Abnormal Twinning Behavior Induced by Local Stress in Magnesium

Abstract

:1. Introduction

2. Materials and Methods

3. Results

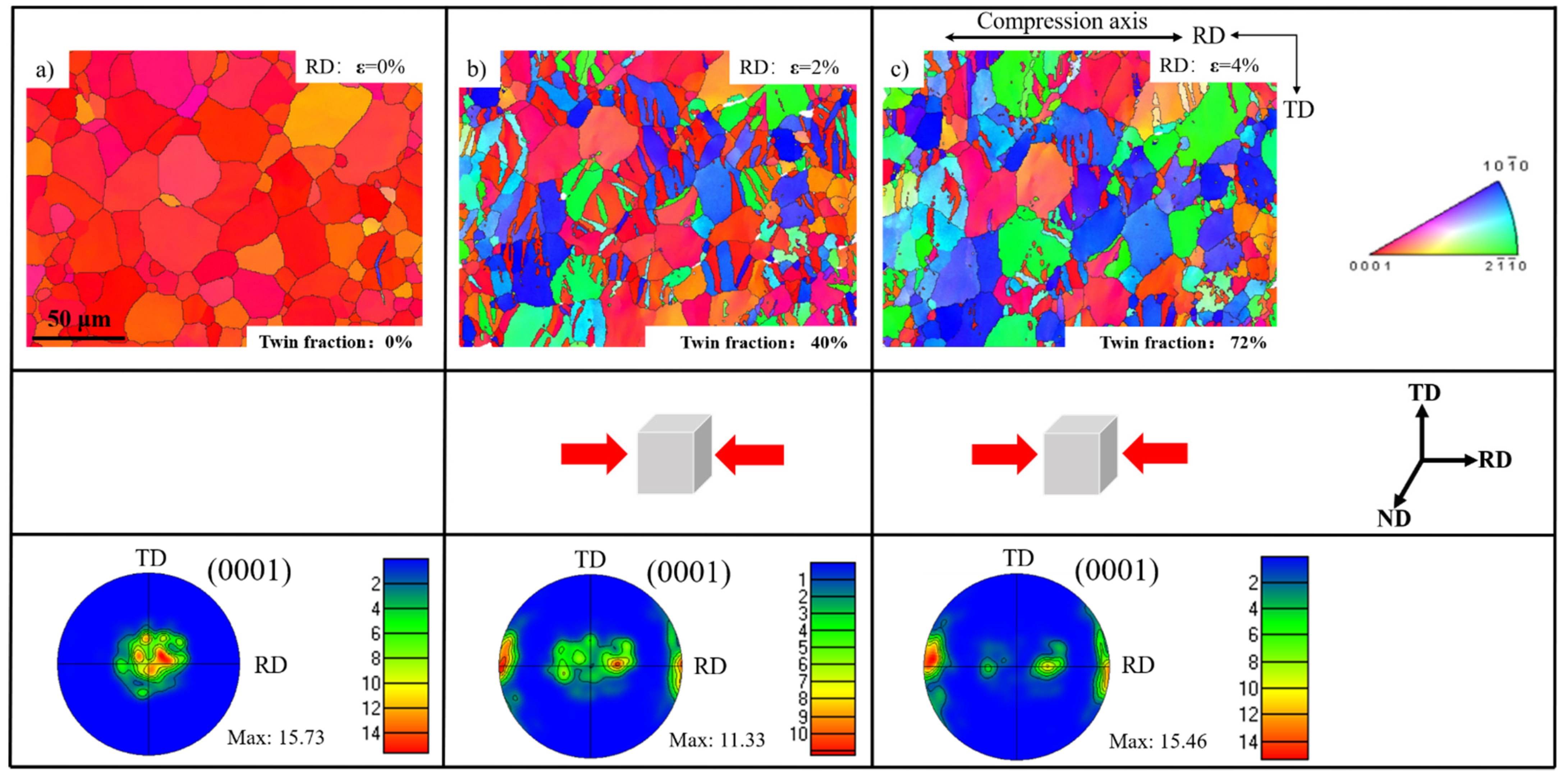

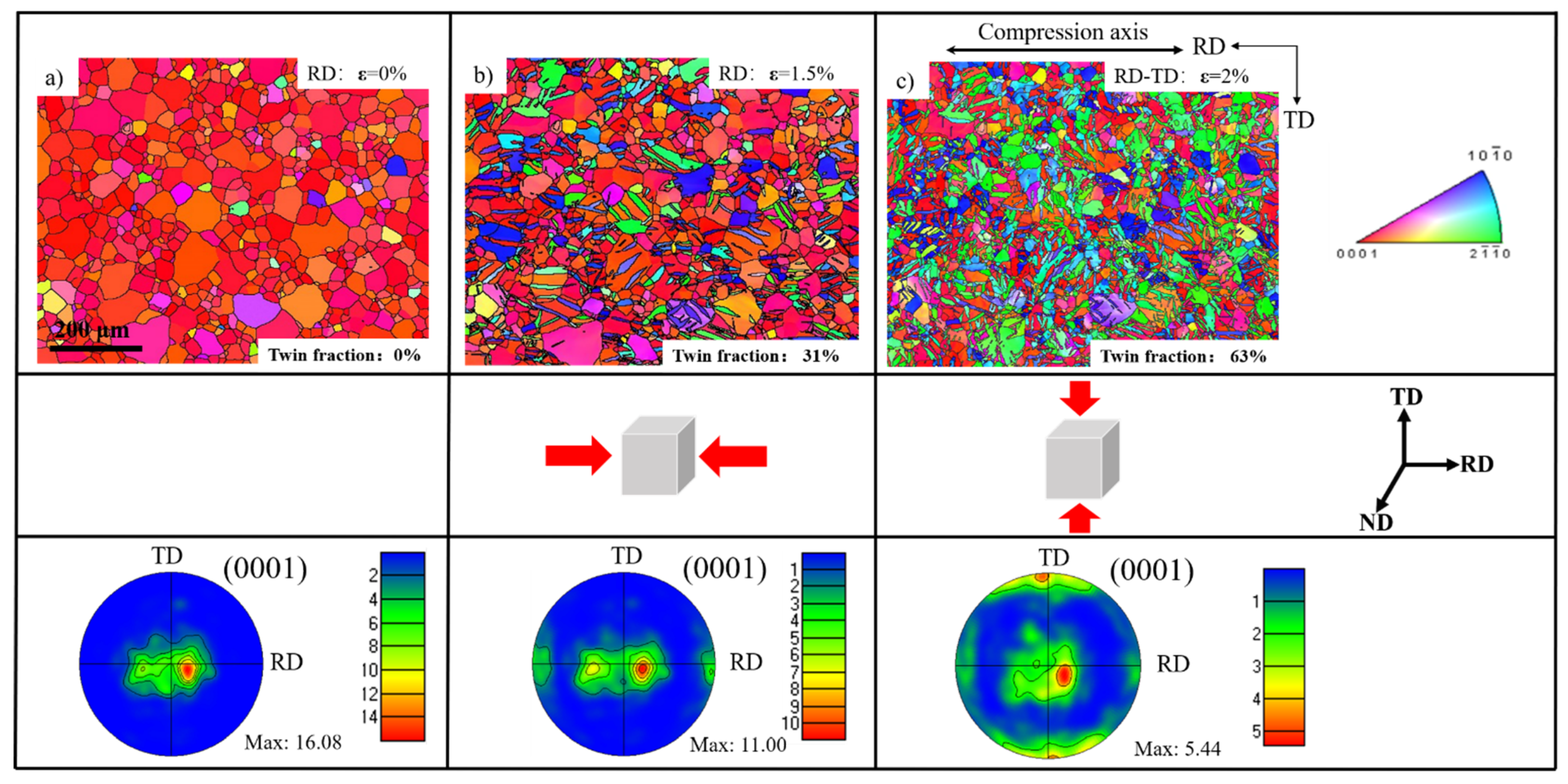

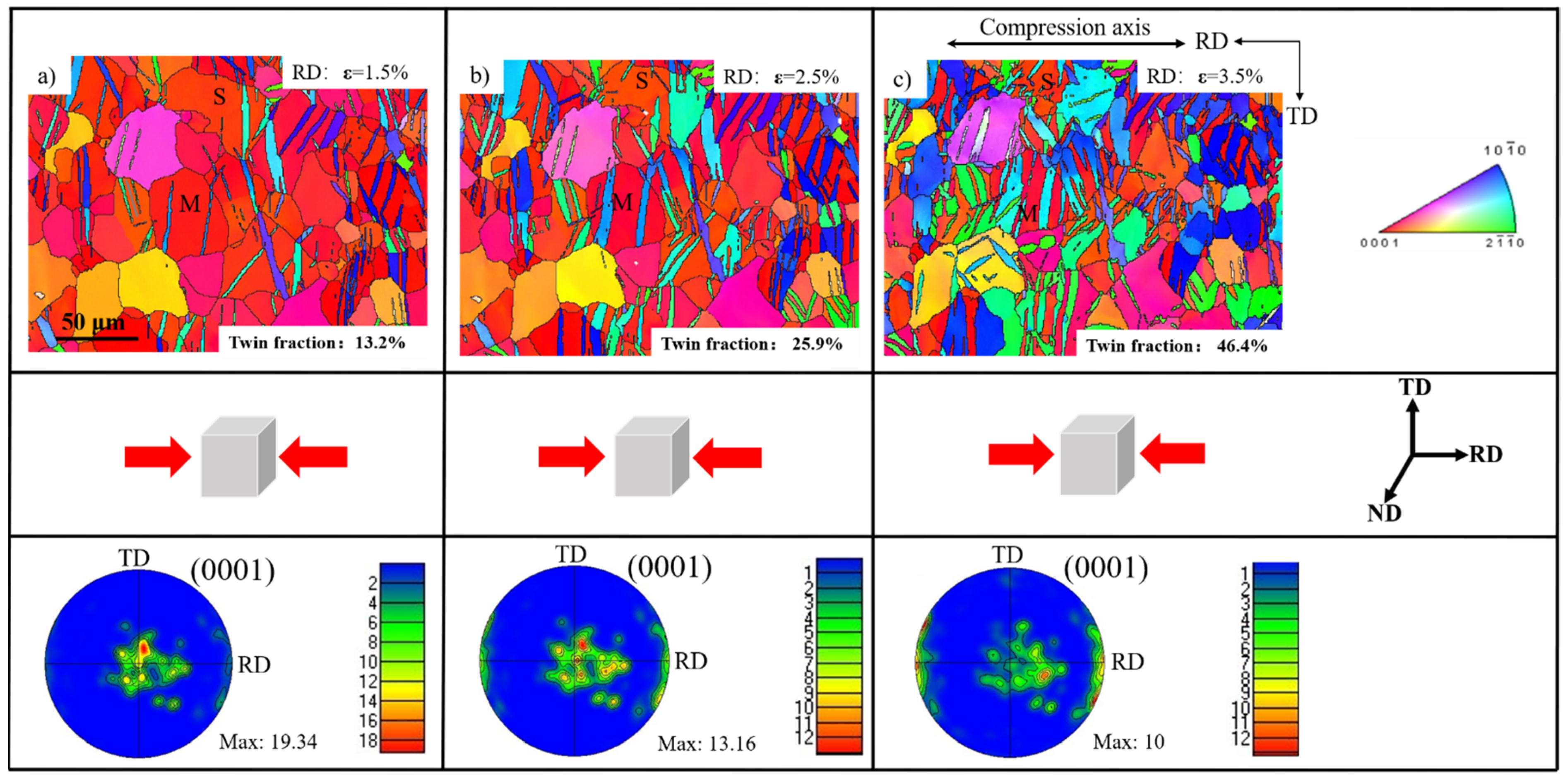

3.1. Microstructure and Texture Evolution

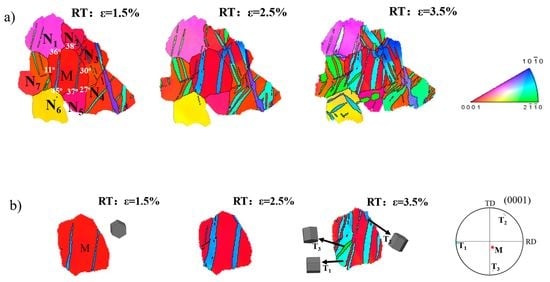

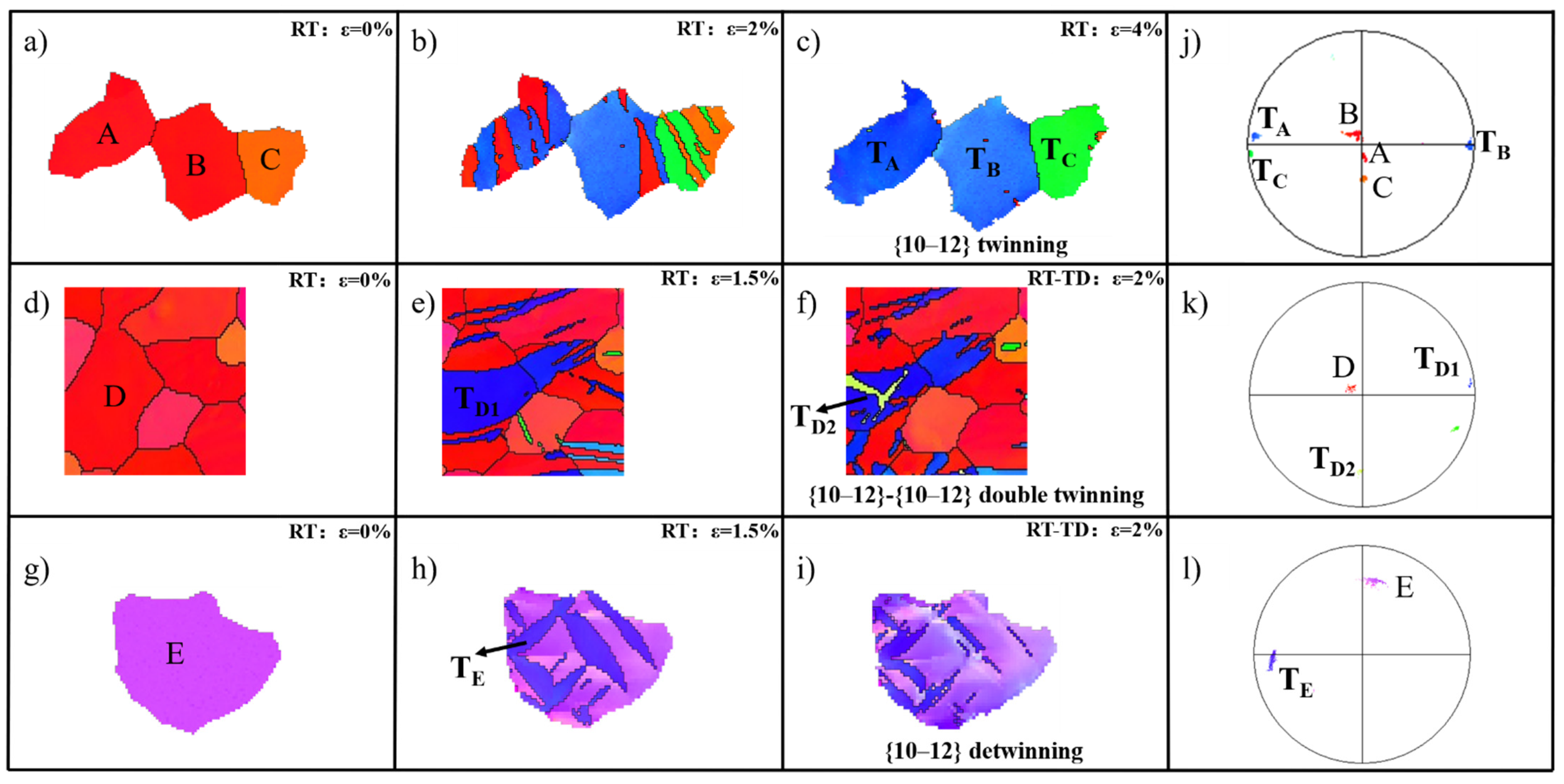

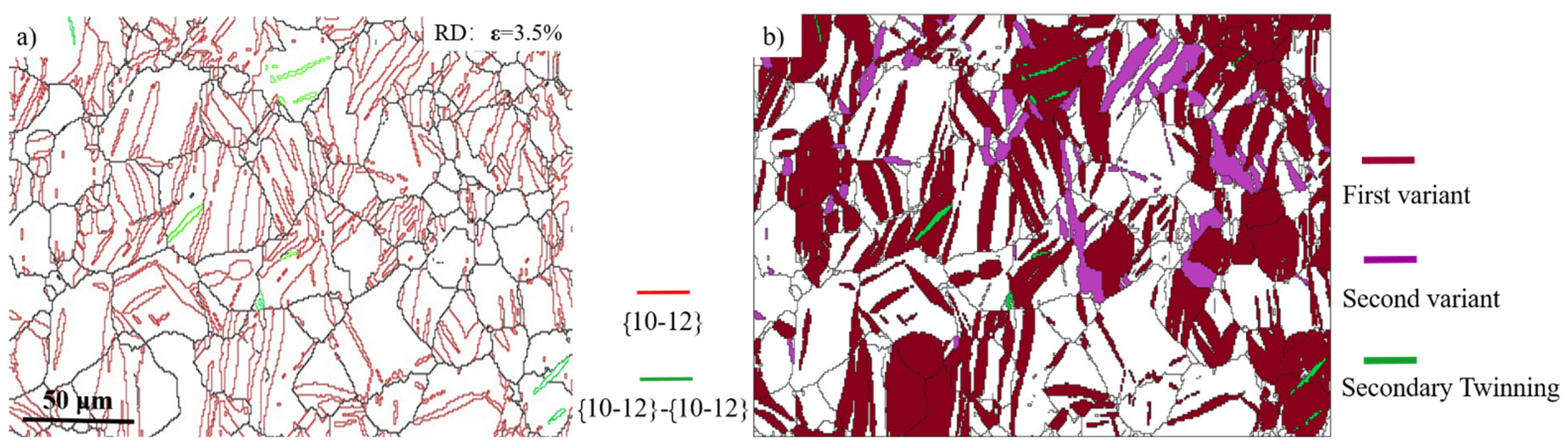

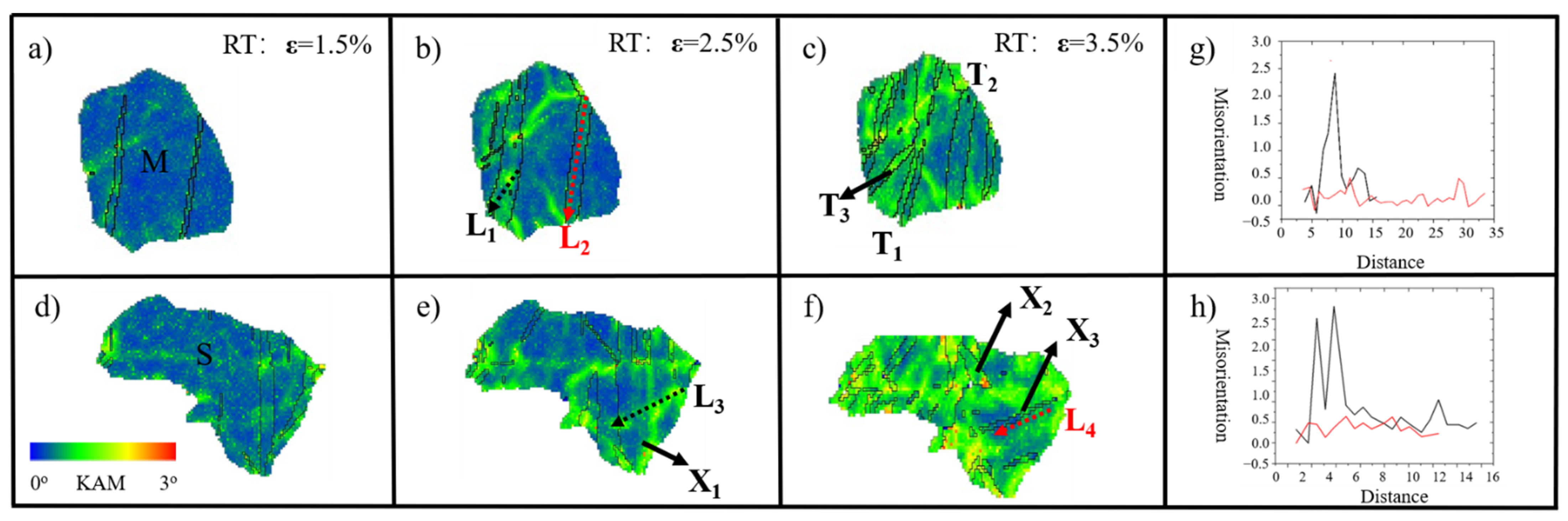

3.2. Unusual Secondary Twinning Behavior

