The Technology of Using Liquid Glass Mixture Waste for Reducing the Harmful Environmental Impact

Abstract

:1. Introduction

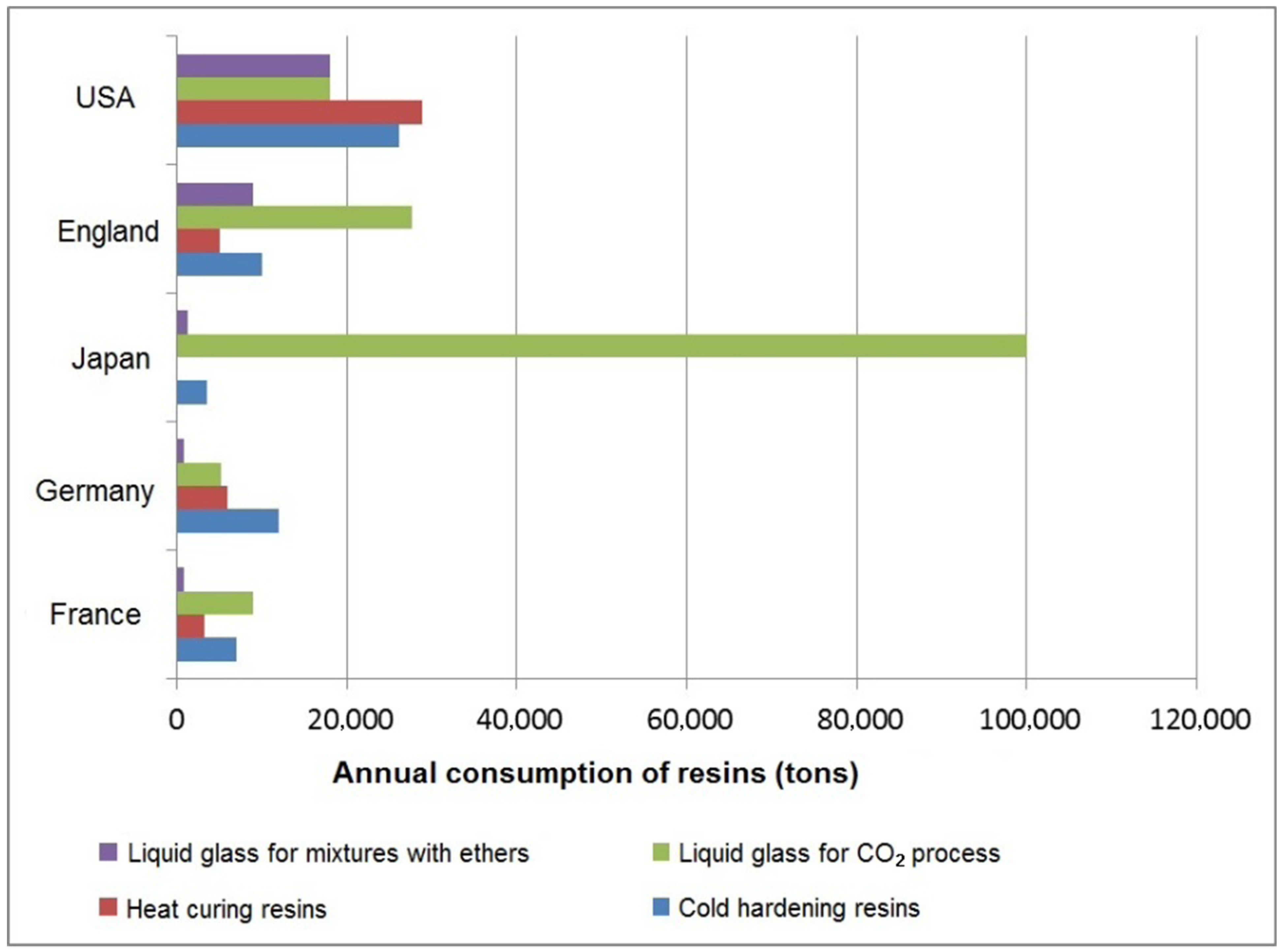

2. Review of Today’s Molding Techniques

2.1. AlpHaset Mold Manufacturing Technology

- The AlpHaset process allowed for the use of flaskless molding technology, with a flow rate of 2–3 tons of sand per 1 ton of liquid.

- The percentage of regenerated sand in the sand can be 70–90%.

- AlpHaset is an efficient and environmentally friendly process of forming and manufacturing cores, which allows for the production of steel, cast iron, and non-ferrous castings, with good surface quality at low labor costs for cleaning and final processing. Thus, the AlpHaset process can be used to replace the casting into shell molds, as well as, in some cases, the exact casting.

- The easy removal of the rod from the equipment, significant reduction in model wear, and reduction in the pollution and breakage of models make it possible to organize the storage of core boxes and models as close as possible to the place of their use.

