Author Contributions

Conceptualization, T.M.H., Y.M.J., Z.A., S.A. and Z.M.Y.; Data curation, M.S.N., Y.M.J., A.K., M.G.B., S.K.A., M.A.A.-O. and Z.M.Y.; Formal analysis, T.M.H., M.S.N., Y.M.J., A.K., Z.A., M.G.B. and M.A.A.-O.; Investigation, T.M.H., A.K., S.K.A. and M.A.A.-O.; Methodology, T.M.H. and Z.M.Y.; Project administration, Z.M.Y.; Resources, M.S.N.; Software, A.K.; Supervision, S.A. and Z.M.Y.; Validation, M.S.N., M.G.B., S.K.A., M.A.A.-O. and S.A.; Visualization, Y.M.J., A.K., Z.A., M.G.B., S.K.A., S.A. and Z.M.Y.; Writing—original draft, T.M.H., Y.M.J., Z.A., M.G.B., S.K.A., M.A.A.-O., S.A. and Z.M.Y.; Writing—review and editing, M.S.N. and Z.M.Y. All authors have read and agreed to the published version of the manuscript.

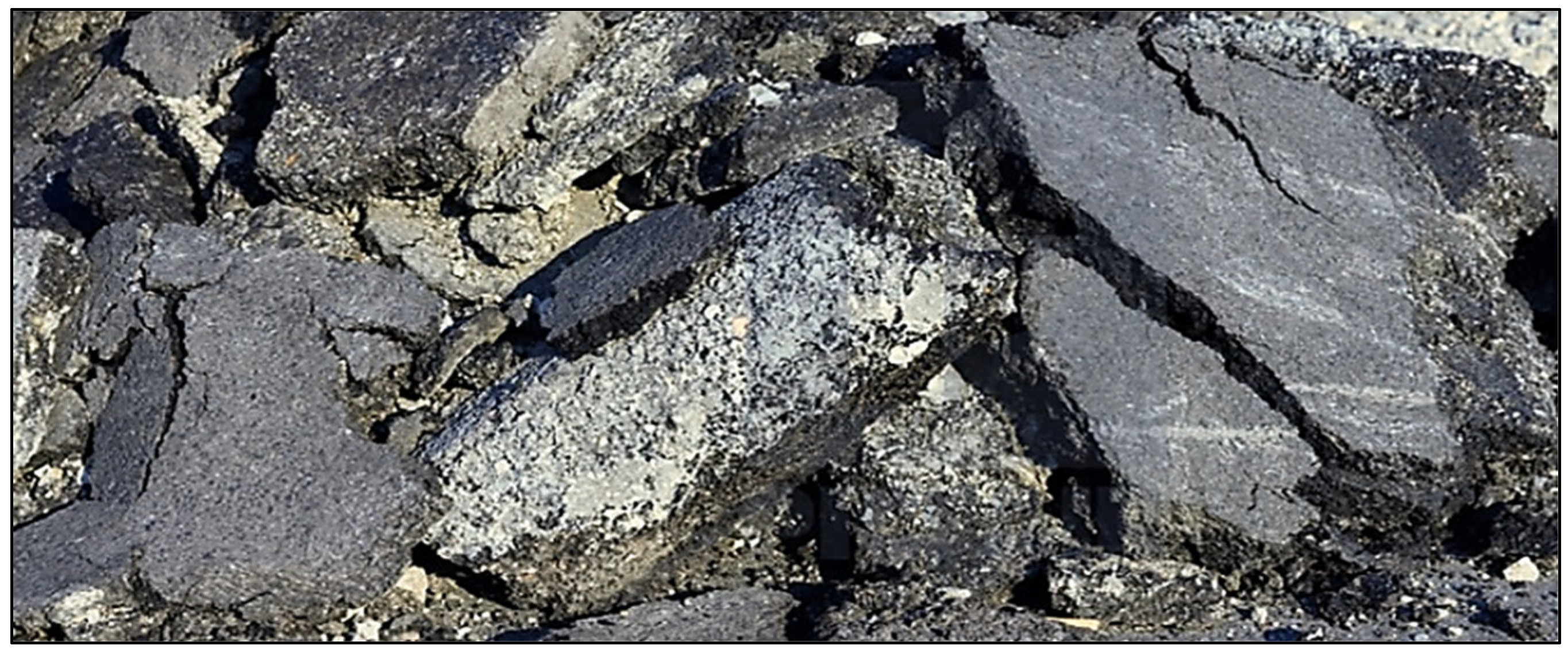

Figure 2.

