Comparison of the Material Quality of AlxIn1−xN (x—0–0.50) Films Deposited on Si(100) and Si(111) at Low Temperature by Reactive RF Sputtering

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussions

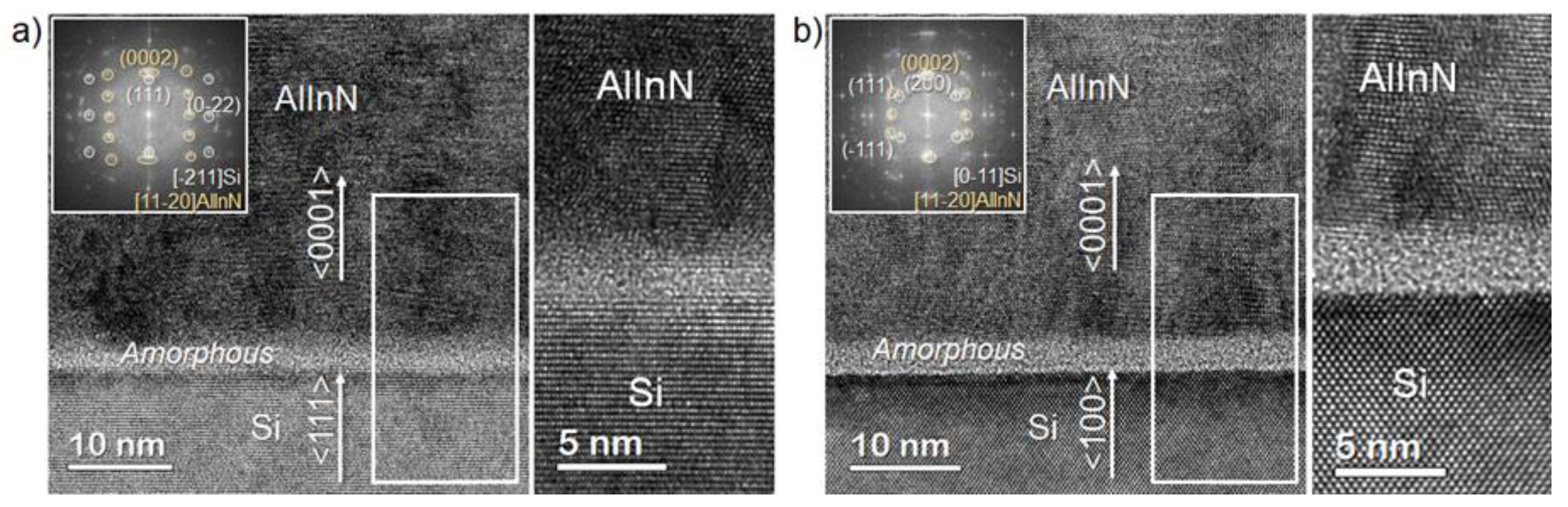

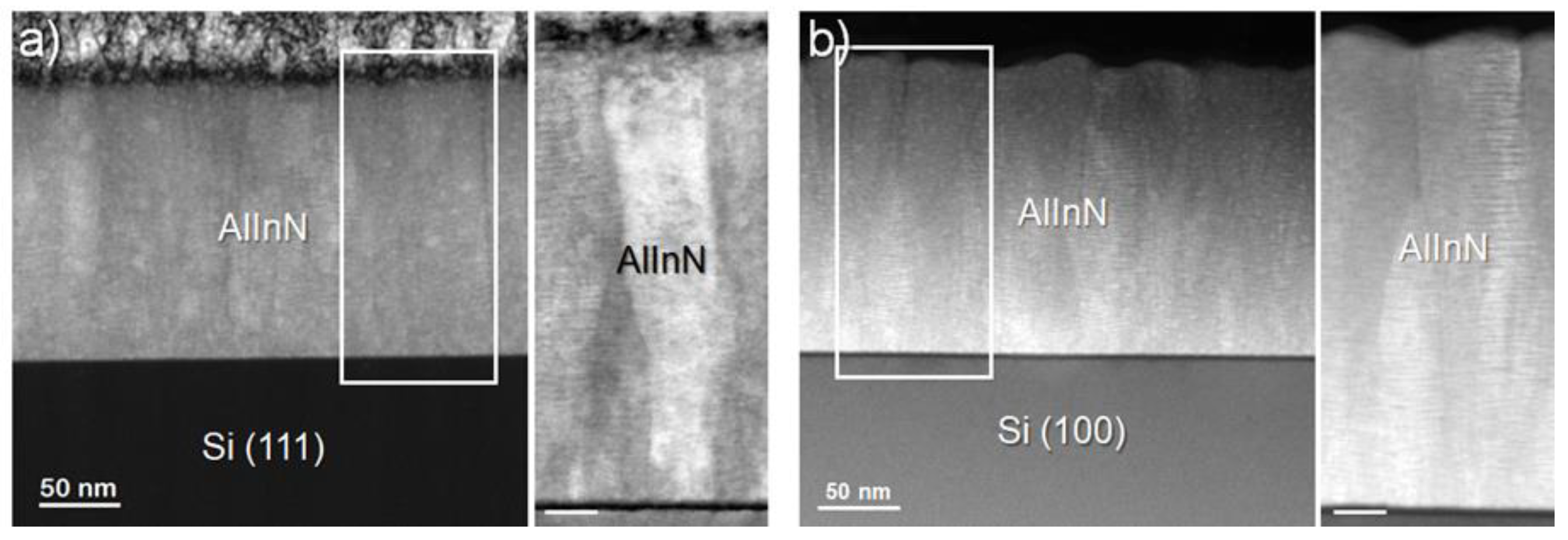

3.1. Structural Characterization

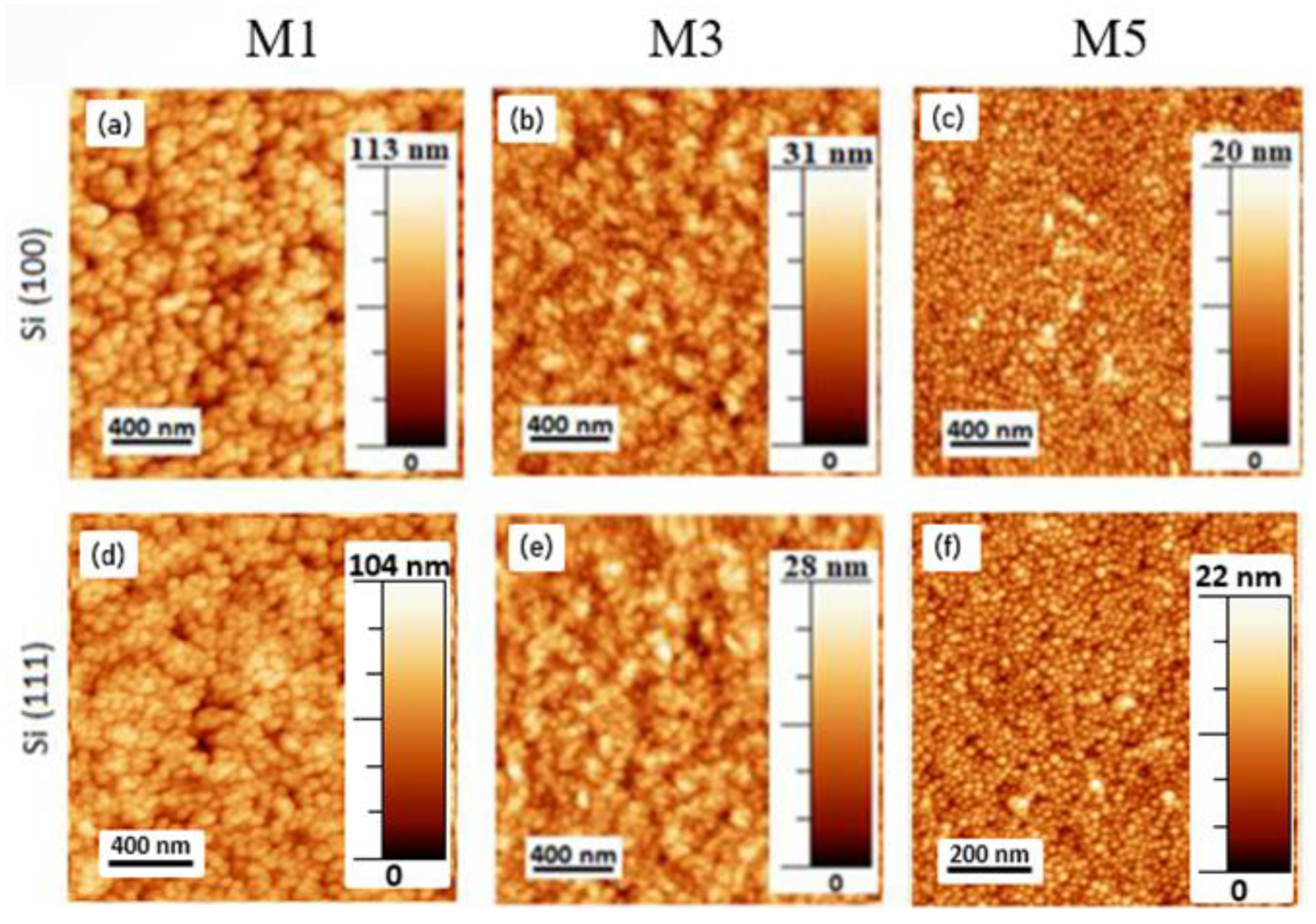

3.2. Morphological Characterization

3.3. Electrical Characterization

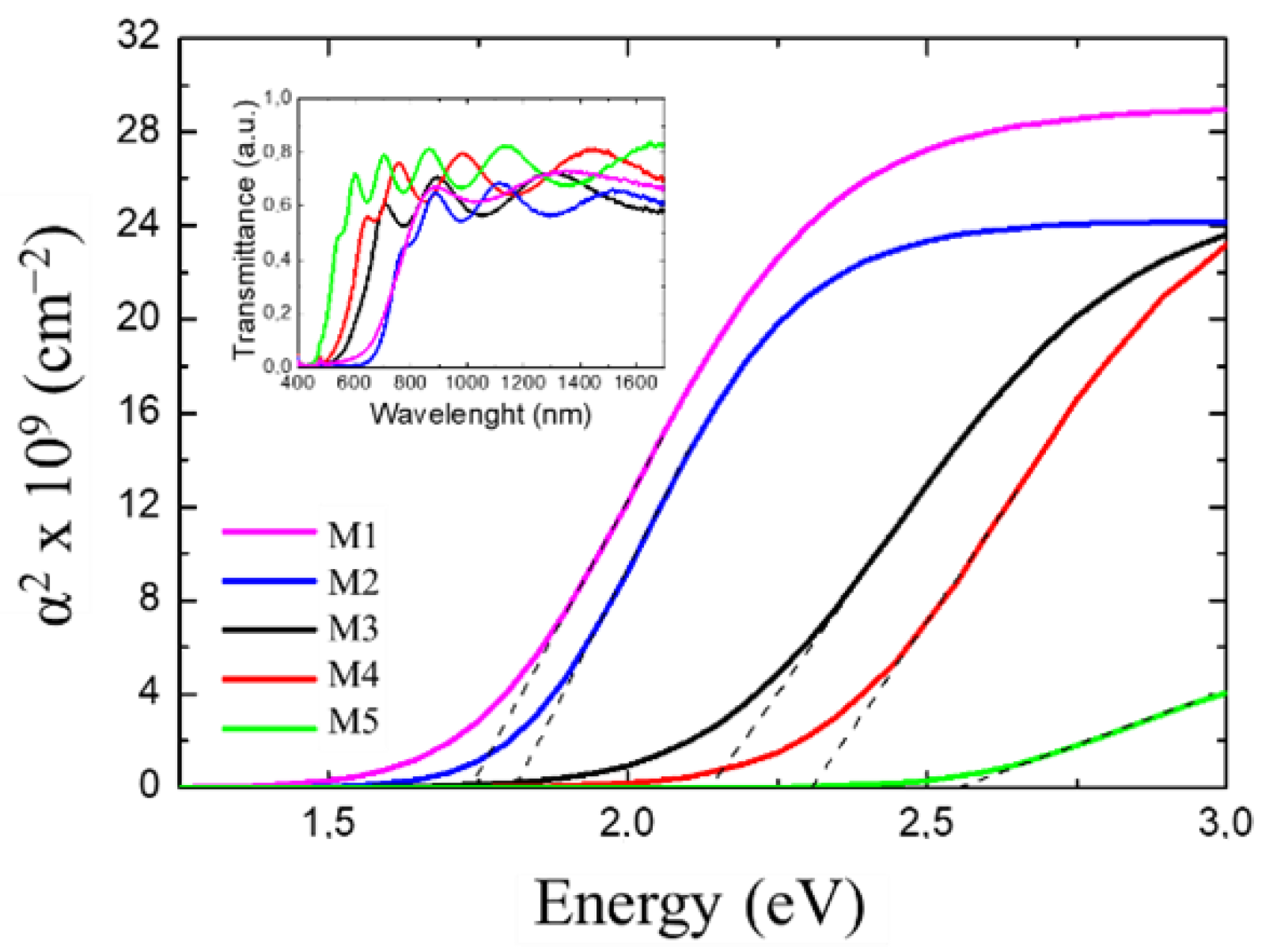

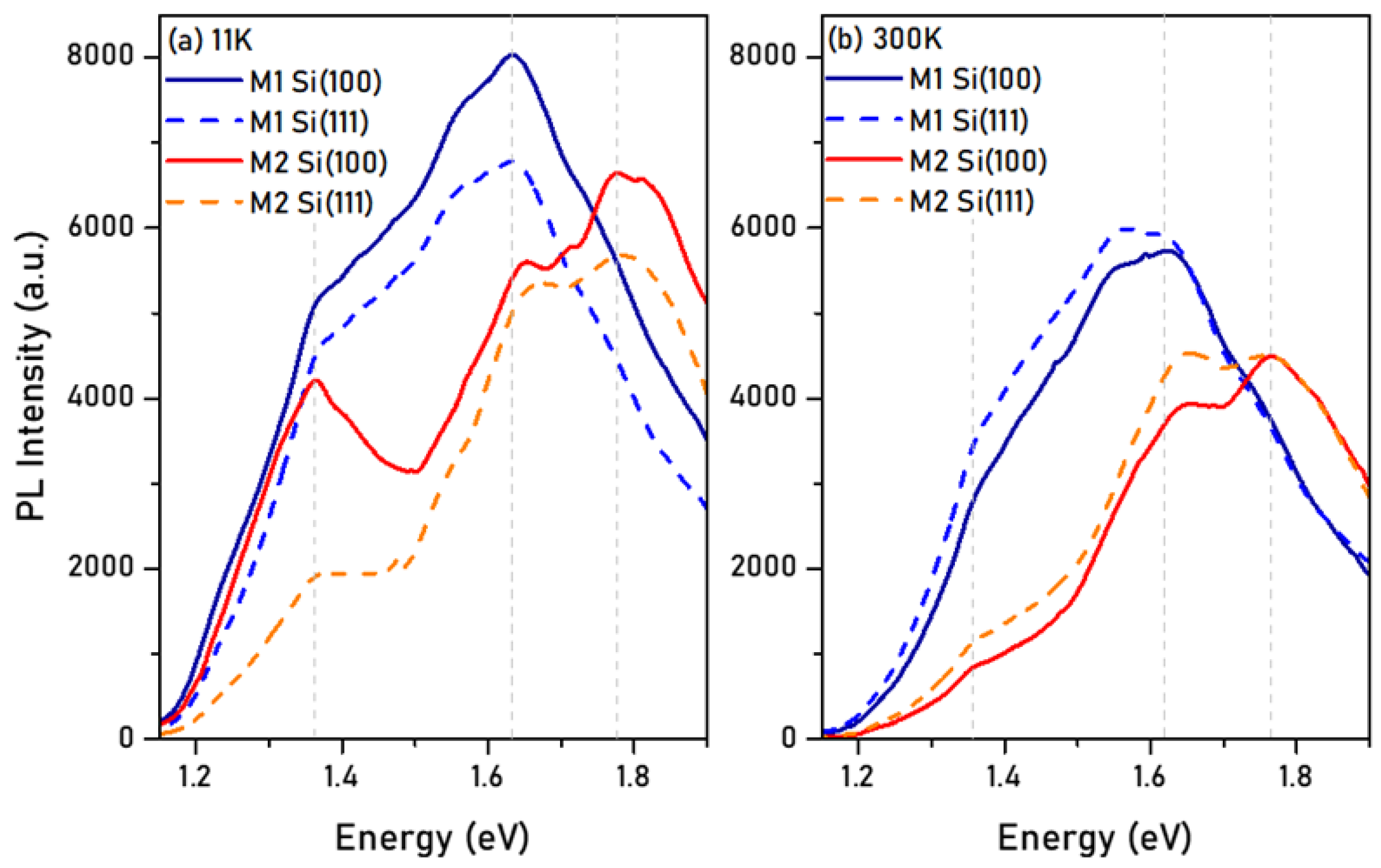

3.4. Optical Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Wu, J.; Walukiewicz, W.; Yu, K.M.; Ager, J.; Haller, E.E.; Lu, H.; Schaff, W.J.; Saito, Y.; Nanishi, Y. Unusual