The Durability of Recycled Fine Aggregate Concrete: A Review

Abstract

:1. Introduction

2. Impermeability

3. Drying Shrinkage

4. Carbonation Resistance

5. Chloride Penetration Resistance

6. Acid Resistance

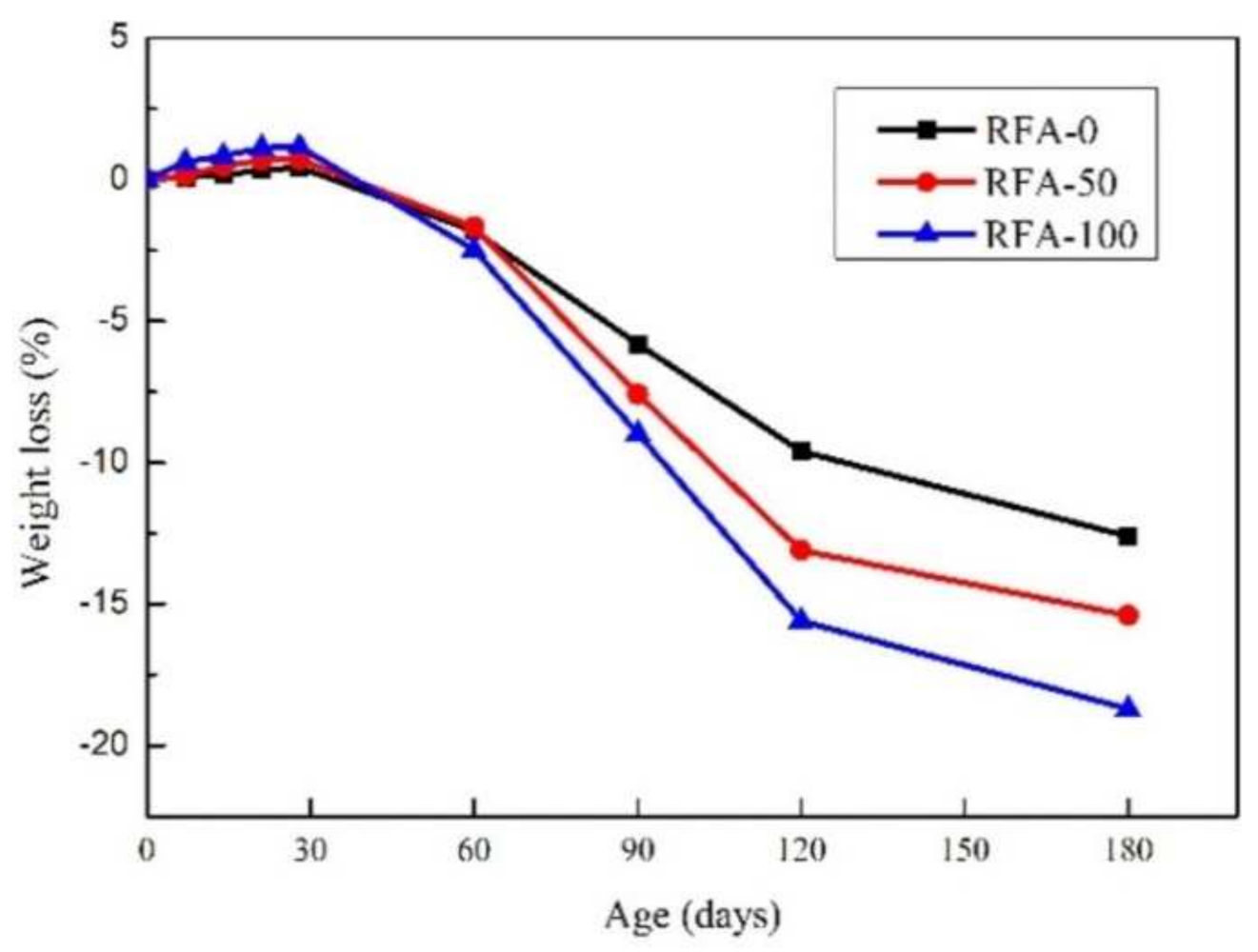

7. Resistance to Freeze–Thaw Cycles

8. Conclusions

- (1)

- The durability of RFAc is closely related to the quality of the RFA, which is mainly influenced by the content of the old mortar, specifically, the higher the content of the old mortar, the higher the porosity and water absorption. The average water absorption of natural sand is about 1.1%, while the average water absorption of RFA can reach about 8.4%.

- (2)

