pu, X. Preparation of Ultra-High Performance Concrete with Common Technology and Materials. Cem. Concr. Compos. 2012, 34, 538–544. [Google Scholar] [CrossRef]

- Hung, C.-C.; Chen, Y.-T.; Yen, C.-H. Workability, Fiber Distribution, and Mechanical Properties of UHPC with Hooked End Steel Macro-Fibers. Constr. Build. Mater. 2020, 260, 119944. [Google Scholar] [CrossRef]

- Mo, Z.; Wang, R.; Gao, X. Hydration and Mechanical Properties of UHPC Matrix Containing Limestone and Different Levels of Metakaolin. Constr. Build. Mater. 2020, 256, 119454. [Google Scholar] [CrossRef]

- Li, S.; Cheng, S.; Mo, L.; Deng, M. Effects of Steel Slag Powder and Expansive Agent on the Properties of Ultra-High Performance Concrete (UHPC): Based on a Case Study. Materials 2020, 13, 683. [Google Scholar] [CrossRef] [Green Version]

- Khatib, J.M. Metakaolin Concrete at a Low Water to Binder Ratio. Constr. Build. Mater. 2008, 22, 1691–1700. [Google Scholar] [CrossRef]

- Parande, A.K.; Babu, B.R.; Karthik, M.A.; Kumaar, K.K.D.; Palaniswamy, N. Study on Strength and Corrosion Performance for Steel Embedded in Metakaolin Blended Concrete/Mortar. Constr. Build. Mater. 2008, 22, 127–134. [Google Scholar] [CrossRef]

- Wild, S.; Khatib, J.M. Portlandite Consumption in Metakaolin Cement Pastes and Mortars. Cem. Concr. Res. 1997, 27, 137–146. [Google Scholar] [CrossRef]

- Weng, T.-L.; Lin, W.-T.; Cheng, A. Effect of Metakaolin on Strength and Efflorescence Quantity of Cement-Based Composites. Sci. World J. 2013, 2013, 606524. [Google Scholar] [CrossRef] [PubMed]

- Givi, A.N.; Rashid, S.A.; Aziz, F.N.A.; Salleh, M.A.M. Experimental Investigation of the Size Effects of SiO2 Nano-Particles on the Mechanical Properties of Binary Blended Concrete. Compos. Part B Eng. 2010, 41, 673–677. [Google Scholar] [CrossRef]

- Horszczaruk, E.; Sikora, P.; Cendrowski, K.; Mijowska, E. The Effect of Elevated Temperature on the Properties of Cement Mortars Containing Nanosilica and Heavyweight Aggregates. Constr. Build. Mater. 2017, 137, 420–431. [Google Scholar] [CrossRef]

- Behfarnia, K.; Rostami, M. Effects of Micro and Nanoparticles of SiO2 on the Permeability of Alkali Activated Slag Concrete. Constr. Build. Mater. 2017, 131, 205–213. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W.; Wang, D. Uniaxial Compression Behavior of Ultra-High Performance Concrete with Hybrid Steel Fiber. J. Mater. Civ. Eng. 2016, 28, 6016017. [Google Scholar] [CrossRef]

- Hamiruddin, N.A.; Abd Razak, R.; Muhammad, K. Effect of Steel Fibre Contents with High Strength Fibre Reinforced Concrete. J. Impact Factor 2018, 3, 113. [Google Scholar]

- Ferdosian, I.; Camões, A.; Ribeiro, M. High-Volume Fly Ash Paste for Developing Ultra-High Performance Concrete (UHPC). Ciência Tecnol. dos Mater. 2017, 29, e157–e161. [Google Scholar] [CrossRef]

- Li, Q.; Geng, H.; Huang, Y.; Shui, Z. Chloride Resistance of Concrete with Metakaolin Addition and Seawater Mixing: A Comparative Study. Constr. Build. Mater. 2015, 101, 184–192. [Google Scholar] [CrossRef]

