Guayule Natural Rubber Latex and Bi2O3 Films for X-ray Attenuating Medical Gloves

Abstract

:1. Introduction

2. Materials and Methods

2.1. Formulation

2.2. Dispersion and Compounding of Bi2O3 in the GNRL

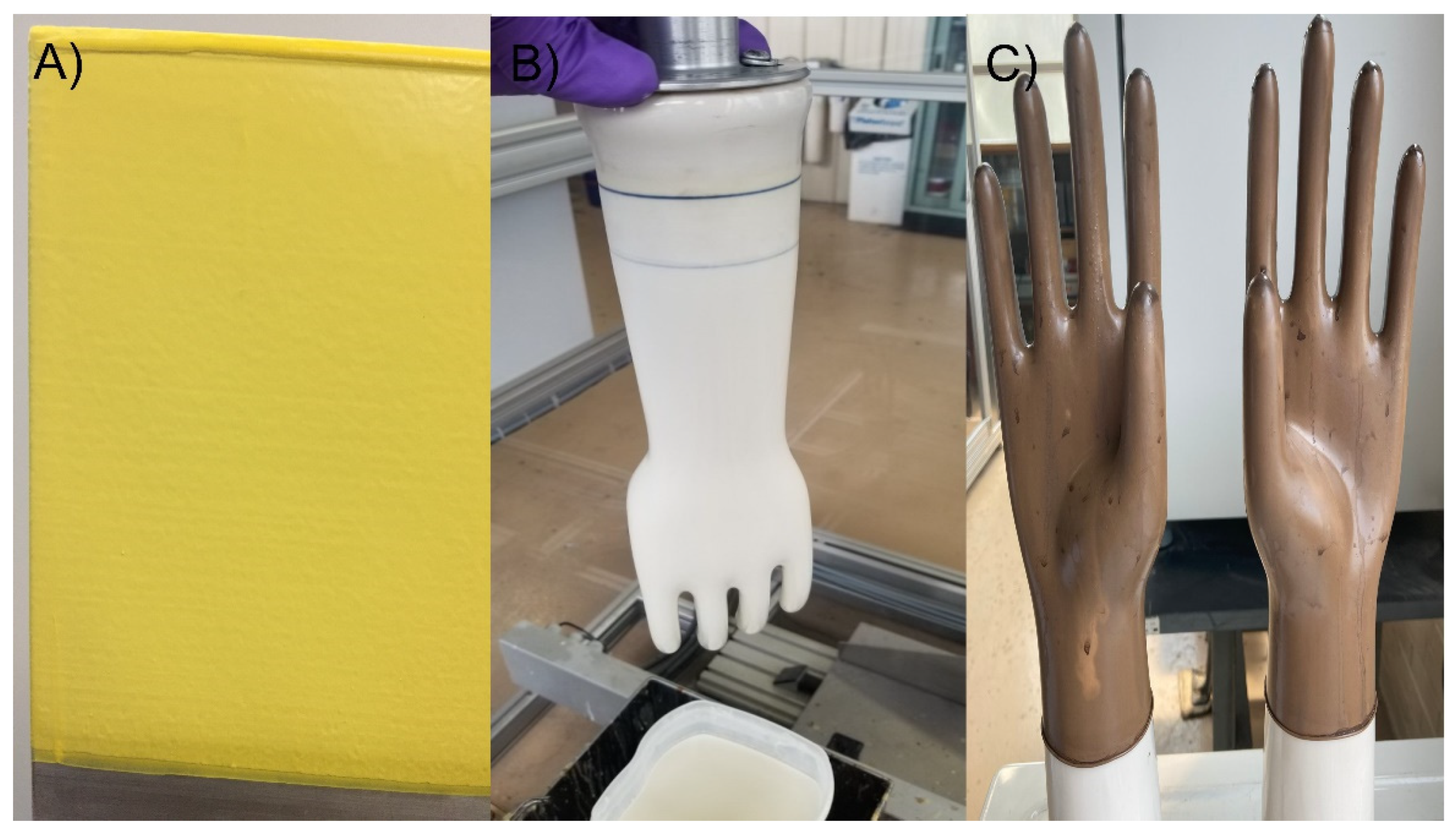

2.3. Film and RA Gloves Preparation

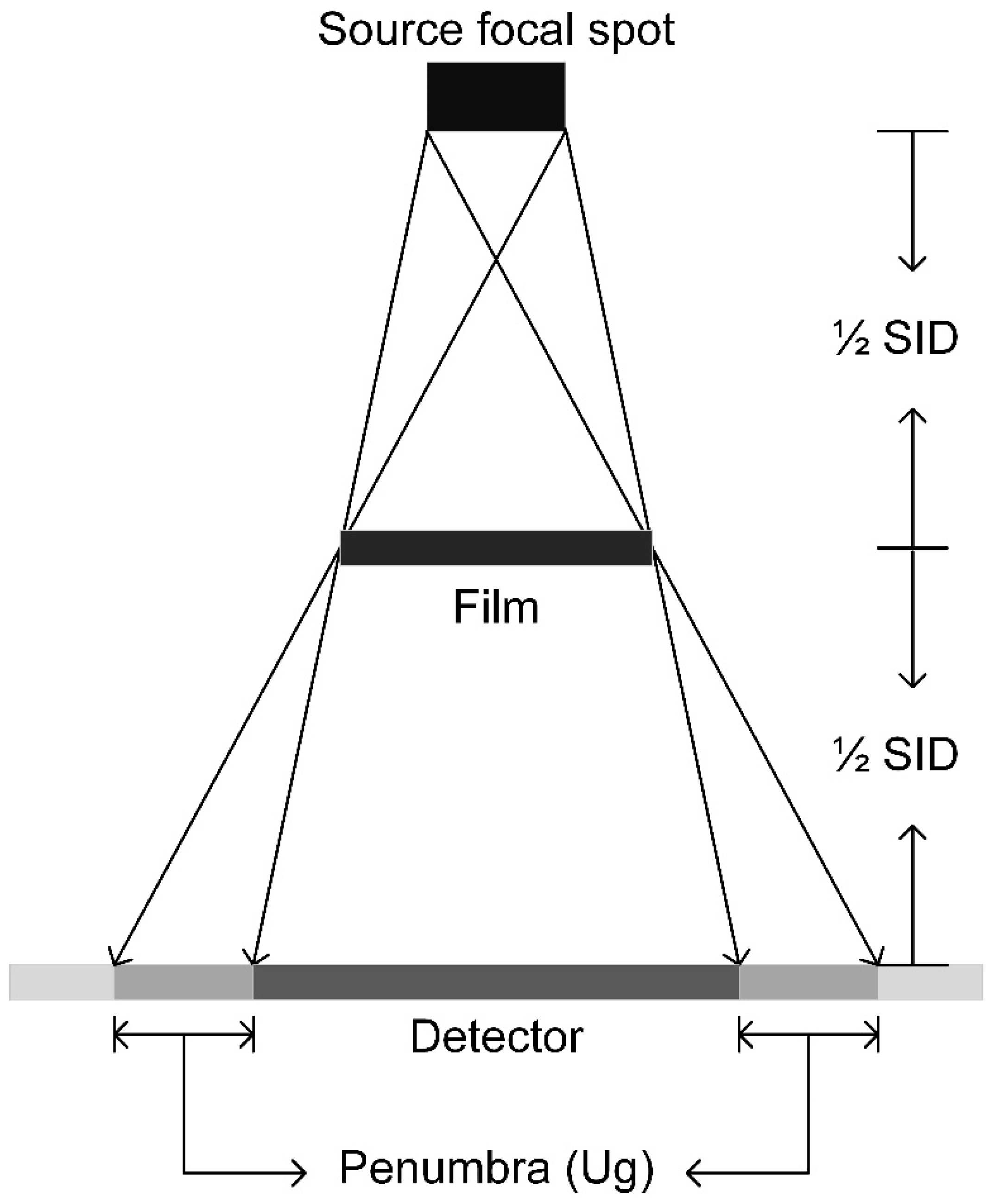

2.4. Radiation Attenuation

2.5. Film Uniformity

2.6. Mechanical Performance

2.7. Statistical Analysis

3. Results and Discussion

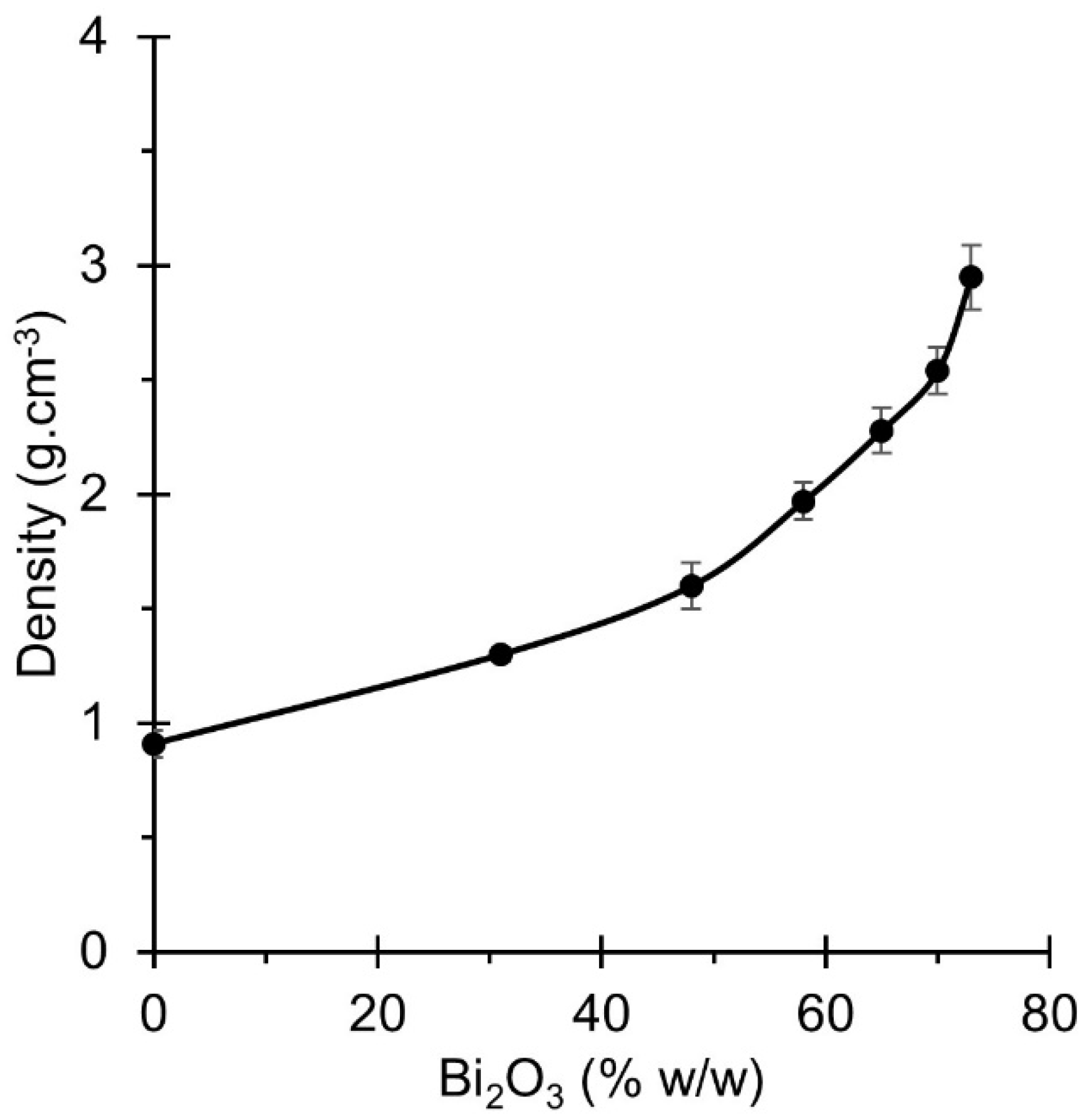

3.1. GNRL/Bi2O3 Film Thickness and Density

