Mechanical Performance of Flax Fiber Composites with Waste Glass Fibers as a Core Structure

Abstract

:1. Introduction

2. Materials and methods

2.1. Materials

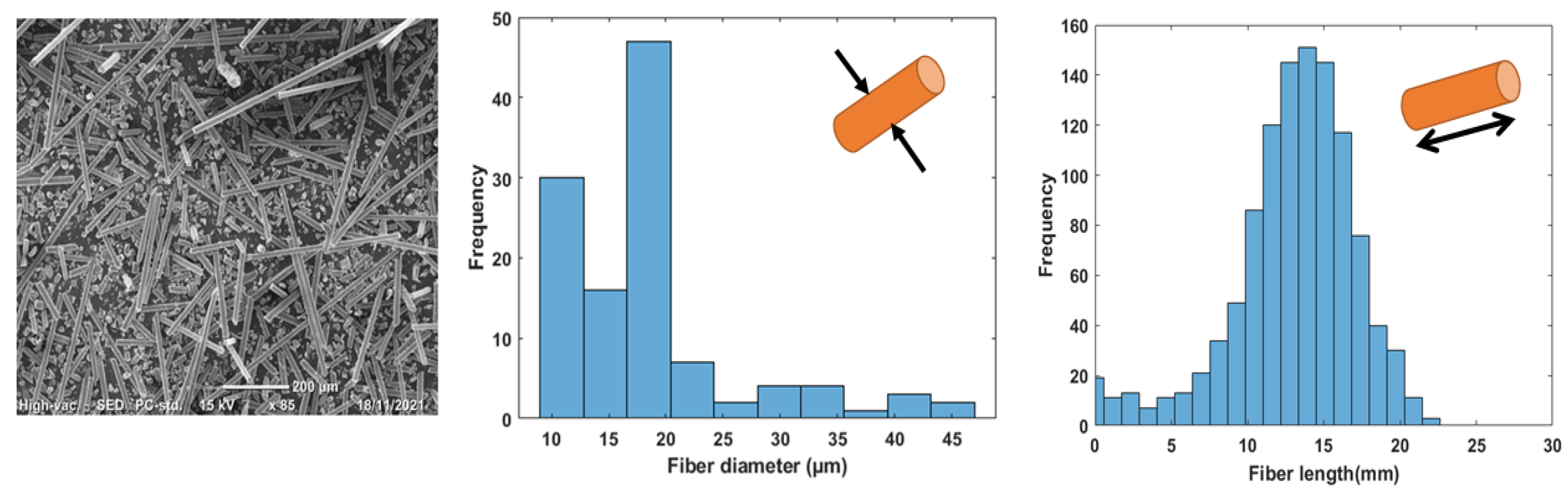

2.2. Fiber Morphology

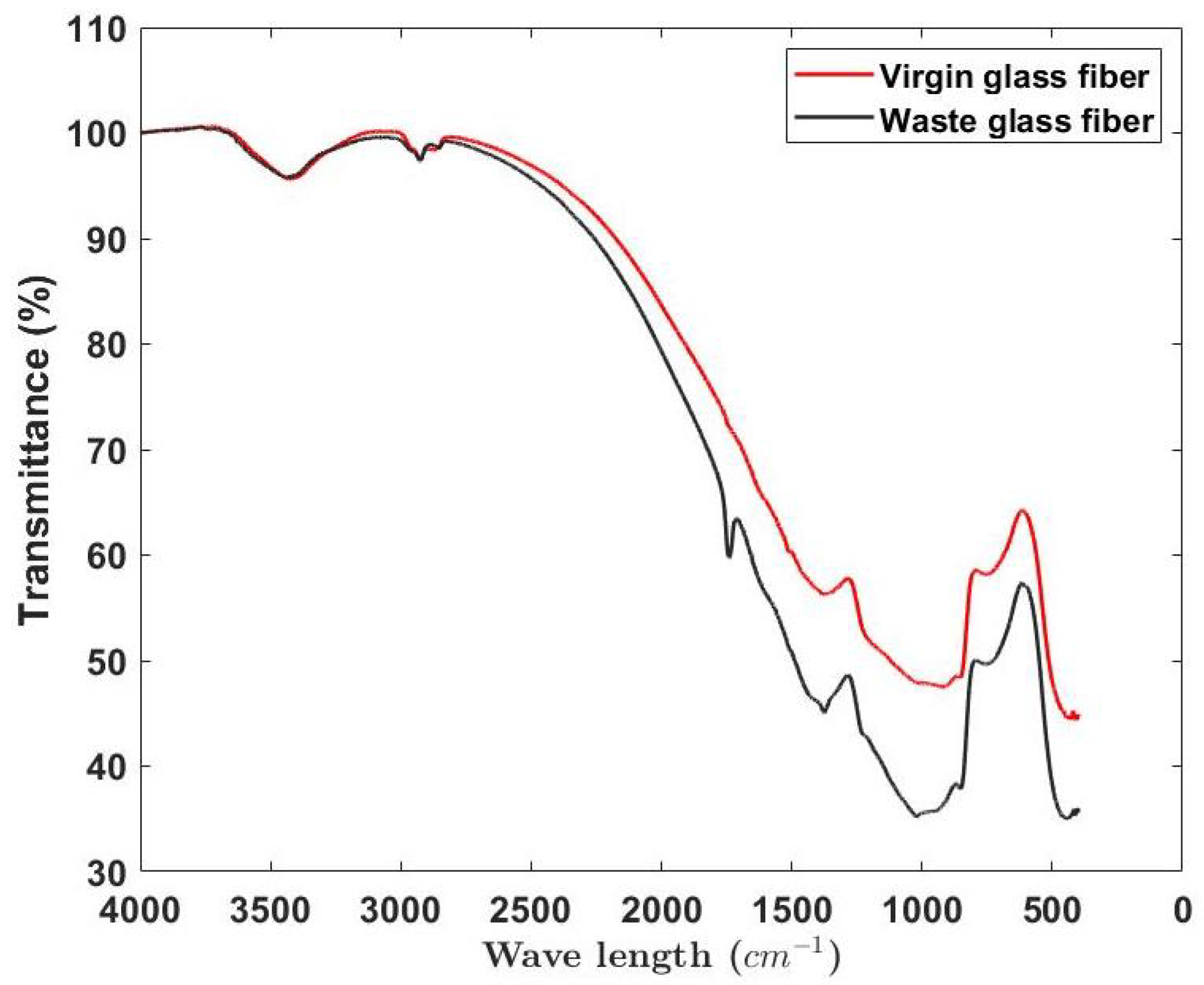

2.3. FTIR

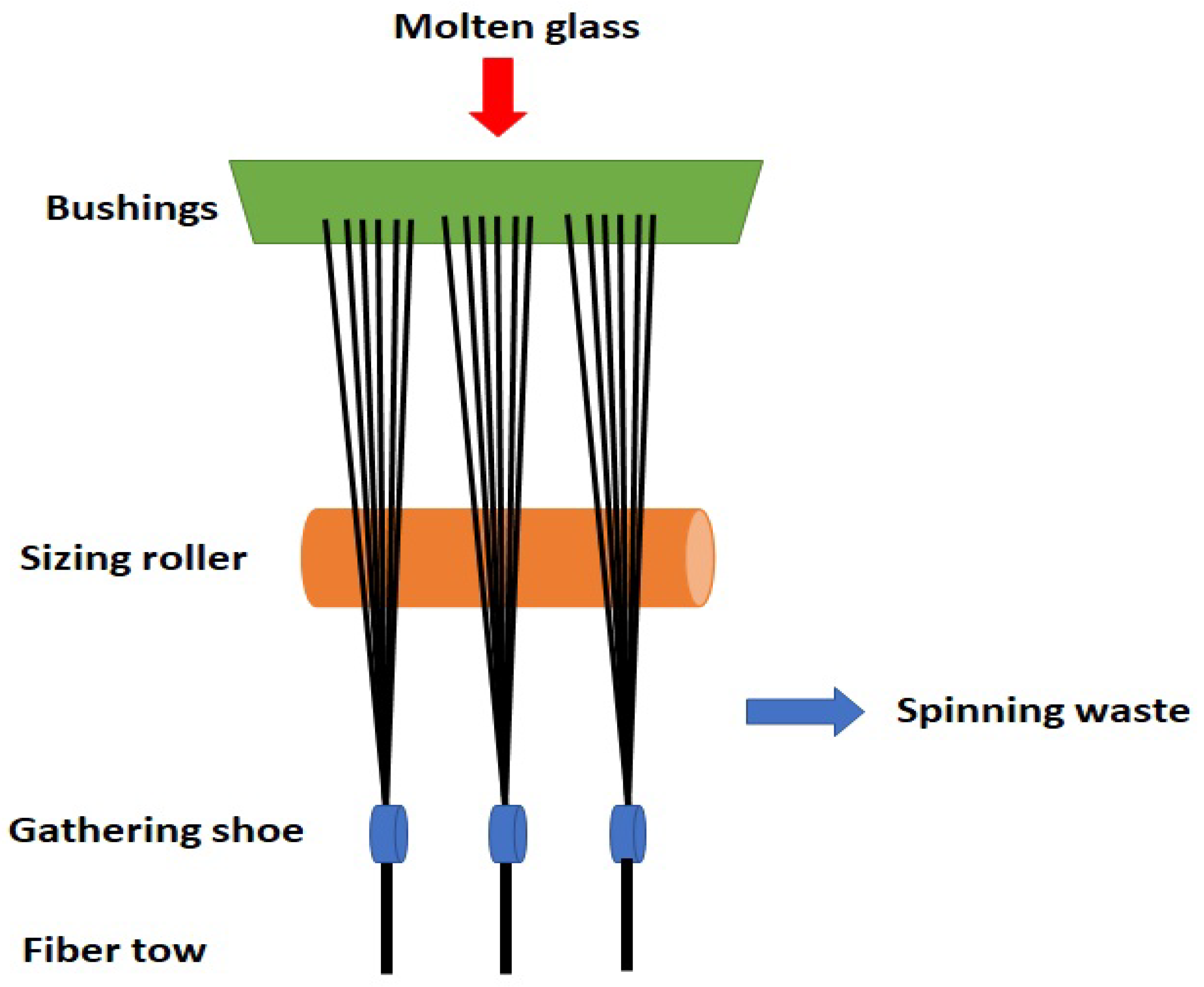

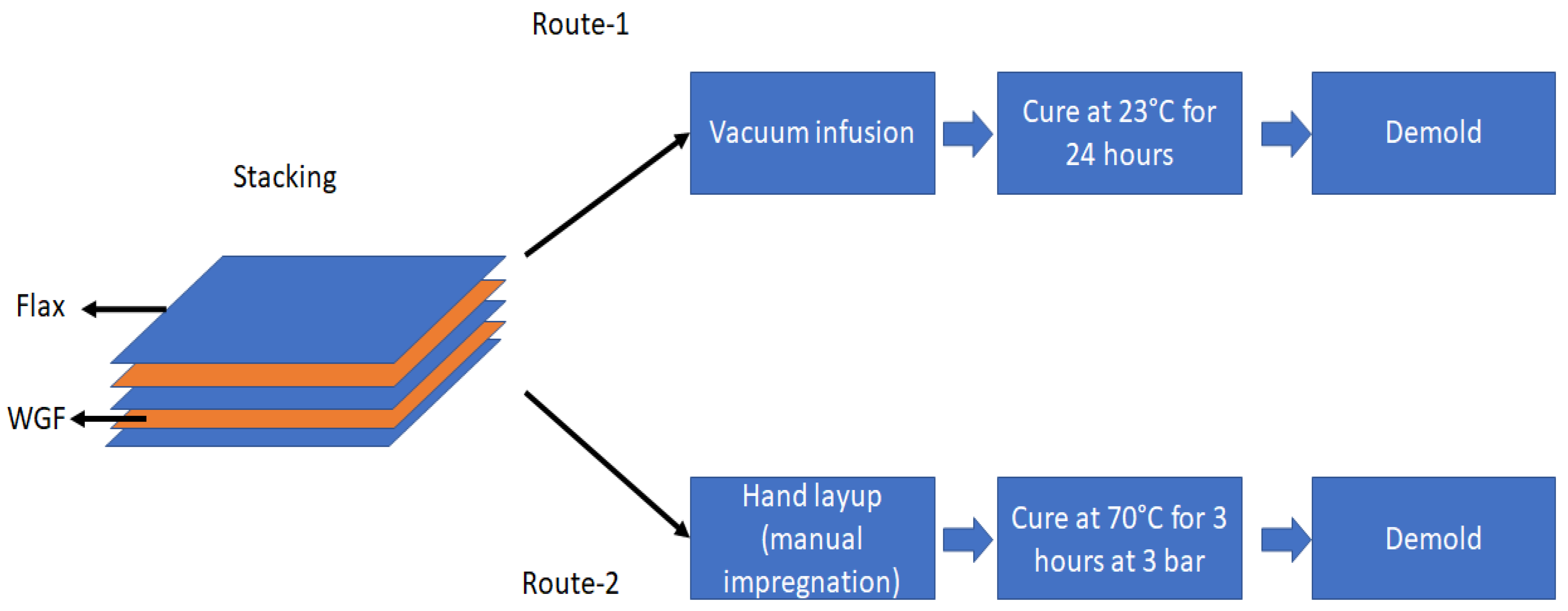

2.4. Composite Manufacturing

2.5. Mechanical Tests

2.6. Void Content Measurements

3. Results and Discussion

3.1. WGF Morphology

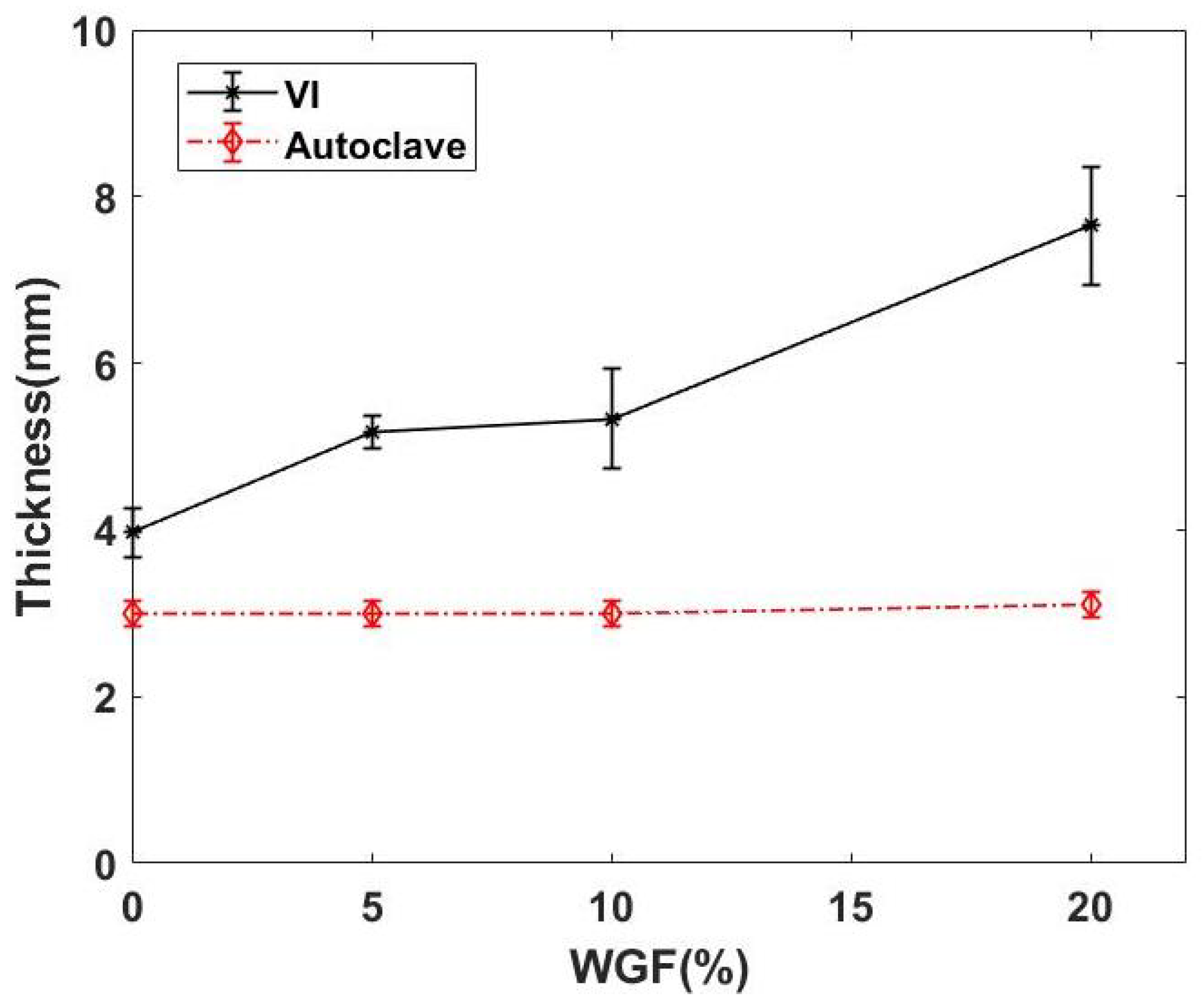

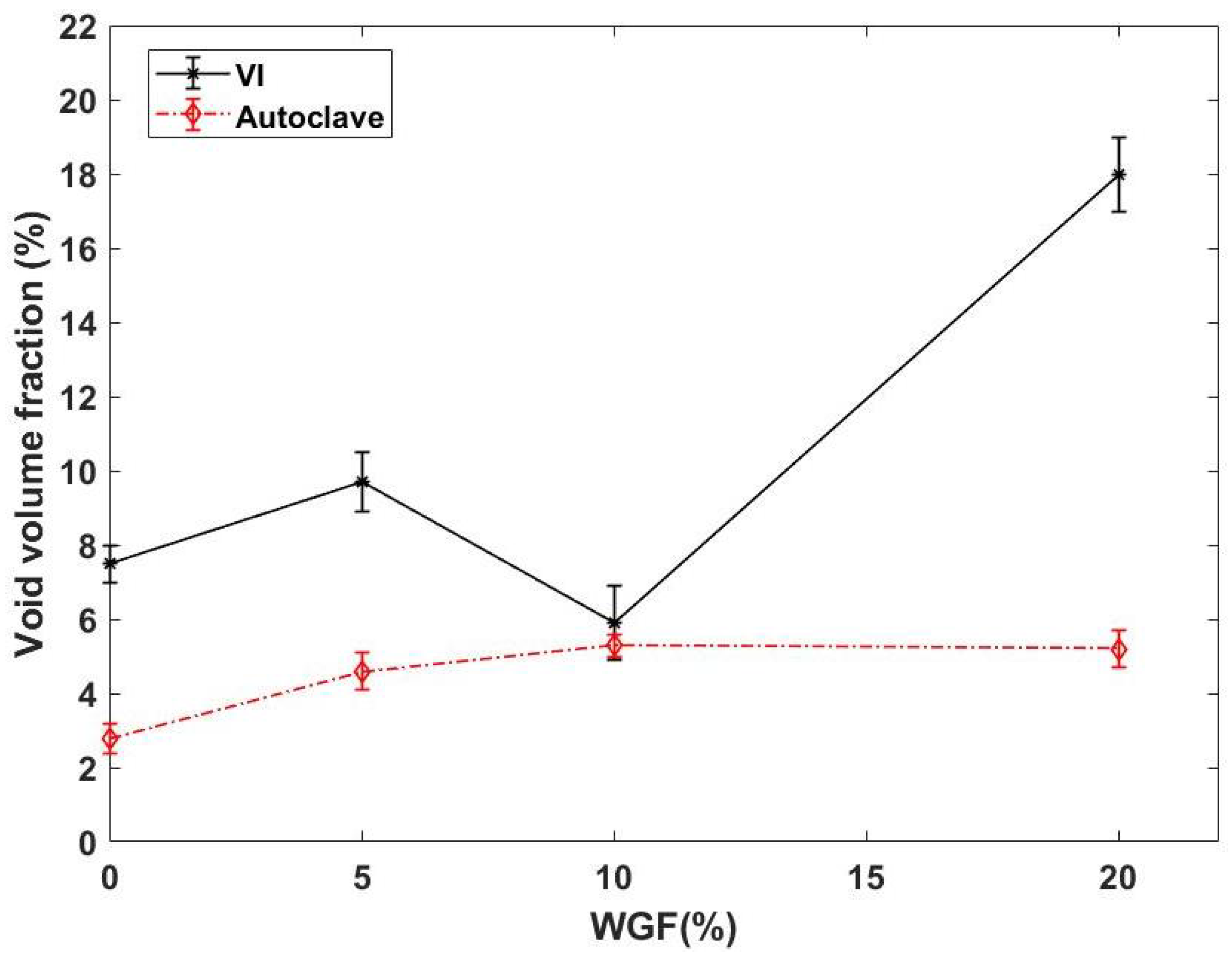

3.2. Residual Void Content

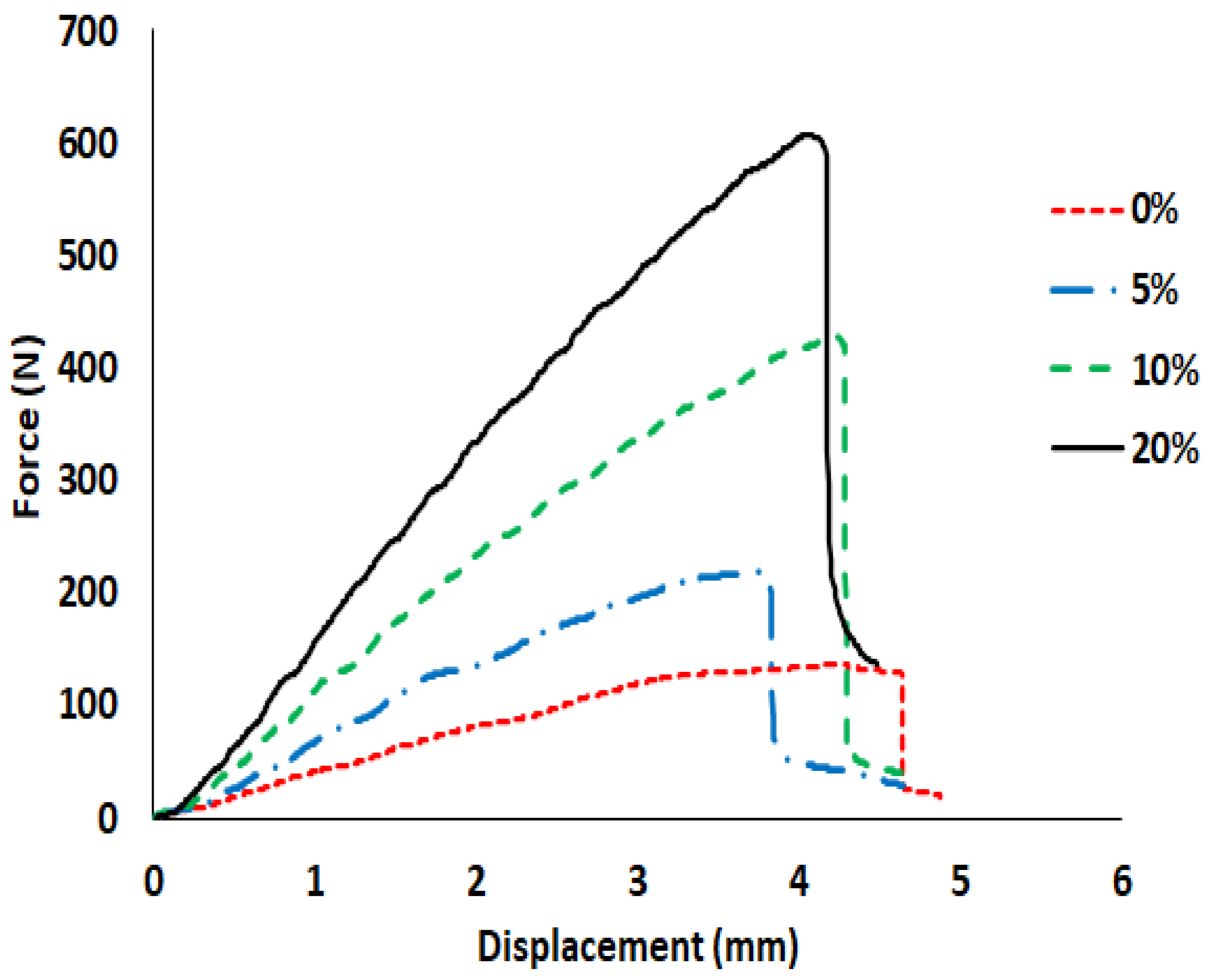

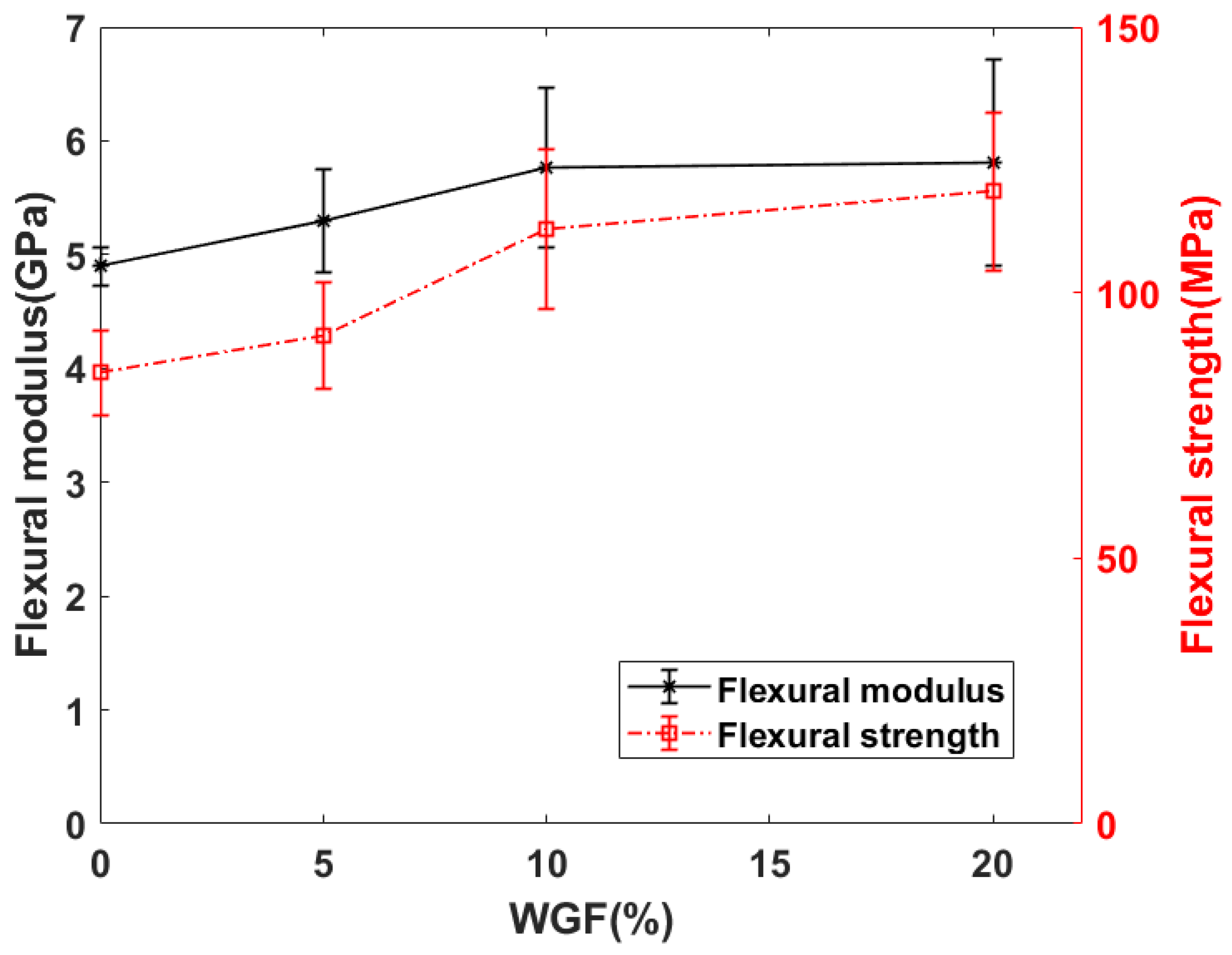

