Selective Laser Melting (SLM) Additively Manufactured CoCrFeNiMn High-Entropy Alloy: Process Optimization, Microscale Mechanical Mechanism, and High-Cycle Fatigue Behavior

Abstract

:1. Introduction

2. Experimental Method and Material

2.1. SLM Details

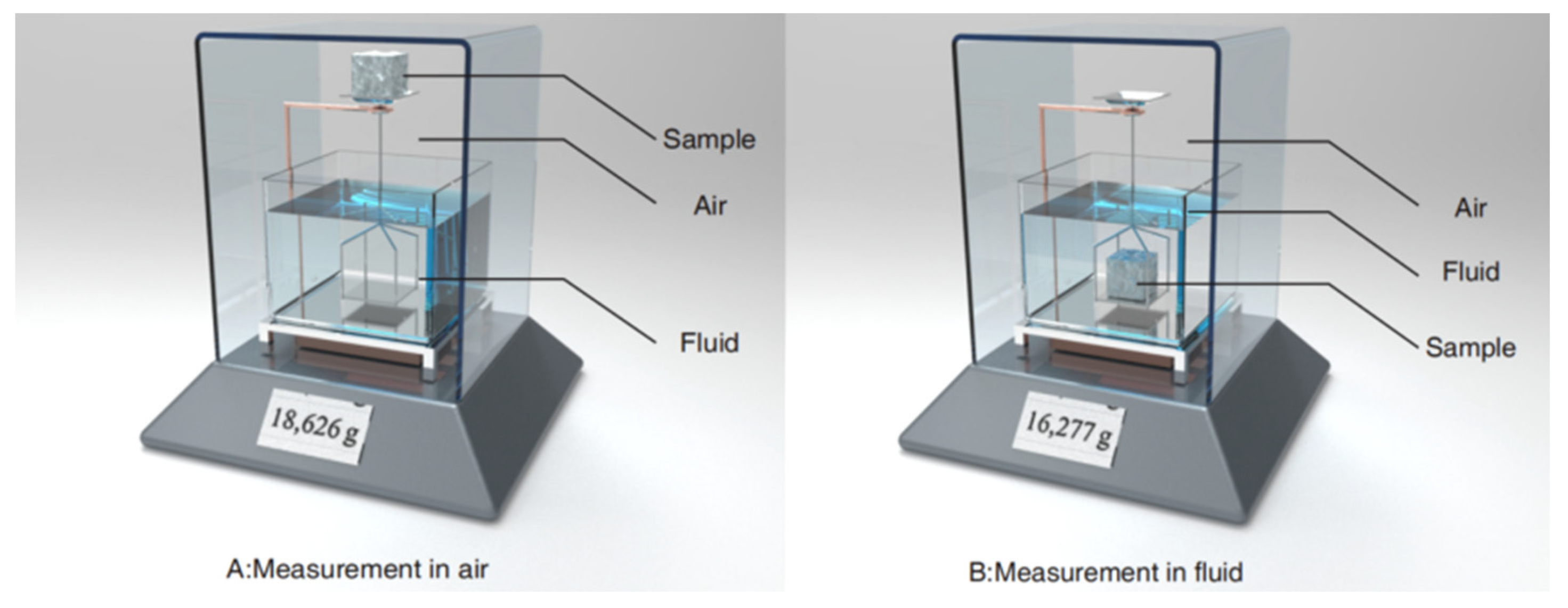

2.2. Measurement of Density

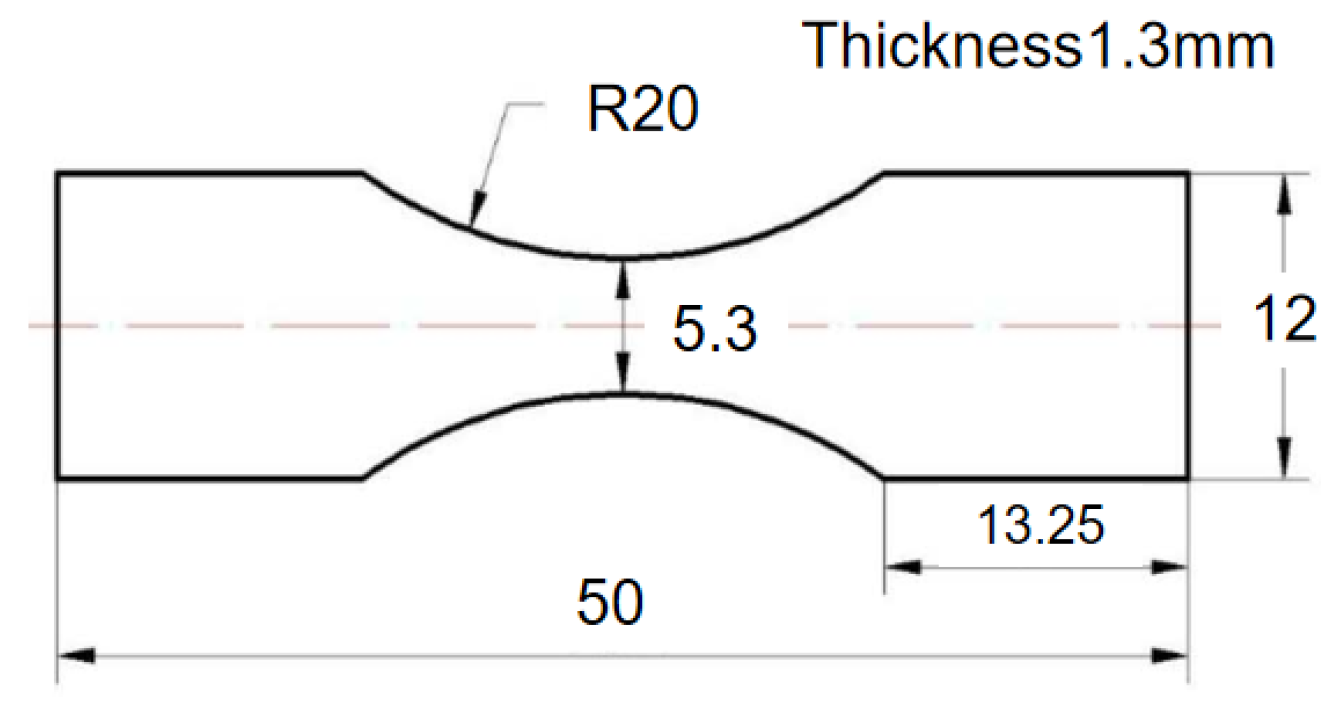

2.3. High-Cycle Fatigue Experiment Details

3. Results and Discussion

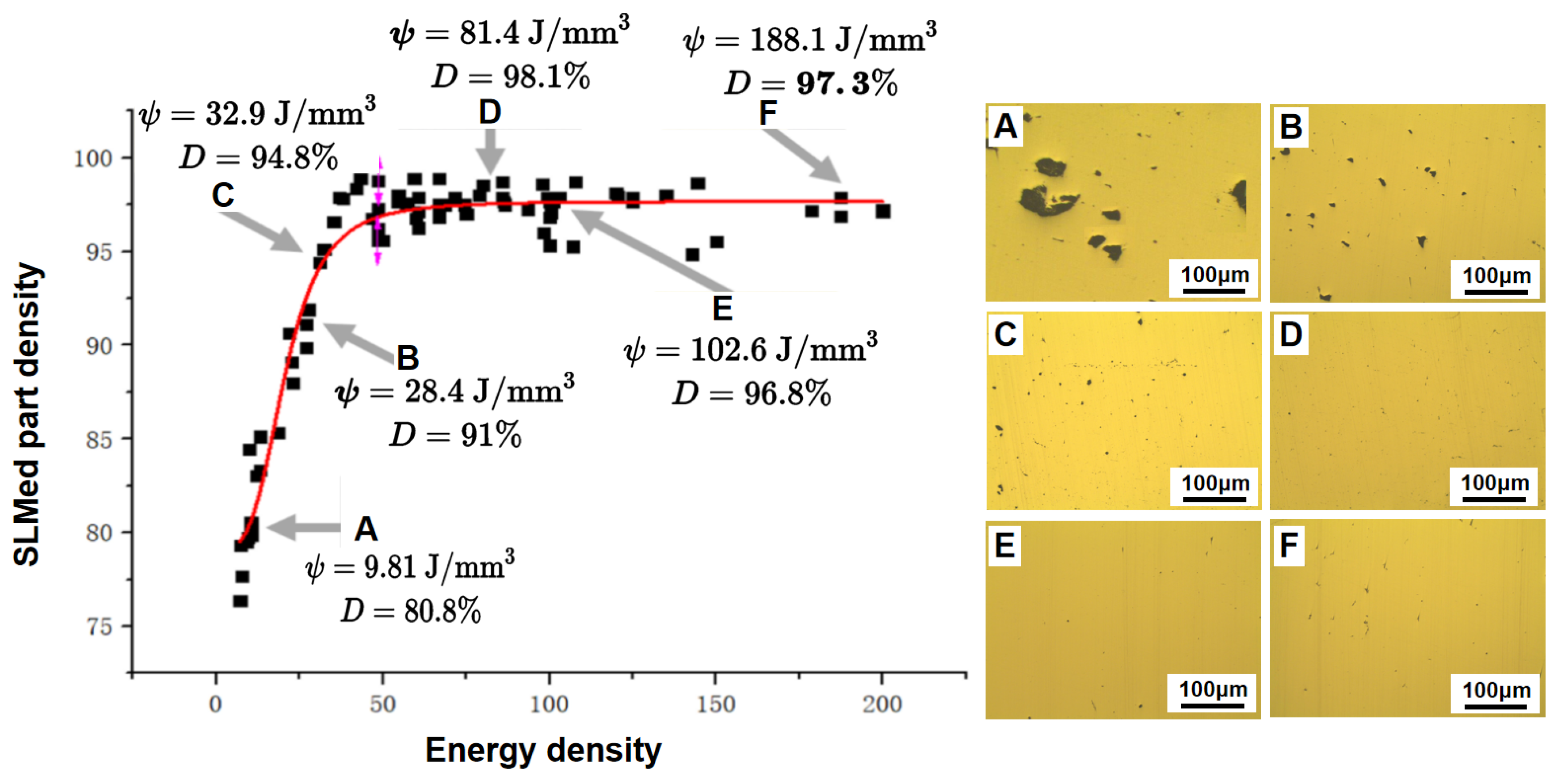

3.1. SLM Parameter Optimization for Cantor HEA

Effect of Energy Density on Part Density

3.2. Analysis of Pore Defects in SLMed Parts

3.2.1. Formation of Pore Defects

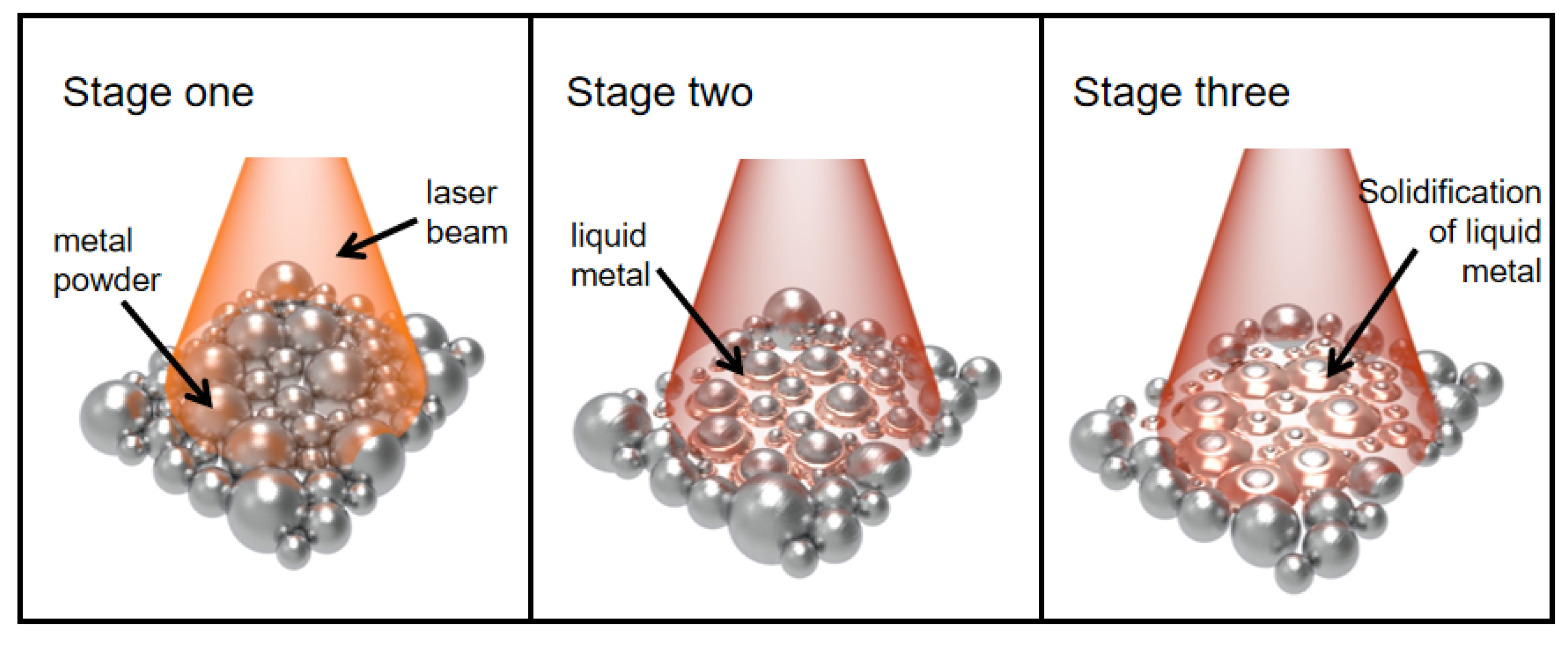