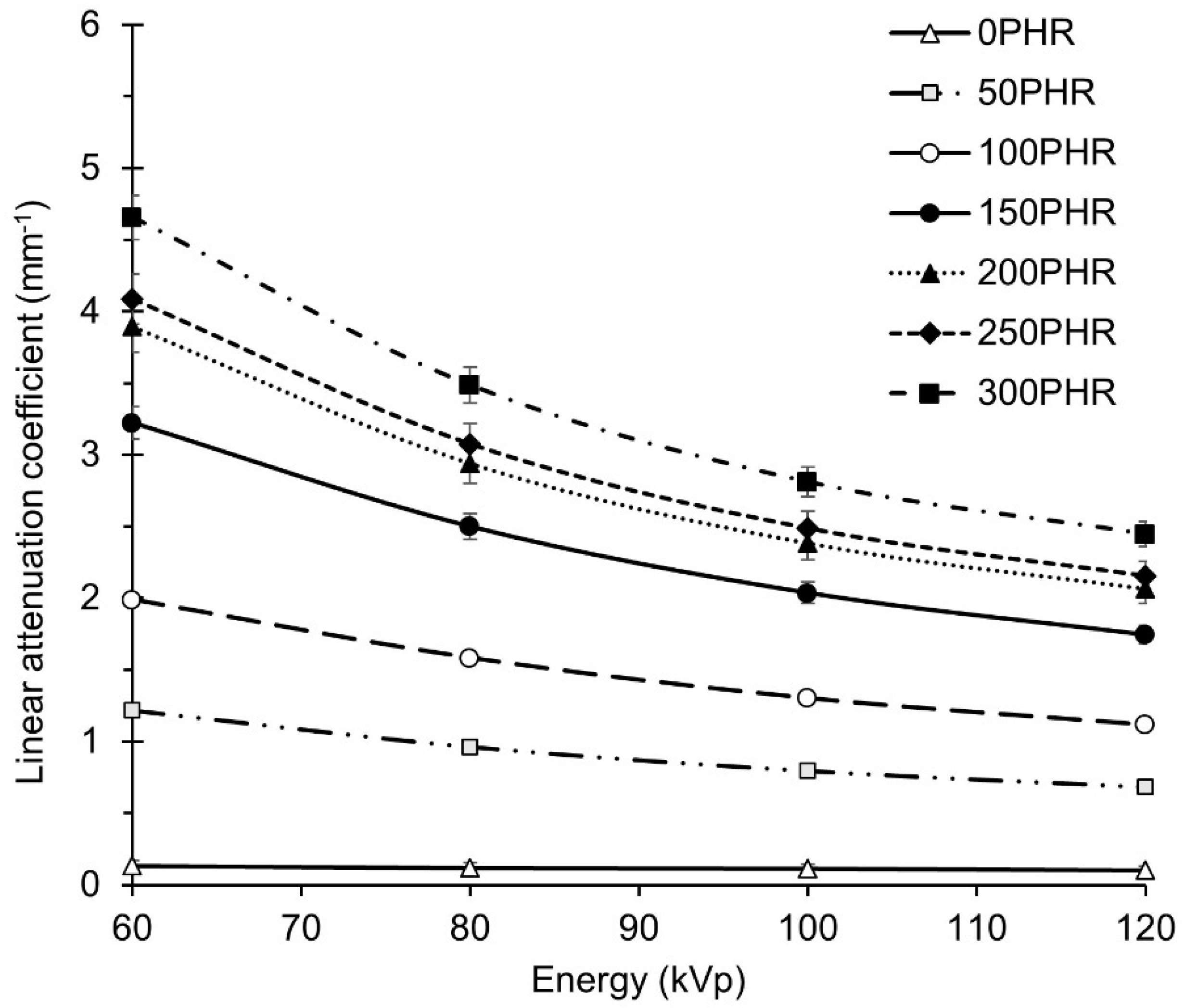

3.2. Attenuation Properties of GNRL/Bi2O3 Films

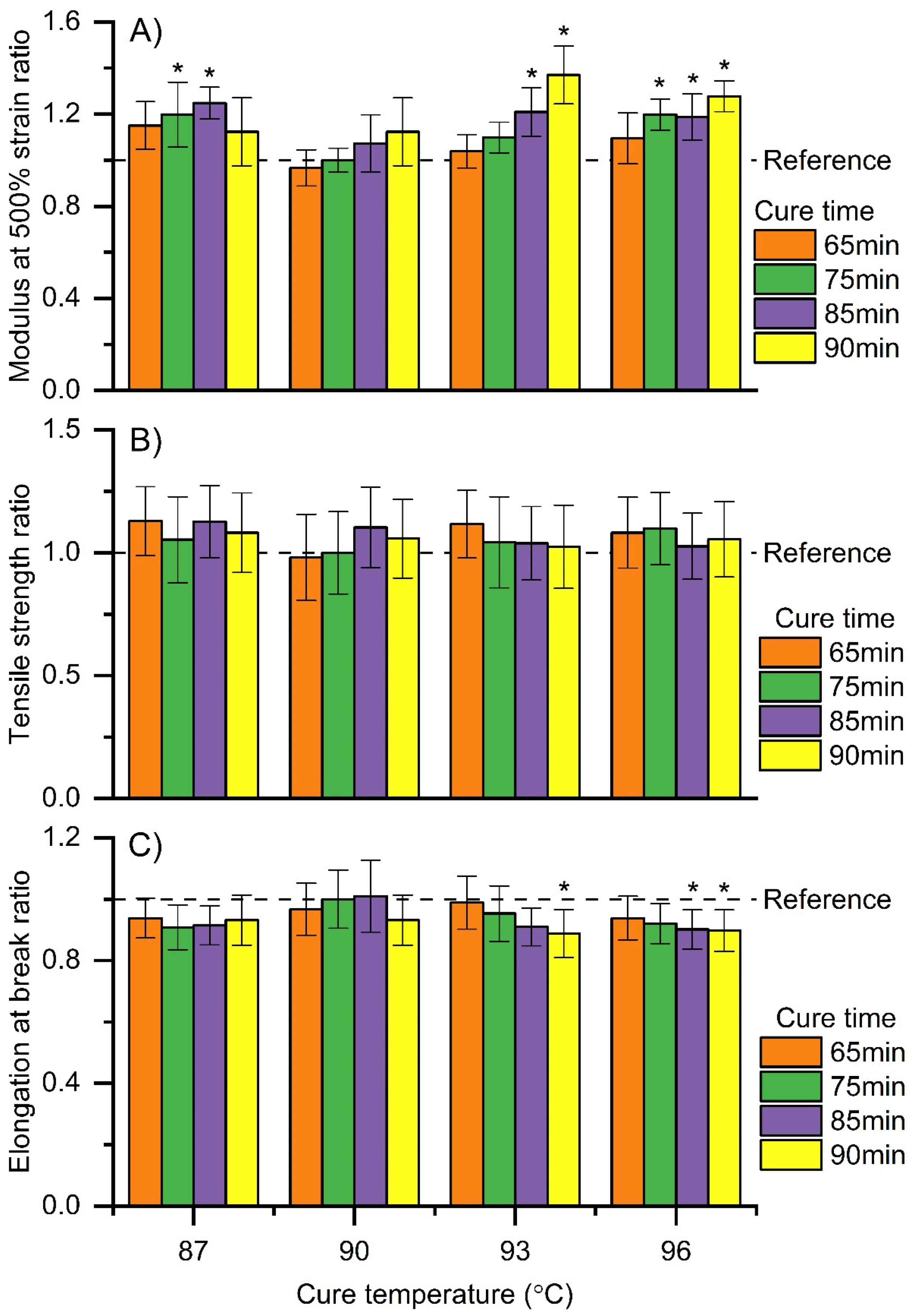

3.3. Optimization of Curing Conditions for GNRL/Bi2O3 Dipped Film

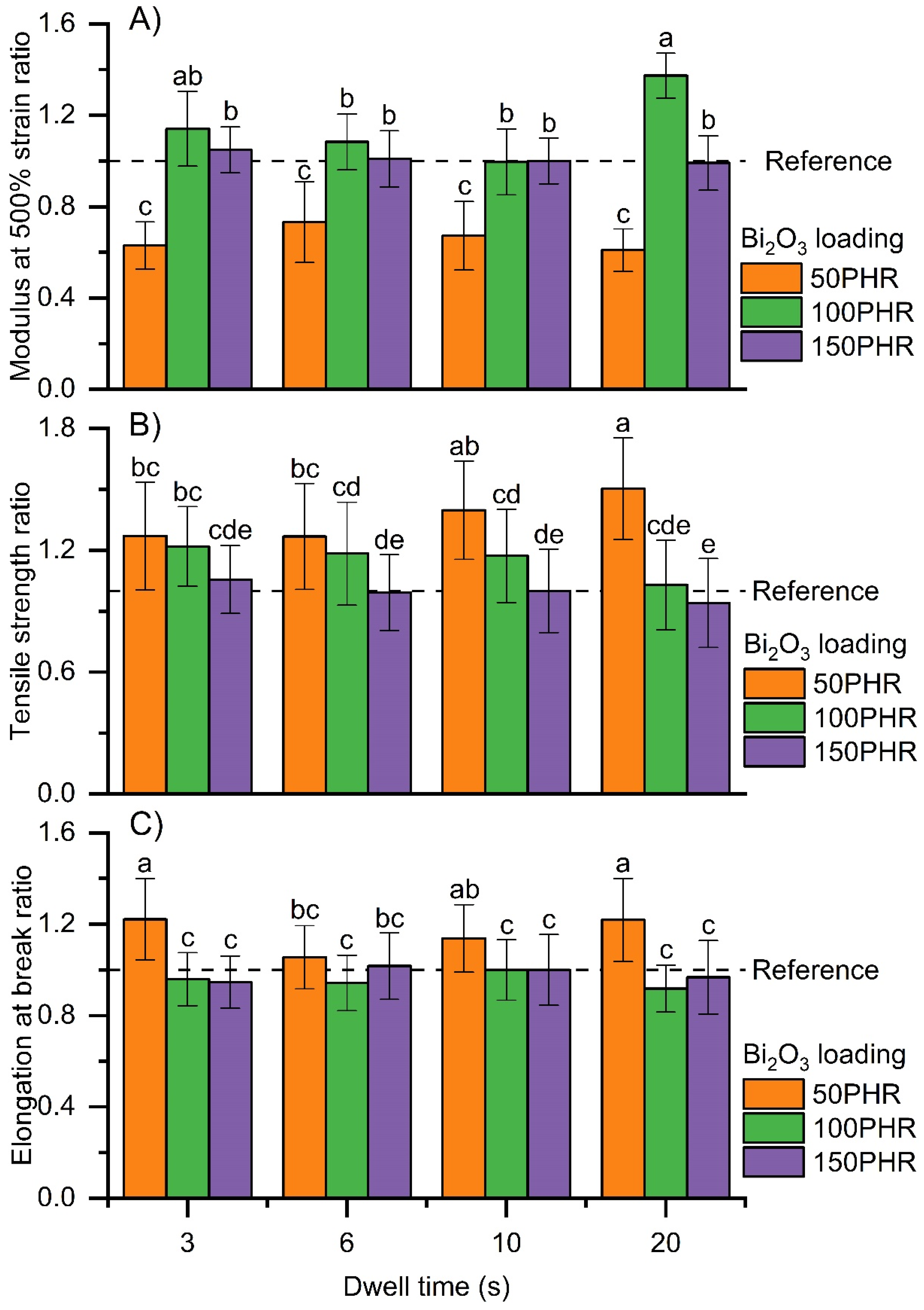

3.4. Effect of Bi2O3 Loading on GNRL/Bi2O3 Dipped Film Thickness and Tensile Properties

3.5. Attenuation Uniformity

3.6. GNRL RA Gloves

4. Conclusions

5. Patents

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature and Abbreviations

| RAG | Radiation attenuation gloves |

| FDA | Food and Drug Administration |

| GNRL | Guayule natural rubber latex |

| PHR | Parts per hundred of rubber |

| AE | Attenuation efficiency |

| kVp | Kilovoltage peak |

| Bi2O3 | Bismuth oxide |

| CT | Computed tomography |

| HCW | Heath care workers |

| NRC | Nuclear Regulatory Commission |

| ALARA | A slow as reasonably achievable |

| HNRL | Hevea natural rubber latex |

| Z | Atomic number |

| D | Particle size average |

| ZDNC | Zinc di-isononyl dithiocarbamate |

| DIXP | Di-isopropyl xanthogen polysulfide |

| SID | Source-to-image distance |

| d | Thickness of the film |

| Peak intensity of the X-ray with a film of thickness d | |

| Peak intensity of the X-ray without a film | |

| Linear attenuation coefficient | |

| Pixel value of radial regions of interest | |

| Pixel value of the center region of interest | |

| The number of radial regions of interest measured | |

| Lavg | Average loading of Bi2O3 |

| Aavg | Market average attenuation |

| Tavg | Market average glove thickness |

| Lmin | Minimum average loading of Bi2O3 required to achieve the ASTM market average attenuation |

