Enhancement of Confinement in Scaled RC Columns using Steel Fibers Extracted from Scrap Tyres

Abstract

:1. Introduction

2. Materials

2.1. Cement

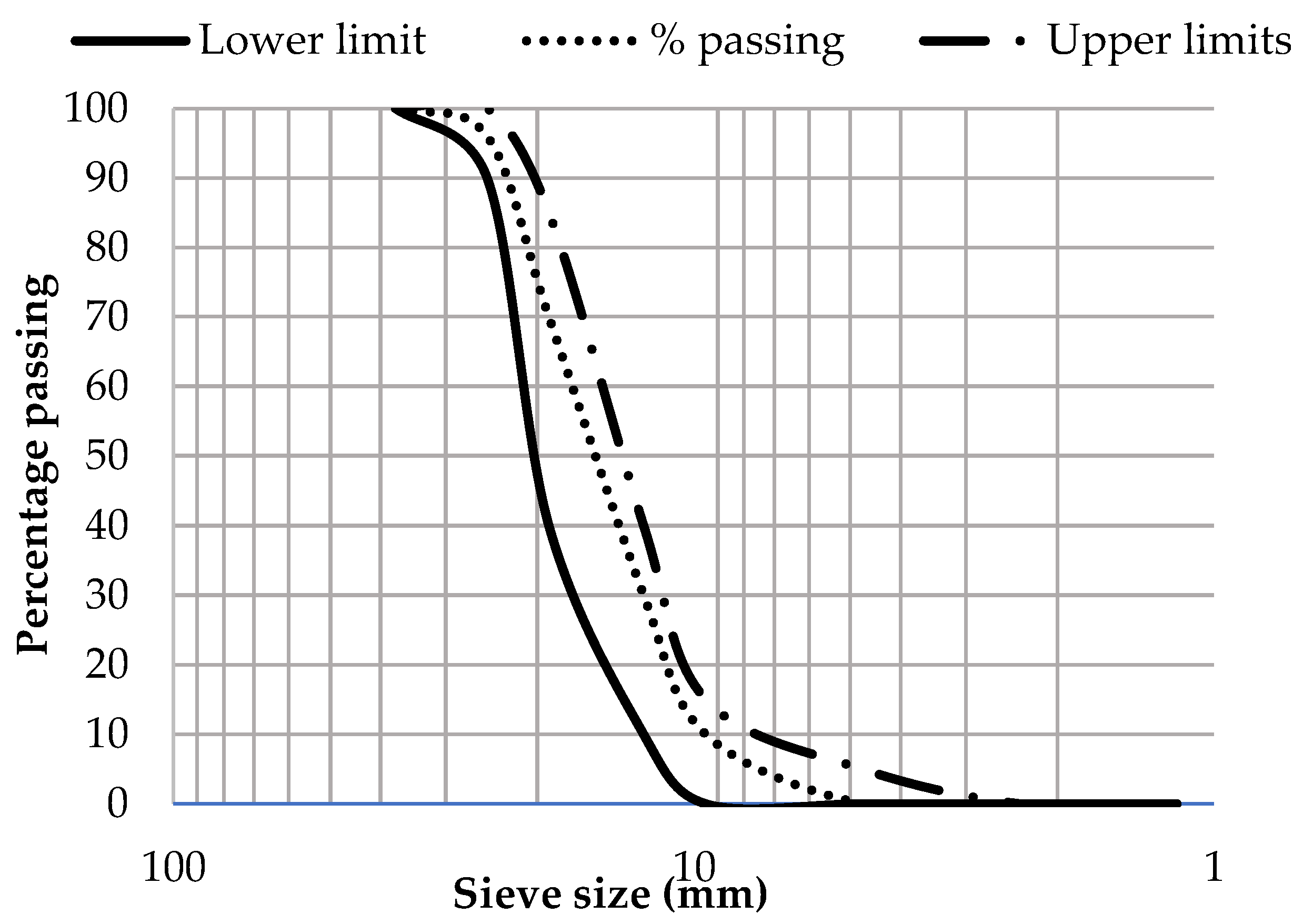

2.2. Coarse Aggregates

2.3. Fine Aggregate

2.4. Steel Fiber

2.5. Main Reinforcement (Rebars)

3. Mix Proportioning of Concrete

4. Specimen Preparation

4.1. Cylinder Preparation

4.2. Columns Preparation (Confined Concrete)

5. Experimental Setup for Fresh and Hardened Concrete

5.1. Slump Cone Test