properties of the fundamental band gap of InN. Appl. Phys. Lett. 2002, 80, 3967–3969. [Google Scholar] [CrossRef]

- Yim, W.M.; Stofko, E.J.; Zanzucchi, P.J.; Pankove, J.I.; Ettenberg, M.; Gilbert, S.L. Epitaxially grown AlN and its optical band gap. J. Appl. Phys. 1973, 44, 292–296. [Google Scholar] [CrossRef]

- Lu, N.; Ferguson, I. III-nitrides for energy production: Photovoltaic and thermoelectric applications. Semicond. Sci. Technol. 2013, 28, 074023. [Google Scholar] [CrossRef]

- Hums, C.; Bläsing, J.; Dadgar, A.; Diez, A.; Hempel, T.; Christen, J.; Krost, A.; Lorenz, K.; Alves, E. Metal-organic vapor phase epitaxy and properties of AlInN in the whole compositional range. Appl. Phys. Lett. 2007, 90, 022105. [Google Scholar] [CrossRef]

- Senda, S.; Jiang, H.; Egawa, T. AlInN-based ultraviolet photodiode grown by metal organic chemical vapor deposition. Appl. Phys. Lett. 2008, 92, 203507. [Google Scholar] [CrossRef]

- Yun, L.; Wei, T.; Yan, J.; Liu, Z.; Wang, J.; Li, J. MOCVD epitaxy of InAlN on different templates. J. Semicond. 2011, 32, 093001. [Google Scholar] [CrossRef]

- Dinh, D.V.; Hu, N.; Honda, Y.; Amano, H.; Pristovsek, M. Indium icorporation and optical properties of polar, semipolar and nonpolar InAlN. Semicond. Sci. Technol. 2019, 35, 035004. [Google Scholar] [CrossRef]