4. Discussion

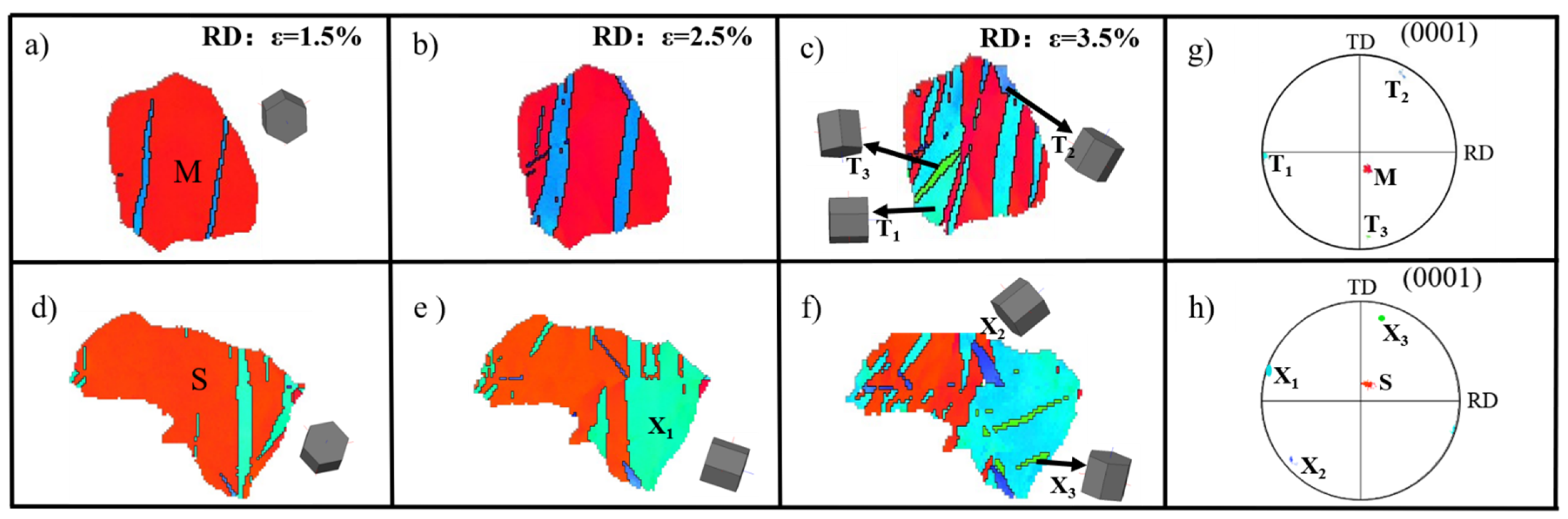

4.1. Schmid Factor (SF) Analysis

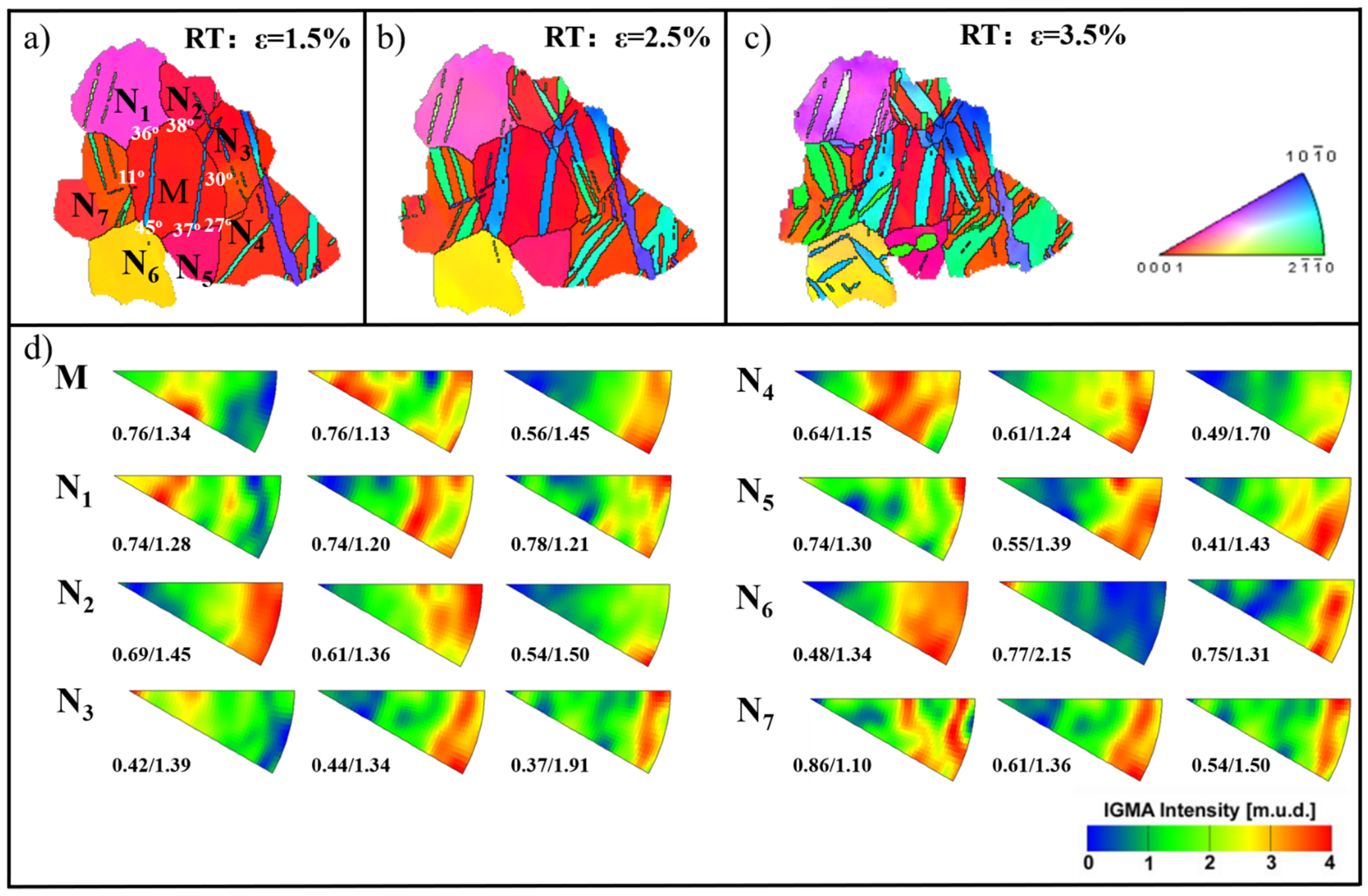

4.2. Twinning Behavior Is Affected by Surrounding Grains

4.3. Local Stress State inside the Grain

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Barnett, M.R.; Stanford, N.; Ghaderi, A.; Siska, F. Plastic relaxation of the internal stress induced by twinning. Acta Mater. 2013, 61, 7859–7867. [Google Scholar] [CrossRef]

