Influence of Constant Magnetic Field upon Fatigue Life of Commercially Pure Titanium

Abstract

:1. Introduction

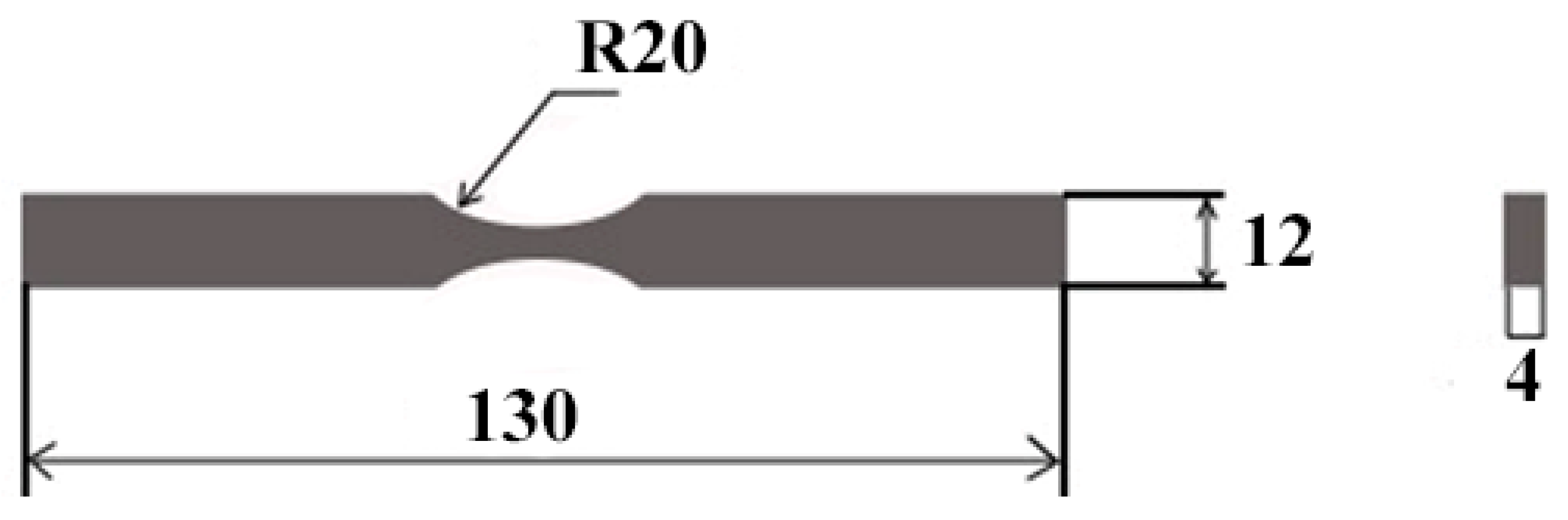

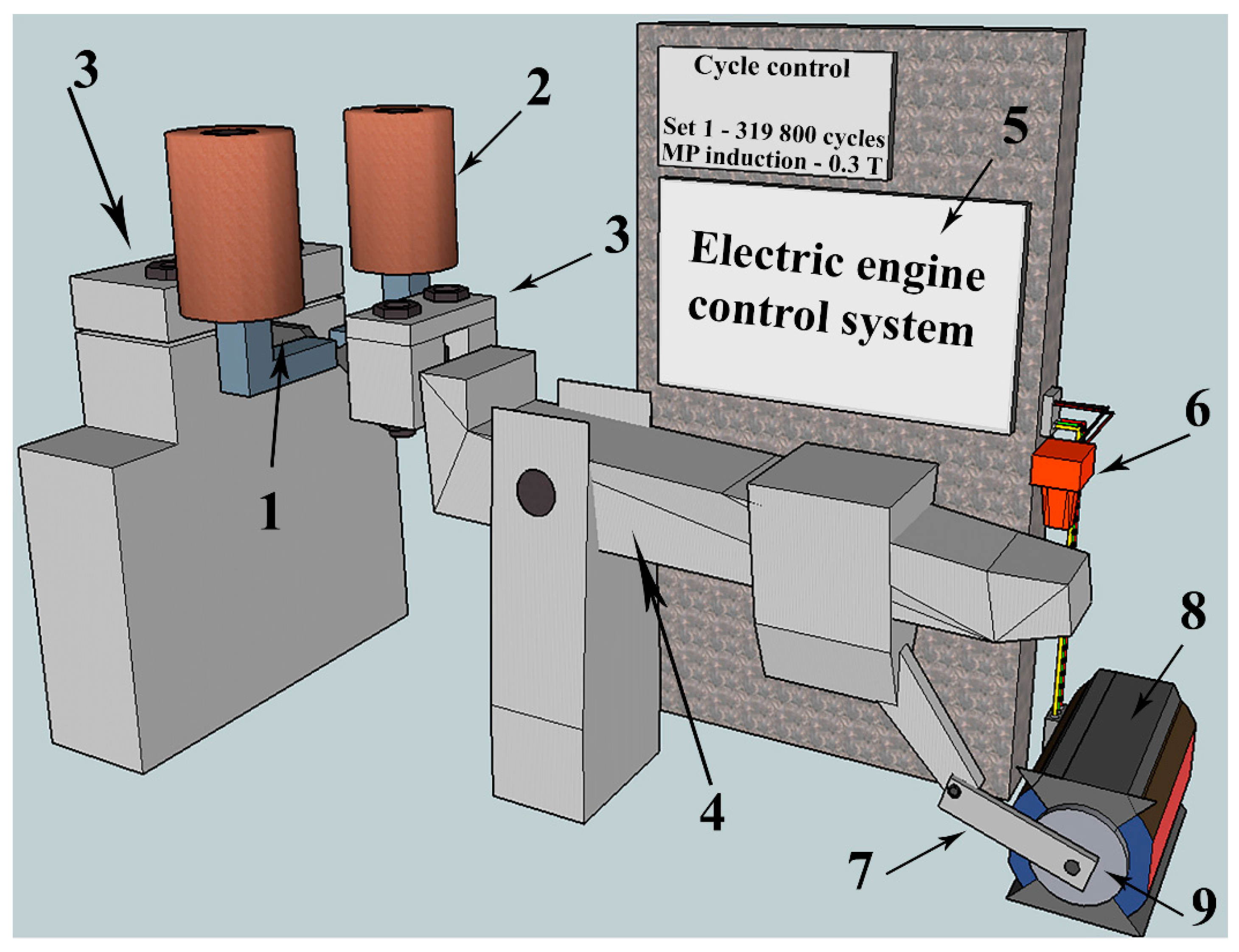

2. Materials and Methods

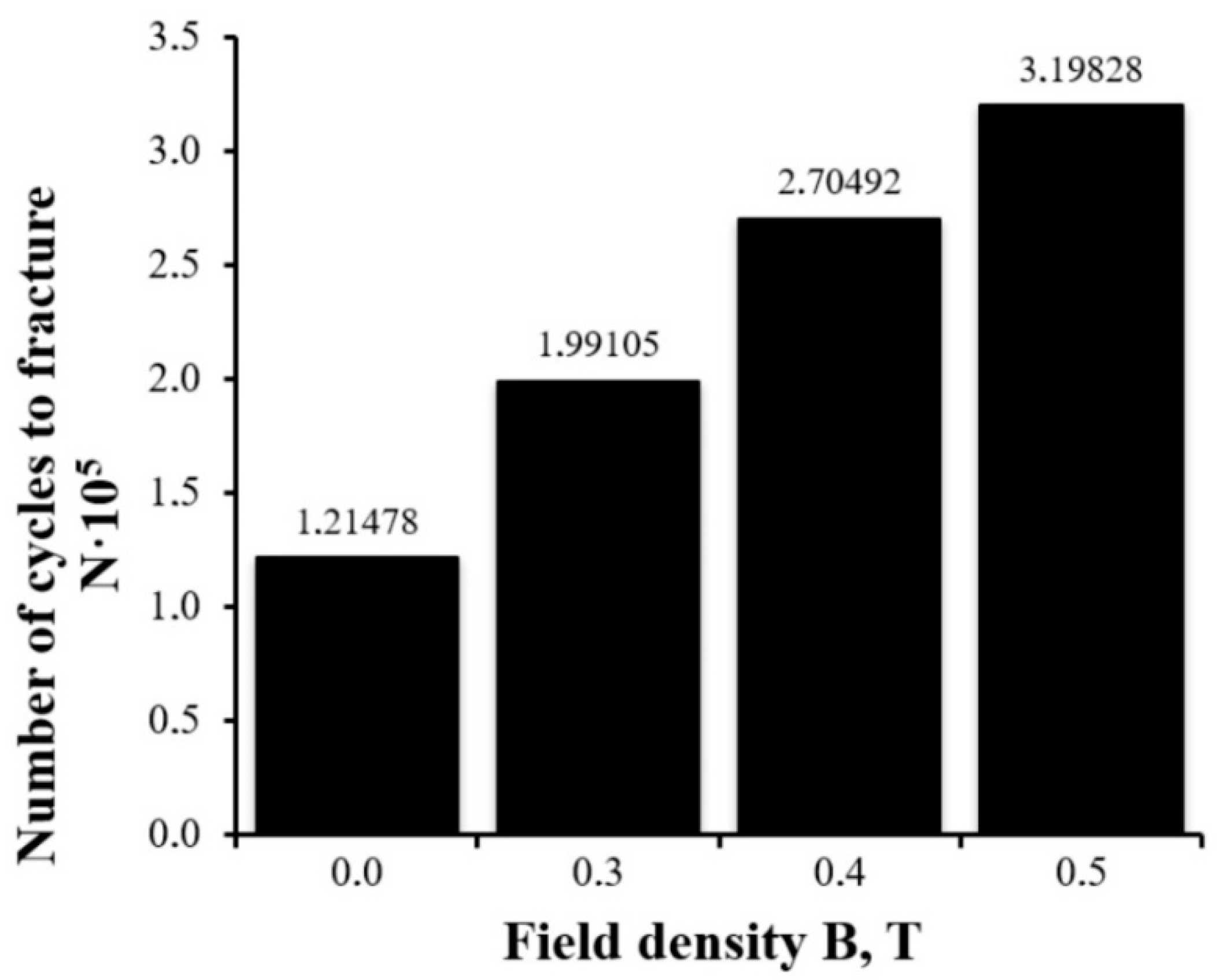

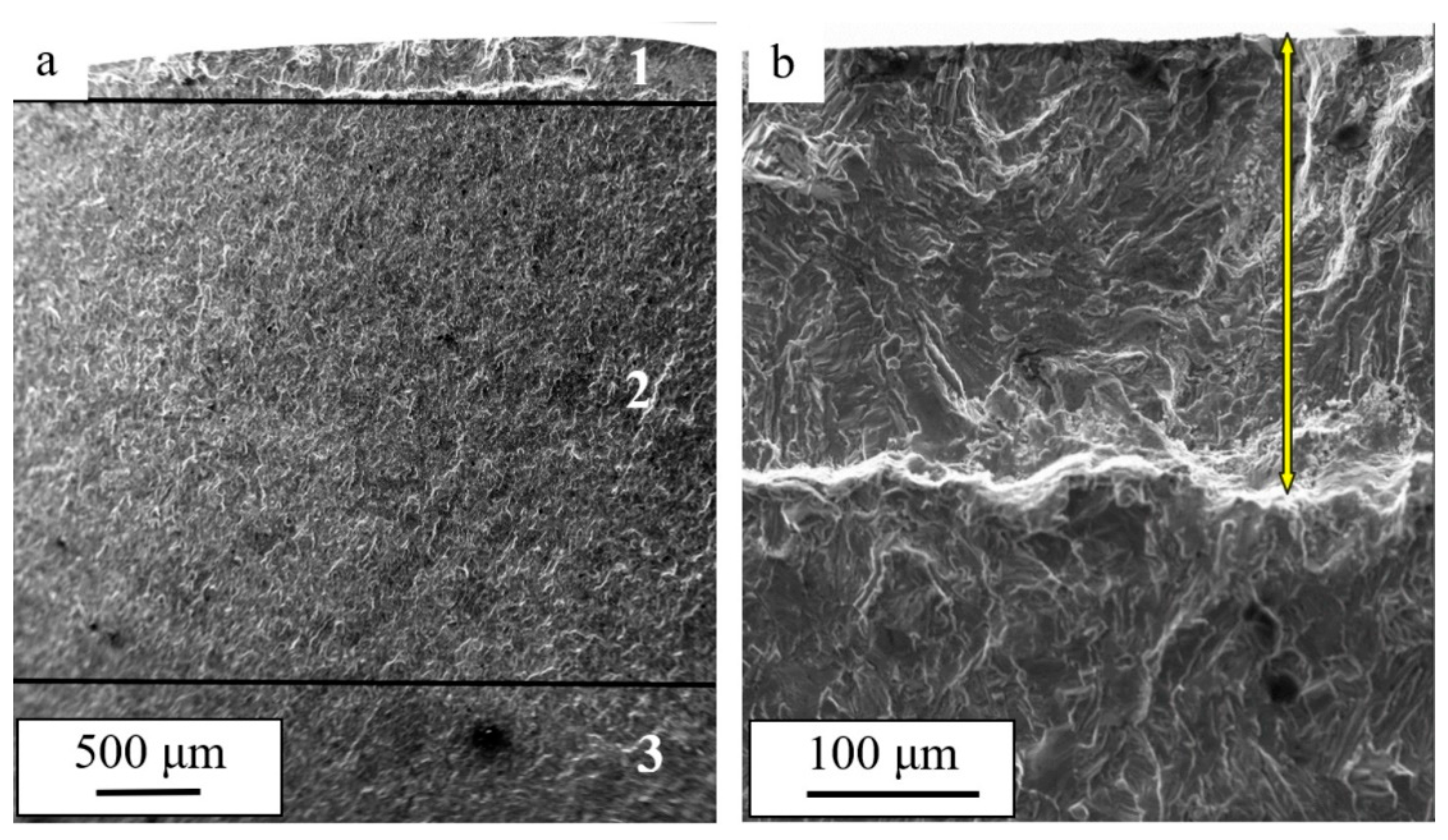

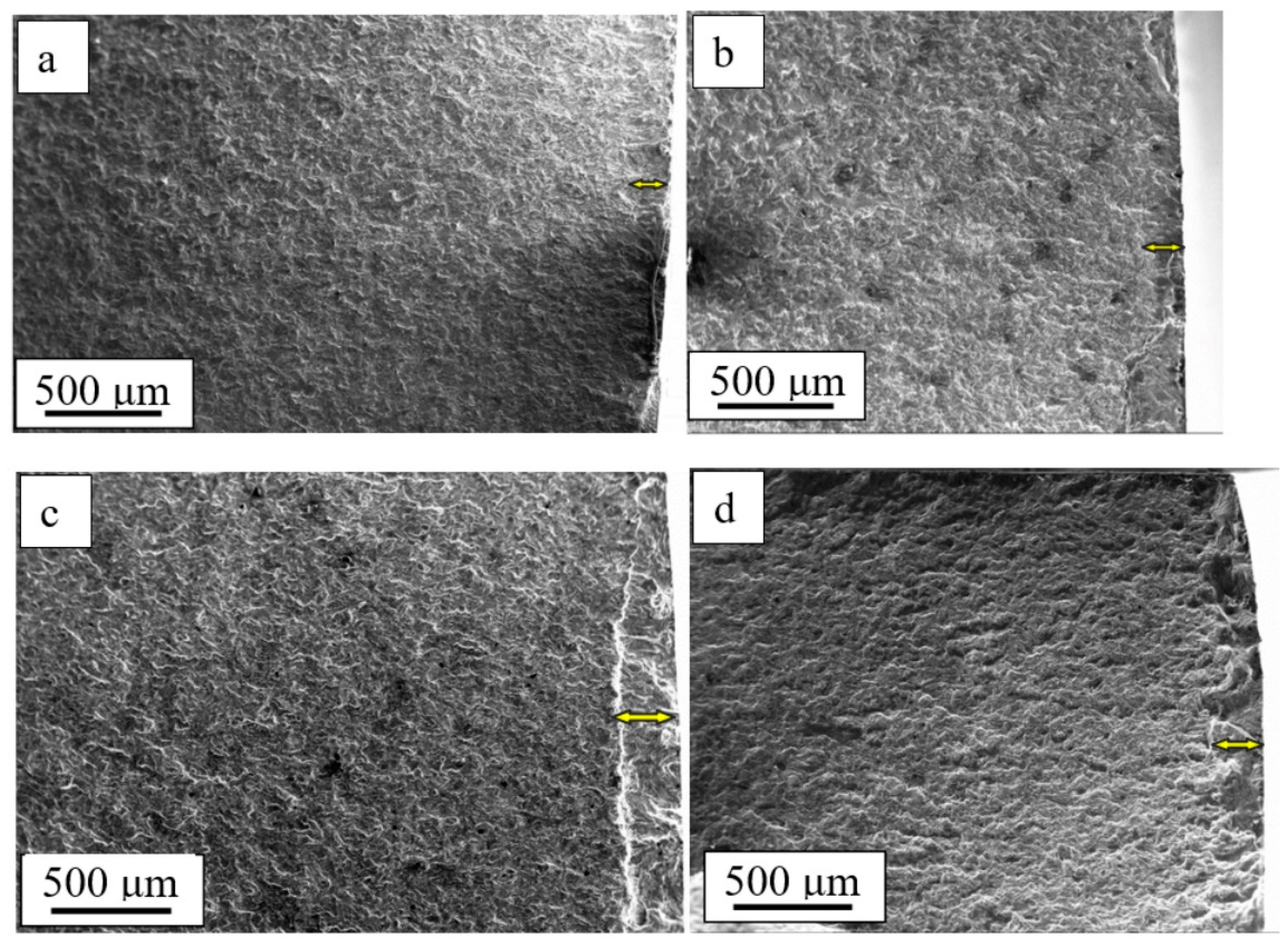

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Peralta, P.; Laird, C. Fatigue of Metals. In Physical Metallurgy, 5th