3.3. Flexural Properties

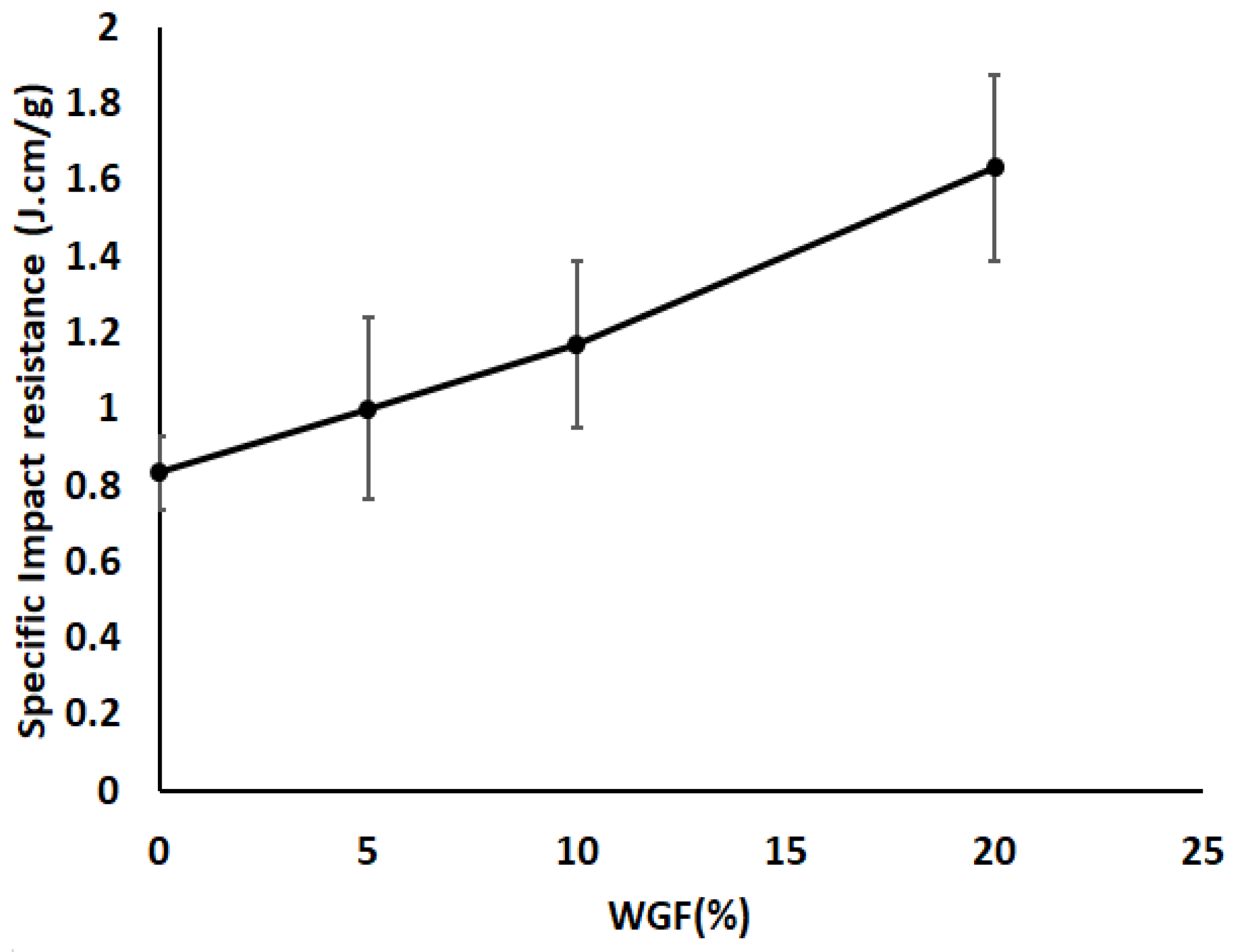

3.4. Impact Resistance

3.5. Environmental Impact

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stratégie Nationale Bas-Carbone (SNBC) | Ministères Écologie Énergie Territoires. Available online: https://www.ecologie.gouv.fr/sites/default/files/2020-03-25_MTES_SNBC2.pdf (accessed on 8 December 2022).

- Pakdel, E.; Kashi, S.; Varley, R.; Wang, X. Recent progress in recycling carbon fibre reinforced composites and dry carbon fibre wastes. Resour. Conserv. Recycl. 2021, 166, 105340. [Google Scholar] [CrossRef]

- Nilakantan, G.; Nutt, S. Reuse and upcycling of aerospace prepreg scrap and waste. Reinf. Plast. 2015, 59, 44–51. [Google Scholar] [CrossRef]

