Microstructure and Antimicrobial Properties of Zr-Cu-Ti Thin-Film Metallic Glass Deposited Using High-Power Impulse Magnetron Sputtering

Abstract

:1. Introduction

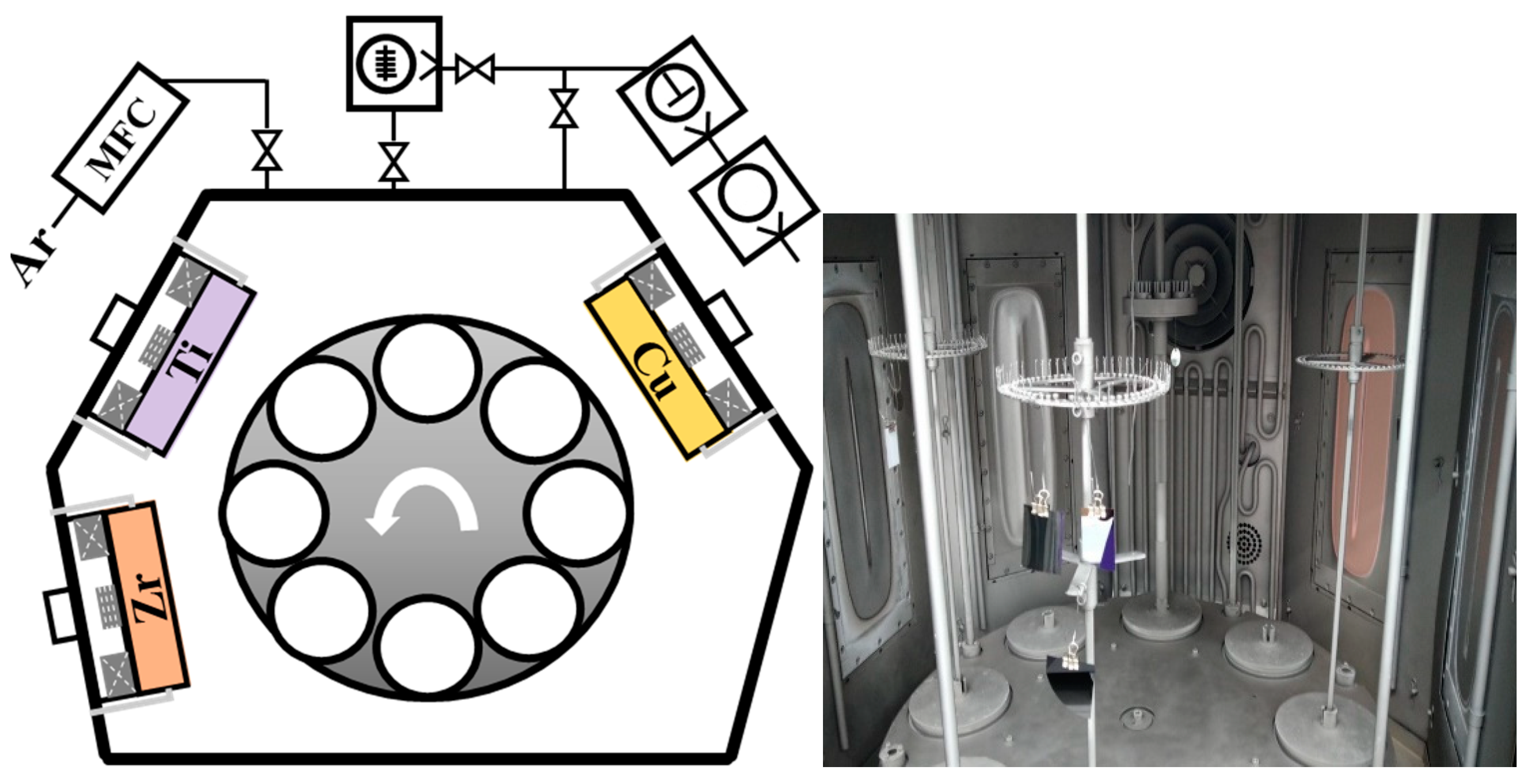

2. Experimental

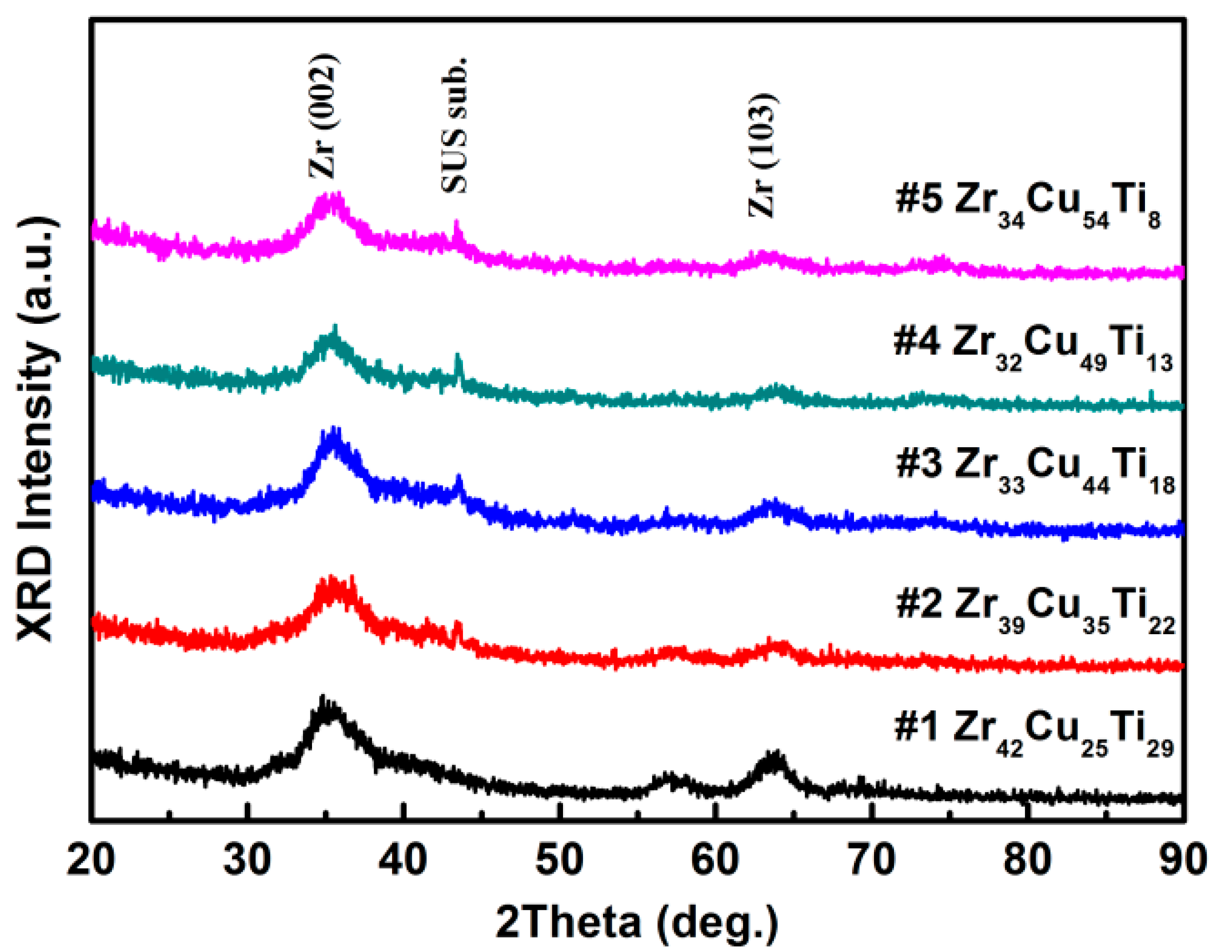

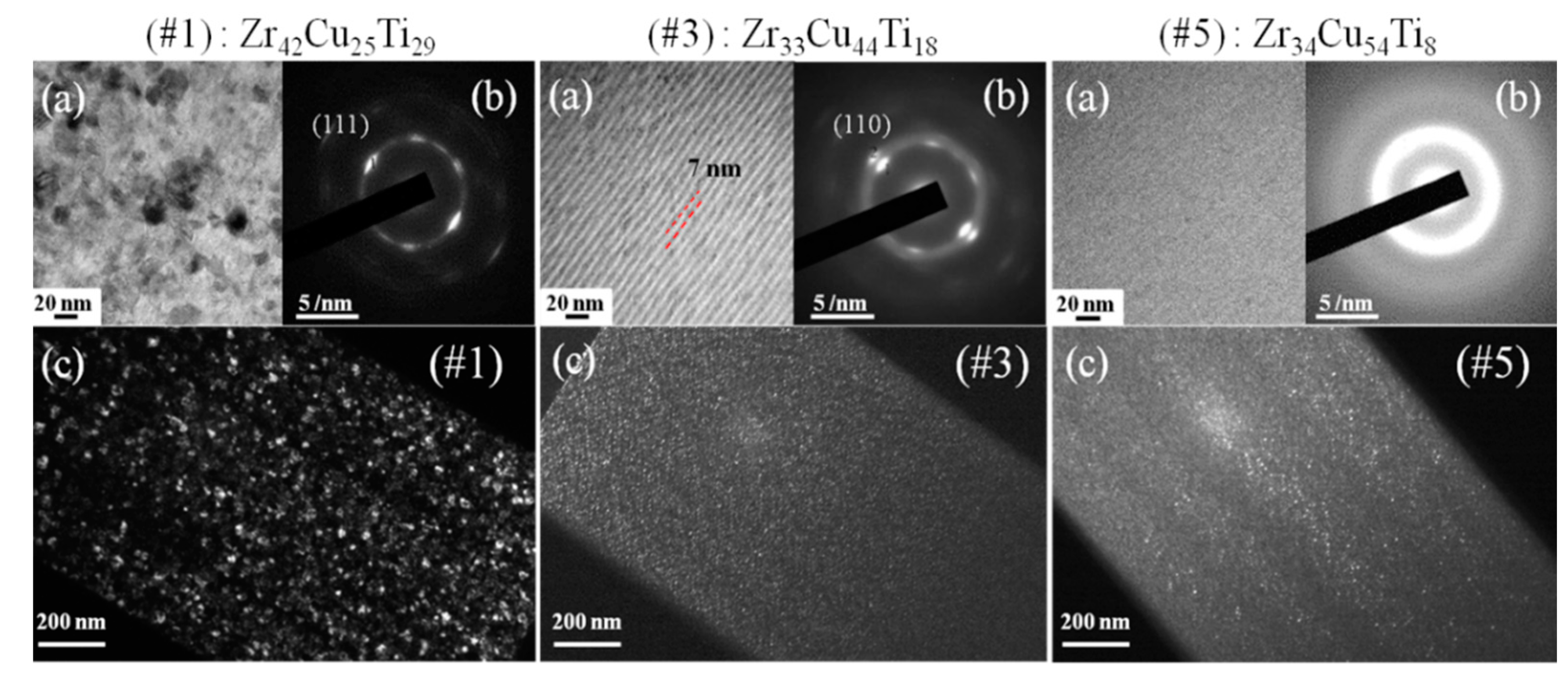

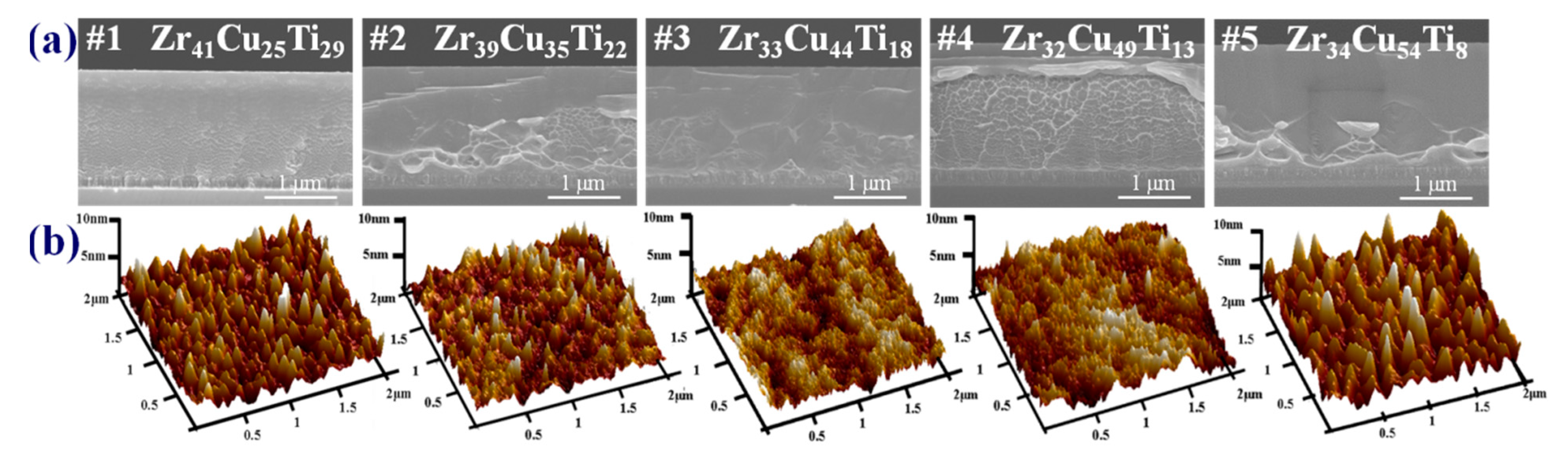

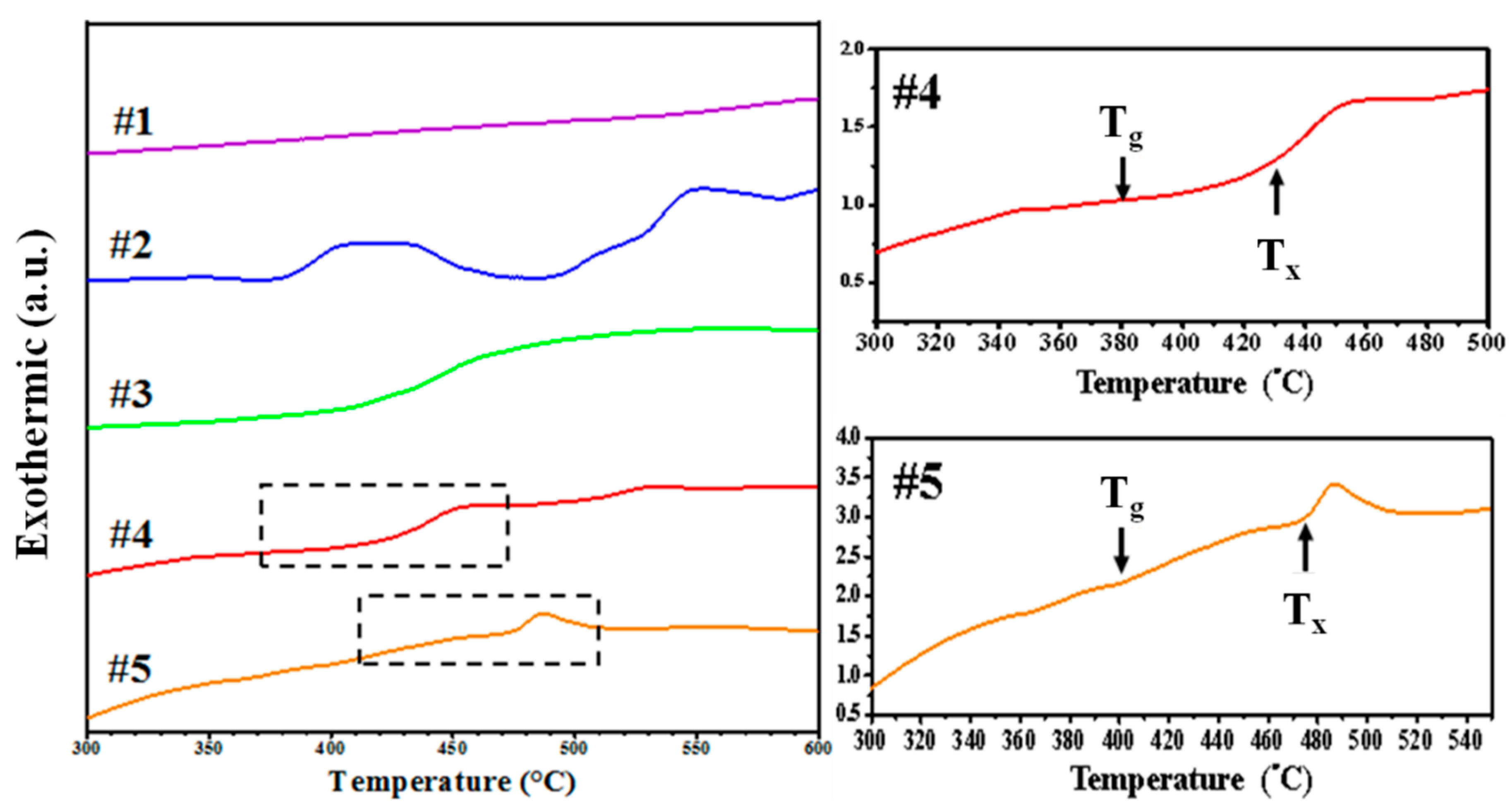

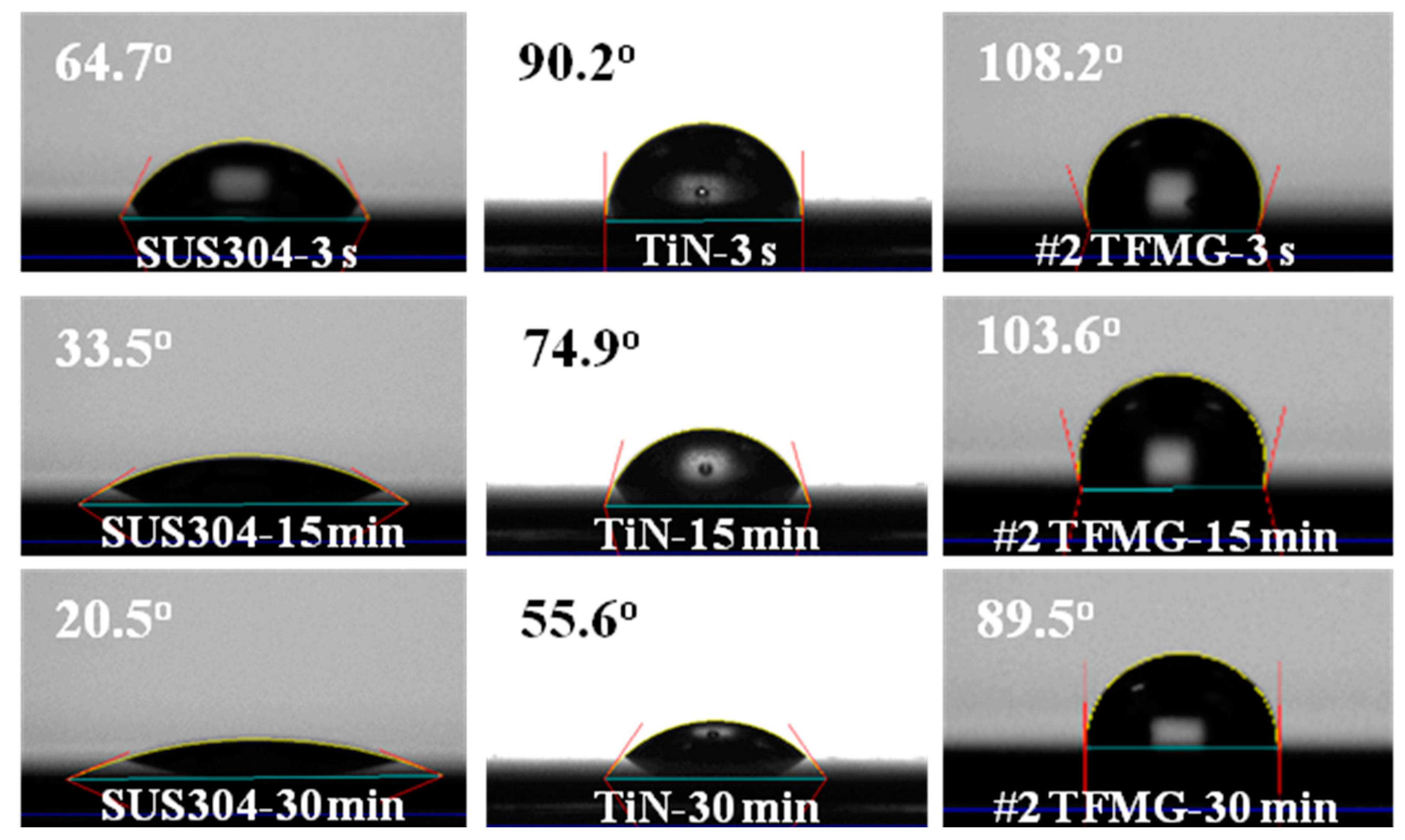

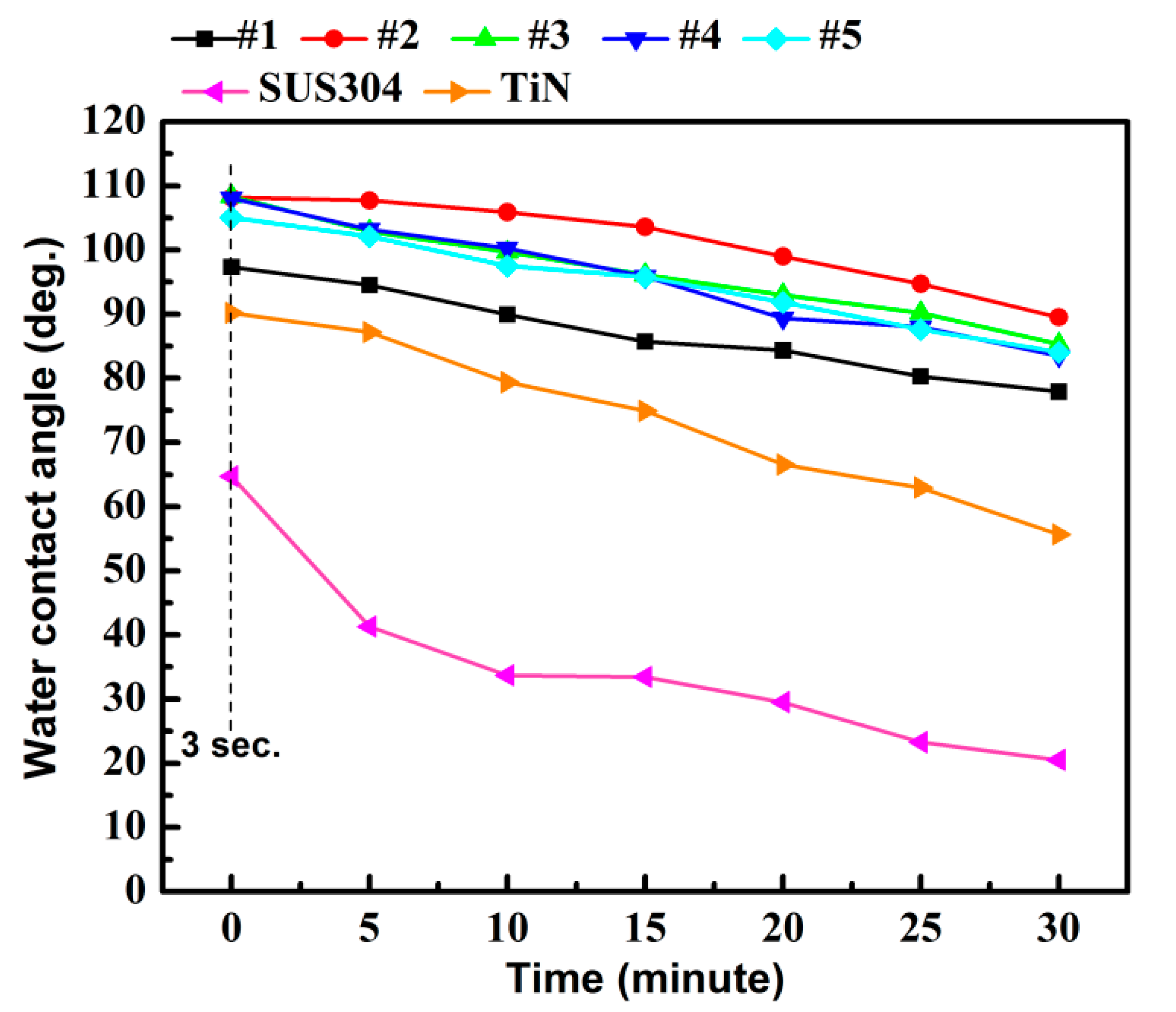

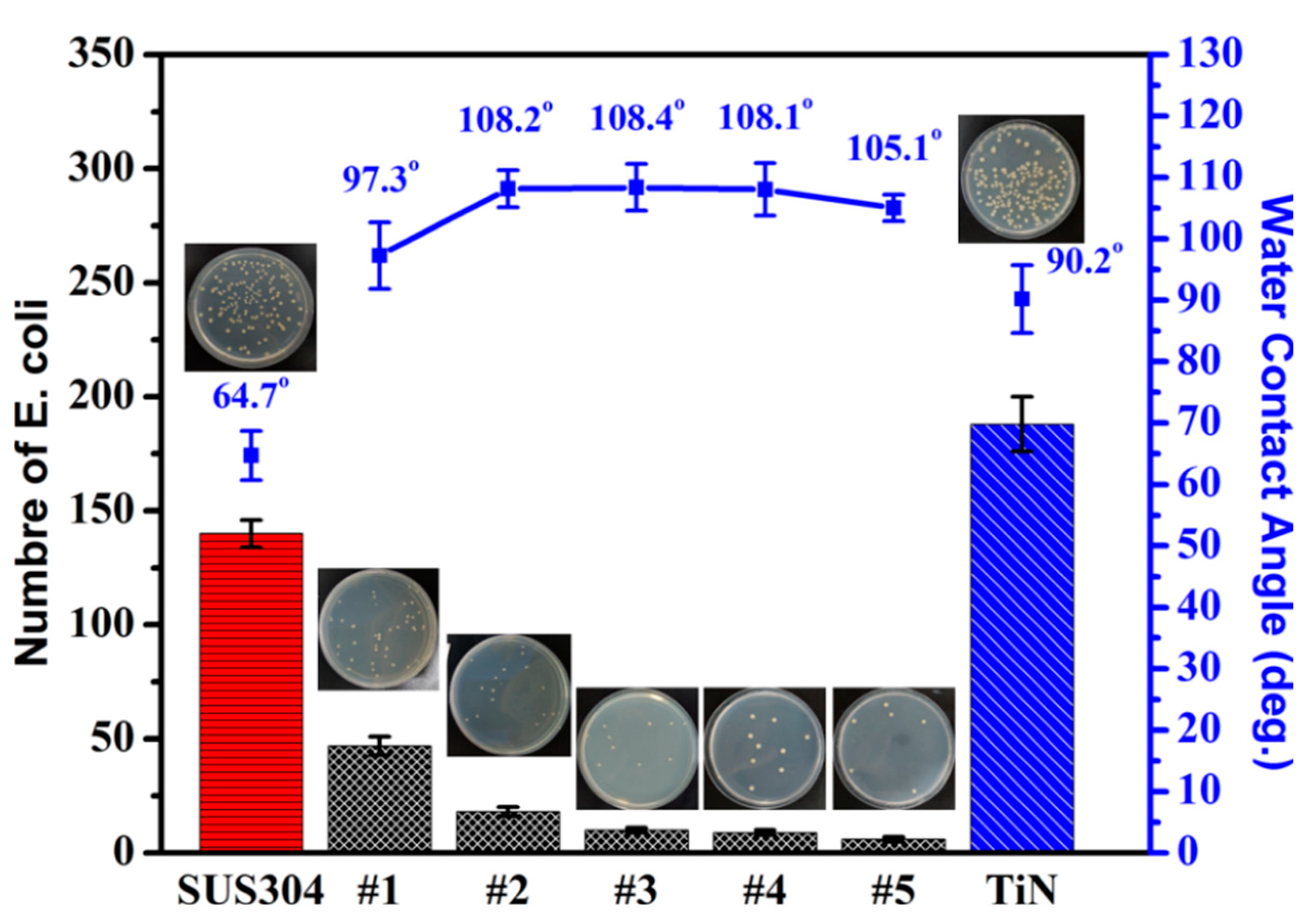

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Johnson, W. Bulk amorphous metal—An emerging engineering material. Jom 2002, 54, 40–43. [Google Scholar] [CrossRef]