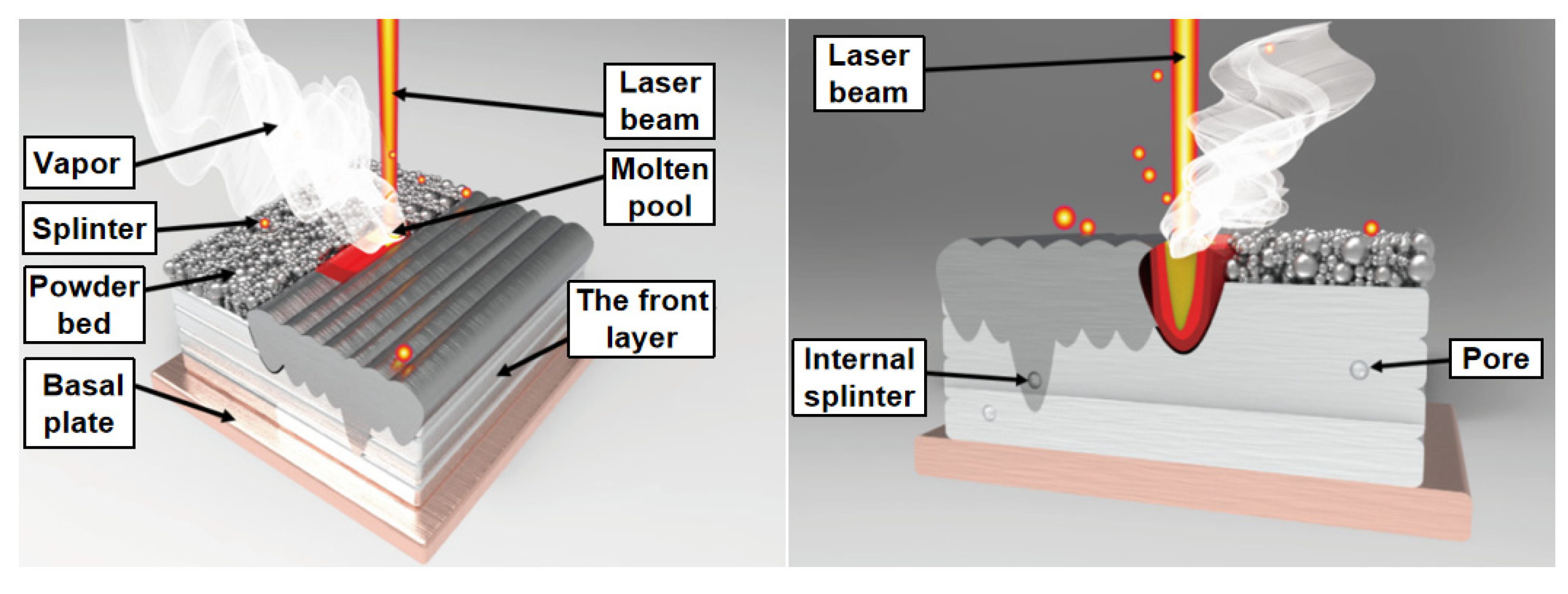

- When the laser beam scans through loose powder, the laser irradiates several powder particles simultaneously (Stage I), heating the particles. Subsequently, heat flows to the center of the particle until the particle temperature is locally steady [44]. Only the surface of the powder particles melts into a liquid at low laser energy, while the center remains solid. The liquid rapidly gathers between the particles, forming a liquid “bridge” (Stage II). When the laser is moved away, the liquid solidifies, and the surface-molten particles bind together, thus forming pores between the solidified metal agglomerate (Stage III). Figure 7 illustrates the pore formation mechanism.

- Under laser irradiation, the melt in the molten pool inevitably splashes to either side of the molten pool, forming spherical metal or ablating into the forming surface and forming tiny pores. Some pores are formed during subsequent powder spreading, melting, and solidification, as shown in Figure 8.

- The pores are mainly caused by moisture or contaminants on the surface of the powder particles [45], such as oxides.

- Small amounts of oxygen and carbon in HEAs can react at high temperatures to form gaseous products, such as CO or CO2. Pores are included in the parts under the gas retention effect.