- Abdelmelek, N.; Lubloy, E. Flexural Strength of Silica Fume, Fly Ash, and Metakaolin of Hardened Cement Paste after Exposure to Elevated Temperatures. J. Therm. Anal. Calorim. 2021, 11, 1–11. [Google Scholar] [CrossRef]

- Kwon, S.; Nishiwaki, T.; Kikuta, T.; Mihashi, H. Tensile Behavior of Ultra High Performance Hybrid Fiber Reinforced Cement-Based Composites. In Proceedings of the 8th International Conference on Fracture Mechanics of Concrete and Concrete Structures (FraMCoS-8), Toledo, Spain, 10–14 March 2013; pp. 1309–1314. [Google Scholar]

- Sabet, F.A.; Libre, N.A.; Shekarchi, M. Mechanical and Durability Properties of Self Consolidating High Performance Concrete Incorporating Natural Zeolite, Silica Fume and Fly Ash. Constr. Build. Mater. 2013, 44, 175–184. [Google Scholar] [CrossRef]

- Rossi, P. Influence of Fibre Geometry and Matrix Maturity on the Mechanical Performance of Ultra High-Performance Cement-Based Composites. Cem. Concr. Compos. 2013, 37, 246–248. [Google Scholar] [CrossRef]

- Heinz, D.; Ludwig, H.-M. Heat Treatment and the Risk of DEF Delayed Ettringite Formation in UHPC. In Proceedings of the International Symposium on UHPC, Kassel, Germany, 13–15 September 2004; pp. 717–730. [Google Scholar]

- Abbas, S.; Soliman, A.M.; Nehdi, M.L. Exploring Mechanical and Durability Properties of Ultra-High Performance Concrete Incorporating Various Steel Fiber Lengths and Dosages. Constr. Build. Mater. 2015, 75, 429–441. [Google Scholar] [CrossRef]

- Dobias, D.; Pernicova, R.; Mandlik, T. Water Transport Properties and Depth of Chloride Penetration in Ultra High Performance Concrete. Key Eng. Mater. 2016, 711, 137–142. [Google Scholar]

- Ahmad, J.; Aslam, F.; Zaid, O.; Alyousef, R.; Alabduljabbar, H. Mechanical and Durability Characteristics of Sustainable Concrete Modified with Partial Substitution of Waste Foundry Sand. Struct. Concr. 2021, 22, 2775–2790. [Google Scholar] [CrossRef]

- Du, H.; Du, S.; Liu, X. Durability Performances of Concrete with Nano-Silica. Constr. Build. Mater. 2014, 73, 705–712. [Google Scholar] [CrossRef] [Green Version]

- Thomas, M.; Green, B.; O’Neal, E.; Perry, V.; Hayman, S.; Hossack, A. Marine Performance of UHPC at Treat Island. In Proceedings of the 3rd International Symposium on UHPC and Nanotechnology for High Performance Construction Materials, Kassel, Germany, 7–9 March 2012; pp. 365–370. [Google Scholar]

- Yuan, Q.; Shi, C.; De Schutter, G.; Audenaert, K.; Deng, D. Chloride Binding of Cement-Based Materials Subjected to External Chloride Environment—A Review. Constr. Build. Mater. 2009, 23, 1–13. [Google Scholar] [CrossRef]

- Joshi, R.C.; Chatterji, S.; Achari, G.; Mackie, P. Reexamination of ASTM C 1202—Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. J. Test. Eval. 2000, 28, 59–61. [Google Scholar]

- Chen, Y.; Yu, R.; Wang, X.; Chen, J.; Shui, Z. Evaluation and Optimization of Ultra-High Performance Concrete (UHPC) Subjected to Harsh Ocean Environment: Towards an Application of Layered Double Hydroxides (LDHs). Constr. Build. Mater. 2018, 177, 51–62. [Google Scholar] [CrossRef]