- The AlpHaset binder completely decomposes thermally around the casting when casting bronze, cast iron, and steel; therefore, knocking out forms and rods is easy.

- There is a minor odor when mixing and filling the equipment, as well as limited toxicity.

- The water solubility of the binder allows mixers’ cleaning with water.

- There is weak adhesion to wood and metal (except aluminum) tooling.

- The storage time of the rods and forms is not limited, and the mixture that already hardens is not hygroscopic.

2.2. Specificity of AlpHaset Technology Use in Russia

- There is a significant smell, not only in the casting and knockout but also in the molding area;

- Water rinsing of the mixer is complicated;

- The half-mold or core removal from the fitting is complicated;

- Mixture knockout from complex geometry castings is complicated;

- Due to the increased resin and hardener consumption, the material costs and, therefore, produced casting costs are increasing.

- Quartz—1.0–1.8;

- Olivine—2.0–2.5;

- Zirconia—0.9–1.3;

- Chromite—1.0–1.5;

- Bauxite—1.0–1.2.

2.3. Other Molding Techniques

3. Materials and Methods

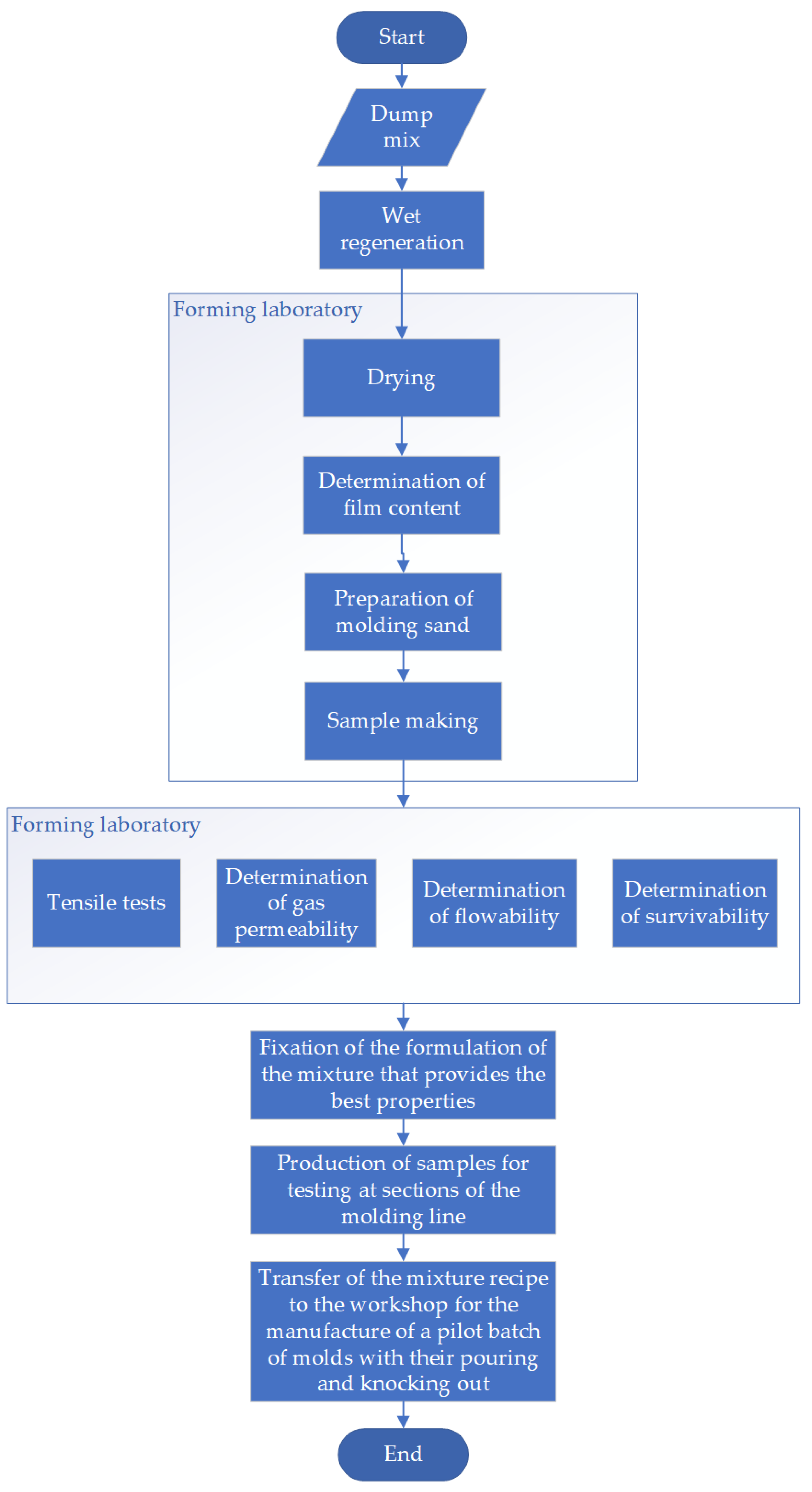

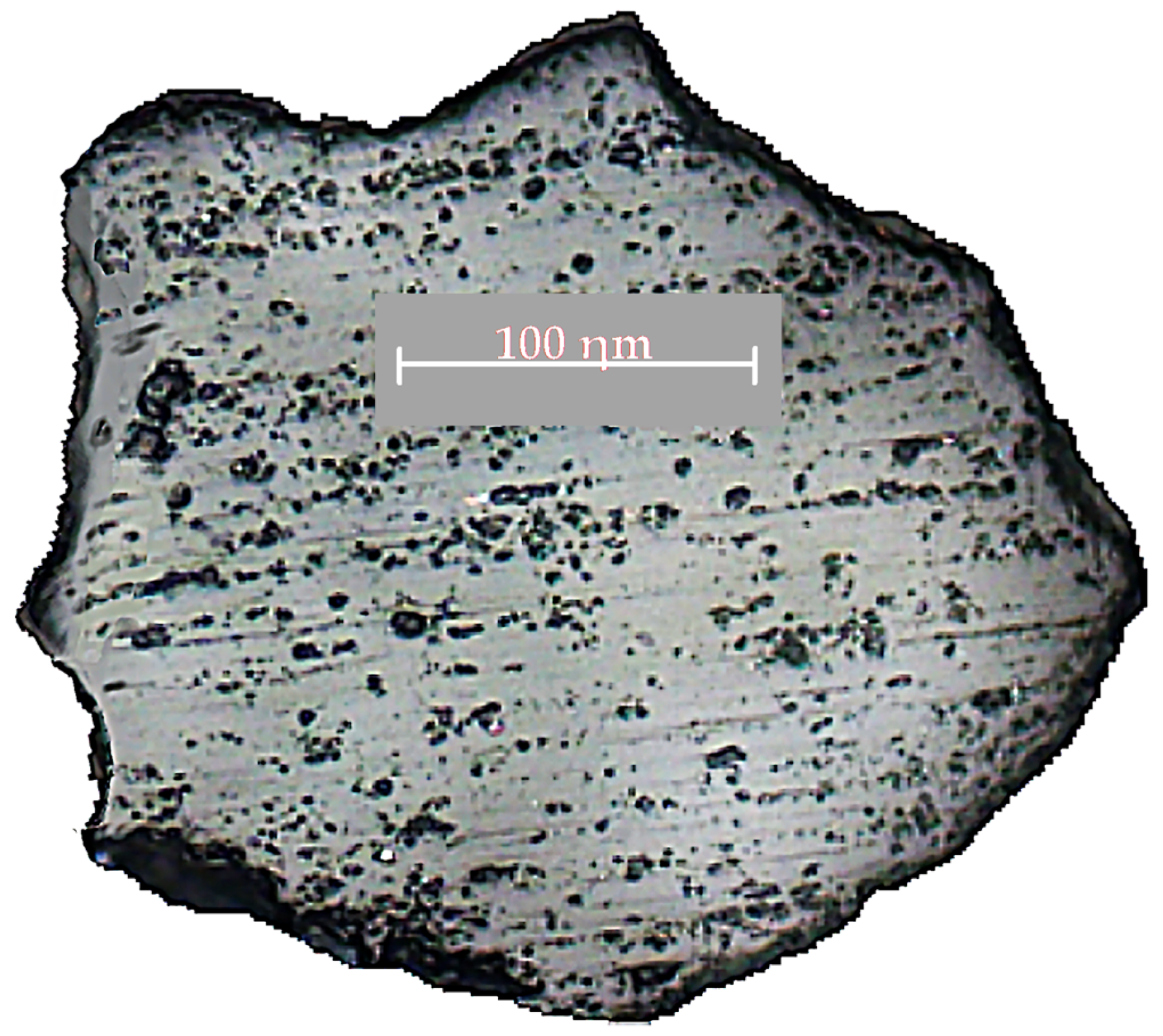

3.1. Used Liquid Glass Mixture Regeneration

3.2. Proposed Regeneration Technology for the Used Liquid Glass Mixture

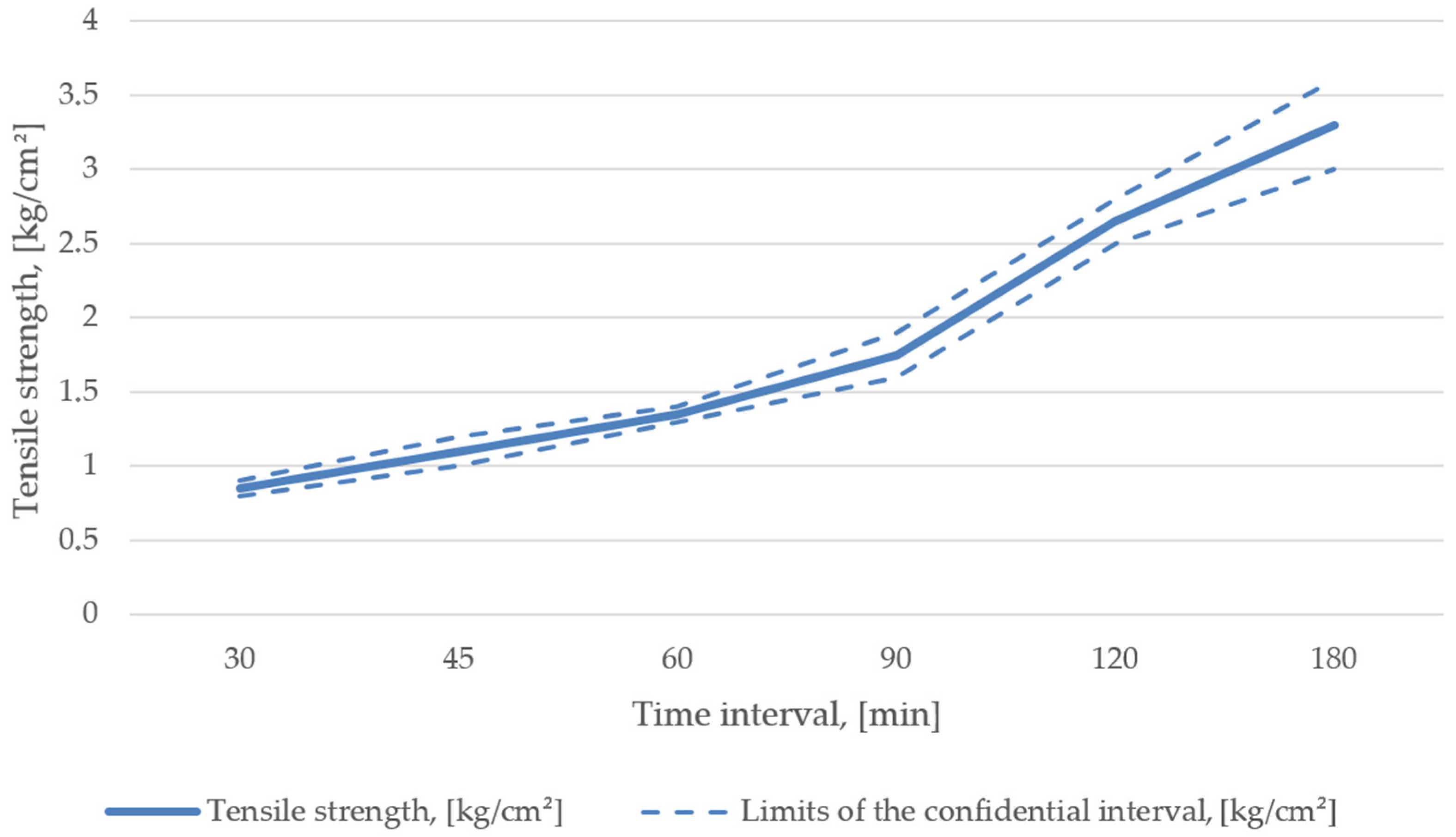

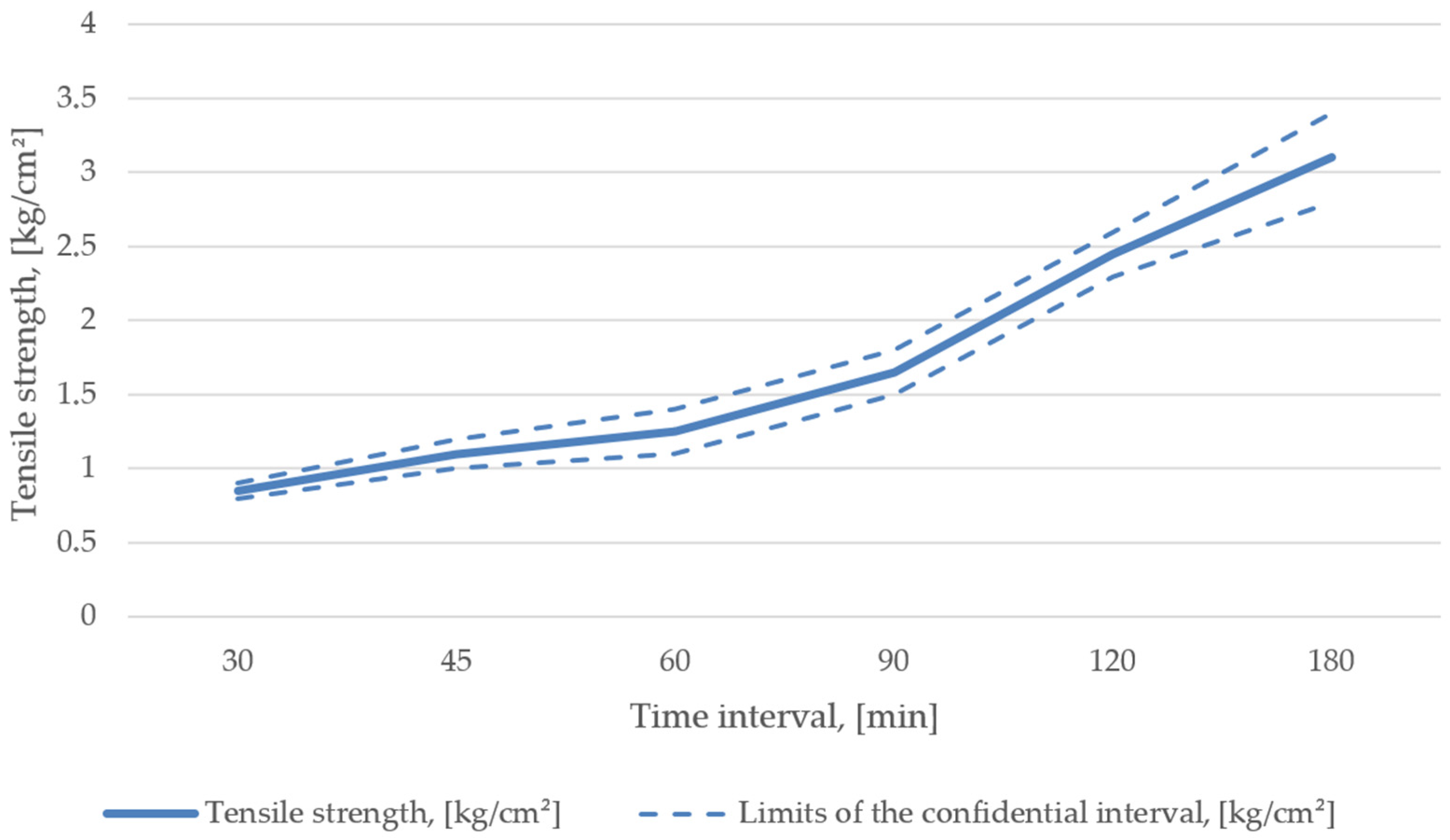

- After 25–30 min: 0.7–0.9;

- After 60 min: 1.3–1.7;

- After 120 min: 2.2–2.7.

