Modeling and Control of Layer Height in Laser Wire Additive Manufacturing

Abstract

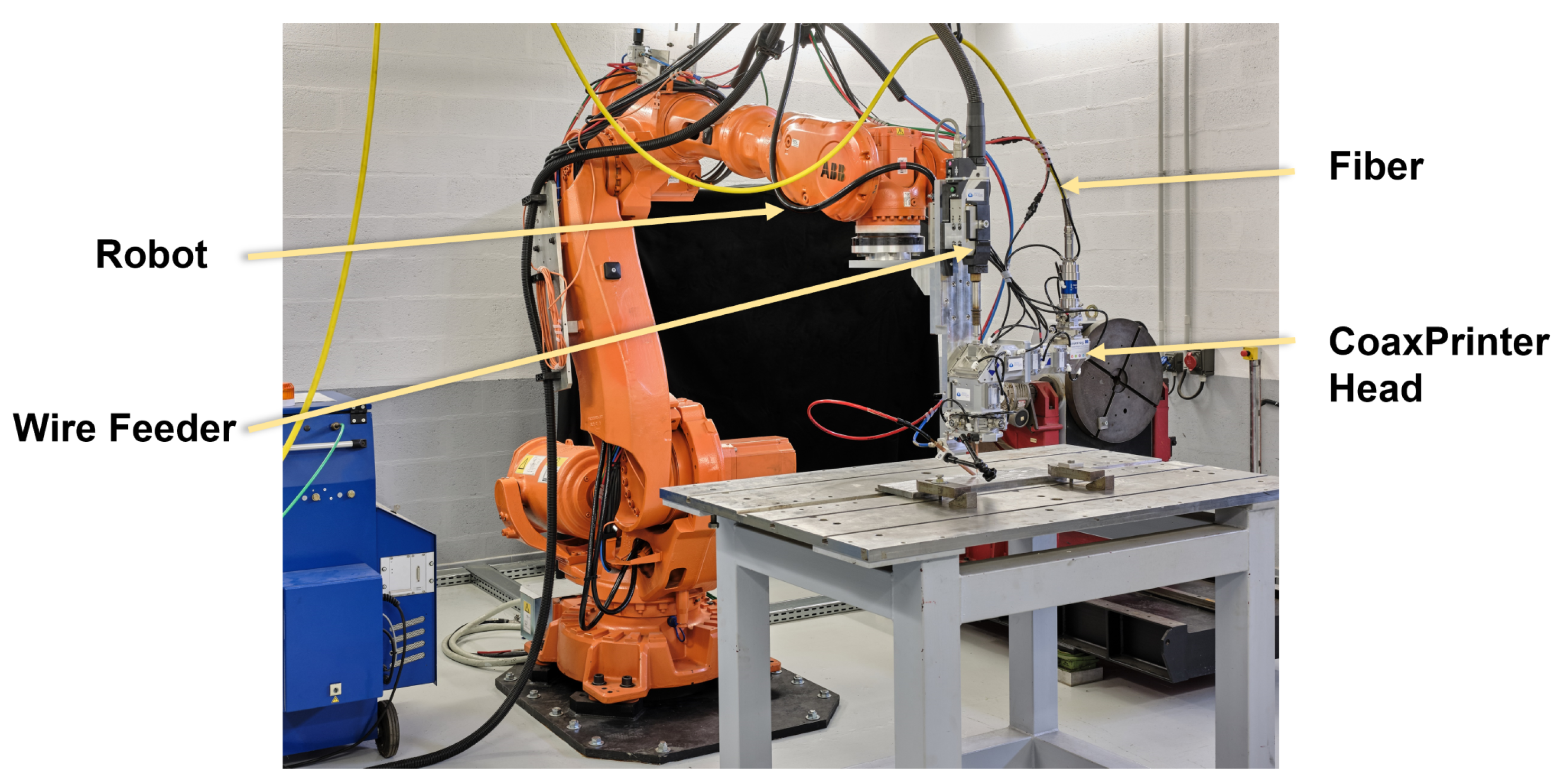

:1. Introduction

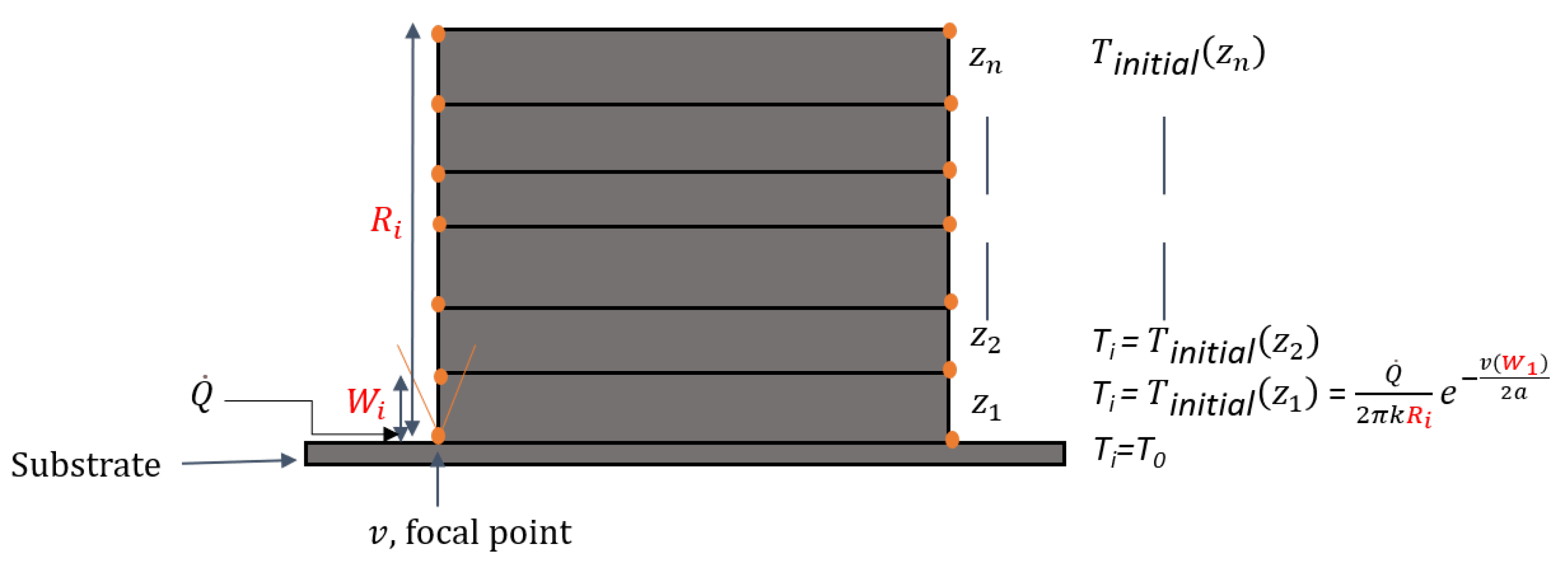