5.2. Compressive Strength Test of Confined (Short RC Columns) and Unconfined Concrete Specimen

6. Results

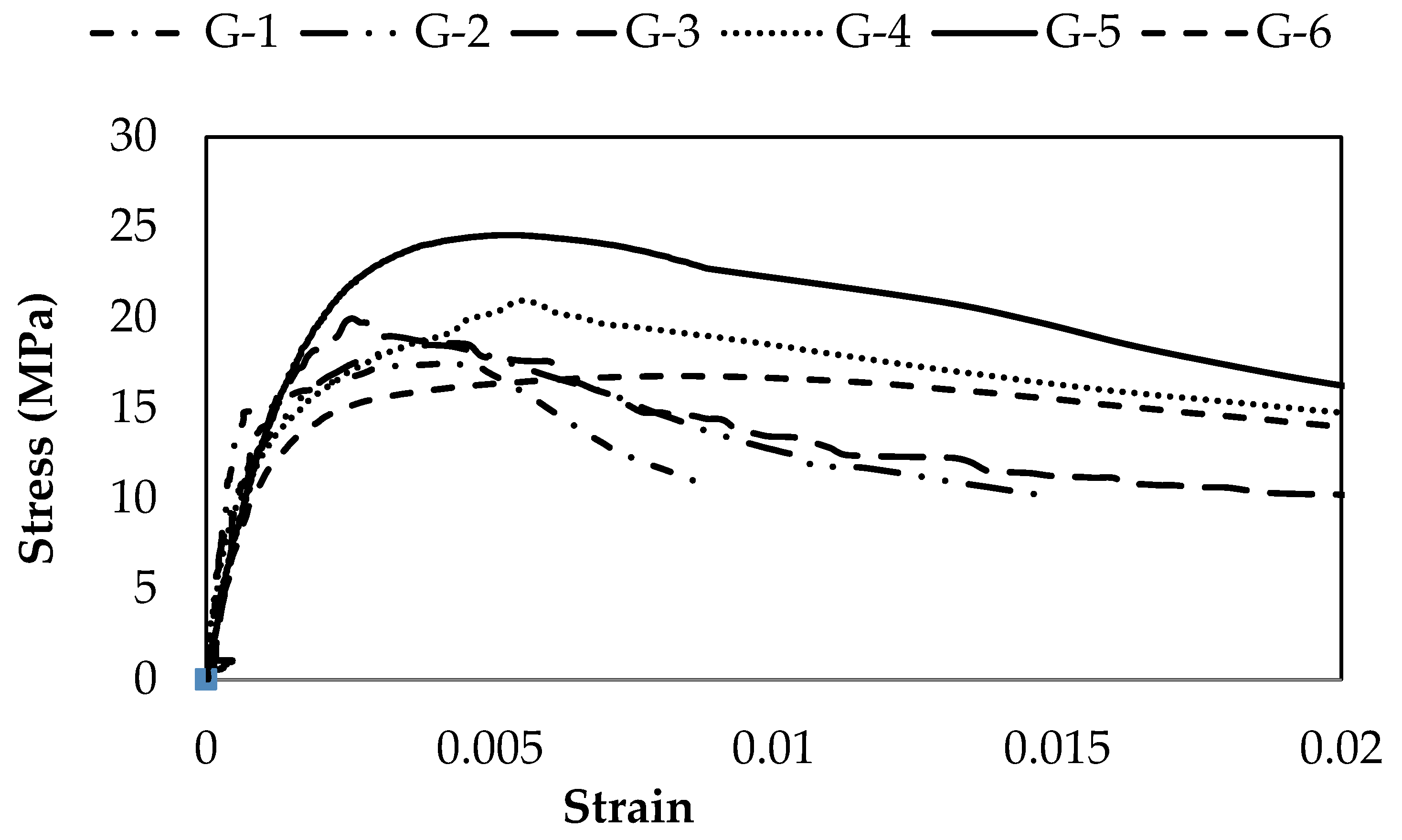

6.1. Compressive Strength Test of Unconfined Concrete

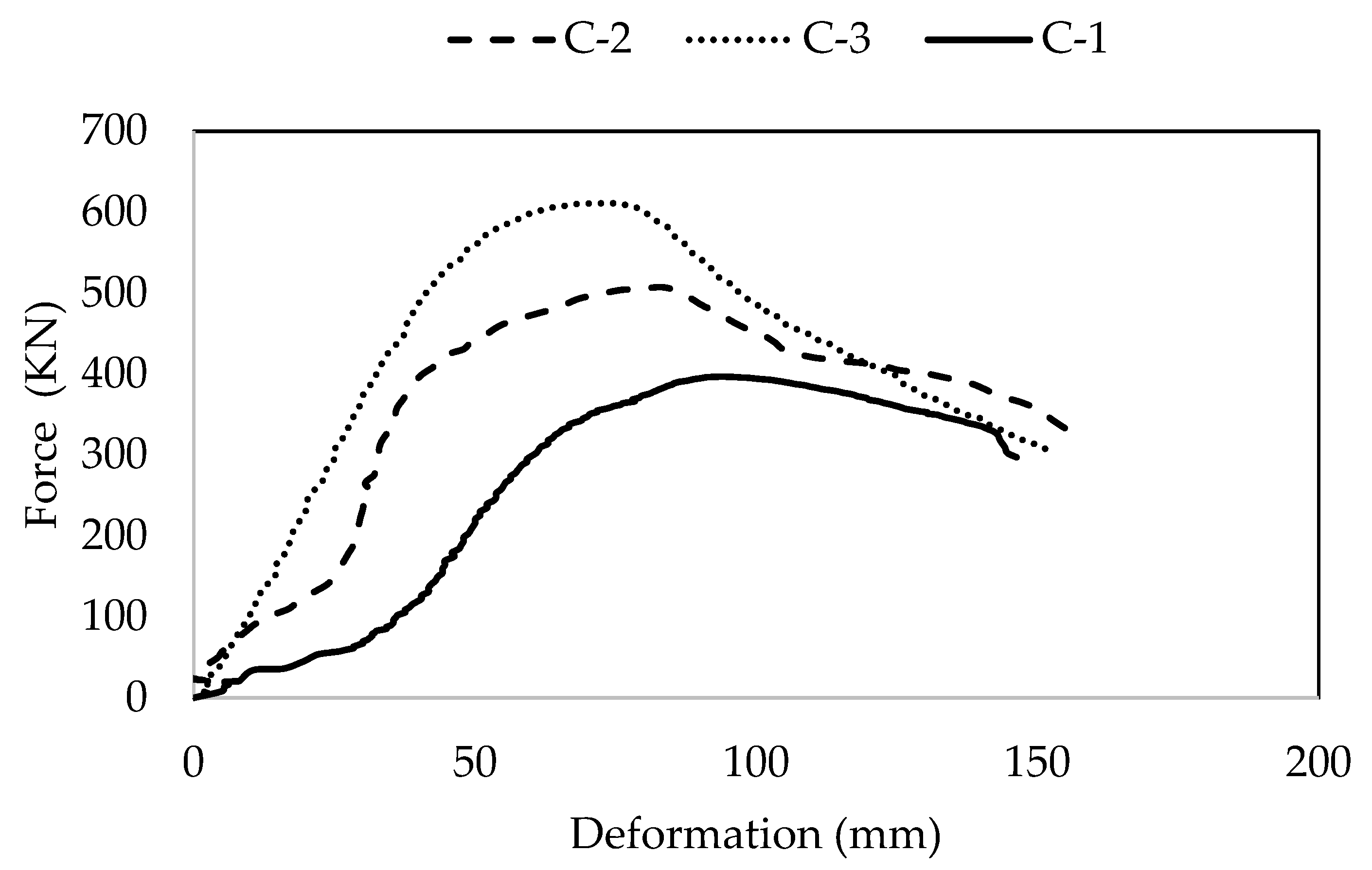

6.2. Axial Behavior of Column

6.3. Failure Modes

7. Conclusions

- In unconfined concrete, 0%, 1%, 1.5%, 2% and 2.5% steel fiber amounts were used in different mixes. An increase in the percentage of steel fibers increased the compressive strength; however, beyond 2.5%, the compression strength decreased. Thus, 2.5% of steel fibers is recommended as an optimum replacement proportion.

- The use of an optimum replacement ratio of 2.5% has resulted in an increase in the compressive strength by 38.97% as compared to unconfined concrete, accompanied by a substantial increase in ductility. It was further noted that beyond 2.5%, the addition of steel fibers adversely affects the strength and durability of concrete.

