Consideration of Critical Parameters for Improving the Efficiency of Concrete Structures Reinforced with FRP

Abstract

:1. Introduction and Aim of the Technical Note

2. Material Characteristics

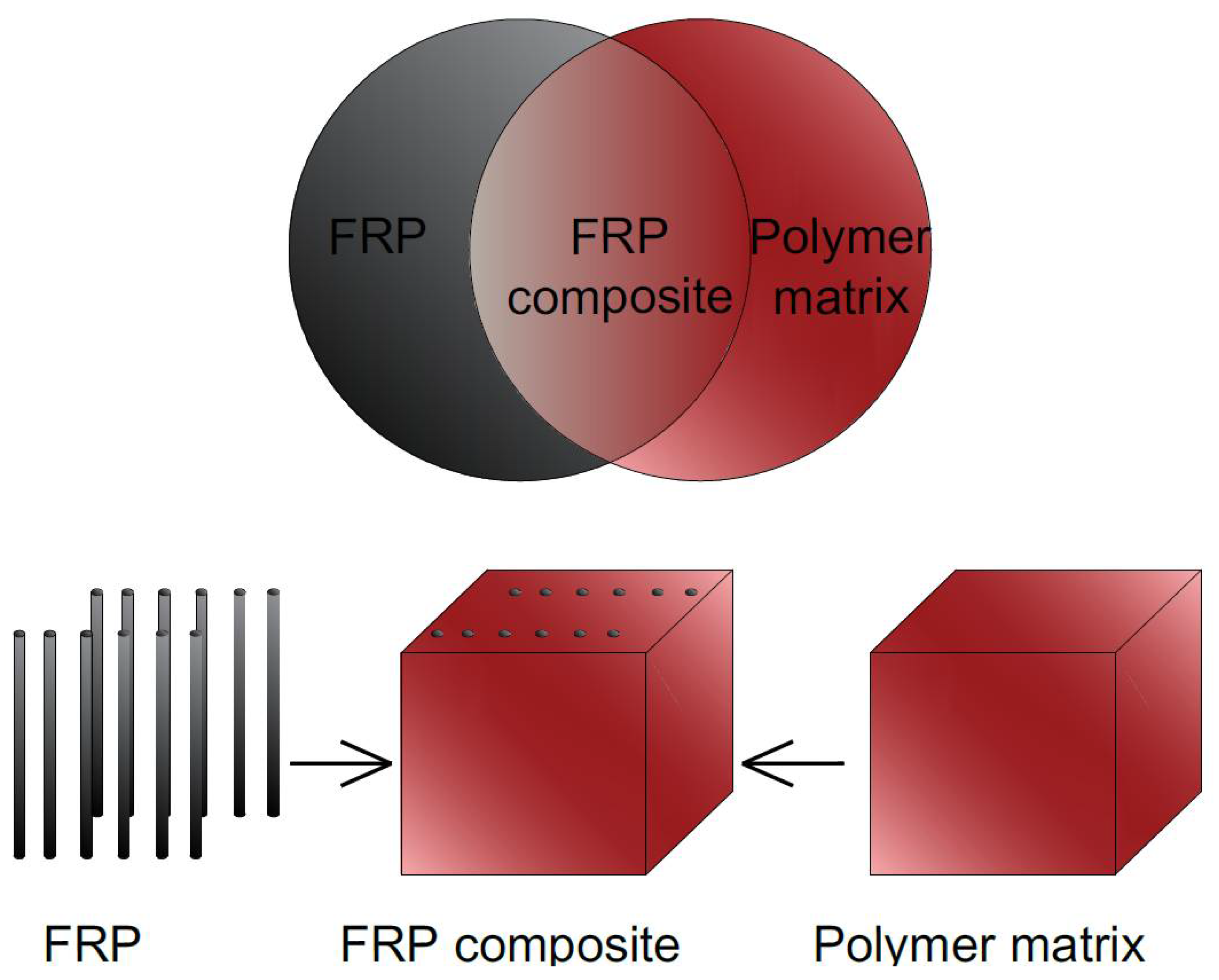

2.1. Composites

- To maintain the entire system in a compact form (combines reinforcement);

- To transfer external loads to the reinforcement;

- To provide appropriate strength;

- To influence the chemical and thermal properties;

- To protect reinforcement against mechanical damage;

- To give products a specific shape.

- To improve strength properties;

- To increase resistance to abrasion;

- To reduce thermal expansion;

- To increase resistance to thermal shock;

- To stop the propagation of cracks;

- To increase the load-bearing capacity of structures.

2.2. FRP Composites

2.3. The Importance of FRP Materials in Civil Engineering

- Increase resistance to the seismic loads of masonry structures;

- Increase the strength of concrete and reinforced columns;

- Replace missing reinforcements;

- Enable the reassignment of buildings;

- Increase the strength of individual elements and the entire structure;

- Improve the load capacity of a structure that is weakened due to structural errors;

- Adapt the load capacity of a structure to the applicable standards and requirements;

- Enhancement of service loads;

- Increase service life and durability;

- Improve resistance to seismic loads.

