1. Introduction

Cement manufacture, which accounts for 12% to 15% of all industrial energy consumed worldwide and 5% to 7% of carbon dioxide (CO

2) emissions, is one of the priority targets for lowering energy consumption and the generation of greenhouse gases [

1].

One avenue for enhancing energy and environmental efficiency, while raising cement sustainability, is to use industrial waste as a partial replacement. Worldwide waste management has come to acquire vital importance, for the steep growth in the demand for natural resources is placing enormous pressure on the environment and society. One outcome has been the coining of new phrases in cement nomenclature such as green cement, the name applied to binders with a low clinker content and smaller carbon footprint than ordinary Portland cement (OPC). All such new eco-cements bear industrial waste as partial cement replacements. In light of their importance, these new cements are being studied as a priority line of research in initiatives such as the European Commission’s circular economy strategies, the European Environment Agency’s Green Deal, the United Nations’ Agenda 2030, and the general pursuit of carbon neutrality by 2050.

Existing European legislation [

2] addresses the partial replacement of cement with mineralogical additions from industrial waste, focusing in particular on those exhibiting pozzolanicity and which are consequently usable for the manufacture of binary and ternary eco-cements. Blended cements are known to be mechanically stronger and more durable than unadditioned binders [

3,

4,

5,

6].

The vast volumes of construction and demolition waste (CDW) generated globally is one of the types of industrial waste that has attracted the greatest researcher attention in recent years. Such waste is primarily applied as a recycled aggregate in eco-mortar and eco-concrete manufacture, which requires huge quantities of such materials [

7,

8,

9,

10,

11]. The use of concrete waste as coarse aggregate is presently envisaged in many countries’ structural legislation and codes [

12,

13,

14,

15].

Concrete waste is crushed and sieved to different particle size distributions for commercialisation. Coarse aggregate is used for the aforementioned applications as well as for other industrial activities (roads, concretes, embankments), whilst, for want of any industrial use, the fines (< 5mm) are simply stockpiled, unprotected in management plant yards.

A number of research teams [

16,

17,

18,

19,

20,

21], studying the scientific–technical viability of partially replacing cement with such fines, reported no substantial change in end-product chemistry or strength relative to OPC.

Due to their moderate pozzolanicity, further benefit might be drawn from fines if blended with highly pozzolanic mineralogical additions such as silica fume, activated rice-husk ash, bagasse ash, and glass [

20,

21,

22]. Glass is a non-crystalline, non-biodegradable ceramic that owes its high silica content (and indirectly, its properties) to non-crystalline silicates bearing variable amounts of oxides such as CaO, Na

2O, K

2O, and Al

2O

3 [

23,

24]. Approximately 10 Mt of today’s worldwide glass output of 130 Mt [

25] end up in landfills.

Soda–lime glass, the predominant type of glass, contains 66% to 75% SiO

2, 12% to 17% Na

2O, and 6% to 12% CaO [

26]. Its high reactive silica content informs its speedy pozzolanic reaction when added to cement, with the formation of secondary C-S-H gels in addition to those generated during anhydrous cement phase hydration [

27,

28].

Recent studies have attested to the substantial synergies between glass and concrete CDW fines, where the primary hydration product has been identified as C-S-H gels with sodium in their composition. Such products are characterised by a more highly polymerised structure than those generated in the absence of waste [

27].

To carry that line of research further, this study explored the synergies between two types of pozzolanic CDWs in a pozzolan/cement system bearing 7% of the addition at concrete/glass ratios of 1:2 and 2:1. The respective pastes were cured up to a total of 90 days. The ternary cements were characterised and the hydrated phases monitored using X-ray fluorescence (XRF), laser granulometry, Rietveld-refined X-ray diffraction (XRD), Fourier-transform infrared spectroscopy (FT-IR), nuclear magnetic resonance spectroscopy (NMR), thermogravimetric analysis/differential thermal analysis (TG/DTA), and scanning electron microscopy/energy dispersive X-ray analysis (SEM/EDX). The respective findings will play a significant role in the microstructure and engineering performance of future eco-mortars and eco-concretes.

2. Materials and Methods

2.1. Materials

Three types of CDW were chosen to prepare binary blends for the ternary cement pastes. Two consisted in fines (<5 mm) stockpiled at management plant yards, one in the region of Madrid, the by-product of processing waste concrete with natural siliceous aggregate (HsT), and the other at a yard in the Basque Country resulting from processing waste concrete from calcareous aggregate (HcG). The third waste was glass collected from a demolition site involving a residential building.

The ternary cement pastes (labelled as shown in

Table 1) were prepared with a binder in which 7% of commercial cement type CEM I 42.5R (Cementos Lemona, S.A., Lemoa, Bilbao, Spain) was replaced with the binary blend of recycled CDW pozzolans containing different portions of concrete fines and glass. The 7% replacement ratio was defined on the grounds of previous research [

16,

27].

The XRF-determined chemical composition of the resulting binders is listed in

Table 2 and their particle size distribution parameters are D10, D50, and D90 in

Table 3.