- Levy, A.; Hubert, P. Interstrand void content evolution in compression moulding of randomly oriented strands (ROS) of thermoplastic composites. Compos. Part A Appl. Sci. Manuf. 2015, 70, 121–131. [Google Scholar] [CrossRef]

- Picher-Martel, G.P.; Levy, A.; Hubert, P. Compression moulding of Carbon/PEEK Randomly-Oriented Strands composites: A 2D Finite Element model to predict the squeeze flow behaviour. Compos. Part A Appl. Sci. Manuf. 2016, 81, 69–77. [Google Scholar] [CrossRef]

- Wu, M.S.; Centea, T.; Nutt, S.R. Compression molding of reused in-process waste–effects of material and process factors. Adv. Manuf. Polym. Compos. Sci. 2018, 4, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Centea, T.; Nutt, S.R. Manufacturing cost relationships for vacuum bag-only prepreg processing. J. Compos. Mater. 2016, 50, 2305–2321. [Google Scholar] [CrossRef]

- Visweswaraiah, S.B.; Lessard, L.; Hubert, P. Interlaminar shear behaviour of hybrid fibre architectures of randomly oriented strands combined with laminate groups. Compos. Struct. 2017, 176, 823–832. [Google Scholar] [CrossRef]

- Visweswaraiah, S.B.; Lessard, L.; Hubert, P. Tensile behaviour of hybrid fibre architectures of randomly oriented strands combined with laminate groups. J. Compos. Mater. 2019, 53, 3725–3740. [Google Scholar] [CrossRef]

