Determining the Vapour Resistance of Breather Membrane Adhesive Joints

Abstract

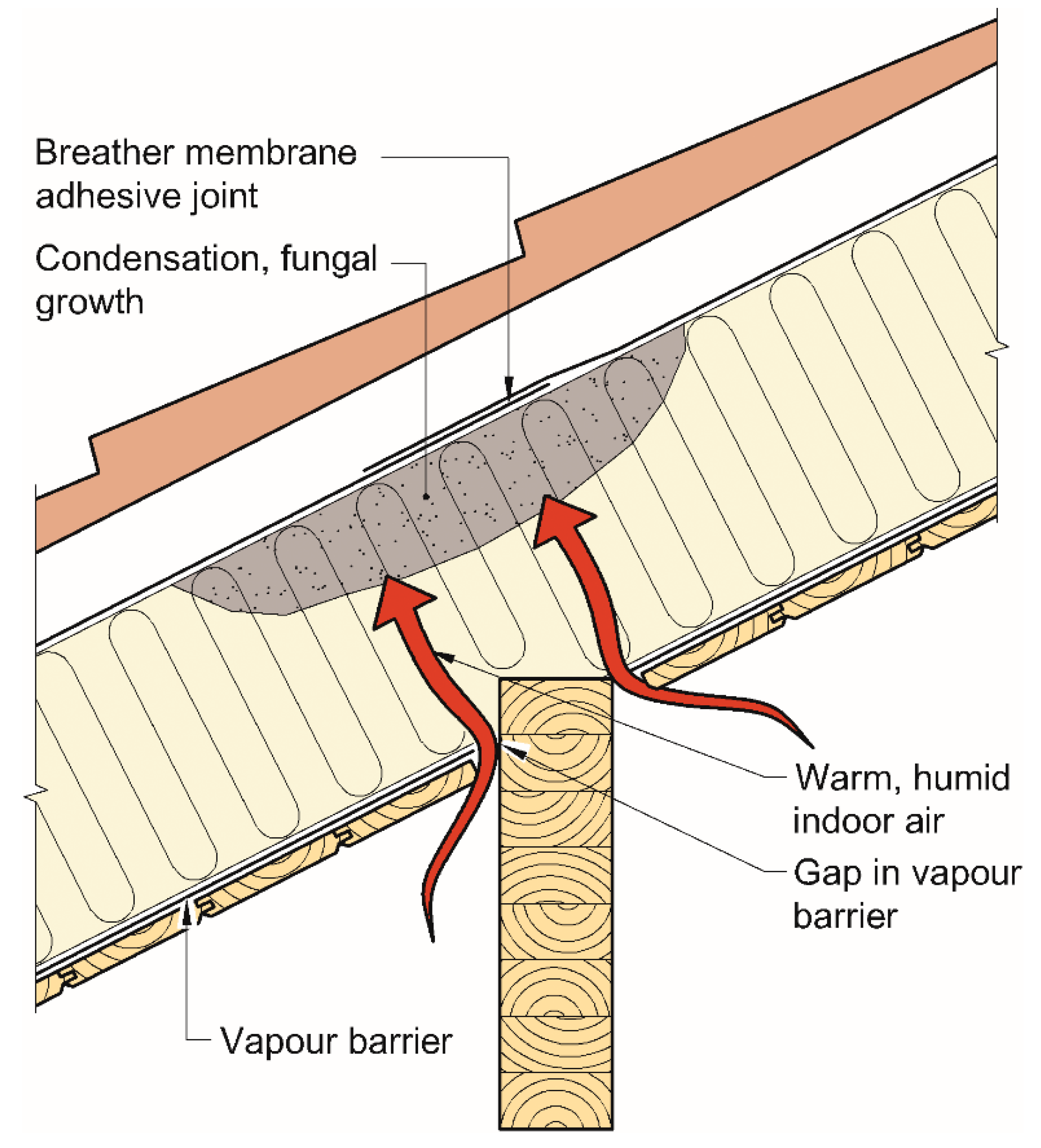

:1. Introduction

2. Materials and Methods

2.1. Tested Materials

2.2. Test Sample Preparation

2.3. Test Procedure

2.4. Simulation of Moisture Transport and Mould Growth

3. Results

4. Discussion

4.1. Determination of Water Vapour Resistance

4.2. Measured Water Vapour Resistance

4.3. Implications

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Commission Proposal for a Directive of the European Parliament and of the Council on Energy Efficiency (Recast), EUR-Lex Document 52021PC0558; 2021. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52021PC0558 (accessed on 6 September 2022).

- KMD, Royal Norwegian Ministry of Local Government and Regional Development. Meld. St. 28 (2011–2012); 2012. Available online: https://www.regjeringen.no/no/dokumenter/meld-st-28-20112012/id685179/ (accessed on 6 September 2022).