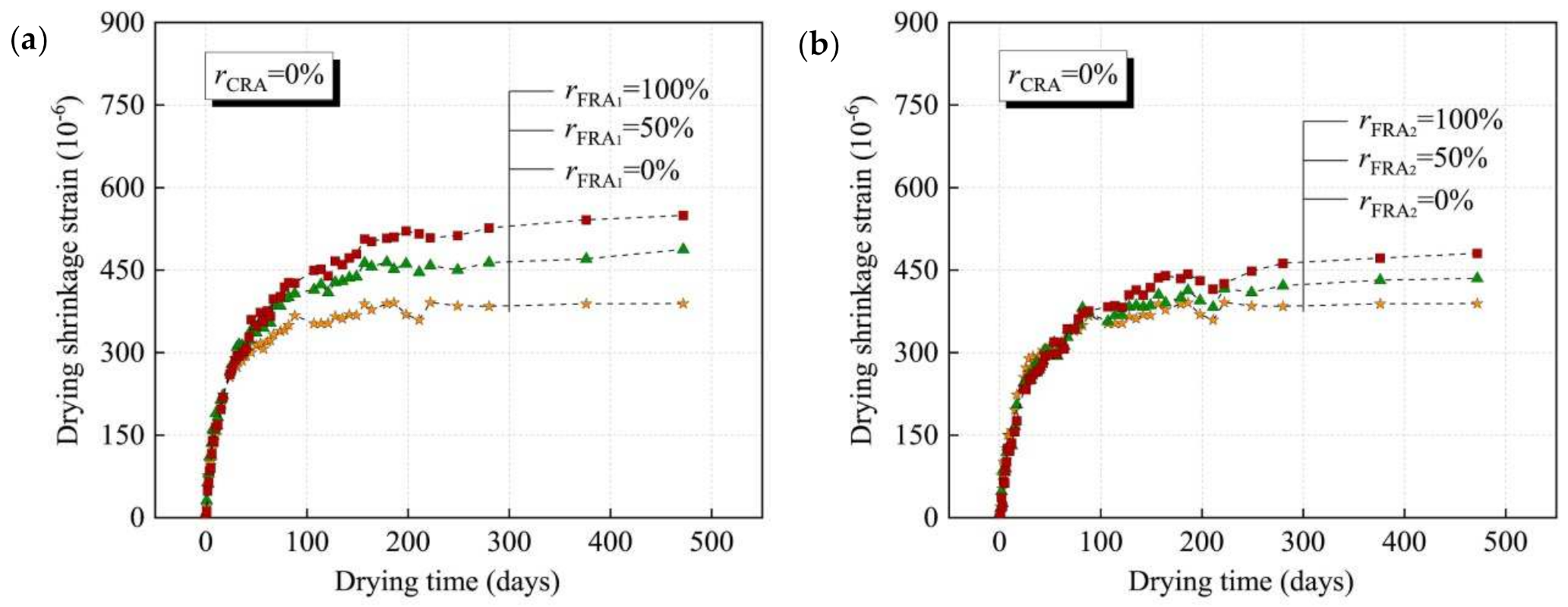

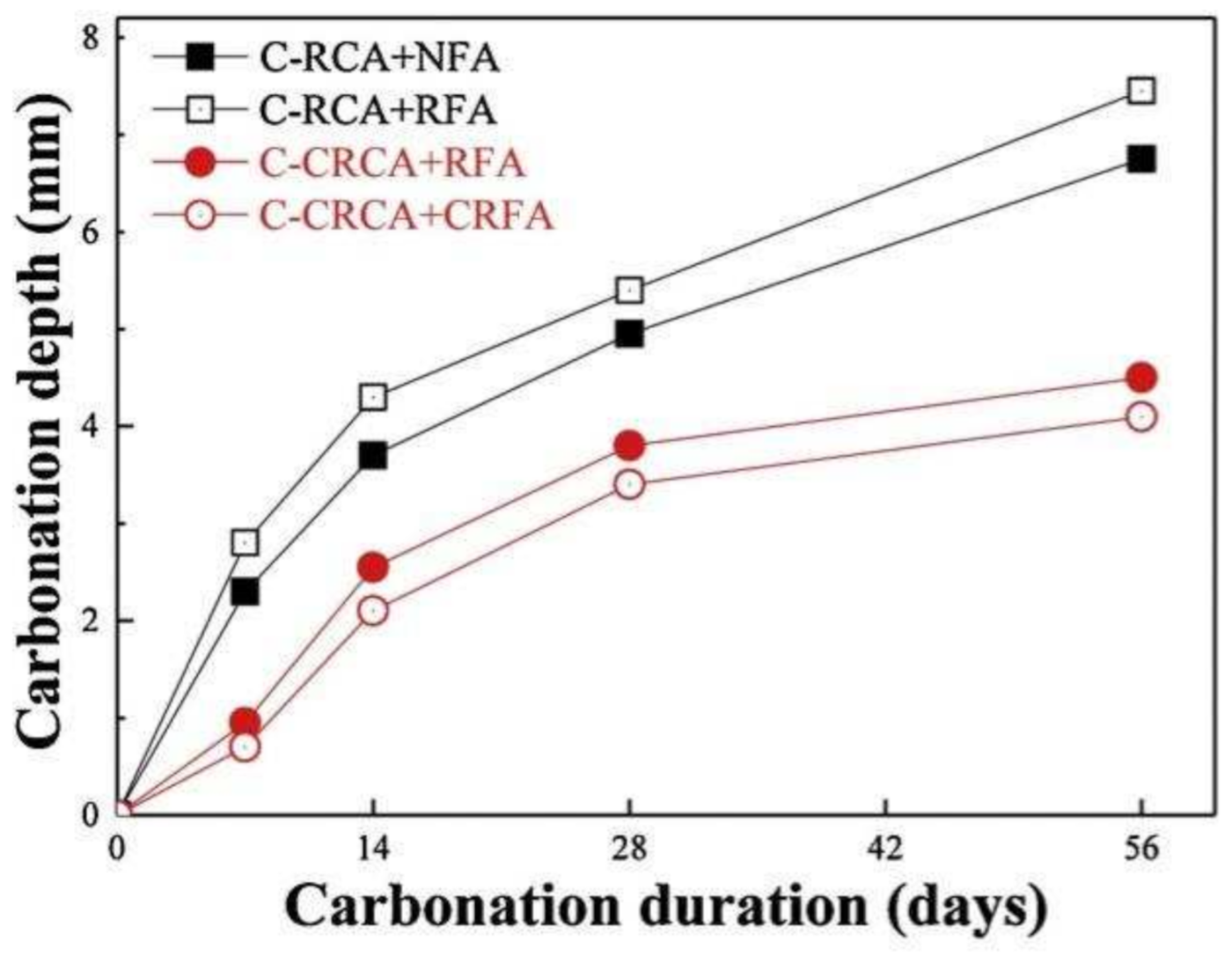

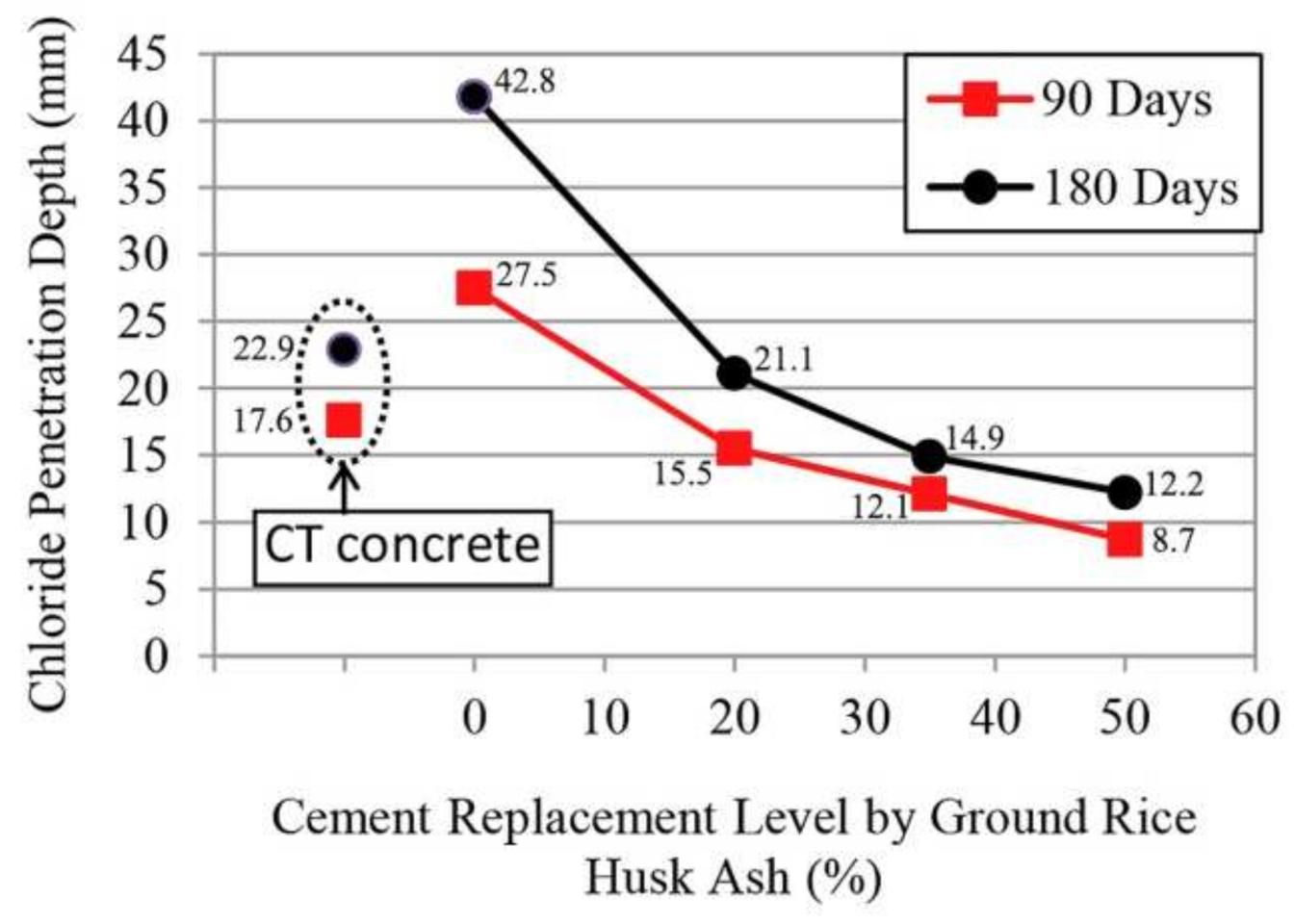

- The impermeability, drying shrinkage, resistance to chloride ion penetration, carbonation, acid resistance, and freeze–thaw cycle resistance of RFAc decrease as the RFA replacement rate improves. For example, the drying shrinkage value at a 100% RFA replacement rate is twice that of normal concrete, and the depth of carbonation increases by approximately 110%.

- (3)

- The impermeability, carbonation resistance, and freeze–thaw cycle resistance of RFAc decrease as the effective water–cement ratio increases. For example, when the water-to-ash ratio is reduced from 0.7 to 0.5, the mass