- In the case of confined concrete, the addition of steel fibers sufficiently increased the strength alongside a pronounced effect on the ductility of reinforced concrete. The confined increased in terms of an increase in concrete strength; however, a detailed study is needed to evaluate its effectiveness in reducing the spacing of stirrups.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sheikh, S.A. Effectiveness of Rectangular Ties as Confinement Steel in Reinforced Concrete Columns. Ph.D. Thesis, University of Toronto, Toronto, ON, Canada, 1980; p. 377. [Google Scholar]

- Mourad, S.; Shannag, M. Repair and strengthening of reinforced concrete square columns using ferrocement jackets. Cem. Concr. Compos. 2012, 34, 288–294. [Google Scholar] [CrossRef]

- Rathish Kumar, P.; Oshima, T.; Mikami, S. Ferrocement confinement of plain and reinforced concrete. Prog. Struct. Eng. Mater. 2004, 6, 241–251. [Google Scholar] [CrossRef]

- Saatcioglu, M.; Grira, M. Confinement of reinforced concrete columns with welded reinforced grids. Struct. J. 1999, 96, 29–39. [Google Scholar]

- Ding, Y.; Zhang, F.; Torgal, F.; Zhang, Y. Shear behaviour of steel fibre reinforced self-consolidating concrete beams based on the modified compression field theory. Compos. Struct. 2012, 94, 2440–2449. [Google Scholar] [CrossRef] [Green Version]

- Rajamony Laila, L.; Gurupatham, B.G.A.; Roy, K.; Lim, J.B.P. Effect of super absorbent polymer on microstructural and mechanical properties of concrete blends using granite pulver. Struct. Concr. 2021, 22, E898–E915. [Google Scholar] [CrossRef]

- Rajamony Laila, L.; Gurupatham, B.G.A.; Roy, K.; Lim, J.B.P. Influence of super absorbent polymer on mechanical, rheological, durability, and microstructural properties of self-compacting concrete using non-biodegradable granite pulver. Struct. Concr. 2021, 22, E1093–E1116. [Google Scholar] [CrossRef]

- Ferrara, L.; Bamonte, P.; Caverzan, A.; Musa, A.; Sanal, I. A comprehensive methodology to test the performance of steel fibre reinforced self-compacting concrete (SFR-SCC). Constr. Build. Mater. 2012, 37, 406–424. [Google Scholar] [CrossRef]

- Michels, J.; Christen, R.; Waldmann, D. Experimental and numerical investigation on postcracking behavior of steel fiber reinforced concrete. Eng. Fract. Mech. 2013, 98, 326–349. [Google Scholar] [CrossRef] [Green Version]

- Kayali, O.; Haque, M.; Zhu, B. Some characteristics of high strength fiber reinforced lightweight aggregate concrete. Cem. Concr. Compos. 2003, 25, 207–213. [Google Scholar] [CrossRef]

- Huang, S.-S.; Angelakopoulos, H.; Pilakoutas, K.; Burgess, I. Reused tyre polymer fibre for fire-spalling mitigation. In Proceedings of the International Conference, Dubrovnik, Croatia, 15–16 October 2015. [Google Scholar]

- Qian, C.; Stroeven, P. Development of hybrid polypropylene-steel fibre-reinforced concrete. Cem. Concr. Res. 2000, 30, 63–69. [Google Scholar] [CrossRef]

- Olivito, R.; Zuccarello, F. An experimental study on the tensile strength of steel fiber reinforced concrete. Compos. Part B Eng. 2010, 41, 246–255. [Google Scholar] [CrossRef]

- Siddiqui, N.A.; Alsayed, S.H.; Al-Salloum, Y.A.; Iqbal, R.A.; Abbas, H. Experimental investigation of slender circular RC columns strengthened with FRP composites. Constr. Build. Mater. 2014, 69, 323–334. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Lim, J.C. Axial compressive behavior of FRP-confined concrete: Experimental test database and a new design-oriented model. Compos. Part B Eng. 2013, 55, 607–634. [Google Scholar] [CrossRef] [Green Version]

- Pham, T.M.; Doan, L.V.; Hadi, M.N. Strengthening square reinforced concrete columns by circularisation and FRP confinement. Constr. Build. Mater. 2013, 49, 490–499. [Google Scholar] [CrossRef] [Green Version]

- Hu, B.; Wang, J.-G.; Li, G.-Q. Numerical simulation and strength models of FRP-wrapped reinforced concrete columns under eccentric loading. Constr. Build. Mater. 2011, 25, 2751–2763. [Google Scholar] [CrossRef]

- Lignola, G.P.; Nardone, F.; Prota, A.; Manfredi, G. Analytical model for the effective strain in FRP-wrapped circular RC columns. Compos. Part B Eng. 2012, 43, 3208–3218. [Google Scholar] [CrossRef]

- Zhao, X.; He, X.-J.; Yan, S.; Anh, N.P. Computational and simulation analysis of pull-out fiber reinforced concrete. Adv. Mater. Sci. Eng. 2014, 2014, 576052. [Google Scholar] [CrossRef] [Green Version]