Cement matrix hydration reactivity at a constant water/binder ratio of 0.5 was determined on 1 × 1 × 6 cm3 prismatic specimens following Koch–Steinegger methodology. The hydration reaction was detained after 2 days, 28 days, or 90 days by soaking the specimens in acetone for 24 h, followed by vacuum drying for a further 24 h.

2.2. Methods

The majority oxides in the blended and control cements were quantified on pressed wafers with a Philips PW-1404 X-ray fluorescence spectrometer fitted with a Sc-Mo dual anode tube, Philips, Eindhoven, The Netherlands.

Variation in cement TG/DTA was measured in 40 mg to 50 mg samples on a Texas Instruments 600 SDT analyser (New Castle, DE) in a nitrogen atmosphere, ramping the temperature at a rate of 10 °C/min.

Cement fineness was found with dry dispersion laser diffraction particle-size analysis on a Malvern Mastersizer 3000 analyser (Pananalytical, Madrid, Spain) bearing red and blue (He-Ne and LED) light sources. The measuring range was 0.01 µm to 3500 μm.

The mineralogical phases were identified with a PANalytical X’Pert PRO diffractometer (Madrid, Spain) fitted with a copper anode, a 0.5° divergence slit, and 0.5 mm receiving slit, operating at 40 mA and 45 kV. Samples were studied over a 2θ angle range of 5° to 60°. The powder method was applied, using 5% rutile as the internal standard to quantify the crystalline phases, and the proportion of amorphous matter in the samples. Quantification was performed with Match v.3 and Rietveld analysis with Fullprof software (Crystal Impact, Dr. H. Putz & Dr. K. Brandenburg GbR, Bonn, Germany) [

29,

30]. The mineralogical phases present were identified using Crystallography Open Database (COD) entries as a reference (

Table 4).

NMR/MAS scans were recorded with a Bruker Avance-400 spectrometer (Bruker, Kontich, Germany). The recording conditions for the 29Si spectra were: resonance frequency, 79.5 MHz; rotational speed (NMR), 10 kHz; pulse length, 5 s; recycle delay, 10 s; external standard: tetramethylsilane (TMS). The respective conditions for 27Al were: resonance frequency, 104.3 MHz; rotational speed (NMR), 10 kHz; pulse length, 2 s; recycle delay, 5 s; external standard: (H2O)6+3.