loss of RFAc under freeze–thaw cycles is reduced. Meanwhile, the drying shrinkage is less affected by the change in the water–cement ratio.

- (4)

- RFA with appropriate moisture benefits the permeation resistance and freeze–thaw cycle resistance of RFAc.

- (5)

- The treatment of RFA with CO2 has a positive effect on the anticarbonation performance of RFAc. However, it is unfavorable to the resistance to chloride ion penetration.

- (6)

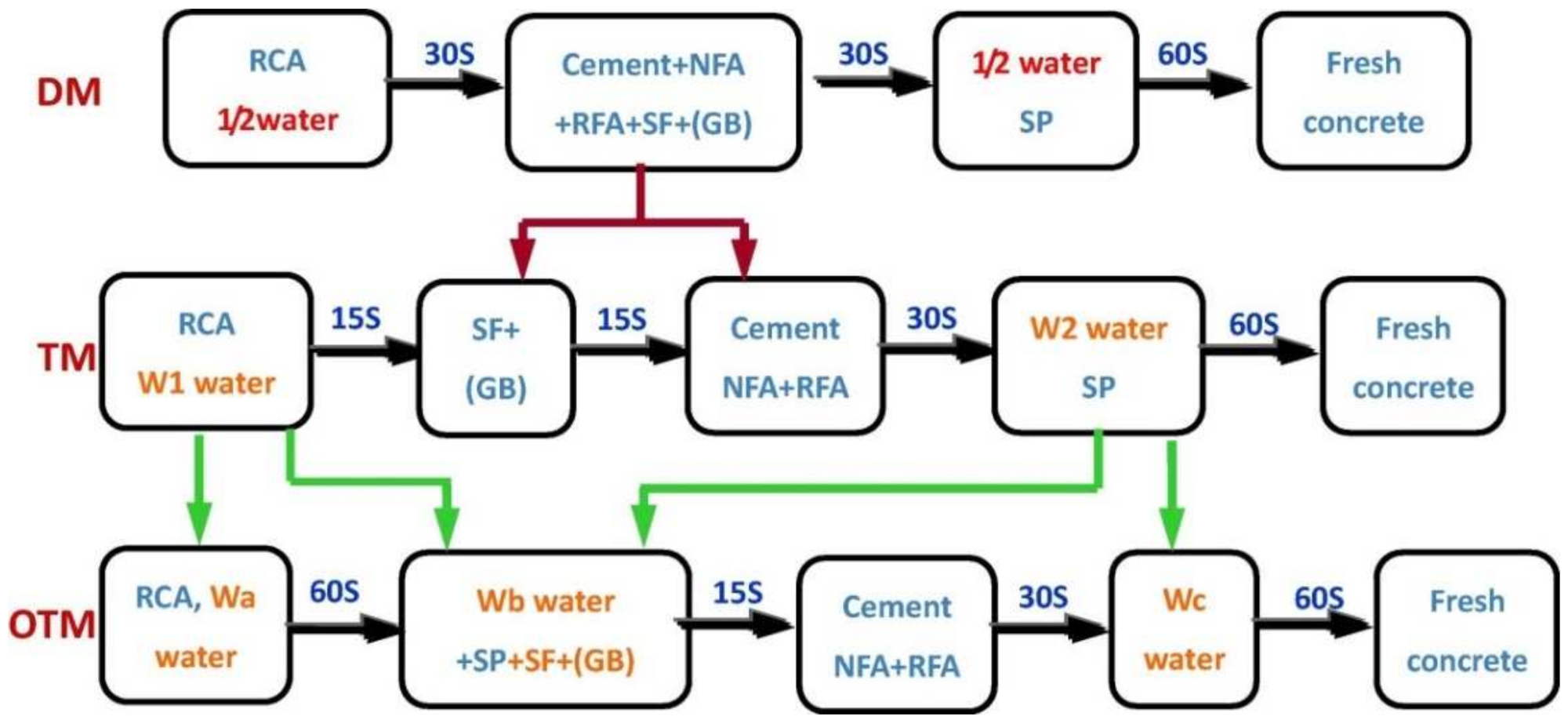

- Advanced mixing methods focused on improving the ITZ have been reported, and they can partially compensate for the poor performance of recycled concrete fine aggregates. Thus, the relative durability of RFAc can be optimized.

