Micromechanisms and Characterization of Low-Velocity Impact Damage in 3D Woven Composites

Abstract

:1. Introduction

2. Experiment

2.1. Materials

2.2. Low-Velocity Impact Tests

2.3. Compressive Tests after Impact

3. Numerical Simulation

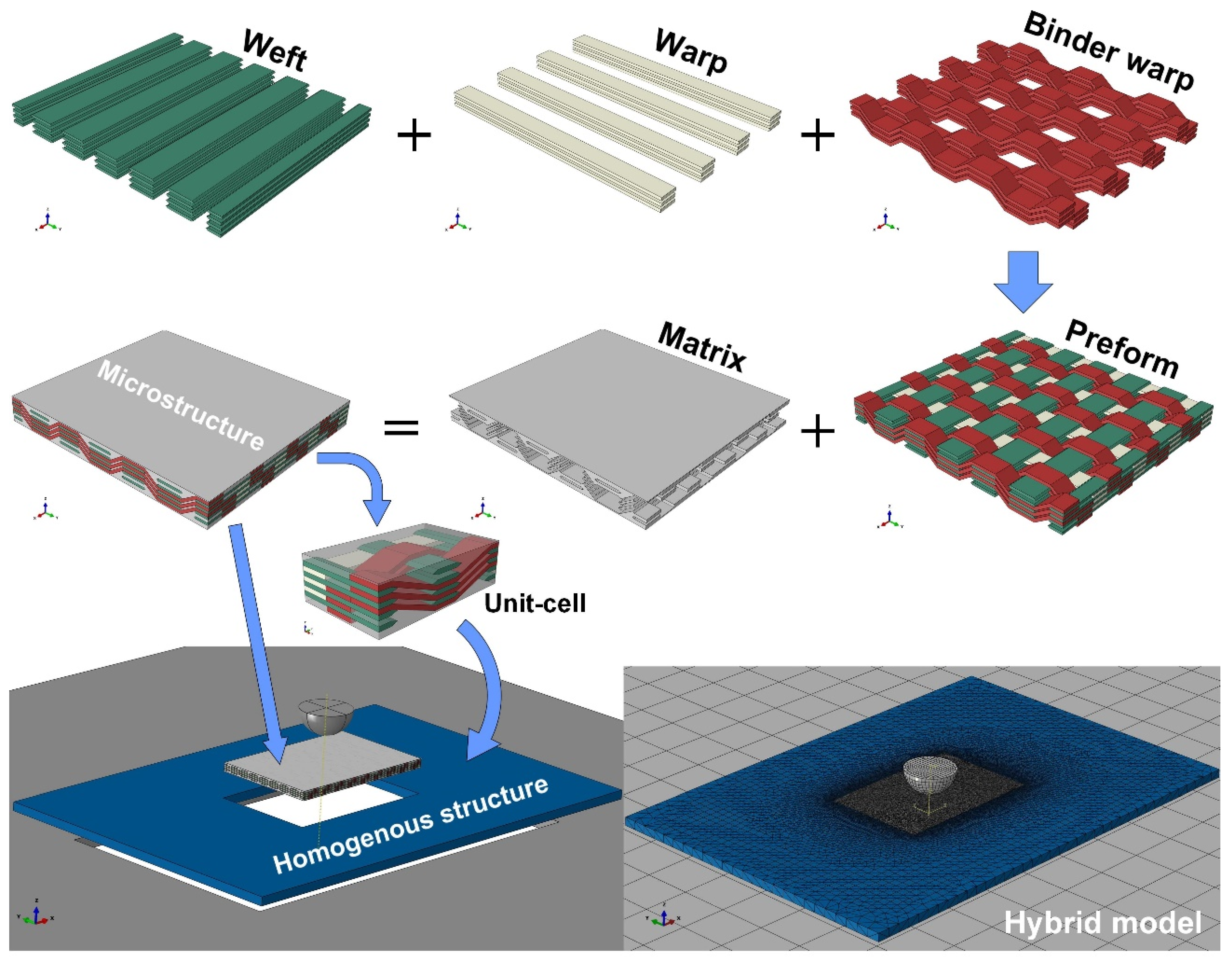

3.1. Low-Velocity Impact Model

3.2. Material Model

3.2.1. Resin Matrix

3.2.2. Fiber Bundles

4. Results and Discussion