ed.; Laughlin, D.E., Hono, K., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 1765–1880. [Google Scholar]

- Li, G.; Sun, C. High-temperature failure mechanism and defect sensitivity of TC17 titanium alloy in high cycle fatigue. J. Mater. Sci. Technol. 2022, 122, 128–140. [Google Scholar] [CrossRef]

- Jung, J.; Ju, Y.; Morita, Y.; Toku, Y. Effect of pulsed electric current on the growth behavior of fatigue crack in Al alloy. Procedia Struct. Integr. 2016, 2, 2989–2993. [Google Scholar] [CrossRef] [Green Version]

- Mohin, M.; Toofanny, H.; Babutskyi, A.; Lewis, A.; Xu, Y. Effect of electromagnetic treatment on fatigue resistance of 2011 aluminum alloy. J. Multiscale Model. 2016, 7, 1650004. [Google Scholar] [CrossRef]

- Huang, S.; Sheng, J.; Zhou, J.Z.; Lu, J.Z.; Meng, X.K.; Xu, S.Q.; Zhang, H.F. On the influence of laser peening with different coverage areas on fatigue response and fracture behavior of Ti–6Al–4V alloy. Eng. Fract. Mech. 2015, 147, 72–82. [Google Scholar] [CrossRef]

- Ren, X.; Chen, B.; Jiao, J.; Yang, Y.; Zhou, W.; Tong, Z. Fatigue behavior of double-sided laser shock peened Ti-6Al-4V thin blade subjected to foreign object damage. Opt. Laser Technol. 2020, 121, 105784. [Google Scholar] [CrossRef]

- Sun, R.; Li, L.; Guo, W.; Peng, P.; Zhai, T.; Che, Z.; Li, B.; Guo, C.; Zhu, Y. Laser shock peening induced fatigue crack retardation in Ti-17 titanium alloy. Mater. Sci. Eng. A 2018, 737, 94–104. [Google Scholar] [CrossRef]

- Qi, K.; Yang, Y.; Liang, W.; Jin, K.; Xiong, L. Effect of magnetic field on the microstructure and wear properties of TiB2/metal composite layers synthesized in situ by laser cladding on Ti–6Al–4V alloy. Ceram. Int. 2021, 47, 29463–29474. [Google Scholar] [CrossRef]

- Donii, O.; Narizhna, T.; Voron, M.; Berest, D. Influence of the external magnetic field on the structure and properties of the hypereutectic aluminum-silicon alloy. Mater. Sci. Non-Equilib. Phase Transform. 2018, 4, 79–82. [Google Scholar]