- (7)

- Existing studies report an optimized triple mixing method, where the SP is added together with additional gelling material. This addition promotes the dispersion of that gelling material, which, in turn, leads to a higher content of additional gel material in the ITZ, a better volcanic ash effect at a later stage, and a reduction in the porosity of the RFAc, thus allowing for an impermeability rating of 8 for the RAC using this method. In addition, because a water-reducing agent is added early on, together with the additional gelling material in this method, a thin layer of additional gelling material can be formed, even when the mixture is insufficient.

9. Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hu, M.; Yang, M. Analysis of China’s construction waste resourcing policy based on policy tools. Constr. Econ. 2019, 40, 22–26. [Google Scholar]

- Chen, X.Y.; Cheng, Z.Y.; Zhan, X.; Wu, Q. Experimental study and numerical simulation of mechanical properties of recycled concrete with nano-SiO2-rubber powder. Mater. Guide 2021, 35, 23235–23240, 23245. [Google Scholar]

- Ma, M.; Tam, V.W.; Le, K.N.; Li, W. Challenges in current construction and demolition waste recycling: A China study. Waste Manag. 2020, 118, 610–625. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Wang, Z.; Gao, S. A study on foreign legislation on resource utilization of construction waste. Law Soc. 2018, 26, 206–208. [Google Scholar]

- Mohammed, M.S.; ElKady, H.; Abdel-Gawwad, H.A. Utilization of construction and demolition waste and synthetic aggregates. J. Build. Eng. 2021, 43, 103207. [Google Scholar] [CrossRef]

- Pu, Y.; Li, L.; Wang, Q.; Shi, X.; Luan, C.; Zhang, G.; Fu, L.; Abomohra, A.E.F. Accelerated carbonation technology for enhanced treatment of recycled concrete aggregates: A state-of-the-art review. Constr. Build. Mater. 2021, 282, 122671. [Google Scholar] [CrossRef]

- Mariaková, D.; Anna Mocová, K.; Fořtová, K.; Ryparová, P.; Pešta, J.; Pavlů, T. Ecotoxicity and Essential Properties of Fine-Recycled Aggregate. Materials 2021, 14, 463. [Google Scholar] [CrossRef]

- Feng, C.; Cui, B.; Ge, H.; Huang, Y.; Zhang, W.; Zhu, J. Reinforcement of recycled aggregate by Microbial-Induced mineralization and deposition of calcium carbonate—Influencing factors, mechanism and effect of reinforcement. Crystals 2021, 11, 887. [Google Scholar] [CrossRef]

- Fang, X.; Zhan, B.; Poon, C.S. Enhancement of recycled aggregates and concrete by combined treatment of spraying Ca2+ rich wastewater and flow-through carbonation. Constr. Build. Mater. 2021, 277, 122202. [Google Scholar] [CrossRef]

- Gebremariam, A.T.; Vahidi, A.; Di Maio, F.; Moreno-Juez, J.; Vegas-Ramiro, I.; Łagosz, A.; Mróz, R.; Rem, P. Comprehensive study on the most sustainable concrete design made of recycled concrete, glass and mineral wool from C&D wastes. Constr. Build. Mater. 2021, 273, 121697. [Google Scholar]

- Farzampour, A. Temperature and humidity effects on behavior of grouts. Adv. Concr. Constr. 2017, 5, 659. [Google Scholar]

- Chalangaran, N.; Farzampour, A.; Paslar, N. Nano silica and metakaolin effects on the behavior of concrete containing rubber crumbs. CivilEng 2020, 1, 17. [Google Scholar] [CrossRef]

- Mansouri, I.; Shahheidari, F.S.; Hashemi, S.M.A.; Farzampour, A. Investigation of steel fiber effects on concrete abrasion resistance. Adv. Concr. Constr. 2020, 9, 367–374. [Google Scholar]

- Pacheco, J.; De Brito, J. Recycled Aggregates Produced from Construction and Demolition Waste for Structural Concrete: Constituents, Properties and Production. Materials 2021, 14, 5748. [Google Scholar] [CrossRef]

- Reis, G.S.D.; Quattrone, M.; Ambrós, W.M.; Grigore Cazacliu, B.; Hoffmann Sampaio, C. Current Applications of Recycled Aggregates from Construction and Demolition: A Review. Materials 2021, 14, 1700. [Google Scholar] [CrossRef]

- Zhu, Z.; Gu, S.E.; Tang, Z.; Song, L. Experimental Study on Recycling of Waste Concrete Based on Geopolymer Technology. In The International Congress on Environmental Geotechnics; Springer: Singapore, 2018; pp. 336–343. [Google Scholar]

- van Deventer, J.S.; Provis, J.L.; Duxson, P.; Brice, D.G. Chemical research and climate change as drivers in the commercial adoption of alkali activated materials. Waste Biomass Valorization 2010, 1, 145–155. [Google Scholar] [CrossRef]

- Davidovits, J. Why alkali-activated materials (AAM) are not geopolymers. Publ. Tech. Pap. 2018. [Google Scholar] [CrossRef]

- Shi, C.; Cao, Z.; Xie, Z. Research progress on the mechanical properties of recycled concrete. Mater. Guide 2016, 30, 96–103, 126. [Google Scholar]

- Chindaprasirt, P.; Rukzon, S. Strength and chloride resistance of the blended Portland cement mortar containing rice husk ash and ground river sand. Mater. Struct. 2015, 48, 3771–3777. [Google Scholar] [CrossRef]

