A Design for the High Yield Photoneutron Source Target Station

Abstract

1. Introduction

2. Principles of Neutron Production

2.1. The Reactions for Neutron Production

2.1.1. Hadron-Based Method

2.1.2. Photon-Based Method

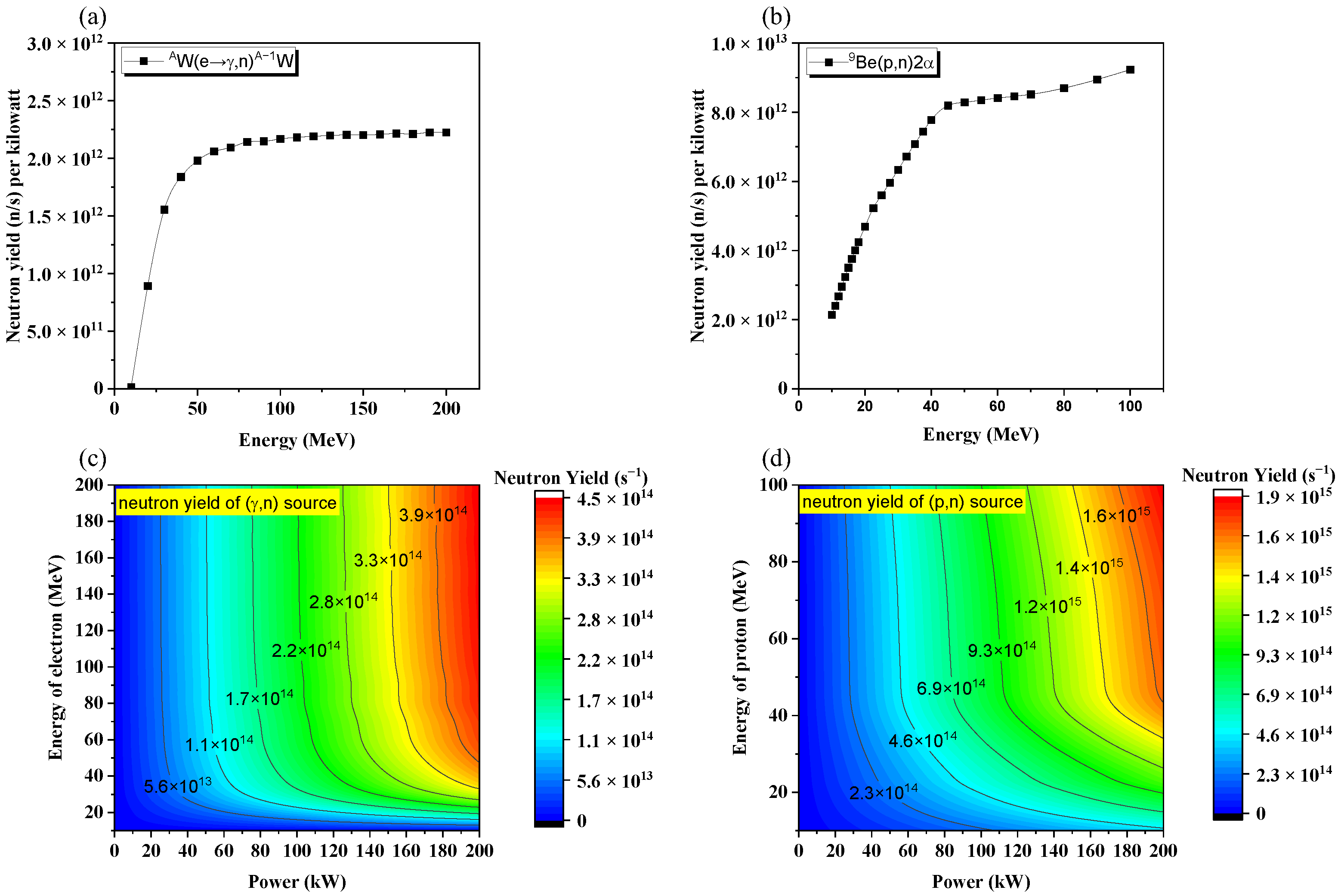

2.2. The Reaction Yield and the Yield of the Neutron Source

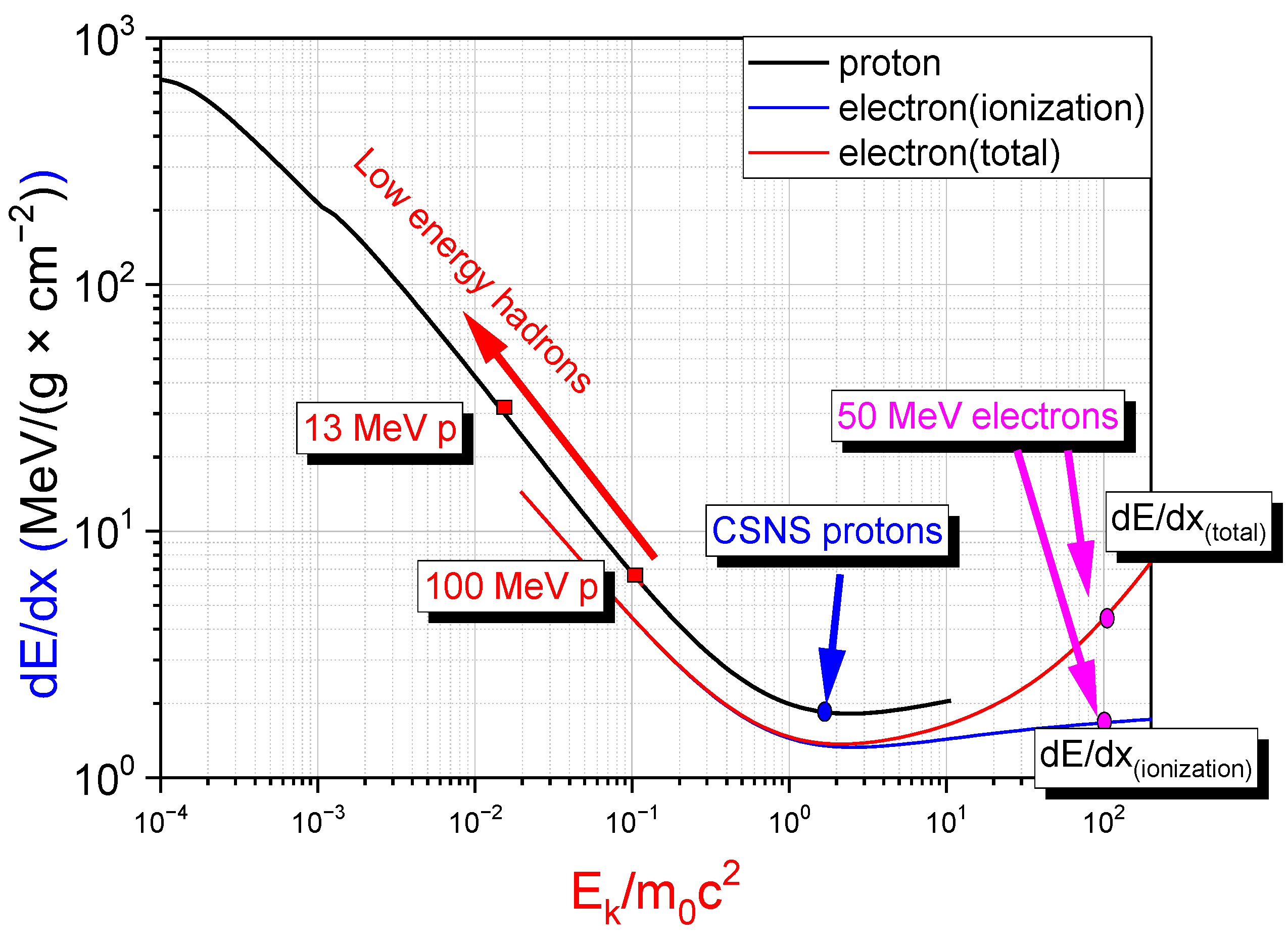

2.3. Short Term Consideration: The Power Deposition and Heat Dissipation

2.3.1. Hadron-Based Method