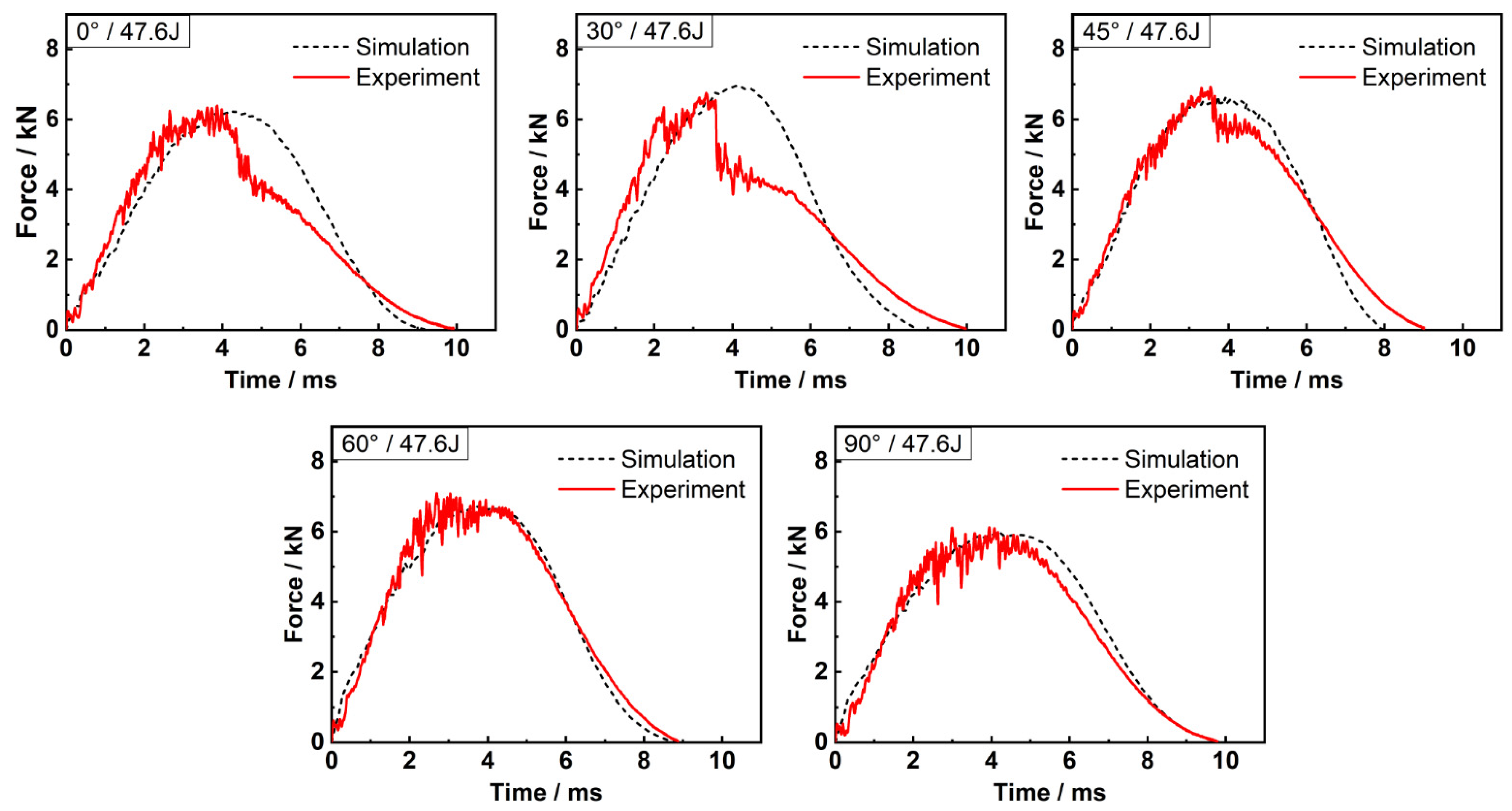

4.1. Validation of Numerical Model

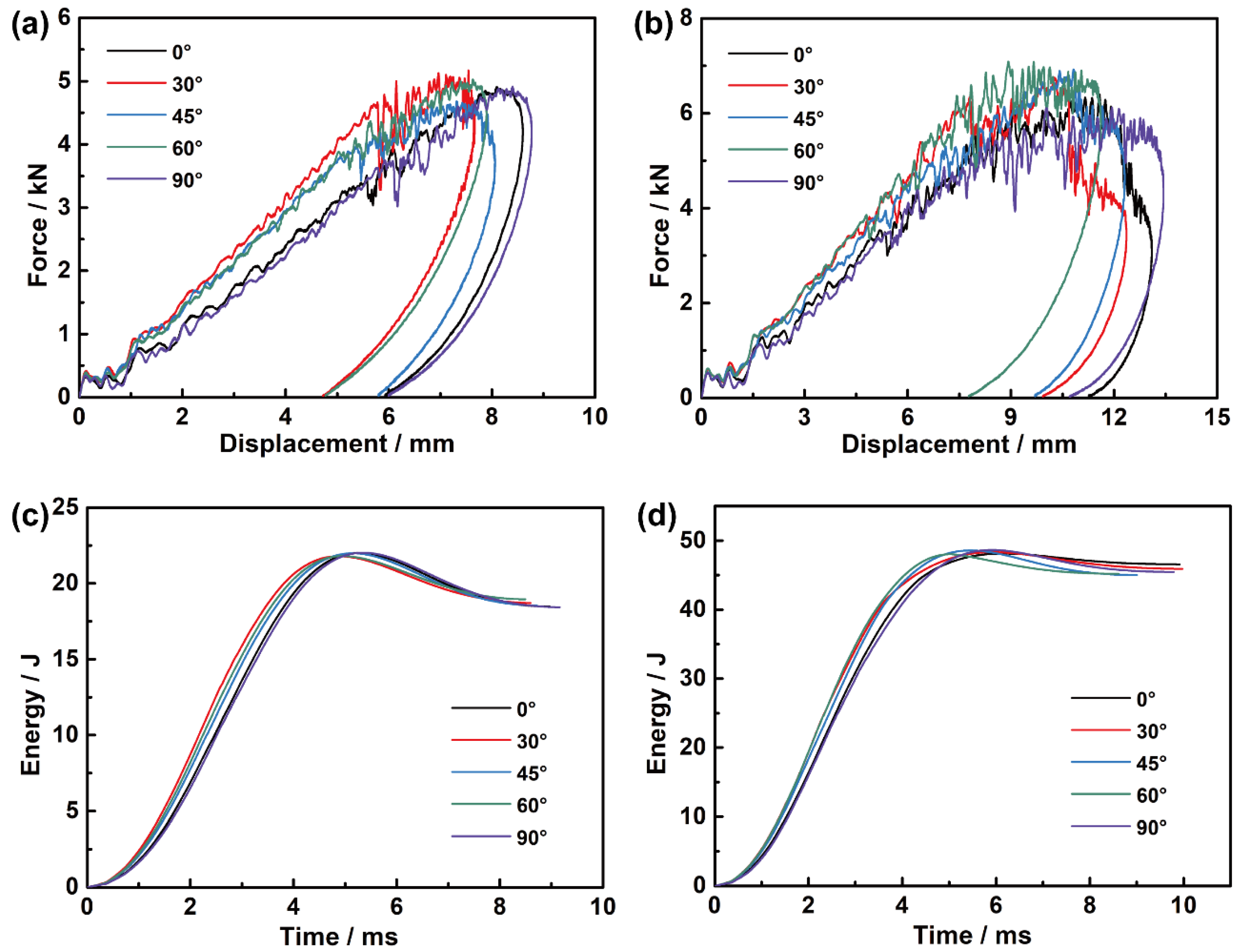

4.2. Low-Velocity Impact Response

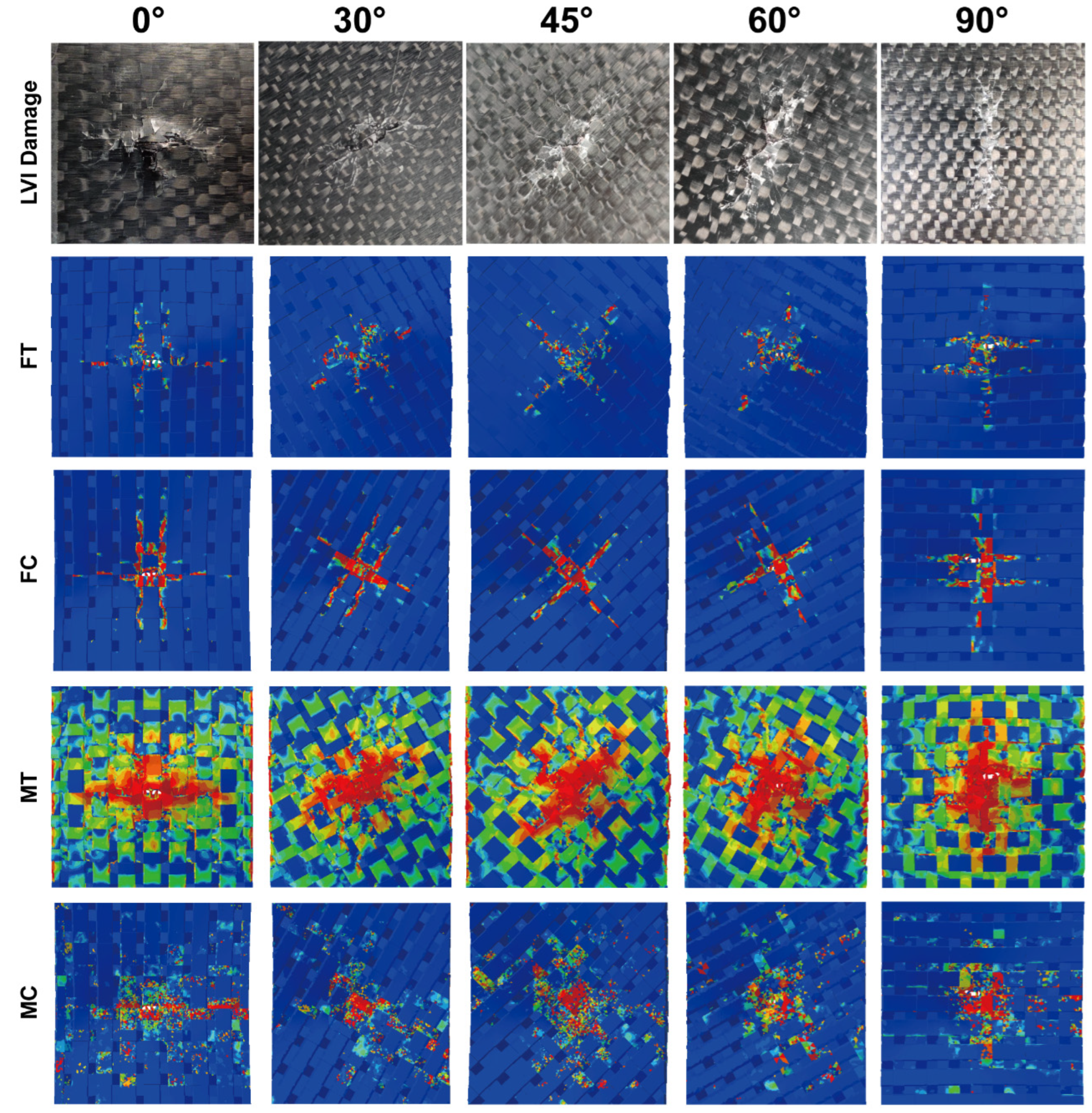

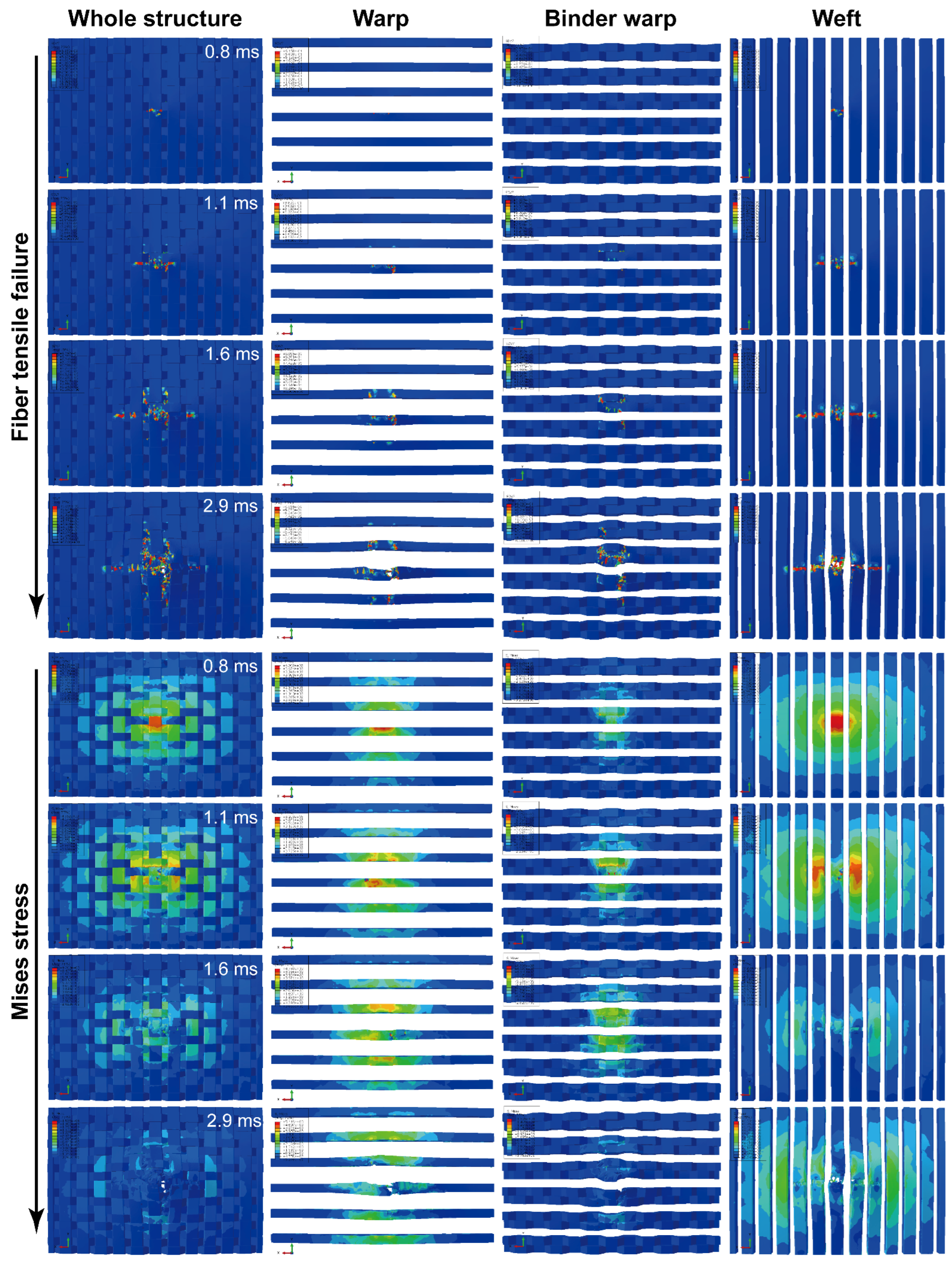

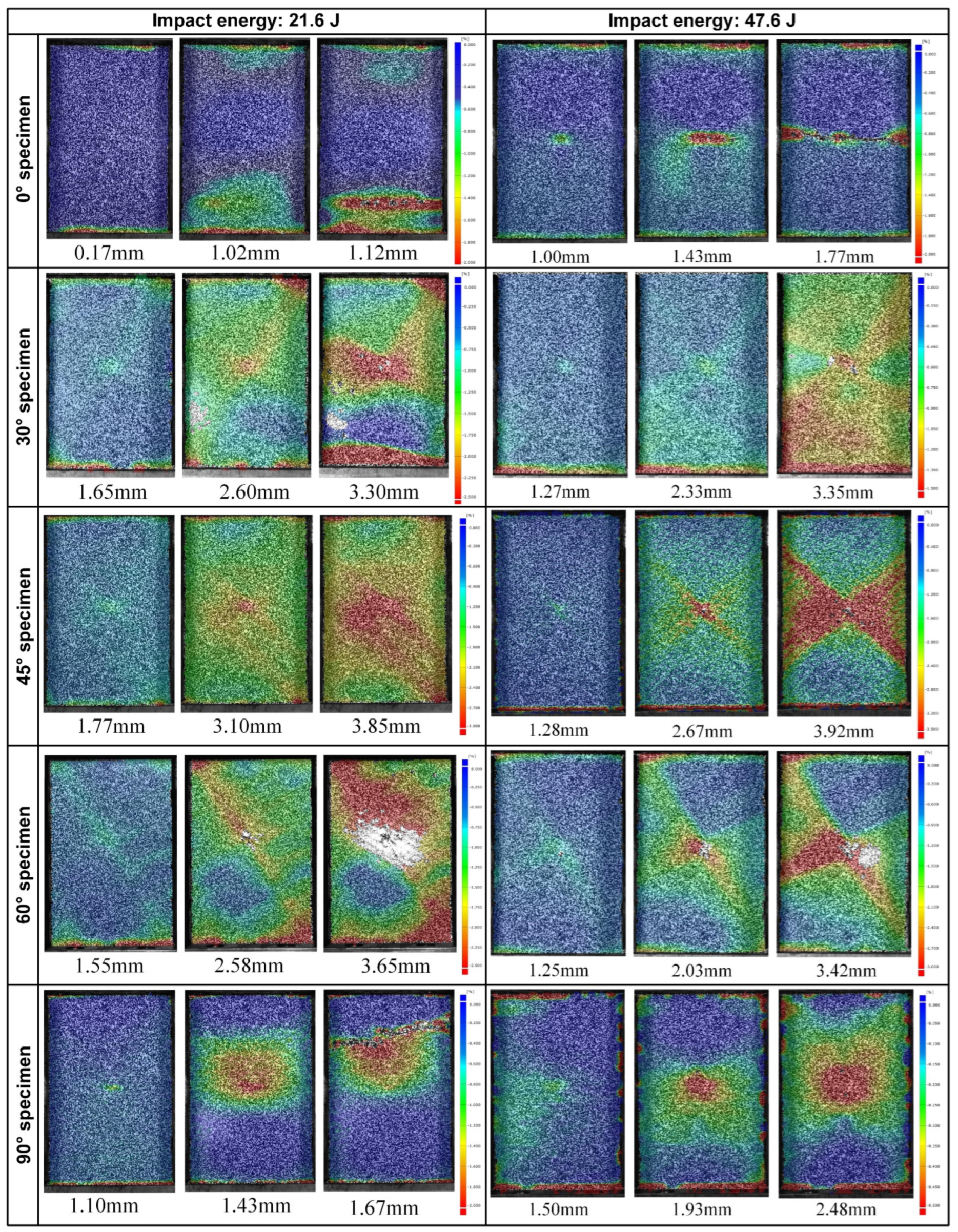

4.3. Impact Damage Analysis

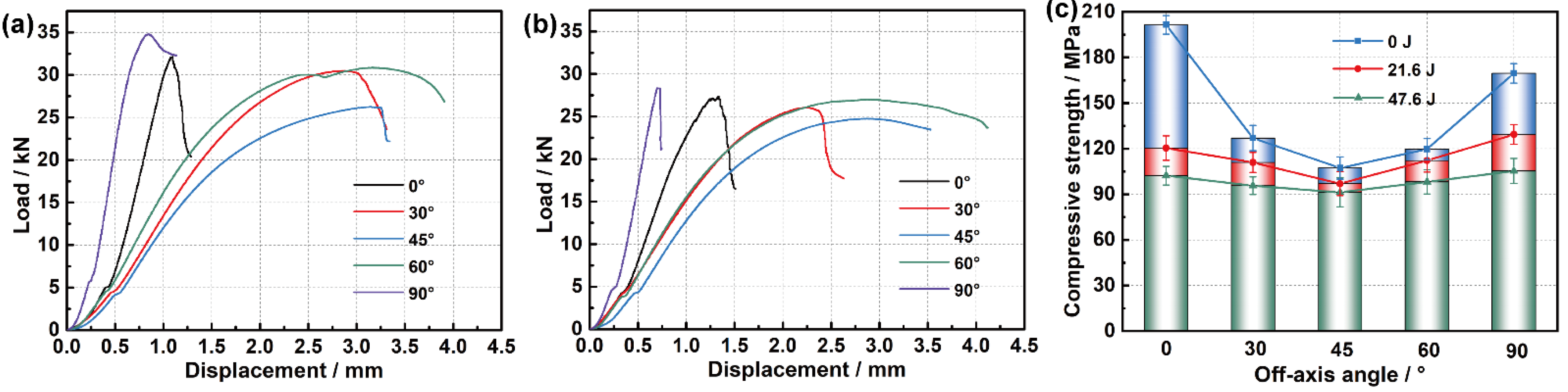

4.4. CAI Properties

5. Conclusions

- The experimental observation and numerical simulation show that the impact damage always extends along weft yarns, warp yarns, or binder warp yarns, indicating that the damage has obvious directionality determined by weft/warp orientation;

- The impact damage begins at the bottom of the impacted area and then expands outwards and upwards simultaneously, accompanied by in-plane and out-of-plane stress transfers. The carrying order and damage degree of various component yarns are different. The straight-line distributed weft/warp yarns bear most of the loads at the beginning of loading, whose stress concentrations and damage are produced relatively early, while the w-shape distributed binder warp yarns can absorb a certain impact deformation, whose carrying capacity is gradually mobilized. The binder warp yarns play an important role in toughening the whole structure to resist impact;

- The effect of impact damage on residual compression performance was analyzed by performing CAI tests. The closer to the principal directions, the more sensitive the CAI strength is to the impact. The damage mode is significantly influenced by the loading direction. The principal direction specimens show certain brittle failure characteristics, while the off-axis direction specimens exhibit some ductile failure.