- Selezneva, M.; Roy, S.; Meldrum, S.; Lessard, L.; Yousefpour, A. Modelling of mechanical properties of randomly oriented strand thermoplastic composites. J. Compos. Mater. 2017, 51, 831–845. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Post, W.; Susa, A.; Blaauw, R.; Molenveld, K.; Knoop, R.J. A Review on the Potential and Limitations of Recyclable Thermosets for Structural Applications. Polym. Rev. 2020, 60, 359–388. [Google Scholar] [CrossRef]

- Thomason, J.L.; Nagel, U.; Yang, L.; Sáez, E. Regenerating the strength of thermally recycled glass fibres using hot sodium hydroxide. Compos. Part A Appl. Sci. Manuf. 2016, 87, 220–227. [Google Scholar] [CrossRef] [Green Version]

- Rahimizadeh, A.; Tahir, M.; Fayazbakhsh, K.; Lessard, L. Tensile properties and interfacial shear strength of recycled fibers from wind turbine waste. Compos. Part A Appl. Sci. Manuf. 2020, 131, 105786. [Google Scholar] [CrossRef]

- Hasan, M.M.; Nitsche, S.; Abdkader, A.; Cherif, C. Carbon fibre reinforced thermoplastic composites developed from innovative hybrid yarn structures consisting of staple carbon fibres and polyamide 6 fibres. Compos. Sci. Technol. 2018, 167, 379–387. [Google Scholar] [CrossRef]

- Davidson, J.R.; Quinn, J.A.; Rothmann, C.; Bajpai, A.; Robert, C.; Ó Brádaigh, C.M.; McCarthy, E.D. Mechanical characterisation of pneumatically-spliced carbon fibre yarns as reinforcements for polymer composites. Mater. Des. 2022, 213, 110305. [Google Scholar] [CrossRef]

