Thermoelectric Properties of Co-Substituted Al–Pd–Re Icosahedral Quasicrystals

Abstract

:1. Introduction

2. Methods and Materials

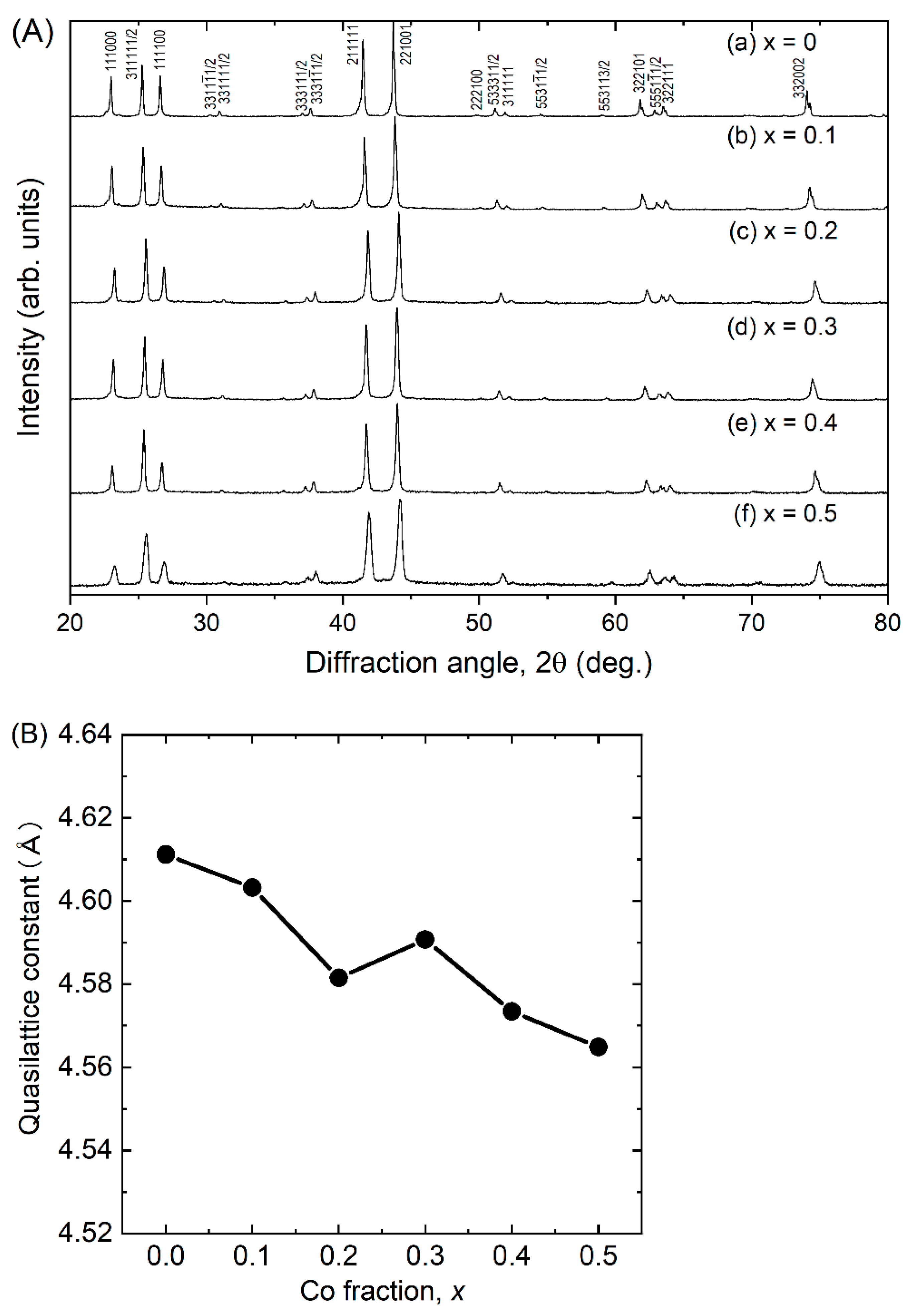

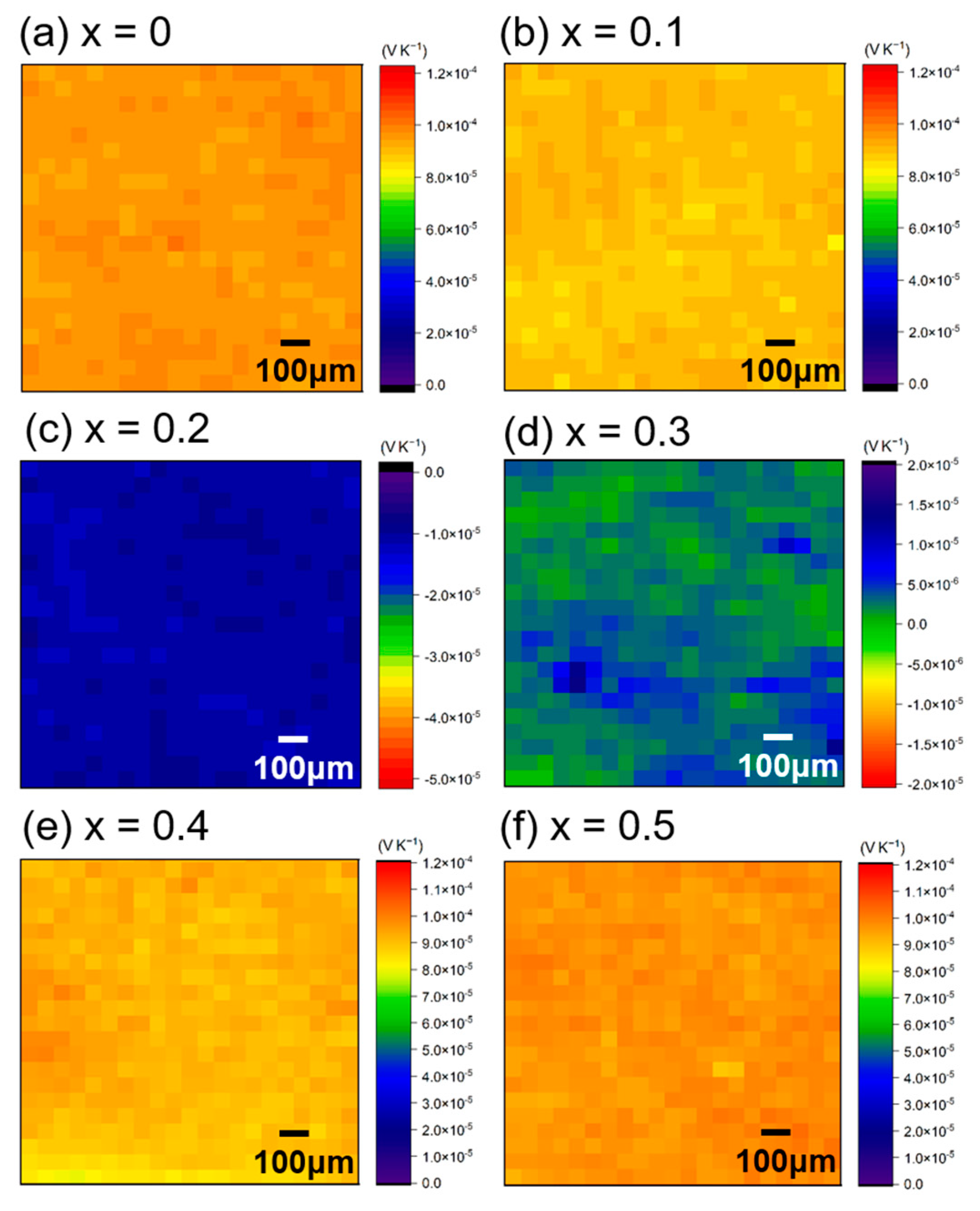

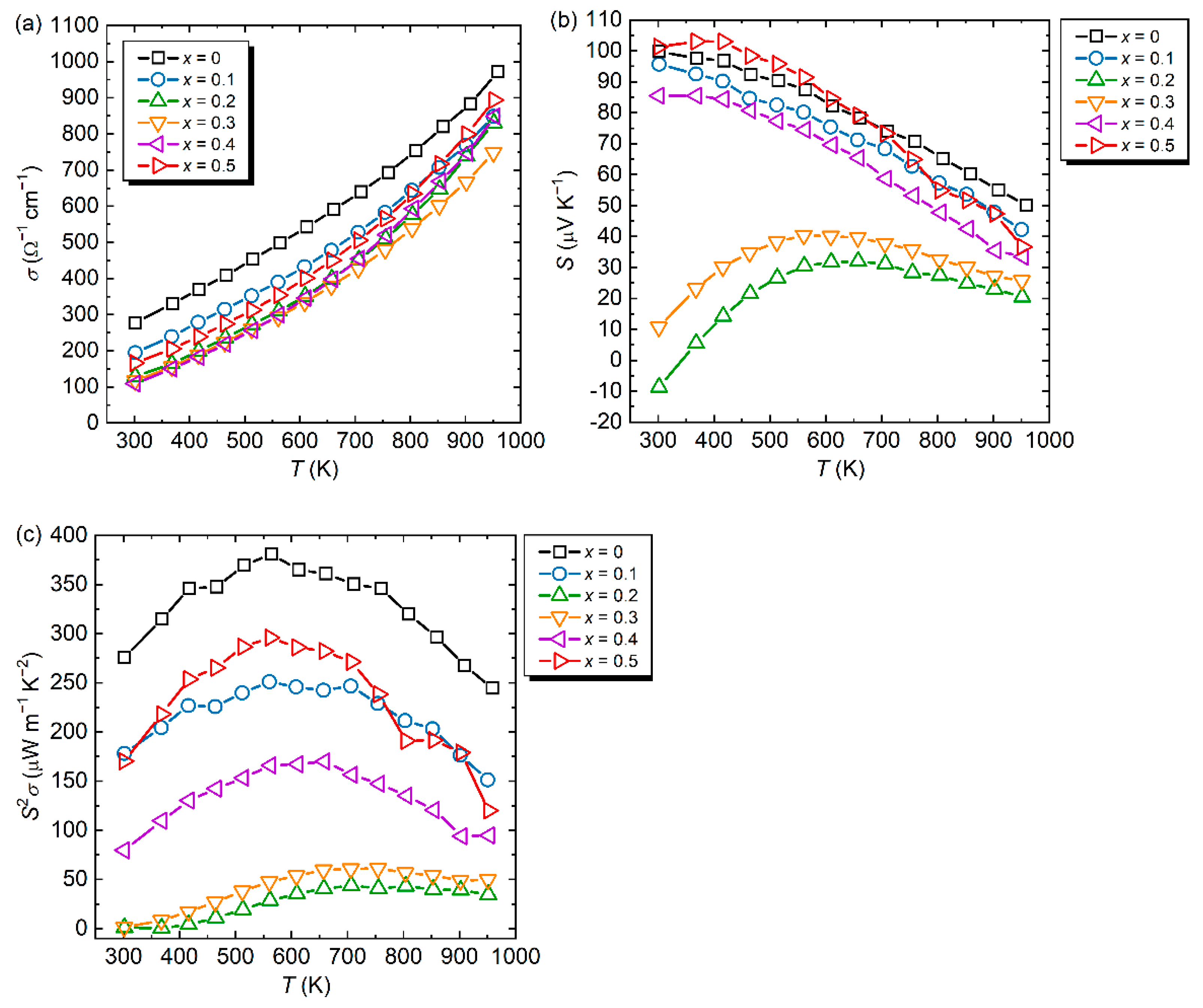

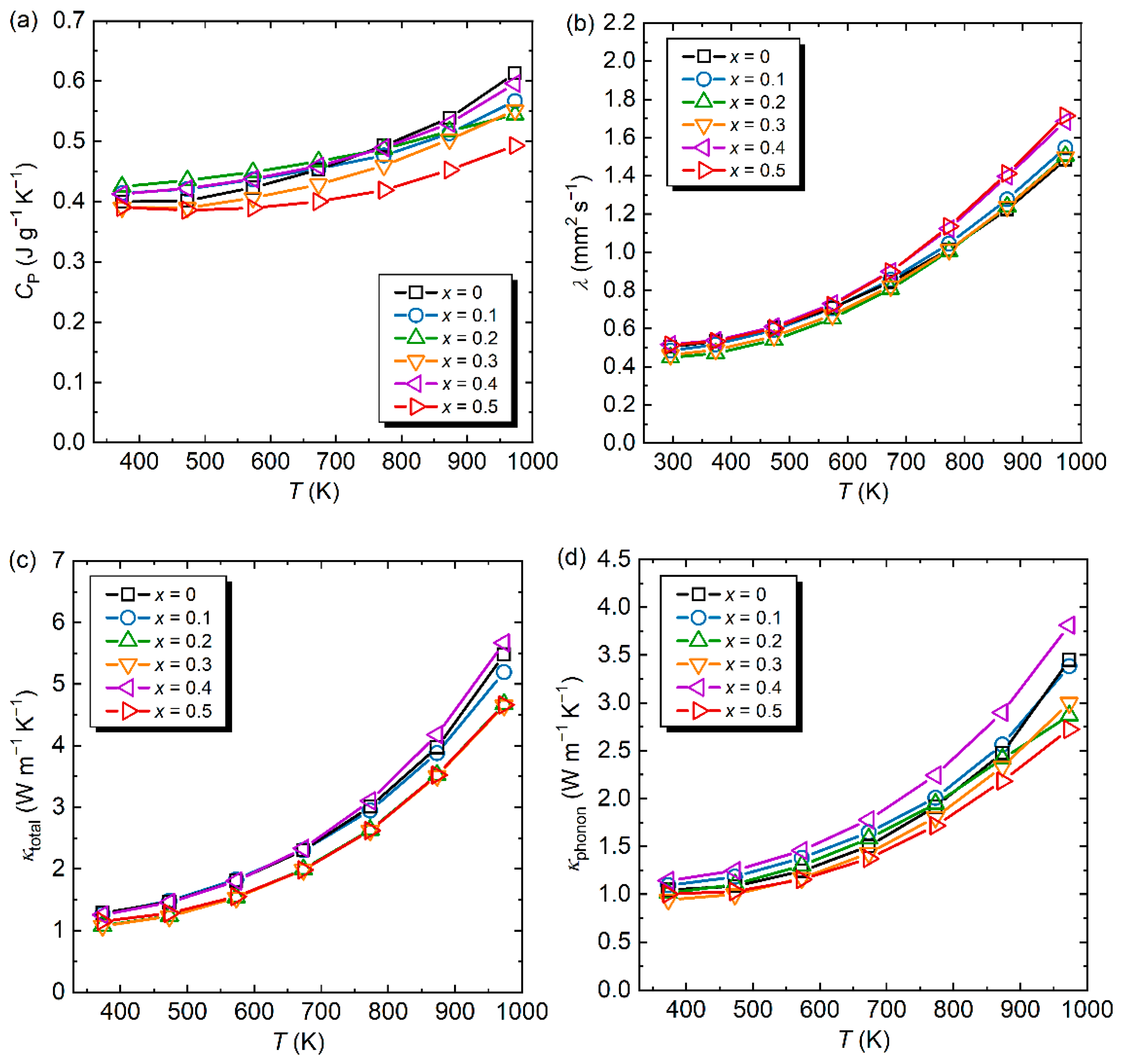

3. Results and Discussion