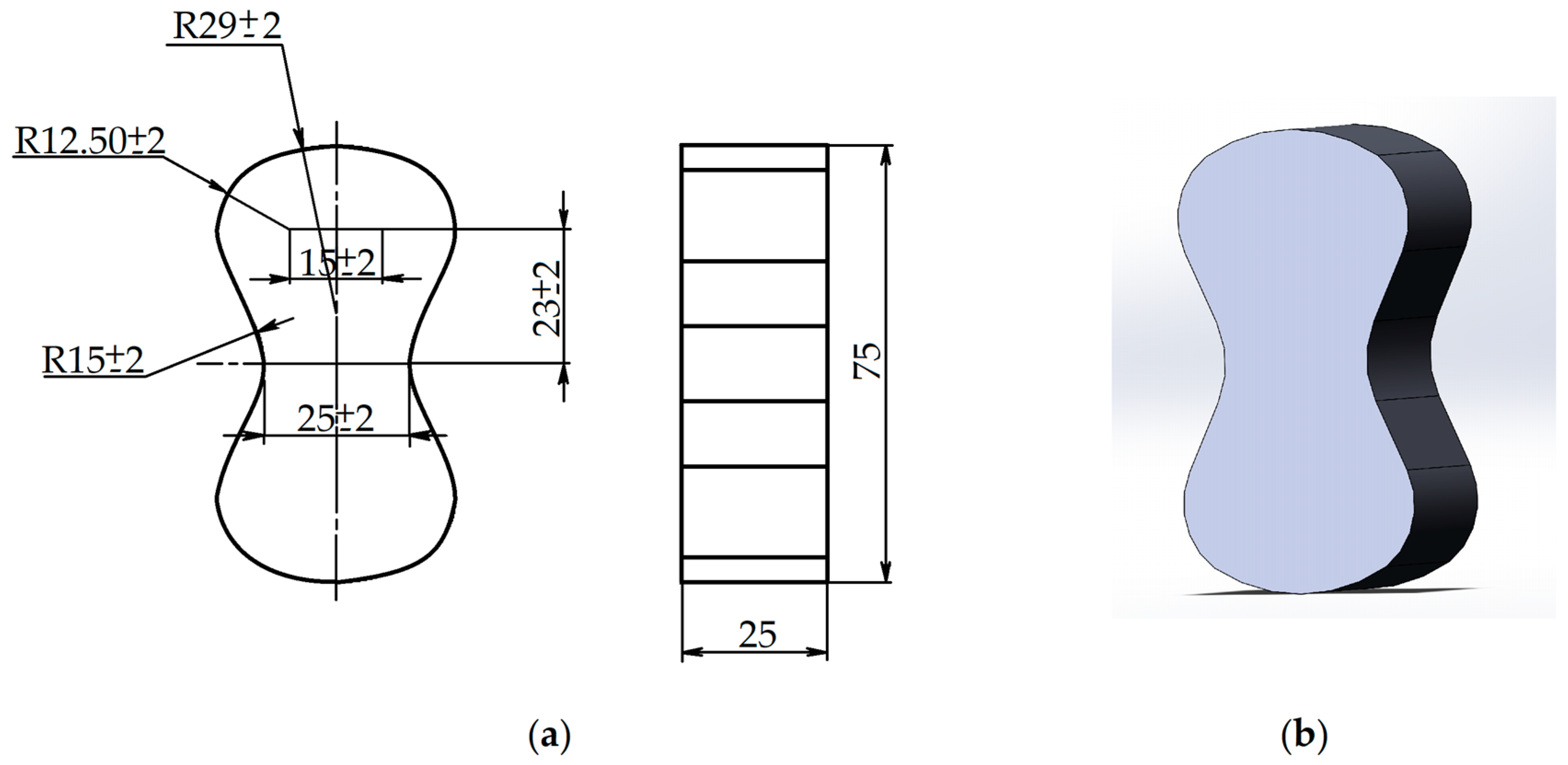

3.3. Research Methods and Equipment

- Laboratory runners (mixers) with a bowl capacity of 6 kg;

- Installation for testing the tensile strength of mixture samples, in the form of “eights”;

- Set of laboratory sieves;

- Device for determining humidity;

- Laboratory dryer;

- Device for crumbling determining;

- Laboratory pile driver;

- Laboratory scales.

- Stirring the reclaimed mixture with water glass and adding the hardener Katasil 1M. Stirring was continued until a homogeneous mass was obtained, which was assessed by color uniformity. The dosage of all components was carried out in measuring containers, with preliminary weighing on a laboratory balance.

- Pouring the mixture into a multi-slot core box, with internal dimensions that ensure the receipt of samples (eights).

- Manual sealing of the mixture.

- Removing samples from the box for subsequent testing at regular intervals, in accordance with the requirements for the mechanical properties of the mixture by the developers of the automatic molding line.

4. Results and Discussion

4.1. Mixture Recipe No. 1

4.2. Mixture Recipe No. 2

4.3. Mixture Recipe No. 3

4.4. Analysis of the Mechanical Properties of the Mixtures under Study

5. Conclusions

- If the used liquid glass mixture has been stored outdoors for a long period of time, the liquid glass film on the sand grains can be removed by hydraulic regeneration (by 85–90%).

- The reclaimed product can be used for manufacturing molds on automated molding lines with the AlpHaset process.

- The proposed technology is a way of using old, dumped liquid glass mixtures, thus reducing the harmful impact on the environment.

- The proposed technology is economically efficient, as it reduces the material costs. In this case, the largest cost reduction would occur in the foundries with in-house liquid glass production (as in most foundries using liquid glass mixture molding manufacturing technology).

- To completely eliminate odor when working on traditional mix recipes: sand, resin, and hardener.

- To return to the production own waste, stored at the industrial landfill, and thereby reduce the purchase of raw materials.

- To reduce the need for raw sand, which will reduce the development of quarries and environmental harm.

- To admit businesses to make castings using their own waste, eliminate the heavy manual labor involved in punching out molds, and further increase production efficiency by reducing the cost of purchasing raw materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Holtzer, M.; Danko, R.; Zymankowska-Kumon, S. Foundry industry—Current state and future development. Metalurgija 2012, 51, 337–340. [Google Scholar]

- Costache, B.; Pencea, M.I.; Funar, S.P. Waste and environment protection management of the typical German small and medium-sized foundries. In Annals of DAAAM and Proceedings of the International DAAAM Symposium; DAAAM International Vienna: Vienna, Austria, 2007; Volume 10, pp. 173–174. [Google Scholar]

- Tkachenko, S.S.; Evseev, V.I. State and prospects for the development of foundry in the machine tool industry of Russia. Industry 2009, 4, 20–21. [Google Scholar]

- Orekhova, A.I. Foundry environmental problems. Ecol. Prod. 2005, 1, 26–27. [Google Scholar]

- Penko, T. Resin/CO2 Core and Moldmaking Process: Emission Characterization. AFS Trans. 2005, 10, 1029–1037. [Google Scholar]

- Melnikov, A.P.; Sadokha, M.A. Features of manufacturing and classification of castings according to the technological complexity of production. Cast. Metall. 2007, 1, 88–92. [Google Scholar]