2. Numerical Model

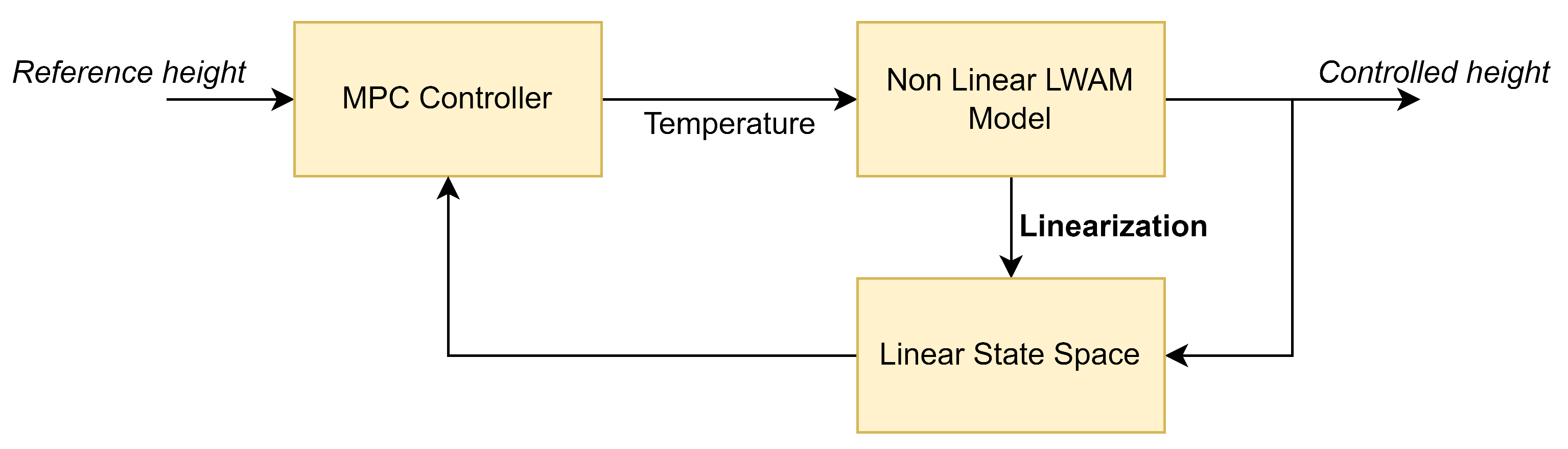

3. Model Predictive Controller Design

3.1. Model Linearization

3.2. Controller Design