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Freer, R.; Ekren, D.; Ghosh, T.; Biswas, K.; Qiu, P.; Wan, S.; Chen, L.; Han, S.; Fu, C.; Zhu, T.; et al. Key properties of inorganic thermoelectric materials-tables (version 1). J. Phys. Energy 2022, 4, 022002. [Google Scholar] [CrossRef]

- Shi, X.-L.; Zou, J.; Chen, Z.-G. Advanced Thermoelectric Design: From Materials and Structures to Devices. Chem. Rev. 2020, 120, 7399–7515. [Google Scholar] [CrossRef]

- Zevalkink, A.; Smiadak, D.M.; Blackburn, J.L.; Ferguson, A.J.; Chabinyc, M.L.; Delaire, O.; Wang, J.; Kovnir, K.; Marin, J.; Schelhas, L.T.; et al. A practical field guide to thermoelectrics: Fundamentals, synthesis, and characterization. Appl. Phys. Rev. 2018, 5, 021303. [Google Scholar] [CrossRef]

- Beretta, D.; Neophytou, N.; Hodges, J.M.; Kanatzidis, M.G.; Narducci, D.; Martin-Gonzalez, M.; Beekman, M.; Balke, B.; Cerretti, G.; Tremel, W.; et al. Thermoelectrics: From history, a window to the future. Mater. Sci. Eng. Rep. 2019, 138, 210–255. [Google Scholar] [CrossRef]

