Evaluation on Improvement Effect of Different Anti-Stripping Agents on Pavement Performance of Granite–Asphalt Mixture

Abstract

:1. Introduction

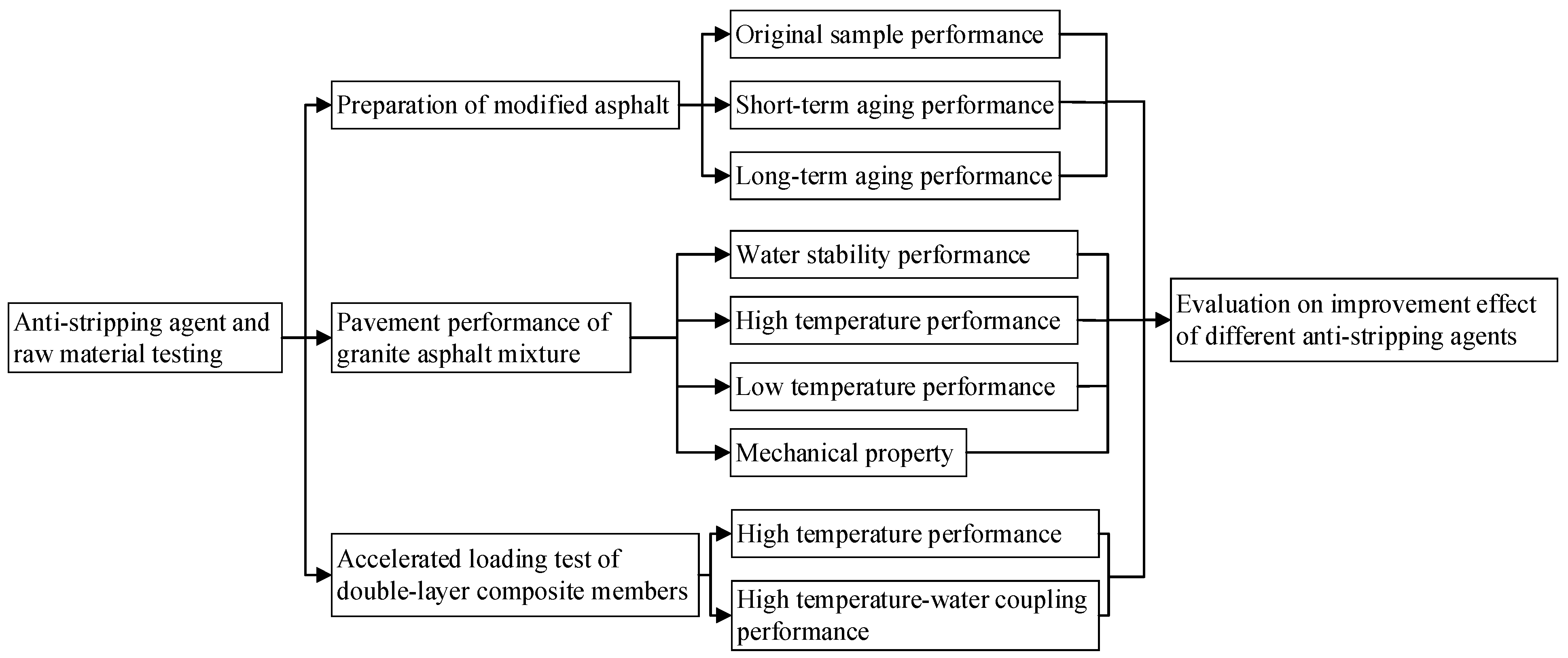

2. Materials and Methods

2.1. Materials

2.2. Modification Scheme and Preparation of Modified Asphalt Binders

2.2.1. RMA

2.2.2. SCAMA

2.2.3. SCA&RMA

2.3. Tests for Asphalt Binder with Different Modification Schemes

2.4. Pavement Performance Tests for Granite–Asphalt Mixture

2.4.1. Anti-Stripping Measures and Schemes

2.4.2. Water Stability Test

2.4.3. Low Temperature Performance of Granite–Asphalt Mixture

2.4.4. Hamburg Wheel-Track Test

2.4.5. Mechanical Property

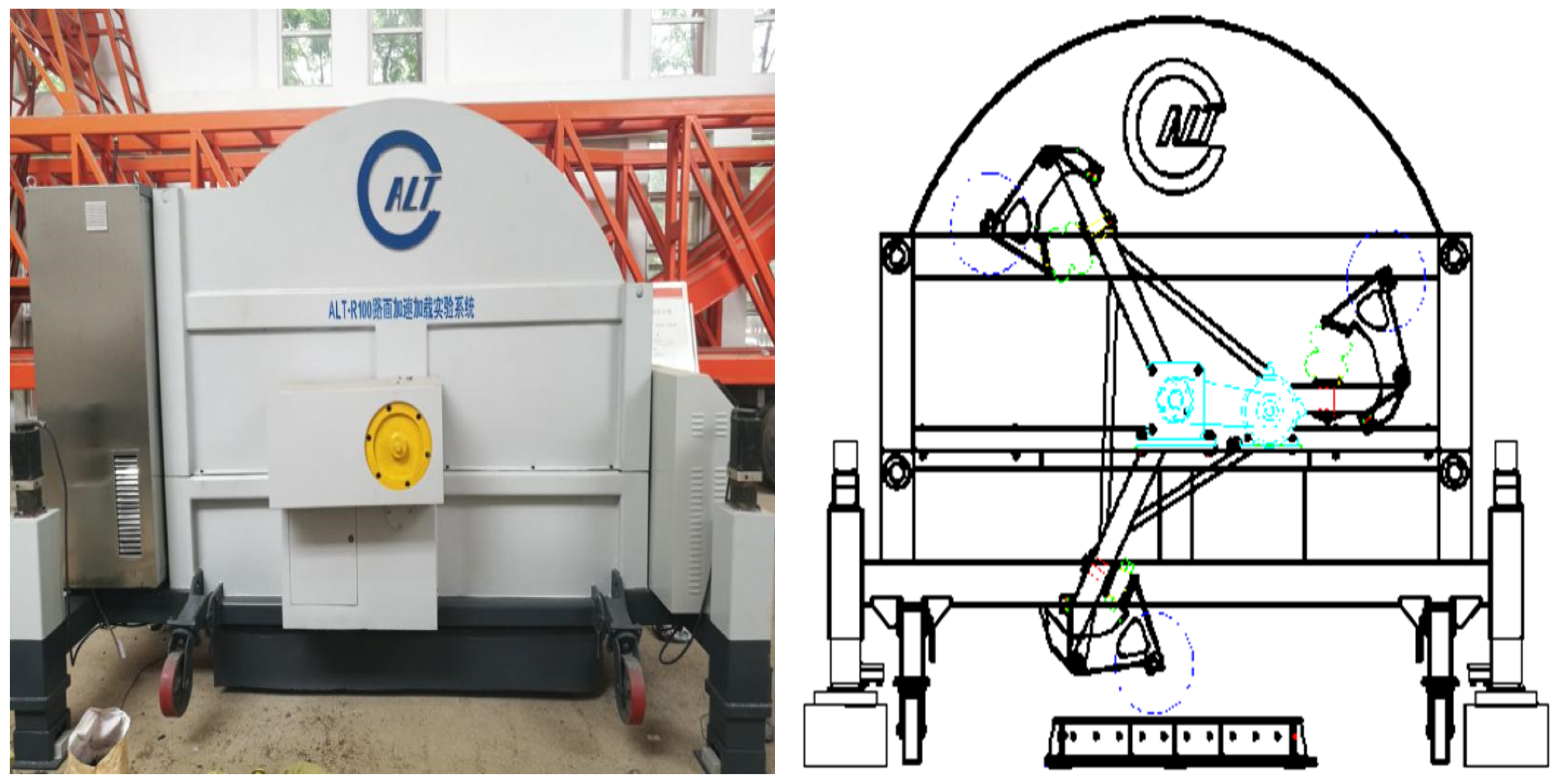

2.5. Accelerated Loading Test

2.5.1. Test Specimen

2.5.2. Test Procedure

2.5.3. High-Temperature-Coupled Water Stability Evaluation

3. Results and Discussion

3.1. Conventional and Rheological Properties of Asphalt Binder