| Amin | Market average attenuation |

| Tmin | Minimum thickness to meet the ASTM standard at the Bi2O3 loading 300 PHR |

| MPa | Mega Pascals |

| s.d. | Standard deviation |

References

- Kim, A.N.; Chang, Y.J.; Cheon, B.K.; Kim, J.H. How effective are radiation reducing gloves in c-arm fluoroscopy-guided pain interventions? Korean J. Pain. 2014, 27, 145–151. [Google Scholar] [CrossRef] [PubMed]

- FDA. Fluoroscopy. Available online: https://www.fda.gov/radiation-emitting-products/medical-x-ray-imaging/fluoroscopy (accessed on 29 June 2020).

- Bratschitsch, G.; Leitner, L.; Stücklschweiger, G.; Guss, H.; Sadoghi, P.; Puchwein, P.; Leithner, A.; Radl, R. Radiation exposure of patient and operating room personnel by fluoroscopy and navigation during spinal surgery. Sci. Rep. 2019, 9, 17652. [Google Scholar] [CrossRef]

- Smith-Bindman, R.; Kwan, M.L.; Marlow, E.C.; Theis, M.K.; Bolch, W.; Cheng, S.Y.; Bowles, E.J.A.; Duncan, J.R.; Greenlee, R.T.; Kushi, L.H.; et al. Trends in Use of Medical Imaging in US Health Care Systems and in Ontario, Canada, 2000–2016. JAMA 2019, 322, 843–856. [Google Scholar] [CrossRef] [PubMed]

- Linet, M.S.; Kitahara, C.M.; Ntowe, E.; Kleinerman, R.A.; Gilbert, E.S.; Naito, N.; Lipner, R.S.; Miller, D.L.; Berrington de Gonzalez, A.; Multi-Specialty Occupational Health Group. Mortality in U.S. physicians likely to perform fluoroscopy-guided interventional procedures compared with psychiatrists, 1979 to 2008. Radiology 2017, 284, 482–494. [Google Scholar] [CrossRef] [PubMed]

- NCRP. Medical Radiation Exposure of Patients in the United States; 184; National Council on Radiation Protection and Measurements: Bethesda, MD, USA, 2019. [Google Scholar]

- Hahn, P.F.; Guimaraes, A.R.; Arellano, R.S.; Mueller, P.R.; Gervais, D.A. Nonvascular Interventional Procedures in an Urban General Hospital: Analysis of 2001–2010 with Comparison to the Previous Decade. Acad. Radiol. 2015, 22, 904–908. [Google Scholar] [CrossRef] [PubMed]

- Martin, C.J.; Whitby, M. Application of ALARP to extremity doses for hospital workers. J. Radiol. Prot. Off. J. Soc. Radiol. Prot. 2003, 23, 405–421. [Google Scholar] [CrossRef]

- NCRP. Implementation of the Principle of as Low as Reasonably Achievable (ALARA) for Medical and Dental Personnel; 107; National Council on Radiation Protection and Measurements: Bethesda, MD, USA, 1990. [Google Scholar]

- Marx, M.V.; Ellis, J.H. Radiation protection of the hand in interventional radiology: Should it fit like a glove? Radiology 1996, 200, 24–25. [Google Scholar] [CrossRef]

- Cantlon, M.B.; Ilyas, A.M. Assessment of radiation protection in hand-shielding products with mini c-arm fluoroscopy. HAND 2021, 16, 505–510. [Google Scholar] [CrossRef]

- FDA. Product Classification: Radiographic Protective Glove. Available online: https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfpcd/classification.cfm?id=5388 (accessed on 3 July 2020).

- Meisinger, Q.C.; Stahl, C.M.; Andre, M.P.; Kinney, T.B.; Newton, I.G. Radiation protection for the fluoroscopy operator and staff. Am. J. Roentgenol. 2016, 207, 745–754. [Google Scholar] [CrossRef]

- Kazempour, M.; Saeedimoghadam, M.; Shekoohi Shooli, F.; Shokrpour, N. Assessment of the radiation attenuation properties of several lead free composites by monte carlo simulation. J. Biomed. Phys. Eng. 2015, 5, 67–76. [Google Scholar]

- ASTM D3577-19; Standard Specification for Rubber Surgical Gloves. ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

- ASTM D3578-19; Standard Specification for Rubber Examination Gloves. ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

- Holden, G.; Stephens, H.L.; Baranwal, K.C. Basic Elastomer Technology; Ruber Division, American Chemical Society, The University of Akron: Akron, OH, USA, 2001. [Google Scholar]

- Meleth, J.P. An Introduction to Latex Gloves: Types, Manufacture, Properties and Quality Control; LAP Lambert Academic Publishing: Saarbrücken, Germany, 2012. [Google Scholar]

- Sussman, G.L.; Beezhold, D.H.; Liss, G. Latex allergy: Historical perspective. Methods 2002, 27, 3–9. [Google Scholar] [CrossRef]

- Grzybowski, M.; Ownby, D.R.; Peyser, P.A.; Johnson, C.C.; Schork, M.A. The prevalence of anti-latex IgE antibodies among registered nurses. J. Allergy Clin. Immunol. 1996, 98, 535–544. [Google Scholar] [CrossRef]

- Hamilton, R.G.; Cornish, K. Immunogenicity studies of guayule and guayule latex in occupationally exposed workers. Ind. Crops Prod. 2010, 31, 197–201. [Google Scholar] [CrossRef]

- Hager, T.; MacArthur, A.; McIntyre, D.; Seeger, R. Chemistry and structure of natural rubbers. Rubber Chem. Technol. 1979, 52, 693–709. [Google Scholar] [CrossRef]