- Guo, H.; Shi, C.; Guan, X.; Zhu, J.; Ding, Y.; Ling, T.C.; Zhang, H.; Wang, Y. Durability of recycled aggregate concrete—A review. Cem. Concr. Compos. 2018, 89, 251–259. [Google Scholar] [CrossRef]

- Estanqueiro, B.; Dinis Silvestre, J.; de Brito, J.; Duarte Pinheiro, M. Environmental life cycle assessment of coarse natural and recycled aggregates for concrete. Eur. J. Environ. Civ. Eng. 2018, 22, 429–449. [Google Scholar] [CrossRef]

- Limbachiya, M.C.; Leelawat, T.; Dhir, R.K. RCA concrete: A study of properties in the fresh state, strength development and durability. In Sustainable Construction: Use of Recycled Concrete Aggregate: Proceedings of the International Symposium Organised by the Concrete Technology Unit, University of Dundee and Held at the Department of Trade and Industry Conference Centre, London, UK, 11–12 November 1998; Thomas Telford Publishing: London, UK, 1998; pp. 227–237. [Google Scholar]

- Kurda, R.; de Brito, J.; Silvestre, J.D. Influence of recycled aggregates and high contents of fly ash on concrete fresh properties. Cem. Concr. Compos. 2017, 84, 198–213. [Google Scholar] [CrossRef]

- Zhang, H.; Ji, T.; Zeng, X.; Yang, Z.; Lin, X.; Liang, Y. Mechanical behavior of ultra-high performance concrete (UHPC) using recycled fine aggregate cured under different conditions and the mechanism based on integrated microstructural parameters. Constr. Build. Mater. 2018, 192, 489–507. [Google Scholar] [CrossRef]

- Pandurangan, K.; Dayanithy, A.; Prakash, S.O. Influence of treatment methods on the bond strength of recycled aggregate concrete. Constr. Build. Mater. 2016, 120, 212–221. [Google Scholar] [CrossRef]

- Juan MS, D.; Gutiérrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2008, 23, 872–877. [Google Scholar] [CrossRef]

- Ismail, S.; Ramli, M. Engineering properties of treated recycled concrete aggregate (RCA) for structural applications. Constr. Build. Mater. 2013, 44, 464–476. [Google Scholar] [CrossRef]

- Katz, A. Treatments for the improvement of recycled aggregate. J. Mater. Civ. Eng. 2004, 16, 597–603. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Ong, K.C.G.; Zhang, M.H.; Tam, C.T.; Foo, T.W.J. Microwave-assisted beneficiation of recycled concrete aggregates. Constr. Build. Mater. 2011, 25, 3469–3479. [Google Scholar] [CrossRef]

- Yang, Y.; Liang, S.; Mo, H.; Chen, Y.W. Treatment and Recycling Method of Construction Waste. CN101099974, 9 January 2008. [Google Scholar]

- Yang, Y.; Su, Y.; Li, Z.; Chen, C.P.; Chen, B.X.; Guo, W.E.; Wang, H.C. Pilot-scale technology research on fully recycled fine aggregate made from waste concrete. Concrete 2020, 10, 80–84. [Google Scholar]

- Barbucci, A.; Delucchi, M.; Cerisola, G. Organic coatings for concrete protection: Liquid water and water vapour permeabilities. Prog. Org. Coat. 1997, 30, 293–297. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, G.; Wan, B.; Lin, H.; Zhang, J. Behavior of innovative circular ice filled steel tubular stub columns under axial compression. Constr. Build. Mater. 2018, 171, 680–689. [Google Scholar] [CrossRef]

- Brenna, A.; Bolzoni, F.; Beretta, S.; Ormellese, M. Long-term chloride-induced corrosion monitoring of reinforced concrete coated with commercial polymer-modified mortar and polymeric coatings. Constr. Build. Mater. 2013, 48, 734–744. [Google Scholar] [CrossRef]

- Zhang, Y.; Kong, X. Influences of superplasticizer, polymer latexes and asphalt emulsions on the pore structure and impermeability of hardened cementitious materials. Constr. Build. Mater. 2014, 53, 392–402. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Booya, E.; Mermerdaş, K. Strength and permeability properties of self-compacting concrete with cold bonded fly ash lightweight aggregate. Constr. Build. Mater. 2015, 74, 17–24. [Google Scholar] [CrossRef]

- Duan, P.; Shui, Z.; Chen, W.; Shen, C. Efficiency of mineral admixtures in concrete: Microstructure, compressive strength and stability of hydrate phases. Appl. Clay Sci. 2013, 83, 115–121. [Google Scholar] [CrossRef]

- Sun, Y.; Li, D.; Xu, Y.; Huang, H. Experimental study on mechanical properties and durability of recycled fine aggregate concrete in actual production. Build. Struct. 2019, 49, 81–84. [Google Scholar]

- Mardani-Aghabaglou, A.; Tuyan, M.; Ramyar, K. Mechanical and durability performance of concrete incorporating fine recycled concrete and glass aggregates. Mater. Struct. 2015, 48, 2629–2640. [Google Scholar] [CrossRef]

- Sasanipour, H.; Aslani, F. Durability properties evaluation of self-compacting concrete prepared with waste fine and coarse recycled concrete aggregates. Constr. Build. Mater. 2020, 236, 117540. [Google Scholar] [CrossRef]

- Kapoor, K.; Singh, S.; Singh, B. Permeability of self-compacting concrete made with recycled concrete aggregates and metakaolin. J. Sustain. Cem.-Based Mater. 2017, 6, 293–313. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Hosseini, S.M.; Nosouhian, F.; Ozbakkaloglu, T.; Tehrani, B.N. Durability of concrete containing recycled concrete coarse and fine aggregates and milled waste glass in magnesium sulfate environment. J. Build. Eng. 2020, 29, 101182. [Google Scholar] [CrossRef]

- Gesoglu, M.; Güneyisi, E.; Öz, H.Ö.; Yasemin, M.T.; Taha3, I. Durability and shrinkage characteristics of self-compacting concretes containing recycled coarse and/or fine aggregates. Adv. Mater. Sci. Eng. 2015, 2015, 278296. [Google Scholar] [CrossRef] [Green Version]

- Hemalatha, T.; Ramaswamy, A. A review on fly ash characteristics–Towards promoting high volume utilization in developing sustainable concrete. J. Clean. Prod. 2017, 147, 546–559. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Jaturapitakkul, C.; Sinsiri, T. Effect of fly ash fineness on microstructure of blended cement paste. Constr. Build. Mater. 2007, 21, 1534–1541. [Google Scholar] [CrossRef]