- Wu, Y.-H.; Wong, Y.-Y.; Chen, W.-C.; Tsai, D.-S.; Peng, C.-Y.; Tian, J.-S.; Chang, L.; Chang, E.Y. Indium-rich InAlN films on GaN/sapphire by molecular beam epitaxy. Mater. Res. Express 2014, 1, 015904. [Google Scholar] [CrossRef]

- Kamimura, J.; Kouno, T.; Ishizawa, S.; Kikuchi, A.; Kishino, K. Growth of high-In-content InAlN nanocolumns on Si (111) by RF-plasma-assisted molecular-beam epitaxy. J. Cryst. Growth 2007, 300, 160–163. [Google Scholar] [CrossRef]

- Bhuiyan, A.G.; Islam, S.; Hashimoto, A. Molecular beam epitaxy of InAlN alloys in the whole compositional range. AIP Adv. 2020, 10, 015053. [Google Scholar] [CrossRef]

- Chen, W.-C.; Wu, Y.-H.; Tian, J.-S.; Yen, T.-C.; Lin, P.-Y.; Chen, J.-Y.; Hsiao, C.-N.; Chang, L. Effect of Growth Temperature on Structural Quality of In-Rich InxAl1−xN Alloys on Si (111) Substrate by RF-MOMBE. ISRN Nanomater. 2014, 2014, 1–6. [Google Scholar] [CrossRef]

- Yodo, T.; Ando, H.; Nosei, D.; Harada, Y. Growth and characterization of InN heteroepitaxial layers grown on Si substrates by ECR-assisted MBE. Phys. Status Solidi Basic Res. 2001, 228, 21–26. [Google Scholar] [CrossRef]

- Afzal, N.; Devarajan, M.; Ibrahim, K. Growth of AlInN films via elemental layers annealing at different temperatures. Mod. Phys. Lett. B 2015, 29, 1550169. [Google Scholar] [CrossRef]