4. Simulation and Experimental Results

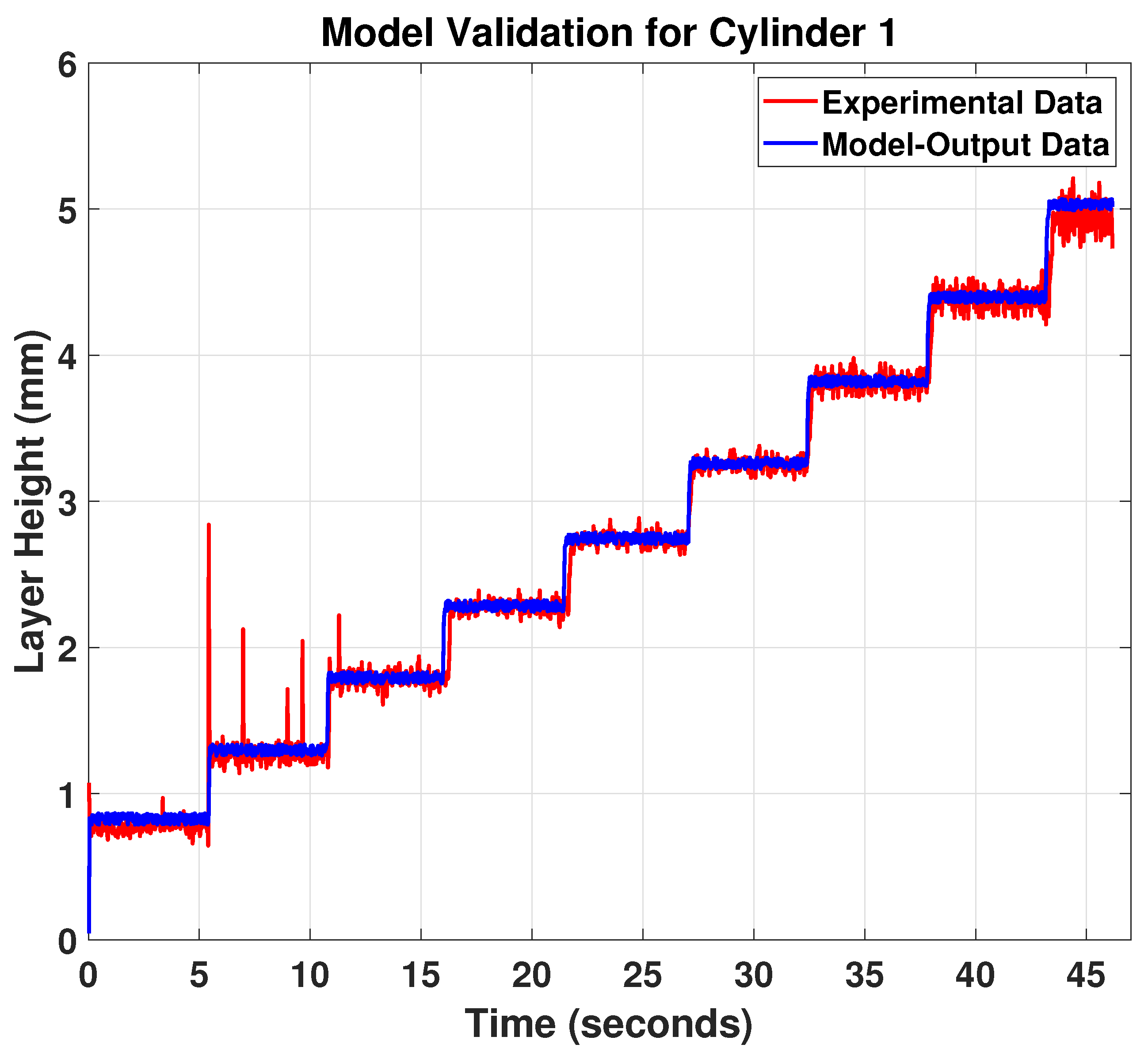

4.1. Numerical Model Validation

4.2. Layer Height Controller

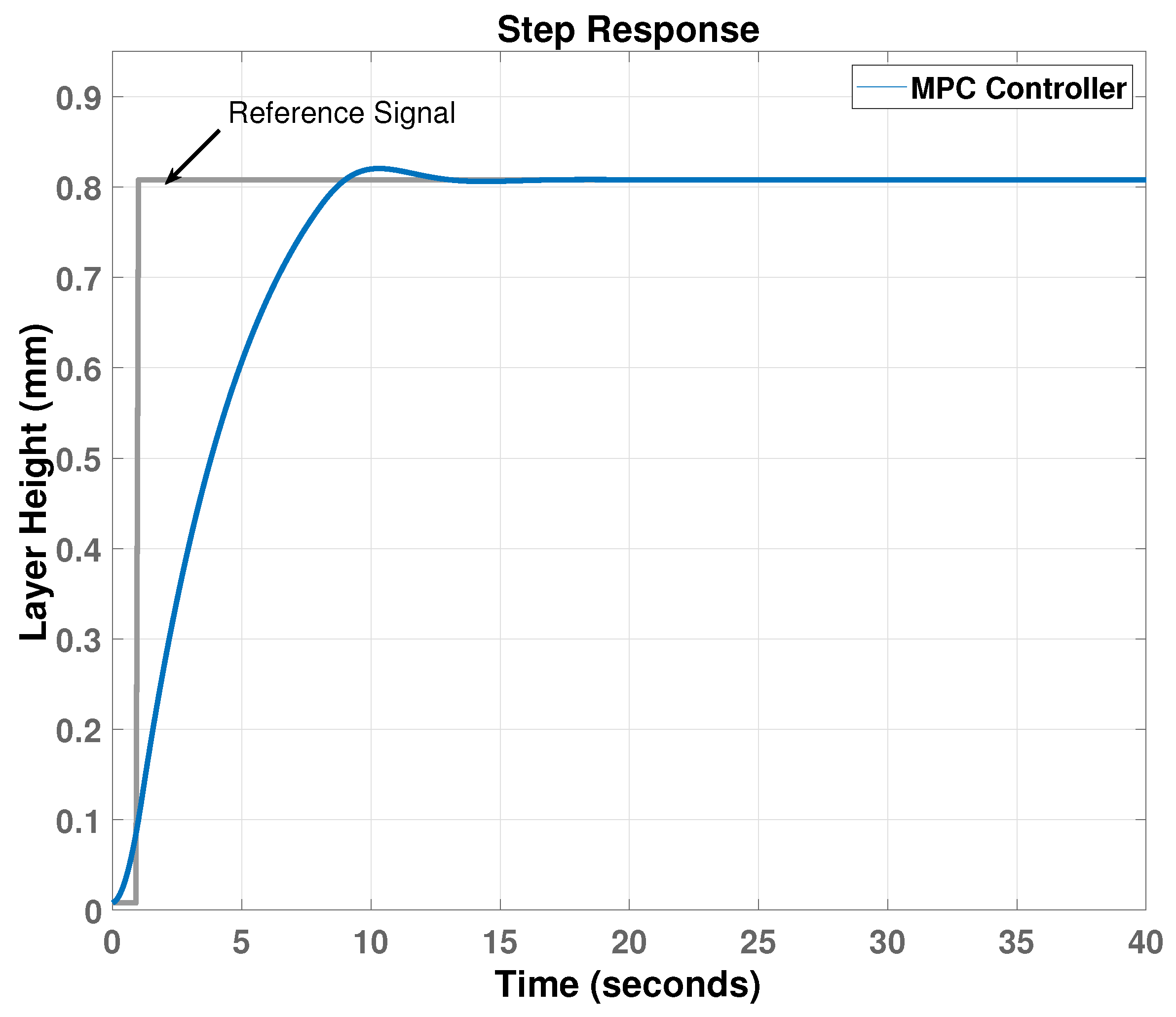