- Zhang, M.-H.; Li, L.; Paramasivam, P. Shrinkage of high-strength lightweight aggregate concrete exposed to dry environment. Mater. J. 2005, 102, 86–92. [Google Scholar]

- Tam, V.W. Comparing the implementation of concrete recycling in the Australian and Japanese construction industries. J. Clean. Prod. 2009, 17, 688–702. [Google Scholar] [CrossRef]

- Kong, D.; Lei, T.; Zheng, J.; Ma, C.; Jiang, J.; Jiang, J. Effect and mechanism of surface-coating pozzalanics materials around aggregate on properties and ITZ microstructure of recycled aggregate concrete. Constr. Build. Mater. 2010, 24, 701–708. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, S.; Zhao, P.; Lu, L.; Cheng, X. Effect of the optimized triple mixing method on the ITZ microstructure and performance of recycled aggregate concrete. Constr. Build. Mater. 2019, 203, 601–607. [Google Scholar] [CrossRef]

- Mefteh, H.; Kebaïli, O.; Oucief, H.; Berredjem, L.; Arabi, N. Influence of moisture conditioning of recycled aggregates on the properties of fresh and hardened concrete. J. Clean. Prod. 2013, 54, 282–288. [Google Scholar] [CrossRef]

- Zhuang, Y.; Liang, Y.; Nabizadeh, A.; Ng, Z.; Ji, T. Influence of the moisture state of recycled fine aggregate on the impermeability of concrete. Mater. Test. 2019, 61, 991–998. [Google Scholar] [CrossRef]

- Videla, C.; Aguilar, C. An updated look at drying shrinkage of Portland and blended Portland cement concretes. Mag. Concr. Res. 2006, 58, 459–476. [Google Scholar] [CrossRef]

- Mokarem, D.W.; Weyers, R.E.; Lane, D.S. Development of a shrinkage performance specifications and prediction model analysis for supplemental cementitious material concrete mixtures. Cem. Concr. Res. 2005, 35, 918–925. [Google Scholar] [CrossRef]

- De Domenico, D.; Faleschini, F.; Pellegrino, C.; Ricciardi, G. Structural behavior of RC beams containing EAF slag as recycled aggregate: Numerical versus experimental results. Constr. Build. Mater. 2018, 171, 321–337. [Google Scholar] [CrossRef]

- Arribas, I.; Santamaria, A.; Ruiz, E.; Ortega-Lopez, V.; Manso, J.M. Electric arc furnace slag and its use in hydraulic concrete. Constr. Build. Mater. 2015, 90, 68–79. [Google Scholar] [CrossRef]

- Jang, S.-J.; Yun, H.-D. Mechanical properties of ready-mixed concrete incorporating fine recycled aggregate. Mag. Concr. Res. 2015, 67, 621–632. [Google Scholar] [CrossRef]

- Kirthika, S.; Singh, S. Durability studies on recycled fine aggregate concrete. Constr. Build. Mater. 2020, 250, 118850. [Google Scholar] [CrossRef]

- Guo, Z.; Chen, C.; Lehman, D.E.; Xiao, W.; Zheng, S.; Fan, B. Mechanical and durability behaviours of concrete made with recycled coarse and fine aggregates. Eur. J. Environ. Civ. Eng. 2020, 24, 171–189. [Google Scholar] [CrossRef]

- Pedro, D.D.; De Brito, J.; Evangelista, L. Structural concrete with simultaneous incorporation of fine and coarse recycled concrete aggregates: Mechanical, durability and long-term properties. Constr. Build. Mater. 2017, 154, 294–309. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Y.; Lehman, D.E.; Geng, Y.; Kuder, K. Time-dependent drying shrinkage model for concrete with coarse and fine recycled aggregate. Cem. Concr. Compos. 2020, 105, 103426. [Google Scholar] [CrossRef]

- Zega, C.J.; Di Maio, Á.A. Use of recycled fine aggregate in concretes with durable requirements. Waste Manag. 2011, 31, 2336–2340. [Google Scholar] [CrossRef] [Green Version]

- Pereira, P.; Evangelista, L.; Brito, J.D. The effect of superplasticisers on the workability and compressive strength of concrete made with fine recycled concrete aggregates. Constr. Build. Mater. 2011, 28, 722–729. [Google Scholar] [CrossRef] [Green Version]

- Pereira, P.; Evangelista, L.; De Brito, J. The effect of superplasticizers on the mechanical performance of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2012, 34, 1044–1052. [Google Scholar] [CrossRef] [Green Version]

- Barbudo, A.; De Brito, J.; Evangelista, L.; Bravo, M.; Agrela, F. Influence of water-reducing admixtures on the mechanical performance of recycled concrete. J. Clean. Prod. 2013, 59, 93–98. [Google Scholar] [CrossRef]

- Cartuxo, F.; De Brito, J.; Evangelista, L.; Jiménez, J.R.; Ledesma, E.F. Rheological behaviour of concrete made with fine recycled concrete aggregates—Influence of the superplasticizer. Constr. Build. Mater. 2015, 89, 36–47. [Google Scholar] [CrossRef]

- Khan, M.I.; Siddique, R. Utilization of silica fume in concrete: Review of durability properties. Resour. Conserv. Recycl. 2011, 57, 30–35. [Google Scholar] [CrossRef]

- Tam, V.W.; Gao, X.; Tam, C.M. Microstructural analysis of recycled aggregate concrete produced from two-stage mixing approach. Cem. Concr. Res. 2005, 35, 1195–1203. [Google Scholar] [CrossRef] [Green Version]

- Sivamani, J.; Renganathan, N.T. Effect of fine recycled aggregate on the strength and durability properties of concrete modified through two-stage mixing approach. Environ. Sci. Pollut. Res. 2021. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Y.; Xu, M.; Zhao, Q. Effect of carbon dioxide corrosion on compressive strength of oilwell cement. J. Chin. Ceram. Soc. 2009, 37, 642–647. [Google Scholar]

- Geng, J.; Sun, J. Characteristics of the carbonation resistance of recycled fine aggregate concrete. Constr. Build. Mater. 2013, 49, 814–820. [Google Scholar] [CrossRef]