3.1.1. Conventional and Rheological Properties of Original Asphalt Binder

3.1.2. Conventional and Rheological Properties of Aged Asphalt Binder

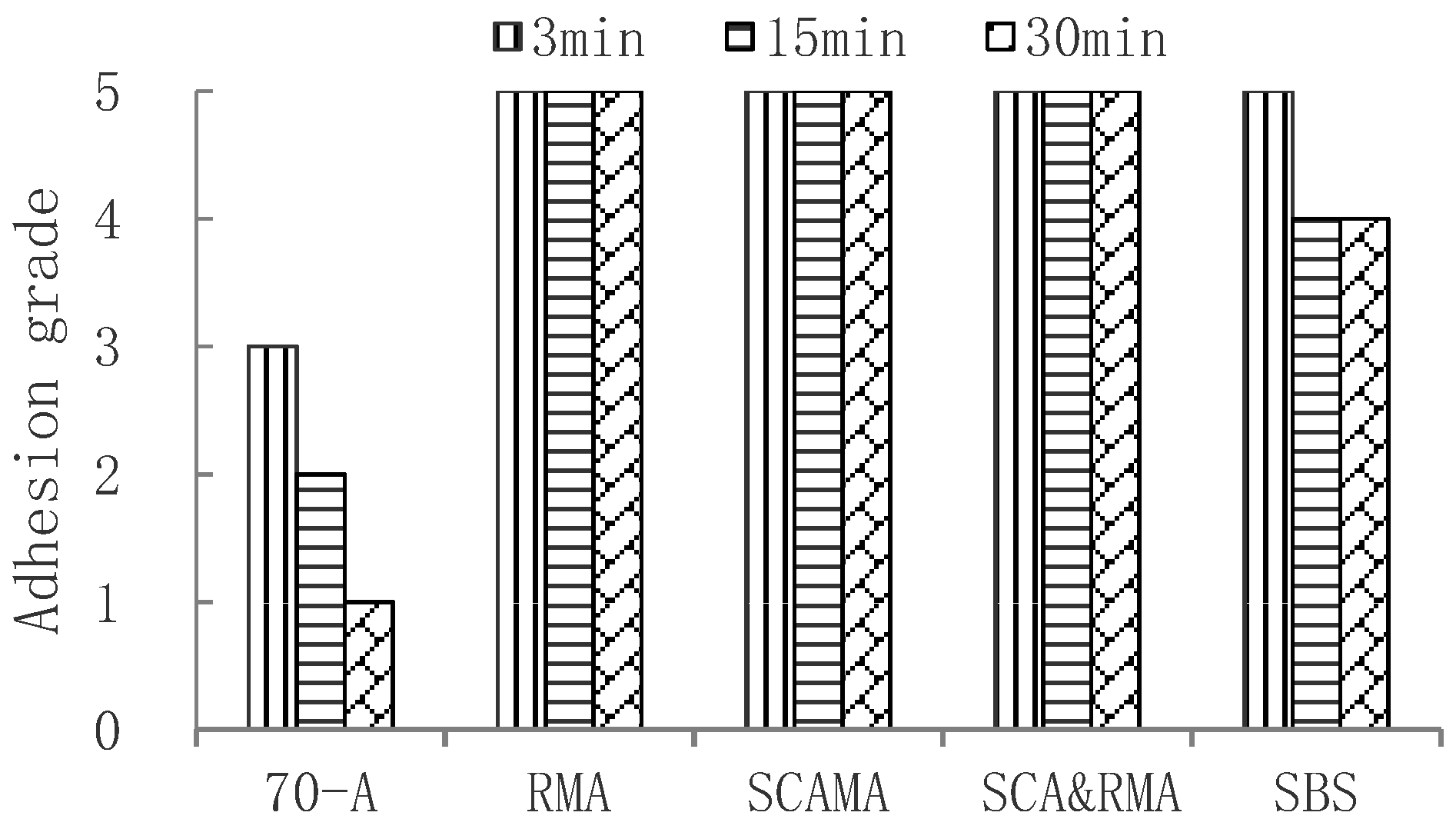

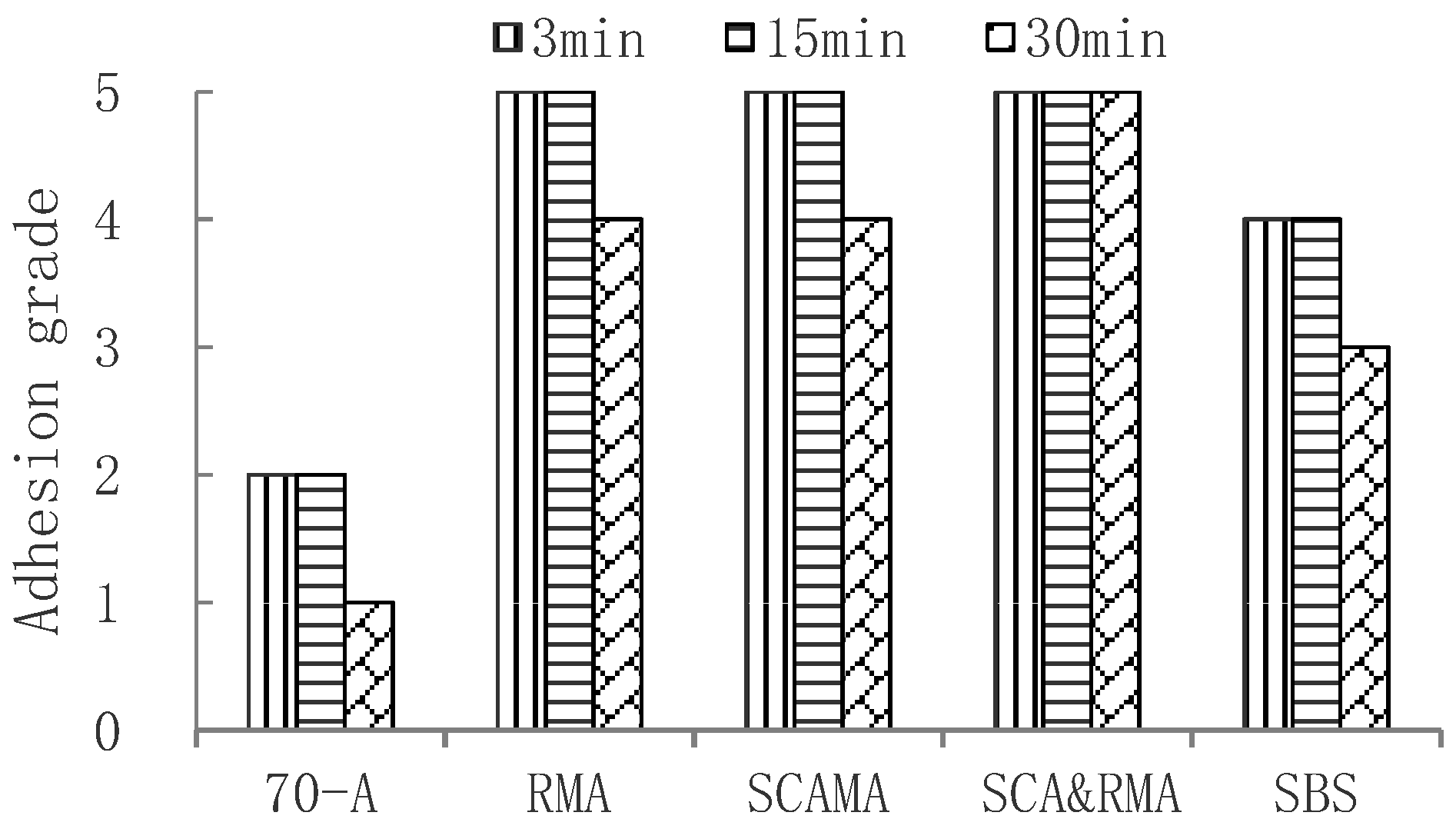

3.2. Adhesion Evaluation between Granite Aggregate and Asphalt

3.3. Water Stability Evaluation

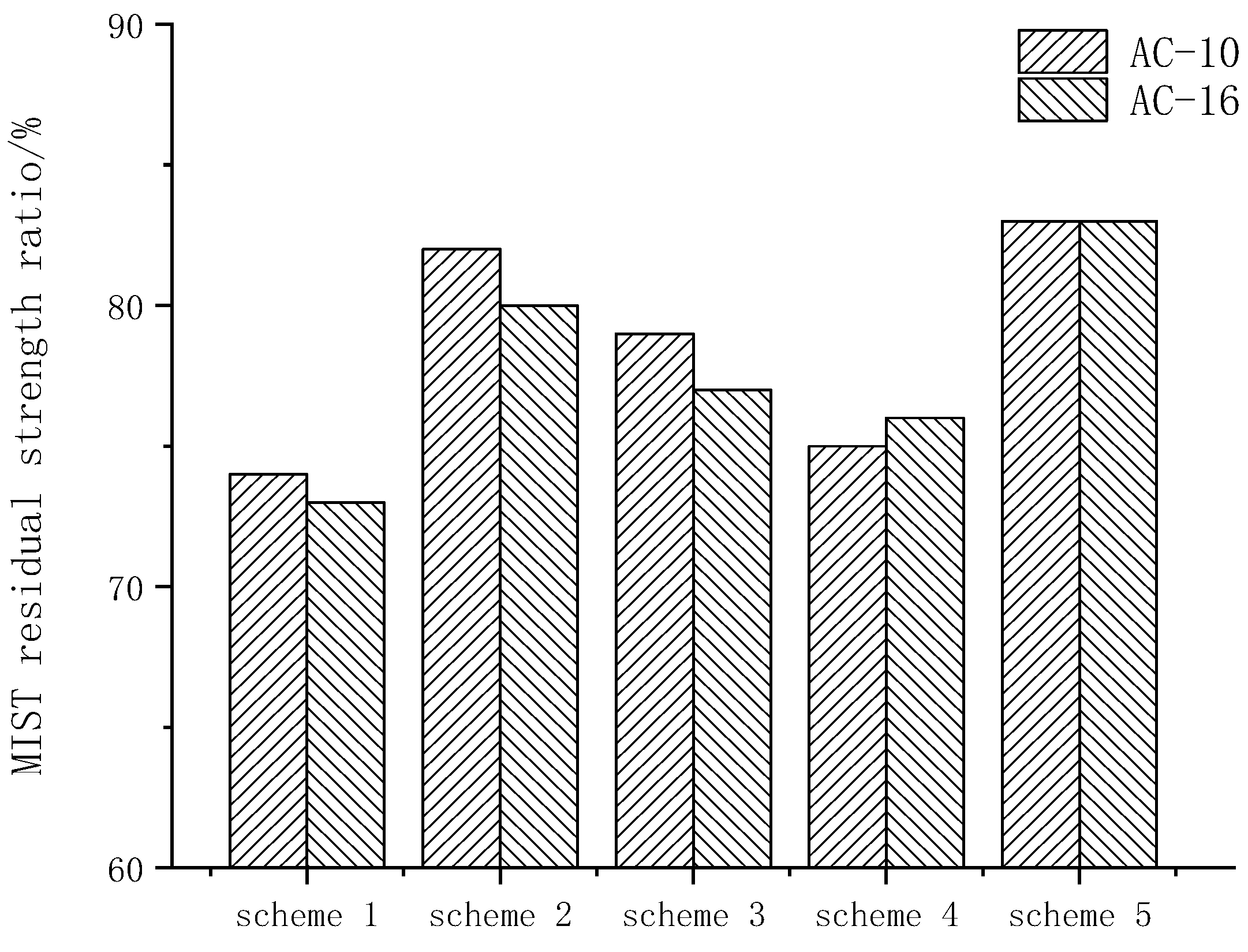

3.3.1. Water Immersion Marshall Test

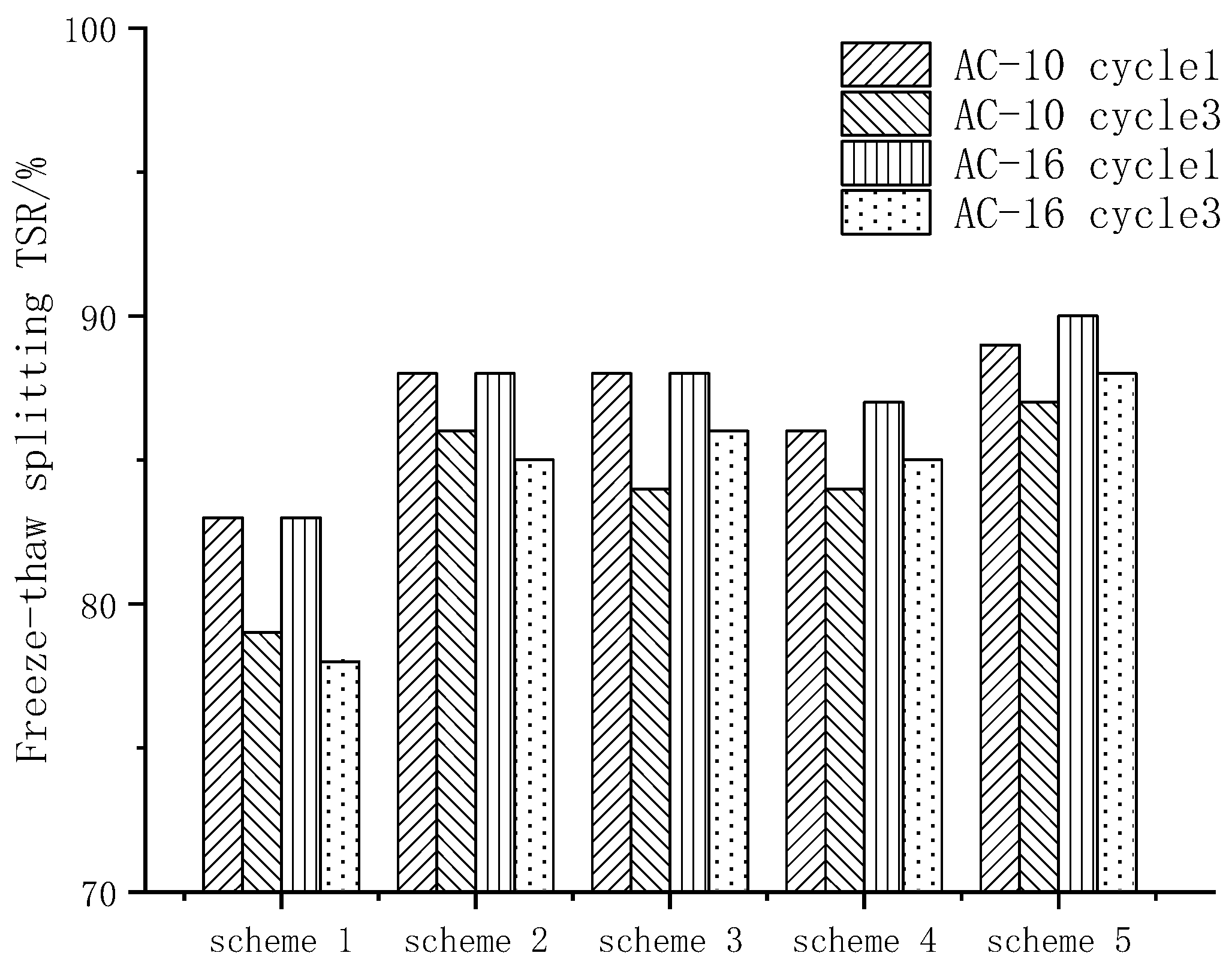

3.3.2. Freeze–Thaw Splitting Test

3.3.3. Water Damage Sensitivity Analysis Test

3.4. Low-Temperature Crack Resistance

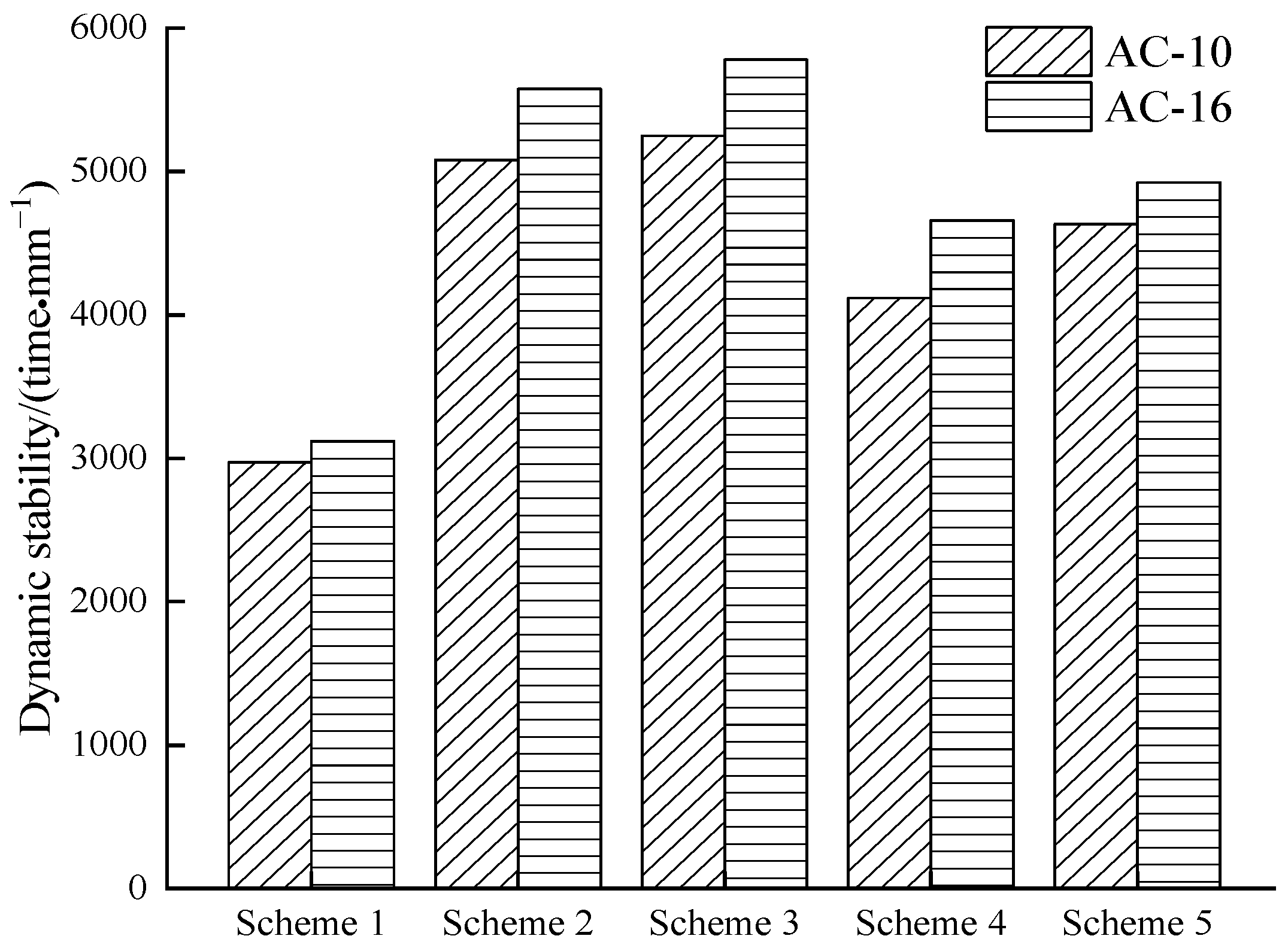

3.5. High-Temperature Rutting Resistance

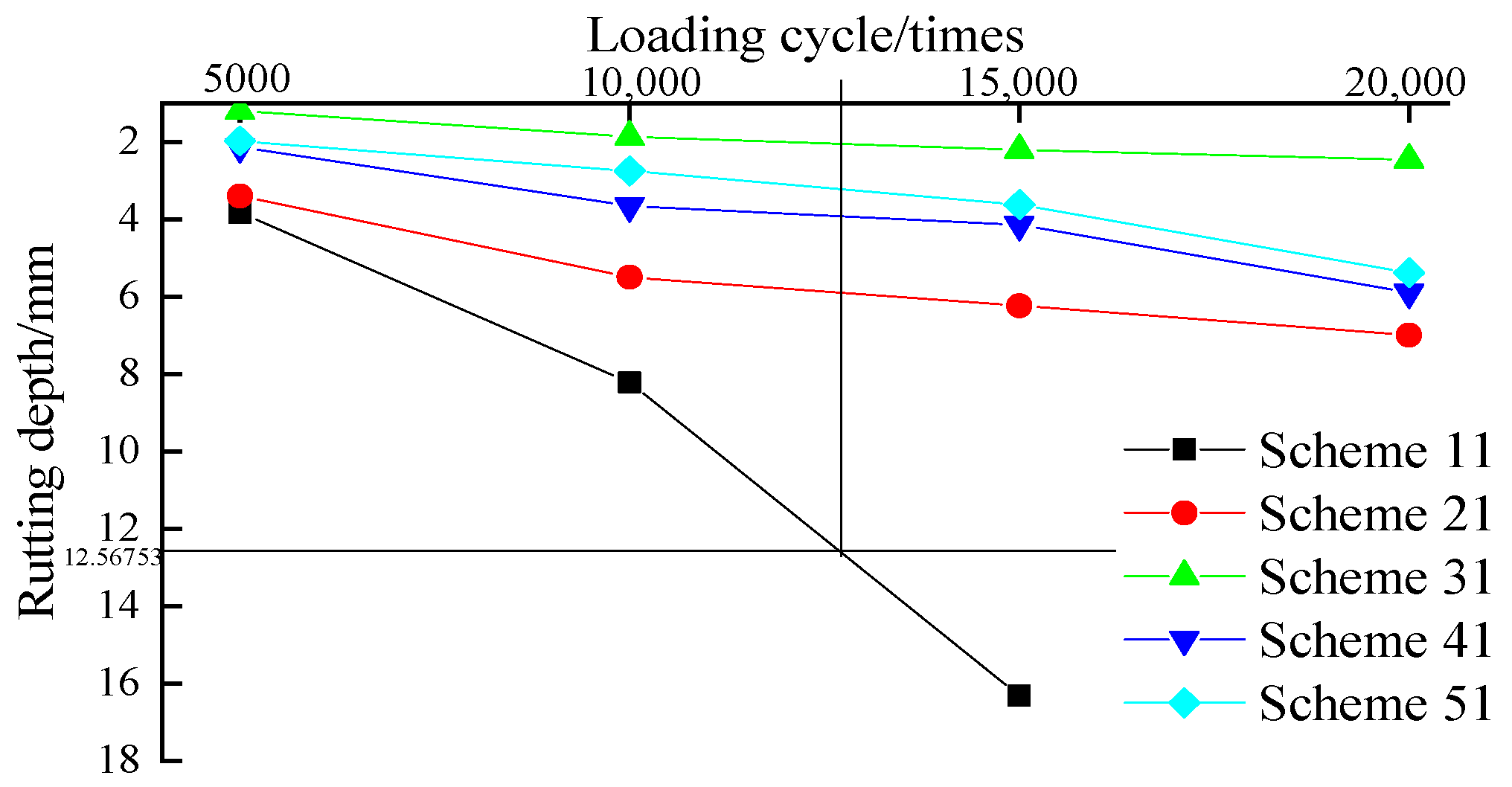

3.6. High-Temperature and Water Stability of Double-Layer Composite Specimen

3.7. Mechanical Properties of Granite Double-Layer Composite Specimens

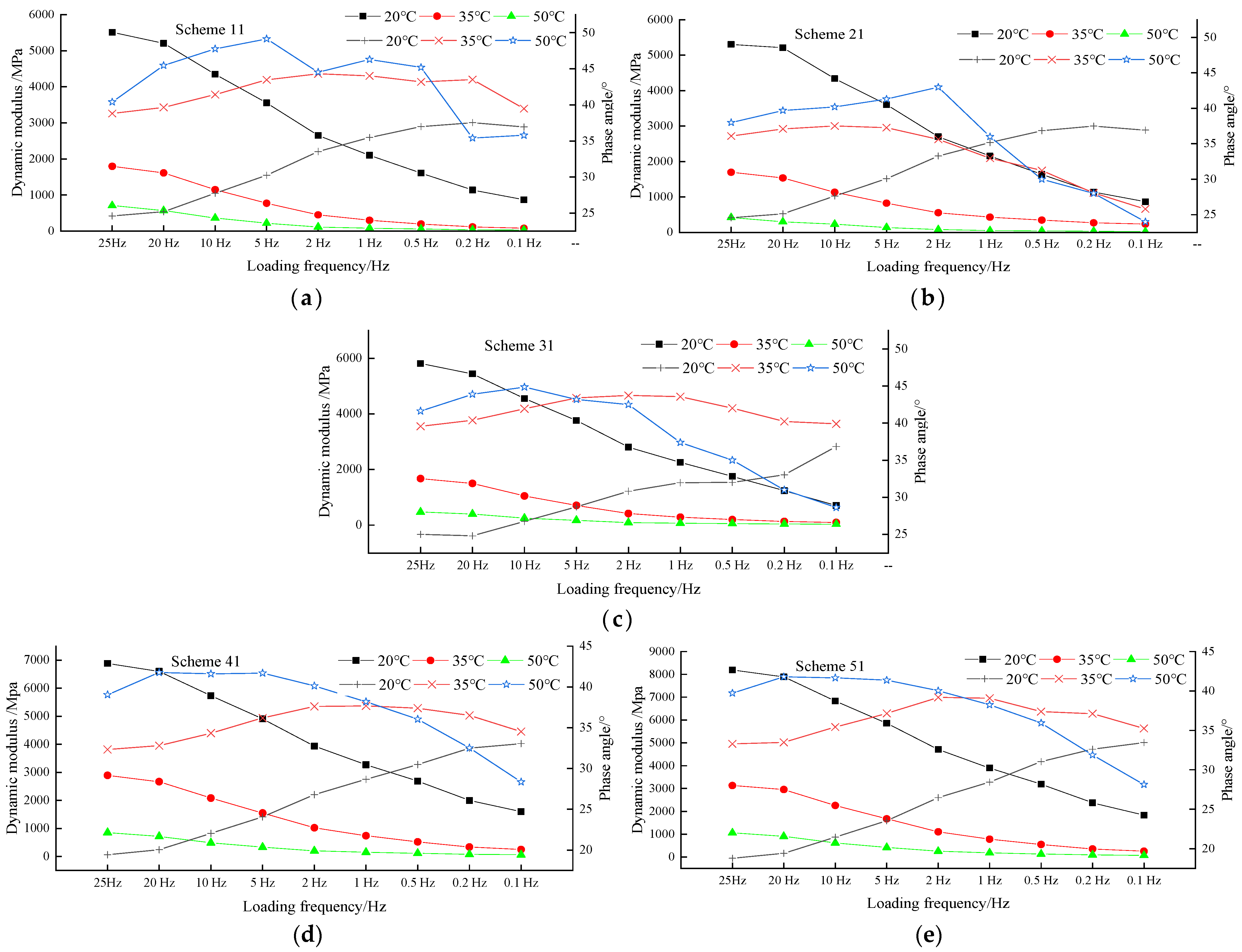