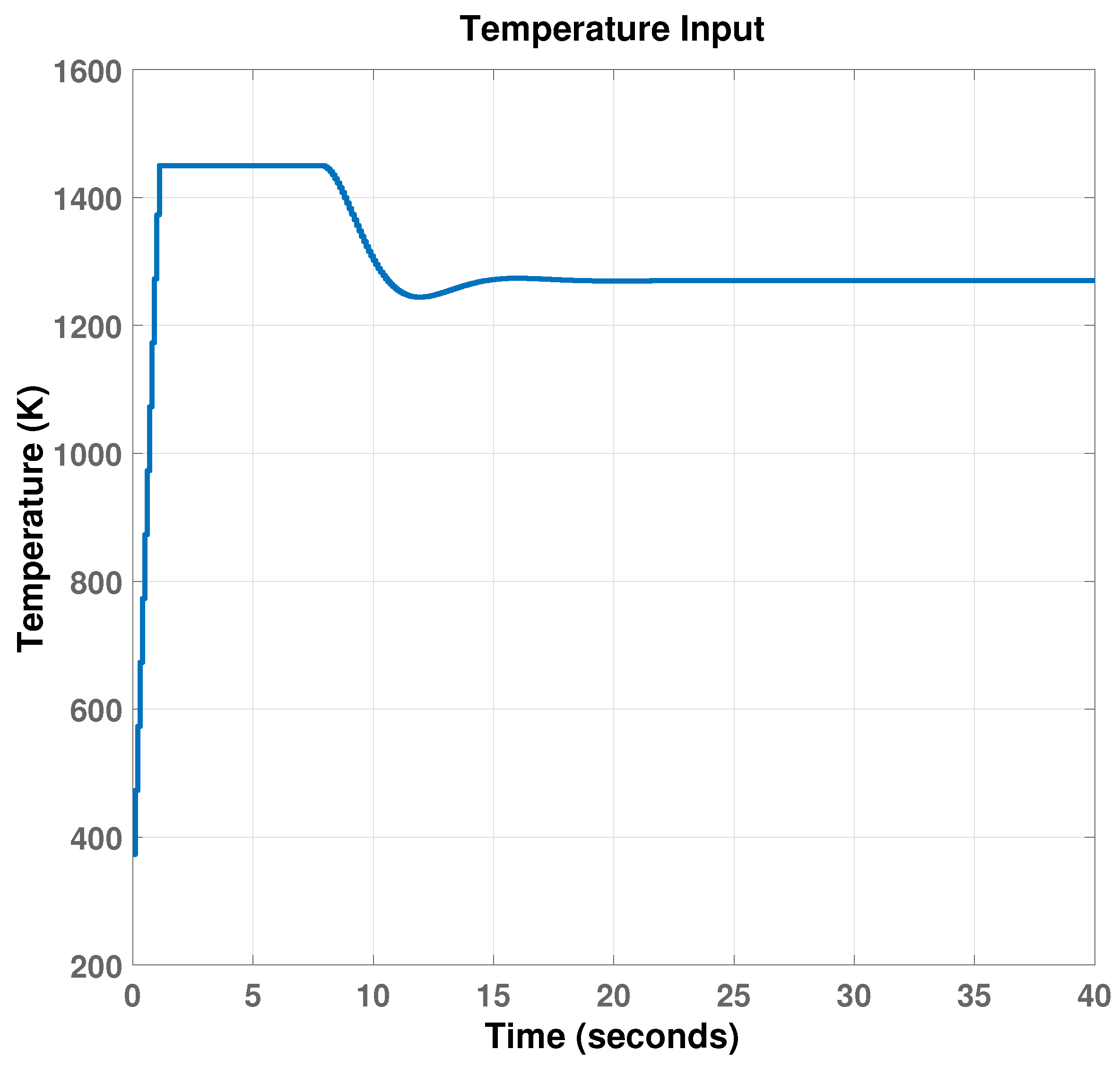

5. Conclusions

- The proposed model describes and simulates the behavior of the bead geometry in the laser wire additive manufacturing process.