3. Factors Influencing Strengthening of Concrete Structures with FRP Composites

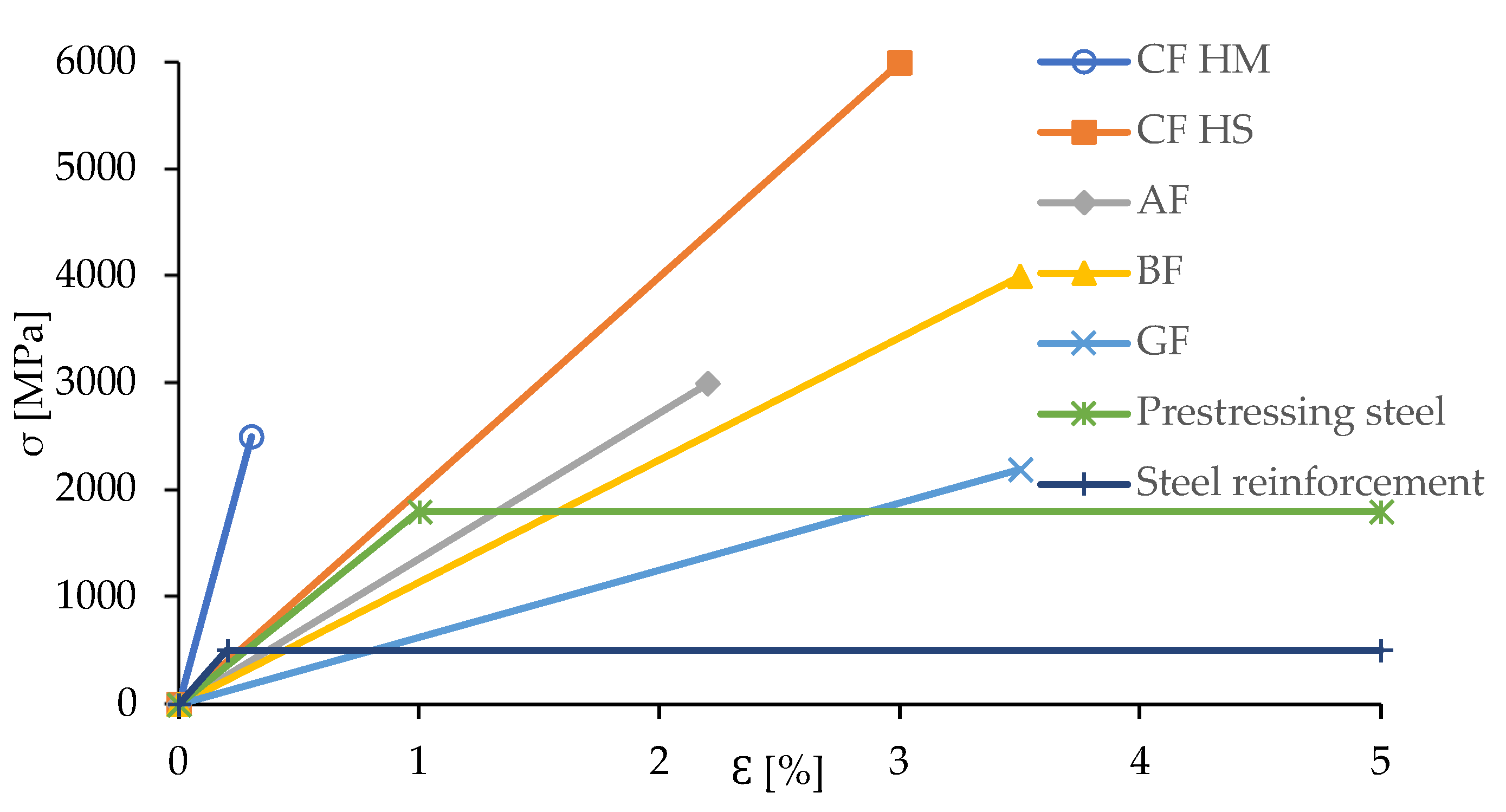

3.1. Type of Fibres

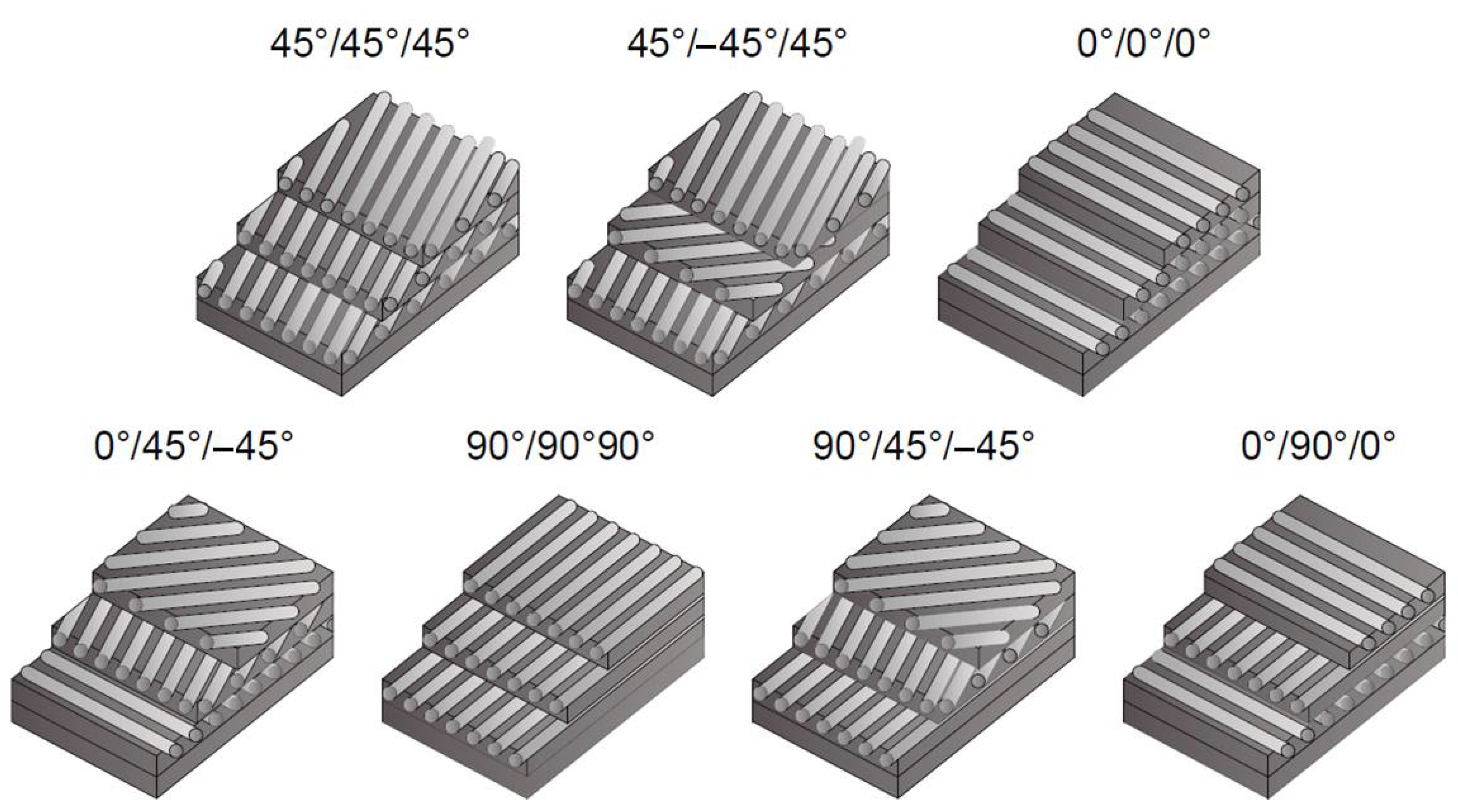

3.2. Orientation of Fibres in FRP Composites

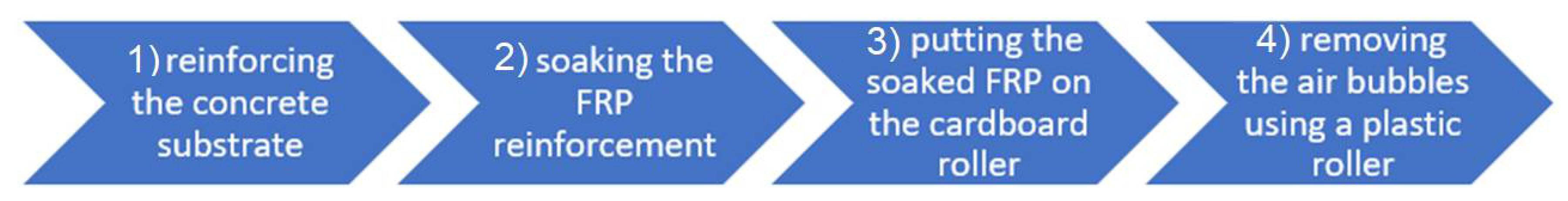

3.3. Lamination Process

3.4. Matrix

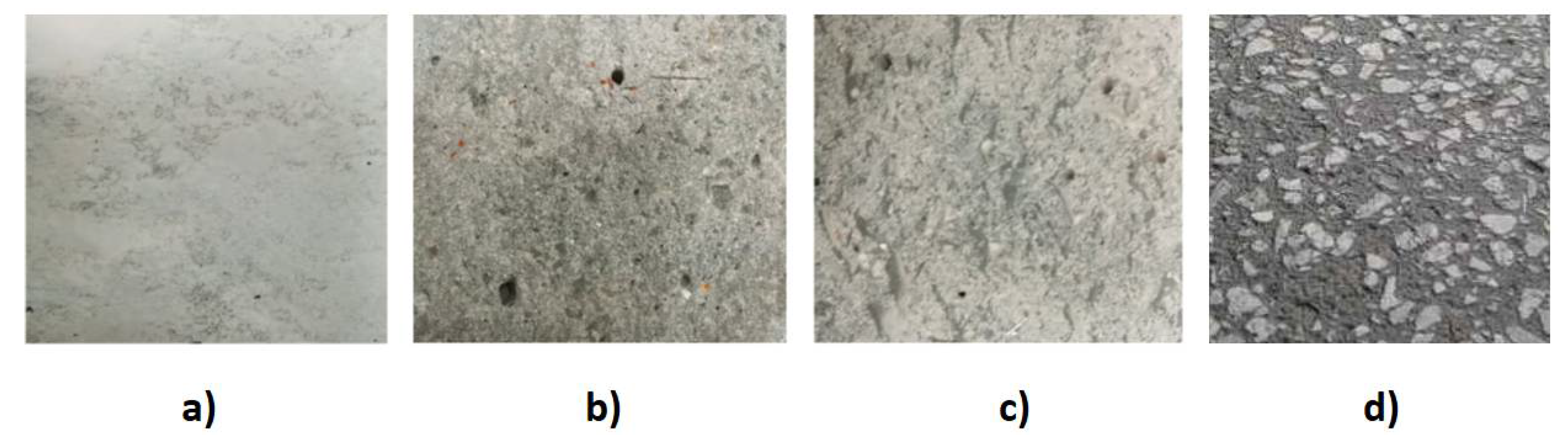

3.5. Preparation of Concrete Substrate

3.6. Concrete Surface Moisture and Temperature during Lamination

3.7. High-Temperature Protection

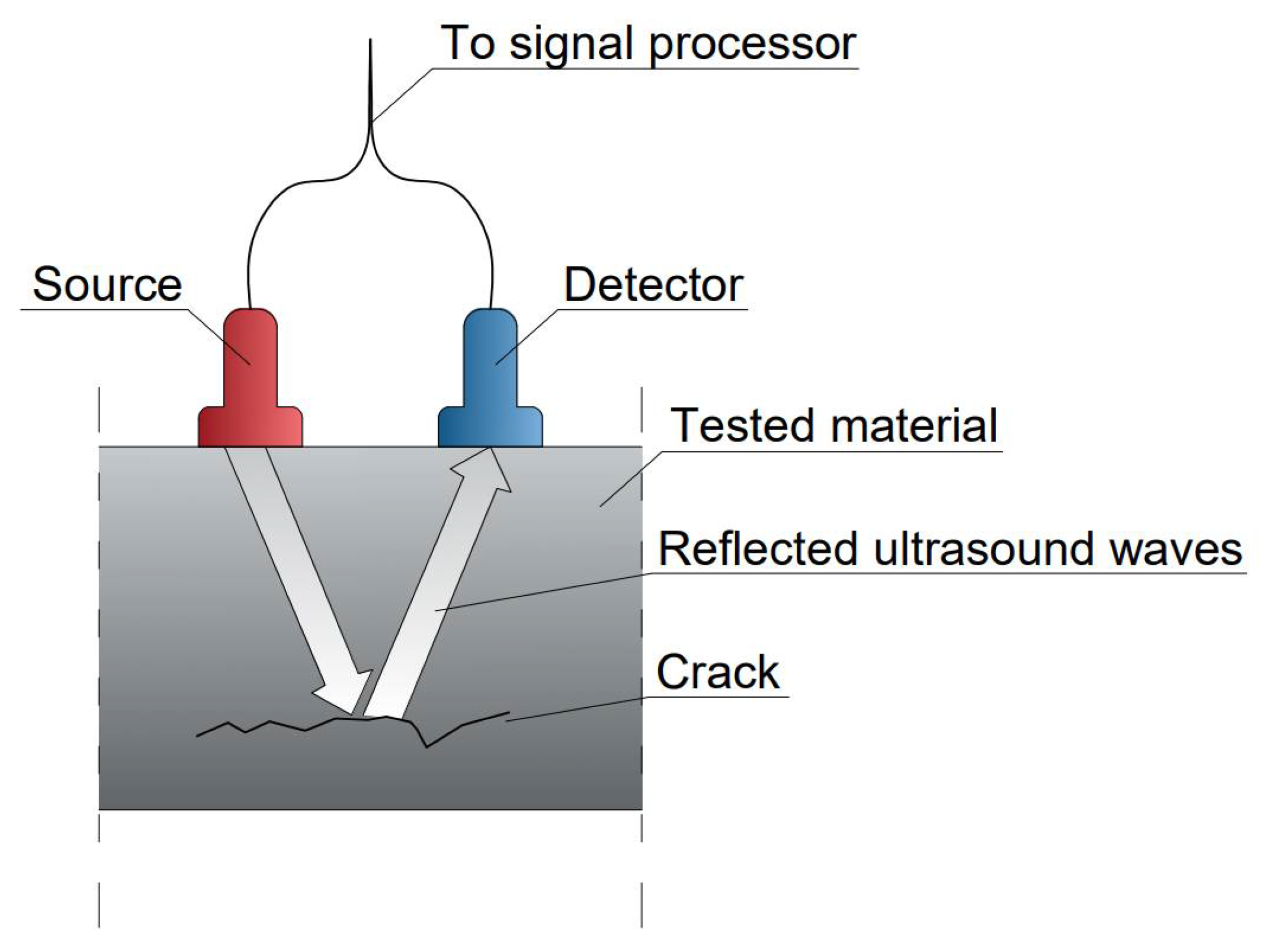

3.8. Non-Destructive Testing of FRP Laminates

4. Concrete Reinforced with FRP Composites

5. Durability of Concrete Structures Reinforced with FRP Materials

- —environmental factor;

- —ultimate tensile strength of FRP material reported by manufacturer;

- —specified compressive strength of concrete;

- —number of layers of FRP reinforcements;

- —tensile modulus of elasticity of FRP;

- —nominal thickness of one layer of FRP reinforcement.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Hansson, C.M. Concrete: The advanced industrial material of the 21st century. Metall. Mater. Trans. B 1995, 26, 417–437. [Google Scholar] [CrossRef]

- Stanton, T.E. Expansion of concrete through reaction between cement and aggregate. Trans. Am. Soc. Civ. Eng. 1942, 107, 54–84. [Google Scholar] [CrossRef]