- (1)

- Under the conditions of 20 °C, 35 °C, and 50 °C, respectively, the dynamic modulus of granite–asphalt mixture specimens formed in the same scheme decreased with the decrease in loading frequency, and the five schemes showed the same variation law. The analysis showed that the elasticity of asphalt mixture decreased and that the viscosity increased when the loading frequency decreased gradually. Under the condition of a certain loading frequency, the dynamic modulus decreased with the increase in temperature, which was mainly due to the gradual decrease in asphalt stiffness modulus as binder with the increase in mixture temperature. Under the action of stress, the resilience decreased, which was reflected in the decrease in dynamic modulus.

- (2)

- As the temperature increased or the load frequency decreased, the phase angles all increased first, and then decreased after the peak. When exposed to high-temperature and low frequency, the viscosity of the asphalt binder decreased, and the effect on the performance of the asphalt mix was also reduced. At this time, the mineral aggregate skeleton had become the main factor affecting the asphalt mixture, and the mineral aggregate was an elastic material and its phase angle was zero, so the phase angle of the asphalt mixture would decrease.

- (3)

- As the loading frequency changed from high to low, the slope of the main curve first increased and then decreased, indicating that the dynamic modulus of the asphalt mixture did not change much with loading frequency under the conditions of extremely high frequency and extremely low frequency. In the intermediate frequency range (the frequency range expanded with the increasing temperature), the loading frequency had a great influence on the dynamic modulus of the mixture.