- The temperature is an important input parameter and significantly influences the layer by layer deposition.

- The MPC controller can track the reference height and regulate the temperature input while keeping the parameters in their region of operation.

- The system response shows an acceptable transient response with less overshoot.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| MDPI | Multidisciplinary Digital Publishing Institute |

| DOAJ | Directory of open access journals |

| TLA | Three letter acronym |

| LD | Linear dichroism |

Appendix A

References

- Sing, S.; Tey, C.; Tan, J.; Huang, S.; Yeong, W.Y. 3D printing of metals in rapid prototyping of biomaterials: Techniques in additive manufacturing. In Rapid Prototyping of Biomaterials; Woodhead Publishing: Cambridge, UK, 2020; pp. 17–40. [Google Scholar] [CrossRef]

- Molitch-Hou, M. Overview of Additive Manufacturing Process; Elsevier: Cambridge, UK, 2018. [Google Scholar]

- Yakout, M.; Elbestawi, M.; Veldhuis, S.C. A Review of Metal Additive Manufacturing Technologies. Solid State Phenom. 2018, 278, 1–14. [Google Scholar] [CrossRef]

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Application of Directed Energy Deposition-Based Additive Manufacturing in Repair. Appl. Sci. 2019, 9, 3316. [Google Scholar] [CrossRef] [Green Version]

- Domack, C.S. Challenges in Metal Additive Manufacturing for Large-Scale Aerospace Applications. In Women in Aerospace Materials; Springer: Cham, Switzerland, 2020; pp. 105–124. [Google Scholar]

- Khorasani, A.M.; Gibson, I.; Goldberg, M.; Littlefair, G. A survey on mechanisms and critical parameters on solidification of selective laser melting during fabrication of Ti-6Al-4V prosthetic acetabular cup. Mater. Des. 2016, 103, 348–355. [Google Scholar] [CrossRef]

- Sreekanth, S.; Ghassemali, E.; Hurtig, K.; Joshi, S.; Andersson, J. Effect of Direct Energy Deposition Process Parameters on Single-Track Deposits of Alloy 718. Metals 2020, 10, 96. [Google Scholar] [CrossRef] [Green Version]

- Huang, W.; Chen, S.; Xiao, J.; Jiang, X.; Jia, Y. Laser wire-feed metal additive manufacturing of the Al alloy. Opt. Laser Technol. 2021, 134, 106627. [Google Scholar] [CrossRef]

- Mbodj, N.G.; Abuabiah, M.; Plapper, P.; Kandaoui, M.E.; Yaacoubi, S. Bead Geometry Prediction in Laser-Wire Additive Manufacturing Process Using Machine Learning: Case of Study. Appl. Sci. 2021, 11, 11949. [Google Scholar] [CrossRef]

- Magerramova, L.; Isakov, V.; Shcherbinina, L.; Gukasyan, S.; Petrov, M.; Povalyukhin, D.; Volosevich, D.; Klimova-Korsmik, O. Design, Simulation and Optimization of an Additive Laser-Based Manufacturing Process for Gearbox Housing with Reduced Weight Made from AlSi10Mg Alloy. Metals 2021, 12, 67. [Google Scholar] [CrossRef]

- Liu, F.; Zhang, Q.; Zhou, W.; Zhao, J.; Chen, J. Micro scale 3D FEM simulation on thermal evolution within the porous structure in selective laser sintering. J. Mater. Process. Technol. 2012, 212, 2058–2065. [Google Scholar] [CrossRef]

- Fetni, S.; Enrici, T.M.; Niccolini, T.; Tran, H.S.; Dedry, O.; Duchêne, L.; Mertens, A.; Habraken, A.M. Thermal model for the directed energy deposition of composite coatings of 316L stainless steel enriched with tungsten carbides. Mater. Des. 2021, 204, 109661. [Google Scholar] [CrossRef]

- Corbin, D.J.; Nassar, A.R.; Reutzel, E.W.; Beese, A.M.; Kistler, N.A. Effect of directed energy deposition processing parameters on laser deposited Inconel® 718: External morphology. J. Laser Appl. 2017, 29, 022001. [Google Scholar] [CrossRef]

- Numerical Simulation Development and Computational Optimization for Directed Energy Deposition Additive Manufacturing Process. Materials 2020, 13, 2666. [CrossRef] [PubMed]

- Gockel, J.; Beuth, J.; Taminger, K. Integrated control of solidification microstructure and melt pool dimensions in electron beam wire feed additive manufacturing of Ti-6Al-4V. Addit. Manuf. 2014, 1–4, 119–126. [Google Scholar] [CrossRef]