- Xin, J.; Tang, Y.; Liu, Y.; Zhao, X.; Pan, H.; Zhu, T. Valleytronics in thermoelectric materials. NPJ Quantum Mater. 2018, 3, 9. [Google Scholar] [CrossRef]

- Kanatzidis, M.G. Nanostructured thermoelectrics: The new paradigm? Chem. Mater. 2010, 22, 648–659. [Google Scholar] [CrossRef]

- Prauzek, M.; Konecny, J.; Borova, M.; Janosova, K.; Hlavica, J.; Musilek, P. Energy Harvesting Sources, Storage Devices and System Topologies for Environmental Wireless Sensor Networks: A Review. Sensors 2018, 18, 2446. [Google Scholar] [CrossRef]

- Takagiwa, Y.; Ikeda, T.; Kojima, H. Earth-Abundant Fe-Al-Si Thermoelectric (FAST) Materials: From Fundamental Materials Research to Module Development. ACS Appl. Mater. Interfaces 2020, 12, 48804–48810. [Google Scholar] [CrossRef] [PubMed]

- Takagiwa, Y.; Hou, Z.; Tsuda, K.; Ikeda, T.; Kojima, H. Fe–Al–Si Thermoelectric (FAST) Materials and Modules: Diffusion-Couple and Machine-Learning Assisted Materials Development. ACS Appl. Mater. Interfaces 2021, 13, 53346–53354. [Google Scholar] [CrossRef]

- Dolinšek, J. Electrical and thermal transport properties of icosahedral and decagonal quasicrystals. Chem. Soc. Rev. 2012, 41, 6730–6744. [Google Scholar] [CrossRef]

- Dubois, J.-M. Properties and applications of quasicrystals and complex metallic alloys. Chem. Soc. Rev. 2012, 41, 6760–6777. [Google Scholar] [CrossRef] [PubMed]

- Singh, A. Tailoring microstructure of Mg–Zn–Y alloys with quasicrystal and related phases for high mechanical strength. Sci. Technol. Adv. Mater. 2014, 15, 044803. [Google Scholar] [CrossRef] [PubMed]

- Takeuchi, T. Very large thermal rectification in bulk composites consisting partly of icosahedral quasicrystals. Sci. Technol. Adv. Mater. 2014, 15, 064801. [Google Scholar] [CrossRef] [PubMed]

- Takagiwa, Y.; Kimura, K. Metallic-covalent bonding conversion and thermoelectric properties of Al-based icosahedral quasicrystals and approximants. Sci. Technol. Adv. Mater. 2014, 15, 044802. [Google Scholar] [CrossRef] [PubMed]

- Maćia, E. Thermoelectric figure of merit of AlPdRe icosahedral quasicrystals: Composition-dependent effects. Phys. Rev. B 2004, 69, 184202. [Google Scholar] [CrossRef]

- Takagiwa, Y.; Kimura, K. Reinvestigation of the Thermoelectric Properties of Fe-Substituted Icosahedral Al–Pd–Re Quasicrytals. Phys. Status Solidi A 2022, 219, 2200073. [Google Scholar] [CrossRef]

- Trambly de Laissardière, G.; Nguyen-Manh, N.; Mayou, D. Electronic structure of complex Hume-Rothery phases and quasicrystals in transition metal aluminides. Prog. Mater. Sci. 2005, 50, 679–788. [Google Scholar] [CrossRef]

- Steurer, W. Why are quasicrystals quasiperiodic? Chem. Soc. Rev. 2012, 41, 6719–6729. [Google Scholar] [CrossRef]

- Takagiwa, Y.; Kamimura, T.; Okada, J.T.; Kimura, K. Thermoelectric Properties of Icosahedral Al–Pd–(Mn or Re) Quasicrystals: Improvement of the ZT Value by Ga Substitution for Al Atoms. J. Electron. Mater. 2010, 39, 1885–1889. [Google Scholar] [CrossRef]

- Takagiwa, Y.; Kamimura, T.; Hosoi, S.; Okada, J.T.; Kimura, K. Thermoelectric properties of polygrained icosahedral Al71−xGaxPd20Mn9 (x = 0, 2, 3, 4) quasicrystals. J. Appl. Phys. 2008, 104, 073721. [Google Scholar] [CrossRef]