- May, D.; Goergen, C.; Friedrich, K. Multifunctionality of polymer composites based on recycled carbon fibers: A review. Adv. Ind. Eng. Polym. Res. 2021, 4, 70–81. [Google Scholar] [CrossRef]

- Bourmaud, A.; Dhakal, H.; Habrant, A.; Padovani, J.; Siniscalco, D.; Ramage, M.H.; Beaugrand, J.; Shah, D.U. Exploring the potential of waste leaf sheath date palm fibres for composite reinforcement through a structural and mechanical analysis. Compos. Part A Appl. Sci. Manuf. 2017, 103, 292–303. [Google Scholar] [CrossRef] [Green Version]

- Alshahrani, H.; Arun Prakash, V.R. Mechanical, fatigue and DMA behaviour of high content cellulosic corn husk fibre and orange peel biochar epoxy biocomposite: A greener material for cleaner production. J. Clean. Prod. 2022, 374, 133931. [Google Scholar] [CrossRef]

- Corbière-Nicollier, T.; Gfeller Laban, B.; Lundquist, L.; Leterrier, Y.; Månson, J.A.; Jolliet, O. Life cycle assessment of biofibres replacing glass fibres as reinforcement in plastics. Resour. Conserv. Recycl. 2001, 33, 267–287. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites—A review. Compos. Part B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Barouni, A.K.; Dhakal, H.N. Damage investigation and assessment due to low-velocity impact on flax/glass hybrid composite plates. Compos. Struct. 2019, 226, 111224. [Google Scholar] [CrossRef]

- Barouni, A.; Lupton, C.; Jiang, C.; Saifullah, A.; Giasin, K.; Zhang, Z.; Dhakal, H.N. Investigation into the fatigue properties of flax fibre epoxy composites and hybrid composites based on flax and glass fibres. Compos. Struct. 2022, 281, 115046. [Google Scholar] [CrossRef]

- Saidane, E.H.; Scida, D.; Pac, M.J.; Ayad, R. Mode-I interlaminar fracture toughness of flax, glass and hybrid flax-glass fibre woven composites: Failure mechanism evaluation using acoustic emission analysis. Polym. Test. 2019, 75, 246–253. [Google Scholar] [CrossRef]

- Judawisastra, H.; Harito, C.; Anindyajati, D.; Purnama, H.; Abdullah, A.H.D. Mechanical properties of carbon nanotubes/epoxy nanocomposites: Pre-curing, curing temperature, and cooling rate. High Perform. Polym. 2021, 33, 741–750. [Google Scholar] [CrossRef]

- Pisupati, A.; Ayadi, A.; Deléglise-Lagardère, M.; Park, C.H. Influence of resin curing cycle on the characterization of the tensile properties of flax fibers by impregnated fiber bundle test. Compos. Part A Appl. Sci. Manuf. 2019, 126, 105572. [Google Scholar] [CrossRef]

- Kretsis, G.; He, Y.; Makeev, A.; Concrete, R.; Goh, G.D.L.; Dikshit, V.; Nagalingam, A.P.; Goh, G.D.L.; Agarwala, S.; Sing, S.L.; et al. CRAG (Composite Research Advisory Group) Test Methods for the Measurement of the Engineering Properties of Fibre Reinforced Plastics. Fifth Conf. Compos. Mater. Test. Des. 1988, 18, 631–738. [Google Scholar]

- Ning, H.; Lu, N.; Hassen, A.A.; Chawla, K.; Selim, M.; Pillay, S. A review of Long fibre thermoplastic (LFT) composites. Int. Mater. Rev. 2020, 65, 164–188. [Google Scholar] [CrossRef]

- Fiore, V.; Calabrese, L.; Miranda, R.; Badagliacco, D.; Sanfilippo, C.; Palamara, D.; Valenza, A.; Proverbio, E. Assessment of performance degradation of hybrid flax-glass fiber reinforced epoxy composites during a salt spray fog/dry aging cycle. Compos. Part B Eng. 2022, 238, 109897. [Google Scholar] [CrossRef]

- Kourkoutsaki, T.; Comas-Cardona, S.; Binetruy, C.; Upadhyay, R.K.; Hinterhoelzl, R. The impact of air evacuation on the impregnation time of Out-of-Autoclave prepregs. Compos. Part A Appl. Sci. Manuf. 2015, 79, 30–42. [Google Scholar] [CrossRef]

- Mehdikhani, M.; Gorbatikh, L.; Verpoest, I.; Lomov, S.V. Voids in fiber-reinforced polymer composites: A review on their formation, characteristics, and effects on mechanical performance. J. Compos. Mater. 2019, 53, 1579–1669. [Google Scholar] [CrossRef]

- Ramlee, N.A.; Jawaid, M.; Zainudin, E.S.; Yamani, S.A.K. Tensile, physical and morphological properties of oil palm empty fruit bunch/sugarcane bagasse fibre reinforced phenolic hybrid composites. J. Mater. Res. Technol. 2019, 8, 3466–3474. [Google Scholar] [CrossRef]

- Mesquita, F.; van Gysel, A.; Selezneva, M.; Swolfs, Y.; Lomov, S.V.; Gorbatikh, L. Flexural behaviour of corrugated panels of self-reinforced polypropylene hybridised with carbon fibre: An experimental and modelling study. Compos. Part B Eng. 2018, 153, 437–444. [Google Scholar] [CrossRef]

- Swolfs, Y.; Gorbatikh, L.; Verpoest, I. Fibre hybridisation in polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2014, 67, 181–200. [Google Scholar] [CrossRef]

- Espinach, F.X.; Delgado-Aguilar, M.; Puig, J.; Julian, F.; Boufi, S.; Mutjé, P. Flexural properties of fully biodegradable alpha-grass fibers reinforced starch-based thermoplastics. Compos. Part B Eng. 2015, 81, 98–106. [Google Scholar] [CrossRef]

- Habibi, M.; Lebrun, G.; Laperrière, L. Experimental characterization of short flax fiber mat composites: Tensile and flexural properties and damage analysis using acoustic emission. J. Mater. Sci. 2017, 52, 6567–6580. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, D.; Li, B.; Wan, G.; Zhao, G.; Zhang, A. Strong and thermal-resistance glass fiber-reinforced polylactic acid (PLA) composites enabled by heat treatment. Int. J. Biol. Macromol. 2019, 129, 448–459. [Google Scholar] [CrossRef]