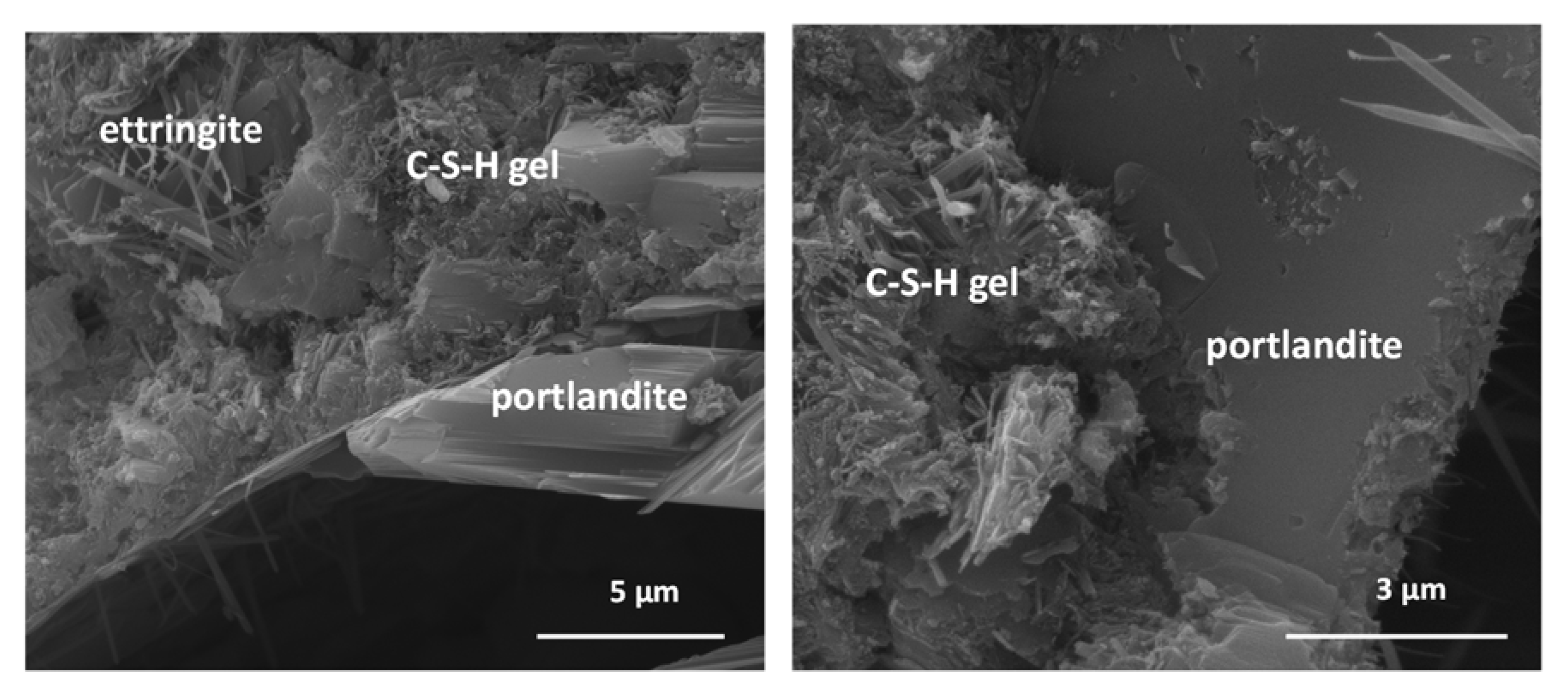

Morphological and elemental microanalyses were conducted on an Inspect FEI Company scanning electron microscope (SEM) fitted with an energy dispersive X-ray (EDX) analyser and a Si/Li detector. The semiquantitative chemical analysis values shown are the mean of 10 analyses per spot.

FTIR spectra were recorded with a Bruker Alpha spectrometer operating with a He–Ne laser at a range of 450 cm−1 to 4000 cm−1. The spectroscopy-grade 1% KBr pressed wafers and reference calcined clay samples were stored overnight at 250 °C to remove any adsorbed water.

4. Discussion

The synergies in a blend of pozzolans present in (calcareous and siliceous) waste concrete fines with recycled CDW glass were analysed in depth in the study reported in this article.

Ettringite and portlandite were the hydrated phases identified in the reference OPC paste. Their content, along with the amounts of C-S-H gels, rose with reaction time.

Partially replacing OPC with 7% of the binary blend, either HcG/glass or HsT/glass at ratios of 2:1 or 1:2, had no qualitative effect on the mineralogical phases produced with cement hydration. Quantitative changes were nonetheless observed. In the pastes with the higher HcG/glass ratio (2:1), ettringite, portlandite, and amorphous phase formation was enhanced, whereas in the pastes containing siliceous concrete (HsT/glass) C-S-H gel formation was favoured. In both cases, higher glass contents (1:2) delayed hydration, with a concomitant decline in the relative amounts of reaction product.

Cement hydration yielded portlandite as the primary reaction product, although the type of CDW used conditioned the content of the mineral and its variation over time. Portlandite content was higher in the blends containing calcareous waste and glass than in OPC at all ages. Hydration was accelerated in the 28-day materials in particular due to the filler effect prompted by the waste [

16]. At later ages (90 days), the presence of glass at whichever proportion (2:1 or 1:2) delayed hydration due to the decline in portlandite solubility as a result of the sodium in the medium [

37,

38], which neutralised the pozzolanic effect in the binary blends of CDW. The pastes with siliceous concrete were slightly more pozzolanic than the ones with calcareous waste at both ratios (

Table 9).

Ettringite, in turn, is highly sensitive to the composition of the medium, depending primarily on the presence of sulfur, pH, and calcite content. This phase usually forms by non-uniform nucleation on C-S-H gel substrates in the presence of sulfur ions [

39,

40], whilst the presence of calcite in the medium, which prevents its conversion to monosulfoaluminate, favours stabilisation [

41].

Here, due to the presence of calcite in the waste itself, a component absent from OPC, the ettringite precursor monocarboaluminate was observed to form in all the blended pastes. This is consistent with earlier research [

42], according to which a higher content of this phase, ettringite, was found in pastes prepared with calcareous concrete waste.

The type of CDW used in the cement pastes modified C-S-H gel composition relative to the gel found in OPC paste. The presence of the waste favoured silicon uptake in the C-S-H gels, as attested to by the shift in the

29Si NMR signals, most prominently in the mixes containing HsT/glass where the Ca/Si and Al/Si ratios declined (

Table 8). Al uptake into the C-S-H gel, observed in both the OPC and all the blended pastes analysed but especially in the material (2:1) HsT/glass, tended to lengthen the respective chains, which would explain the fibre-like structure visible in the SEM micrographs.

5. Conclusions

Adding calcareous or siliceous waste concrete/waste glass blends to cement pastes affects the proportion although not the nature of the mineralogical phases present in the hydration product. Pastes bearing calcareous concrete waste (HcG/glass ratio) enhance ettringite, portlandite, and amorphous phase formation, whereas the generation of C-S-H gels is favoured in pastes containing siliceous concrete (HsT/glass). In both cases, higher glass contents (1:2) delay hydration, with a concomitant decline in the relative amounts of reaction product. In the mixes bearing glass waste, the presence of calcite determines the formation of the ettringite precursor monocarboaluminate, which also acts as calcareous filler. The nature of the waste affects C-S-H gel composition, with a decline of approximately 36% to 44% in the Ca/Si and 50% to 76% in the Al/Si ratios.

Despite the scientific advances reported here, further research is needed to analyse the effect of such microstructural changes on ternary eco-cement mechanical strength and durability.