- Stark, D. Alkali-silica reactions in concrete. In Significance of Tests and Properties of Concrete and Concrete-Making Materials; ASTM Special Technical Publication: West Conshohocken, PA, USA, 1994; Volume 169, pp. 365–371. [Google Scholar]

- Li, Z. 2011 Advanced Concrete Technology; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2011. [Google Scholar]

- Paul, S.C.; van Zijl, G.P.; Šavija, B. Effect of fibers on durability of concrete: A practical review. Materials 2020, 13, 4562. [Google Scholar] [CrossRef] [PubMed]

- Chajes, M.J.; Thomson, T.A., Jr.; Farschman, C.A. Durability of concrete beams externally reinforced with composite fabrics. Constr. Build. Mater. 1995, 9, 141–148. [Google Scholar] [CrossRef]

- Roberts-Wollmann, C.L.; Guirola, M.; Easterling, W.S. Strength and performance of fiber-reinforced concrete composite slabs. J. Struct. Eng. 2004, 130, 520–528. [Google Scholar] [CrossRef]

- Rajczyk, M.; Stachecki, B. Współczesne materiały kompozytowe. Wybrane kierunki nowych technologii. Budownictwo o Zoptymalizowanym Potencjale Energetycznym 2011, 8, 202–211. [Google Scholar]

- Holmes, M. Carbon fibre reinforced plastics market continues growth path. Reinf. Plast. 2013, 57, 24–29. [Google Scholar] [CrossRef]

- Job, S. Recycling glass fibre reinforced composites–history and progress. Reinf. Plast. 2013, 57, 19–23. [Google Scholar] [CrossRef]

- Lis, J. Kompozyty [Composites]; Academic Lecture; AGH University of Science and Technology: Kraków, Poland, 2017. [Google Scholar]