2.3.2. Photon-Based Method

2.3.3. Estimation of the Neutron Yield Affected by the Heat Dissipation

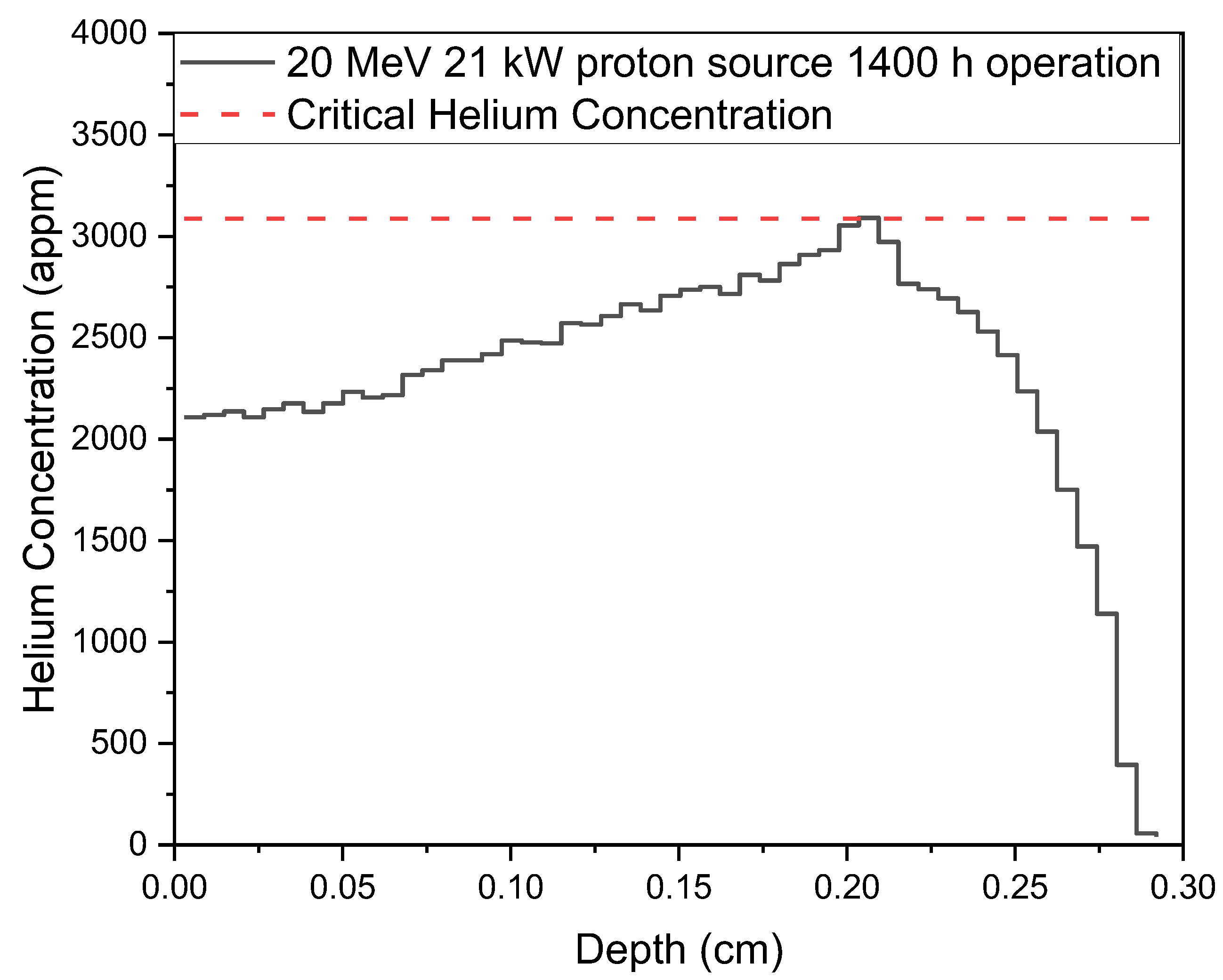

2.4. Long Term Consideration: Light Nuclides Production along with the Emission of Neutrons

