Stiffness and Frequency Response Characteristics of Glass Fiber Reinforced Plastic Wave Springs with Different Periods and Its Finite Element Analysis

Abstract

:1. Introduction

2. Structure Design and Fabrication of GFRP Wave Springs

2.1. Material

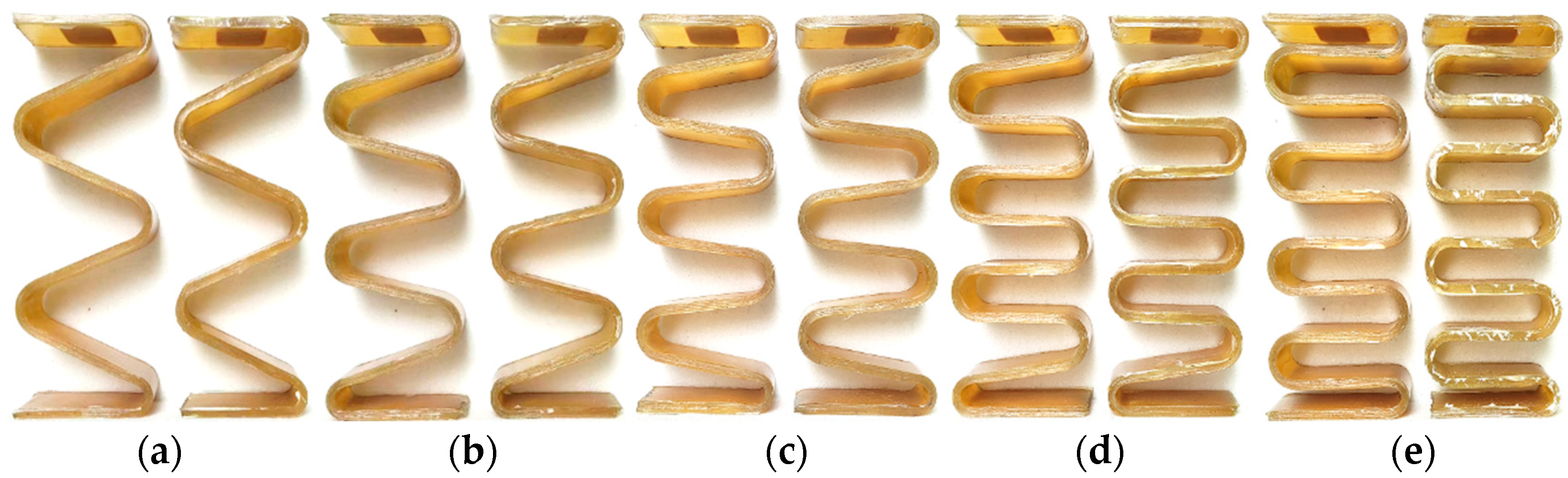

2.2. Structural Design of GFRP Wave Springs

2.3. Fabrication of GFRP Wave Springs

3. Theoretical Calculation of GFRP Wave Spring

4. Experimental and FEA

4.1. FEA of GFRP Wave Springs

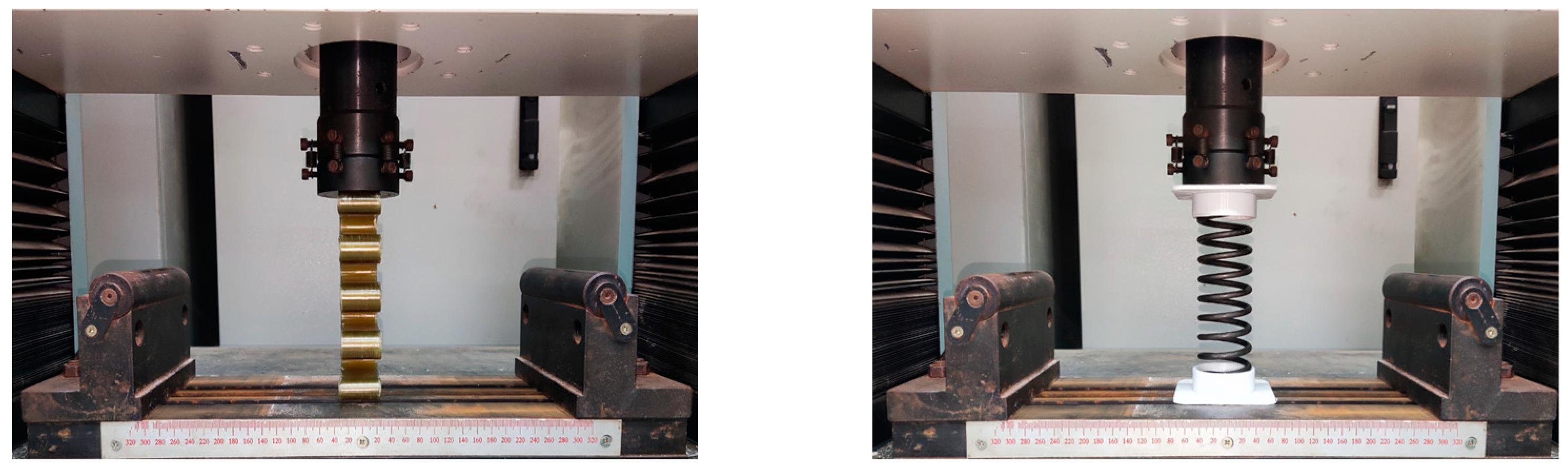

4.2. The Experiment of Stiffness

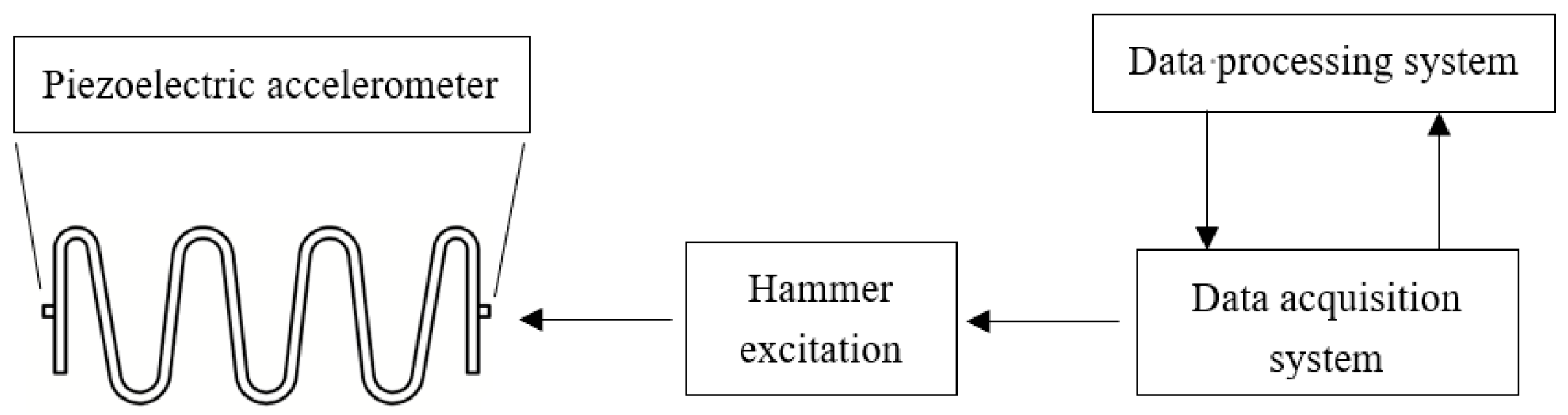

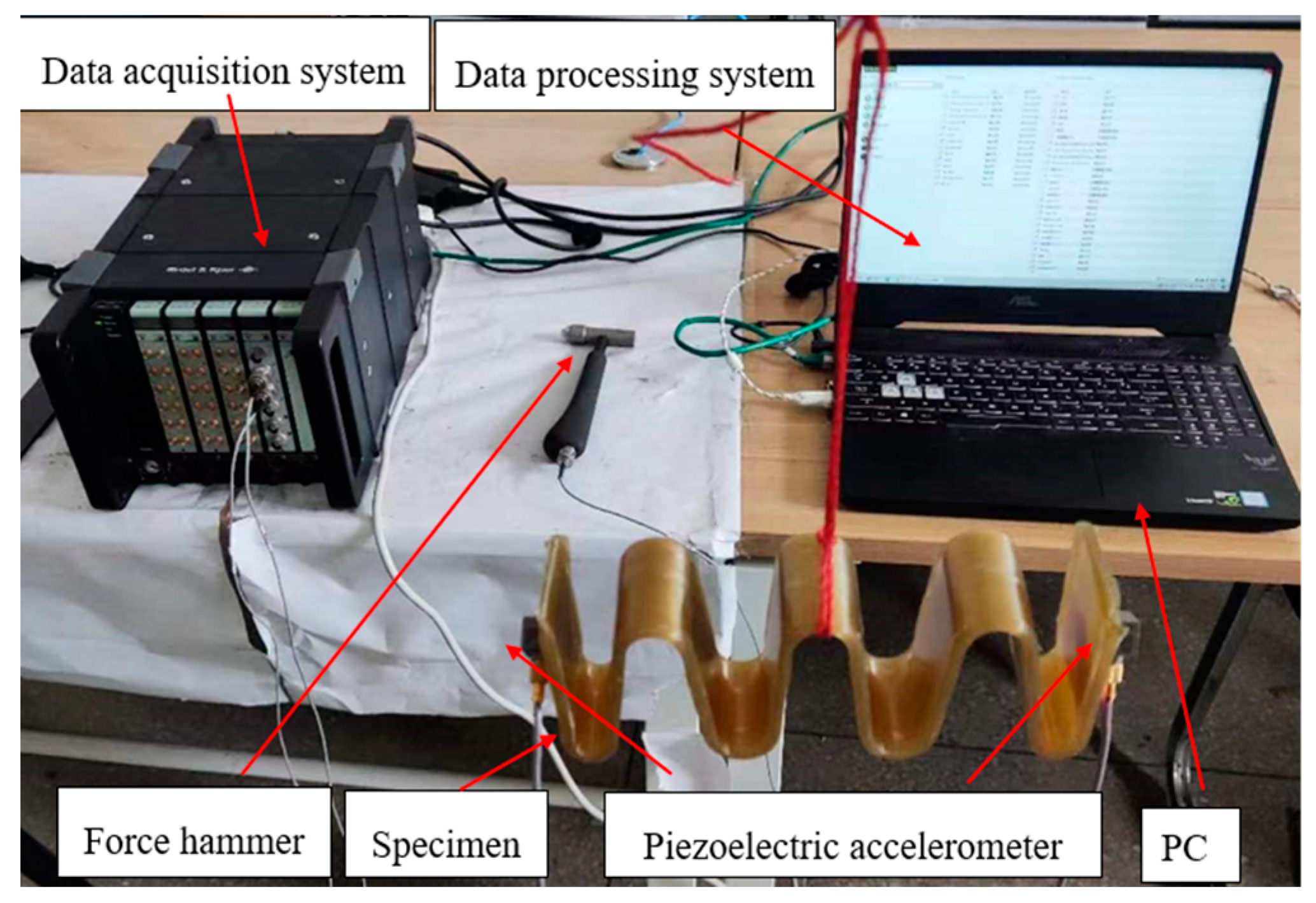

4.3. The Experiment of Frequency Response Characteristics

5. Results and Discussion

5.1. The Result of Stiffness