- Shibata, S.; Cao, Y.; Fukumoto, I. Press forming of short natural fiber-reinforced biodegradable resin: Effects of fiber volume and length on flexural properties. Polym. Test. 2005, 24, 1005–1011. [Google Scholar] [CrossRef]

- Sawpan, M.A.; Pickering, K.L.; Fernyhough, A. Flexural properties of hemp fibre reinforced polylactide and unsaturated polyester composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 519–526. [Google Scholar] [CrossRef]

- Du, S.S.; Li, F.; Xiao, H.M.; Li, Y.Q.; Hu, N.; Fu, S.Y. Tensile and flexural properties of graphene oxide coated-short glass fiber reinforced polyethersulfone composites. Compos. Part B Eng. 2016, 99, 407–415. [Google Scholar] [CrossRef]

- Monti, M.; Scrivani, M.T.; Kociolek, I.; Larsen, Å.G.; Olafsen, K.; Lambertini, V. Enhanced Impact Strength of Recycled PET/Glass Fiber Composites. Polymers 2021, 13, 1471. [Google Scholar] [CrossRef]

- Wambua, P.; Ivens, J.; Verpoest, I. Natural fibres: Can they replace glass in fibre reinforced plastics? Compos. Sci. Technol. 2003, 63, 1259–1264. [Google Scholar] [CrossRef]

- Stiller, H. Material Intensity of Advanced Composite Materials Results of a Study for the Wissenschaftszentrum Nordrhein-Westfalen; Wuppertal Institute: Wuppertal, Germany, 1999; Nr. 90. [Google Scholar]

- Gomez-Campos, A.; Vialle, C.; Rouilly, A.; Sablayrolles, C.; Hamelin, L. Flax fiber for technical textile: A life cycle inventory. J. Clean. Prod. 2021, 281, 125177. [Google Scholar] [CrossRef]

- Quintana, A.; Alba, J.; del Rey, R.; Guillén-Guillamón, I. Comparative Life Cycle Assessment of gypsum plasterboard and a new kind of bio-based epoxy composite containing different natural fibers. J. Clean. Prod. 2018, 185, 408–420. [Google Scholar] [CrossRef]

- PwC Sustainable Performance and Strategy. Life Cycle Assessment of CFGF—Continuous Filament Glass Fibre Products; Technical Report; Glass Fiber Europe: Bruxelles, Belgium, 2016. [Google Scholar]

- van der Werf, H.M.; Turunen, L. The environmental impacts of the production of hemp and flax textile yarn. Ind. Crop. Prod. 2008, 27, 1–10. [Google Scholar] [CrossRef]

- Dissanayake, N.P.; Summerscales, J.; Grove, S.M.; Singh, M.M. Energy Use in the Production of Flax Fiber for the Reinforcement of Composites. J. Nat. Fibers 2009, 6, 331–346. [Google Scholar] [CrossRef]

- Fernando, A.L.; Duarte, M.P.; Vatsanidou, A.; Alexopoulou, E. Environmental aspects of fiber crops cultivation and use. Ind. Crop. Prod. 2015, 68, 105–115. [Google Scholar] [CrossRef]

- Boustead, I. Ecoprofiles of the European Plastics Industry-Liquid Epoxy Resins; Technical Report; Plastics Europe: Brussels, Belgium, 2005. [Google Scholar]

- Le Duigou, A.; Davies, P.; Baley, C. Environmental impact analysis of the production of flax fibres to be used as composite material reinforcement. J. Biobased Mater. Bioenergy 2011, 5, 153–165. [Google Scholar] [CrossRef]

| Designation | ||

|---|---|---|

| WGF-0 | 0 | 28 |

| WGF-5 | 5 | 28 |

| WGF-10 | 10 | 28 |

| WGF-20 | 20 | 28 |

| Flexural Strength | Flexural Modulus | Density | Specific Strength | Specific Modulus | Reinforcement | Ref |

|---|---|---|---|---|---|---|

| (MPa) | (GPa) | (g/cm) | (MPa·cm/g) | (GPa·cm/g) | ||

| 119.8 | 5.1 | 1.16 | 103.27 | 4.39 | glass | [35] |

| 115.3 | 8.1 | 1.26 | 91.5 | 6.42 | flax | [36] |

| 97.5 | 7.3 | 1.27 | 76.77 | 5.47 | flax | [37] |

| 120.8 | 8.3 | 1.31 | 92.4 | 6.33 | glass | [37] |

| 50 | 3.9 | 1.29 | 38.76 | 3.02 | kenaf | [38] |

| 90 | 6.4 | 1.3 | 69.23 | 4.92 | hemp | [39] |

| 41.8 | NA | 1.12 | 37.32 | NA | glass | [40] |

| 92.0 | 5.3 | 1.3 | 73.35 | 4.23 | This work | |

| 112.0 | 5.8 | 1.3 | 87.28 | 4.50 | This work | |

| 119.0 | 5.8 | 1.4 | 87.84 | 4.29 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pisupati, A.; Deléglise Lagardère, M. Mechanical Performance of Flax Fiber Composites with Waste Glass Fibers as a Core Structure. Materials 2022, 15, 9017. https://doi.org/10.3390/ma15249017

Pisupati A, Deléglise Lagardère M. Mechanical Performance of Flax Fiber Composites with Waste Glass Fibers as a Core Structure. Materials. 2022; 15(24):9017. https://doi.org/10.3390/ma15249017

Chicago/Turabian StylePisupati, Anurag, and Myléne Deléglise Lagardère. 2022. "Mechanical Performance of Flax Fiber Composites with Waste Glass Fibers as a Core Structure" Materials 15, no. 24: 9017. https://doi.org/10.3390/ma15249017

APA StylePisupati, A., & Deléglise Lagardère, M. (2022). Mechanical Performance of Flax Fiber Composites with Waste Glass Fibers as a Core Structure. Materials, 15(24), 9017. https://doi.org/10.3390/ma15249017