Author Contributions

Funding

Conflicts of Interest

References

- Ge, X.X.; Zhang, P.; Zhao, F.; Liu, M.; Liu, J.; Cheng, Y.S. Experimental and numerical investigations on the dynamic response of woven carbon fiber reinforced thick composite laminates under low-velocity impact. Compos. Struct. 2022, 279, 114792. [Google Scholar] [CrossRef]

- Banik, A.; Zhang, C.; Khan, M.H.; Wilson, M.; Tan, K.T. Low-velocity ice impact response and damage phenomena on steel and CFRP sandwich composite. Int. J. Impact Eng. 2022, 162, 104134. [Google Scholar] [CrossRef]

- Wang, A.; Wang, X.J.; Xian, G.J. The influence of stacking sequence on the low-velocity impact response and damping behavior of carbon and flax fabric reinforced hybrid composites. Polym. Test. 2021, 104, 107384. [Google Scholar] [CrossRef]

- Choi, J.I.; Park, S.E.; Nguyen, H.H.; Lee, Y.; Lee, B.Y. Resistance of hybrid layered composite panels composed of fiber-reinforced cementitious composites against high-velocity projectile impact. Compos. Struct. 2022, 281, 114993. [Google Scholar] [CrossRef]

- Long, S.C.; Chen, C.; Wang, H.R.; Yao, X.H.; Zhang, X.Q. Distribution and propagation of matrix cracks within composite laminates under impact. Compos. Struct. 2022, 281, 115005. [Google Scholar] [CrossRef]

- Kuteneva, S.V.; Gladkovsky, S.V.; Vichuzhanin, D.I.; Nedzvetsky, P.D. Microstructure and properties of layered metal/rubber composites subjected to cyclic and impact loading. Compos. Struct. 2022, 285, 115078. [Google Scholar] [CrossRef]

- Cao, W.J.; Wu, Y.Y.; Sun, B.Z.; Gu, B.H.; Hu, M.Q. Impact crack quantification analyses in 3-D angle-interlock woven composite using image segmentation method. Eng. Fract. Mech. 2022, 269, 108529. [Google Scholar] [CrossRef]

- Falcó, O.; Lopes, C.; Sommer, D.; Thomson, D.; Ávila, R.; Tijs, B. Experimental analysis and simulation of low-velocity impact damage of composite laminates. Compos. Struct. 2022, 287, 115278. [Google Scholar] [CrossRef]

- Kazemianfar, B.; Nami, M.R. Influence of oblique low velocity impact on damage behavior of 2D and 3D woven composites: Experimental and numerical methods. Thin-Walled Struct. 2021, 167, 108253. [Google Scholar] [CrossRef]

- Yang, W.C.; Huang, R.X.; Liu, J.Y.; Liu, J.X.; Huang, W. Ballistic impact responses and failure mechanism of composite double-arrow auxetic structure. Thin-Walled Struct. 2022, 174, 109087. [Google Scholar] [CrossRef]

- Deng, Y.F.; Zeng, X.Z.; Wang, Y.T.; Du, J.; Zhang, Y.B. Research on the low-velocity impact performance of composite sandwich structure with curved-crease origami foldcore. Thin-Walled Struct. 2022, 174, 109106. [Google Scholar] [CrossRef]

- Ekici, R.; Kosedag, E.; Demir, M. Repeated low-velocity impact responses of SiC particle reinforced Al metal-matrix composites. Ceram. Int. 2022, 48, 5338–5351. [Google Scholar] [CrossRef]

- Munoz, R.; Seltzer, R.; Sket, F.; Gonzalez, C.; Llorca, J. Influence of hybridization on energy absorption of 3D woven composites under low-velocity impact loading. Model. Exp. Valid. Int. J. Impact Eng. 2022, 165, 104229. [Google Scholar] [CrossRef]

- Li, Z.J.; Sun, B.Z.; Gu, B.H. FEM simulation of 3D angle-interlock woven composite under ballistic impact from unit cell approach. Comput. Mater. Sci. 2010, 49, 171–183. [Google Scholar] [CrossRef]

- Shah, S.Z.H.; Yusoff, P.S.M.M.; Karuppanan, S.; Choudhry, R.S.; Din, I.U.; Othman, A.R.; Sharp, K.; Gerard, P. Compression and buckling after impact response of resin-infused thermoplastic and thermoset 3D woven composites. Compos. Part B 2021, 207, 108592. [Google Scholar] [CrossRef]

- Elias, A.; Laurin, F.; Kaminski, M.; Gornet, L. Experimental and numerical investigations of low energy/velocity impact damage generated in 3D woven composite with polymer matrix. Compos. Struct. 2017, 159, 228–239. [Google Scholar] [CrossRef]

- Han, D.; Jia, X.; Zhang, H.J.; Gao, X.G.; Han, X.; Sun, L.; Zheng, Z.K.; Zhang, L.; Wang, F.; Song, Y.D. Foreign object damage and post-impact tensile behavior of plain-woven SIC/SIC composites. Compos. Struct. 2022, 295, 115767. [Google Scholar] [CrossRef]