- Junkong, P.; Cornish, K.; Ikeda, Y. Characteristics of mechanical properties of sulphur cross-linked guayule and dandelion natural rubbers. RSC Adv. 2017, 7, 50739–50752. [Google Scholar] [CrossRef] [Green Version]

- Cornish, K.; Lytle, C.D. Viral impermeability of hypoallergenic, low protein, guayule latex films. J. Biomed. Mater. Res. 1999, 47, 434–437. [Google Scholar] [CrossRef]

- Tishkevich, D.I.; Grabchikov, S.S.; Lastovskii, S.B.; Trukhanov, S.V.; Zubar, T.I.; Vasin, D.S.; Trukhanov, A.V. Correlation of the synthesis conditions and microstructure for Bi-based electron shields production. J. Alloy. Compd. 2018, 749, 1036–1042. [Google Scholar] [CrossRef]

- Sayyed, M.I.; Akman, F.; Kaçal, M.R.; Kumar, A. Radiation protective qualities of some selected lead and bismuth salts in the wide gamma energy region. Nucl. Eng. Technol. 2019, 51, 860–866. [Google Scholar] [CrossRef]

- Nambiar, S.; Osei, E.K.; Yeow, J.T.W. Polymer nanocomposite-based shielding against diagnostic X-rays. J. Appl. Polym. Sci. 2013, 127, 4939–4946. [Google Scholar] [CrossRef]

- Ambika, M.R.; Nagaiah, N.; Harish, V.; Lokanath, N.K.; Sridhar, M.A.; Renukappa, N.M.; Suman, S.K. Preparation and characterisation of Isophthalic-Bi2O3 polymer composite gamma radiation shields. Radiat. Phys. Chem. 2017, 130, 351–358. [Google Scholar] [CrossRef]

- Tishkevich, D.I.; Grabchikov, S.S.; Grabchikova, E.A.; Vasin, D.S.; Lastovskiy, S.B.; Yakushevich, A.S.; Vinnik, D.A.; Zubar, T.I.; Kalagin, I.V.; Mitrofanov, S.V.; et al. Modeling of paths and energy losses of high-energy ions in single-layered and multilayered materials. IOP Conf. Ser. Mater. Sci. Eng. 2020, 848, 012089. [Google Scholar] [CrossRef]

- Tishkevich, D.I.; Grabchikov, S.S.; Lastovskii, S.B.; Trukhanov, S.V.; Vasin, D.S.; Zubar, T.I.; Kozlovskiy, A.L.; Zdorovets, M.V.; Sivakov, V.A.; Muradyan, T.R.; et al. Function composites materials for shielding applications: Correlation between phase separation and attenuation properties. J. Alloys Compd. 2019, 771, 238–245. [Google Scholar] [CrossRef]

- Maghrabi, H.A.; Vijayan, A.; Deb, P.; Wang, L. Bismuth oxide-coated fabrics for X-ray shielding. Text. Res. J. 2016, 86, 649–658. [Google Scholar] [CrossRef]

- Verma, S.; Mili, M.; Sharma, C.; Bajpai, H.; Pal, K.; Qureshi, D.; Hashmi, S.A.R.; Srivastava, A.K. Advanced X-ray shielding and antibacterial smart multipurpose fabric impregnated with polygonal shaped bismuth oxide nanoparticles in carbon nanotubes via green synthesis. Green Chem. Lett. Rev. 2021, 14, 272–285. [Google Scholar] [CrossRef]

- Manjunatha, H.C.; Seenappa, L.; Chandrika, B.M.; Hanumantharayappa, C. A study of photon interaction parameters in barium compounds. Ann. Nucl. Energy 2017, 109, 310–317. [Google Scholar] [CrossRef]

- Meyer, P.A.; Brown, M.J.; Falk, H. Global approach to reducing lead exposure and poisoning. Mutat. Res. 2008, 659, 166–175. [Google Scholar] [CrossRef]

- Nikbin, I.M.; Mohebbi, R.; Dezhampanah, S.; Mehdipour, S.; Mohammadi, R.; Nejat, T. Gamma ray shielding properties of heavy-weight concrete containing Nano-TiO2. Radiat. Phys. Chem. 2019, 162, 157–167. [Google Scholar] [CrossRef]

- Singh, N.; Singh, K.J.; Singh, K.; Singh, H. Comparative study of lead borate and bismuth lead borate glass systems as gamma-radiation shielding materials. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2004, 225, 305–309. [Google Scholar] [CrossRef]

- Bartoli, M.; Jagdale, P.; Tagliaferro, A. A Short Review on Biomedical Applications of Nanostructured Bismuth Oxide and Related Nanomaterials. Materials 2020, 13, 5234. [Google Scholar] [CrossRef]

- Shahbazi, M.-A.; Faghfouri, L.; Ferreira, M.P.A.; Figueiredo, P.; Maleki, H.; Sefat, F.; Hirvonen, J.; Santos, H.A. The versatile biomedical applications of bismuth-based nanoparticles and composites: Therapeutic, diagnostic, biosensing, and regenerative properties. Chem. Soc. Rev. 2020, 49, 1253–1321. [Google Scholar] [CrossRef] [Green Version]

- McCaffrey, J.P.; Shen, H.; Downton, B.; Mainegra-Hing, E. Radiation attenuation by lead and nonlead materials used in radiation shielding garments. Med. Phys. 2007, 34, 530–537. [Google Scholar] [CrossRef]

- D’Souza, S.F. Applications of Radioisotopes in Agriculture; Kalasalingam University: Kalasalingam, India, 2012. [Google Scholar]

- Wang, R.; Li, H.; Sun, H. Bismuth: Environmental Pollution and Health Effects. Encycl. Environ. Health 2019, 415–423. [Google Scholar] [CrossRef]

- Moral-Vico, J.; Casañ-Pastor, N.; Camón, A.; Pobes, C.; Jáudenes, R.M.; Strichovanec, P.; Fàbrega, L. Microstructure and electrical transport in electrodeposited Bi films. J. Electroanal. Chem. 2019, 832, 40–47. [Google Scholar] [CrossRef]

- Hofmann, P. The surfaces of bismuth: Structural and electronic properties. Prog. Surf. Sci. 2006, 81, 191–245. [Google Scholar] [CrossRef]