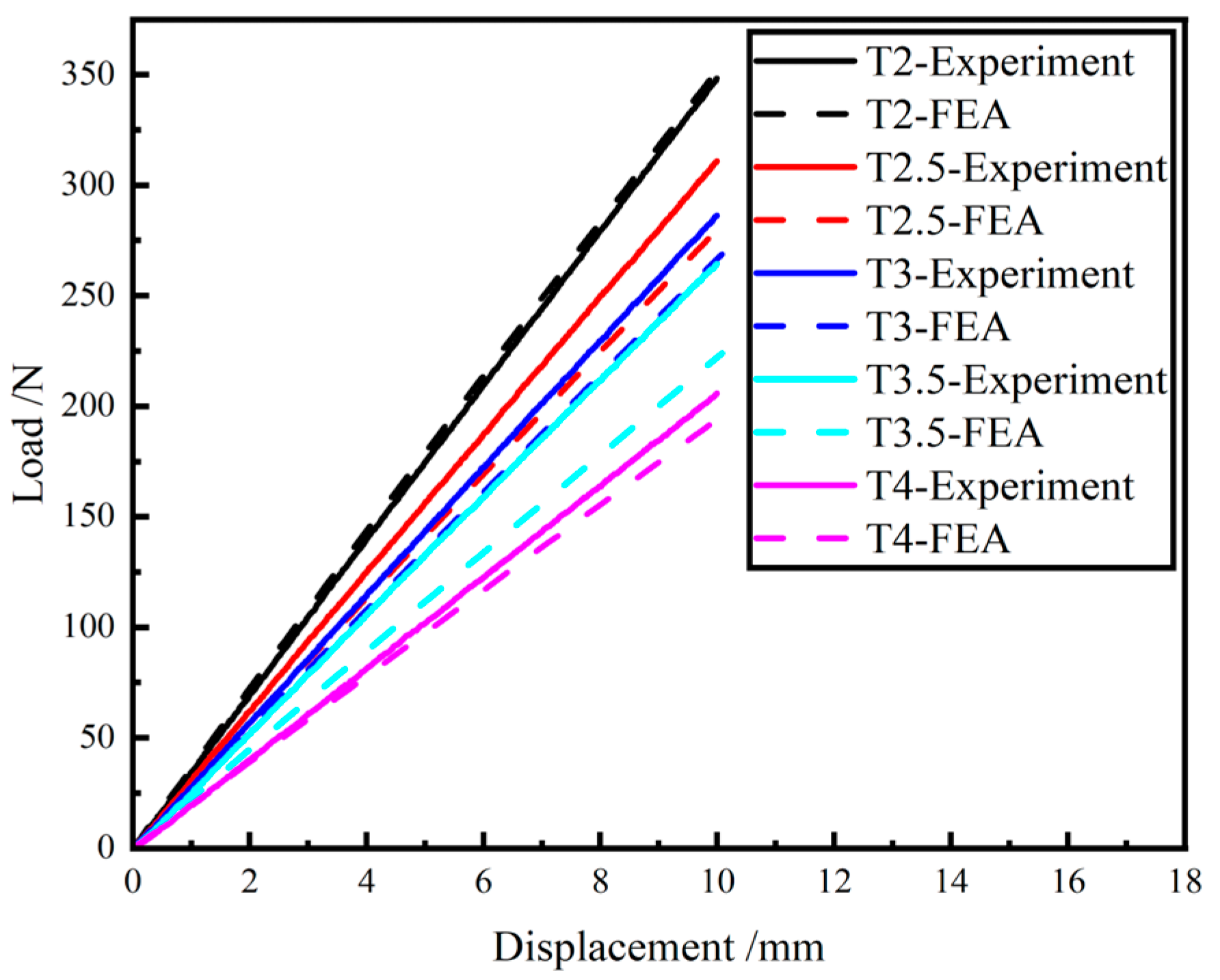

5.1.1. FEA and Experimental Results on the Stiffness of the GFRP Springs

5.1.2. Comparison of Stiffness Results of GFRP Wave Spring and Metal Helical Spring

5.2. Results of Frequency Response Characteristics

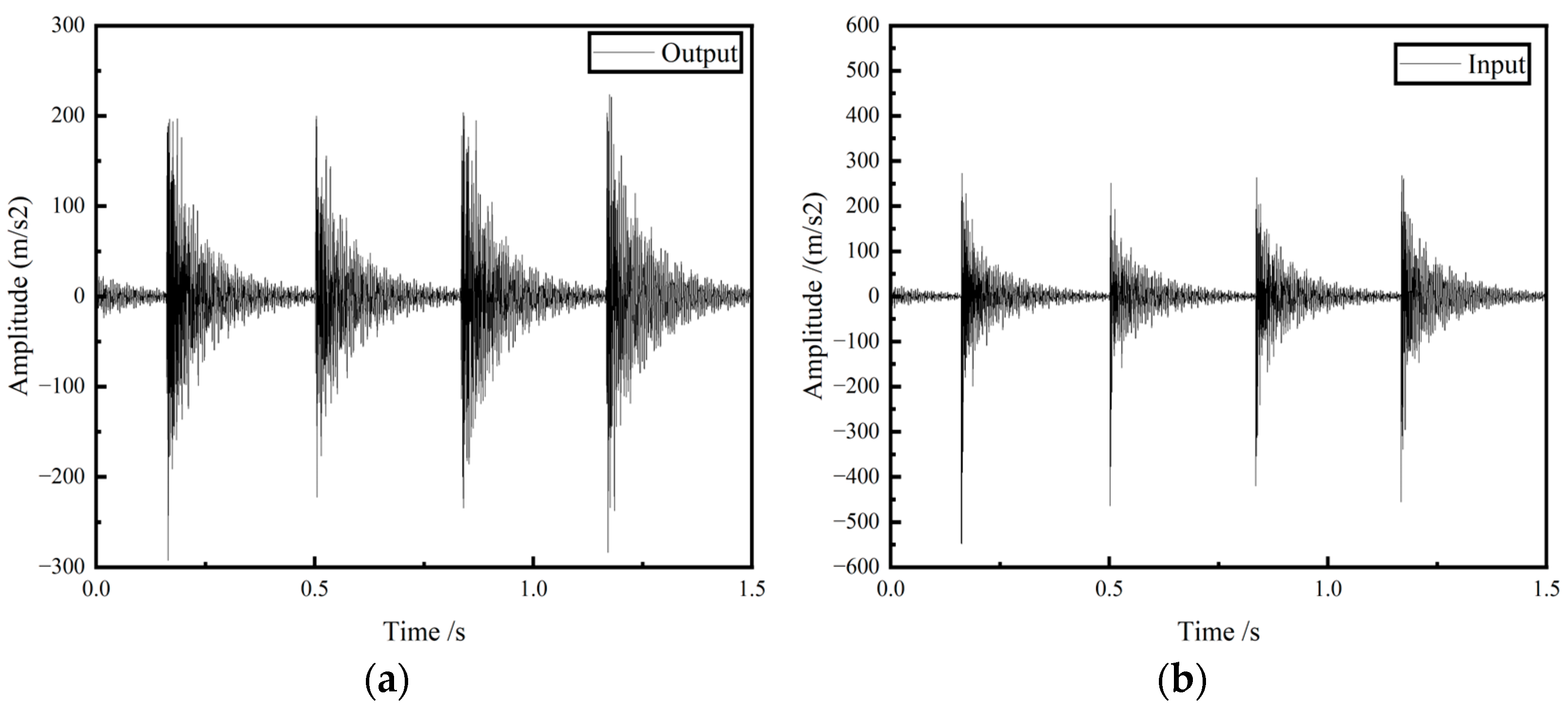

5.2.1. Results of Frequency Response Characteristics of GFRP Wave Springs

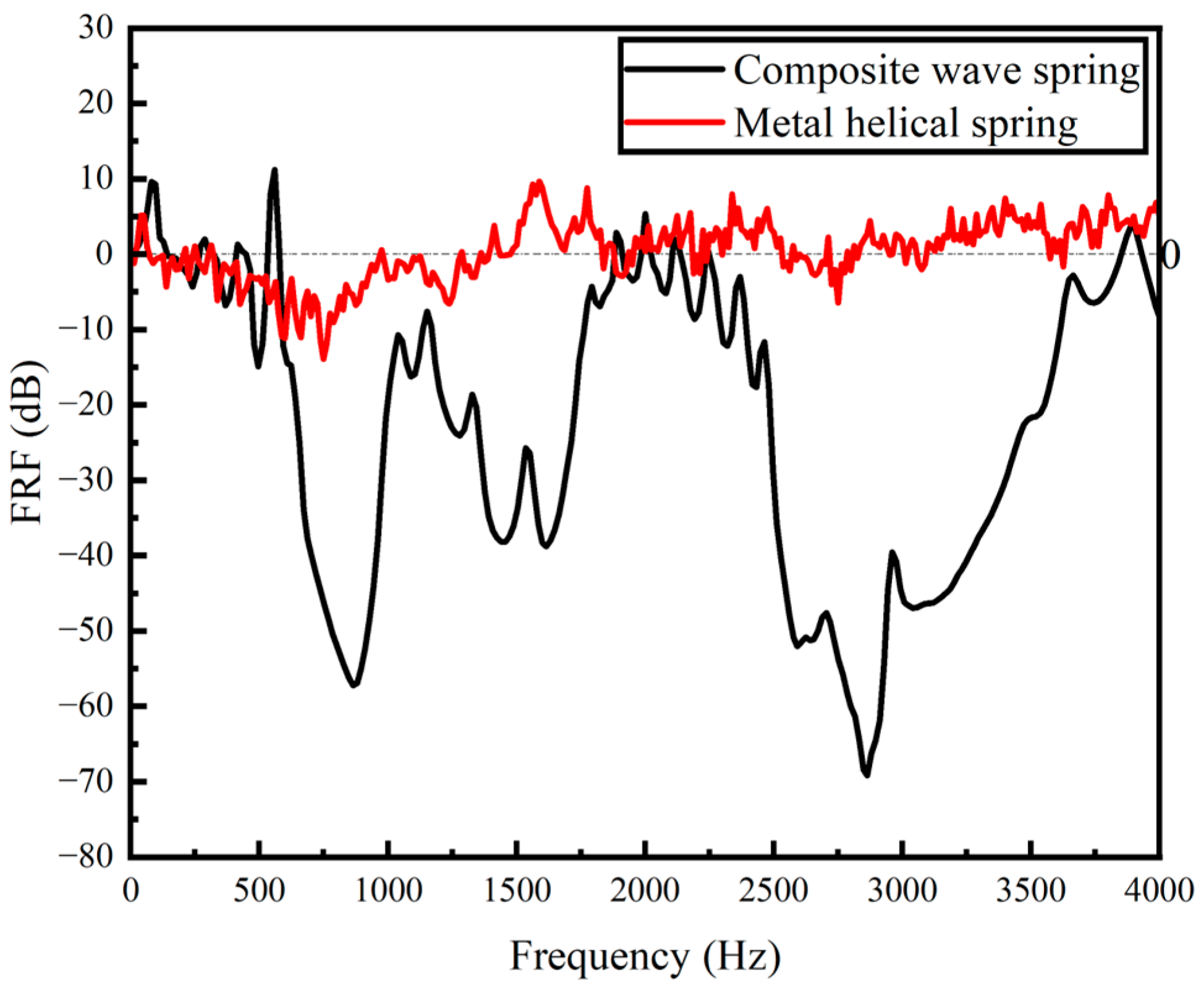

5.2.2. Comparison of Frequency Response Characteristics Results of GFRP Wave Spring and Metal Coil Spring

6. Conclusions

- GFRP wave springs which are prepared by using the autoclave are designed.

- The trend of the simulation and experiment results are consistent, and the stiffness of the GFRP wave spring gradually decreased as the period