Samples of the used noncommercial additives.

Figure 2.

Samples of the used noncommercial additives.

Figure 3.

SonneWarmix RTTM sample.

Figure 3.

SonneWarmix RTTM sample.

Figure 4.

Asphalt sample compacted using SGC.

Figure 4.

Asphalt sample compacted using SGC.

Figure 5.

RTFOT apparatus. (A) Rotating oven; (B) RTFO bottle.

Figure 5.

RTFOT apparatus. (A) Rotating oven; (B) RTFO bottle.

Figure 6.

Rotational Brookfield viscometer.

Figure 6.

Rotational Brookfield viscometer.

Figure 7.

Viscosity–temperature logarithmic chart of virgin binder.

Figure 7.

Viscosity–temperature logarithmic chart of virgin binder.

Figure 10.

Pneumatic compactor.

Figure 10.

Pneumatic compactor.

Figure 11.

Sample rectangular mold.

Figure 11.

Sample rectangular mold.

Figure 12.

Volumetric properties of trial mixtures.

Figure 12.

Volumetric properties of trial mixtures.

Figure 13.

Blending process.

Figure 13.

Blending process.

Figure 14.

Rotational viscosity of combined (aged + virgin) binder blend of 20% RAP.

Figure 14.

Rotational viscosity of combined (aged + virgin) binder blend of 20% RAP.

Figure 15.

Rotational viscosity of combined (aged + virgin) binder blend of 40% RAP.

Figure 15.

Rotational viscosity of combined (aged + virgin) binder blend of 40% RAP.

Figure 16.

Rotational viscosity of combined (aged + virgin) binder blend of 60% RAP.

Figure 16.

Rotational viscosity of combined (aged + virgin) binder blend of 60% RAP.

Figure 17.

The change in viscosity level from adding WCO as a rejuvenator to the combined blend of binders in comparison to the control viscosity of the virgin binder.

Figure 17.

The change in viscosity level from adding WCO as a rejuvenator to the combined blend of binders in comparison to the control viscosity of the virgin binder.

Figure 18.

The change in viscosity level from adding WEO as a rejuvenator to the combined blend of binders in comparison to the control viscosity of the virgin binder.

Figure 18.

The change in viscosity level from adding WEO as a rejuvenator to the combined blend of binders in comparison to the control viscosity of the virgin binder.

Figure 19.

The change in viscosity level from adding DSO as a rejuvenator to the combined blend of binders in comparison to the control viscosity of the virgin binder.

Figure 19.

The change in viscosity level from adding DSO as a rejuvenator to the combined blend of binders in comparison to the control viscosity of the virgin binder.

Figure 20.

The change in viscosity level from adding SonneWarmix RTTM as a rejuvenator to the combined blend of binders in comparison to the control viscosity of the virgin binder.

Figure 20.

The change in viscosity level from adding SonneWarmix RTTM as a rejuvenator to the combined blend of binders in comparison to the control viscosity of the virgin binder.

Figure 21.

Rutting index (G*/sin δ) for the aged blends of binders rejuvenated by WCO.

Figure 21.

Rutting index (G*/sin δ) for the aged blends of binders rejuvenated by WCO.

Figure 22.

Rutting index (G*/sin δ) for the aged blends of binders rejuvenated by WEO.

Figure 22.

Rutting index (G*/sin δ) for the aged blends of binders rejuvenated by WEO.

Figure 23.

Rutting index (G*/sin δ) for the aged blends of binders rejuvenated by DSO.

Figure 23.

Rutting index (G*/sin δ) for the aged blends of binders rejuvenated by DSO.

Figure 24.

Rutting index (G*/sin δ) for the aged blends of binders rejuvenated by SonneWarmix RTTM.

Figure 24.

Rutting index (G*/sin δ) for the aged blends of binders rejuvenated by SonneWarmix RTTM.

Figure 25.

Rutting depths of recycled HMA mixtures rejuvenated by WCO.