- Kaliyavaradhan, S.K.; Ling, T.-C. Potential of CO2 sequestration through construction and demolition (C&D) waste—An overview. J. CO2 Util. 2017, 20, 234–242. [Google Scholar]

- Liang, C.; Lu, N.; Ma, H.; Ma, Z.; Duan, Z. Carbonation behavior of recycled concrete with CO2 -curing recycled aggregate under various environments. J. CO2 Util. 2020, 39, 101185. [Google Scholar] [CrossRef]

- Evangelista, L.; De Brito, J. Durability performance of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2010, 32, 9–14. [Google Scholar] [CrossRef]

- Zhu, P.; Chen, K.; Hu, K. Carbonation Behavior of Repeated Recycled Fine Aggregate Concrete under Bending Load. KSCE J. Civ. Eng. 2019, 23, 729–736. [Google Scholar] [CrossRef]

- Singh, N.; Singh, S. Validation of carbonation behavior of self compacting concrete made with recycled aggregates using microstructural and crystallization investigations. Eur. J. Environ. Civ. Eng. 2020, 24, 2187–2210. [Google Scholar] [CrossRef]

- Evangelista, L.; De Brito, J. Durability of crushed fine recycled aggregate concrete assessed by permeability-related properties. Mag. Concr. Res. 2019, 71, 1142–1150. [Google Scholar] [CrossRef]

- Sim, J.; Park, C. Compressive strength and resistance to chloride ion penetration and carbonation of recycled aggregate concrete with varying amount of fly ash and fine recycled aggregate. Waste Manag. 2011, 31, 2352–2360. [Google Scholar] [CrossRef]

- Cartuxo, F.; De Brito, J.; Evangelista, L.; Jiménez, J.R.; Enrique, F.L. Increased durability of concrete made with fine recycled concrete aggregates using superplasticizers. Materials 2016, 9, 98. [Google Scholar] [CrossRef] [Green Version]

- Angst, U.; Elsener, B.; Larsen, C.K.; Vennesland, Ø. Critical chloride content in reinforced concrete—A review. Cem. Concr. Res. 2009, 39, 1122–1138. [Google Scholar] [CrossRef]

- Shi, X.; Xie, N.; Fortune, K.; Gong, J. Durability of steel reinforced concrete in chloride environments: An overview. Constr. Build. Mater. 2012, 30, 125–138. [Google Scholar] [CrossRef]

- Butler, W.B.; Janssen, D.J.; Schell, H.C.; Cabrera, J.G. Guide to Durable Concrete; ACI: Montreal, QC, Canada, 2001. [Google Scholar]

- Bazant, Z.P. Physical model for steel corrosion in concrete sea structures-theory. ASCE J. Struct. Div. 1979, 105, 1137–1153. [Google Scholar] [CrossRef]

- Zhenhua, D.; Shaodan, H.; Zhisheng, P.; Shanshan, J.; Jianzhuang, X. Rheology of recycled fine aggregate concrete and its influence on strength and durability. J. Build. Struct. 2020, S2, 420–426. [Google Scholar]

- Velay-Lizancos, M.; Martinez-Lage, I.; Azenha, M.; Granja, J.; Vazquez-Burgo, P. Concrete with fine and coarse recycled aggregates: E-modulus evolution, compressive strength and non-destructive testing at early ages. Constr. Build. Mater. 2018, 193, 323–331. [Google Scholar] [CrossRef]

- Fan, C.-C.; Huang, R.; Hwang, H.; Chao, S.-J. Properties of concrete incorporating fine recycled aggregates from crushed concrete wastes. Constr. Build. Mater. 2016, 112, 708–715. [Google Scholar] [CrossRef]

- Salahuddin, H.; Qureshi, L.A.; Nawaz, A.; Razad, S.S. Effect of recycled fine aggregates on performance of Reactive Powder Concrete. Constr. Build. Mater. 2020, 243, 118223. [Google Scholar] [CrossRef]

- Chinzorigt, G.; Lim, M.K.; Yu, M.; Lee, H.; Enkbold, O.; Choi, D. Strength, shrinkage and creep and durability aspects of concrete including CO2 treated recycled fine aggregate. Cem. Concr. Res. 2020, 136, 106062. [Google Scholar] [CrossRef]

- Kapoor, K.; Singh, S.P.; Singh, B. Evaluating the durability properties of self compacting concrete made with coarse and fine recycled concrete aggregates. Eur. J. Environ. Civ. Eng. 2020, 24, 2383–2399. [Google Scholar] [CrossRef]

- Siddique, R.; Klaus, J. Influence of metakaolin on the properties of mortar and concrete: A review. Appl. Clay Sci. 2008, 43, 392–400. [Google Scholar] [CrossRef]

- Hossain, M.; Karim, M.; Hasan, M.; Hossain, M.K.; Zain, M.F.M. Durability of mortar and concrete made up of pozzolans as a partial replacement of cement: A review. Constr. Build. Mater. 2016, 116, 128–140. [Google Scholar] [CrossRef]

- Givi, A.N.; Rashid, S.A.; Aziz FN, A.; Salleh MA, M. Contribution of rice husk ash to the properties of mortar and concrete: A review. J. Am. Sci. 2010, 6, 157–165. [Google Scholar]

- Bie, R.-S.; Song, X.-F.; Liu, Q.-Q.; Ji, X.-Y.; Chen, P. Studies on effects of burning conditions and rice husk ash (RHA) blending amount on the mechanical behavior of cement. Cem. Concr. Compos. 2015, 55, 162–168. [Google Scholar] [CrossRef]

- He, Z.-H.; Li, L.-Y.; Du, S.-G. Creep analysis of concrete containing rice husk ash. Cem. Concr. Compos. 2017, 80, 190–199. [Google Scholar] [CrossRef]

- Msinjili, N.S.; Schmidt, W.; Rogge, A.; Kühne, H.C. Performance of rice husk ash blended cementitious systems with added superplasticizers. Cem. Concr. Compos. 2017, 100, 202–208. [Google Scholar] [CrossRef]

- Rattanachu, P.; Toolkasikorn, P.; Tangchirapat, W.; Chindaprasirt, P.; Jaturapitakkul, C. Performance of recycled aggregate concrete with rice husk ash as cement binder. Cem. Concr. Compos. 2020, 108, 103533. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Vo, D.-H.; Tran, V.-A.; Yehualaw, M.-D. Effect of high MgO content on the performance of alkali-activated fine slag under water and air curing conditions. Constr. Build. Mater. 2018, 186, 503–513. [Google Scholar] [CrossRef]