- Hanssen-Bauer, I.; Førland, E.J.; Haddeland, I.; Hisdal, H.; Mayer, S.; Nesje, A.; Nilsen, J.E.Ø.; Sandven, S.; Sandø, A.B.; Sorteberg, A.; et al. Klima i Norge 2100—Kunnskapsgrunnlag for Klimatilpasning Oppdatert i 2015; Norwegian Environmental Agency/Norwegian Climate Service Center: Oslo, Norway, 2015. [Google Scholar]

- Pachauri, R.K.; Mayer, L. Intergovernmental Panel on Climate Change (Eds.) Climate Change 2014: Synthesis Report. Contribution of Working Groups I, II and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2015; ISBN 978-92-9169-143-2. [Google Scholar]

- Thodesen, B.; Kvande, T.; Tajet, H.T.T.; Time, B.; Lohne, J. Adapting Green-Blue Roofs to Nordic Climate. Nord. Arkit. 2018, 30, 99123. [Google Scholar]

- Lisø, K.R. Building Envelope Performance Assessments in Harsh Climates: Methods for Geographically Dependent Design. Doctoral Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2006. [Google Scholar]

- Bunkholt, N.S.; Gullbrekken, L.; Kvande, T. Influence of Local Weather Conditions on Ventilation of a Pitched Wooden Roof. J. Civ. Eng. Archit. 2020, 14, 37–45. [Google Scholar] [CrossRef]

- Ingebretsen, S.B.; Andenæs, E.; Kvande, T. Microclimate of Air Cavities in Ventilated Roof and Façade Systems in Nordic Climates. Buildings 2022, 12, 683. [Google Scholar] [CrossRef]

- Einstabland, H. Undertak. Byggforskserien 525.866; SINTEF: Oslo, Norway, 2009. [Google Scholar]

- Vogdt, F.U. Determination of Driving Rain Resistance of Breathable Membranes; TU Berlin: Berlin, Germany, 2014. [Google Scholar]

- Würth Underlay Membrane and Roof Protection Film WÜTOP (R) Trio. Available online: https://media.wuerth.com/stmedia/wuerth/documents/documents/std.lang.all/30220843.pdf (accessed on 6 September 2022).

- Masterplast, Masterplast General Catalogue 2019. Available online: https://www.masterplastinternational.com/document_category/catalogues-en-2/ (accessed on 6 September 2022).

- BMI Group DIVOROLL ELITE 200 2S. Available online: https://www.bmigroup.com/uk/p/divoroll-elite-200-2s-grey-3560938321/ (accessed on 6 September 2022).

- DuPont Tyvek Product Portfolio 2022. Available online: https://www.dupont.co.uk/content/dam/dupont/amer/us/en/performance-building-solutions/public/documents/en/Product_Portfolio_Pocket_booklet_EN.pdf (accessed on 6 September 2022).

- Geving, S.; Thue, J.V. Fukt i Bygninger; Håndbok 50; Norsk byggforskningsinstitutt: Oslo, Norway, 2002. [Google Scholar]

- Fufa, S.M.; Labonnote, N.; Frank, S.; Rüther, P.; Jelle, B.P. Durability Evaluation of Adhesive Tapes for Building Applications. Constr. Build. Mater. 2018, 161, 528–538. [Google Scholar] [CrossRef]

- Kalamees, T.; Alev, Ü.; Pärnalaas, M. Air Leakage Levels in Timber Frame Building Envelope Joints. Build. Environ. 2017, 116, 121–129. [Google Scholar] [CrossRef]

- Johnsen, I.-H.; Andenæs, E.; Gullbrekken, L.; Kvande, T. Vapour Resistance of Wind Barrier Tape: Laboratory Measurements and Hygrothermal Performance Implications. J. Build. Phys. 2022, 46, 923–940. [Google Scholar] [CrossRef]

- Nilsen, M.S. Vanndampmotstanden Til Tapen På Kombinert Undertak Og Vindsperre. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2020. [Google Scholar]

- Thue, J.V. Bygningsfysikk Grunnlag; Fagbokforlaget: Bergen, Norway, 2016; ISBN 978-82-450-1994-0. [Google Scholar]

- Bøhlerengen, T. Fukt i Bygninger. Teorigrunnlag. Byggforskserien 421.132; SINTEF: Oslo, Norway, 2018. [Google Scholar]

- Adin, M.Ş.; Kılıçkap, E. Strength of Double-Reinforced Adhesive Joints. Mater. Test. 2021, 63, 176–181. [Google Scholar] [CrossRef]

- Adïn, H.; Sağlam, Z.; Adïn, M.Ş. Numerical Investigation of Fatigue Behavior of Non-Patched and Patched Aluminum/Composite Plates. Eur. Mech. Sci. 2021, 5, 168–176. [Google Scholar] [CrossRef]