- Zubel, I. Composites; Academic Lecture; Wroclaw University of Technology: Wrocław, Poland, 2010. [Google Scholar]

- Mayer, P.; Kaczmar, J.W. Właściwości i zastosowania włókien węglowych i szklanych. Tworzywa Sztuczne i Chemia 2008, 6, 52–56. [Google Scholar]

- Lim, J.C.; Ozbakkaloglu, T. Confinement model for FRP-confined high-strength concrete. J. Compos. Constr. 2014, 18, 04013058. [Google Scholar] [CrossRef]

- Wei, Y.; Wu, G.; Li, G. Performance of circular concrete-filled fiber-reinforced polymer-steel composite tube columns under axial compression. J. Reinf. Plast. Compos. 2014, 33, 1911–1928. [Google Scholar] [CrossRef]

- Barbieri, G.; Biolzi, L.; Bocciarelli, M.; Cattaneo, S. Pull out of FRP reinforcement from masonry pillars: Experimental and numerical results. Compos. Part B Eng. 2015, 69, 516–525. [Google Scholar] [CrossRef]

- Abdul-Salam, B. Behaviour of Shear Critical FRP Reinforced Concrete One-Way Slabs. Ph.D. Thesis, Université de Sherbrooke, Sherbrooke, QC, Canada, 2014. [Google Scholar]

- Ostrowski, K.; Dudek, M.; Sadowski, Ł. Compressive behaviour of concrete-filled carbon fiber-reinforced polymer steel composite tube columns made of high performance concrete. Compos. Struct. 2020, 234, 111668. [Google Scholar] [CrossRef]

- Ali, A.; Shaker, Z.R.; Khalina, A.; Sapuan, S.M. Development of anti-ballistic board from ramie fiber. Polym.-Plast. Technol. Eng. 2011, 50, 622–634. [Google Scholar] [CrossRef]