- Angst, U.M.; Elsener, B.; Larsen, C.K.; Vennesland, Ø. Chloride Induced Reinforcement Corrosion: Electrochemical Monitoring of Initiation Stage and Chloride Threshold Values. Corros. Sci. 2011, 53, 1451–1464. [Google Scholar] [CrossRef]

- Li, G.; Zhou, J.; Yue, J.; Gao, X.; Wang, K. Effects of Nano-SiO2 and Secondary Water Curing on the Carbonation and Chloride Resistance of Autoclaved Concrete. Constr. Build. Mater. 2020, 235, 117465. [Google Scholar] [CrossRef]

- Voo, Y.L.; Foster, S.J. Characteristics of Ultra-High Performance ‘Ductile’Concrete and Its Impact on Sustainable Construction. IES J. Part A Civ. Struct. Eng. 2010, 3, 168–187. [Google Scholar] [CrossRef] [Green Version]

- AÏtcin, P.-C. Cements of Yesterday and Today: Concrete of Tomorrow. Cem. Concr. Res. 2000, 30, 1349–1359. [Google Scholar] [CrossRef]

- Schmidt, M.; Fehling, E.; Bornemann, R.; Bunje, K.; Teichmann, T. Ultra-High Performance Concrete: Perspective for the Precast Concrete Industry. Betonw. UND Fert. 2003, 69, 16–29. [Google Scholar]

- Mu, R.; Miao, C.; Luo, X.; Sun, W. Interaction between Loading, Freeze–Thaw Cycles, and Chloride Salt Attack of Concrete with and without Steel Fiber Reinforcement. Cem. Concr. Res. 2002, 32, 1061–1066. [Google Scholar] [CrossRef]

- Graybeal, B.A. Material Property Characterization of Ultra-High Performance Concrete; Federal Highway Administration Office of Infrastructure Research and Development: McLean, VA, USA, 2006. Available online: https://scholar.google.com/scholar?hl=en&as_sdt=0%2C5&q=87.%09Graybeal%2C+B.A.+Material+Property+Characterization+of+Ultra-High+Performance+Concrete%3B+United+States.+Federal+Highway+Admin-istration.+Office+of+Infrastructure+Research+and+Development+%3A+2006.&btnG= (accessed on 17 March 2022).

- Vernet, C.P. Ultra-Durable Concretes: Structure at the Micro-and Nanoscale. MRS Bull. 2004, 29, 324–327. [Google Scholar] [CrossRef]

- Bonneau, O.; Vernet, C.; Moranville, M.; AÏtcin, P.-C. Characterization of the Granular Packing and Percolation Threshold of Reactive Powder Concrete. Cem. Concr. Res. 2000, 30, 1861–1867. [Google Scholar] [CrossRef]

- Liu, J.; Song, S.; Wang, L. Durability and Micro-Structure of Reactive Powder Concrete. J. Wuhan Univ. Technol. Sci. Ed. 2009, 24, 506–509. [Google Scholar] [CrossRef]

- Wang, L.; Guo, F.; Yang, H.; Wang, Y.A.N.; Tang, S. Comparison of Fly Ash, PVA Fiber, MgO and Shrinkage-Reducing Admixture on the Frost Resistance of Face Slab Concrete via Pore Structural and Fractal Analysis. Fractals 2021, 29, 2140002. [Google Scholar] [CrossRef]

- Dowd, W.M.; Dauriac, C.E. Reactive Powder Concrete: A French Engineering Company Has Developed a Concrete with a Compressive Strength Two to Four Times Greater than That of HPC. Constr. Specif. 1996, 49, 47–53. [Google Scholar]

- Yazıcı, H. The Effect of Silica Fume and High-Volume Class C Fly Ash on Mechanical Properties, Chloride Penetration and Freeze–Thaw Resistance of Self-Compacting Concrete. Constr. Build. Mater. 2008, 22, 456–462. [Google Scholar] [CrossRef]