- Wang, X.; Hu, B.; Feng, Y.; Liang, F.; Mo, J.; Xiong, J.; Qiu, Y. Low velocity impact properties of 3D woven basalt/aramid hybrid composites. Compos. Sci. Technol. 2008, 68, 444–450. [Google Scholar] [CrossRef]

- Ahmed, S.; Zheng, X.T.; Yan, L.L.; Zhang, C.; Wang, X. Influence of asymmetric hybridization on impact response of 3D orthogonal woven composites. Compos. Sci. Technol. 2020, 199, 108326. [Google Scholar] [CrossRef]

- Kazemianfar, B.; Esmaeeli, M.; Nami, M.R. Response of 3D woven composites under low velocity impact with different impactor geometries. Aerosp. Sci. Technol. 2020, 102, 105849. [Google Scholar] [CrossRef]

- Hart, K.R.; Chia, P.X.L.; Sheridan, L.E.; Wetzel, E.D.; Sottos, N.R.; White, S.R. Mechanisms and characterization of impact damage in 2D and 3D woven fiber-reinforced composites. Compos. Part A 2017, 101, 432–443. [Google Scholar] [CrossRef]

- Tuo, H.L.; Lu, Z.X.; Ma, X.P.; Xing, J.; Zhang, C. Damage and failure mechanism of thin composite laminates under low-velocity impact and compression-after-impact loading conditions. Compos. Part B 2019, 163, 642–654. [Google Scholar] [CrossRef]

- Zhang, D.T.; Sun, M.Y.; Liu, X.D.; Xiao, X.L.; Qian, K. Off-axis bending behaviors and failure characterization of 3D woven composites. Compos. Struct. 2019, 208, 45–55. [Google Scholar] [CrossRef]

- Seltzer, R.; Gonzalez, C.; Munoz, R.; Lorca, J.L.; Varela, T.B. X-ray microtomography analysis of the damage micromechanisms in 3D woven composites under low-velocity impact. Compos. Part A 2013, 45, 49–60. [Google Scholar] [CrossRef]

- Ralph, C.; Dahale, M.; Neale, G.; Ramaswamy, K.; McCarthy, M.; Yoo, S.; Toso, N.; Kelly, J.; McGarrigle, C.; Archer, E.; et al. Influence of binder float length on the out-of-plane and axial impact performance of 3D woven composites. Compos. Part A 2021, 147, 106459. [Google Scholar] [CrossRef]

- Wang, C.Z.; Su, D.D.; Xie, Z.F.; Zhang, K.; Wu, N.; Han, M.Y.; Zhou, M. Low-velocity impact response of 3D woven hybrid epoxy composites with carbon and heterocyclic aramid fibres. Polym. Test. 2021, 101, 107314. [Google Scholar] [CrossRef]

- Hart, K.R.; Chia, P.X.L.; Sheridan, L.E.; Wetzel, E.D.; Sottos, N.R.; White, S.R. Comparison of Compression-After-Impact and Flexure-After-Impact protocols for 2D and 3D woven fiber-reinforced composites. Compos. Part A 2017, 101, 471–479. [Google Scholar] [CrossRef]

- Zhao, Q.L.; Wang, W.H.; Liu, Y.T.; Hou, Y.L.; Li, J.S.; Li, C. Multiscale modeling framework to predict the low-velocity impact and compression after impact behaviors of plain woven CFRP composites. Compos. Struct. 2022, 299, 116090. [Google Scholar] [CrossRef]

- Zhang, X.F.; Xiao, Y.R.; Meyer, C.S.; O’Brien, D.J.; Ghosh, S. Impact damage modeling in woven composites with two-level Parametrically-Upscaled Continuum Damage Mechanics Models (PUCDM). Compos. Part B 2022, 233, 109607. [Google Scholar] [CrossRef]

- Shah, S.Z.H.; Yusoff, P.S.M.M.; Karuppanan, S.; Choudhry, R.S.; Sajid, Z. Multiscale damage modelling of 3D woven composites under static and impact loads. Compos. Part A 2021, 151, 106659. [Google Scholar] [CrossRef]

- Zhang, J.J.; Zhang, W.; Huang, S.W.; Gu, B.H. An experimental-numerical study on 3D angle-interlock woven composite under transverse impact at subzero temperatures. Compos. Struct. 2021, 268, 113936. [Google Scholar] [CrossRef]

- Wu, Z.Y.; Zhang, L.C.; Ying, Z.P.; Ke, J.; Hu, X.D. Low-velocity impact performance of hybrid 3D carbon/glass woven orthogonal composite: Experiment and simulation. Compos. Part B 2020, 196, 108098. [Google Scholar] [CrossRef]

- Patel, D.K.; Waas, A.M.; Yen, C.F. Direct numerical simulation of 3D woven textile composites subjected to tensile loading: An experimentally validated multiscale approach. Compos. Part B 2018, 152, 102–115. [Google Scholar] [CrossRef]

- Patel, D.K.; Waas, A.M.; Yen, C.F. Compressive response of hybrid 3D woven textile composites (H3DWTCs): An experimentally validated computational model. J. Mech. Phys. Solids 2019, 122, 381–405. [Google Scholar] [CrossRef]