- Yeung, K.H.; Rao, K.P. Mechanical properties of Kevlar-49 fibre reinforced thermoplastic composites. Polym. Polym. Compos. 2012, 20, 411–424. [Google Scholar] [CrossRef]

- Manigandan, S. Determination of fracture behavior under biaxial loading of Kevlar 149. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Freienbach, Switzerland, 2015; Volume 766, pp. 1127–1132. [Google Scholar]

- Qiu, Y.; Schwartz, P. Micromechanical behavior of Kevlar-149/S-glass hybrid seven-fiber microcomposites: I. Tensile strength of the hybrid composite. Compos. Sci. Technol. 1993, 47, 289–301. [Google Scholar] [CrossRef]

- Dobrzański, L.A. Podstawy Nauki o Materiałach i Metaloznawstwo [Fundamentals of Materials Science and Metal Science]; Wydawnictwa Naukowo-Techniczne: Warsaw, Poland, 2002. [Google Scholar]

- Cantwell, W.J. The mechanical properties of fibre-metal laminates based on glass fibre reinforced polypropylene. Compos. Sci. Technol. 2000, 60, 1085–1094. [Google Scholar]

- Grace, N.F.; Sayed, G.A.; Soliman, A.K.; Saleh, K.R. Strengthening reinforced concrete beams using fiber reinforced polymer (FRP) laminates. ACI Struct. J.-Am. Concr. Inst. 1999, 96, 865–874. [Google Scholar]

- Li, Z.; Ma, J.; Ma, H.; Xu, X. Properties and applications of basalt fiber and its composites. IOP Conf. Ser. Earth Environ. Sci. 2018, 186, 012052. [Google Scholar] [CrossRef]

- John, V.J.; Dharmar, B. Influence of basalt fibers on the mechanical behavior of concrete—A review. Struct. Concr. 2021, 22, 491–502. [Google Scholar] [CrossRef]

- Tosh, M.W.; Kelly, D.W. On the design, manufacture and testing of trajectorial fibre steering for carbon fibre composite laminates. Compos. Part A Appl. Sci. Manuf. 2000, 31, 1047–1060. [Google Scholar] [CrossRef]

- Mirdehghan, S.A. Fibrous polymeric composites. In Engineered Polymeric Fibrous Materials; Woodhead Publishing: Sawston, UK, 2021; pp. 1–58. [Google Scholar]

- Ostrowski, K.A.; Kinasz, R.; Dybeł, P. The Impact of Surface Preparation for Self-Compacting, High-Performance, Fiber-Reinforced Concrete Confined with CFRP Using a Cement Matrix. Materials 2020, 13, 2830. [Google Scholar] [CrossRef] [PubMed]

- Leda, H. Szklane czy węglowe włókna w kompozytach polimerowych [Glass or carbon fibers in polymer composites]. Kompozyty 2003, 3, 209–215. [Google Scholar]

- Kobets, L.P.; Deev, I.S. Carbon fibres: Structure and mechanical properties. Compos. Sci. Technol. 1998, 57, 1571–1580. [Google Scholar] [CrossRef]

- Carolin, A. Carbon Fibre Reinforced Polymers for Strengthening of Structural Elements. Ph.D. Thesis, Luleå Tekniska Universitet, Luleå, Sweden, 2003. [Google Scholar]

- Bhatnagar, N.; Ramakrishnan, N.; Naik, N.K.; Komanduri, R. On the machining of fiber reinforced plastic (FRP) composite laminates. Int. J. Mach. Tools Manuf. 1995, 35, 701–716. [Google Scholar] [CrossRef]

- Frangopol, D.M.; Recek, S. Reliability of fiber-reinforced composite laminate plates. Probabilistic Eng. Mech. 2003, 18, 119–137. [Google Scholar] [CrossRef]

- Tyczynski, P.; Sliwa, R.E.; Ostrowski, R. Analysis of possibilities for modification of drill bit geometrical parameters used to drill holes in composite materials of various composition. Aircr. Eng. Aerosp. Technol. Int. J. 2015, 87, 120–130. [Google Scholar] [CrossRef]

- Mourad, A.H.; Zaaroura, N.; Cherupurakal, N. Wet lay-up technique for manufacturing of advanced laminated composites. Karbala Int. J. Mod. Sci. 2019, 5, 5. [Google Scholar] [CrossRef]

- de Azevedo, A.R.G.; Cruz, A.S.A.; Marvila, M.T.; de Oliveira, L.B.; Monteiro, S.N.; Vieira, C.M.F.; Fediuk, R.; Timokhin, R.; Vatin, N.; Daironas, M. Natural Fibers as an Alternative to Synthetic Fibers in Reinforcement of Geopolymer Matrices: A Comparative Review. Polymers 2021, 13, 2493. [Google Scholar] [CrossRef]

- Azevedo, A.R.G.D.; Klyuev, S.; Marvila, M.T.; Vatin, N.; Alfimova, N.; Lima, T.E.S.D.; Fediuk, R.; Olisov, A. Investigation of the Potential Use of Curauá Fiber for Reinforcing Mortars. Fibers 2020, 8, 69. [Google Scholar] [CrossRef]

- Ostrowski, K.A.; Furtak, K. The influence of concrete surface preparation on the effectiveness of reinforcement using carbon fibre-reinforced polymer in high-performance, self-compacting, fibre-reinforced concrete. Compos. Struct. 2021, 276, 114522. [Google Scholar] [CrossRef]

- Qin, D.; Gao, P.; Aslam, F.; Sufian, M.; Alabduljabbar, H. A comprehensive review on fire damage assessment of reinforced concrete structures. Case Stud. Constr. Mater. 2022, 16, e00843. [Google Scholar] [CrossRef]

- Michels, J.; Widmann, R.; Czaderski, C.; Allahvirdizadeh, R.; Motavalli, M. Glass transition evaluation of commercially available epoxy resins used for civil engineering applications. Compos. Part B Eng. 2015, 77, 484–493. [Google Scholar] [CrossRef]

- Krzywoń, R. Wpływ podwyższonej temperatury na skuteczność wzmocnienia belek żelbetowych taśmami typu CFRP i SRP [Influence of elevated temperature on efficiency of rc beams strengthening with CFRP strips and SRP tapes]. Czasopismo Inżynierii Lądowej, Środowiska i Architektury 2017, 64, 271–280. [Google Scholar]

- Sika Poland 2019 Instructions for Use Sikacrete®-213 F, Technical Card, Warsaw, Poland. Available online: https://www.buildsite.com/pdf/sika/Sikacrete-213-F-SDS-1855871.pdf (accessed on 5 April 2022).