- Švancara, I.; Prior, C.; Hočevar, S.B.; Wang, J. A Decade with Bismuth-Based Electrodes in Electroanalysis. Electroanalysis 2010, 22, 1405–1420. [Google Scholar] [CrossRef]

- Abdel-Aziz, M.M.; Gwaily, S.E. Thermal and mechanical properties of styrene-butadiene rubber/lead oxide composites as gamma-radiation shields. Polym. Degrad. Stab. 1997, 55, 269–274. [Google Scholar] [CrossRef]

- Kim, E.-C.; Lee, B.-C.; Chang, H.-S.; Lee, W.; Hong, C.-U.; Min, K.-S. Evaluation of the radiopacity and cytotoxicity of Portland cements containing bismuth oxide. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endodontol. 2008, 105, e54–e57. [Google Scholar] [CrossRef]

- Liao, Y.-C.; Xu, D.-G.; Zhang, P.-C. Preparation and characterization of Bi2O3/XNBR flexible films for attenuating gamma rays. Nucl. Sci. Tech. 2018, 29, 99. [Google Scholar] [CrossRef]

- Issa, S.A.M.; Mostafa, A.M.A. Effect of Bi2O3 in borate-tellurite-silicate glass system for development of gamma-rays shielding materials. J. Alloys Compd. 2017, 695, 302–310. [Google Scholar] [CrossRef]

- Hao, W.; Gao, Y.; Jing, X.; Zou, W.; Chen, Y.; Wang, T. Visible light photocatalytic properties of metastable γ-Bi2O3 with different morphologies. J. Mater. Sci. Technol. 2014, 30, 192–196. [Google Scholar] [CrossRef]

- ASTM D7866-14a; Standard Specification for Radiation Attenuating Protective Gloves. ASTM International: West Conshohocken, PA, USA, 2014. [CrossRef]

- ASTM D412-16; Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension. ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- Mehrara, R.; Malekie, S.; Kotahi, S.M.S.; Kashian, S. Introducing a novel low energy gamma ray shield utilizing Polycarbonate Bismuth Oxide composite. Sci. Rep. 2021, 11, 10614. [Google Scholar] [CrossRef] [PubMed]

- Cornish, K.; Li, Z. Guayule rubber medical radiation attenuation glove. Rubber Plastics News, 2 October 2017; 20–25. [Google Scholar]

- Zdrazil, M.; Scott, K.F. The determination of surface polarity of bismuth-molybdenum oxidation catalysts by gas chromatography. Chromatographia 1980, 13, 85–92. [Google Scholar] [CrossRef]