- Cao, W.J.; Zhang, J.J.; Sun, B.Z.; Gu, B.H. X-ray tomography and numerical study on low-velocity impact damages of three-dimensional angle-interlock woven composites. Compos. Struct. 2019, 230, 111525. [Google Scholar] [CrossRef]

- Liao, B.B.; Liu, P.F. Finite element analysis of dynamic progressive failure of plastic composite laminates under low velocity impact. Compos. Struct. 2017, 159, 567–578. [Google Scholar] [CrossRef]

| Property | T700 Carbon Fiber | E-51 Epoxy Matrix |

|---|---|---|

| Elastic modulus (GPa) | Longitudinal: Ef1 = 232 | Em = 3.5 |

| Transverse: Ef2 = 15 | ||

| Shear modulus (GPa) | Longitudinal: Gf12 = 24 | Gm = 1.296 |

| Transverse: Gf23 = 5.03 | ||

| Poisson’s ratio | μf12 = 0.28 | μm = 0.35 |

| Tension strength (MPa) | Xft = 4850 | Smt = 80 |

| Compression strength (MPa) | Xfc = 2470 | Smc = 241 |

| Shear strength (MPa) | \ | Sms = 60 |

| Sample Name | Fabric Parameters | Composites Parameters | Impact Energies (J) | ||||

|---|---|---|---|---|---|---|---|

| Number of Layers | Warp Density (tows/cm) | Binder Warp Density (tows/cm) | Weft Density (tows/cm) | Thickness (mm) | Fiber Volume Fractions (%) | ||

| 0° sample | 4 | 5 | 5 | 2 | 2.67 | 45.8 | 21.6 |

| 4 | 5 | 5 | 2 | 2.67 | 45.8 | 47.6 | |

| 30° sample | 4 | 5 | 5 | 2 | 2.75 | 47.2 | 21.6 |

| 4 | 5 | 5 | 2 | 2.75 | 47.2 | 47.6 | |

| 45° sample | 4 | 5 | 5 | 2 | 2.71 | 46.5 | 21.6 |

| 4 | 5 | 5 | 2 | 2.71 | 46.5 | 47.6 | |

| 60° sample | 4 | 5 | 5 | 2 | 2.75 | 47.2 | 21.6 |

| 4 | 5 | 5 | 2 | 2.75 | 47.2 | 47.6 | |

| 90° sample | 4 | 5 | 5 | 2 | 2.69 | 46.1 | 21.6 |

| 4 | 5 | 5 | 2 | 2.69 | 46.1 | 47.6 | |

| Sample | Fmax (kN) | Error (%) | Dismax (mm) | Error (%) | t (ms) | Error (%) | |||

|---|---|---|---|---|---|---|---|---|---|

| Exp. | FEM | Exp. | FEM | Exp. | FEM | ||||

| 0°/21.6 J | 4.91 | 5.10 | 3.87 | 8.60 | 8.11 | −5.70 | 8.97 | 9.00 | 0.33 |

| 30°/21.6 J | 5.17 | 5.18 | 0.19 | 7.66 | 6.71 | −12.40 | 8.56 | 8.33 | −2.69 |

| 45°/21.6 J | 4.69 | 4.67 | −0.43 | 8.06 | 7.94 | −1.49 | 8.76 | 8.67 | −1.03 |

| 60°/21.6 J | 5.03 | 4.98 | −0.99 | 7.89 | 7.07 | −10.39 | 8.73 | 8.14 | −6.76 |

| 90°/21.6 J | 4.91 | 4.89 | −0.41 | 8.77 | 8.10 | −7.64 | 9.18 | 9.17 | −0.11 |

| 0°/47.6 J | 6.40 | 6.23 | −2.66 | 13.10 | 11.37 | −13.21 | 9.92 | 9.03 | −8.97 |

| 30°/47.6 J | 6.75 | 6.92 | 2.52 | 12.36 | 11.10 | −10.19 | 9.97 | 8.78 | −11.94 |

| 45°/47.6 J | 6.93 | 6.67 | −3.75 | 12.31 | 10.96 | −10.97 | 9.01 | 7.98 | −11.43 |

| 60°/47.6 J | 7.09 | 6.72 | −5.22 | 11.62 | 10.71 | −7.83 | 8.87 | 8.68 | −2.14 |

| 90°/47.6 J | 6.12 | 5.98 | −2.29 | 13.44 | 11.47 | −14.66 | 9.76 | 9.87 | 1.13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, J.; Dai, Y.; Huang, L.; Zhang, D.; Zhao, J. Micromechanisms and Characterization of Low-Velocity Impact Damage in 3D Woven Composites. Materials 2022, 15, 6636. https://doi.org/10.3390/ma15196636

Sun J, Dai Y, Huang L, Zhang D, Zhao J. Micromechanisms and Characterization of Low-Velocity Impact Damage in 3D Woven Composites. Materials. 2022; 15(19):6636. https://doi.org/10.3390/ma15196636

Chicago/Turabian StyleSun, Jin, Yunfeng Dai, Linhai Huang, Diantang Zhang, and Junhua Zhao. 2022. "Micromechanisms and Characterization of Low-Velocity Impact Damage in 3D Woven Composites" Materials 15, no. 19: 6636. https://doi.org/10.3390/ma15196636