- Szymanowski, J. Evaluation of the adhesion between overlays and substrates in concrete floors: Literature survey, recent non-destructive and semi-destructive testing methods, and research gaps. Buildings 2019, 9, 203. [Google Scholar] [CrossRef] [Green Version]

- Sadowski, Ł.; Czarnecki, S.; Hoła, J. Evaluation of the height 3D roughness parameters of concrete substrate and the adhesion to epoxy resin. Int. J. Adhes. Adhes. 2016, 67, 3–13. [Google Scholar] [CrossRef]

- Jamil, M.; Khan, A.M.; Hegab, H.; Sarfraz, S.; Sharma, N.; Mia, M.; Gupta, M.K.; Zhao, G.; Moustabchir, H.; Pruncu, C.I. Internal cracks and non-metallic inclusions as root causes of casting failure in sugar mill roller shafts. Materials 2019, 12, 2474. [Google Scholar] [CrossRef] [Green Version]

- Ostrowski, K.; Kinasz, R.; Cieślik, J.; Wałach, D.; Ahmida, B. Nośność elementów osiowo ściskanych na przykładzie kolumn z betonu i fibrobetonu wysokowartościowego wzmocnionych włóknami węglowymi. Czasopismo Inżynierii Lądowej Środowiska i Architektury 2016, 63, 309–316. [Google Scholar] [CrossRef]

- Ostrowski, K.; Kinasz, R.; Cieślik, J.; Wałach, D. 2016 The influence of CFRP sheets on the strength of short columns produced from normal strength concrete and fibre reinforced concrete. Czasopismo Techniczne 2016, 2016, 145–156. [Google Scholar]

- Ostrowski, K. Does the Carbon Fibre Coating Reinforcement Have an Influence on the Bearing Capacity of High-Performance Self-Compacting Fibre-Reinforced Concrete? Materials 2019, 12, 4054. [Google Scholar] [CrossRef] [Green Version]

- Ostrowski, K. The influence of CFRP sheets on the strength of specimens produced using normal concrete and high-performance concrete assessed using uniaxial compression tests. Tech. Trans. 2017, 114, 41–51. [Google Scholar]

- Eid, R.; Paultre, P. Compressive behavior of FRP-confined reinforced concrete columns. Eng. Struct. 2017, 132, 518–530. [Google Scholar] [CrossRef]

- Wang, W.; Wu, C.; Liu, Z.; Si, H. Compressive behavior of ultra-high performance fiber-reinforced concrete (UHPFRC) confined with FRP. Compos. Struct. 2018, 204, 419–437. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, X.; Xing, F.; Cui, H.; Sui, L. Axial compressive behavior of FRP-confined lightweight aggregate concrete: An experimental study and stress-strain relation model. Constr. Build. Mater. 2016, 119, 1–15. [Google Scholar] [CrossRef]

- Youssf, O.; Hassanli, R.; Mills, J.E. Mechanical performance of FRP-confined and unconfined crumb rubber concrete containing high rubber content. J. Build. Eng. 2017, 11, 115–126. [Google Scholar] [CrossRef]

- Campione, G.; La Mendola, L.; Monaco, A.; Valenza, A.; Fiore, V. Behavior in compression of concrete cylinders externally wrapped with basalt fibers. Compos. Part B Eng. 2015, 69, 576–586. [Google Scholar] [CrossRef]

- Sadeghian, P.; Fillmore, B. Strain distribution of basalt FRP-wrapped concrete cylinders. Case Stud. Constr. Mater. 2018, 9, e00171. [Google Scholar] [CrossRef]

- Kissman, V.; Sundar, L. An experimental study on strengthening of RC column with GFRP. Mater. Today Proc. 2020, 21, 278–285. [Google Scholar] [CrossRef]

- Silva, M.A.; Rodrigues, C.C. Size and relative stiffness effects on compressive failure of concrete columns wrapped with glass FRP. J. Mater. Civ. Eng. 2006, 18, 334–342. [Google Scholar] [CrossRef]

- Toutanji, H.; Deng, Y. Strength and durability performance of concrete axially loaded members confined with AFRP composite sheets. Compos. Part B Eng. 2002, 33, 255–261. [Google Scholar] [CrossRef]

- Bompa, D.V.; Elghazouli, A.Y. Stress–strain response and practical design expressions for FRP-confined recycled tyre rubber concrete. Constr. Build. Mater. 2020, 237, 117633. [Google Scholar] [CrossRef]

- Vincent, T.; Ozbakkaloglu, T. Compressive behavior of prestressed high-strength concrete-filled aramid FRP tube columns: Experimental observations. J. Compos. Constr. 2015, 19, 04015003. [Google Scholar] [CrossRef]

- Fanggi, B.A.L.; Ozbakkaloglu, T. Compressive behavior of aramid FRP–HSC–steel double-skin tubular columns. Constr. Build. Mater. 2013, 48, 554–565. [Google Scholar] [CrossRef]

- Wu, G.; Wu, Z.S.; Lu, Z.T.; Ando, Y.B. Structural performance of concrete confined with hybrid FRP composites. J. Reinf. Plast. Compos. 2008, 27, 1323–1348. [Google Scholar] [CrossRef]

- Djafar-Henni, I.; Kassoul, A. Stress–strain model of confined concrete with Aramid FRP wraps. Constr. Build. Mater. 2018, 186, 1016–1030. [Google Scholar] [CrossRef]

- El-Hacha, R.; Wight, R.G.; Green, M.F. Prestressed fibre-reinforced polymer laminates for strengthening struc-tures. Prog. Struct. Eng. Mater. 2001, 3, 111–121. [Google Scholar] [CrossRef]

- De Lorenzis, L.; Miller, B.; Nanni, A. Bond of FRP laminates to concrete. ACI Mater. J. 2001, 98, 256–264. [Google Scholar]