increased, and the maximum error between the simulation and experiment stiffness is 15.35%, and the minimum error is 1.8%.

- As the period of the GFRP wave springs increases, the vibration isolation interval and vibration attenuation become larger, with a maximum attenuation of 69.17 dB.

- The stiffness of the GFRP wave spring is increased by 90.30% and the weight is reduced by 26.82% compared to the metal helical spring. The vibration isolation interval and vibration attenuation of the GFRP wave spring are higher than the metal helical spring.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ekanthappa, J.; Basavarajappa, S.; Sogalad, I. Investigation on design and fabrication of continuous fiber reinforced composite helical spring for automobile suspension. In Proceedings of the National Conference on Challenges in Research & Technology in the Coming Decades, CRT, Karnataka, India, 27–28 September 2013. [Google Scholar]

- Ke, J.; Wu, Z.-y.; Liu, Y.-s.; Xiang, Z.; Hu, X.-d. Design method, performance investigation and manufacturing process of composite helical springs: A review. Compos. Struct. 2020, 252, 112747. [Google Scholar] [CrossRef]

- Nassiraei, H.; Rezadoost, P. Local joint flexibility of tubular T/Y-joints retrofitted with GFRP under in-plane bending moment. Mar. Struct. 2021, 77, 102936. [Google Scholar] [CrossRef]

- Stephen, C.; Selvam, R.; Suranjan, S. A comparative study of steel and composite helical springs using finite element analysis. In Proceedings of the 2019 Advances in Science and Engineering Technology International Conferences, ASET 2019, Dubai, United Arab Emirates, March 26–April 10 2019. [Google Scholar]

- Budan, D.A.; Manjunatha, T.S. Investigation on the feasibility of composite coil spring for automotive applications. Int. J. Mech. Aerosp. Ind. Mechatron. Manuf. Eng. 2010, 4, 1035–1039. [Google Scholar]

- Chiu, C.-H.; Hwan, C.-L.; Tsai, H.-S.; Lee, W.-P. An experimental investigation into the mechanical behaviors of helical composite springs. Compos. Struct. 2007, 77, 331–340. [Google Scholar] [CrossRef]

- Sain, T.; Meaud, J.; Hulbert, G.; Arruda, E.M.; Waas, A.M. Simultaneously high stiffness and damping in a class of wavy layered composites. Compos. Struct. 2013, 101, 104–110. [Google Scholar] [CrossRef]