- Kamen, A. Time Dependent Behaviour of Ultra High Performance Fibre Reinforced Concrete (UHPFRC). In Proceedings of the 6th International PhD Symposium in Civil Engineering, Zurich, Switzerland, 23–26 August 2006. [Google Scholar]

- Shen, P.; Lu, L.; He, Y.; Rao, M.; Fu, Z.; Wang, F.; Hu, S. Experimental Investigation on the Autogenous Shrinkage of Steam Cured Ultra-High Performance Concrete. Constr. Build. Mater. 2018, 162, 512–522. [Google Scholar] [CrossRef]

- Garas, V.Y.; Kahn, L.F.; Kurtis, K.E. Short-Term Tensile Creep and Shrinkage of Ultra-High Performance Concrete. Cem. Concr. Compos. 2009, 31, 147–152. [Google Scholar] [CrossRef]

- Burkart, I.; Müller, H.S. Creep and Shrinkage Characteristics of Ultra High Strength Concrete (UHPC). In Proceedings of the Second International Symposium on Ultra High Performance Concrete, Kassel, Germany, 5–7 March 2008; pp. 469–476. [Google Scholar]

- Kamen, A.; Denarié, E.; Sadouki, H.; Brühwiler, E. UHPFRC Tensile Creep at Early Age. Mater. Struct. 2009, 42, 113–122. [Google Scholar] [CrossRef]

- Graybeal, B.A. Characterization of the Behavior of Ultra-High Performance Concrete; University of Maryland: College Park, MD, USA, 2005; ISBN 0542183056. [Google Scholar]

- Fanourakis, G.C.; Ballim, Y. Predicting Creep Deformation of Concrete: A Comparison of Results from Different Investigations. In Proceedings of the 11th FIG Symposium on Deformation Measurements, Santorini, Greece, 25–28 May 2003; Volume 11. [Google Scholar]

- Bărbos, G. Long-Term Behavior of Ultra–High Performance Concrete (UHPC) Bended Beams. Procedia Technol. 2016, 22, 203–210. [Google Scholar] [CrossRef] [Green Version]

- Shihada, S.; Arafa, M. Effects of Silica Fume, Ultrafine and Mixing Sequences on Properties of Ultra High Performance Concrete. Asian J. Mater. Sci. 2010, 2, 137–146. [Google Scholar] [CrossRef] [Green Version]

- Liang, X.; Wu, C.; Su, Y.; Chen, Z.; Li, Z. Development of Ultra-High Performance Concrete with High Fire Resistance. Constr. Build. Mater. 2018, 179, 400–412. [Google Scholar] [CrossRef]

- Way, R.; Wille, K. Material Characterization of an Ultra-High Performance Fibre-Reinforced Concrete under Elevated Temperature. In Proceedings of the 3rd International Symposium on UHPC and Nanotechnology for High Performance Construction Materials, Kassel, Germany, 7–9 March 2012; pp. 565–572. [Google Scholar]

- Buttignol, T.E.T.; Sousa, J.; Bittencourt, T.N. Ultra High-Performance Fiber-Reinforced Concrete (UHPFRC): A Review of Material Properties and Design Procedures. Rev. IBRACON Estruturas e Mater. 2017, 10, 957–971. [Google Scholar] [CrossRef] [Green Version]

- Tai, Y.-S.; Pan, H.-H.; Kung, Y.-N. Mechanical Properties of Steel Fiber Reinforced Reactive Powder Concrete Following Exposure to High Temperature Reaching 800 °C. Nucl. Eng. Des. 2011, 241, 2416–2424. [Google Scholar] [CrossRef]

- Li, H.; Liu, G. Tensile Properties of Hybrid Fiber-Reinforced Reactive Powder Concrete after Exposure to Elevated Temperatures. Int. J. Concr. Struct. Mater. 2016, 10, 29–37. [Google Scholar] [CrossRef] [Green Version]