- Afzal, N.; Devarajan, M.; Subramani, S.; Ibrahim, K. Structural and surface analysis of AlInN thin films synthesized by elemental stacks annealing. Mater. Res. Express 2014, 1, 026403. [Google Scholar] [CrossRef]

- Afzal, N.; Devarajan, M.; Ibrahim, K. Influence of substrate temperature on the growth and properties of reactively sputtered In-rich InAlN films. J. Mater. Sci. Mater. Electron. 2016, 27, 4281–4289. [Google Scholar] [CrossRef]

- He, H.; Cao, Y.; Fu, R.; Guo, W.; Huang, Z.; Wang, M.; Huang, C.; Huang, J.; Wang, H. Band gap energy and bowing parameter of In-rich InAlN films grown by magnetron sputtering. Appl. Surf. Sci. 2010, 256, 1812–1816. [Google Scholar] [CrossRef]

- Guo, Q.; Okazaki, Y.; Kume, Y.; Tanaka, T.; Nishio, M.; Ogawa, H. Reactive sputter deposition of AlInN thin films. J. Cryst. Growth 2007, 300, 151–154. [Google Scholar] [CrossRef]

- Guo, Q.; Yahata, K.; Tanaka, T.; Nishio, M.; Ogawa, H. Growth and characterization of reactive sputtered AlInN films. Phys. Status Solidi 2003, 2533–2536. [Google Scholar] [CrossRef]

- Lv, W.; Shen, L.; Liu, J.; Chen, J.; Wu, L.; Qi, D.; Zhang, G.; Li, X. Mechanical properties of single-phase Al1−In N films across the compositional range (0 ≤ x ≤ 0.7) grown by radio-frequency magnetron sputtering. Appl. Surf. Sci. 2019, 504, 144335. [Google Scholar] [CrossRef]

- Zhou, Y.; Peng, W.; Li, J.; Liu, Y.; Zhu, X.; Wei, J.; Wang, H.; Zhao, Y. Substrate temperature induced physical property variation of InxAl1−xN alloys prepared on Al2O3 by magnetron sputtering. Vacuum 2020, 179, 109512. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, H.; Li, X.; Li, J.; Shi, Z.; Wu, G.; Zhuang, S.; Yin, C.; Yang, F. Parametric study on the well-oriented growth of InxAl1-xN nanodots by magnetron sputtering. Mater. Sci. Semicond. Process. 2019, 102, 104583. [Google Scholar] [CrossRef]

- Afzal, N.; Devarajan, M.; Ibrahim, K. A comparative study on the growth of InAlN films on different substrates. Mater. Sci. Semicond. Process. 2016, 51, 8–14. [Google Scholar] [CrossRef]

- He, H.; Cao, Y.; Fu, R.; Wang, H.; Huang, J.; Huang, C.; Wang, M.; Deng, Z. Structure and optical properties of InN and InAlN films grown by rf magnetron sputtering. J. Mater. Sci. Mater. Electron. 2010, 21, 676–681. [Google Scholar] [CrossRef]

- Afzal, N.; Devarajan, M.; Ibrahim, K. Synthesis of aluminium indium nitride (AlInN) thin films by stacked elemental layers method. Eur. Phys. J. Appl. Phys. 2014, 67, 10301. [Google Scholar] [CrossRef]

- Valdueza-Felip, S.; Núñez-Cascajero, A.; Blasco, R.; Montero, D.; Grenet, L.; de la Mata, M.; Fernández, S.; Marcos, L.R.-D.; Molina, S.I.; Olea, J.; et al. Influence of the AlN interlayer thickness on the photovoltaic properties of in-rich AlInN on Si heterojunctions deposited by RF sputtering. AIP Adv. 2018, 8, 115315. [Google Scholar] [CrossRef]

- Núñez-Cascajero, A.; Valdueza-Felip, S.; Monteagudo-Lerma, L.; Monroy, E.; Taylor-Shaw, E.; Martin, R.W.; González-Herráez, M.; Naranjo, F.B. In-rich AlxIn1−xN grown by RF-sputtering on sapphire: From closely-packed columnar to high-surface quality compact layers. J. Phys. D Appl. Phys. 2017, 50, 065101. [Google Scholar] [CrossRef]