2.4.1. Hadron-Based Method

2.4.2. Photon-Based Method

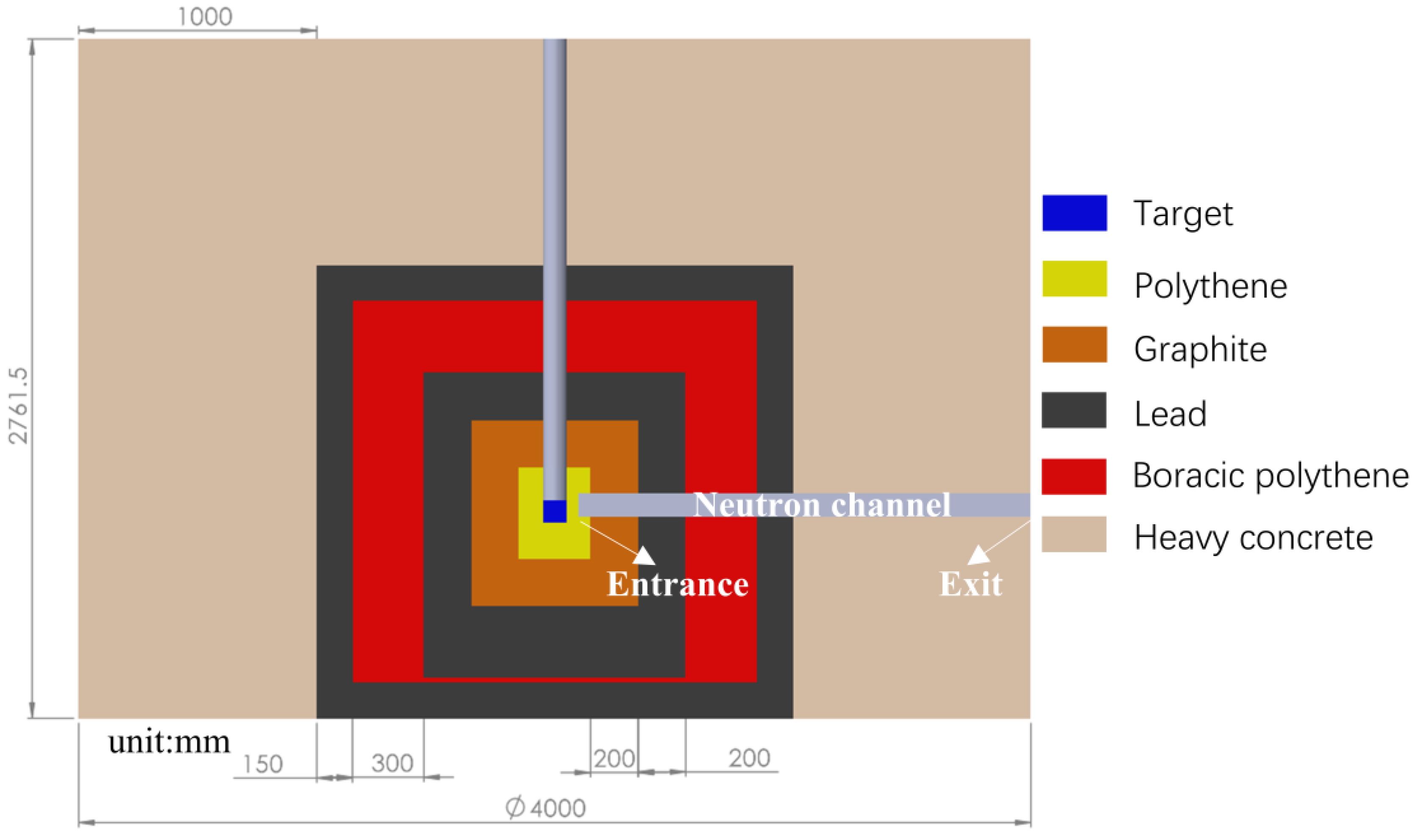

3. The Physical Design of a 50 MeV e-LINAC Based Photoneutron Target-Moderator-Reflector (TMR)

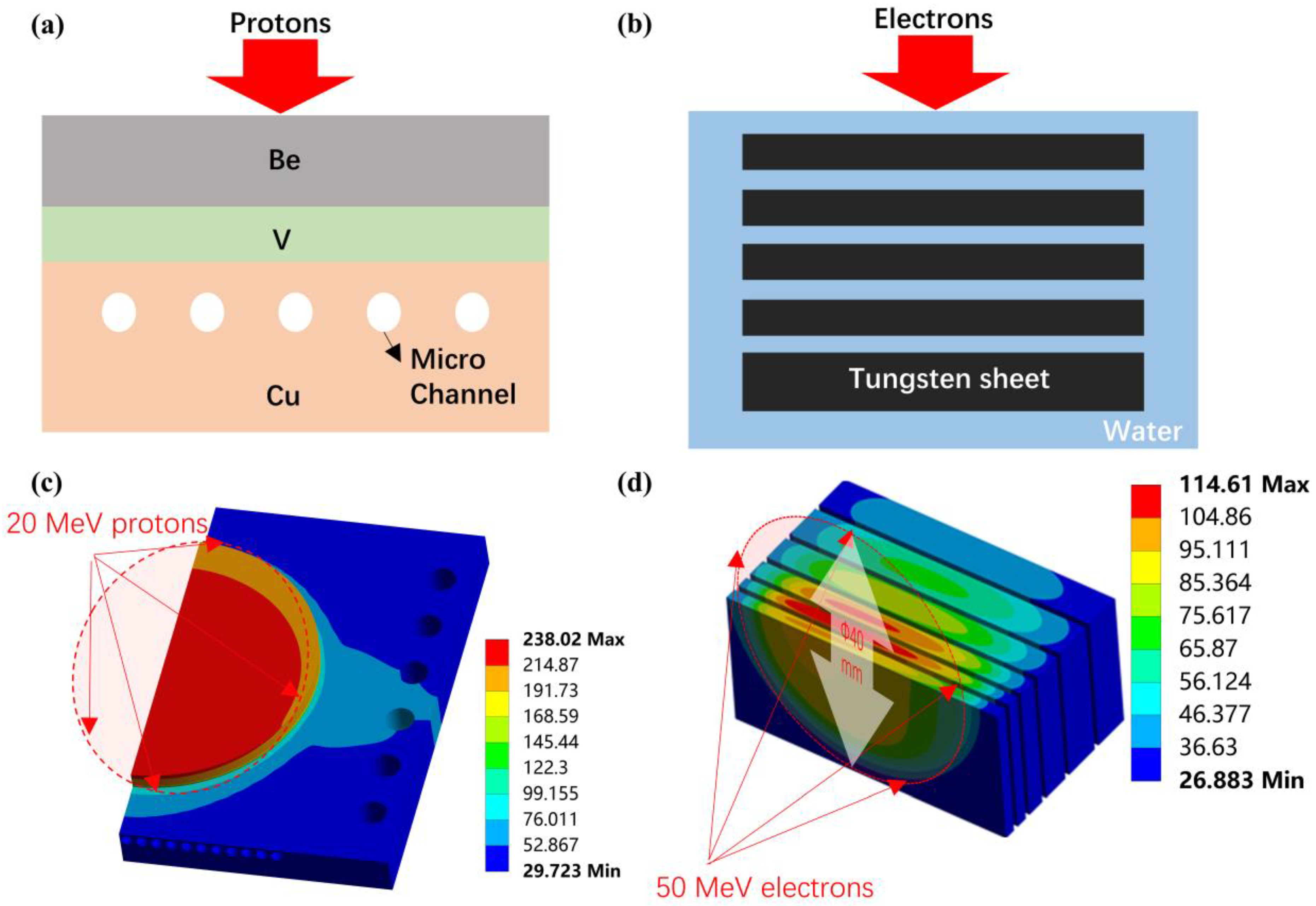