- Iwasaki, Y.; Kashimura, T.; Kitahara, K.; Kimura, K. Possibility of Semiconducting Electronic Structure on AlPdCo 1/1 Cubic Quasicrystalline Approximant. Mater. Trans. 2021, 62, 317–320. [Google Scholar] [CrossRef]

- Takagiwa, Y.; Kamimura, T.; Hosoi, S.; Okada, J.T.; Kimura, K. Thermoelectric properties of Al–Pd–Re quasicrystal sintered by Spark Plasma Sintering (SPS): Effect of improvement of microstructure. Z. Kristallogr. 2009, 224, 79–83. [Google Scholar] [CrossRef]

- Birch, F. Finite Elastic Strain of Cubic Crystals. Phys. Rev. 1947, 71, 809–824. [Google Scholar] [CrossRef]

- Anderson, O.L. A simplified method for calculating the debye temperature from elastic constants. J. Phys. Chem. Solids 1963, 24, 909–917. [Google Scholar] [CrossRef]

- Shiota, Y.; Muta, H.; Yamamoto, K.; Ohishi, Y.; Kurosaki, K.; Yamanaka, S. A new semiconductor Al2Fe3Si3 with complex crystal structure. Intermetallics 2017, 89, 51–56. [Google Scholar] [CrossRef]

- Stadnik, Z.M.; Zhang, G.W.; Tsai, A.-P.; Inoue, A. Electronic structure of icosahedral Al65Cu20Ru15 studied by photoemission spectroscopy. Phys. Rev. B 1995, 81, 4023–4041. [Google Scholar] [CrossRef] [PubMed]

- Nagata, T.; Kirihara, K.; Kimura, K. Effect of Ru substitution for Re on the thermoelectric properties of AlPdRe icosahedral quasicrystals. J. Appl. Phys. 2003, 94, 6560–6565. [Google Scholar] [CrossRef]

- Okada, J.T.; Hamamatsu, T.; Hosoi, S.; Nagata, T.; Kimura, K. Improvement of thermoelectric properties of icosahedral AlPdRe quasicrystals by Fe substitution for Re. J. Appl. Phys. 2007, 101, 103702. [Google Scholar] [CrossRef]

- Mizutani, U.; Sato, H.; Inukai, M.; Zijlstra, E.S. e/a determination for 4d- and 5d-transition metal elements and their intermetallic compounds with Mg, Al, Zn, Cd and In. Philos. Mag. 2013, 93, 3353–3390. [Google Scholar] [CrossRef]

- Takeuchi, T. Unusual Increase of Electron Thermal Conductivity Caused by a Pseudogap at the Fermi Level. J. Electron. Mater. 2009, 38, 1354–1359. [Google Scholar] [CrossRef]

- Maciá, E.; Rodríguez-Oliveros, R. Theoretical assessment on the validity of the Wiedemann-Franz law for icosahedral quasicrystals. Phys. Rev. B 2007, 75, 104210. [Google Scholar] [CrossRef]

- Kim, H.-S.; Gibbs, Z.M.; Tang, Y.; Wang, H.; Snyder, G.J. Characterization of Lorenz number with Seebeck coefficient measurement. APL Mater. 2015, 3, 041506. [Google Scholar] [CrossRef]

- Cahill, D.G.; Pohl, R.O. Heat flow and lattice vibrations in glasses. Solid State Commun. 1989, 70, 927–930. [Google Scholar] [CrossRef]

- Cahill, D.G.; Watson, S.K.; Pohl, R.O. Lower limit to the thermal conductivity of disordered crystals. Phys. Rev. B 1992, 46, 6131–6140. [Google Scholar] [CrossRef]

- Fukushima, K.; Suyama, H.; Tokumoto, Y.; Kamimura, Y.; Takagiwa, Y.; Edagawa, K. Comparative study of high-temperature specific heat for Al-Pd-Mn icosahedral quasicrystals and crystal approximants. J. Phys. Commun. 2021, 5, 085002. [Google Scholar] [CrossRef]

- Putatunda, A.; Singh, D.J. Lorenz number in relation to estimates based on the Seebeck coefficient. Mater. Today Phys. 2019, 8, 49–55. [Google Scholar] [CrossRef]

- Hou, Z.; Takagiwa, Y.; Shinohara, Y.; Xu, Y.; Tsuda, K. First-principles study of electronic structures and elasticity of Al2Fe3Si3. J. Phys. Condens. Matter 2021, 33, 195501. [Google Scholar] [CrossRef]