3.8. Performance of Double-Layer Asphalt Mixture Based on Accelerated Loading Test

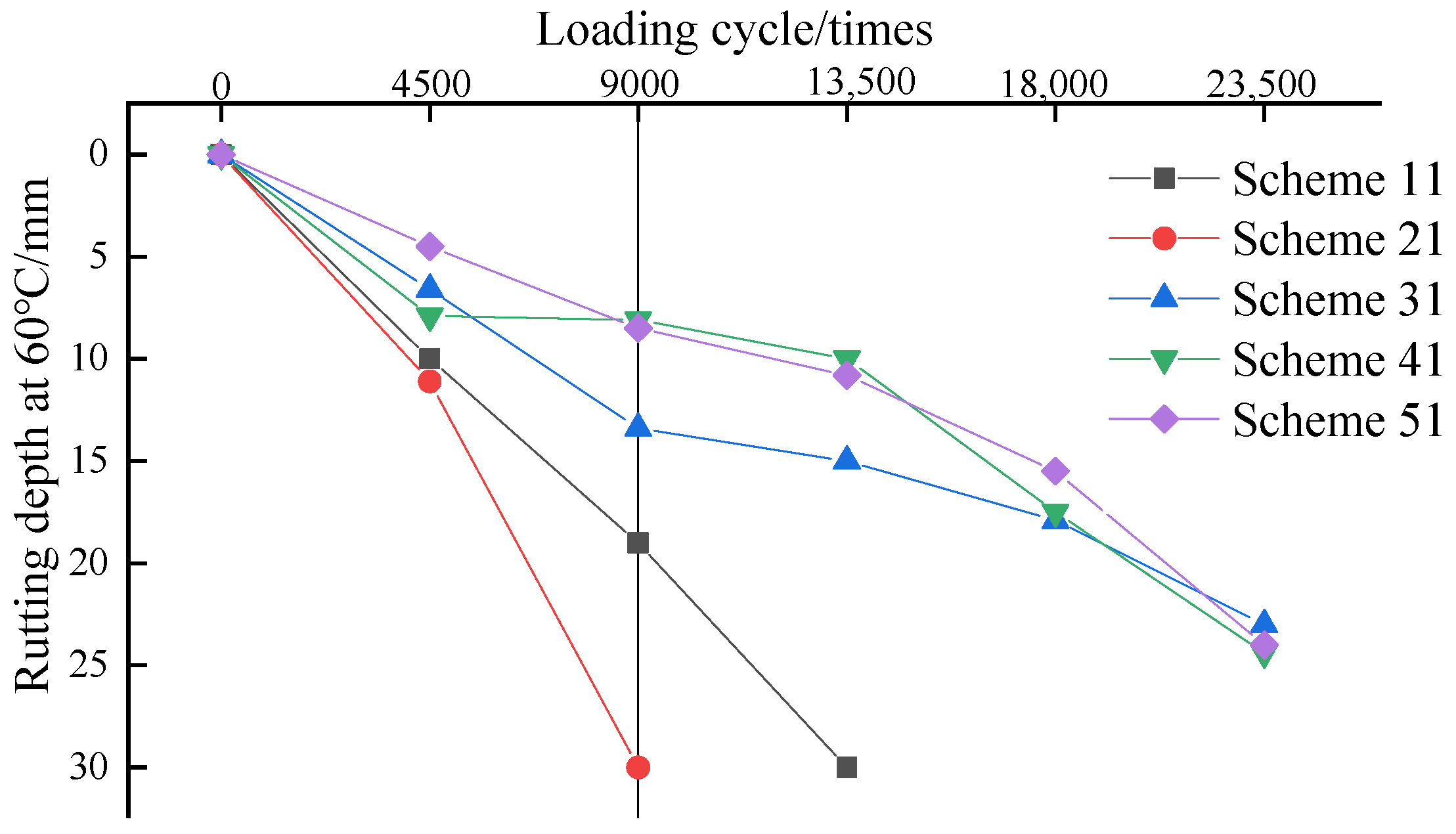

3.8.1. High-Temperature Stability of Double-Layer Composite Specimens

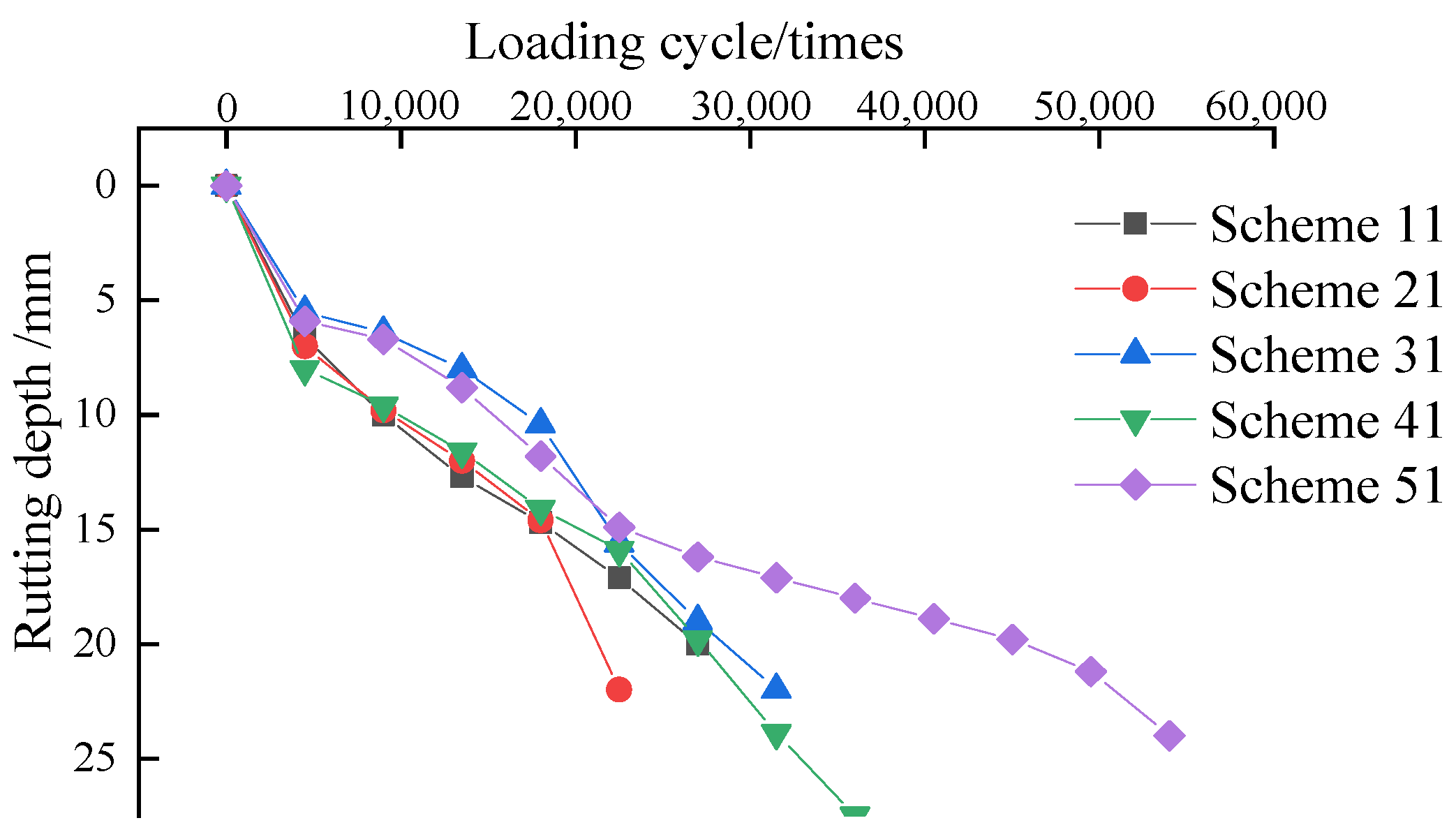

3.8.2. Performance of Composite Specimens under High-Temperature and Water

3.9. Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ba, H.D.; Park, D.W.; Phan, T.M. Healing Performance of Granite and Steel Slag Asphalt Mixtures Modified with Steel Wool Fibers. KSCE. J. Civ. Eng. 2018, 22, 2064–2072. [Google Scholar]

- Shtayat, A. A review of monitoring systems of pavement condition in paved and unpaved roads. J. Traffic Transp. Eng. 2020, 7, 629–638. [Google Scholar] [CrossRef]

- Lv, J. Research on the Method and Pavement Performance of Acidic Aggregate Modified by Silane Coupling Agent. Master’s Thesis, Jilin University, Jilin, China, 2013. (In Chinese). [Google Scholar]

- Zhang, Y. Study on Adhesion of Interface between Asphalt and Aggregate. Master’s Thesis, Chang’an University, Xi’an, China, 2014. (In Chinese). [Google Scholar]

- Xu, S.A.; Wang, S.N.; Gu, Y.Y. Microstructure and adhesion properties of cerium conversion coating modified with silane coupling agent on the aluminum foil for lithiumion battery. Results Phys. 2019, 13, 102262. [Google Scholar] [CrossRef]

- JTG E42-2005; Test Methods of Aggregate for Highway Engineering. People’s Communications Press: Beijing, China, 2005.

- JTG F40-2004; Technical Specifications for Construction of Highway Asphalt Pavement. People’s Communications Press: Beijing, China, 2004.

- Mazumder, M.; Ahmed, R.; Ali, A.W. SEM and ESEM techniques used for analysis of asphalt binder and mixture: A state of the art review. Constr. Build. Mater. 2018, 18, 313–329. [Google Scholar] [CrossRef]

- Liu, W.Z. The introduction of SBS modification asphalt processing and its application on the road construction. Shanxi Arch. 2010, 36, 172–173. (In Chinese) [Google Scholar]

- Xiao, Q.; Qian, C.; Xie, J. Experimental research on modification of asphalt concrete performance and asphalt-aggregate interface by coupling agent. J. Southeast Univ. 2004, 34, 485–489. (In Chinese) [Google Scholar]