- Banerji, S.; Solhmirzaei, R.; Kodur, V.K.R. Fire Response of Ultra High Performance Concrete Beams. Proc. Int. Interact. Sympos. Ultra-High Perform. Concr. 2019, 2. [Google Scholar] [CrossRef]

- Kodur, V.; Banerji, S.; Solhmirzaei, R. Effect of Temperature on Thermal Properties of Ultrahigh-Performance Concrete. J. Mater. Civ. Eng. 2020, 32, 4020210. [Google Scholar] [CrossRef]

- Alkaysi, M.; El-Tawil, S.; Liu, Z.; Hansen, W. Effects of Silica Powder and Cement Type on Durability of Ultra High Performance Concrete (UHPC). Cem. Concr. Compos. 2016, 66, 47–56. [Google Scholar] [CrossRef]

- Ghafari, E.; Costa, H.; Júlio, E.; Portugal, A.; Durães, L. The Effect of Nanosilica Addition on Flowability, Strength and Transport Properties of Ultra High Performance Concrete. Mater. Des. 2014, 59, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Scheydt, J.C.; Müller, H.S. Microstructure of Ultra High Performance Concrete (UHPC) and Its Impact on Durability. In Proceedings of the 3rd International Symposium on UHPC and Nanotechnology for High Performance Construction Materials, Kassel, Germany, 7–9 March 2012; pp. 349–356. [Google Scholar]

- Teichmann, T.; Schmidt, M. Influence of the Packing Density of Fine Particles on Structure, Strength and Durability of UHPC. In Proceedings of the International Symposium on Ultra High Performance Concrete, Kassel, Germany, 13–15 September 2004; pp. 313–323. [Google Scholar]

- Piérard, J.; Dooms, B.; Cauberg, N. Durability Evaluation of Different Types of UHPC. In Proceedings of the RILEM-fib-AFGC International Symposium on Ultra-High Performance Fiber-Reinforced Concrete, Marseille, France, 1–3 October 2013; pp. 275–284. [Google Scholar]

- Huang, H.; Gao, X.; Wang, H.; Ye, H. Influence of Rice Husk Ash on Strength and Permeability of Ultra-High Performance Concrete. Constr. Build. Mater. 2017, 149, 621–628. [Google Scholar] [CrossRef]

- Coutinho, J.S. The Combined Benefits of CPF and RHA in Improving the Durability of Concrete Structures. Cem. Concr. Compos. 2003, 25, 51–59. [Google Scholar] [CrossRef]

- Valipour, M.; Khayat, K.H. Coupled Effect of Shrinkage-Mitigating Admixtures and Saturated Lightweight Sand on Shrinkage of UHPC for Overlay Applications. Constr. Build. Mater. 2018, 184, 320–329. [Google Scholar] [CrossRef]

- Hájek, P.; Fiala, C. Environmentally Optimized Floor Slabs Using UHPC-Contribution to Sustainable Building. In Proceedings of the 2nd International Symposium on Ultra-High Performance Concrete, Kassel, Germany, 5–7 March 2008; pp. 879–886. [Google Scholar]

- Racky, P. Cost-Effectiveness and Sustainability of UHPC. In Proceedings of the International Symposium on Ultra High Performance Concrete, Kassel, Germany, 13–15 September 2004; pp. 797–805. [Google Scholar]

- Walraven, J. On the Way to Design Recommendations for UHPFRC. In Proceedings of the Second International Symposium on UHPC, Kassel, Germany, 5–7 March 2008; pp. 45–56. [Google Scholar]