- Inoue, A.; Shen, B.; Takeuchi, A. Developments and applications of bulk glassy alloys in late transition metal base system. Mater. Trans. 2006, 47, 1275–1285. [Google Scholar] [CrossRef] [Green Version]

- Kruzic, J.J. Bulk metallic glasses as structural materials: A review, Advanced Engineering Materials. Adv. Eng. Mater. 2016, 18, 1308–1331. [Google Scholar] [CrossRef]

- Korkmaz, S.; Kariper, İ.A. Glass formation, production and superior properties of Zr-based thin film metallic glasses (TFMGs): A status review. J. Non-Cryst. Solids 2020, 527, 119753. [Google Scholar] [CrossRef]

- Rajan, S.T.; Arockiarajan, A. Thin Film Metallic Glasses for Bioimplants and Surgical Tools: A Review. J. Alloys Compd. 2021, 876, 159939. [Google Scholar] [CrossRef]

- Deng, Y.P.; Guan, Y.F.; Fowlkes, J.D.; Wen, S.Q.; Liu, F.X.; Pharr, G.M.; Liaw, P.K.; Liu, C.T.; Rack, P. A combinatorial thin film sputtering approach for synthesizing and characterizing ternary ZrCuAl metallic glasses. Intermetallics 2007, 15, 1208–1216. [Google Scholar] [CrossRef]

- Achache, S.; Sanchette, F. Effect of Tantalum Addition on Properties of Cu–Zr–Based Thin Film Metallic Glasses (TFMGs). Coatings 2020, 10, 515. [Google Scholar] [CrossRef]