- Balogh, L.; Niezgoda, S.R.; Kanjarla, A.K.; Brown, D.W.; Clausen, B.; Liu, W.; Tomé, C.N. Spatially resolved in situ strain measurements from an interior twinned grain in bulk polycrystalline AZ31 alloy. Acta Mater. 2013, 61, 3612–3620. [Google Scholar] [CrossRef]

- Shi, D.; Liu, T.; Zhang, L.; Hou, D.; Chen, H.; Pan, F.; Lu, L. Localised de-twining in AZ31 Mg alloy sheet during uniaxial compression deformation. Mater. Sci. Eng. A 2016, 667, 132–138. [Google Scholar] [CrossRef]

- Clausen, B.; Tomé, C.N.; Brown, D.W.; Agnew, S.R. Reorientation and stress relaxation due to twinning: Modeling and experimental characterization for Mg. Acta Mater. 2008, 56, 2456–2468. [Google Scholar] [CrossRef]

- Yoo, M.H. Slip, twinning, and fracture in hexagonal close-packed metals. Metall. Trans. A 1981, 12, 409–418. [Google Scholar] [CrossRef]

- Wang, F.; Sandlöbes, S.; Diehl, M.; Sharma, L.; Roters, F.; Raabe, D. In situ observation of collective grain-scale mechanics in Mg and Mg-rare earth alloys. Acta Mater. 2014, 80, 77–93. [Google Scholar] [CrossRef]