3.1. Target Layout and Thermal Hydraulic Simulation

3.2. Moderation and Shielding of Neutrons

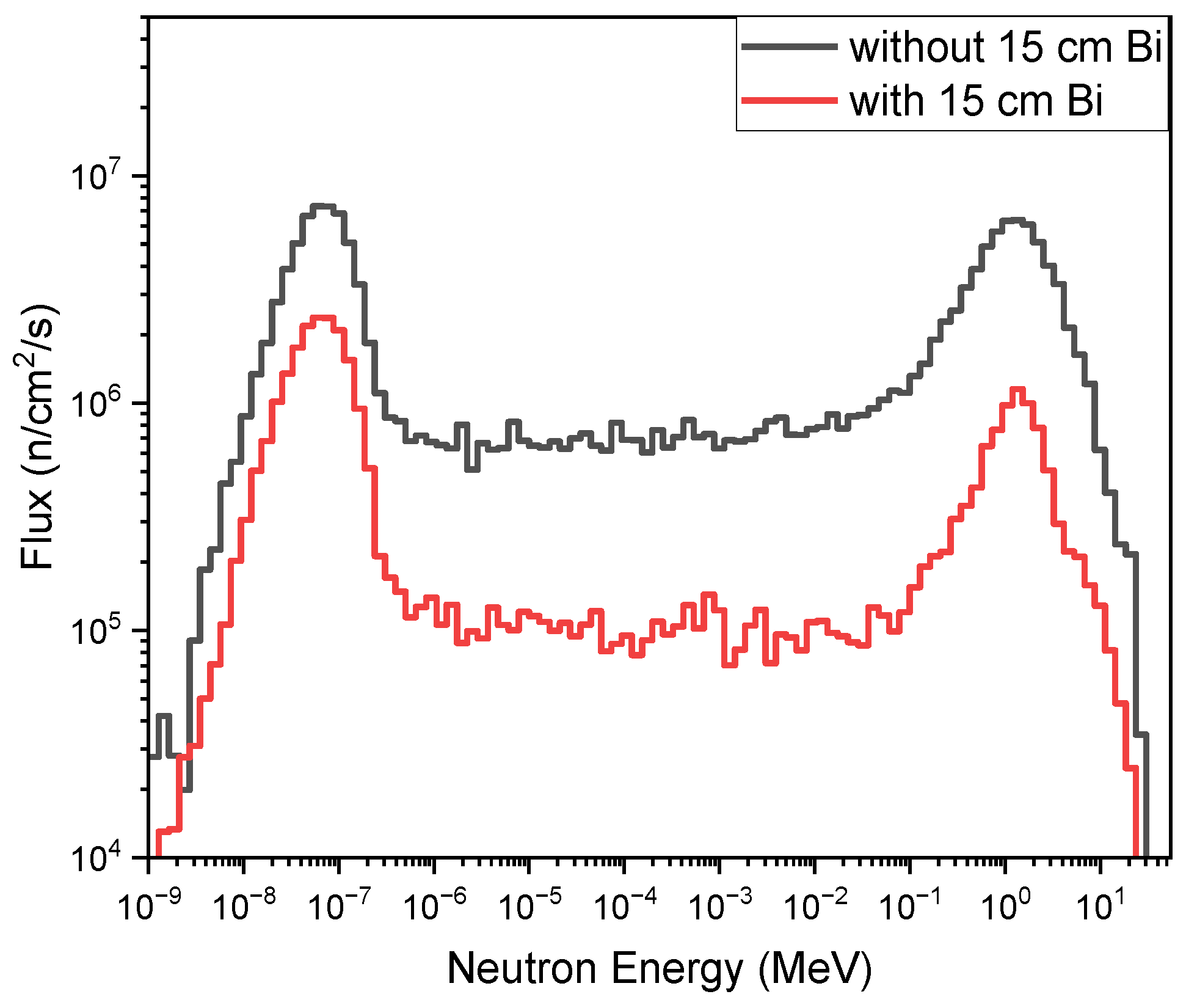

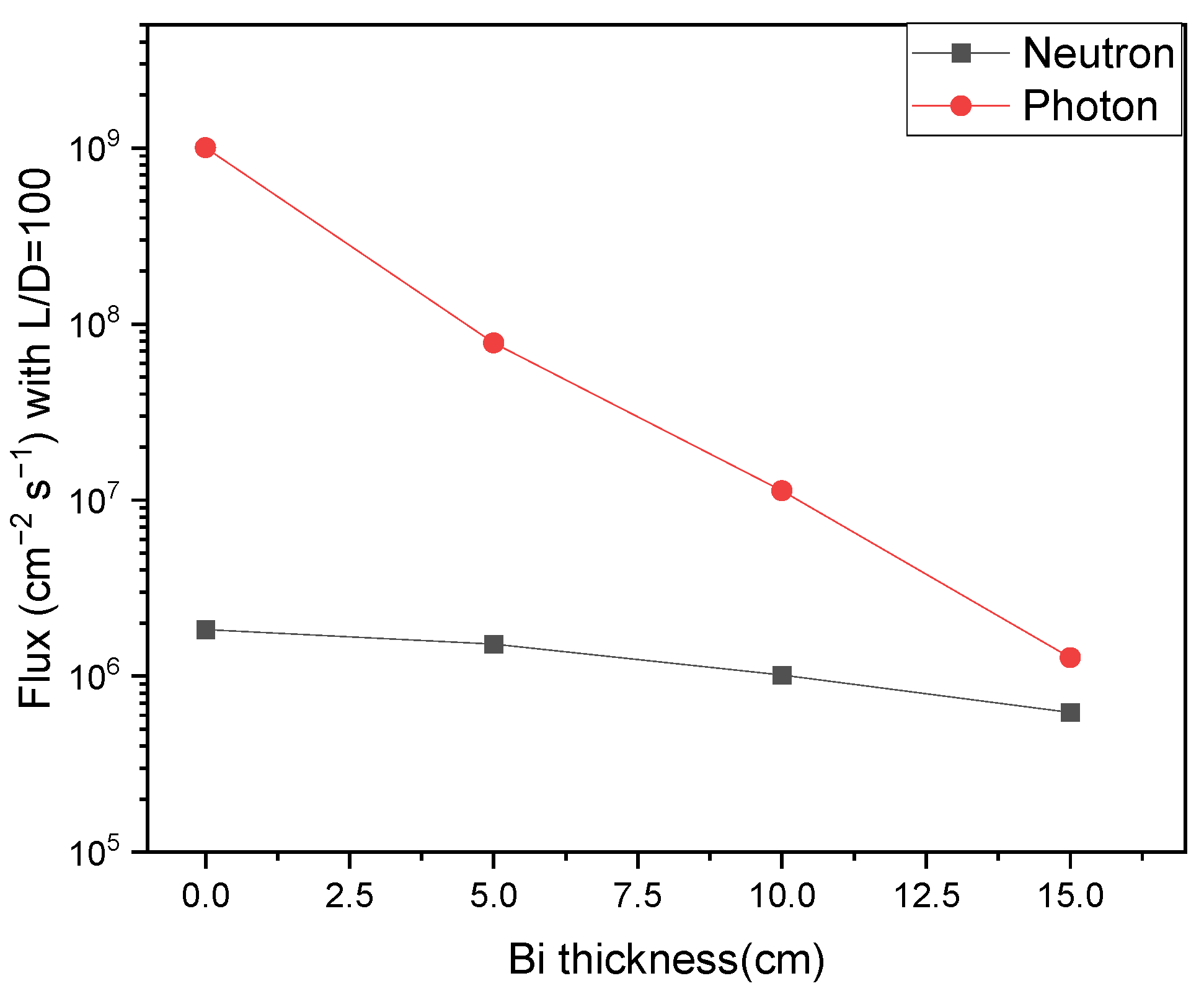

3.3. Tailoring the Ratio between the Bremsstrahlung Photons and the Emitted Neutrons

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chadwick, J. The existence of a neutron. Proceedings of the Royal Society of London. Ser. A Contain. Pap. A Math. Phys. Character 1932, 136, 692–708. [Google Scholar]