- El-Eskandarany, M.S.; Ali, N. Synthesizing of Novel Bulk (Zr67Cu33) 100−xWx (x; 5–30 at%) Glassy Alloys by Spark Plasma Sintering of Mechanically Alloyed Powders. Molecules 2020, 25, 1906. [Google Scholar] [CrossRef] [Green Version]

- Deng, L.; Wang, S.; Wang, P.; Kühn, U.; Pauly, S. Selective laser melting of a Ti-based bulk metallic glass. Mater. Lett. 2018, 212, 346–349. [Google Scholar] [CrossRef]

- Coddet, P.; Sanchette, F.; Rousset, J.-C.; Rapaud, O.; Coddet, C. On the elastic modulus and hardness of co-sputtered Zr–Cu–(N) thin metal glass films. Surf. Coat. Technol. 2012, 206, 3567–3571. [Google Scholar] [CrossRef]

- Wojcieszak, D.; Kaczmarek, D.; Antosiak, A.; Mazur, M.; Rybak, Z.; Rusak, A.; Osekowska, M.; Poniedzialek, A.; Gamian, A.; Szponar, B. Influence of Cu–Ti thin film surface properties on antimicrobial activity and viability of living cells. Mater. Sci. Eng. C 2015, 56, 48–56. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Thouas, G.A. Metallic implant biomaterials. Mater. Sci. Eng. R Rep. 2015, 87, 1–57. [Google Scholar] [CrossRef]

- Smieszek, A.; Seweryn, A.; Marcinkowska, K.; Sikora, M.; Lawniczak-Jablonska, K.; Witkowski, B.; Kuzmiuk, P.; Godlewski, M.; Marycz, K. Titanium dioxide thin films obtained by atomic layer deposition promotes osteoblasts’ viability and differentiation potential while inhibiting osteoclast activity—Potential application for osteoporotic bone regeneration. Materials 2020, 13, 4817. [Google Scholar] [CrossRef] [PubMed]

- Niinomi, M. Recent titanium R&D for biomedical applications in Japan. JOM 1999, 51, 32–34. [Google Scholar]

- Wu, J.H.; Chen, K.K.; Chao, C.Y.; Chang, Y.H.; Du, J.K. Effect of Ti2Cu precipitation on antibacterial property of Ti-5Cu alloy. Mater. Sci. Eng. C 2020, 108, 110433. [Google Scholar] [CrossRef] [PubMed]

- Barber, R.; Grenier, Z.; Burkhead, J. Copper toxicity is not just oxidative damage: Zinc systems and insight from Wilson disease. Biomedicines 2021, 9, 316. [Google Scholar] [CrossRef] [PubMed]