- Doumanidis, C.; Kwak, Y.M. Geometry Modeling and Control by Infrared and Laser Sensing in Thermal Manufacturing with Material Deposition. J. Manuf. Sci. Eng. 2001, 123, 45–52. [Google Scholar] [CrossRef]

- Wang, Q.; Li, J.; Gouge, M.; Nassar, A.R.; Michaleris, P.P.; Reutzel, E.W. Physics-Based Multivariable Modeling and Feedback Linearization Control of Melt-Pool Geometry and Temperature in Directed Energy Deposition. J. Manuf. Sci. Eng. 2017, 139, 021013. [Google Scholar] [CrossRef]

- Huang, Y.; Khamesee, M.B.; Toyserkani, E. A comprehensive analytical model for laser powder-fed additive manufacturing. Addit. Manuf. 2016, 12, 90–99. [Google Scholar] [CrossRef]

- Huang, Y.; Khamesee, M.B.; Toyserkani, E. A new physics-based model for laser directed energy deposition (powder-fed additive manufacturing): From single-track to multi-track and multi-layer. Opt. Laser Technol. 2019, 109, 584–599. [Google Scholar] [CrossRef]

- Farshidianfar, M.H.; Khajepour, A.; Gerlich, A. Real-time control of microstructure in laser additive manufacturing. Int. J. Adv. Manuf. Technol. 2016, 82, 1173–1186. [Google Scholar] [CrossRef]

- Garmendia, I.; Pujana, J.; Lamikiz, A.; Madarieta, M.; Leunda, J. Structured light-based height control for laser metal deposition. J. Manuf. Process. 2019, 42, 20–27. [Google Scholar] [CrossRef]

- Heralić, A.; Christiansson, A.K.; Lennartson, B. Height control of laser metal-wire deposition based on iterative learning control and 3D scanning. Opt. Lasers Eng. 2012, 50, 1230–1241. [Google Scholar] [CrossRef]

- Gibson, B.T.; Bandari, Y.K.; Richardson, B.S.; Henry, W.C.; Vetland, E.J.; Sundermann, T.W.; Love, L.J. Melt pool size control through multiple closed-loop modalities in laser-wire directed energy deposition of Ti-6Al-4V. Addit. Manuf. 2020, 32, 100993. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Brandt, M. Model predictive control of laser metal deposition. Int. J. Adv. Manuf. Technol. 2019, 105, 1055–1067. [Google Scholar] [CrossRef]

- Xiong, J.; Yin, Z.; Zhang, W. Closed-loop control of variable layer width for thin-walled parts in wire and arc additive manufacturing. J. Mater. Process. Technol. 2016, 233, 100–106. [Google Scholar] [CrossRef]

- Farshidianfar, M.H.; Khajepour, A.; Zeinali, M.; Gelrich, A. System identification and height control of laser cladding using adaptive neuro-fuzzy inference systems. Int. Congr. Appl. Lasers Electro-Opt. 2013, 2013, 615–623. [Google Scholar] [CrossRef]

- Zeinali, M.; Khajepour, A. Height Control in Laser Cladding Using Adaptive Sliding Mode Technique: Theory and Experiment. J. Manuf. Sci. Eng. 2010, 132, 041016. [Google Scholar] [CrossRef]

- Melt Pool Temperature Control for Laser Metal Deposition Processes—Part II: Layer-to-Layer Temperature Control. J. Manuf. Sci. Eng. 2010, 132, 011011. [CrossRef] [Green Version]

- Eagar, T.W.; Tsai, N.S. Temperature fields produced by traveling distributed heat sources. Weld. Res. Suppl. 1983, 62, 346–355. [Google Scholar]

- Pinkerton, A.J.; Li, L. The significance of deposition point standoff variations in multiple-layer coaxial laser cladding (coaxial cladding standoff effects). Int. J. Mach. Tools Manuf. 2004, 44, 573–584. [Google Scholar] [CrossRef]

- Rosenthal, D. The Theory of Moving Sources of Heat and Its Application of Metal Treatments. Trans. ASME 1946, 68, 849–866. [Google Scholar]

- Morgan, R. Linearization and Stability Analysis of Nonlinear Problems. Rose–Hulman Undergrad. Math. J. 2015, 16, 5. [Google Scholar]

- Voos, H. Nonlinear state-dependent Riccati equation control of a quadrotor UAV. In Proceedings of the 2006 IEEE Conference on Computer Aided Control System Design, 2006 IEEE International Conference on Control Applications, 2006 IEEE International Symposium on Intelligent Control, Munich, Germany, 4–6 October 2006; pp. 2547–2552. [Google Scholar] [CrossRef] [Green Version]

- Brüls, O.; Eberhard, P. On the complete integrability and linearization of nonlinear ordinary differential equations. III. Coupled first-order equations. Proc. R. Soc. A Math. Phys. Eng. Sci. 2009, 465, 585–608. [Google Scholar] [CrossRef]

- Brüls, O.; Eberhard, P. Sensitivity analysis for dynamic mechanical systems with finite rotations. Int. J. Numer. Methods Eng. 2008, 74, 1897–1927. [Google Scholar] [CrossRef]