- Mott, P.H.; Roland, C.M. Limits to Poisson’s ratio in isotropic materials. Phys. Rev. B 2009, 80, 132104. [Google Scholar] [CrossRef]

- Tanaka, K.; Mitarai, Y.; Koiwa, M. Elastic constants of Al-based icosahedral quasicrystals. Philos. Mag. 1996, 73, 1715–1723. [Google Scholar] [CrossRef]

- Duquesne, J.-Y.; Perrin, B. Elastic wave interaction in icosahedral AlPdMn. Phys. B 2002, 316, 317–320. [Google Scholar] [CrossRef]

| Sample | TS (K) | dbulk (g cm–3) | dcalc (g cm–3) | dbulk/dcalc (%) |

|---|---|---|---|---|

| x = 0 [16] | 1223 | 6.026 | 6.30 [22] | 95.7 |

| x = 0.1 | 1233 | 5.924 | 6.17 | 96.0 |

| x = 0.2 | 1233 | 5.810 | 6.05 | 96.0 |

| x = 0.3 | 1233 | 5.656 | 5.92 | 95.5 |

| x = 0.4 | 1223 | 5.648 | 5.80 | 97.4 |

| x = 0.5 | 1223 | 5.517 | 5.67 | 97.3 |

| Sample | κtotal,373K | κphonon,373K | κmin,373K | vlong/vtrans |

|---|---|---|---|---|

| (W m–1 K–1) | (W m–1 K–1) | (W m–1 K–1) | (m s–1) | |

| x = 0 [16] | 1.28 | 1.05 | 1.05 | 6430/3420 |

| x = 0.1 | 1.27 | 1.09 | 1.07 | 6400/3500 |

| x = 0.2 | 1.16 | 1.01 | 1.09 | 6430/3660 |

| x = 0.3 | 1.08 | 0.94 | 1.06 | 6370/3490 |

| x = 0.4 | 1.25 | 1.14 | 1.09 | 6480/3590 |

| x = 0.5 | 1.15 | 1.00 | 1.11 | 6690/3660 |

| Sample | vs | Δvs/vs | CP,373K | ΔCP,373K/CP,373K |

| (m s–1) | (%) | (J g−1 K−1) | (%) | |

| x = 0 [16] | 3820 | - | 0.3997 | - |

| x = 0.1 | 3900 | 2.1 | 0.4138 | 3.5 |

| x = 0.2 | 4070 | 6.5 | 0.4249 | 6.3 |

| x = 0.3 | 3890 | 1.8 | 0.3902 | −2.4 |

| x = 0.4 | 4000 | 4.7 | 0.4124 | 3.1 |

| x = 0.5 | 4080 | 6.8 | 0.3903 | 2.4 |

| Sample | ν | E | G | B |

|---|---|---|---|---|

| (-) | (GPa) | (GPa) | (GPa) | |

| x = 0 | 0.303 | 184 | 70.5 | 155 |

| x = 0.1 | 0.287 | 187 | 72.6 | 146 |

| x = 0.2 | 0.260 | 196 | 77.8 | 136 |

| x = 0.3 | 0.286 | 177 | 68.9 | 138 |

| x = 0.4 | 0.279 | 186 | 72.8 | 140 |

| x = 0.5 | 0.286 | 190 | 73.9 | 148 |

| i-Al–Pd–Mn [39] | 0.254 | - | 72.4 | 123 |

| i-Al–Pd–Mn [40] | 0.256 | - | 70.4 | 121 |

| i-Al–Cu–Fe [39] | 0.232 | - | 68.1 | 104 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Takagiwa, Y. Thermoelectric Properties of Co-Substituted Al–Pd–Re Icosahedral Quasicrystals. Materials 2022, 15, 6816. https://doi.org/10.3390/ma15196816

Takagiwa Y. Thermoelectric Properties of Co-Substituted Al–Pd–Re Icosahedral Quasicrystals. Materials. 2022; 15(19):6816. https://doi.org/10.3390/ma15196816

Chicago/Turabian StyleTakagiwa, Yoshiki. 2022. "Thermoelectric Properties of Co-Substituted Al–Pd–Re Icosahedral Quasicrystals" Materials 15, no. 19: 6816. https://doi.org/10.3390/ma15196816