3.2.2. Effect of Energy Density on Pore Formation

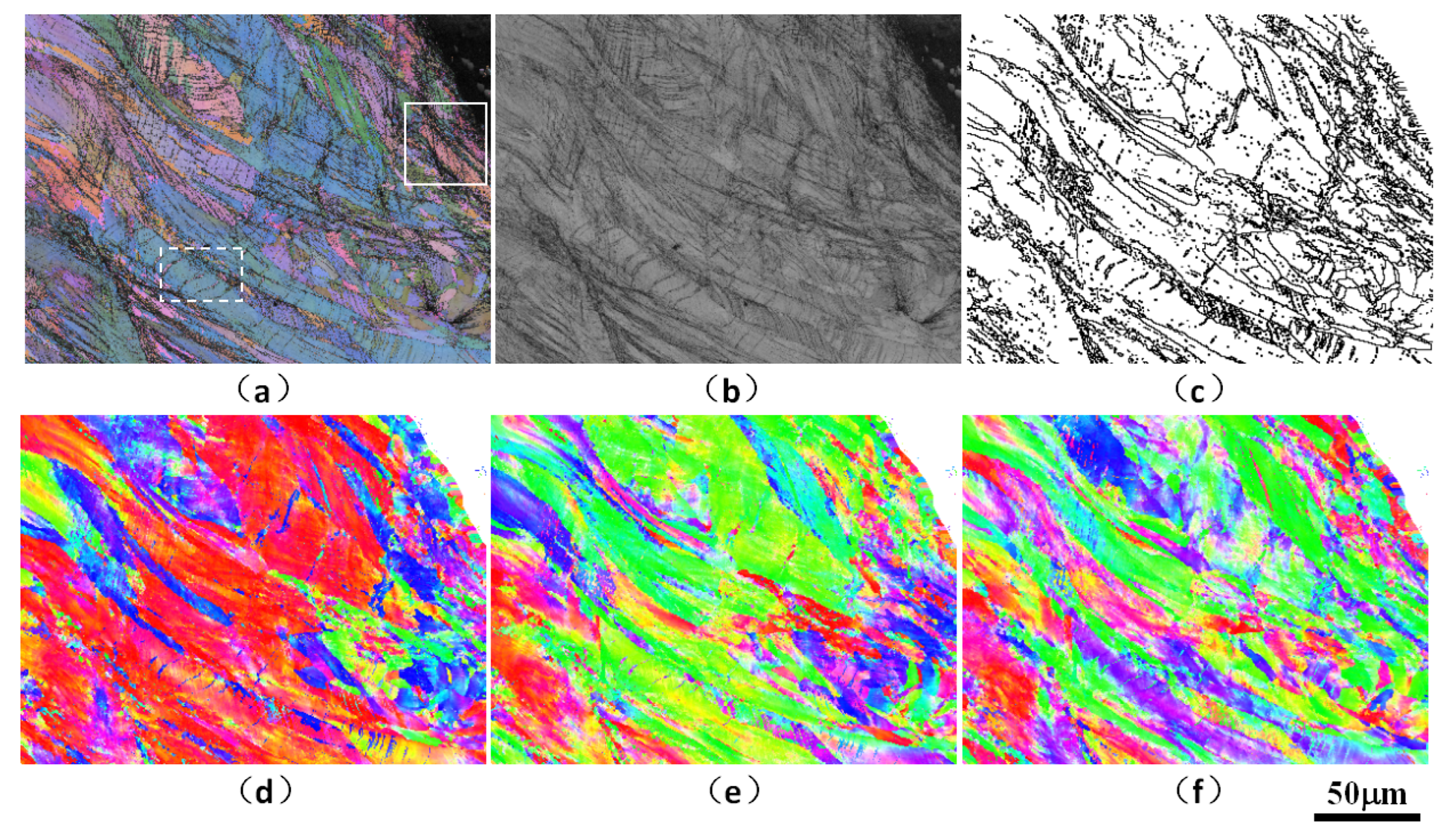

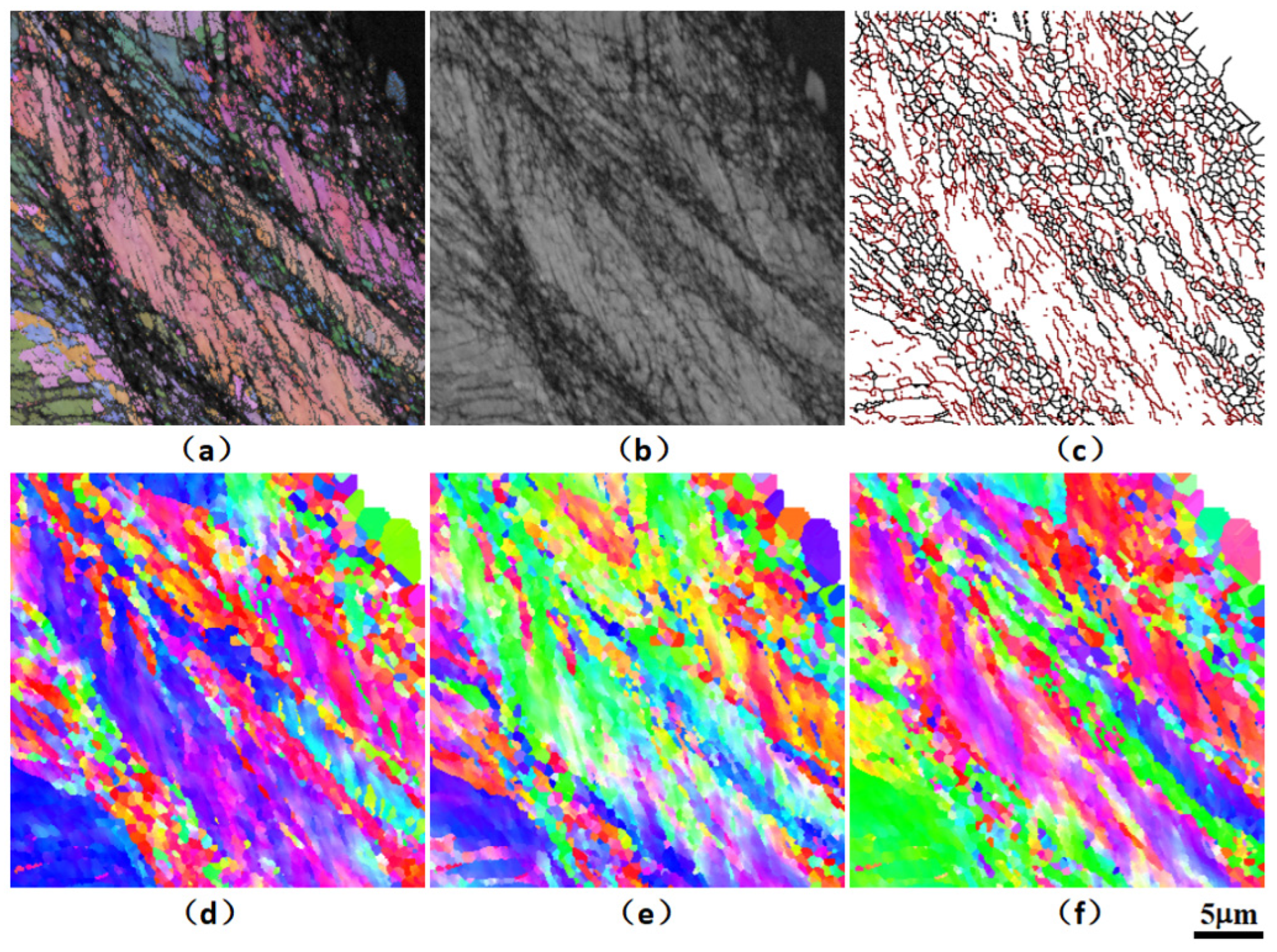

3.3. Microscale Mechanical Mechanism of Cantor HEAs

3.3.1. Experiment on Micro-Scale Quasi-Static Compression Mechanics

3.3.2. Analysis of Micro-Scale Strength Mechanism

3.3.3. Effect of Forming Process on Micro-Scale Intrinsic Strength

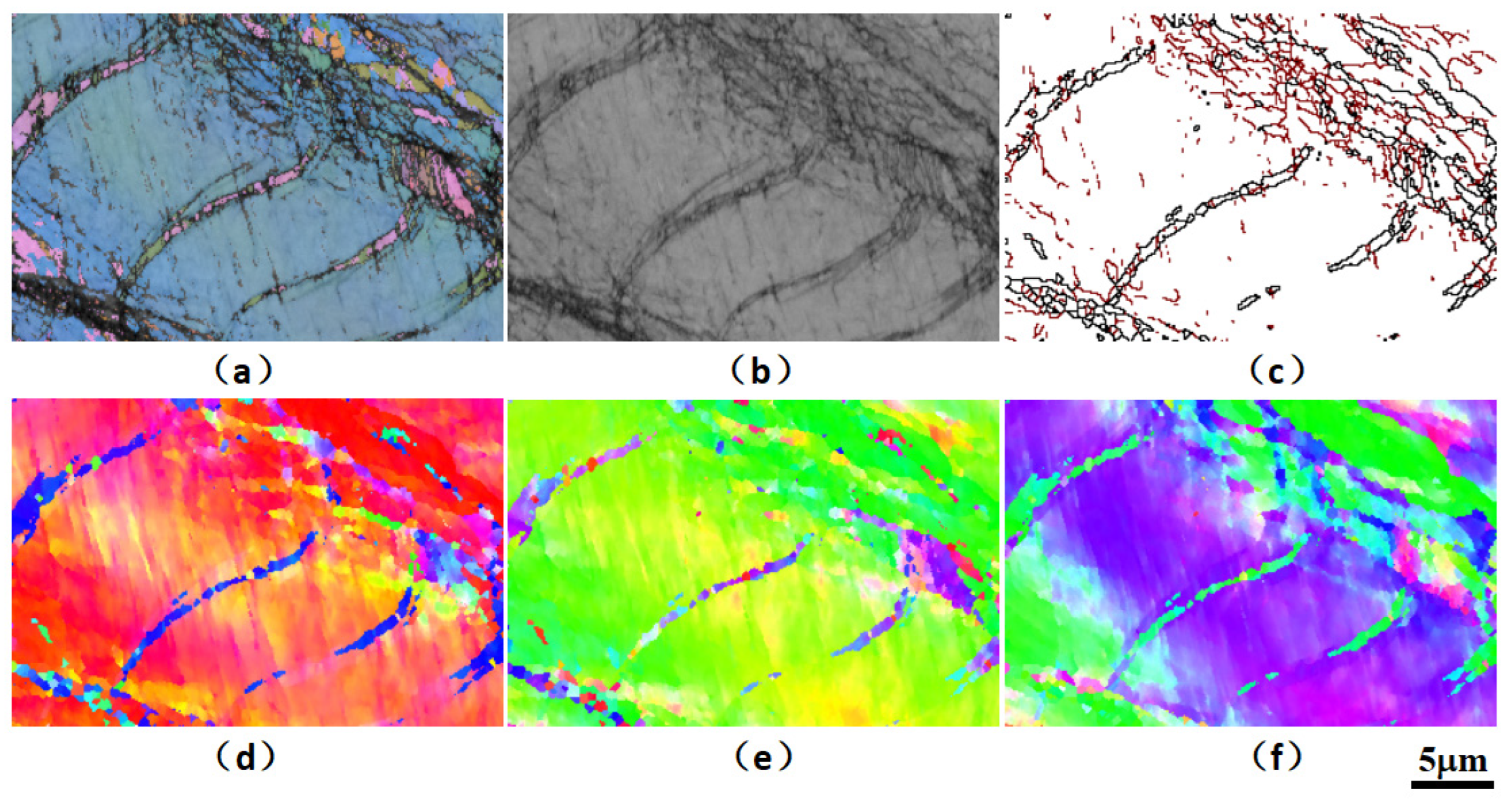

3.4. Research on High-Cycle Fatigue Properties of SLMed HEAs

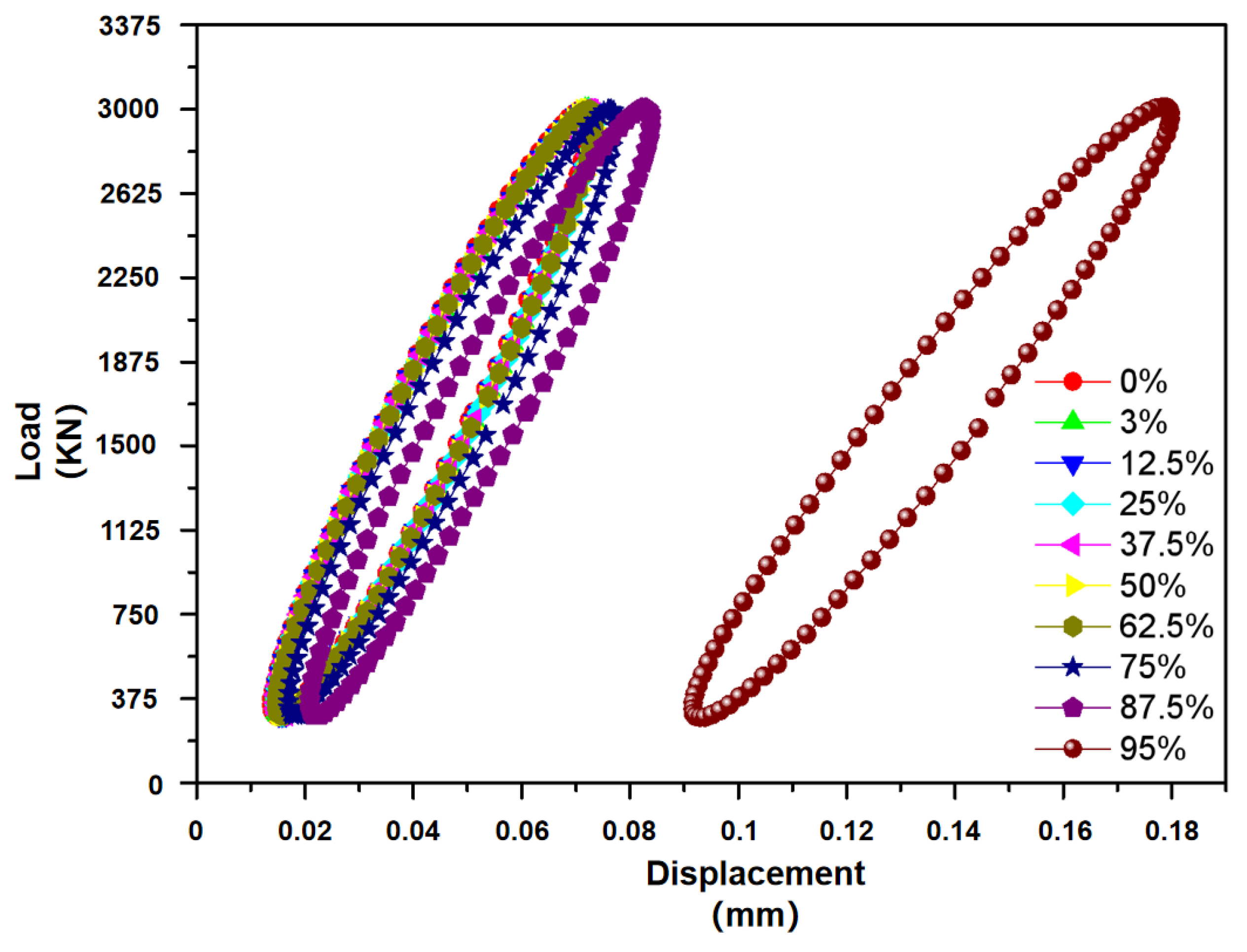

3.4.1. High-Cycle Fatigue Experiment Results

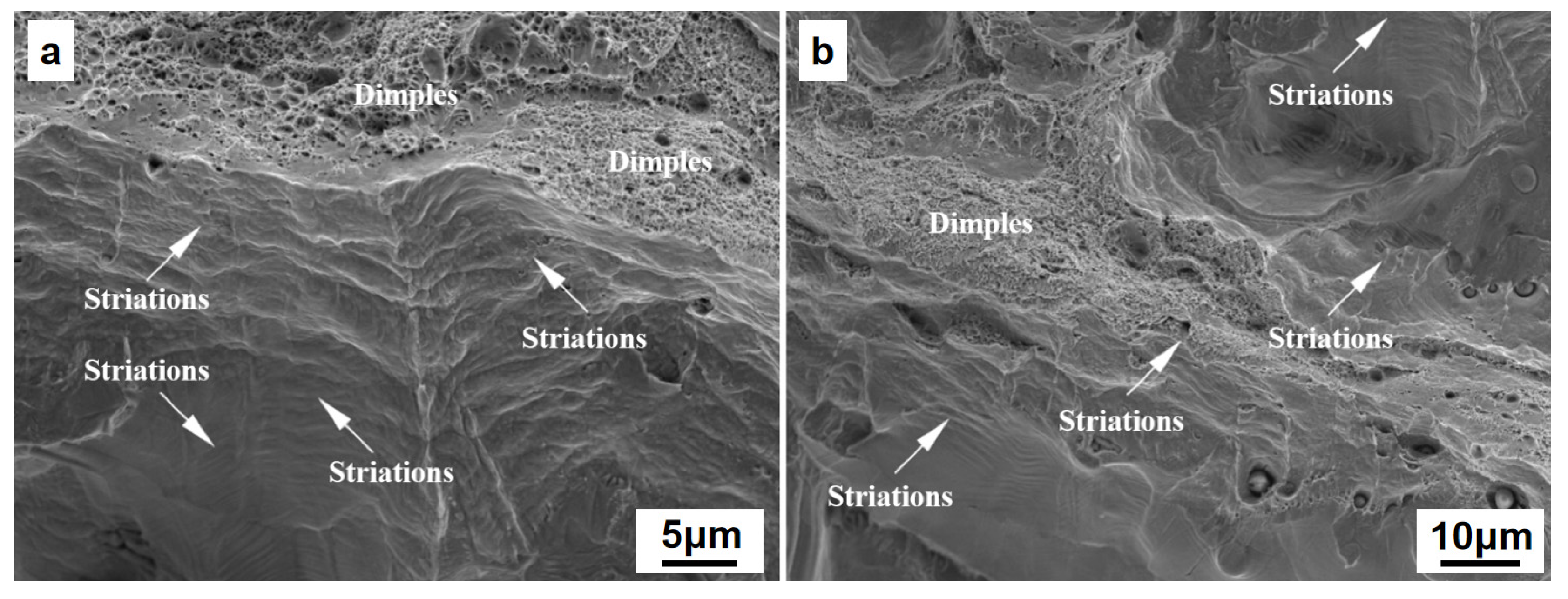

3.4.2. High-Cycle Fatigue Failure Mechanism and Micro-Analysis

3.4.3. Effect of Process Parameters on Fatigue Properties of Cantor HEAs

4. Conclusions

- The SLM parameter is optimized based on density. The results show that the increase in laser energy density can significantly improve the