Tailoring of Dissimilar Friction Stir Lap Welding of Aluminum and Titanium

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

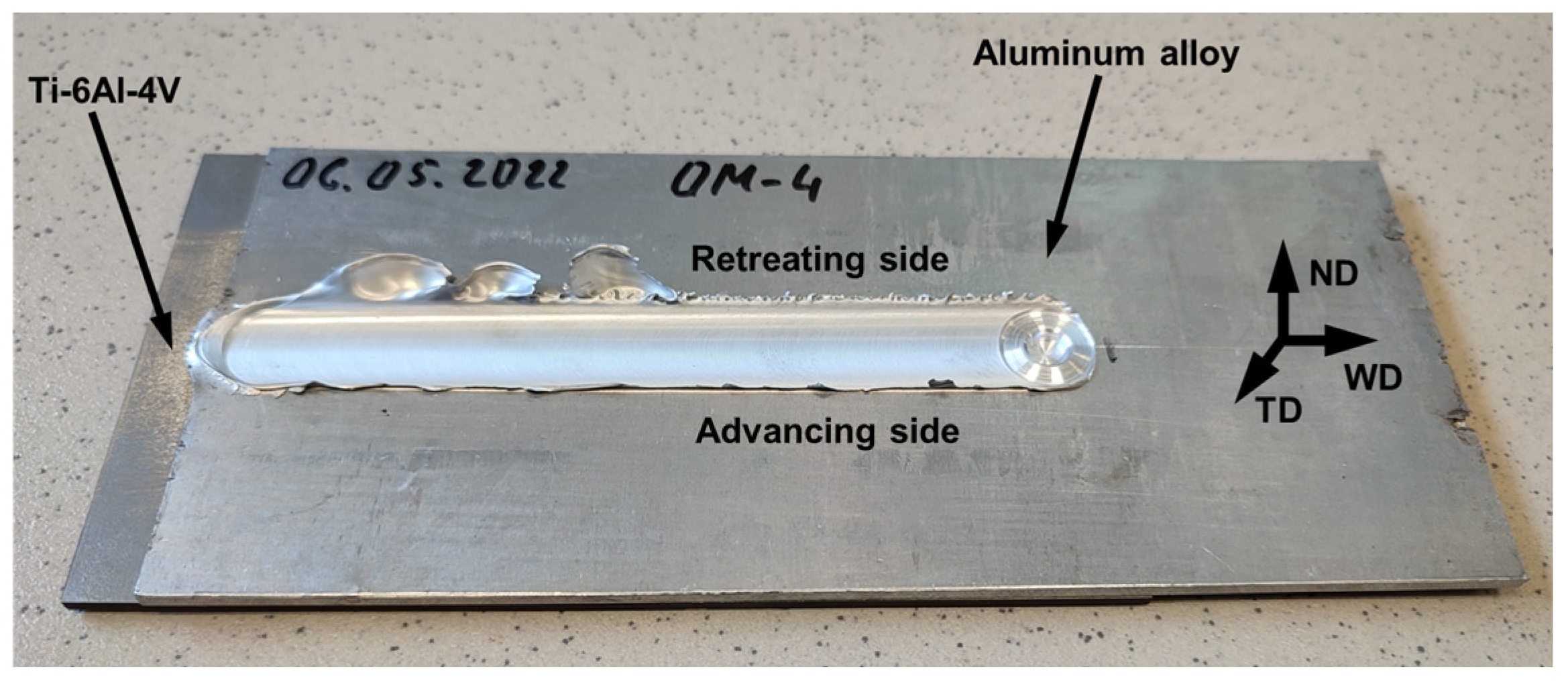

3.1. Weldability

3.2. FSW Thermal Cycle

3.3. SEM–EDS Observations

3.4. Lap-Shear Tests

3.5. Microhardness

3.6. EBSD Measurements

4. Summary

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Simar, A.; Avettand-Fenoel, M.-N. State of the art about dissimilar metal friction stir welding. Sci. Technol. Weld. Join. 2017, 22, 389–403. [Google Scholar] [CrossRef]

- Jain, S.; Bhuva, K.; Patel, P.; Badheka, V.J. A Review on Dissimilar Friction Stir Welding of Aluminum Alloys to Titanium Alloys. In Innovations in Infrastructure. Advances in Intelligent Systems and Computing; Springer: Singapore, 2019. [Google Scholar]