- Dubrovin, V.K.; Kulakov, B.A.; Karpinsky, A.V.; Dubrovina, A.V. Influence of recycled molding sand on the quality of castings. Bull. South Ural. State Univ. 2014, 14, 35–40. [Google Scholar]

- Tipner, L.M.; Iskhakova, N.R. Problems of organization in the conditions of single and small-scale production. Econ. Bus. Theory Pract. 2019, 5-3, 97–102. [Google Scholar] [CrossRef]

- Lotosh, V.E. Recycling of Environmental Waste; Polygraphist: Yekaterinburg, Russia, 2007. [Google Scholar]

- Drummers, D.A.; Serdyukova, A.F. Utilization of industrial waste. Young Sci. 2017, 25, 101–104. [Google Scholar]

- Dobrynina, A.V. Rational use of foundry waste. Sci. Alm. 2018, 6-2, 22–25. [Google Scholar] [CrossRef]

- Boyko, N.I.; Odaryuk, V.A.; Safonov, A.V. The main directions of waste-free and low-waste technologies. Civ. Secur. Technol. 2015, 12, 68–72. [Google Scholar]

- Shevchenko, O.A.; Mozharova, N.V. Experience of using waste foundry in the conditions of JSC “EZTM”. Foundry Processes 2012, 11, 205–215. [Google Scholar]

- Kralj, D. Recycling and environmental waste management in constructions. WSEAS Trans. Environ. Dev. 2008, 4, 389–398. [Google Scholar]

- Pribulova, A.; Bartosova, M. Wastes created in foundry and their treatment. In Proceedings of the 8th International Scientific Conference on Modern Management of Mine Producing, Geology and Environmental Protection, Albena, Bulgaria, 16–20 June 2008; Volume 2, pp. 201–208. [Google Scholar]

- Bolden, J.; Abu-Lebdeh, T.; Fini, E. Utilization of recycled and waste materials in various construction applications. Am. J. Environ. Sci. 2013, 9, 14–24. [Google Scholar] [CrossRef]

- Kukui, D.M.; Skvortsov, V.A.; Andrianov, N.V. Foundry Theory and Technology; INFRA-M: Moscow, Russia, 2011. [Google Scholar]

- Gross, I.; Woldert, F. Modern system for the regeneration of molding sand based on furan resins. Cast. Ukr. 2012, 12, 19–20. [Google Scholar]

- Gedik, A.; Hilmi Lav, A.; Aysen Lav, M. Investigation of alternative ways for recycling waste foundry sand: An extensive review to present benefits. Can. J. Civ. Eng. 2018, 45, 423–434. [Google Scholar] [CrossRef] [Green Version]

- Izdebska-Szanda, I.; Angrecki, M.; Palma, A. Recycling of waste moulding sands with new binders. Arch. Foundry Eng. 2013, 13, 43–48. [Google Scholar] [CrossRef]

- Pyrikov, A.N.; Chernousov, P.I.; Martynov, N.N. Environmental Engineering and Environmental Security of the Russian Federation, 1st ed.; Center for Innovative Technologies: Moscow, Russia, 2012; pp. 129–148.

- Tkachenko, S.S.; Kolodiy, G.A.; Znamensky, L.G.; Ermolenko, A.A. Cold-hardening mixtures on an inorganic binder: State and development prospects (inorganic versus organic). Cast. Metall. 2018, 2, 16–22. [Google Scholar]

- Salokhel, E.P.; Desai, D.B. Application of foundry waste sand in manufacture of concrete. IOSR J. Mech. Civ. Eng. 2014, 43–48. [Google Scholar]

- Vasková, I.; Smolková, M.; Malik, J.; Eperješi, Š. Experience in forming and core mixtures by AlpHhaset technology. Arch. Foundry Eng. 2008, 8, 141–144. [Google Scholar]

- Orkas, J. Technical and Environmental Requirements for Surplus Foundry Sand Utilization; Report TKK-VAL-3/2001; Helsinki University of Technology: Espoo, Finland, 2001. [Google Scholar]

- Psimenos, A.K.; Eder, G.; Sipos, M.M. Cold-curing resins with low emission of harmful substances and odor (Cold-Box)—Absolutely free of aromatic solvents. Cast. Metall. 2011, 2, 23–31. [Google Scholar]

- Vdovin, K.N.; Feoktistov, N.A.; Deryabin, D.A.; Khrenov, I.B. Investigation of the properties of a refractory filler of cold-hardening mixtures. Theory Technol. Metall. Prod. 2016, 1, 47–51. [Google Scholar]

- Roczniak, A.; Holtzer, M.; Kmita, A. Research of emission of commercial binders used in ALPHASET technology—Estimated quantitative analysis. Arch. Foundry Eng. 2018, 18, 109–114. [Google Scholar] [CrossRef]

- Nybergh, C.J. AlpHaset Process and Its Use in Russia, 3rd ed.; Russian Caster: Moscow, Russia, 2002; pp. 35–40. [Google Scholar]