- Boehlert, C.J.; Chen, Z.; Gutiérrez-Urrutia, I.; Llorca, J.; Pérez-Prado, M.T. In situ analysis of the tensile and tensile-creep deformation mechanisms in rolled AZ31. Acta Mater. 2012, 60, 1889–1904. [Google Scholar] [CrossRef]

- Yu, Q.; Wang, J.; Jiang, Y.; McCabe, R.J.; Li, N.; Tomé, C.N. Twin-twin interactions in magnesium. Acta Mater. 2014, 77, 28–42. [Google Scholar] [CrossRef]

- Hou, D.; Liu, T.; Luo, L.; Lu, L.; Chen, H.; Shi, D. Twinning behaviors of a rolled AZ31 magnesium alloy under multidirectional loading. Mater. Charact. 2017, 124, 122–128. [Google Scholar] [CrossRef]

- Qiao, H.; Guo, X.Q.; Hong, S.G.; Wu, P.D. Modeling of {10-12}-{10-12} secondary twinning in pre-compressed Mg alloy AZ31. J. Alloys Compd. 2017, 725, 96–107. [Google Scholar] [CrossRef]

- Lou, C.; Zhang, X.; Ren, Y. Non-Schmid-based {10-12} twinning behavior in polycrystalline magnesium alloy. Mater. Charact. 2015, 107, 249–254. [Google Scholar] [CrossRef]