- Bastos, G.; Seifried, R.; Brüls, O. Analysis of stable model inversion methods for constrained underactuated mechanical systems. Mech. Mach. Theory 2017, 111, 99–117. [Google Scholar] [CrossRef]

- Xia, C.; Pan, Z.; Polden, J.; Li, H.; Xu, Y.; Chen, S.; Zhang, Y. A review on wire arc additive manufacturing: Monitoring, control and a framework of automated system. J. Manuf. Syst. 2020, 57, 31–45. [Google Scholar] [CrossRef]

- Rossiter, J.A. Model-Based Predictive Control: A Practical Approach; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Cao, L.; Yuan, X. Study on the Numerical Simulation of the SLM Molten Pool Dynamic Behavior of a Nickel-Based Superalloy on the Workpiece Scale. Materials 2019, 12, 2272. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Promoppatum, P.; Yao, S.C.; Pistorius, P.C.; Rollett, A.D. A Comprehensive Comparison of the Analytical and Numerical Prediction of the Thermal History and Solidification Microstructure of Inconel 718 Products Made by Laser Powder-Bed Fusion. Engineering 2017, 3, 685–694. [Google Scholar] [CrossRef]

- Curry, E.B.; Sahoo, S.; Herrera, C.; Sochnikov, I.; Alpay, S.P.; Hebert, R.J.; Willis, B.G.; Qi, J.; Hancock, J.N. Optical response of nickel-based superalloy Inconel-718 for applications in additive manufacturing. J. Appl. Phys. 2020, 127, 245111. [Google Scholar] [CrossRef]

- Díaz-Álvarez, J.; Tapetado, A.; Vázquez, C.; Miguélez, H. Temperature Measurement and Numerical Prediction in Machining Inconel 718. Sensors 2017, 17, 1531. [Google Scholar] [CrossRef]

- Cazic, I.; Zollinger, J.; Mathieu, S.; El Kandaoui, M.; Plapper, P.; Appolaire, B. New insights into the origin of fine equiaxed microstructures in additively manufactured Inconel 718. Scr. Mater. 2021, 195, 113740. [Google Scholar] [CrossRef]

| Power (W) | Travel Speed (m/min) | Wire Feed Rate (m/min) | Standoff Distance (mm) | Number of Layers | Layer Thickness (mm) | |

|---|---|---|---|---|---|---|

| Cylinder 1 | 2700 | 2.0 | 2.4 | 1.5 | 9 | 0.7 |

| Cylinder 2 | 2100 | 0.6 | 2.1 | 1.5 | 8 | 1.2 |

| Symbols | Parameters Name | Parameters Value | Sources | Units |

|---|---|---|---|---|

| Gain | Variable | Experiments | Unitless | |

| Q | Power | Variable | Experiments | W |

| C | Melt specific heat | 760–800 | [39] | J/(kg K) |

| Melting temperature | 1570 | [39] | K | |

| Temperature of the preceeding layer | Variable | Experiments | K | |

| Absorptivity of the melt pool | 0.5 | [40] | Unitless | |

| f | Focal length of the objective lens | 160 × 10−3 | laser beam is focess | m |