- Langmans, J.; Desta, T.Z.; Alderweireldt, L.; Roels, S. Durability of Self-Adhesive Tapes for Exterior Air Barrier Applications: A Laboratory Investigation. Int. J. Vent. 2017, 16, 30–41. [Google Scholar] [CrossRef]

- Gullbrekken, L.; Kvande, T.; Jelle, B.P.; Time, B. Norwegian Pitched Roof Defects. Buildings 2016, 6, 24. [Google Scholar] [CrossRef]

- Bunkholt, N.S.; Gullbrekken, L.; Time, B.; Kvande, T. Process Induced Building Defects in Norway—Development and Climate Risks. J. Phys. Conf. Ser. 2021, 2069, 012040. [Google Scholar] [CrossRef]

- Josephson, P.-E.; Hammarlund, Y. The Causes and Costs of Defects in Construction: A Study of Seven Building Projects. Autom. Constr. 1999, 8, 681–687. [Google Scholar] [CrossRef]

- Mills, A.; Love, P.E.; Williams, P. Defect Costs in Residential Construction. J. Constr. Eng. 2009, 135, 12–16. [Google Scholar] [CrossRef]

- Andenæs, E.; Kvande, T.; Bohne, R.A. Footprints of Failure: Quantifying Carbon Impacts of Roof Leakages in a Single-Family Residential Building. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 042053. [Google Scholar] [CrossRef]

- ISO 12572:2016; ISO Hygrothermal Performance of Building Materials and Products—Determination of Water Vapour Transmission Properties—Cup Method. ISO: Geneva, Switzerland, 2016.

- SINTEF Technical Approval (TG) SINTEF Certification. Available online: https://www.sintefcertification.no/portalpage/index/180 (accessed on 2 November 2018).

- SINTEF Certification Approved and Certified Products—Roofing and Underlays. Available online: https://www.sintefcertification.no/Contents/Index/19 (accessed on 6 September 2022).

- Viitanen, H.; Ritschkoff, A.-C. Mould Growth in Pine and Spruce Sapwood in Relation to Air Humidity and Temperature; Swedish University of Agricultural Sciences, Department of Forest Products: Uppsala, Sweden, 1991. [Google Scholar]

- Hukka, A.; Viitanen, H.A. A Mathematical Model of Mould Growth on Wooden Material. Wood Sci. Technol. 1999, 33, 475–485. [Google Scholar] [CrossRef]

- Uvsløkk, S.; Vågen, M.; Korsnes, S. Vapour Resistance of Modern Roof Underlay Products at Real Winter Conditions. In Proceedings of the 10th Nordic Symposium on Building Physics, Lund, Sweden, 15–19 June 2014. [Google Scholar]

| Product Identification | Width of Adhesive Area (mm) | Specimen Thickness (mm) |

|---|---|---|

| A | 60 | 1.83 |

| B | 50 | 2.10 |

| C | 40 | 1.32 |

| D | 45 | 1.63 |

| E | 75 | 1.80 |

| F | 90 top side/45 back side | 1.33 |

| G | 50 | 1.57 |

| H | 50 | 1.61 |

| I | 70 | 1.34 |

| J | 30 | 1.58 |

| K | 50 | 0.84 |

| sd-value | <0.5 m | 0.5–2 m | 2–10 m | >10 m | >50 m |

| Measuring interval | Morning and afternoon | 1 day | 2–7 days | 7–14 days | 14–28 days |

| WUFI 2D Settings | Standard Parameters | Variations |

|---|---|---|

| Start date | 1 September | 1 April |

| Number of Time Steps | 8760 | |

| sd-value | 32 m | 18 m, 11 m |

| Placement of adhesive joint | Above rafter | Above insulation |

| Built-in moisture | 20% | 18%, 15% |

| Distance between rafters (c/c) | 600 mm | 300 mm |

| Exterior climate | Kristiansund | Oslo, Tromsø, Trondheim |

| Orientation | North | |

| Inclination | 30° | |

| Short-Wave Radiation Absorptivity | 0.8 | |

| Indoor Climate Temperature | 20 °C | |

| Indoor Relative Humidity | Humidity Class 2 | |

| WUFI Mould Index settings | ||

| Sensitivity Class | Sensitive | |

| Material Class | Relevant decline | |

| Type of Surface | Planed | |

| Type of Wood | Softwood | |

| Occupant exposition class | Surfaces inside constructions without direct contact to indoor air |

| Materials | Density (kg/m3) | Heat Conductivity (W/mK) | Sd-Value (m) |

|---|---|---|---|

| Scandinavian spruce transverse direction II | 390 | 0.13 | 38 |

| Mineral Wool | 60 | 0.040 | 0.46 |

| Breather membrane | 210 | 2.3 | 0.099 |

| Adhesive joint | 210 | 2.3 | 32, 18, 11 |

| Product Identification | Measured Sd-Value of Breather Membrane (m) | Sd-Value from Declaration of Performance (m) | Measured Sd-Value of Adhesive Joints (m) | Standard Deviation of the Mean Sd-Value of Adhesive Joints (m) |