- Shankar, S.; Mehta, K.P.; Chattopadhyaya, S.; Vilaca, P. Dissimilar friction stir welding of Al to non-Al metallic materials: An overview. Mater. Chem. Phys. 2022, 288, 126371. [Google Scholar] [CrossRef]

- Mironov, S.; Sato, Y.S.; Kokawa, H. Friction-stir welding and processing of Ti-6Al-4V titanium alloy: A review. J. Mater. Sci. Technol. 2018, 34, 58–72. [Google Scholar] [CrossRef]

- Pereira, V.F.; Fonseca, E.B.; Costa, A.M.S.; Bettini, J.; Lopes, E.S.N. Nanocrystalline structural layer acts as interfacial bond in Ti/Al dissimilar joints produced by friction stir welding in power control mode. Scr. Mater. 2020, 174, 80–86. [Google Scholar] [CrossRef]

- Choi, J.-W.; Liu, H.; Fujii, H. Dissimilar friction stir welding of pure Ti and pure Al. Mater. Sci. Eng. A 2018, 730, 168–176. [Google Scholar] [CrossRef]

- Kar, A.; Suwas, S.; Kailas, S.V. Two-pass friction stir welding of aluminum alloy to titanium alloy: A simultaneous improvement in mechanical properties. Mater. Sci. Eng. A 2018, 733, 199–210. [Google Scholar] [CrossRef]

- Li, B.; Shen, Y.; Luo, L.; Hu, W. Effects of processing variables and heat treatments on Al/Ti-6Al-4V interface microstructure of bimetal clad-plate fabricated via a novel route employing friction stir lap welding. J. Alloy. Compd. 2016, 658, 904–913. [Google Scholar] [CrossRef]

- Zhao, H.; Yu, M.; Jiang, Z.; Zhou, L.; Song, X. Interfacial microstructure and mechanical properties of Al/Ti dissimilar joints fabricated via friction stir welding. J. Alloy. Compd. 2019, 789, 139–149. [Google Scholar] [CrossRef]

- Huang, Y.; Lv, Z.; Wan, L.; Shen, J.; dos Santos, J.F. A new method of hybrid friction stir welding assisted by friction surfacing for joining dissimilar Ti/Al alloy. Mater. Lett. 2017, 207, 172–175. [Google Scholar] [CrossRef]

- Wu, A.; Song, Z.; Nakata, K.; Liao, J.; Zhou, L. Interface and properties of the friction stir welded joints of titanium alloy Ti6Al4V with aluminum alloy 6061. Mater. Des. 2015, 71, 85–92. [Google Scholar] [CrossRef]

- Aonuma, M.; Nakata, K. Dissimilar metal joining of 2024 and 7075 aluminum alloys to titanium alloys by friction stir welding. Mater. Trans. 2011, 52, 948–952. [Google Scholar] [CrossRef] [Green Version]

- Yu, M.; Zhao, H.; Jiang, Z.; Guo, F.; Zhou, L.; Song, X. Microstructure and mechanical properties of friction stir lap AA6061-Ti6Al4V welds. J. Mater. Proc. Technol. 2019, 270, 274–284. [Google Scholar] [CrossRef]

- Kar, A.; Kailas, S.V.; Suwas, S. Effect of zinc interlayer in microstructure evolution and mechanical properties in dissimilar friction stir welding of aluminum to titanium. J. Mater. Eng. Perform. 2018, 27, 6016–6026. [Google Scholar] [CrossRef]

- Shehabeldeen, T.A.; Yin, Y.; Ji, X.; Shen, X.; Zhang, Z.; Zhou, J. Investigation of the microstructure, mechanical properties and fracture mechanisms of dissimilar friction stir welded aluminium/titanium joints. J. Mater. Res. Technol. 2021, 11, 507–518. [Google Scholar] [CrossRef]

- Kar, A.; Suwas, S.; Kailas, S.V. Significance of tool offset and copper interlayer during friction stir welding of aluminum to titanium. Int. J. Adv. Manuf. Technol. 2019, 100, 435–443. [Google Scholar] [CrossRef]