Figure 25.

Rutting depths of recycled HMA mixtures rejuvenated by WCO.

Figure 26.

Rutting depths of recycled HMA mixtures rejuvenated by WEO.

Figure 26.

Rutting depths of recycled HMA mixtures rejuvenated by WEO.

Figure 27.

Rutting depths of recycled HMA mixtures rejuvenated by DSO.

Figure 27.

Rutting depths of recycled HMA mixtures rejuvenated by DSO.

Figure 28.

Rutting depths of recycled HMA mixtures rejuvenated by SonneWarmix RTTM.

Figure 28.

Rutting depths of recycled HMA mixtures rejuvenated by SonneWarmix RTTM.

Table 1.

Physical characteristics of RAP.

Table 1.

Physical characteristics of RAP.

| Property | Bulk s.g. of Coarse RAP | Bulk s.g. of Fine RAP | Absolute Viscosity@60 °C (Poise) | Binder Content | Moisture Content |

|---|

| Result | 2.512 | 2.501 | 18,900 | 3.6% | 1.03% |

| Standards | ASTM C-127/C-128 | ASTM D2171 | AASHTO T 308 | AASHTO T 255 |

Table 2.

RAP’s gradation.

Table 2.

RAP’s gradation.

| English Sieves | Standard Sieves (mm) | RAP Gradation (% Passing) |

|---|

| 3/4” | 19 | 100 |

| 1/2” | 12.5 | 92.4 |

| 3/8” | 9.5 | 81.3 |

| No.4 | 4.75 | 49.5 |

| No.8 | 2.36 | 42.6 |

| No.50 | 0.3 | 9.5 |

| No.200 | 0.075 | 1.9 |

Table 3.

Aggregate gradation of a surface layer.

Table 3.

Aggregate gradation of a surface layer.

| English Sieves | Standard Sieves (mm) | Specification Limit | Surface Layer Gradation |

|---|

| 3/4” | 19 | 100 | 100 |

| 1/2” | 12.5 | 100-90 | 96 |

| 3/8” | 9.5 | 90-76 | 82 |

| No.4 | 4.75 | 74-44 | 60 |

| No.8 | 2.36 | 58-28 | 44 |

| No.50 | 0.3 | 21-5 | 14 |

| No.200 | 0.075 | 10-4 | 7 |

Table 4.

Physical characteristics of the aggregate.

Table 4.

Physical characteristics of the aggregate.

| Property | Bulk s.g. | Apparent s.g. | Los Angeles (Abrasion) | Angularity | Water Absorption |

|---|

| Coarse aggregate | 2.532 | 2.661 | 22% | 94% | 1.0% |

| Fine aggregate | 2.583 | 2.693 | / | / | 0.74% |

| ASTM Standards | C-127/C-128 | C-131 | D-5821 | C-127/C-128 |

Table 5.

Physical characteristics of the used binder.

Table 5.

Physical characteristics of the used binder.

| Property | Penetration@25 °C, 100 gm, 5 s | Ductility@25 °C, 5 cm/min | Kinematic Viscosity@135 °C | Flashpoint (Cleveland open cup) | Softening Point | s.g.@25 °C |

|---|

| Result | 45 | 133 | 384 cSt | 241 °C | 54 °C | 1.05 |

| ASTM Standards | D5 | D113-99 | D-2170 | D92 | D36 | D70 |

Table 6.

Physical characteristics of the Portland cement as filler.

Table 6.

Physical characteristics of the Portland cement as filler.

| Property | Fineness, Blaine, (cm2/gm) | s.g@25 °C | Passing Sieve No.200 |

|---|

| Result | 3210 | 3.15 | 97% |

Table 7.

Physical characteristics of WCO.

Table 7.

Physical characteristics of WCO.

| Property | s.g.@25 °C | Kinematic Viscosity@40 °C | Dynamic Viscosity mPa.s | Flash Point |

|---|

| Result | 0.942 | 46.31 | 42.45 | 306 °C |

| ASTM Standards | D1298 | D445 | D7042 | D93 |

Table 8.

Chemical characteristics of WCO.

Table 8.