- Blasco, R.; Valdueza-Felip, S.; Montero, D.; Sun, M.; Olea, J.; Naranjo, F.B. Low-to-Mid Al Content (x = 0–0.56) AlxIn1−x N Layers Deposited on Si(100) by Radio-Frequency Sputtering. Phys. Status Solidi 2020, 257, 1900575. [Google Scholar] [CrossRef]

- Núñez-Cascajero, A.; Valdueza-Felip, S.; Blasco, R.; de la Mata, M.; Molina, S.I.; Gonzalez-Herraez, M.; Monroy, E.; Naranjo, F. Quality improvement of AlInN/p-Si heterojunctions with AlN buffer layer deposited by RF-sputtering. J. Alloy. Compd. 2018, 769, 824–830. [Google Scholar] [CrossRef]

- Blasco, R.; Núñez-Cascajero, A.; Jiménez-Rodríguez, M.; Montero, D.; Grenet, L.; Olea, J.; Naranjo, F.B.; Valdueza-Felip, S. Influence of the AlInN Thickness on the Photovoltaic Characteristics of AlInN on Si Solar Cells Deposited by RF Sputtering. Phys. Status Solidi 2019, 216, 1800494. [Google Scholar] [CrossRef]

- Núñez-Cascajero, A.; Blasco, R.; Naranjo, F.N.; Valdueza-Felip, S. High quality Al0.37In0.63N layers grown at low temperature (<300 °C) by radio-frequency sputtering. Mater. Sci. Semicond. Process. 2019, 100, 8–14. [Google Scholar] [CrossRef]

- Núñez-cascajero, A.; Monteagudo-Lerma, L.; Valdueza-Felip, S.; Navío, C.; Monroy, E.; González-Herráez, M.; Naranjo, F.B. Study of high In-content AlInN deposition on p-Si (111) by RF-sputtering. Jpn. J. Appl. Phys. 2016, 55, 05FB07. [Google Scholar] [CrossRef]

- Darakchieva, V.; Lorenz, K.; Barradas, N.P.; Alves, E.; Monemar, B.; Schubert, M.; Franco, N.; Hsiao, C.-L.; Chen, L.-C.; Schaff, W.J.; et al. Hydrogen in InN: A ubiquitous phenomenon in molecular beam epitaxy grown material. Appl. Phys. Lett. 2010, 96, 081907. [Google Scholar] [CrossRef]

- Darakchieva, V.; Barradas, N.P.; Xie, M.-Y.; Lorenz, K.; Alves, E.; Schubert, M.; Persson, P.; Giuliani, F.; Munnik, F.; Hsiao, C.-L.; et al. Role of impurities and dislocations for the unintentional n-type conductivity in InN. Phys. B Condens. Matter 2009, 404, 4476–4481. [Google Scholar] [CrossRef]

- Butcher, K.; Tansley, T. InN, latest development and a review of the band-gap controversy. Superlattices Microstruct. 2005, 38, 1–37. [Google Scholar] [CrossRef]

- Bashir, U.; Hassan, Z.; Ahmed, N.M. A comparative study of InN growth on quartz, silicon, C-sapphire and bulk GaN substrates by RF magnetron sputtering. J. Mater. Sci. Mater. Electron. 2017, 28, 9228–9236. [Google Scholar] [CrossRef]

- Han, Q.; Duan, C.; Du, G.; Shi, W.; Ji, L. Magnetron Sputter Epitaxy and Characterization of Wurtzite AlInN on Si(111) Substrates. J. Electron. Mater. 2010, 39, 489–493. [Google Scholar] [CrossRef]

- Dong, C.J.; Xu, M.; Chen, Q.Y.; Liu, F.S.; Zhou, H.P.; Wei, Y.; Ji, H.X. Growth of well-oriented AlxIn1−xN films by sputtering at low temperature. J. Alloy. Compd. 2009, 479, 812–815. [Google Scholar] [CrossRef]

- Liu, H.F.; Tan, C.C.; Dalapati, G.K.; Chi, D.Z. Magnetron-sputter deposition of high-indium-content n-AlInN thin film on p-Si(001) substrate for photovoltaic applications. J. Appl. Phys. 2012, 112, 063114. [Google Scholar] [CrossRef]