quality of the parts when other process parameters remain unchanged. The density of the parts can reach up to 98.87%, but the density of the parts will slightly decrease with increasing laser energy, and finally tend to stabilize. The part density decreases with increasing layer thickness and scanning spacing.

- The causes of porosity defects and the effect of process parameters are elaborated. Pore defects are caused by metal agglomeration, spatter, moisture or contaminants, gaseous products, etc.; the laser energy increases with increasing temperature and fluidity of the molten pool, in which case pore defects are easily eliminated, but the pores in the final parts cannot be eliminated due to moisture, solidification shrinkage, etc.

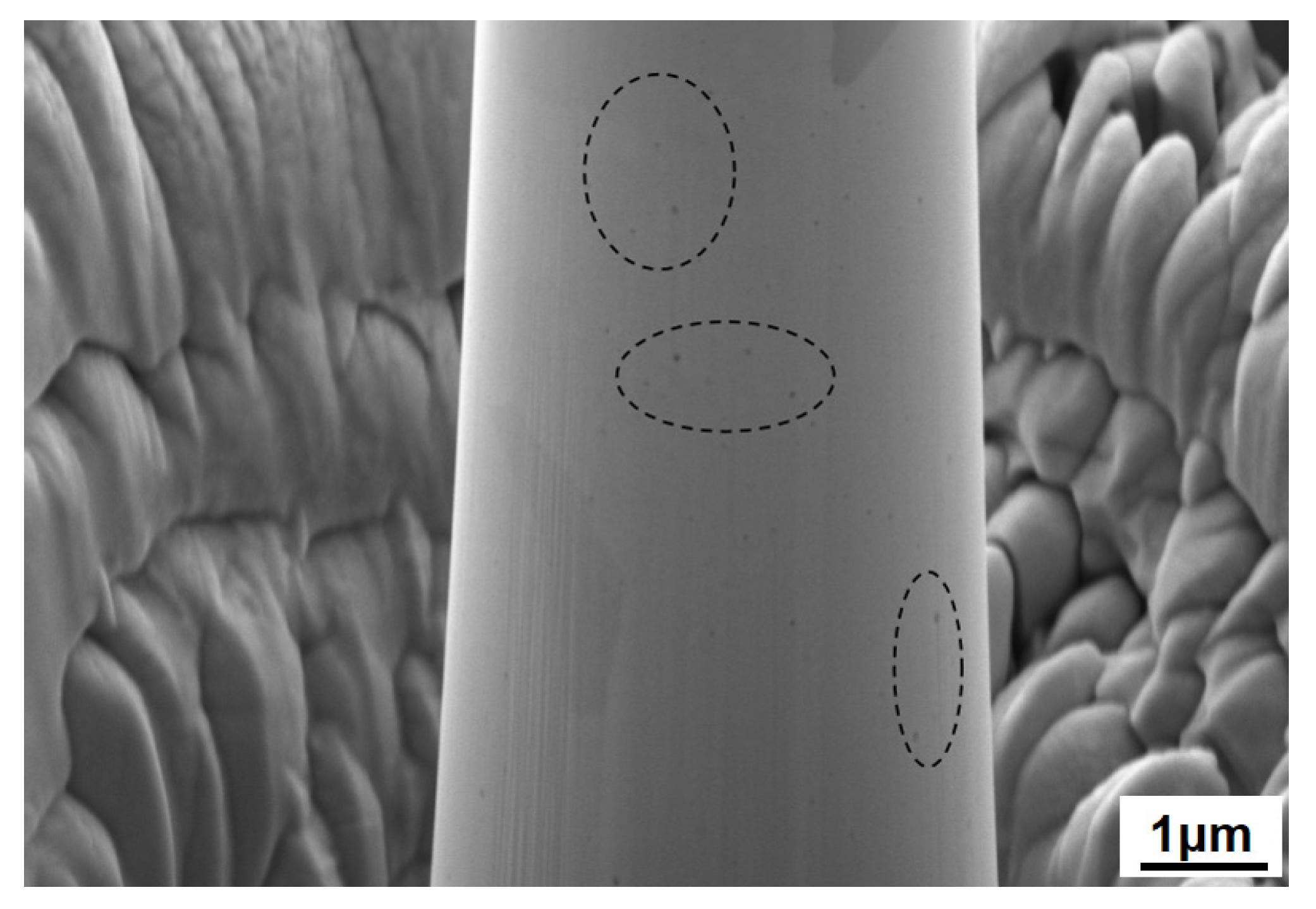

- This research analyzes the effect of different typical SLM process conditions on the quasi-static and dynamic mechanical properties, investigates the strength and toughness of the micro-scale and macro-scale samples, reveals the stress–strain changes resulting from repeated slippage in quasi-static compression behavior of micro-scale materials and “dislocation avalanche” behavior mechanism, and finds that laser rapid non-equilibrium melting and solidification lead to that a large number of nano twin crystals induced by fatigue stress exist near high-density low-angle grain boundaries and micro-plastic deformation and ductility are improved in the low-load high-cycle fatigue process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yeh, J.-W.; Chen, S.K.; Lin, S.-J.; Gan, J.-Y.; Chin, T.-S.; Shun, T.-T.; Tsau, C.-H.; Chang, S.-Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cantor, B. Multicomponent high-entropy Cantor alloys. Prog. Mater. Sci. 2020, 120, 100754. [Google Scholar] [CrossRef]