Chemical characteristics of WCO.

| Type of Fatty Acid and Formulation | Percentage of the Weight |

|---|

| Linoleic acid/C18:2 (Cis) | 25% |

| Lignoceric acid/C24:0 | 0.08% |

| Pentadecylic acid/C15:0 | 0.04% |

| Margaric acid/C17:0 | 0.05% |

| Myristic acid/C14:0 | 0.63% |

| Lauric acid/C12:0 | 0.12% |

| Vaccenic acid/C18:1 t | 0.3% |

| α-Linolenic acid/C18:3 alpha | 0.8% |

| Palmitoleic acid/C16:1 | 0.3% |

| Palmitic acid/C16:0 | 28.4% |

| Oleic acid/C18:1 (Cis 9) | 39.8% |

| Stearic acid/C18:0 | 4.2% |

| Linoleic acid/C18:2 t | 0.17% |

Table 9.

Physical characteristics of WEO.

Table 9.

Physical characteristics of WEO.

| Property | Color | s.g.@25 °C | Absolute viscosity@60 °C (poise) | State |

|---|

| Result | Black to dark brown | 0.877 | 0.56 | Oily |

| ASTM Standards | / | D1298 | D7042 | / |

Table 10.

Physical characteristics of DSO.

Table 10.

Physical characteristics of DSO.

| Property | Color | Odor | Absolute Viscosity@60 °C (poise) | s.g @ 25 °C | Moisture Content | Texture |

|---|

| Result | Yellow or pale yellow | pleasant | 0.17 | 0.92 | 9.6% | viscous |

| ASTM Standards | / | / | D7042 | D1298 | D6304 | / |

Table 11.

Chemical characteristics of DSO.

Table 11.

Chemical characteristics of DSO.

| Fatty Acid Type | Lauric | Myristic | Linoleic | Palmitic | Capric | Stearic | Oleic |

|---|

| Percentage % | 10.4 | 7.9 | 18.8 | 9.9 | 0.2 | 1.7 | 50.3 |

Table 12.

Physical characteristics of SonneWarmix RTTM.

Table 12.

Physical characteristics of SonneWarmix RTTM.

| Property | Color | Oder | Density gm/cm3@100 °C | Melting Point | Boiling Point | Flash Point | Kinematic Viscosity@100 °C |

|---|

| Result | Dark brown | Petroleum | 0.81 | 125 °C | >230 °C | >93.4 °C | 18 cSt |

Table 13.

Levels of design gyrations according to SHRP-A-407.

Table 13.

Levels of design gyrations according to SHRP-A-407.

| Design Traffic (ESALs) × 106 | <0.3 | 0.3 to <3 | 3 to <10 | 10 to <30 | ≥30 |

|---|

| Ndesign | 50 | 75 | 100 | 100 | 125 |

Table 14.

The estimated volumetric properties of the mix.

Table 14.

The estimated volumetric properties of the mix.

| Property | Result | AASHTO M323 Standards [43] |

|---|

| Estimated Binder (Pb) | 4.9% | / |

| Estimated Voids of Mineral Aggregate (VMA) | 14.7 | Min. 14% |

| Estimated Voids Filled with Asphalt (VFA) | 72.33 | (65–75)% |

| Estimated Effective Binder (Pbe) | 4.94% | / |

| Dust Proportion | 1.32 | 0.6–1.2 |

| Estimated Gmm at Ninitial | 87 | <89% |

Table 15.

The dosages of recycling agents.

Table 15.

The dosages of recycling agents.

| The Aged Binder | WCO% by Weight of Aged RAP Binder * | WEO% by Weight of Aged RAP Binder | DSO% by Weight of Aged RAP Binder | SonneWarmix RTTM by Weight of Total Binder |

|---|

| 20% RAP | (0–10%) | (0–10%) | (0–10%) | (0.5–1.0%) |

| 40% RAP | (12.5–17.5%) | (12.5–17.5%) | (12.5–17.5%) | (1.0–1.5%) |

| 60% RAP | (17.5–20%) | (17.5–20%) | (17.5–20%) | (1.5–2.0%) |

Table 16.

The volumetric properties of the trial mixtures.

Table 16.