- Blais, P.Y.; Couture, M. Precast, Prestressed Pedestrian Bridge—World’s First Reactive Powder Concrete Structure. PCI J. 1999, 44, 60–71. [Google Scholar] [CrossRef] [Green Version]

| Reference | Fiber Type | Length (mm) | Diameter (mm) | Tensile Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|---|---|

| Wu et al. (a) [27] | Straight Hooked-end Corrugated | 13 | 0.2 | 2800 | 300 |

| Shafieifar et al. [28] | Straight steel fiber | 12.5 | 0.2 | 2600 | 278 |

| Wu et al. (b) [29] | Straight brass-coated steel fibers | 13 | 0.2 | 1900 | 203 |

| Meng et al. [30] | Straight steel fiber Carbon nanofibers Graphite nanoplates Graphite nanoplates | 13 50–200 × 103 25 30 | 0.2 100 2–10 2–10 | 1900 30,000 5000 5000 | 203 240 1000 1000 |

| Kim et al. [31] | Brass-coated smooth steel fibers | 19.5 | 0.2 | 2450 | 203 |

| Azmee et al. [32] | Straight steel fiber Hooked-end steel fiber | 20 25 | 0.2 0.3 | >2300 >2300 | >246 >246 |

| Park et al. [33] | Straight fiber Hooked-end fiber | 6 30 | 60 × 10−3 380 × 10−3 | 2000 3000 | 206 206 |

| Meszoly et al. [34] | Steel fibers | 15 | 0.2 | >2000 | 200 |

| Christ et al. [35] | Steel fibers Polypropylene | 13 6 | 0.21 0.12 | 2750 500–700 | 200 5 |

| Reference | Material | Utilization (Kg/m3) |

|---|---|---|

| Prem et al. [44] | Cement Silica fume Quartz W/C Steel fiber 13 mm × 0.16 Ø 6 mm × 0.16 Ø | 788 197 315 0.22 ----- 2–2.5% 2–2.5% |

| Teng et al. [45] | Cement Fly ash (Class-C) Silica fume Welan gun powder Steel fiber W/C | 642–662 401–413 41–42 0.18–0.27% 1–3% 0.2 |

| Ibrahim et al. [46] | Cement Fine sand Silica fume Ground silica HRWRA Steel fiber W/C | 712 1020 231 161.5 31 0–2% 0.18–0.24 |

| Azmee et al. [32] | Cement Silica fume Fly ash Sand Steel fiber W/C | 360–900 90 or (10%) 270–450 or (30, 40, 50%) 620 1% 0.16 |

| Yu et al. [47] | Cement Fly ash GGBS Limestone powder Sand Micro-sand Nano-silica Steel fiber W/C | 582.1–896.3 259.9–267.9 266.1–274.5 264.6–272.9 1039.5–1106.6 216.6–230.5 24.3–25.8 0 0.16–0.2 |

| He et al. [48] | Cement Silica fume Quartz powder Quartz sand-I Quartz sand-II W/C Superplasticizers Glass fiber High-performance polypropylene fiber | 750 90 263 306 714 0.255 12 0–2 0–2 |

| Chen et al. [49] | Cement Silica fume Ultra-fine silica powder Viscous agent Steel fiber Polypropylene fiber W/C Superplasticizers | 737–1005 0–191 0–31 1 0–0.8 0–78 0.195 25 |

| Fadzil et al. [50] | Cement Metakaolin Nano metakaolin Superplasticizers W/C | 720 and 800 80 0–72 16 0.2 |

| Authors/ Reference | Material | W/C | SP | Fiber (%) | Slump (mm) | Spread (mm) | Air Content (%) |

|---|---|---|---|---|---|---|---|

| Wu et al. [27] | Silica fume | 0.18 | Polycarboxylate | Straight 0 1 2 3 Corrugated 1 2 3 Hooked 1 2 3 | ------- 215 190 165 138 ------- 178 153 123 ------ 179 139 104 | ------- | ------- |

| Wang et al. [53] | SF 10% GGBS 0 20 40 LP 0 20 40 | 0.18 | Amino sulfonic acid | NA | 245 255 210 ----- 210 285 287 | 570 565 490 ----- 445 685 690 | ------- |

| Hung et al. [54] | SF + QP | 0.135 | Polycarboxylate | Macro-steel fiber 0 1 2 | 135 265 330 | 410 645 740 | ---- |