- Song, X.J.; Jiang, F.; Shen, Q.J. A Study on Pavement Performance of Chinese-Made Natural Rock Asphalt Modified Asphalt Mixture. Highway 2009, 12, 135–139. (In Chinese) [Google Scholar]

- Zhang, A.Q.; Gong, B.H.; Hao, X.H.; Wang, K. Study on improving adhesion between granite and asphalt by titanate coupling agent. China Foreign Highw. 2008, 3, 176–180. (In Chinese) [Google Scholar]

- Kong, Z.Z.; Zhang, Y.M.; Zhang, A.Q. Influence of Granite Powder Filler on Water Stability of Asphalt Concrete. China Foreign Highw. 2014, 34, 287–290. (In Chinese) [Google Scholar]

- Gao, C.; Feng, D.C. Study on Road Performance of Granite Asphalt Mixture. Highway 2008, 10, 161–166. (In Chinese) [Google Scholar]

- Zhang, W.T. Application Research of Granite in Upper Layer of Asphalt Pavement in Megathermal and Rainy Area. Master’s Thesis, Southeast University, Nanjing, China, 2016. (In Chinese). [Google Scholar]

- Li, M.T. Research on Adhesion between Asphalt and Aggregate Based on Surface Energy Theory. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2017. (In Chinese). [Google Scholar]

- Peng, C.; Chen, P.X. Effect of silane coupling agent on improving the adhesive properties between asphalt binder and aggregates. Constr. Build. Mater. 2018, 169, 591–600. [Google Scholar] [CrossRef]

- Han, S.; Dong, S.; Liu, M. Study on improvement of asphalt adhesion by hydrated lime based on surface free energy method. Constr. Build. Mater. 2019, 227, 116794.1–116794.9. [Google Scholar] [CrossRef]

- Wang, F.Q.; Yang, L.J.; Mo, P.J. Experimental Study on Improving Water Stability of Granite Asphalt Mixture. Highway 2020, 65, 328–330. (In Chinese) [Google Scholar]

- Liu, Z.Z.; Huang, X.N.; Sha, A.M. Improvement of Asphalt-Aggregate Adhesion Using Plant Ash Byproduct. Materials 2019, 12, 605. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chew, J.W.; Poo, V.; Aneshvaran, S.; Hasan, M. Microscopic analysis and mechanical properties of Recycled Paper Mill Sludge modified asphalt mixture using granite and limestone aggregates. Constr. Build. Mater. 2020, 243, 118172. [Google Scholar] [CrossRef]

- Yin, Y.; Chen, H.; Kuang, D. Effect of chemical composition of aggregate on interfacial adhesion property between aggregate and asphalt. Constr. Build. Mater. 2017, 146, 231–237. [Google Scholar] [CrossRef]