- Goins, P.E.; Murdoch, H.A.; Hernández-Rivera, E.; Tschopp, M.A. Effect of magnetic fields on microstructure evolution. Comput. Mater. Sci. 2018, 150, 464–474. [Google Scholar] [CrossRef]

- Vdovin, K.N.; Dubsky, G.A.; Deev, V.B.; Egorova, L.G.; Nefediev, A.A.; Prusov, E.S. Influence of a Magnetic Field on Structure Formation during the Crystallization and Physicomechanical Properties of Aluminum Alloys. Russ. J. Non-Ferr. Met. 2019, 2, 51–57. [Google Scholar] [CrossRef]

- Cai, Q.; Zhai, C.; Luo, Q.; Zhang, T.-Y. Effects of magnetic field on the microstructure and mechanical property of Mg-Al-Gd alloys. Mater. Charact. 2019, 154, 233–240. [Google Scholar] [CrossRef]

- Weidong, X.; Lufa, D.; Yu, H.; Wei, S.; Huaiwei, Z.; Jiang, W.; Yunbo, Z.; Zhongming, R. Investigation on microstructure and creep properties of nickel based single crystal superalloys PWA1483 during heat treatment under an alternating magnetic field. Mater. Sci. Eng. A 2019, 762, 138087. [Google Scholar]

- Skvortsov, A.A.; Pshonkin, D.E.; Luk’yanov, M.N.; Rybakova, M.R. Influence of permanent magnetic fields on creep and microhardness of iron-containing aluminum alloy. J. Mater. Res. Technol. 2019, 8, 2481–2485. [Google Scholar] [CrossRef]

- Luo, J.; Luo, H.; Liu, C.; Zhao, T.; Wang, R.; Ma, Y. Effect of magnetic field on precipitation kinetics of an ultrafine grained Al–Zn–Mg–Cu alloy. Mater. Sci. Eng. 2020, 798, 139990. [Google Scholar] [CrossRef]

- Li, G.R.; Li, Y.M.; Wang, F.F.; Wang, H.M. Microstructure and performance of solid TC4 titanium alloy subjected to the high pulsed magnetic field treatment. J. Alloy. Compd. 2015, 644, 750–756. [Google Scholar] [CrossRef]

- Li, G.R.; Wang, F.F.; Wang, H.M.; Cheng, J.F. Microstructure and Mechanical Properties of TC4 Titanium Alloy Subjected to High Static Magnetic Field. Mater. Sci. Forum 2017, 898, 345–354. [Google Scholar] [CrossRef]

- Li, G.R.; Qin, T.; Fei, A.G.; Wang, H.M.; Zhao, Y.T.; Chen, G.; Kai, X.Z. Performance and microstructure of TC4 titanium alloy subjected to deep cryogenic treatment and magnetic field. J. Alloy. Compd. 2019, 802, 50–69. [Google Scholar] [CrossRef]

- Seidametov, S.V.; Loskutov, S.V.; Shchetinina, M.O. Magnetoplastic effect at kinetic indentation tests. Phys. Met. Latest Technol. 2015, 37, 615–624. [Google Scholar] [CrossRef] [Green Version]

- Seidametov, S.V.; Loskutov, S.V. Influence of pulsed electromagnetic treatment upon the structural relocations of VT3-1 titanium alloy. J. Phys. Surf. Eng. 2016, 1, 4–8. [Google Scholar]

- Pang, J.C.; Li, S.X.; Wang, Z.G.; Zhang, Z.F. General relation between tensile strength and fatigue strength of metallic materials. Mater. Sci. Eng. A 2013, 564, 331–341. [Google Scholar] [CrossRef]

- Kyoung, J.C.; Seung, C.Y.; Junhyuk, H.; Kim, J.H.; Jeong, S.Y.; Choi, Y.S. Fatigue behavior of AISI 8620 steel exposed to magnetic field. J. Alloy. Compd. 2018, 764, 73–79. [Google Scholar]

- Gu, Q.; Huang, X.; Xi, J.; Gao, Z. The Influence of Magnetic Field on Fatigue and Mechanical Properties of a 35CrMo Steel. Metals 2021, 11, 542. [Google Scholar] [CrossRef]

- Akram, S.; Babutskyi, A.; Chrysanthou, A.; Montalvão, D.; Pizurova, N. Effect of Alternating Magnetic Field on the Fatigue Behaviour of EN8 Steel and 2014-T6 Aluminium Alloy. Metals 2019, 9, 984. [Google Scholar] [CrossRef] [Green Version]