- Andrew, J.J.; Srinivasan, S.M.; Arockiarajan, A.; Dhakal, H.N. Parameters influencing the impact response of fiber-reinforced polymer matrix composite materials: A critical review. Compos. Struct. 2019, 224, 111007. [Google Scholar] [CrossRef]

- Khoddam, S.; Estrin, Y.; Kim, H.; Bouaziz, O. Torsional and compressive behaviours of a hybrid material: Spiral fibre reinforced metal matrix composite. Mater. Des. 2015, 85, 404–411. [Google Scholar] [CrossRef]

- Aminzadeh, A.; Parvizi, A.; Moradi, M. Multi-objective topology optimization of deep drawing dissimilar tailor laser welded blanks; experimental and finite element investigation. Opt. Laser Technol. 2019, 125, 106029. [Google Scholar] [CrossRef]

- Aminzadeh, A.; Karganroudi, S.S.; Barka, N.; El Ouafi, A. A real-time 3D scanning of aluminum 5052-H32 laser welded blanks; geometrical and welding characterization. Mater. Lett. 2021, 296, 129883. [Google Scholar] [CrossRef]

- Alm, F.F. Dynamic analysis of composite coil springs of arbitrary shape(Article). Compos. Part B Eng. 2009, 40, 741–757. [Google Scholar]

- Yildirim, V. Free vibration of uniaxial composite cylindrical helical springs with circular section. J. Sound Vib. 2001, 239, 321–333. [Google Scholar] [CrossRef]

- Yıldırım, V. Free Vibration Characteristics of Composite Barrel and Hyperboloidal Coil Springs. Mech. Compos. Mater. Struct. 2001, 8, 205–217. [Google Scholar] [CrossRef]

- Hao, Y. Parametric effect on natural frequencies of unidirectional composite non- cylindrical helical springs with rectangular cross-section. In Proceedings of the 46th US Rock Mechanics/Geomechanics Symposium 2012, Chicago, IL, USA, 15 December 2012. [Google Scholar]

- Hao, Y.; Yu, A. Free vibration of unidirectional composite cylindrical helical springs with rectangular cross-section. J. Tongji Univ. 2012, 40, 1870–1875. [Google Scholar]

- Hao, Y.; Yu, A.-M. Free vibration of laminated composite non-cylindrical helical springs with rectangular cross-section. J. Vib. Eng. 2013, 26, 335–342. [Google Scholar]

- Yu, A.; Hao, Y. Warping effect in free vibration analysis of unidirectional composite non-cylindrical helical springs (Article). Meccanica 2013, 48, 2453–2465. [Google Scholar] [CrossRef]

- Kacar, I.; Yildirim, V. Free vibration/buckling analyses of noncylindrical initially compressed helical composite springs (Article). Mech. Based Des. Struct. Mach. 2016, 44, 340–353. [Google Scholar] [CrossRef]

- Kacar, İ.; Yildirim, V. Natural frequencies of composite cylindrical helical springs under compression. Vib. Probl. ICOVP 2011 2011, 139, 119–124. [Google Scholar]

- Ayadi, S.; Taïeb, E.H. Natural frequencies of composite cylindrical helical Springs. Appl. Mech. Behav. Mater. Eng. Syst. 2017, 13, 227–238. [Google Scholar]

- Gupta, N.; Bagha, A.K.; Bahl, S. State space method to predict the modal model of a five degree of freedom spring mass vibratory system. Lect. Notes Mech. Eng. 2021, 52, 517–524. [Google Scholar]

- Boisse, P.; Akkerman, R.; Carlone, P.; Kärger, L.; Lomov, S.V.; Sherwood, J.A. Advances in composite forming through 25 years of ESAFORM. Int. J. Mater. Form. 2022, 15, 1–30. [Google Scholar] [CrossRef]

- Chen, L.; Xing, W.; Wu, L.; Chong, J.; Lei, T.; Jiang, Q.; Tang, Y. Understanding multiple parameters affecting static and dynamic performances of composite helical springs. J. Mater. Res. Technol. 2022, 20, 532–550. [Google Scholar] [CrossRef]

- Sahu, D.K.; Dandsena, J.; Mahapatra, T.R.; Mishra, D. Design and Characterization of Progressive Coil Spring for Suspension Systems. J. Inst. Eng. (India) Ser. C 2022, 103, 705–715. [Google Scholar] [CrossRef]

- Öztoprak, N.; Gunes, M.D.; Tanoglu, M.; Aktas, E.; Eğilmez, O.; Senocak, C.; Kulac, G. Developing polymer composite-based leaf spring systems for automotive industry. Sci. Eng. Compos. Mater. 2018, 25, 1167–1176. [Google Scholar] [CrossRef]

- Li, H.; Lin, Y.; Wang, L.; Xu, Q.; Ke, Y. A manta-ray-inspired bionic curing mold for autoclave process of composite manufacturing. J. Reinf. Plast. Compos. 2022, 1. [Google Scholar] [CrossRef]