- Zhou, L.; Yu, M.; Zhao, H.; Jiang, Z.; Guo, F.; Song, X. Dissimilar friction stir welding of AA6061 and Ti6Al4V alloys: A study on microstructure and mechanical properties. J. Manuf. Proc. 2019, 48, 119–126. [Google Scholar] [CrossRef]

- Chen, Y.; Yu, L.; Ni, Q. Influence of zinc on the microstructure and brittle phases of friction stir welded joint of Al/Ti dissimilar alloys. Adv. Mater. Res. 2012, 413, 439–443. [Google Scholar] [CrossRef]

- Kar, A.; Kailas, S.V.; Suwas, S. Effect of mechanical mixing in dissimilar friction stir welding of aluminum to titanium with zinc Interlayer. Trans. Ind. Inst. Metal. 2019, 72, 1533–1536. [Google Scholar] [CrossRef] [Green Version]

- Klassen, T.; Oehring, M.; Bormann, R. The early stages of phase formation during mechanical alloying of Ti-Al. J. Mater. Res. 1994, 9, 47–52. [Google Scholar] [CrossRef]

- Nasir, T.; Kalaf, O.; Asmael, M.; Zeeshan, Q.; Safaei, B.; Hussain, G.; Motallebzadeh, A. The experimental study of CFRP interlayer of dissimilar joint AA7075-T651/T-6Al-4V alloys by friction stir spot welding on mechanical and microstructural properties. Nanotechnol. Rev. 2021, 10, 401–413. [Google Scholar] [CrossRef]

- Chen, Z.W.; Yazdanian, S. Microstructures in interface region and mechanical behaviours of friction stir lap Al6060 to Ti–6Al–4V welds. Mater. Sci. Eng. A 2015, 634, 37–45. [Google Scholar] [CrossRef]

- Dressler, U.; Biallas, G.; Mercado, U.A. Friction stir welding of titanium alloy TiAl6V4 to aluminium alloy AA2024-T3. Mater. Sci. Eng. A 2009, 526, 113–117. [Google Scholar] [CrossRef]

- Yu, M.; Zhao, H.; Xu, F.; Chen, T.; Zhou, L.; Song, X.; Ma, N. Effects of ultrasonic on friction stir Al–Ti welds: A comparative study. Sci. Technol. Weld. Join. 2021, 26, 551–558. [Google Scholar] [CrossRef]

- Wei, Y.; Li, J.; Xiong, J.; Huang, F.; Zhang, F.; Raza, S.H. Joining aluminum to titanium alloy by friction stir lap welding with cutting pin. Mater. Character. 2012, 71, 1–5. [Google Scholar] [CrossRef]

- Chen, Y.C.; Nakata, K. Microstructural characterization and mechanical properties in friction stir welding of aluminum and titanium dissimilar alloys. Mater. Des. 2009, 30, 469–474. [Google Scholar] [CrossRef]

- Ma, Z.; Jin, Y.; Ji, S.; Meng, X.; Ma, L.; Li, Q. A general strategy for the reliable joining of Al/Ti dissimilar alloys via ultrasonic assisted friction stir welding. J. Mater. Sci. Technol. 2019, 35, 94–99. [Google Scholar] [CrossRef]

- Li, B.; Zhang, Z.; Shen, Y.; Hu, W.; Luo, L. Dissimilar friction stir welding of Ti–6Al–4V alloy and aluminum alloy employing a modified butt joint configuration: Influences of process variables on the weld interfaces and tensile properties. Mater. Des. 2014, 53, 838–848. [Google Scholar] [CrossRef]

- Kar, A.; Yadav, D.; Suwas, S.; Kailas, S.V. Role of plastic deformation mechanisms during the microstructural evolution and intermetallics formation in dissimilar friction stir weld. Mater. Character. 2020, 164, 110371. [Google Scholar] [CrossRef]

- Kar, A.; Malopheyev, S.; Mironov, S.; Kaibyshev, R.; Suwas, S.; Kailas, S.V. A new method to elucidate fracture mechanism and microstructure evolution in titanium during dissimilar friction stir welding of aluminum and titanium. Mater. Character. 2021, 171, 110791. [Google Scholar] [CrossRef]