- Von, L.V. Die Konstitution der Mischkristalle und die Raumfullung der Atome. Z. Phys. 1921, 5, 17–26. [Google Scholar]

| Sample | Substrate | PAl (W) | c (Å) | Al Mole Fraction x | FWHM Rocking Curve (°) | Thickness 1 (nm) | Deposition Rate 2 (nm/h) | Rms Surface Roughness 3 (nm) |

|---|---|---|---|---|---|---|---|---|

| M1 | Si(100) | 0 | 5.73 | 0 | 4.6 | 390 | 130 | 11.5 |

| M2 | 100 | 5.61 | 0.12 | 2.4 | 790 | 160 | 9.5 | |

| M3 | 150 | 5.45 | 0.35 | 6.2 | 650 | 160 | 3.5 | |

| M4 | 175 | 5.42 | 0.40 | 3.2 | 620 | 155 | 3.5 | |

| M5 | 225 | 5.36 | 0.48 | 2.8 | 910 | 230 | 2.5 | |

| M1 | Si(111) | 0 | 5.73 | 0 | 4.7 | 380 | 125 | 13.0 |

| M2 | 100 | 5.59 | 0.16 | 2.9 | 780 | 160 | 8.0 | |

| M3 | 150 | 5.44 | 0.36 | 6.1 | 640 | 160 | 3.5 | |

| M4 | 175 | 5.40 | 0.42 | 3.1 | 630 | 160 | 3.5 | |

| M5 | 225 | 5.35 | 0.49 | 2.8 | 585 | 150 | 2.5 |

| Sample | Al Mole Fraction x | |||

|---|---|---|---|---|

| M1 | 0 | 17.2 | 1.70 | 160 |

| M2 | 0.12 | 20.3 | 1.80 | 120 |

| M3 | 0.35 | 18.4 | 2.10 | 210 |

| M4 | 0.40 | 18.3 | 2.30 | 210 |

| M5 | 0.48 | 10.0 | 2.60 | 180 |

| Sample | Temperature (K) | Substrate | Main Peak Emission Energy 1 (eV) | FWHM 2 (meV) | Integrated Intensity 3 (a.u.) |

|---|---|---|---|---|---|

| M1 | 11 | Si(100) | 1.60 | 560 | 4500 |

| Si(111) | 1.60 | 515 | 3600 | ||

| 300 | Si(100) | 1.60 | 460 | 2750 | |

| Si(111) | 1.60 | 465 | 2920 | ||

| M2 | 11 | Si(100) | 1.80 | 565 | 3750 |

| Si(111) | 1.80 | 480 | 3100 | ||

| 300 | Si(100) | 1.80 | 500 | 2250 | |

| Si(111) | 1.75 | 490 | 2400 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, M.; Blasco, R.; Nwodo, J.; de la Mata, M.; Molina, S.I.; Ajay, A.; Monroy, E.; Valdueza-Felip, S.; Naranjo, F.B. Comparison of the Material Quality of AlxIn1−xN (x—0–0.50) Films Deposited on Si(100) and Si(111) at Low Temperature by Reactive RF Sputtering. Materials 2022, 15, 7373. https://doi.org/10.3390/ma15207373

Sun M, Blasco R, Nwodo J, de la Mata M, Molina SI, Ajay A, Monroy E, Valdueza-Felip S, Naranjo FB. Comparison of the Material Quality of AlxIn1−xN (x—0–0.50) Films Deposited on Si(100) and Si(111) at Low Temperature by Reactive RF Sputtering. Materials. 2022; 15(20):7373. https://doi.org/10.3390/ma15207373

Chicago/Turabian StyleSun, Michael, Rodrigo Blasco, Julian Nwodo, María de la Mata, Sergio I. Molina, Akhil Ajay, Eva Monroy, Sirona Valdueza-Felip, and Fernando B. Naranjo. 2022. "Comparison of the Material Quality of AlxIn1−xN (x—0–0.50) Films Deposited on Si(100) and Si(111) at Low Temperature by Reactive RF Sputtering" Materials 15, no. 20: 7373. https://doi.org/10.3390/ma15207373

APA StyleSun, M., Blasco, R., Nwodo, J., de la Mata, M., Molina, S. I., Ajay, A., Monroy, E., Valdueza-Felip, S., & Naranjo, F. B. (2022). Comparison of the Material Quality of AlxIn1−xN (x—0–0.50) Films Deposited on Si(100) and Si(111) at Low Temperature by Reactive RF Sputtering. Materials, 15(20), 7373. https://doi.org/10.3390/ma15207373