- Suh, T.; Yang, Y.; Sohn, H.W.; DiStasio, R.A., Jr.; Engstrom, J.R. Area-selective atomic layer deposition enabled by competitive adsorption. J. Vac. Sci. Technol. A Vac. Surf. Film. 2020, 38, 062411. [Google Scholar] [CrossRef]

- Chang, C.-L.; Luo, G.-J.; Yang, F.-C.; Tang, J.-F. Effects of duty cycle on microstructure of TiN coatings prepared using CAE/HiPIMS. Vacuum 2021, 192, 110449. [Google Scholar] [CrossRef]

- Reolon, L.W.; Aguirre, M.H.; Yamamoto, K.; Zhao, Q.; Zhitomirsky, I.; Fox-Rabinovich, G.; Veldhuis, S.C. A Comprehensive Study of Al0.6Ti0.4N Coatings Deposited by Cathodic Arc and HiPIMS PVD Methods in Relation to Their Cutting Performance during the Machining of an Inconel 718 Alloy. Coatings 2021, 11, 723. [Google Scholar] [CrossRef]

- Mouche, P.A.; Koyanagi, T.; Patel, D.; Katoh, Y. Adhesion, structure, and mechanical properties of Cr HiPIMS and cathodic arc deposited coatings on SiC. Surf. Coat. Technol. 2021, 410, 126939. [Google Scholar] [CrossRef]

- Purandare, Y.; Ehiasarian, A.; Santana, A.; Hovsepian, P. ZrN coatings deposited by high power impulse magnetron sputtering and cathodic arc techniques. Vac. Sci. Technol. A Vac. Surf. Film. 2014, 32, 031507. [Google Scholar] [CrossRef] [Green Version]

- Chang, C.-L.; Ho, C.-T.; Chen, P.-H.; Chen, W.-C.; Wang, D.-Y.; Wu, W.-Y. Synergetic effect for improved deposition of titanium nitride films. Surf. Coat. Technol. 2018, 350, 1098–1104. [Google Scholar] [CrossRef]

- Zeman, P.; Zítek, M.; Zuzjaková, Š.; Čerstvý, R. Amorphous Zr-Cu thin-film alloys with metallic glass behavior. J. Alloys Compd. 2017, 696, 1298–1306. [Google Scholar] [CrossRef]

- Bönninghoff, N.; Diyatmika, W.; Chu, J.P.; Mráz, S.; Schneider, J.M.; Lin, C.-L.; Eriksson, F.; Greczynski, G. ZrCuAlNi thin film metallic glass grown by high power impulse and direct current magnetron sputtering. Surf. Coat. Technol. 2021, 412, 127029. [Google Scholar] [CrossRef]

- Chang, C.-L.; Lin, C.-Y.; Yang, F.-C.; Tang, J.-F. The Effect of Match between High Power Impulse and Bias Voltage: TiN Coating Deposited by High Power Impulse Magnetron Sputtering. Coatings 2021, 11, 822. [Google Scholar] [CrossRef]

- Tang, J.-F.; Huang, S.-Y.; Lin, J.-H.; Yang, F.-C.; Chang, C.-L. Mechanical properties of TiN deposited in synchronous bias mode through high-power impulse magnetron sputtering. Surf. Coat. Technol. 2022, 434, 128201. [Google Scholar] [CrossRef]

- Hsieh, P.-H.; Lu, Y.-M.; Hwang, W.-S.; Yeh, J.-J.; Jang, W.-L. Effect of Al content on electrical conductivity and transparency of P-type Cu-Al-O thin film. Surf. Coat. Technol. 2010, 205, S206–S209. [Google Scholar] [CrossRef]

- Tang, J.-F.; Lin, C.-Y.; Yang, F.-C.; Chang, C.-L. Effects of Input Power Ratio of AlCr/Ti Target on the Microstructural and Mechanical Properties of AlTiCrN Coatings Synthesized by a High-Power Impulse Magnetron Sputtering Process. Coatings 2021, 11, 826. [Google Scholar] [CrossRef]

- Chu, J.-H.; Lee, J.; Chang, C.-C.; Chan, Y.-C.; Liou, M.-L.; Lee, J.-W.; Jang, J.S.-C.; Duh, J.-G. Antimicrobial characteristics in Cu-containing Zr-based thin film metallic glass. Surf. Coat. Technol. 2014, 259, 87–93. [Google Scholar] [CrossRef]

- Lee, J.; Liou, M.-L.; Duh, J.-G. The development of a Zr-Cu-Al-Ag-N thin film metallic glass coating in pursuit of improved mechanical, corrosion, and antimicrobial property for bio-medical application. Surf. Coat. Technol. 2017, 310, 214–222. [Google Scholar] [CrossRef]

- Lu, H.-B.; Li, Y.; Wang, F.-H. Corrosion behavior and porous structure formation of sputtered Cu–Zr nanostructured films. J. Alloys Compd. 2008, 465, 139–144. [Google Scholar] [CrossRef]

- Abboud, M.; Özerinç, S. Size-independent strength of amorphous–HCP crystalline metallic nanolayers. J. Mater. Res. 2019, 34, 2275–2284. [Google Scholar] [CrossRef]

- Ohring, M. The materials science of thin films. Appl. Opt. 1992, 31, 7162. [Google Scholar]

- Xie, L.; Brault, P.; Thomann, A.-L.; Bedra, L. Molecular dynamic simulation of binary ZrxCu100−x metallic glass thin film growth. Appl. Surf. Sci. 2013, 274, 164–170. [Google Scholar] [CrossRef] [Green Version]