| Meng et al. [30] | GNPs, SF, FA | 0.2 | Polycarboxylate | %GNP’s/%CNF’s 0/0 0.05/0.05 0.1/0.1 0.15/0.15 0.2/0.2 0.3/0.3 | ----- | ----- | GNP’s/CNF’s 2.5/2.5 2.61/2.62 2.5/2.5 2.6/2.8 2.98/3.01 2.82/3.20 |

| Mo et al. [55] | LS-30% MK 0 5 10 15 20 | 0.2 | Polycarboxylate | NA | ----- | 296 287 274 267 248 | 7.89 7.57 7.42 7.30 7.67 |

| Teng et al. [45] | Class-C fly ash 40% Silica fume 5% Air-detraining admixture, polyether, 0.8% | 0.2 | Polycarboxylate | WG 0% 0.18% 0.22% 0.27% | 280 270 265 260 | Mini V-funnel Flow Tim-Sec | 1 1.51 2.51 3.03 |

| 11 20 32 60 | |||||||

| Chen et al. [49] | Silica fume-SF Ultra-fine silicon powder-SFP | 0.195 | Polycarboxylate | (StF + PPF + SF + SFP) % | ID | 262 255 257 ---- 260 255 250 | 690 530 540 ---- 490 530 510 |

| 0 + 0 + 0 + 0 0.5 + 0.03 + 17.4 + 2.2 1 + 0.06 + 18.7 + 2.2 ----------------- 0.75 + 0.03 + 18.7 + 3.2 0.75 + 0.09 + 20 + 2.2 1 + 0.03 + 20 + 2.7 | UHPC1 UHPC2 UHPC3 --------- UHPC4 UHPC5 UHPC6 | ||||||

| Yu et al. [51] | Nano-silica (%) 0 1 2 3 4 5 | 0.4 | Polycarboxylic ether | Macro-steel fiber (0–2.5)% | 337 331 315 284 263 225 | ----- | 2 2.1 2.3 2.4 2.8 3.4 |

| Christ et al. [35] | Fly ash (45%) silica fume (90%) | 0.45 | Polycarboxylate | St. F = 3% | PPF = 3% | 210 216 219 218 220 221 240 | ----- |

| 0% 50% 60% 705 80% 90% 100% | 100% 50% 40% 30% 20% 10% 0% | ||||||

| Li et al. [56] | -LS = 20% and SF = 10% -Steel slag powder (SSP) -Hybrid magnesia expansive agent (EA) | 0.16 | Polycarboxylate | Straight steel fibers 2% | ----- | ||

| ----- | 610 610 605 600 590 585 560 | ||||||

| SSP% | EA% | ||||||

| 0 10 15 20 0 15 15 | 0 0 0 0 5 5 8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ullah, R.; Qiang, Y.; Ahmad, J.; Vatin, N.I.; El-Shorbagy, M.A. Ultra-High-Performance Concrete (UHPC): A State-of-the-Art Review. Materials 2022, 15, 4131. https://doi.org/10.3390/ma15124131

Ullah R, Qiang Y, Ahmad J, Vatin NI, El-Shorbagy MA. Ultra-High-Performance Concrete (UHPC): A State-of-the-Art Review. Materials. 2022; 15(12):4131. https://doi.org/10.3390/ma15124131

Chicago/Turabian StyleUllah, Rahat, Yuan Qiang, Jawad Ahmad, Nikolai Ivanovich Vatin, and Mohammed A. El-Shorbagy. 2022. "Ultra-High-Performance Concrete (UHPC): A State-of-the-Art Review" Materials 15, no. 12: 4131. https://doi.org/10.3390/ma15124131

APA StyleUllah, R., Qiang, Y., Ahmad, J., Vatin, N. I., & El-Shorbagy, M. A. (2022). Ultra-High-Performance Concrete (UHPC): A State-of-the-Art Review. Materials, 15(12), 4131. https://doi.org/10.3390/ma15124131