- Tu, R.; Liu, T.; Steinke, K.; Nasser, J.; Sodano, H.A. Laser induced graphene-based out-of-autoclave curing of fiberglass reinforced polymer matrix composites. Compos. Sci. Technol. 2022, 226, 109529. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, J.; Pan, J.; Yan, Z.; Tan, J. A New Nonlinear Spatial Compliance Model Method for Flexure Leaf Springs with Large Width-to-Length Ratio under Large Deformation. Micromachines 2022, 13, 1090. [Google Scholar] [CrossRef]

- Yildirim, M.C.; Sendur, P.; Kansizoglu, A.T.; Uras, U.; Bilgin, O.; Emre, S.; Yapici, G.G.; Arik, M.; Ugurlu, B. Design and development of a durable series elastic actuator with an optimized spring topology. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 7848–7858. [Google Scholar] [CrossRef]

- Xie, L.; Du, R. On spiral spring in elastic deformation materials, mechanical engineering and manufacture, PTS 1-3. Appl. Mech. Mater. 2013, 268–270, 1105. [Google Scholar]

- Rees, D.W.A. Energy methods. In The Mechanics of Engineering Structures; CRC Press: Boca Raton, FL, USA, 2015; pp. 373–432. [Google Scholar]

- Roesler, J. Mechanical Behaviour of Engineering Materials: Metals, Ceramics, Polymers, and Composites; Springer: Berlin, Germany; New York, NY, USA, 2011. [Google Scholar]

- Jun, K.; Jingen, X.; Zhenyu, W.; Zhiping, Y. A theoretical model used for stiffness matching design and structure optimization of composite helical spring with nonlinear stiffness. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 1–17. [Google Scholar] [CrossRef]

- Zhang, J.; Xia, X.; Wen, X.; Zang, M.; Dou, Y. Investigations on the Band-Gap Characteristics of Variable Cross-Section Periodic Structure Support Made of Acrylonitrile-Butadiene-Styrene. Materials 2022, 15, 4308. [Google Scholar] [CrossRef]

- Zhang, J.; Rao, J.; Ma, L.; Wen, X. Investigation of the Damping Capacity of CFRP Raft Frames. Materials 2022, 15, 653. [Google Scholar] [CrossRef]

- Wei, Z.D.; Li, B.R.; Du, J.M.; Yang, G. Theoretical and Experimental Investigation of Flexural Vibration Transfer Properties of High-Pressure Periodic Pipe. Chin. Phys. Lett. 2016, 33, 72–75. [Google Scholar] [CrossRef]

- Ma, L.; He, J.; Gu, Y.; Zhang, Z.; Yu, Z.; Zhou, A.; Tam, L.-H.; Wu, C. Structure Design of GFRP Composite Leaf Spring: An Experimental and Finite Element Analysis. Polymers 2021, 13, 1193. [Google Scholar] [CrossRef]

- Jolaiy, S.; Yousefi, A.; Mashhadi, M.M.; Amoozgar, M.; Bodaghi, M. Dynamic behaviors of composite leaf springs with viscoelastic cores. Mech. Based Des. Struct. Mach. 2021, 1–23. [Google Scholar] [CrossRef]