- Bravo, M.; De Brito, J.; Evangelista, L.; Pacheco, J. Durability and shrinkage of concrete with CDW as recycled aggregates: Benefits from superplasticizer’s incorporation and influence of CDW composition. Constr. Build. Mater. 2018, 168, 818–830. [Google Scholar] [CrossRef]

- Debnath, B.; Li, M.; Liu, S.; Pan, T.; Ma, C.; Qiu, D. Melatonin-mediate acid rain stress tolerance mechanism through alteration of transcriptional factors and secondary metabolites gene expression in tomato. Ecotoxicol. Environ. Saf. 2020, 200, 110720. [Google Scholar] [CrossRef]

- Berredjem, L.; Arabi, N.; Molez, L. Mechanical and durability properties of concrete based on recycled coarse and fine aggregates produced from demolished concrete. Constr. Build. Mater. 2020, 246, 118421. [Google Scholar] [CrossRef]

- Vigneshwari, M.; Arunachalam, K.; Angayarkanni, A. Replacement of silica fume with thermally treated rice husk ash in Reactive Powder Concrete. J. Clean. Prod. 2018, 188, 264–277. [Google Scholar] [CrossRef]

- Kumar, B.V.; Ananthan, H.; Balaji, K. Experimental studies on utilization of recycled coarse and fine aggregates in high performance concrete mixes. Alex. Eng. J. 2018, 57, 1749–1759. [Google Scholar] [CrossRef]

- Huang, J.; Zou, C.; Sun, D.; Yang, B.; Yan, J. Effect of recycled fine aggregates on alkali-activated slag concrete properties. Structures 2021, 30, 89–99. [Google Scholar] [CrossRef]

- Omrane, M.; Kenai, S.; Kadri, E.-H.; Aït-Mokhtar, M. Performance and durability of self compacting concrete using recycled concrete aggregates and natural pozzolan. J. Clean. Prod. 2017, 165, 415–430. [Google Scholar] [CrossRef]

- Richardson, A.; Coventry, K.; Bacon, J. Freeze/thaw durability of concrete with recycled demolition aggregate compared to virgin aggregate concrete. J. Clean. Prod. 2011, 19, 272–277. [Google Scholar] [CrossRef]

- Farzampour, A. Compressive behavior of concrete under environmental effects. In Compressive Strength of Concrete; IntechOpen: London, UK, 2019. [Google Scholar]

- Powers, T.C.; Willis, T. The air requirement of frost resistant concrete. Highw. Res. Board Proc. 1950, 29, 184–211. [Google Scholar]

- Bager, D.H. Qualitative description of the micro ice body freeze–thaw damage mechanism in concrete. Free. -Thaw Test. Concr. 2010, 1, 9–36. [Google Scholar]

- Bogas, J.A.; De Brito, J.; Ramos, D. Freeze–thaw resistance of concrete produced with fine recycled concrete aggregates. J. Clean. Prod. 2016, 115, 294–306. [Google Scholar] [CrossRef]

- Yildirim, S.T.; Meyer, C.; Herfellner, S. Effects of internal curing on the strength, drying shrinkage and freeze–thaw resistance of concrete containing recycled concrete aggregates. Constr. Build. Mater. 2015, 91, 288–296. [Google Scholar] [CrossRef]

- Bentz, D.P.; Weiss, W.J. Internal Curing: A 2010 State-of-the-Art Review; US Department of Commerce, National Institute of Standards and Technology: Gaithersburg, MD, USA, 2011. [Google Scholar]

- El-Hawary, M.; Al-Sulily, A. Internal curing of recycled aggregates concrete. J. Clean. Prod. 2020, 275, 122911. [Google Scholar] [CrossRef]

- Ghafari, S.; Moghadas Nejad, F.; Corbu, O. Durability and Mechanical Properties of Self-Compacting Concrete Incorporating Recovered Filler from Hot Mix Asphalt Plants and Recycled Fine Aggregate. Key Eng. Mater. 2021, 894, 95–101. [Google Scholar] [CrossRef]

| Factor | Change | Influence |

|---|---|---|

| RFA % | Increase | Negative |

| W/C ratio | Increase | Negative |

| RFA water content | Increase | Positive |

| Optimized triple mixing method (OTM) | - | Positive |

| Mineral admixture | - | Positive |

| Factor | Change | Influence |

|---|---|---|

| RFA minimum particle size | Decrease | Negative |

| RFA% | Increase | Negative |

| W/C ratio | Increase | Negative |

| CO2 pretreatment RFA | - | Positive |

| Mineral admixture | - | Positive |

| Factor | Change | Influence |

|---|---|---|

| RFA% | Increase | Negative |

| Thermal curing | - | Negative |

| CO2 pretreatment RFA | - | Negative |

| Surface coating treatment RFA | - | Positive |

| Mineral admixture | - | Positive |

| Factor | Change | Influence |

|---|---|---|

| RFA% | Increase | Negative |

| W/C ratio | Decrease | Positive |

| RFA as an internal conservation source | - | Positive |

| RFA moisture content: 50%/100% | - | Positive |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bu, C.; Liu, L.; Lu, X.; Zhu, D.; Sun, Y.; Yu, L.; OuYang, Y.; Cao, X.; Wei, Q. The Durability of Recycled Fine Aggregate Concrete: A Review. Materials 2022, 15, 1110. https://doi.org/10.3390/ma15031110

Bu C, Liu L, Lu X, Zhu D, Sun Y, Yu L, OuYang Y, Cao X, Wei Q. The Durability of Recycled Fine Aggregate Concrete: A Review. Materials. 2022; 15(3):1110. https://doi.org/10.3390/ma15031110

Chicago/Turabian StyleBu, Changming, Lei Liu, Xinyu Lu, Dongxu Zhu, Yi Sun, Linwen Yu, Yuhui OuYang, Xuemei Cao, and Qike Wei. 2022. "The Durability of Recycled Fine Aggregate Concrete: A Review" Materials 15, no. 3: 1110. https://doi.org/10.3390/ma15031110

APA StyleBu, C., Liu, L., Lu, X., Zhu, D., Sun, Y., Yu, L., OuYang, Y., Cao, X., & Wei, Q. (2022). The Durability of Recycled Fine Aggregate Concrete: A Review. Materials, 15(3), 1110. https://doi.org/10.3390/ma15031110