- Yang, M.; Huang, T.; Lv, S.T. Effect and mechanism of acidic aggregate surface silane modification on water stability of asphalt mixture. Road. Mater. Pavement. 2020, 22, 1654–1666. [Google Scholar] [CrossRef]

- Lv, S.T.; Fan, X.Y.; Lu, W.W. Preparation and characterization of surface modification of aggregate by silane coupling agent. J. Funct. Mater. 2020, 51, 4199–4206. (In Chinese) [Google Scholar]

- Ding, G.; Yu, X.; Dong, F. Using Silane Coupling Agent Coating on Acidic Aggregate Surfaces to Enhance the Adhesion between Asphalt and Aggregate: A Molecular Dynamics Simulation. Materials 2020, 13, 5580. [Google Scholar] [CrossRef]

- Valentin, J.; Trejbal, J.; Neerka, V. A comprehensive study on adhesion between modified bituminous binders and mineral aggregates. Constr. Build. Mater. 2021, 305, 124686. [Google Scholar] [CrossRef]

- Fan, X.; Lu, W.; Lv, S. Improvement of Low-Temperature Performance of Buton Rock Asphalt Composite Modified Asphalt by Adding Styrene-Butadiene Rubber. Materials 2019, 12, 2358. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. People’s Communications Press: Beijing, China, 2011.

- AASHTO T 315; Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2012.

- AASHTO TP 125; Standard Method of Test for Determining the Flexural Creep Stiffness of Asphalt Mixtures Using the Bending Beam Rheometer (BBR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2016.

- AASHTO T 240; Standard Method of Test for Effect of Heat and Air on a Moving Film of Asphalt Binder (Rolling Thin-Film Oven Test). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2013.

- AASHTO R 28; Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2012.

- Fu, Q.; Xu, G.; Chen, X. Rheological properties of SBS/CR-C composite modified asphalt binders in different aging conditions. Constr. Build. Mater. 2019, 215, 1–8. [Google Scholar] [CrossRef]

- AASHTO TP 140; Standard Method of Test for Moisture Sensitivity Using Hydrostatic Pore Pressure to Determine Cohesion and Adhesion Strength of Compacted Asphalt Mixture Specimens. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2020.

- AASHTO T 324; Standard Method of Test for Hamburg Wheel-Track Testing of Compacted Hot Mix Asphalt (HMA). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2014.

- Lv, Q.; Huang, W.; Zheng, M. Influence of gradation on asphalt mix rutting resistance measured by Hamburg Wheel-Tracking test. Constr. Build. Mater. 2020, 238, 117674. [Google Scholar] [CrossRef]

| Asphalt | Original | RTFOT | |||||

|---|---|---|---|---|---|---|---|

| Penetration Degree (25 °C, 100 g, 5 s)/0.1 mm | PI | Softening Point/°C | Ductility (5 cm/min)/cm | Penetration Ratio/% | Ductility (5 cm/min)/cm | Mass Loss/% | |

| 70-A | 72.0 | −0.81 | 47.5 | 38 ① | 70 | 17 ① | −0.10 |

| SBS | 55.7 | 0.15 | 69.0 | 25.4 ② | 73 | 18 ② | −0.12 |

| Index | Test Results | Technical Requirement | |

|---|---|---|---|

| Aggregate crushing value/% | 18.8 | ≯26 | |

| Apparent density | 3–5 | 2.712 | ≮2.60 |

| 5–10 | 2.642 | ||

| 10–15 | 2.621 | ||

| 10–20 | 2.630 | ||

| Water absorption/% | 1.8 | ≯2.0 | |

| Adhesion level | 2 | ≮4 grade | |

| Needle flake particle content/% | 9 | ≯15 | |

| Water absorption of fine aggregate/% | 0.4 | ≯1 | |

| Soft stone content/% | 1.2 | ≯3 | |

| Los Angeles abrasion value/% | 19 | ≯28 | |

| Index | Test Results | Technical Requirement |

|---|---|---|

| Apparent density | 2.658 | ≮2.50 |

| Sediment percentage/% | 1 | ≯3 |

| Sand equivalent/% | 87 | ≮60 |

| Methylene blue value/g/kg | 15 | ≯25 |

| Index | Apparent Density | Water Content/% | Sieve Size | ||

|---|---|---|---|---|---|

| <0.6 mm | <0.15 mm | <0.075 mm | |||

| Test results | 2.632 | 0.68 | 100 | 95.8 | 86.4 |

| Technical requirement | ≥2.5 | ≤1.0 | 100 | 90–100 | 75–100 |

| Technical Indicators | Test Results | Test Method |

|---|---|---|

| Appearance | Brown Powder | Visual inspection |

| Ash content | 9.6 | JTG E20 T0614 |

| Density/25 °C | 1.201 | JTG E20 T0603 |

| Water content/% | 1.03 | JTG E20 T0612 |

| Appearance | Odor | Melting Point | Density |

|---|---|---|---|

| White solid powder | Light acidity | 120–140 °C | 0.92 g/cm3 |

| Index | Technical Requirement | Test Results |

|---|---|---|

| Apparent density | ≥2.5 | 2.612 |

| Particle size range | <0.6 mm/% 100–100 | 100.0 |

| <0.15 mm/% 90–100 | 97.6 | |

| <0.075 mm/% 85–100 | 86.7 | |

| Moisture content | ≤1% | 0.4% |

| Hydrophilic coefficient | ≤1 | 0.4 |

| Plasticity index | ≤4 | 2.8 |

| Scheme | Asphalt | Filler |

|---|---|---|

| 1 | 70-A | Mineral powder/lime powder = 4:3 |

| 2 | SCAMA | Mineral powder/lime powder = 4:3 |

| 3 | SBS | Mineral powder/lime powder = 4:3 |

| 4 | RMA | Mineral powder |

| 5 | SCA&RMA | Mineral powder |

| Scheme | Asphalt Temperature/°C | Aggregate Temperature/°C | Trial Temperature/°C | Mineral Powder Temperature/°C | Mixing Pot Temperature/°C | Mixing Temperature/°C | Molding Temperature/°C |

|---|---|---|---|---|---|---|---|

| 1 | 155 | 170 | 120 | 120 | 165 | 155 | 150 |

| 2 | 165 | 180 | 120 | 120 | 175 | 165 | 155 |

| 3 | 170 | 185 | 120 | 120 | 180 | 170 | 160 |

| 4 | 165 | 180 | 120 | 120 | 175 | 165 | 155 |

| 5 | 165 | 180 | 120 | 120 | 175 | 165 | 155 |

| Scheme | 3 cm AC-10 Surface Layer | 5 cm AC-16 Lower Layer | ||

|---|---|---|---|---|

| Asphalt | Filler | Asphalt | Filler | |

| 11 | 70-A | Mineral powder/lime powder = 4:3 | 70-A | Mineral powder/lime powder = 4:3 |

| 21 | SCAMA | Mineral powder/lime powder = 4:3 | 70-A | Mineral powder/lime powder = 4:3 |

| 31 | SBS | Mineral powder/lime powder = 4:3 | 70-A | Mineral powder/lime powder = 4:3 |

| 41 | RMA | Mineral powder | 70-A | Mineral powder/lime powder = 4:3 |

| 51 | SCA&RMA | Mineral powder | 70-A | Mineral powder/lime powder = 4:3 |

| Test Projects | Index | 70-A | RMA | SCAMA | SCA&RMA | SBS | |

|---|---|---|---|---|---|---|---|

| Conventional properties | 25 °C Penetration/0.1 mm | 72 | 52 | 70 | 54 | 55.7 | |