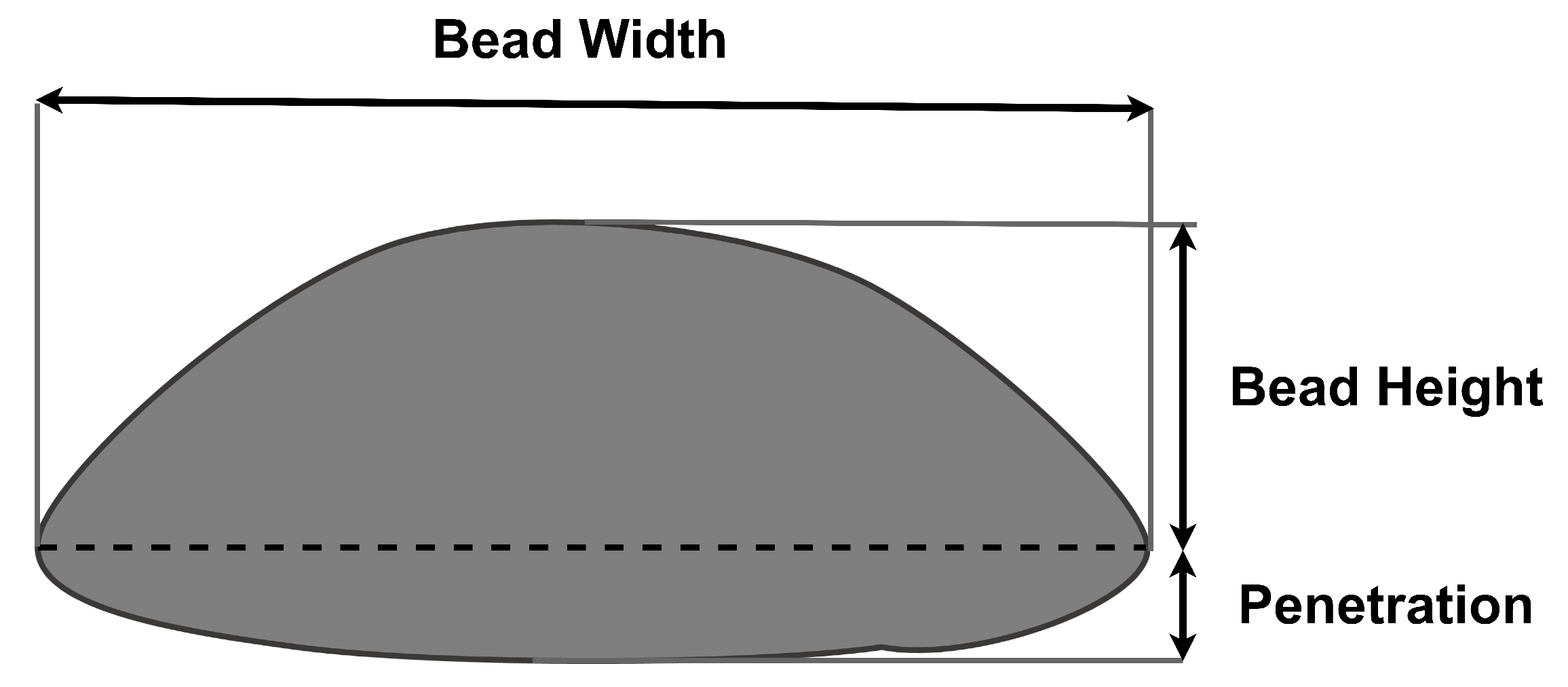

| w | Melt pool width | Variable | Experiments | m |

| Proportion of laser power | 0.7 | [41] | Unitless | |

| k | Thermal conductivity | 33 | [39] | W/m·K |

| Height of the product | Variable | Experiments | m | |

| D | Laser beam diameter of the laser | 3.95 × 10−3 | Relative to the printed head | m |

| Standoff distance | Variable | Experiments | m | |

| v | Travel speed of the robot | Variable | Experiments | m/s |

| Layer thickness | Variable | Experiments | m | |

| a | Thermal diffusivity | [42] | m2/s | |

| Melt pool density | Variable | material | kg/m3 | |

| r | Width over height ratio | Variable | Experiments | Unitless |

| h | Melt pool height | Output | Calculated using the model | m |

| Parameter | Definition |

|---|---|

| Constant gain | |

| Q | Input laser power |

| C | Quantity of heat needed to increase the temperature 1 K per unit mass (kg) |

| Melting temperature of the material | |

| Temperature of the layer where a new deposition will be done | |

| The degree to which the material absorbs the laser power | |

| f | The distance from the last lens to the point at which the laser beam is focussed |

| w | The measured width of a deposited bead |

| Reflected laser power from the material wire | |

| k | The rate at which the heat is transferred by conduction through a unit cross-section area of material |

| Total height of the part to be produced | |

| D | The diameter of the focuses laser beam |

| Distance from the substrate to the nozzle tip | |

| v | Deposition speed |

| Theoretical layer thickness | |

| a | The ability of the material to conduct thermal energy thermal energy |

| Density of the material - the mass of a unit volume of the material | |

| r | The ratio of the width to the height |

| h | Height of the deposited beads |

| Parameter | Value | Parameter | Value | Parameter | Value |

|---|---|---|---|---|---|

| 0.15 | D | 1.5 × 10−3 (m) | 0.7 (m) | ||

| C | 800 (J/(kg K) | 1570 (K) | 273 (K) | ||

| f | 160 × 10−3 (m) | w | 2.8 × 10−3 (m) | 0.7 | |

| r | 2.33 × 10−3 (m) | k | 33 (W/m·K) | 8145 (kg/m3) | |

| 12 × 10−3 (m) | a | 5.0 × 10−6 (m2/s) | 0.5 (m) |

| MPC Parameter | Min Value | Value | Max Value |

|---|---|---|---|

| Sampling time ( in s) | - | 0.1 | - |

| Prediction horizon () | - | 15 | - |

| Control horizon () | - | 3 | - |

| Input constraint (K) | 273 | - | 1450 |

| Output constraint (mm) | 0.75 | - | 0.9 |

| Input weight | - | 0 | - |

| Output weight (mm) | - | 5 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mbodj, N.G.; Abuabiah, M.; Plapper, P.; El Kandaoui, M.; Yaacoubi, S. Modeling and Control of Layer Height in Laser Wire Additive Manufacturing. Materials 2022, 15, 4479. https://doi.org/10.3390/ma15134479

Mbodj NG, Abuabiah M, Plapper P, El Kandaoui M, Yaacoubi S. Modeling and Control of Layer Height in Laser Wire Additive Manufacturing. Materials. 2022; 15(13):4479. https://doi.org/10.3390/ma15134479

Chicago/Turabian StyleMbodj, Natago Guilé, Mohammad Abuabiah, Peter Plapper, Maxime El Kandaoui, and Slah Yaacoubi. 2022. "Modeling and Control of Layer Height in Laser Wire Additive Manufacturing" Materials 15, no. 13: 4479. https://doi.org/10.3390/ma15134479

APA StyleMbodj, N. G., Abuabiah, M., Plapper, P., El Kandaoui, M., & Yaacoubi, S. (2022). Modeling and Control of Layer Height in Laser Wire Additive Manufacturing. Materials, 15(13), 4479. https://doi.org/10.3390/ma15134479