- Sharma, A.S.; Yadav, S.; Biswas, K.; Basu, B. High-entropy alloys and metallic nanocomposites: Processing challenges, microstructure development and property enhancement. Mater. Sci. Eng. R Rep. 2018, 131, 1–42. [Google Scholar] [CrossRef]

- Yeh, J.-W. Alloy Design Strategies and Future Trends in High-Entropy Alloys. J. Miner. Met. Mater. Soc. 2013, 65, 1759–1771. [Google Scholar] [CrossRef]

- Günen, A. Tribocorrosion behavior of boronized Co1.19Cr1.86Fe1.30Mn1.39Ni1.05Al0.17B0.04 high entropy alloy. Surf. Coat. Technol. 2021, 5, 127426. [Google Scholar] [CrossRef]

- Arif, Z.U.; Khalid, M.Y.; Rehman, E.U.; Ullah, S.; Atif, M.; Tariq, A. A review on laser cladding of high-entropy alloys, their recent trends and potential applications. J. Manuf. Process. 2021, 68, 225–273. [Google Scholar] [CrossRef]

- Ahsan, M.; Seo, G.-J.; Fan, X.; Liaw, P.K.; Motaman, S.; Haase, C.; Kim, D.B. Effects of process parameters on bead shape, microstructure, and mechanical properties in wire + arc additive manufacturing of Al0.1CoCrFeNi high-entropy alloy. J. Manuf. Process. 2021, 68, 1314–1327. [Google Scholar] [CrossRef]

- Günen, A.; Lindner, T.; Karakaş, M.; Kanca, E.; Töberling, G.; Vogt, S.; Gök, M.; Lampke, T. Effect of the boriding environment on the wear response of laser-clad AlCoCrFeNi high entropy alloy coatings. Surf. Coatings Technol. 2022, 447, 128830. [Google Scholar] [CrossRef]

- Kim, Y.-K.; Baek, M.-S.; Yang, S.; Lee, K.-A. In-situ formed oxide enables extraordinary high-cycle fatigue resistance in additively manufactured CoCrFeMnNi high-entropy alloy. Addit. Manuf. 2021, 38, 101832. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Chatterjee, A.; Kumar, S.; Saha, P.; Mishra, P.; Choudhury, A. An experimental design approach to selective laser sintering of low carbon steel. J. Mater. Process. Technol. 2003, 136, 151–157. [Google Scholar] [CrossRef]

- Kruth, J. Selective laser melting of iron-based powders. J. Mater. Process. Technol. 2004, 149, 616–622. [Google Scholar] [CrossRef]

- Wang, Z.; Guan, K.; Gao, M.; Li, X.; Chen, X.; Zeng, X. The microstructure and mechanical properties of deposited-IN718 by selective. J. Alloys Compd. 2012, 513, 518–523. [Google Scholar] [CrossRef]

- Mumtaz, K.A.; Erasenthiran, P.; Hopkinson, N. High density selective laser melting of Waspaloy. J. Mater. Process. Technol. 2008, 195, 77–87. [Google Scholar] [CrossRef]

- Cherry, J.A.; Davies, H.M.; Mehmood, S.; Lavery, N.P.; Brown, S.G.R.; Sienz, J. Investigation into the effect of process parameters on microstructural and physical properties of 316L stainless steel parts by selective laser melting. Int. J. Adv. Manuf. Technol. 2015, 76, 869–879. [Google Scholar] [CrossRef] [Green Version]

- Gong, H.; Rafi, K.; Gu, H.; Ram, G.D.J.; Starr, T.; Stucker, B. Influence of defects on mechanical properties of Ti–6Al–4V components produced by selective laser melting and electron beam melting. Mater. Des. 2015, 86, 545–554. [Google Scholar] [CrossRef]

- Leary, M.; Mazur, M.; Williams, H.; Yang, E.; Alghamdi, A.; Lozanovski, B.; Zhang, X.; Shidid, D.; Farahbod-Sternahl, L.; Witt, G.; et al. Inconel 625 lattice structures manufactured by selective laser melting (SLM): Mechanical properties, deformation and failure modes. Mater. Des. 2018, 157, 179–199. [Google Scholar] [CrossRef]

- Dallago, M.; Zanini, F.; Carmignato, S.; Pasini, D.; Benedetti, M. Effect of the geometrical defectiveness on the mechanical properties of SLM biomedical Ti6Al4V lattices. Procedia Struct. Integr. 2018, 13, 161–167. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.D.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Ahmadi, S.; Campoli, G.; Yavari, S.A.; Sajadi, B.; Wauthle, R.; Schrooten, J.; Weinans, H.; Zadpoor, A. Mechanical behavior of regular open-cell porous biomaterials made of diamond lattice unit cells. J. Mech. Behav. Biomed. Mater. 2014, 34, 106–115. [Google Scholar] [CrossRef] [PubMed]

- Zadpoor, A.A. Mechanical performance of additively manufactured meta-biomaterials. Acta Biomater. 2019, 85, 41–59. [Google Scholar] [CrossRef] [PubMed]

- Bacchewar, P.B.; Singhal, S.K.; Pandey, P.M. Statistical modelling and optimization of surface roughness in the selective laser sintering process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2007, 221, 35–52. [Google Scholar] [CrossRef]

- Pattanayak, D.K.; Fukuda, A.; Matsushita, T.; Takemoto, M.; Fujibayashi, S.; Sasaki, K.; Nishida, N.; Nakamura, T.; Kokubo, T. Bioactive Ti metal analogous to human cancellous bone: Fabrication by selective laser melting and chemical treatments. Acta Biomater. 2011, 7, 1398–1406. [Google Scholar] [CrossRef]

- Lhuissier, P.; de Formanoir, C.; Martin, G.; Dendievel, R.; Godet, S. Geometrical control of lattice structures produced by EBM through chemical etching: Investigations at the scale of individual struts. Mater. Des. 2016, 110, 485–493. [Google Scholar] [CrossRef]

- Zhang, X.Z.; Tang, H.P.; Leary, M.; Song, T.; Jia, L.; Qian, M. Toward Manufacturing Quality Ti-6Al-4V Lattice Struts by Selective Electron Beam Melting (SEBM) for Lattice Design. J. Miner. Met. Mater. Soc. 2018, 70, 1870–1876. [Google Scholar] [CrossRef]

- Rehme, O.; Emmelmann, C. Rapid manufacturing of lattice structures with selective laser melting. In Proceedings of the SPIE, Laser-Based Micropackaging, San Jose, CA, USA, 23 February 2006. [Google Scholar]