| Engineering Constants | Values | Engineering Constants | Values |

|---|---|---|---|

| E1(GPa) | 30 | Xt(MPa) | 850 |

| E2(GPa) | 8 | Yt(MPa) | 35 |

| E3(GPa) | 8 | Zt(MPa) | 35 |

| ν12(GPa) | 0.3 | Xc(MPa) | 500 |

| ν13(GPa) | 0.3 | Yc(MPa) | 120 |

| ν23(GPa) | 0.4 | Zc(MPa) | 120 |

| G12(GPa) | 4.5 | S12(MPa) | 104 |

| G13(GPa) | 4.5 | S13(MPa) | 104 |

| G23(GPa) | 3.8 | S23(MPa) | 70 |

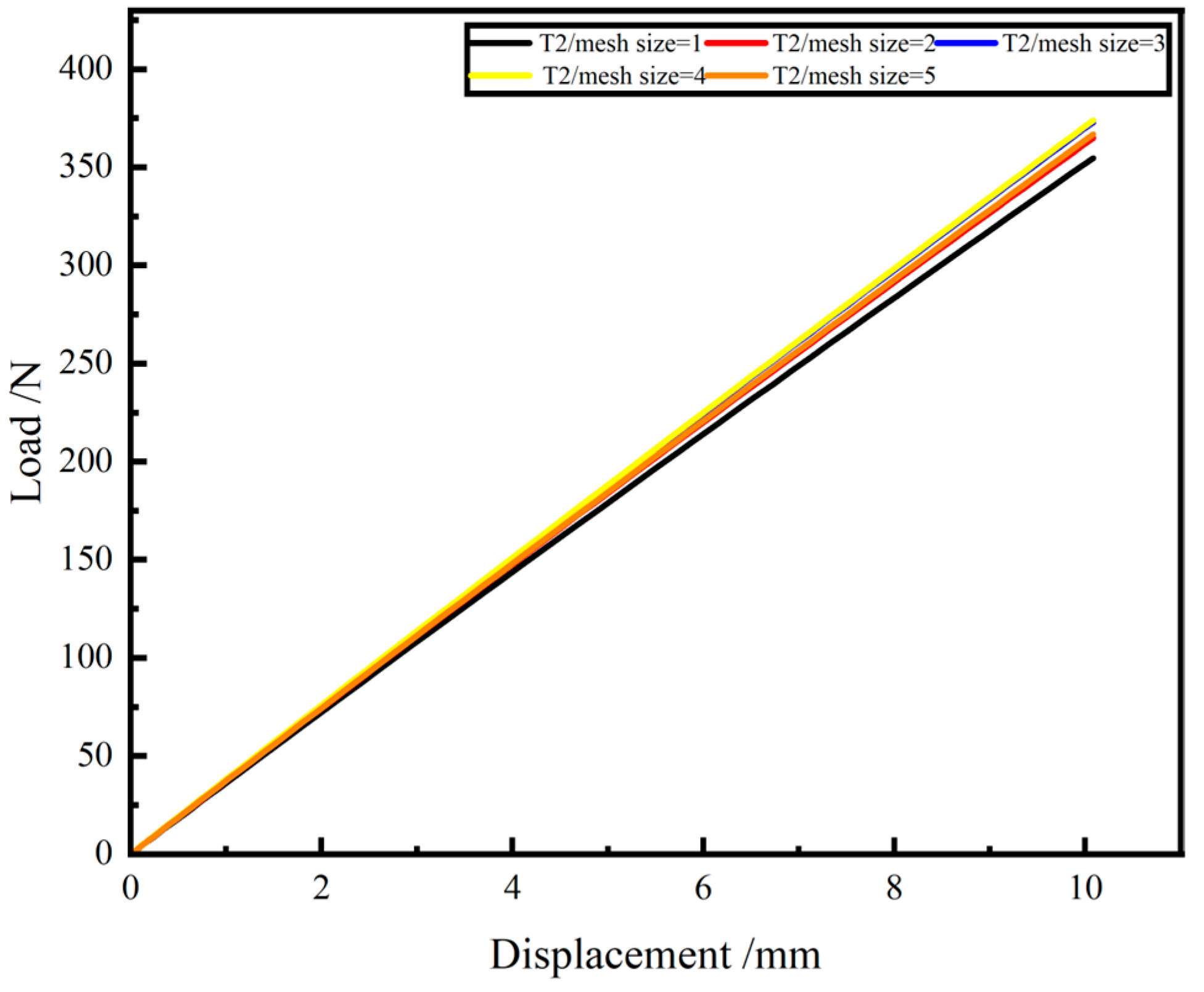

| Mesh Size/mm | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Stiffness simulation N/mm | 35.47 | 36.49 | 37.30 | 37.38 | 36.67 |

| %error simulation | / | 2.88% | 5.16% | 5.38% | 3.38% |

| Equipment | Model | Parameters |

|---|---|---|

| Piezoelectric accelerometer | 4507Bx | 9.688 mV/(m/s2) |

| Force hammer (Force Sensor) | 8206-002 | 2.27 mV/N |

| Data acquisition system | 3660-C-LAN-XI | - |

| Analyzing software | BK Connect | - |

| Type of Springs | T = 2 | T = 2.5 | T = 3 | T = 3.5 | T = 4 |

|---|---|---|---|---|---|

| Stiffness experiment-A N/mm | 35.25 | 31.33 | 27.60 | 25.97 | 21.41 |

| Stiffness experiment-B N/mm | 34.43 | 30.85 | 29.66 | 27.11 | 19.77 |

| Average value N/mm | 34.84 | 31.09 | 28.63 | 26.45 | 20.59 |

| Stiffness simulation N/mm | 35.47 | 28.21 | 26.88 | 22.39 | 19.57 |

| %error simulation | 1.80% | 9.26% | 6.11% | 15.35% | 4.95% |

| Periods | Vibration Attenuation Interval/Hz | Min of FRF/dB |

|---|---|---|

| T = 2 | 496–2048 | −37.39 |

| T = 2.5 | 512–2064 2336–2576 2752–3264 | −51.88 −16.32 −5.7 |

| T = 3 | 560–2192 2352–3024 3072–3632 | −59.85 −54.15 −13.97 |

| T = 3.5 | 576–2240 2256–3792 | −59.88 −61.26 |

| T = 4 | 576–1920 2256–3681 | −57.24 −69.16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, X.; Fu, K.; Dou, Y.; Xia, X.; Zhang, J. Stiffness and Frequency Response Characteristics of Glass Fiber Reinforced Plastic Wave Springs with Different Periods and Its Finite Element Analysis. Materials 2022, 15, 9045. https://doi.org/10.3390/ma15249045

Wen X, Fu K, Dou Y, Xia X, Zhang J. Stiffness and Frequency Response Characteristics of Glass Fiber Reinforced Plastic Wave Springs with Different Periods and Its Finite Element Analysis. Materials. 2022; 15(24):9045. https://doi.org/10.3390/ma15249045

Chicago/Turabian StyleWen, Xianglong, Kai Fu, Yukuan Dou, Xu Xia, and Jinguang Zhang. 2022. "Stiffness and Frequency Response Characteristics of Glass Fiber Reinforced Plastic Wave Springs with Different Periods and Its Finite Element Analysis" Materials 15, no. 24: 9045. https://doi.org/10.3390/ma15249045