- Xin, R.; Guo, C.; Jonas, J.J.; Chen, G.; Liu, Q. Variant selection of {10-12}-{10-12} double twins during the tensile deformation of an AZ31 Mg alloy. Mater. Sci. Eng. A 2017, 700, 226–233. [Google Scholar] [CrossRef]

- Barnett, M.R. Twinning and the ductility of magnesium alloys. Part I: “Tension” twins. Mater. Sci. Eng. A 2007, 464, 1–7. [Google Scholar] [CrossRef]

- Barnett, M.R. Twinning and the ductility of magnesium alloys. Part II. “Contraction” twins. Mater. Sci. Eng. A 2007, 464, 8–16. [Google Scholar] [CrossRef]

- Xu, W.; Yu, J.; Jia, L.; Wu, G.; Zhang, Z. Deformation behavior of Mg-13Gd-4Y-2Zn-0.5Zr alloy on the basis of LPSO kinking, dynamic recrystallization and twinning during compression-torsion. Mater. Charact. 2021, 178, 111215. [Google Scholar] [CrossRef]

- Wang, Y.N.; Huang, J.C. The role of twinning and untwinning in yielding behavior in hot-extruded Mg-Al-Zn alloy. Acta Mater. 2007, 55, 897–905. [Google Scholar] [CrossRef]

- Jonas, J.J.; Mu, S.; Al-Samman, T.; Gottstein, G.; Jiang, L.; Martin, E. The role of strain accommodation during the variant selection of primary twins in magnesium. Acta Mater. 2011, 59, 2046–2056. [Google Scholar] [CrossRef]

- Yildirim, D.; Tükel, S.S.; Alptekin, Ö.; Alagöz, D. Immobilized Aspergillus niger epoxide hydrolases: Cost-effective biocatalysts for the prepation of enantiopure styrene oxide, propylene oxide and epichlorohydrin. J. Mol. Catal. B Enzym. 2013, 88, 84–90. [Google Scholar] [CrossRef]

- Shi, Z.Z. Secondary twin variant selection in Mg alloy after a strain-path change. J. Alloys Compd. 2017, 696, 510–515. [Google Scholar] [CrossRef]

- Yu, Q.; Zhang, J.; Jiang, Y. Direct observation of twinning-detwinning-retwinning on magnesium single crystal subjected to strain-controlled cyclic tension-compression in [0 0 0 1] direction. Philos. Mag. Lett. 2011, 91, 757–765. [Google Scholar] [CrossRef]

- Arul Kumar, M.; Beyerlein, I.J.; McCabe, R.J.; Tomé, C.N. Grain neighbour effects on twin transmission in hexagonal close-packed materials. Nat. Commun. 2016, 7, 13826. [Google Scholar] [CrossRef]

- Arul Kumar, M.; Beyerlein, I.J.; Tomé, C.N. Effect of local stress fields on twin characteristics in HCP metals. Acta Mater. 2016, 116, 143–154. [Google Scholar] [CrossRef] [Green Version]

- Shi, D.; Liu, T.; Wang, T.; Hou, D.; Zhao, S.; Hussain, S. {10–12} Twins across twin boundaries traced by in situ EBSD. J. Alloys Compd. 2017, 690, 699–706. [Google Scholar] [CrossRef]

- Shi, D.; Liu, T.; Hou, D.; Chen, H.; Pan, F.; Chen, H. The effect of twin-twin interaction in Mg-3Al-1Zn alloy during compression. J. Alloys Compd. 2016, 685, 428–435. [Google Scholar] [CrossRef]

- Hong, S.G.; Park, S.H.; Lee, C.S. Strain path dependence of {1 0–1 2} twinning activity in a polycrystalline magnesium alloy. Scr. Mater. 2011, 64, 145–148. [Google Scholar] [CrossRef]

- El Kadiri, H.; Kapil, J.; Oppedal, A.L.; Hector, L.G.; Agnew, S.R.; Cherkaoui, M.; Vogel, S.C. The effect of twin-twin interactions on the nucleation and propagation of {1.0–1.2} twinning in magnesium. Acta Mater. 2013, 61, 3549–3563. [Google Scholar] [CrossRef]

- Khosravani, A.; Fullwood, D.T.; Adams, B.L.; Rampton, T.M.; Miles, M.P.; Mishra, R.K. Nucleation and propagation of { 1 0 1 ¯ 2 } twins in AZ31 magnesium alloy. Acta Mater. 2015, 100, 202–214. [Google Scholar] [CrossRef] [Green Version]

- Park, S.H.; Hong, S.G.; Lee, C.S. Activation mode dependent {1 0–1 2} twinning characteristics in a polycrystalline magnesium alloy. Scr. Mater. 2010, 62, 202–205. [Google Scholar] [CrossRef]

- Park, S.H.; Hong, S.G.; Lee, J.H.; Lee, C.S. Multiple twinning modes in rolled Mg-3Al-1Zn alloy and their selection mechanism. Mater. Sci. Eng. A 2012, 532, 401–406. [Google Scholar] [CrossRef]

- Park, S.H.; Hong, S.G.; Lee, J.H.; Huh, Y.H. Texture evolution of rolled Mg-3Al-1Zn alloy undergoing a {10-12} twinning dominant strain path change. J. Alloys Compd. 2015, 646, 573–579. [Google Scholar] [CrossRef]