|---|---|---|---|---|

| A | 0.18 | ≤0.14 | 32 | 0.64 |

| B | 0.073 | ≤0.08 | 8.1 | 1.7 |

| B * | 0.073 | ≤0.08 | 7.5 | 2.1 |

| C | - | ≤0.06 | 2.9 | 0.33 |

| D | - | 0.08 − 0.02/+0.10 | 1.5 | 0.024 |

| E | 0.20 | 0.08 (0.05–0.19) | 1.1 | 0.014 |

| F | 0.027 | 0.03 | 3.7 | 0.18 |

| G | 0.10 | ≤0.10 | 4.8 | 0.5 |

| H | - | 0.03 ± 0.02 | 1.7 | 0.05 |

| I | 0.077 | 0.06 ± 0.01 | 11 | 0.09 |

| I * | 0.077 | 0.06 ± 0.01 | 10 | 0.12 |

| J | 0.12 | 0.12 | 18 | 0.17 |

| K | 0.049 | 0.03 ± 0.02 | 1.7 | 0.015 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Adhesive joint above rafter | X | X | X | X | X | X | X | X | X | X | X | ||||

| Adhesive joint above insulation | X | X | X | X | |||||||||||

| Start date: 1 September | X | X | X | X | X | X | X | X | X | X | |||||

| Start date: 1 April | X | X | X | X | X | ||||||||||

| Vapour resistance adhesive joints: 32 m | X | X | X | X | X | X | |||||||||

| Vapour resistance adhesive joints: 18 m | X | X | X | X | X | X | |||||||||

| Vapour resistance adhesive joints: 11 m | X | X | X | ||||||||||||

| Exterior Climate: Kristiansund | X | X | X | X | X | X | X | X | X | X | |||||

| Exterior Climate: Oslo | X | X | X | ||||||||||||

| Exterior Climate: Tromsø | X | X | |||||||||||||

| Exterior Climate: Trondheim | |||||||||||||||

| Built-in Moisture: 20% | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X |

| Built-in Moisture: 18% | |||||||||||||||

| Built-in Moisture: 15% | |||||||||||||||

| c/c: 600 mm | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X |

| c/c: 300 mm | |||||||||||||||

| Mould Index: | 3.4 | 1.7 | 0.5 | 0.1 | 3.2 | 1.6 | 0.4 | 0.1 | 2.5 | 1.5 | 2.1 | 1.9 | 1.4 | 1.9 | 1.8 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Adhesive joint above rafter | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X |

| Adhesive joint above insulation | |||||||||||||||

| Start date: 1 September | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X |

| Start date: 1 April | |||||||||||||||

| Vapour resistance adhesive joints: 32 m | X | X | X | X | X | X | |||||||||

| Vapour resistance adhesive joints: 18 m | X | X | X | X | X | ||||||||||

| Vapour resistance adhesive joints: 11 m | X | X | X | X | |||||||||||

| Exterior Climate: Kristiansund | X | X | X | X | X | X | X | X | X | X | X | ||||

| Exterior Climate: Oslo | |||||||||||||||

| Exterior Climate: Tromsø | X | ||||||||||||||

| Exterior Climate: Trondheim | X | X | X | ||||||||||||

| Built-in Moisture: 20% | X | X | X | X | X | X | X | ||||||||

| Built-in Moisture: 18% | X | X | X | X | X | ||||||||||

| Built-in Moisture: 15% | X | X | X | ||||||||||||

| c/c: 600 mm | X | X | X | X | X | X | X | X | |||||||

| c/c: 300 mm | X | X | X | X | X | X | X | ||||||||

| Mould Index | 1.4 | 3.1 | 2.9 | 2.5 | 2.1 | 0.9 | 1.9 | 0.8 | 4.3 | 4.2 | 3.7 | 3.1 | 2.9 | 2.3 | 1.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fuglestad, F.E.; Andenæs, E.; Geving, S.; Kvande, T. Determining the Vapour Resistance of Breather Membrane Adhesive Joints. Materials 2022, 15, 6619. https://doi.org/10.3390/ma15196619

Fuglestad FE, Andenæs E, Geving S, Kvande T. Determining the Vapour Resistance of Breather Membrane Adhesive Joints. Materials. 2022; 15(19):6619. https://doi.org/10.3390/ma15196619

Chicago/Turabian StyleFuglestad, Fride Engesland, Erlend Andenæs, Stig Geving, and Tore Kvande. 2022. "Determining the Vapour Resistance of Breather Membrane Adhesive Joints" Materials 15, no. 19: 6619. https://doi.org/10.3390/ma15196619