- Mancisidor, A.; Garciandia, F.; Sebastian, M.S.; Álvarez, P.; Díaz, J.; Unanue, I. Reduction of the Residual Porosity in Parts Manufactured by Selective Laser Melting Using Skywriting and High Focus Offset Strategies. Phys. Procedia 2016, 83, 864–873. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.M.; Voisin, T.; McKeown, J.; Ye, J.; Calta, N.; Li, Z.; Zeng, Z.; Zhang, Y.; Chen, W.; Roehling, T.T.; et al. Additively manufactured hierarchical stainless steels with high strength and ductility. Nat. Mater. 2018, 17, 63–71. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brif, Y.; Thomas, M.; Todd, I. The use of high-entropy alloys in additive manufacturing. Scr. Mater. 2015, 99, 93–96. [Google Scholar] [CrossRef]

- Piglione, A.; Dovgyy, B.; Liu, C.; Gourlay, C.; Hooper, P.; Pham, M. Printability and microstructure of the CoCrFeMnNi high-entropy alloy fabricated by laser powder bed fusion. Mater. Lett. 2018, 224, 22–25. [Google Scholar] [CrossRef]

- Johnson, L.; Mahmoudi, M.; Zhang, B.; Seede, R.; Huang, X.; Maier, J.T.; Maier, H.J.; Karaman, I.; Elwany, A.; Arróyave, R. Assessing printability maps in additive manufacturing of metal alloys. Acta Mater. 2019, 176, 199–210. [Google Scholar] [CrossRef]

- Seifi, M.; Salem, A.; Beuth, J.; Harrysson, O.; Lewandowski, J. Overview of Materials Qualification Needs for Metal Additive Manufacturing. J. Occup. Med. 2016, 68, 747–764. [Google Scholar] [CrossRef] [Green Version]

- Baufeld, B.; Vander, B.O.; Gault, R. Additive manufacturing of Tie6Ale4V components by shaped metal deposition: Microstructure and mechanical properties. Mater. Des. 2010, 31, 106–111. [Google Scholar] [CrossRef]

- Dinda, G.; Dasgupta, A.; Mazumder, J. Laser aided direct metal deposition of Inconel 625 superalloy: Microstructural evolution and thermal stability. Mater. Sci. Eng. A 2009, 509, 98–104. [Google Scholar] [CrossRef]

- Zhang, B.; Liao, H.; Coddet, C. Effects of processing parameters on properties of selective laser melting Mg–9%Al powder mixture. Mater. Des. 2012, 34, 753–758. [Google Scholar] [CrossRef]

- Mines, R.; Tsopanos, S.; Shen, Y.; Hasan, R.; McKown, S. Drop weight impact behaviour of sandwich panels with metallic micro lattice cores. Int. J. Impact Eng. 2013, 60, 120–132. [Google Scholar] [CrossRef] [Green Version]

- Di, W.; Yongqiang, Y.; Xubin, S.; Yonghua, C. Study on energy input and its influences on single-track, multi-track, and multi-layer in SLM. Int. J. Adv. Manuf. Technol. 2012, 58, 1189–1199. [Google Scholar] [CrossRef]

- de Terris, T.; Andreau, O.; Peyre, P.; Adamski, F.; Koutiri, I.; Gorny, C.; Dupuy, C. Optimization and comparison of porosity rate measurement methods of Selective Laser Melted metallic parts. Addit. Manuf. 2019, 28, 802–813. [Google Scholar] [CrossRef]

- Weingarten, C.; Buchbinder, D.; Pirch, N.; Meiners, W.; Wissenbach, K.; Poprawe, R. Formation and reduction of hydrogen porosity during selective laser melting of AlSi10Mg. J. Mater. Process. Technol. 2015, 221, 112–120. [Google Scholar] [CrossRef]

- Liang, Q.J. Influence of Process Parameters on Selective Laser Melting of 316L Stainless Steel. J. Guangxi Univ. 2018, 43, 1013–1019. [Google Scholar]

- Murali, K.; Chatterjee, A.; Saha, P.; Palai, R.; Kumar, S.; Roy, S.; Mishra, P.; Choudhury, A. Direct selective laser sintering of iron–graphite powder mixture. J. Mater. Process. Technol. 2003, 136, 179–185. [Google Scholar] [CrossRef]

- Fischer, P.; Romano, V.; Weber, H.; Karapatis, N.; Boillat, E.; Glardon, R. Sintering of commercially pure titanium powder with a Nd:YAG laser source. Acta Mater. 2003, 51, 1651–1662. [Google Scholar] [CrossRef]

- Taha, M.A.; Yousef, A.F.; Gany, K.A.; Sabour, H.A. On selective laser melting of ultra high carbon steel: Effect of scan speed and post heat treatment. Mat. Wiss Werkstofftech 2012, 43, 913–923. [Google Scholar] [CrossRef]

- Duriagina, Z.; Lemishka, I.; Litvinchev, I.; Marmolejo, J.A.; Pankratov, A.; Romanova, T.; Yaskov, G. Optimized Filling of a Given Cuboid with Spherical Powders for Additive Manufacturing. J. Oper. Res. Soc. China 2021, 9, 853–868. [Google Scholar] [CrossRef]

- Burtseva, L.; Salas, B.V.; Romero, R.; Werner, F. Multi-Sized Sphere Packings: Models and Recent Approaches; Technical Report; Otto-von-Guericke-Universität: Magdeburg, Germany, 2015. [Google Scholar]

- Hao, L.; Dadbakhsh, S.; Seaman, O.; Felstead, M. Selective laser melting of a stainless steel and hydroxyapatite composite for load-bearing implant development. J. Mater. Process. Technol. 2009, 209, 5793–5801. [Google Scholar] [CrossRef]

- Simchi, A.; Pohl, H. Effects of laser sintering processing parameters on the microstructure and densification of iron powder. Mater. Sci. Eng. A 2003, 359, 119–128. [Google Scholar] [CrossRef]

| Parameter | Setting |

|---|---|

| Rated output power/W | ≥500 |

| Center wavelength/nm | 1060–1080 |

| Output power fluctuation | ≤3% |

| Minimum spot diameter/mm | ≤0.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Yan, Y.; Li, B. Selective Laser Melting (SLM) Additively Manufactured CoCrFeNiMn High-Entropy Alloy: Process Optimization, Microscale Mechanical Mechanism, and High-Cycle Fatigue Behavior. Materials 2022, 15, 8560. https://doi.org/10.3390/ma15238560

Zhang J, Yan Y, Li B. Selective Laser Melting (SLM) Additively Manufactured CoCrFeNiMn High-Entropy Alloy: Process Optimization, Microscale Mechanical Mechanism, and High-Cycle Fatigue Behavior. Materials. 2022; 15(23):8560. https://doi.org/10.3390/ma15238560

Chicago/Turabian StyleZhang, Jianrui, Yabin Yan, and Bo Li. 2022. "Selective Laser Melting (SLM) Additively Manufactured CoCrFeNiMn High-Entropy Alloy: Process Optimization, Microscale Mechanical Mechanism, and High-Cycle Fatigue Behavior" Materials 15, no. 23: 8560. https://doi.org/10.3390/ma15238560