The volumetric properties of the trial mixtures.

| Property | Binder % |

|---|

| 4.4 | 4.9 | 5.4 | 5.9 |

|---|

| Gmb | 2.322 | 2.384 | 2.355 | 2.343 |

| Gmm | 2.465 | 2.431 | 2.401 | 2.378 |

| Air Voids % | 6.0 | 3.6 | 2.7 | 2.0 |

| VFA% | 57 | 78 | 87 | 93 |

| VMA% | 15.7 | 14.5 | 14.0 | 14.8 |

| Gmm% at Ninitial | 85 | 87 | 91 | 94 |

| Gmm% at Ndesign | 94 | 96.5 | 98 | 99 |

| Gmm% at Nmax | 95.5 | 97.5 | 99 | 100 |

Table 17.

The volumetric properties of the HMA mixture at optimum binder content.

Table 17.

The volumetric properties of the HMA mixture at optimum binder content.

| Property | The Result | AASHTO M 323 Standards |

|---|

| Binder optimum content % | 4.8 | at 4% Air Voids |

| Air content % | 4.0 | 4.0 |

| VMA % | 14.7 | Minimum 15% |

| VFA % | 74 | (65–75)% |

| Gmm at Ninitial | 86.5% | ≤89% |

| Gmm at Ndesign | 96% | 96% |

| Gmm at Nmax | 97% | ≤98% |

| Dust proportion % | 1.1 | 0.6–1.2 |

Table 18.

The added percentages of virgin binder to the recycled mixtures.

Table 18.

The added percentages of virgin binder to the recycled mixtures.

| RAP Percentage in the Mix | Added Virgin Binder (by Weight of Total Mix) | Aged Binder (by Weight of Total Mix) | Total Binder Content | Virgin Binder (by Weight of Total Binder Content) | Aged Binder * (by Weight of Total Binder Content) |

|---|

| 20% | 4.08% | 0.72% | 4.8% | 85% | 15% |

| 40% | 3.36% | 1.44% | 70% | 30% |

| 60% | 2.64% | 2.16% | 55% | 45% |

Table 19.

Rutting indicator (G*/sin δ) for the unaged samples of the binders’ blend.

Table 19.

Rutting indicator (G*/sin δ) for the unaged samples of the binders’ blend.

| Binder Type | G*/sin δ (Unaged) |

|---|

| 64 °C | 70 °C | 76 °C | 82 °C | 88 °C |

|---|

| Virgin binder | 3.12 | 1.62 | 0.88 | | |

| (Aged + virgin) blend of 20% RAP | 4.77 | 2.81 | 1.11 | 0.55 | |

| (Aged + virgin) blend of 20% RAP + 10% WCO | 3.04 | 1.54 | 0.61 | | |

| (Aged + virgin) blend of 20% RAP + 10% WEO | 3.1 | 1.6 | 0.82 | | |

| (Aged + virgin) blend of 20% RAP + 10% DSO | 2.93 | 1.48 | 0.74 | | |

| (Aged + virgin) blend of 20% RAP + 0.5% SonneWarmix RTTM | 3.52 | 2.03 | 0.91 | | |

| (Aged + virgin) blend of 20% RAP + 1.0% SonneWarmix RTTM | 3.14 | 1.91 | 0.9 | | |

| (Aged + virgin) blend of 40% RAP | 5.28 | 4.12 | 2.42 | 1.12 | 0.56 |

| (Aged + virgin) blend of 40% RAP + 12.5% WCO | 3.47 | 1.96 | 0.91 | | |

| (Aged + virgin) blend of 40% RAP + 17.5% WCO | 2.95 | 1.5 | 0.6 | | |

| (Aged + virgin) blend of 40% RAP + 12.5% WEO | 3.25 | 1.73 | 0.87 | | |

| (Aged + virgin) blend of 40% RAP + 17.5% WEO | 3.15 | 1.64 | 0.85 | | |

| (Aged + virgin) blend of 40% RAP + 12.5% DSO | 3.2 | 1.63 | 0.83 | | |

| (Aged + virgin) blend of 40% RAP + 17.5% DSO | 2.83 | 1.24 | 0.6 | | |

| (Aged + virgin) blend of 40% RAP + 1.0% SonneWarmix RTTM | 3.15 | 1.65 | 0.89 | | |

| (Aged + virgin) blend of 40% RAP + 1.5% SonneWarmix RTTM | 2.78 | 1.41 | 0.71 | | |