- Fitzsimmons, M.; Bader, S.; Borchers, J.; Felcher, G.; Furdyna, J.; Hoffmann, A.; Kortright, J.; Schuller, I.K.; Schulthess, T.; Sinha, S.; et al. Neutron scattering studies of nanomagnetism and artificially structured materials. J. Magn. Magn. Mater. 2004, 271, 103–146. [Google Scholar] [CrossRef]

- Garbe, U.; Ahuja, Y.; Ibrahim, R.; Li, H.; Aldridge, L.; Salvemini, F.; Paradowska, A.Z. Industrial Application Experiments on the Neutron Imaging Instrument DINGO. Phys. Procedia 2017, 88, 13–18. [Google Scholar] [CrossRef]

- Moss, R.L. Critical review, with an optimistic outlook, on Boron Neutron Capture Therapy (BNCT). Appl. Radiat. Isot. 2014, 88, 2–11. [Google Scholar] [CrossRef]

- Zhang, R.; Yu, Y.; Zhang, Z.; Yang, Y. An iterative prediction method for designing the moderator used for the boron neutron capture therapy. Med. Phys. 2022, 49, 598–610. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y. Development of high intensity D-T fusion neutron generator HINEG. Int. J. Energy Res. 2016, 42, 68–72. [Google Scholar] [CrossRef]

- Zilges, A.; Balabanski, D.; Isaak, J.; Pietralla, N. Photonuclear reactions—From basic research to applications. Prog. Part. Nucl. Phys. 2021, 122, 103903. [Google Scholar] [CrossRef]

- Agostinelli, S.; Allison, J.; Amako, K.; Apostolakis, J.; Araujo, H.; Arce, P.; Asai, M.; Axen, D.; Banerjee, S.; Barrand, G.; et al. Geant4—A simulation toolkit. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2003, 506, 250–303. [Google Scholar] [CrossRef]

- Knaster, J.; Arbeiter, F.; Cara, P.; Chel, S.; Facco, A.; Heidinger, R.; Ibarra, A.; Kasugai, A.; Kondo, H.; Micciche, G.; et al. IFMIF, the European–Japanese efforts under the Broader Approach agreement towards a Li(d,xn) neutron source: Current status and future options. Nucl. Mater. Energy 2016, 9, 46–54. [Google Scholar] [CrossRef]

- Kandlikar, S.; Garimella, S.; Li, D.; Colin, S.; King, M. Heat Transfer and Fluid Flow in Minichannels and Microchannels; Butter-Worth-Heinemann: Oxford, UK, 2014; pp. 2–5. [Google Scholar]

- Kurihara, T.; Kobayashi, H. Diffusion bonded Be neutron target using 8MeV proton beam. EPJ Web Conf. 2020, 231, 3001. [Google Scholar] [CrossRef]

- Kino, K.; Fujiwara, T.; Furusaka, M.; Hayashizaki, N.; Kuroda, R.; Michishio, K.; Muroga, T.; Ogawa, H.; O’Rourke, B.E.; Oshima, N.; et al. Design of a compact electron accelerator-driven pulsed neutron facility at AIST. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2019, 927, 407–418. [Google Scholar] [CrossRef]

- Rinckel, T.; Baxter, D.; Doskow, J.; Sokol, P.; Todd, T. Target Performance at the Low Energy Neutron Source. Phys. Procedia 2012, 26, 168–177. [Google Scholar] [CrossRef][Green Version]

- Baggemann, J.; Böhm, S.; Doege, P.; Fenske, J.; Feygenson, M.; Glavic, A.; Holderer, O.; Jaksch, S.; Jentschel, M.; Kleefisch, S.; et al. Conceptual Design Report Jülich High Brilliance Neutron Source (HBS). 2020. Available online: https://juser.fz-juelich.de/record/884799/files/Allgemeines_08.pdf (accessed on 27 June 2022).

- Chakin, V.P.; Posevin, A.O.; Obukhov, A.V.; Silantyev, P.P. Radiation growth of beryllium. J. Nucl. Mater. 2009, 386–388, 206–209. [Google Scholar] [CrossRef]

- Bojanowski, C.; Stillman, J.; Mohamed, W.; Feldman, E.; Wilson, E.; Foyto, L.; Solbrekken, G.; Foyto, L.; Solbrekken, G. Impact of MURR LEU Conversion on Beryllium Reflector Lifetime; United States. 2020. Available online: https://publications.anl.gov/anlpubs/2020/09/163045.pdf (accessed on 30 March 2022).