- Kliger, I.R.; Haghani, R.; Brunner, M.; Harte, A.M.; Schober, K.U. Wood-based beams strengthened with FRP laminates: Improved performance with pre-stressed systems. Eur. J. Wood Wood Prod. 2016, 74, 319–330. [Google Scholar] [CrossRef]

- Gharachorlou, A.; Ramezanianpour, A.A. Durability of concrete cylinder specimens strengthened with FRP laminates under penetration of chloride ions. Int. J. Civ. Eng. 2010, 8, 327–336. [Google Scholar]

- Antonini, E.; Boeri, A.; Lauria, M.; Giglio, F. Reversibility and durability as potential indicators for Circular building Technologies. Sustainability 2020, 12, 7659. [Google Scholar] [CrossRef]

- Gajdošová, K.; Sonnenschein, R.; Blaho, S.; Kinčeková, S.; Pecka, J. Durability of FRP Reinforcements and Long-Term Properties. Slovak J. Civ. Eng. 2020, 28, 50–55. [Google Scholar] [CrossRef]

- Burgoyne, C. Fibre reinforced polymers–strengths, weaknesses, opportunities and threats. In Proceedings of the 9th International Symposium on Fiber Reinforced Polymer Reinforcement for Concrete Structures (FRPRCS-9), Sydney, Australia, 13–15 July 2009; pp. 1–6. [Google Scholar]

- Lee, C.; Bonacci, J.F.; Thomas, M.D.; Maalej, M.; Khajehpour, S.; Hearn, N.; Pantazopoulou, S.; Sheikh, S. Accelerated corrosion and repair of reinforced concrete columns using carbon fibre reinforced polymer sheets. Can. J. Civ. Eng. 2000, 27, 941–948. [Google Scholar] [CrossRef]

- Nanni, A. Guide for the design and construction of concrete reinforced with FRP bars (ACI 440.1 R-03). In Structures Congress 2005: Metropolis and Beyond; American Society of Civil Engineers: Reston, VA, USA, 2005; pp. 1–6. [Google Scholar]

- American Concrete Institute. Guide for the Design and Construction of Structural Concrete Reinforced with Fiber-Reinforced Polymer (FRP) Bars. (ACI 440.1 R-15); American Concrete Institute: Farmington Hills, MI, USA, 2015. [Google Scholar]

| Fibre | Type | Young Modulus (GPa) | Tension Strength (MPa) | Ultimate Elongation at Break (%) | Density (kg/m3) |

|---|---|---|---|---|---|

| Carbon | High strength | 200–280 | 2500–5500 | 1.5–2.2 | 1800 |

| High modulus | 330–490 | 2100–2800 | 0.7–1.0 | 2000 | |

| Basalt | - | 90–110 | 4000–4840 | 2.25–3.1 | 2600–2800 |

| Glass | S-glass | 86–93 | 4500–4890 | 1.93 | 2460–2490 |

| E-glass | 72.3 | 3345–3400 | 2.12 | 2540–2580 | |

| Aramid | Kevlar 29 | 70–83 | 2900–2920 | 3.50–3.60 | 1440 |

| Kevlar 49 | 124–151.7 | 2758–3010 | 2.4 | 1467 | |

| Kevlar 149 | 179 | 3450 | 1.3–1.6 | 1470 |

| Temperature Range | Type of Fibre |

|---|---|

| Low temperature (below 100 °C) | All available fibres: natural, glass, carbon, ceramic, boron, organic, metal |

| Raised temperature (100 °C–400 °C) | Some organic, glass, carbon, ceramic, boron, metal |

| High temperature (400 °C–700 °C) | Ceramic, metal, carbon |

| Very high temperature (above 700 °C) | Carbon, ceramic |

| Fiber Angle (°) | Tool Rake Angle | |||

|---|---|---|---|---|

| 12° | 18° | |||

| Cutting Force Fc (N) | Resultant Force Ft (N) | Cutting Force Fc (N) | Resultant Force Ft (N) | |

| −75 | 162 | 110 | 170 | 65 |

| −60 | 200 | 155 | 175 | 115 |

| −45 | 160 | 181 | 160 | 170 |

| −30 | 145 | 200 | 145 | 207 |

| −10 | 135 | 210 | 140 | 215 |

| 0 | 145 | 140 | 120 | 125 |

| 10 | 120 | 120 | 105 | 85 |

| 30 | 115 | 40 | 155 | 45 |

| 45 | 140 | 62 | 105 | 85 |

| 60 | 158 | 61 | 215 | 45 |

| 75 | 140 | 60 | 170 | 40 |

| 90 | 315 | 110 | 300 | 98 |

| Matrix | Advantages | Disadvantages |

|---|---|---|

| Epoxy resin |

|

|

| Cement matrix |

|

|

| Compressive Strength Rc as a Reference (MPa) | Laminate Type | Matrix | FRP Layers | Compressive Strength of Reinforced Specimen in Comparison to the Reference (%) | Reference | Type of Concrete |

|---|---|---|---|---|---|---|

| 64.91 | CFRP | ER | 1 | +33 | [48] | High-performance concrete |

| 40.32 | +99 | [49] | Fibre-reinforced normal concrete | |||

| 81.04 | CM | +4 | [50] | High-performance self-compacting fibre-reinforced concrete | ||