- Hou, D.; Liu, T.; Shi, M.; Wen, H.; Zhao, H. Deformation Mechanisms in a Rolled Magnesium Alloy Under Tension Along the Rolling Direction. Microsc. Microanal. 2018, 24, 207–213. [Google Scholar] [CrossRef] [PubMed]

- Basu, I.; Ocelík, V.; De Hosson, J.T.M. Measurement of spatial stress gradients near grain boundaries. Scr. Mater. 2017, 136, 11–14. [Google Scholar] [CrossRef] [Green Version]

- Basu, I.; Fidder, H.; Ocelík, V.; Th.M. de Hosson, J. Local Stress States and Microstructural Damage Response Associated with Deformation Twins in Hexagonal Close Packed Metals. Crystals 2017, 8, 1. [Google Scholar] [CrossRef] [Green Version]

- Basu, I.; Ocelík, V.; De Hosson, J.T.M. Experimental determination and theoretical analysis of local residual stress at grain scale. WIT Trans. Eng. Sci. 2017, 116, 3–14. [Google Scholar] [CrossRef] [Green Version]

- Martin, É.; Capolungo, L.; Jiang, L.; Jonas, J.J. Variant selection during secondary twinning in Mg-3%Al. Acta Mater. 2010, 58, 3970–3983. [Google Scholar] [CrossRef]

- Chun, Y.B.; Battaini, M.; Davies, C.H.J.; Hwang, S.K. Distribution characteristics of in-grain misorientation axes in cold-rolled commercially pure titanium and their correlation with active slip modes. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2010, 41, 3473–3487. [Google Scholar] [CrossRef]

- Gu, X.F.; Furuhara, T.; Kiguchi, T.; Konno, T.J.; Chen, L.; Yang, P. Strain self-accommodation during growth of 14H type long-period stacking ordered (LPSO) structures in Mg-Zn-Gd alloy. Scr. Mater. 2020, 185, 25–29. [Google Scholar] [CrossRef]

| Compression along RD | Tension along RD | Compression along TD | ||||||

|---|---|---|---|---|---|---|---|---|

| SF Values | M | S | T1 | X1 | T1 | X1 | T1 | X1 |

| V1 | 0.10 | 0.44 | −0.49 | −0.39 | 0.49 | 0.39 | 0.25 | 0.36 |

| V2 | 0.13 | 0.25 | −0.49 | −0.44 | 0.49 | 0.44 | 0.03 | −0.02 |

| V3 | 0.49 | 0.02 | −0.49 | −0.43 | 0.46 | 0.43 | 0.49 | 0.19 |

| V4 | 0.10 | 0.45 | −0.49 | −0.43 | 0.45 | 0.43 | 0.24 | 0.39 |

| V5 | 0.12 | 0.26 | −0.49 | −0.45 | 0.43 | 0.45 | 0.03 | −0.01 |

| V6 | 0.47 | 0.02 | −0.49 | −0.41 | 0.46 | 0.41 | 0.49 | 0.16 |

| V1 | V2 | V3 | V4 | V5 | V6 | Active Twin Variant | Basal SF | |

|---|---|---|---|---|---|---|---|---|

| S | 0.44 | 0.25 | 0.02 | 0.45(X1) | 0.26(X2) | 0.02 | V4,V5 | 0.10 |

| M | 0.10 | 0.13 | 0.49(T1) | 0.10(T2) | 0.12 | 0.47 | V3,V4 | 0.12 |

| N1 | 0.03 | 0.08 | 0.23 | 0.01 | 0.10 | 0.17 | V1,V4 | 0.45 |

| N2 | 0.40 | 0.01 | 0.30 | 0.38 | 0.01 | 0.32 | V1,V6 | 0.13 |

| N3 | 0.47 | 0.04 | 0.24 | 0.47 | 0.04 | 0.24 | V1,V3 | 0.01 |

| N4 | 0.41 | 0.01 | 0.30 | 0.40 | 0.01 | 0.31 | V3,V4 | 0.10 |

| N5 | 0.11 | 0.19 | 0.19 | 0.11 | 0.15 | 0.14 | V1,V2 | 0.36 |

| N6 | 0.26 | 0.06 | 0.04 | 0.25 | 0.11 | 0.10 | V1,V4 | 0.44 |

| N7 | 0.15 | 0.10 | 0.49 | 0.15 | 0.10 | 0.49 | V2,V6 | 0.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, D.; Zhang, J. Abnormal Twinning Behavior Induced by Local Stress in Magnesium. Materials 2022, 15, 5510. https://doi.org/10.3390/ma15165510

Shi D, Zhang J. Abnormal Twinning Behavior Induced by Local Stress in Magnesium. Materials. 2022; 15(16):5510. https://doi.org/10.3390/ma15165510

Chicago/Turabian StyleShi, Dongfeng, and Jin Zhang. 2022. "Abnormal Twinning Behavior Induced by Local Stress in Magnesium" Materials 15, no. 16: 5510. https://doi.org/10.3390/ma15165510

APA StyleShi, D., & Zhang, J. (2022). Abnormal Twinning Behavior Induced by Local Stress in Magnesium. Materials, 15(16), 5510. https://doi.org/10.3390/ma15165510