- Apreutesei, M.; Billard, A.; Steyer, P. Crystallization and hardening of Zr-40 at. % Cu thin film metallic glass: Effects of isothermal annealing. Mater. Des. 2015, 86, 555–563. [Google Scholar] [CrossRef]

- Etiemble, A.; Der Loughian, C.; Apreutesei, M.; Langlois, C.; Cardinal, S.; Pelletier, J.; Pierson, J.-F.; Steyer, P. Innovative Zr-Cu-Ag thin film metallic glass deposed by magnetron PVD sputtering for antibacterial applications. J. Alloys Compd. 2017, 707, 155–161. [Google Scholar] [CrossRef]

- Chang, C.; Lee, C.; Chu, J.; Liaw, P.; Jang, S. Fatigue property improvements of ZK60 magnesium alloy: Effects of thin film metallic glass. Thin Solid Films 2016, 616, 431–436. [Google Scholar] [CrossRef]

- Chuang, C.-Y.; Lee, J.-W.; Li, C.-L.; Chu, J.P. Mechanical properties study of a magnetron-sputtered Zr-based thin film metallic glass. Surf. Coat. Technol. 2013, 215, 312–321. [Google Scholar] [CrossRef]

- El-Eskandrany, M.S.; Al-Azmi, A. Potential applications of cold sprayed Cu50Ti20Ni30 metallic glassy alloy powders for antibacterial protective coating in medical and food sectors. J. Mech. Behav. Biomed. Mater. 2016, 56, 183–194. [Google Scholar] [CrossRef]

- Filho, L.; Schmidt, S.; Leifer, K.; Engqvist, H.; Högberg, H.; Persson, C. Towards functional silicon nitride coatings for joint replacements. Coatings 2019, 9, 73. [Google Scholar] [CrossRef] [Green Version]

- Chiang, P.-T.; Chen, G.-J.; Jian, S.-R.; Shih, Y.-H.; Jang, J.S.-C.; Lai, C.-H. Surface antimicrobial effects of Zr61Al7.5Ni10Cu17.5Si4 thin film metallic glasses on Escherichia coli, Staphylococcus aureus, Pseudomonas aeruginosa, Acinetobacter baumannii and Candida albicans. Fooyin J. Health Sci. 2010, 2, 12–20. [Google Scholar] [CrossRef] [Green Version]

- Park, J.; Kim, D.-J.; Kim, Y.-K.; Lee, K.-H.; Lee, K.-H.; Lee, H.; Ahn, S. Improvement of the biocompatibility and mechanical properties of surgical tools with TiN coating by PACVD. Thin Solid Films 2003, 435, 102–107. [Google Scholar] [CrossRef]

| Samples | #1 | #2 | #3 | #4 | #5 | |

|---|---|---|---|---|---|---|

| Power | ||||||

| Zr (kW) | 5 | |||||

| Cu (kW) | 0.5 | 0.75 | 1 | 1.25 | 1.5 | |

| Ti (kW) | 5 | 4 | 3 | 2 | 1 | |

| Sample | Composition | Bacteria Number | AR for E. coli (%) | Ra (nm) | Rmax (nm) | WCA (deg.) |

|---|---|---|---|---|---|---|

| SUS304 | - | 140 | 44.4 | 3.24 | 35 | 64.72 |

| #1 | Zr42Cu25Ti29 | 47 | 81.4 | 1.48 | 10.31 | 97.32 |

| #2 | Zr39Cu35Ti22 | 18 | 92.9 | 1.25 | 8.89 | 108.15 |

| #3 | Zr33Cu44Ti18 | 10 | 96.0 | 1.43 | 9.74 | 108.40 |

| #4 | Zr32Cu49Ti13 | 9 | 96.4 | 1.29 | 8.97 | 108.06 |

| #5 | Zr34Cu54Ti8 | 6 | 97.6 | 1.49 | 11.29 | 105.04 |

| TiN | Ti49N51 | 188 | 25.4 | 7.44 | 40.10 | 90.18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, J.-F.; Huang, P.-Y.; Lin, J.-H.; Liu, T.-W.; Yang, F.-C.; Chang, C.-L. Microstructure and Antimicrobial Properties of Zr-Cu-Ti Thin-Film Metallic Glass Deposited Using High-Power Impulse Magnetron Sputtering. Materials 2022, 15, 2461. https://doi.org/10.3390/ma15072461

Tang J-F, Huang P-Y, Lin J-H, Liu T-W, Yang F-C, Chang C-L. Microstructure and Antimicrobial Properties of Zr-Cu-Ti Thin-Film Metallic Glass Deposited Using High-Power Impulse Magnetron Sputtering. Materials. 2022; 15(7):2461. https://doi.org/10.3390/ma15072461

Chicago/Turabian StyleTang, Jian-Fu, Po-Yuan Huang, Ja-Hon Lin, Ting-Wei Liu, Fu-Chi Yang, and Chi-Lung Chang. 2022. "Microstructure and Antimicrobial Properties of Zr-Cu-Ti Thin-Film Metallic Glass Deposited Using High-Power Impulse Magnetron Sputtering" Materials 15, no. 7: 2461. https://doi.org/10.3390/ma15072461

APA StyleTang, J.-F., Huang, P.-Y., Lin, J.-H., Liu, T.-W., Yang, F.-C., & Chang, C.-L. (2022). Microstructure and Antimicrobial Properties of Zr-Cu-Ti Thin-Film Metallic Glass Deposited Using High-Power Impulse Magnetron Sputtering. Materials, 15(7), 2461. https://doi.org/10.3390/ma15072461