| 31.74 | ER | +128 | [51] | Normal concrete | ||

| 33.7 | 2 | +33 | [52] | Reinforced normal concrete | ||

| 4 | +71 | |||||

| 136 | 1 | +29 | [53] | Ultra-high performance fibre-reinforced concrete | ||

| 5 | +55 | |||||

| 21.18 | 1 | +80 | [54] | Lightweight aggregate concrete | ||

| 3 | +155 | |||||

| 38.83 | 1 | +46 | ||||

| 3 | +120 | |||||

| 15.45 | 1 | +236 | ||||

| 3 | +407 | |||||

| 64.4 | 1 | +22 | [55] | High-strength concrete | ||

| 2 | +64 | |||||

| 3 | +99 | |||||

| 43.4 | 1 | +20 | [56] | Ready-mixed normal concrete | ||

| 3 | +97 | |||||

| BFRP | 1 | +2 | ||||

| 3 | +3 | |||||

| 55.8 | 2 | +0.8 | [57] | Normal concrete | ||

| 4 | +38 | |||||

| 6 | +69 | |||||

| 56.27 | 2 | +41 | High-performance concrete | |||

| 76.98 | 4 | +92 | ||||

| 94.57 | 6 | +136 | ||||

| 26.26 | GFRP | 1 | +8 | [58] | Low-performance concrete | |

| 2 | +18 | |||||

| 136 | 5 | +35 | [53] | Ultra-high performance fibre-reinforced concrete | ||

| 9 | +45 | |||||

| 27.2 | 2 | +220 | [59] | Low-performance concrete | ||

| 3 | 370 | |||||

| 44 | AFRP | 1 | +242 | [60] | Normal concrete | |

| 69.5 | 1 | +49 | [61] | Recycled tyre rubber concrete | ||

| 2 | +109 | |||||

| 63.7 | 3 | +116 | ||||

| 69.5 | 4 | +180 | ||||

| 23.8 | 1 | +99 | ||||

| 23.9 | 2 | +196 | ||||

| 23.8 | 3 | +296 | ||||

| 25.4 | 4 | +335 | ||||

| 7.1 | 1 | +251 | ||||

| 7.2 | 2 | +450 | ||||

| 3 | +719 | |||||

| 7.8 | 4 | +812 | ||||

| 110.3 | 4 | +27 | [62] | Ultra-high performance concrete | ||

| 100.2 | 4 | +64 | ||||

| 113.8 | 3 | +16 | [63] | Ultra-high performance concrete | ||

| 113.8 | 4 | +39 | ||||

| 113.8 | 6 | +39 | ||||

| 23.1 | 1 | +196 | [64] | Low-performance concrete | ||

| 85.7 | 6 | +94 | [65] | High-performance concrete |

| Parameter | Importance |

|---|---|

| Type of FRP | As fibre strength increases, the load-bearing capacity of a reinforced concrete structure increases. |

| Number of FRP layers | As the number of FRP laminates increases, the load-bearing capacity of a reinforced concrete structure increases. |

| Direction of fibres | Arranging fibres parallel to the tensile stresses increases the load capacity of the composite structure. |

| Different fibres used in the laminates | Combining different FRP fibres in multilayer laminates is possible and does not adversely affect the structure. |

| Matrix | The use of resins is recommended (especially epoxy resins). In the case of reinforcing low-performance concrete, cement mortar could be used, but the load-bearing efficiency, due to adhesion properties, in this case, is low. |

| Lamination process | The high quality of carried out work, including the correct reinforcement of the concrete substrate, accurate venting of the resin, and the correct adhesion of the laminate to the concrete surface guarantees good performance of the structure in accordance with the reinforcement design. |

| Type of concrete | As the strength of the concrete increases, the reinforcement efficiency decreases. It is recommended that concretes with low compressive strength should be reinforced with resin. Especially, concrete elements with low compressive strength may be reinforced with the use of composite meshes and a cement mortar (or matrix). |

| Type of concrete surface | The sandblasting, grinding, and shot blasting of concrete surfaces affect the load-bearing capacity of a reinforced element in comparison to an unprepared concrete surface at the level of several percentages. It has been noted in the literature that the connection between the FRP and the grinded concrete surface was the most favourable. |

| Preparation of concrete substrate | The concrete substrate must be clean, completely dry, and free from dirt and cement milk. It is widely recommended to prepare the concrete surface using mechanical treatment as it improves the adhesion of FRP to the concrete substrate. Epoxy resin has a greater possibility of penetrating into the concrete, thus, increasing the total contact area. The best results can be achieved by using a grinded concrete surface. |

| Geometry of elements for retrofitting | FRP laminate creates a coating that adjusts and adheres to the existing geometry of the element being reinforced. Due to this, most concrete elements, considering their shape, can be reinforced by this method. It is especially useful in strengthening objects that are several dozen or more years old. However, the trend in designing structures already using laminates is beginning to become noticeable. |

| Performance conditions | The lamination process should take place under positive temperature conditions and with low humidity. |

| Temperature | The temperature during the lamination process should be between +10 °C to +40 °C. As the ambient temperature rises, the use time of the resin and the inorganic matrix is shortened due to their accelerated fixation. |

| Insolation | High insolation, dark surfaces that do not reflect radiation and excessive heating of the structure may affect the achievement of the glass transition zone by the organic matrix, beyond which the matrix begins to deteriorate. |

| Humidity | The humidity of concrete substrate should be not more than 5% by weight. High humidity has a negative effect on the penetration depth of resin and cement mortar. |

| Design of new elements | By appropriate selection of FRP laminates, it is possible to make slender elements with smaller cross-sections. Advanced software allows to accurately determine the number of laminate layers. Numerous experimental studies are also helpful. |

| Fire protection | In the case of FRP laminates with epoxy resin, it is recommended to protect them against high temperatures by using insulation or cement matrix to confine the composite structure. FRP laminates with cement matrix do not need additional fire protection if the cement matrix has an appropriate width. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ostrowski, K.A.; Chastre, C.; Furtak, K.; Malazdrewicz, S. Consideration of Critical Parameters for Improving the Efficiency of Concrete Structures Reinforced with FRP. Materials 2022, 15, 2774. https://doi.org/10.3390/ma15082774

Ostrowski KA, Chastre C, Furtak K, Malazdrewicz S. Consideration of Critical Parameters for Improving the Efficiency of Concrete Structures Reinforced with FRP. Materials. 2022; 15(8):2774. https://doi.org/10.3390/ma15082774

Chicago/Turabian StyleOstrowski, Krzysztof Adam, Carlos Chastre, Kazimierz Furtak, and Seweryn Malazdrewicz. 2022. "Consideration of Critical Parameters for Improving the Efficiency of Concrete Structures Reinforced with FRP" Materials 15, no. 8: 2774. https://doi.org/10.3390/ma15082774

APA StyleOstrowski, K. A., Chastre, C., Furtak, K., & Malazdrewicz, S. (2022). Consideration of Critical Parameters for Improving the Efficiency of Concrete Structures Reinforced with FRP. Materials, 15(8), 2774. https://doi.org/10.3390/ma15082774