| (Aged + virgin) blend of 60% RAP | 6.46 | 5.21 | 3.81 | 2.15 | 0.98 |

| (Aged + virgin) blend of 60% RAP + 17.5% WCO | 3.92 | 2.14 | 1.15 | 0.58 | |

| (Aged + virgin) blend of 60% RAP + 20% WCO | 2.97 | 1.54 | 0.61 | | |

| (Aged + virgin) blend of 60% RAP + 17.5% WEO | 3.49 | 2 | 0.95 | | |

| (Aged + virgin) blend of 60% RAP + 20% WEO | 2.59 | 1.27 | 0.6 | | |

| (Aged + virgin) blend of 60% RAP + 17.5% DSO | 4.33 | 2.08 | 1.05 | 0.51 | |

| (Aged + virgin) blend of 60% RAP + 20% DSO | 2.8 | 1.55 | 0.63 | | |

| (Aged + virgin) blend of 60% RAP + 1.5% SonneWarmix RTTM | 5.02 | 2.04 | 1.02 | 0.50 | |

| (Aged + virgin) blend of 60% RAP + 2.0% SonneWarmix RTTM | 3.2 | 1.61 | 0.87 | | |

Table 20.

Rutting indicator (G*/sin δ) for the RTFO aged samples of the developed binder.

Table 20.

Rutting indicator (G*/sin δ) for the RTFO aged samples of the developed binder.

| Binder Type | G*/sin δ (RTFO) |

|---|

| 64 °C | 70 °C | 76 °C | 82 °C | 88 °C |

|---|

| Virgin binder | 5.14 | 1.94 | | | |

| (Aged + virgin) blend of 20% RAP | 6.24 | 3.02 | 1.84 | | |

| (Aged + virgin) blend of 20% RAP + 10% WCO | 5.02 | 1.83 | | | |

| (Aged + virgin) blend of 20% RAP + 10% WEO | 5.11 | 1.97 | | | |

| (Aged + virgin) blend of 20% RAP + 10% DSO | 4.87 | 1.76 | | | |

| (Aged + virgin) blend of 20% RAP + 0.5% SonneWarmix RTTM | 5.46 | 2.24 | 1.89 | | |

| (Aged + virgin) blend of 20% RAP + 1.0% SonneWarmix RTTM | 5.35 | 2.11 | 1.86 | | |

| (Aged + virgin) blend of 40% RAP | 7.34 | 4.22 | 2.65 | 1.94 | |

| (Aged + virgin) blend of 40% RAP + 12.5% WCO | 5.38 | 2.17 | 1.86 | | |

| (Aged + virgin) blend of 40% RAP + 17.5% WCO | 4.89 | 1.79 | | | |

| (Aged + virgin) blend of 40% RAP + 12.5% WEO | 5.35 | 2.2 | 1.87 | | |

| (Aged + virgin) blend of 40% RAP + 17.5% WEO | 5.17 | 1.96 | | | |

| (Aged + virgin) blend of 40% RAP + 12.5% DSO | 5.2 | 2 | | | |

| (Aged + virgin) blend of 40% RAP + 17.5% DSO | 4.65 | 1.54 | | | |

| (Aged + virgin) blend of 40% RAP + 1.0% SonneWarmix RTTM | 5.19 | 1.98 | | | |

| (Aged + virgin) blend of 40% RAP + 1.5% SonneWarmix RTTM | 4.74 | 1.63 | | | |

| (Aged + virgin) blend of 60% RAP | 7.88 | 5.11 | 4.56 | 2.77 | 2.15 |

| (Aged + virgin) blend of 60% RAP + 17.5% WCO | 5.22 | 2.86 | 1.96 | | |

| (Aged + virgin) blend of 60% RAP + 20% WCO | 4.91 | 1.83 | | | |

| (Aged + virgin) blend of 60% RAP + 17.5% WEO | 5.4 | 2.3 | 1.89 | | |

| (Aged + virgin) blend of 60% RAP + 20% WEO | 5.0 | 1.57 | | | |

| (Aged + virgin) blend of 60% RAP + 17.5% DSO | 7.67 | 5.36 | 1.49 | | |

| (Aged + virgin) blend of 60% RAP + 20% DSO | 4.81 | 2.0 | | | |

| (Aged + virgin) blend of 60% RAP + 1.5% SonneWarmix RTTM | 5.77 | 2.94 | 1.98 | | |

| (Aged + virgin) blend of 60% RAP + 2.0% SonneWarmix RTTM | 5.19 | 1.97 | | | |

Table 21.