- Bachmann, M.; Avilov, V.; Gumenyuk, A.; Rethmeier, M. Experimental and numerical investigation of an electromagnetic weld pool support system for high power laser beam welding of austenitic stainless steel. J. Mater. Process. Technol. 2014, 214, 578–591. [Google Scholar] [CrossRef]

- Chen, R.; Jiang, P.; Shao, X.; Mi, G.; Wang, C.; Geng, S.; Gao, S.; Cao, L. Improvement of low-temperature impact toughness for 304 weld joint produced by laser-MIG hybrid welding under magnetic field. J. Mater. Process. Technol. 2017, 247, 306–314. [Google Scholar] [CrossRef]

- Chen, R.; Jiang, P.; Shao, X.; Mi, G.; Wang, C. Effect of magnetic field on crystallographic orientation for stainless steel 316L laser-MIG hybrid welds and its strengthening mechanism on fatigue resistance. Int. J. Fatigue 2018, 112, 308–317. [Google Scholar] [CrossRef]

- Gomez, C.A.L.; Gonzalez-Sanchez, J.; Bilyy, O. Effect of the application of an external magnetic field during the process of fusing welding in stainless steel duplex 2205 in the resistance to cracking by corrosion fatigue. Procedia Struct. Integr. 2019, 16, 265–272. [Google Scholar] [CrossRef]

- Zagulyaev, D.V.; Konovalov, S.V.; Shlyarov, V.V.; Chen, X. Influence of constant magnetic field on plastic characteristics of paramagnetic metals. Mater. Res. Express 2019, 6, 096523. [Google Scholar] [CrossRef]

- Zagulyaev, D.V.; Barannikova, S.A.; Shlyarov, V.V.; Anuchina, E.; Konovalov, S.V. Effect of the 0.3 T magnetic field on the microhardness of commercially pure VT1-0 titanium. AIP Conf. Proc. 2016, 1783, 020233. [Google Scholar]

- Shlyarov, V.V.; Zagulyaev, D.V. Influence of magnetic fields upon the procee of plastic deformation of non-ferrous metals. Fundam. Probl. Mod. Mater. Sci. 2019, 16, 394–398. [Google Scholar]

- ASTM International (B348); B348—Standard Specification for Titanium and Titanium Alloy Bars and Billets. ASTM International: West Conshohocken, PA, USA, 2013. [CrossRef]

- Terentiev, V.F. Fatigue of Metals; Science: Moscow, Russia, 2015; p. 312. [Google Scholar]

- Kotsanda, S. Fatigue Fracture of Metals; Metallurgy: Moscow, Russia, 1990; p. 623. [Google Scholar]

- Anderson, T.L. Fracture Mechanics: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 2005; p. 688. [Google Scholar]

- McEvily, A.J.; Matsunaga, H. On Fatigue Striations. Trans. B Mech. Eng. 2010, 17, 75–82. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aksenova, K.; Zaguliaev, D.; Konovalov, S.; Shlyarov, V.; Ivanov, Y. Influence of Constant Magnetic Field upon Fatigue Life of Commercially Pure Titanium. Materials 2022, 15, 6926. https://doi.org/10.3390/ma15196926

Aksenova K, Zaguliaev D, Konovalov S, Shlyarov V, Ivanov Y. Influence of Constant Magnetic Field upon Fatigue Life of Commercially Pure Titanium. Materials. 2022; 15(19):6926. https://doi.org/10.3390/ma15196926

Chicago/Turabian StyleAksenova, Krestina, Dmitrii Zaguliaev, Sergey Konovalov, Vitalii Shlyarov, and Yurii Ivanov. 2022. "Influence of Constant Magnetic Field upon Fatigue Life of Commercially Pure Titanium" Materials 15, no. 19: 6926. https://doi.org/10.3390/ma15196926

APA StyleAksenova, K., Zaguliaev, D., Konovalov, S., Shlyarov, V., & Ivanov, Y. (2022). Influence of Constant Magnetic Field upon Fatigue Life of Commercially Pure Titanium. Materials, 15(19), 6926. https://doi.org/10.3390/ma15196926