- Kar, A.; Suwas, S.; Kailas, S.V. Multi-length scale characterization of microstructure evolution and its consequence on mechanical properties in dissimilar friction stir welding of titanium to aluminum. MetAlloy. Mater. Trans. A 2019, 50, 5153–5173. [Google Scholar] [CrossRef]

- Ma, Z.; Sun, X.; Ji, S.; Wang, Y.; Yue, Y. Influences of ultrasonic on friction stir welding of Al/Ti dissimilar alloys under different welding conditions. Int. J. Adv. Manuf. Technol. 2021, 112, 2573–2582. [Google Scholar] [CrossRef]

- Sadeghi-Ghoghery, M.; Kasiri-Asgarani, M.; Amini, K. Friction stir welding of dissimilar joints between commercially pure titanium alloy and 7075 aluminim alloy. Trans. Famena 2017, 41, 81–90. [Google Scholar] [CrossRef] [Green Version]

- Song, Z.; Nakata, K.; Wu, A.; Liao, J.; Zhou, L. Influence of probe offset distance on interfacial microstructure and mechanical properties of friction stir butt welded joint of Ti6Al4V and A6061 dissimilar alloys. Mater. Des. 2014, 57, 269–278. [Google Scholar] [CrossRef]

- Shubhavardhan, R.N.; Surendran, S. Microstructure and fracture behavior of friction stir lap welding of dissimilar metals. Eng. Solid Mech. 2018, 6, 1–10. [Google Scholar] [CrossRef]

- Kalinenko, A.; Kim, K.; Vysotskiy, I.; Zuiko, I.; Malopheyev, S.; Mironov, S.; Kaibyshev, R. Microstructure-strength relationship in friction-stir welded 6061-T6 aluminum alloy. Mater. Sci. Eng. A 2020, 793, 139858. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Mironov, S.; Kaibyshev, R.; Cam, G.; Simar, A.; Gerlich, A.; Khodabakhshi, F.; Mostafaei, A.; Field, D.P.; Robson, J.D.; et al. Friction stir welding/processing of metals and alloys: A comprehensive review on microstructural evolution. Progr. Mater. Sci. 2021, 117, 100752. [Google Scholar] [CrossRef]

| Al | Mg | Si | Cu | Mn | Fe | Zn | Cr | Ti |

|---|---|---|---|---|---|---|---|---|

| Bal. | 1.0 | 0.8 | 0.8 | 0.5 | 0.5 | 0.25 | 0.1 | 0.1 |

| AA6013 + 2.0 Si | AA6013 + 0.8 Si + 1.0 Mg | AA6013 + 3.0 Mg | AA6013 + 5.0 Mg |

| Aluminum Alloy | AA6013 | AA6013 + 2.0 Si | AA6013 + 0.8 Si + 1.0 Mg | |||

|---|---|---|---|---|---|---|

| Welding speed, mm/min | 12.7 | 76.2 | 12.7 | 76.2 | 12.7 | 76.2 |

| Width of welded surface, mm | 6.575 | 5.875 | 5.123 | 4.115 | 5.106 | 3.138 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kalinenko, A.; Dolzhenko, P.; Borisova, Y.; Malopheyev, S.; Mironov, S.; Kaibyshev, R. Tailoring of Dissimilar Friction Stir Lap Welding of Aluminum and Titanium. Materials 2022, 15, 8418. https://doi.org/10.3390/ma15238418

Kalinenko A, Dolzhenko P, Borisova Y, Malopheyev S, Mironov S, Kaibyshev R. Tailoring of Dissimilar Friction Stir Lap Welding of Aluminum and Titanium. Materials. 2022; 15(23):8418. https://doi.org/10.3390/ma15238418

Chicago/Turabian StyleKalinenko, Alexander, Pavel Dolzhenko, Yulia Borisova, Sergey Malopheyev, Sergey Mironov, and Rustam Kaibyshev. 2022. "Tailoring of Dissimilar Friction Stir Lap Welding of Aluminum and Titanium" Materials 15, no. 23: 8418. https://doi.org/10.3390/ma15238418

APA StyleKalinenko, A., Dolzhenko, P., Borisova, Y., Malopheyev, S., Mironov, S., & Kaibyshev, R. (2022). Tailoring of Dissimilar Friction Stir Lap Welding of Aluminum and Titanium. Materials, 15(23), 8418. https://doi.org/10.3390/ma15238418