| Softening Point/°C | 47.5 | 52 | 51 | 52 | 69 | ||

| Ductility/cm | >100 | 32 | >100 | >100 | >100 | ||

| 135 °C Brinell viscosity/Pa·s | 0.3 | 0.91 | 0.5 | 0.7 | 2.13 | ||

| DSR | G*/kPa | 64 °C | 1.629 | 2.489 | 2.742 | 3.369 | 3.62 |

| 70 °C | 0.786 | 1.146 | 1.263 | 1.586 | 2.02 | ||

| 76 °C | - | 0.576 | 0.626 | 0.796 | 1.36 | ||

| 82 °C | - | - | - | - | 0.76 | ||

| δ/° | 64 °C | 87.07 | 86.36 | 86.05 | 85.26 | 68.62 | |

| 70 °C | 88.1 | 87.55 | 87.21 | 87 | 65.01 | ||

| 76 °C | - | 88.37 | 88.06 | 87.89 | 63.37 | ||

| 82 °C | - | - | - | - | 59.82 | ||

| G*/sinδ | 64 °C | 1.631 | 2.494 | 2.749 | 3.381 | 3.888 | |

| /kPa | 70 °C | 0.787 | 1.147 | 1.264 | 1.588 | 2.229 | |

| 76 °C | - | 0.577 | 0.626 | 0.797 | 1.521 | ||

| 82 °C | - | - | - | - | 0.879 | ||

| PG high-temperature grade/°C | 64 | 70 | 70 | 70 | 76 | ||

| BBR test | S/MPa | −18 °C | 356 | 420 | 370 | 382 | 361.5 |

| −12 °C | 154 | 226.5 | 206.5 | 187 | 170.5 | ||

| −6 °C | 79.5 | 93.7 | 83.7 | 86.6 | 86.2 | ||

| 0 °C | 35.9 | 43.7 | 41.7 | 42 | 41.4 | ||

| m | −18 °C | 0.248 | 0.224 | 0.244 | 0.231 | 0.28 | |

| −12 °C | 0.328 | 0.32 | 0.33 | 0.331 | 0.32 | ||

| −6 °C | 0.382 | 0.37 | 0.38 | 0.384 | 0.429 | ||

| 0 °C | 0.438 | 0.432 | 0.439 | 0.436 | 0.525 | ||

| PG low-temperature grade/°C | 22 | 22 | 22 | 22 | 22 | ||

| Index | 70-A | RMA | SCAMA | SCA&RMA | SBS | ||

|---|---|---|---|---|---|---|---|

| Conventional properties after RTFOT | 25 °C Penetration/0.1 mm | 50.4 | 33.4 | 49.5 | 40 | 40.7 | |

| Softening Point/°C | 40.4 | 38.1 | 41 | 41 | 52 | ||

| Ductility/cm | 15 °C | 49.9 | 11.6 | 50 | 28 | 40 | |

| DSR after RTFOT | G*/kPa | 64 °C | 3.14 | 5.021 | 5.22 | 5.62 | 11.58 |

| 70 °C | 1.433 | 2.316 | 2.216 | 2.532 | 5.653 | ||

| 76 °C | - | 1.116 | 1.316 | 1.34 | 2.347 | ||

| 82 °C | - | - | - | - | 1.467 | ||

| δ/º | 64 °C | 85.32 | 83.48 | 83.38 | 83.32 | 80.22 | |

| 70 °C | 86.84 | 85.42 | 85.62 | 85.06 | 82.35 | ||

| 76 °C | - | 86.87 | 86.97 | 86.52 | 84.23 | ||

| 82 °C | - | - | - | - | 85.78 | ||

| G*/sinδ | 64 °C | 3.15 | 5.053 | 5.255 | 5.658 | 11.751 | |

| /kPa | 70 °C | 1.435 | 2.323 | 2.222 | 2.541 | 5.704 | |

| 76 °C | - | 1.117 | 1.318 | 1.342 | 2.359 | ||

| 82 °C | - | - | - | - | 1.471 | ||

| PG high-temperature grade/°C | 64 | 70 | 70 | 70 | 76 | ||

| DSR after PAV | G*/kPa | 28 °C | - | 4932 | 5231 | 5514 | 9328 |

| 25 °C | 5118 | 7176 | 7567 | 7960 | 11780 | ||

| 22 °C | 7283 | - | - | - | - | ||

| δ/° | 28 °C | - | 48.44 | 47.23 | 46.36 | 39.94 | |

| 25 °C | 47.39 | 46 | 45.6 | 44.92 | 37.9 | ||

| 22 °C | 43.98 | - | - | - | - | ||

| G*sinδ/kPa | 28 °C | - | 3690 | 3840 | 3990 | 5988 | |

| 25 °C | 3767 | 5162 | 5406 | 5621 | 7236 | ||

| 22 °C | 5058 | - | - | - | - | ||

| PG medium-temperature grade/°C | 25 | 28 | 28 | 28 | 28 | ||

| Scheme Category | AC-10 Results of Immersion Marshall Test | AC-16 Results of Immersion Marshall Test | ||||||

|---|---|---|---|---|---|---|---|---|

| Soaking Time/h | Flow Value/mm | Stability/kN | Residual Stability/% | Soaking Time/h | Flow Value/mm | Stability/kN | Residual Stability/% | |

| Scheme 1 | 0.5 | 3.4 | 18.89 | 84.8 | 0.5 | 3.9 | 15.66 | 85.1 |

| 48 | 4.2 | 16.03 | 48 | 3.6 | 13.32 | |||

| Scheme 2 | 0.5 | 3.8 | 17.17 | 90.3 | 0.5 | 4.4 | 16.06 | 89.2 |

| 48 | 4 | 15.51 | 48 | 4.1 | 14.32 | |||

| Scheme 3 | 0.5 | 4.9 | 22.2 | 92.2 | 0.5 | 4.2 | 16.06 | 91.5 |

| 48 | 4.8 | 20.47 | 48 | 4 | 14.7 | |||

| Scheme 4 | 0.5 | 3.6 | 17.66 | 87.2 | 0.5 | 3.6 | 17.66 | 88.9 |

| 48 | 3.8 | 15.4 | 48 | 3.8 | 15.7 | |||

| Scheme 5 | 0.5 | 3.9 | 20.06 | 94.1 | 0.5 | 3.9 | 20.06 | 92.2 |

| 48 | 4.1 | 18.88 | 48 | 4.1 | 18.5 | |||

| Mixture Type | Relative Density of Gross Volume | Mid-Span Deflection/mm | Maximum Damage Load/N | Flexural Tensile Strength/MPa | Bending Strain/µε | Bending Stiffness Modulus/MPa | |

|---|---|---|---|---|---|---|---|

| AC-10 | Scheme 1 | 2.286 | 0.42 | 798.4 | 6.3 | 2214.79 | 2857 |

| Scheme 2 | 2.258 | 0.56 | 924.5 | 7.2 | 2993.13 | 2411.73 | |

| Scheme 3 | 2.339 | 0.74 | 1204.6 | 9.6 | 3859.41 | 2486.98 | |

| Scheme 4 | 2.301 | 0.36 | 793.7 | 6.1 | 1932.72 | 3166.52 | |

| Scheme 5 | 2.37 | 0.64 | 1149 | 9.3 | 3323.02 | 2799.17 | |

| AC-16 | Scheme 1 | 2.298 | 0.39 | 789.5 | 6.9 | 2066.41 | 3322.34 |

| Scheme 2 | 2.34 | 0.59 | 889.5 | 7 | 2415.21 | 3247.45 | |

| Scheme 3 | 2.375 | 0.66 | 1112.1 | 7.2 | 3466.73 | 2074.52 | |

| Scheme 4 | 2.383 | 0.39 | 924.5 | 7.1 | 1896.44 | 3763.48 | |

| Scheme 5 | 2.321 | 0.45 | 985.2 | 7.7 | 2393.87 | 3211.58 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, Y.; Hao, Y.; Zhuang, C.; Shu, S.; Lv, F. Evaluation on Improvement Effect of Different Anti-Stripping Agents on Pavement Performance of Granite–Asphalt Mixture. Materials 2022, 15, 915. https://doi.org/10.3390/ma15030915

Ye Y, Hao Y, Zhuang C, Shu S, Lv F. Evaluation on Improvement Effect of Different Anti-Stripping Agents on Pavement Performance of Granite–Asphalt Mixture. Materials. 2022; 15(3):915. https://doi.org/10.3390/ma15030915

Chicago/Turabian StyleYe, Yali, Yan Hao, Chuanyi Zhuang, Shiqi Shu, and Fengli Lv. 2022. "Evaluation on Improvement Effect of Different Anti-Stripping Agents on Pavement Performance of Granite–Asphalt Mixture" Materials 15, no. 3: 915. https://doi.org/10.3390/ma15030915

APA StyleYe, Y., Hao, Y., Zhuang, C., Shu, S., & Lv, F. (2022). Evaluation on Improvement Effect of Different Anti-Stripping Agents on Pavement Performance of Granite–Asphalt Mixture. Materials, 15(3), 915. https://doi.org/10.3390/ma15030915