- Ahdida, C.; Bozzato, D.; Calzolari, D.; Cerutti, F.; Charitonidis, N.; Cimmino, A.; Coronetti, A.; D’Alessandro, G.L.; Servelle, A.D.; Esposito, L.S.; et al. New Capabilities of the FLUKA Multi-Purpose Code. Front. Phys. 2022, 9, 788253. [Google Scholar] [CrossRef]

- Battistoni, G.; Boehlen, T.; Cerutti, F.; Chin, P.W.; Esposito, L.S.; Fassò, A.; Ferrari, A.; Lechner, A.; Empl, A.; Mairani, A.; et al. Overview of the FLUKA code. Ann. Nucl. Energy 2015, 82, 10–18. [Google Scholar] [CrossRef]

- Goldhaber, M.; Teller, E. On Nuclear Dipole Vibrations. Phys. Rev. (Ser. I) 1948, 74, 1046–1049. [Google Scholar] [CrossRef]

- Steinwedel, H.; Jensen, J.H.D.; Jensen, P. Nuclear Dipole Vibrations. Phys. Rev. (Ser. I) 1950, 79, 1019. [Google Scholar] [CrossRef]

- Hao, J.-H.; Chen, Q.; Lu, Y.-L.; Wang, S.-L.; Yu, Q.-Z.; Ji, Q.; Liang, T.-J. Thermal Hydraulic Analysis of China Spallation Neutron Source Target System under Abnormal Situations. J. Heat Transf. 2016, 139, 14504. [Google Scholar] [CrossRef]

- Gohar, Y.; Belch, H.; Duo, J.; Naberezhenv, D.; Sofu, T.; Bolshinsky, I. Design and Analyses of Electron Targets for Neutron Generation; American Nuclear Society—ANS: La Grange Park, IL, USA, 2006. [Google Scholar]

- Kraus, A.; Merzari, E.; Sofu, T.; Zhong, Z.; Gohar, Y. CFD Analysis and Design of Detailed Target Configurations for an Ac-celerator-Driven Subcritical System. Nucl. Technol. 2016, 195, 157–168. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, R.; Lu, L.; Yang, Y. The Bimodal Neutron and X-ray Imaging Driven by a Single Electron Linear Accelerator. Appl. Sci. 2021, 11, 6050. [Google Scholar] [CrossRef]

- Ishikawa, H.; Kai, T.; Sato, H.; Kamiyama, T. Neutron spectrum change with thermal moderator temperature in a compact electron accelerator-driven neutron source and its effects on spectroscopic neutron transmission imaging. J. Nucl. Sci. Technol. 2019, 56, 221–227. [Google Scholar] [CrossRef]

- Engineering ToolBox. Solids, Liquids and—Thermal Conductivities. 2003. Available online: https://www.engineeringtoolbox.com/thermal-conductivity-d_429.html (accessed on 27 October 2022).

| Incident Particle | Target | Reaction Yield (Neutron per Incident Particle) |

|---|---|---|

| 20 MeV e− | natW | 2.85 × 10−3 |

| 50 MeV e− | natW | 1.58 × 10−2 |

| 100 MeV e− | natW | 3.47 × 10−2 |

| 100 MeV e− | natU | 7.16 × 10−2 |

| 10 MeV p | natLi | 3.26 × 10−3 |

| 10 MeV p | 9Be | 3.44 × 10−3 |

| 20 MeV p | 9Be | 1.52 × 10−2 |

| 50 MeV p | 9Be | 6.89 × 10−2 |

| 50 MeV p | 181Ta | 7.71 × 10−2 |

| Light Nuclides | 1H | 2H | α | Estimated Lifetime | |

|---|---|---|---|---|---|

| Incident Particles | Ratio of Light Nuclide Reaction Yields to That of the Generated Neutrons (1/n) | ||||

| 20 MeV p (9Be target) | 0.75 | 0.30 | 2.5 | 1400 h | |

| 50 MeV e− (natW target) | 3.5 × 10−4 | 1.5 × 10−5 | 2.1 × 10−6 | Very long | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, Y.; Yang, Y. A Design for the High Yield Photoneutron Source Target Station. Materials 2022, 15, 7674. https://doi.org/10.3390/ma15217674

Lai Y, Yang Y. A Design for the High Yield Photoneutron Source Target Station. Materials. 2022; 15(21):7674. https://doi.org/10.3390/ma15217674

Chicago/Turabian StyleLai, Yuxuan, and Yigang Yang. 2022. "A Design for the High Yield Photoneutron Source Target Station" Materials 15, no. 21: 7674. https://doi.org/10.3390/ma15217674

APA StyleLai, Y., & Yang, Y. (2022). A Design for the High Yield Photoneutron Source Target Station. Materials, 15(21), 7674. https://doi.org/10.3390/ma15217674