Rutting depth for the control and rejuvenated HMA average mixtures.

Table 21.

Rutting depth for the control and rejuvenated HMA average mixtures.

| Mixture Type | Rut Depth (mm) |

|---|

2500

Cycles | 5000

Cycles | 7500

Cycles | 10,000

Cycles |

|---|

| Control HMA Mix | 4.13 | 6.34 | 7.88 | 9.12 |

| HMA of 20% RAP | 5.51 | 8.66 | 9.81 | 11.79 |

| HMA of 20% RAP + 10% WCO | 4.21 | 6.51 | 7.92 | 9.4 |

| HMA of 20% RAP + 10% WEO | 4.15 | 6.37 | 7.9 | 9.17 |

| HMA of 20% RAP + 10% DSO | 5.32 | 8.34 | 9.7 | 11.6 |

| HMA of 20% RAP + 0.5% SonneWarmix RTTM | 3.75 | 5.13 | 6.71 | 7.9 |

| HMA of 20% RAP + 1.0% SonneWarmix RTTM | 3.82 | 5.77 | 7.56 | 8.02 |

| HMA of 40% RAP | 6.15 | 8.95 | 10.48 | 12.20 |

| HMA of 40% RAP + 12.5% WCO | 3.8 | 5.64 | 7.32 | 8 |

| HMA of 40% RAP + 17.5% WCO | 5.3 | 8.3 | 9.7 | 11.58 |

| HMA of 40% RAP + 12.5% WEO | 3.6 | 5.57 | 6.8 | 7.77 |

| HMA of 40% RAP + 17.5% WEO | 4.1 | 6.3 | 7.5 | 9 |

| HMA of 40% RAP + 12.5% DSO | 4 | 6.1 | 5.5 | 9 |

| HMA of 40% RAP + 17.5% DSO | 5.5 | 8.7 | 10.1 | 11.7 |

| HMA of 40% RAP+ 1.0% SonneWarmix RTTM | 4.1 | 6.4 | 7.5 | 9.1 |

| HMA of 40% RAP + 1.5% SonneWarmix RTTM | 5.8 | 8.6 | 10.1 | 11.7 |

| HMA of 60% RAP | 6.95 | 9.28 | 11.70 | 13.11 |

| HMA of 60% RAP + 17.5% WCO | 3 | 5.1 | 6.24 | 7.52 |

| HMA of 60% RAP + 20% WCO | 5.3 | 8.3 | 9.7 | 11.58 |

| HMA of 60% RAP + 17.5% WEO | 3.2 | 5.35 | 6.3 | 7.3 |

| HMA of 60% RAP + 20% WEO | 5.3 | 8.2 | 9.5 | 11.24 |

| HMA of 60% RAP + 17.5% DSO | 3.2 | 4.3 | 5 | 6.2 |

| HMA of 60% RAP + 20% DSO | 5.5 | 8.5 | 9.3 | 10.1 |

| HMA of 60% RAP+ 1.5% SonneWarmix RTTM | 2.9 | 4.1 | 4.9 | 6 |

| HMA of 60% RAP+2.0% SonneWarmix RTTM | 4.1 | 6.3 | 7.86 | 9.12 |

Table 22.

The optimum percentages of the used rejuvenators.

Table 22.

The optimum percentages of the used rejuvenators.

| Rejuvenator Type | Optimum Percentage |

|---|

| @ 20% RAP | @ 40% RAP | @ 60% RAP |

|---|

| WCO by weight of the aged RAP binder | 10% | 12.5% | 17.5% |

| WEO by weight of the aged RAP binder | 10% | 12.5–17.5% | 17.5% |

| DSO by weight of the aged RAP binder | <10% | 12.5% | 17.5% |

| SonneWarmix RTTM by weight of the total binder | 0.5–1.0% | 1.0% | 1.5–2.0% |