| Compound | Chemical | Dry wt (PHR) |

|---|---|---|

| GNRL | Guayule latex | 100.0 |

| Preservative | NH4OH | 0.7 |

| Antioxidant | Wingstay L | 2.3 |

| Activator | ZnO | 0.5 |

| Accelerator 1 | ZDNC | 0.9 |

| Accelerator 2 | DIXP | 1.7 |

| Sulfur | S | 3.2 |

| Component | Chemical | Loading |

|---|---|---|

| % w/w | ||

| Coagulant | Ca(NO3)2·4H2O | 25.4 |

| Detackifier | Zn(C18H35O2)2 | 0.5 |

| Surfactant | Triton X-100 | 0.5 |

| Solvent | Water | 72.9 |

| Bi2O3 | Bi2O3 | GNRL | Suspension | Film Thickness |

|---|---|---|---|---|

| PHR | % w/w | % w/w | g | mm |

| 0 | 0 | 100 | 2.1 | 0.16 ± 0.01 |

| 3.2 | 0.24 ± 0.03 | |||

| 3.8 | 0.26 ± 0.02 | |||

| 4.4 | 0.34 ± 0.02 | |||

| 5.1 | 0.41 ± 0.02 | |||

| 7.3 | 0.52 ± 0.03 | |||

| 150 | 58 | 42 | 3.9 | 0.16 ± 0.02 |

| 5.8 | 0.22 ± 0.00 | |||

| 7.8 | 0.31 ± 0.03 | |||

| 9.6 | 0.39 ± 0.03 | |||

| 11.5 | 0.49 ± 0.03 | |||

| 12.9 | 0.57 ± 0.01 | |||

| 200 | 65 | 35 | 4.1 | 0.15 ± 0.03 |

| 6.2 | 0.23 ± 0.03 | |||

| 8.3 | 0.38 ± 0.03 | |||

| 10.2 | 0.45 ± 0.04 | |||

| 12.3 | 0.50 ± 0.04 | |||

| 14.4 | 0.64 ± 0.05 | |||

| 250 | 70 | 30 | 4.3 | 0.20 ± 0.03 |

| 6.6 | 0.31 ± 0.03 | |||

| 8.7 | 0.38 ± 0.04 | |||

| 11.0 | 0.46 ± 0.04 | |||

| 13.0 | 0.56 ± 0.05 | |||

| 15.0 | 0.63 ± 0.05 | |||

| 300 | 73 | 27 | 4.7 | 0.19 ± 0.03 |

| 6.8 | 0.25 ± 0.03 | |||

| 9.0 | 0.35 ± 0.04 | |||

| 11.3 | 0.43 ± 0.04 | |||

| 13.5 | 0.51 ± 0.04 | |||

| 15.8 | 0.62 ± 0.04 |

| Bi2O3 | Bi2O3 | GNRL | Dwell Time | Film Thickness |

|---|---|---|---|---|

| PHR | % w/w | % w/w | s | mm |

| 0 | 0 | 100 | 10 | 0.19 ± 0.01 |

| 20 | 0.23 ± 0.01 | |||

| 30 | 0.30 ± 0.00 | |||

| 40 | 0.40 ± 0.00 | |||

| 50 | 31 | 69 | 3 | 0.22 ± 0.00 |

| 6 | 0.24 ± 0.01 | |||

| 10 | 0.27 ± 0.01 | |||

| 20 | 0.30 ± 0.01 | |||

| 100 | 48 | 52 | 3 | 0.20 ± 0.00 |

| 6 | 0.22 ± 0.00 | |||

| 10 | 0.25 ± 0.00 | |||

| 20 | 0.29 ± 0.01 | |||

| 150 | 58 | 42 | 3 | 0.20 ± 0.00 |

| 6 | 0.22 ± 0.00 | |||

| 10 | 0.24 ± 0.00 | |||

| 20 | 0.27 ± 0.01 |

| Brand | Thickness | Attenuation | Material | |||

|---|---|---|---|---|---|---|

| 60 kVp | 80 kVp | 100 kVp | 120 kVp | |||

| mm | % | % | % | % | ||

| ASG | 0.23 | 58 | 47 | 40 | NA | Latex-free |

| Attenuator X | 0.35 | 66 | 55 | 43 | NA | Latex |

| IBG | 0.18 | 56 | 47 | 41 | 38 | Latex-free |

| Xguard RR1 | 0.22 | 45 | 35 | 26 | 23 | Latex-free |

| Xguard RR2 | 0.30 | 55 | 45 | 35 | 31 | Latex-free |

| Secure Touch XR1 | 0.20 | 46 | 36 | 30 | 24 | Latex |

| Secure Touch XR2 | 0.35 | 64 | 54 | 48 | 42 | Latex |

| Radiaxon latex | 0.30 | 65 | 51 | 44 | 39 | Latex |

| Radiaxon PI | 0.30 | 62 | 53 | 46 | 40 | Latex-free |

| Kiran NXPG35 | 0.35 | 63 | 53 | 46 | 41 | Latex |

| Kiran NXPG25 | 0.25 | 51 | 44 | 39 | 27 | Latex |

| Kiran NXPG20 | 0.20 | 41 | 33 | 28 | 21 | Latex |

| Average | 0.27 | 56 | 46 | 39 | 33 | |

| ASTM D7866 | n/a | 29 | 22 | 18 | 15 | |

| Bi2O3 | Thickness | Attenuation | Results | |||

|---|---|---|---|---|---|---|

| Loading | 60 kVp | 80 kVp | 100 kVp | 120 kVp | ||

| PHR | mm | % | % | % | % | |

| 150 | 0.20 | 50 | 41 | 35 | 31 | Achieved |

| 150 | 0.27 | 57 | 48 | 41 | 36 | Achieved |

| 150 | 0.15 | 45 | 37 | 31 | 27 | Projected |

| 150 | 0.30 | 59 | 50 | 43 | 39 | Projected |

| Standard ASTM | Glove Type (Polymer Type) | Minimum Thickness | Minimum Tensile Strength | Minimum Ultimate Elongation | Maximum Modulus at 500% Strain |

|---|---|---|---|---|---|

| mm | MPa | % | MPa | ||

| D3577 | Surgical (HNRL) | 0.1 | 24 | 750 | 5.5 |

| D3577 | Surgical (Synthetic) | 0.1 | 17 | 650 | 7.0 |

| D3578 | Exam (HNRL) | 0.08 | 18 | 650 | 6.5 |

| D6977 | Exam (CR) | 0.05 | 14 | 500 | - |

| D6319 | Exam (Nitrile) | 0.05 | 15 | 500 | - |

| Sample | Dwell Time | Thickness | Center | Mean Pixel Value from Raw Images | Uniformity | |||

|---|---|---|---|---|---|---|---|---|

| s | mm | 3 | 6 | 9 | 12 | |||

| 1 | 3 | 0.20 | 4911.0 | 4704.0 | 4996.2 | 5132.4 | 4823.5 | 96.9% |

| 2 | 3 | 0.20 | 4972.4 | 4790.8 | 4966.6 | 5210.0 | 4973.5 | 97.9% |

| 3 | 3 | 0.20 | 4759.6 | 4596.5 | 4686.5 | 5017.9 | 4909.7 | 96.6% |

| 4 | 6 | 0.22 | 4768.5 | 4660.0 | 4642.0 | 4930.2 | 4894.0 | 97.3% |

| 5 | 6 | 0.22 | 4605.5 | 4521.4 | 4573.5 | 4776.2 | 4601.1 | 98.4% |

| 6 | 6 | 0.22 | 5265.7 | 5196.4 | 5414.7 | 5466.5 | 5150.1 | 97.5% |

| 7 | 10 | 0.25 | 5452.6 | 5412.0 | 5552.8 | 5562.3 | 5352.3 | 98.4% |

| 8 | 10 | 0.24 | 4676.6 | 4656.5 | 4660.4 | 4769.4 | 4654.5 | 99.2% |

| 9 | 10 | 0.24 | 5141.8 | 5144.4 | 5005.7 | 5271.4 | 5278.2 | 98.0% |

| 10 | 20 | 0.28 | 5224.7 | 5099.8 | 5339.6 | 5515.8 | 5140.2 | 97.1% |

| 11 | 20 | 0.27 | 4555.8 | 4390.2 | 4531.0 | 4786.7 | 4576.7 | 97.6% |

| 12 | 20 | 0.28 | 4842.8 | 4752.2 | 4732.9 | 5138.2 | 4957.9 | 96.8% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramirez Cadavid, D.A.; Layman, R.R.; Nishino, T.; Slutzky, J.L.; Li, Z.; Cornish, K. Guayule Natural Rubber Latex and Bi2O3 Films for X-ray Attenuating Medical Gloves. Materials 2022, 15, 1184. https://doi.org/10.3390/ma15031184

Ramirez Cadavid DA, Layman RR, Nishino T, Slutzky JL, Li Z, Cornish K. Guayule Natural Rubber Latex and Bi2O3 Films for X-ray Attenuating Medical Gloves. Materials. 2022; 15(3):1184. https://doi.org/10.3390/ma15031184

Chicago/Turabian StyleRamirez Cadavid, David A., Rick R. Layman, Thomas Nishino, J. Lauren Slutzky, Zhenyu Li, and Katrina Cornish. 2022. "Guayule Natural Rubber Latex and Bi2O3 Films for X-ray Attenuating Medical Gloves" Materials 15, no. 3: 1184. https://doi.org/10.3390/ma15031184

APA StyleRamirez Cadavid, D. A., Layman, R. R., Nishino, T., Slutzky, J. L., Li, Z., & Cornish, K. (2022). Guayule Natural Rubber Latex and Bi2O3 Films for X-ray Attenuating Medical Gloves. Materials, 15(3), 1184. https://doi.org/10.3390/ma15031184