- Ryabova, N.A.; Walter, A.I. Self-hardening mixtures. Alpha set process. In Prospects for the Development of Processing Technologies and Equipment in Mechanical Engineering; Defence Science and Technology Group: Edinburgh, Australia, 2021; pp. 194–198. [Google Scholar]

- Kukartsev, V.A. Liquid glass mixtures and modern hardeners. Foundry Russ. 2013, 10, 46–48. [Google Scholar]

- Zhukovskiy, S.S. Technological Parameters of Synthetic Binders Produced by Uralchimplast-Kavenagi Enterprise; Parts 1 and 2; Russian Caster: Moscow, Russia, 2007; pp. 29–33. [Google Scholar]

- Zhukovskiy, S.S. Cold Hardening Binders and Mixtures for Cores and Moulds; Mashinostroyeniye: Moscow, Russia, 2010. [Google Scholar]

- Shalevskaya, I.A.; Gutko, Y.I. Investigation of the possibility of recycling waste molding mixtures. Bull. Don State Mach.-Build. Acad. 2011, 4, 169–173. [Google Scholar]

- Kukui, D.M.; Odinochko, V.F.; Kirilov, I.V.; Busel, A.V.; Vorobiev, V.V.; Korenyuk, G.S. Investigation of the possibility of regeneration of foundry sands from dump mixtures of foundry and the use of regeneration waste. Cast. Metall. 2009, 3, 33–36. [Google Scholar]

- Joseph, M.K.; Banganayi, F.; Oyombo, D. Moulding sand recycling and reuse in small foundries. Procedia Manuf. 2017, 7, 86–91. [Google Scholar] [CrossRef]

- Borsuk, P.A.; Lyass, A.M. Liquid Self-Hardening Mixtures; Mashinostroyeniye: Moscow, Russia, 1979. [Google Scholar]

- Kukartsev, V.A.; Drozdova, T.N.; Kukartsev, V.V.; Atroshenko, A.V. The use of waste heaps liquid mixture in the manufacture of forms. Foundry 2015, 5, 6–8. [Google Scholar]

- Kukartsev, V.A. AlpHaset process and moulding sands of Russia. Procuring Prod. Mech. Eng. 2014, 3, 45–47. [Google Scholar]

- Hu, J.-R.; He, Z.-M. Research of foundry technique and sand, its wastes to environmental effect. Zhuzao/Foundry 2004, 53, 1035–1050. [Google Scholar]

| Alternative | Composition of the Mixture | Tensile Strength (kg/cm2) with the Interval (Min) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Refractory Filler | Binder | Hardener | Reclaimed Product (%) | 30 | 45 | 60 | 90 | 120 | 180 | |

| No. 1 | Molding sand 1K20303 | Alkaset resin NB7 | Katalit 3V | 76–80 | 0.7–0.9 | 1.0–1.2 | 1.3–1.5 | 1.6–1.9 | 2.2–2.7 | 3.0–3.6 |

| No. 2 | Molding sand 1K20303 | Liquid glass | Katasil 1M | 70–75 | 0.8–0.9 | 1.0–1.2 | 1.3–1.4 | 1.6–1.9 | 2.5–2.8 | 3.0–3.6 |

| No. 3 | Reclaimed liquid glass mixture | Liquid glass | Katasil 1M | 65–72 | 0.8–0.9 | 1.0–1.2 | 1.1–1.4 | 1.5–1.8 | 2.3–2.6 | 2.8–3.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kukartsev, V.A.; Kukartsev, V.V.; Tynchenko, V.S.; Bukhtoyarov, V.V.; Tynchenko, V.V.; Sergienko, R.B.; Bashmur, K.A.; Lysyannikov, A.V. The Technology of Using Liquid Glass Mixture Waste for Reducing the Harmful Environmental Impact. Materials 2022, 15, 1220. https://doi.org/10.3390/ma15031220

Kukartsev VA, Kukartsev VV, Tynchenko VS, Bukhtoyarov VV, Tynchenko VV, Sergienko RB, Bashmur KA, Lysyannikov AV. The Technology of Using Liquid Glass Mixture Waste for Reducing the Harmful Environmental Impact. Materials. 2022; 15(3):1220. https://doi.org/10.3390/ma15031220

Chicago/Turabian StyleKukartsev, Viktor Alekseevich, Vladislav Viktorovich Kukartsev, Vadim Sergeevich Tynchenko, Vladimir Viktorovich Bukhtoyarov, Valeriya Valerievna Tynchenko, Roman Borisovich Sergienko, Kirill Aleksandrovich Bashmur, and Aleksey Vasilyevich Lysyannikov. 2022. "The Technology of Using Liquid Glass Mixture Waste for Reducing the Harmful Environmental Impact" Materials 15, no. 3: 1220. https://doi.org/10.3390/ma15031220