- Sheikh, S.A.; Yau, G. Seismic behavior of concrete columns confined with steel and fiber-reinforced polymers. Struct. J. 2002, 99, 72–80. [Google Scholar]

- Kusuma, B.; Suprobo, P. Axial load behavior of concrete columns with welded wire fabric as transverse reinforcement. Procedia Eng. 2011, 14, 2039–2047. [Google Scholar] [CrossRef] [Green Version]

- Vairagade, V.S.; Kene, K.S. Introduction to steel fiber reinforced concrete on engineering performance of concrete. Int. J. Sci. Technol. Res. 2012, 1, 141. [Google Scholar]

- Romualdi, J.P.; Batson, G.B. Mechanics of crack arrest in concrete. J. Eng. Mech. Div. 1963, 89, 147–168. [Google Scholar] [CrossRef]

- ACI Committee 544. State-of-the-Art Report on Fiber Reinforced Concrete. J. Proc. 1973, 70, 729–744. [Google Scholar]

- Nobili, A.; Lanzoni, L.; Tarantino, A.M. Experimental investigation and monitoring of a polypropylene-based fiber reinforced concrete road pavement. Constr. Build. Mater. 2013, 47, 888–895. [Google Scholar] [CrossRef] [Green Version]

- Campione, G.; Fossetti, M.; Papia, M. Behavior of Fiber-Reinforced Concrete Columns under Axially and Eccentrically Compressive Loads. ACI Struct. J. 2010, 107, 272–281. [Google Scholar]

- Bharti, R.; Chidambaram, R.S.; Kwatra, N. Influence of fiber reinforced concrete on plastic behavior on exterior beam column joint under cyclic loading. Procedia Eng. 2017, 173, 1122–1129. [Google Scholar] [CrossRef]

- Campione, G.; Mindness, S.; Zingone, G. Compressive stress-strain behavior of normal and high-strength carbon fiber concrete reinforced with steel spirals. Mater. J. 1999, 96, 27–34. [Google Scholar]

- Aiello, M.A.; Leuzzi, F.; Centonze, G.; Maffezzoli, A. Use of steel fibres recovered from waste tyres as reinforcement in concrete: Pull-out behaviour, compressive and flexural strength. Waste Manag. 2009, 29, 1960–1970. [Google Scholar] [CrossRef]

- ASTM C188-14; Standard Test Method for Density of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2009; pp. 109–188.

- ASTM C786/C786M-17; Standard Test Method for Fineness of Hydraulic Cement by the 150-μm (No. 100) and75-μm (No. 200) Sieves. ASTM: West Conshohocken, PA, USA, 1994.

- ASTM C 33-86; Standard Specification for Concrete Aggregates, Annual Book of ASTM Standards. ASTM: West Conshohocken, PA, USA, 1986.

- ASTM C-127; Test Method for Density, Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM: West Conshohocken, PA, USA, 2001.

- ASTM C-128; Test Method for Density, Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM: West Conshohocken, PA, USA, 2001.

- ASTM A370; Standard Test Methods and Definitions for Mechanical Testing of Steel Products. ASTM: West Conshohocken, PA, USA, 2012.

- Dixon, D.E.; Prestrera, J.R.; Burg, G.R.; Chairman, S.A.; Abdun-Nur, E.A.; Barton, S.G.; Bell, L.W.; Blas, S.J., Jr.; Carrasquillo, R.L.; Carrasquillo, P.M. ACI 211.1-91; Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete. ACI: Indianapolis, IN, USA.

- ASTM C143; Slump Tests for Every Test Cylinders in Accordance with ANSI. ASTM: West Conshohocken, PA, USA, 2002.

- ASTM C469/C469M-10; Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. ASTM International: West Conshohocken, PA, USA, 2010.

- Samarakoon, S.S.M.; Ruben, P.; Pedersen, J.W.; Evangelista, L. Mechanical performance of concrete made of steel fibers from tire waste. Case Stud. Constr. Mater. 2019, 11, e00259. [Google Scholar] [CrossRef]

- Tejchman, J.; Kozicki, J. Experimental and Theoretical Investigations of Steel-Fibrous Concrete; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Yang, J.; Chen, B.; Nuti, C. Influence of steel fiber on compressive properties of ultra-high performance fiber-reinforced concrete. Constr. Build. Mater. 2021, 302, 124104. [Google Scholar] [CrossRef]

- Muthuswamy, K.; Thirugnanam, G. Experimental investigation on behaviour of hybrid fibre reinforced concrete column under Axial loading. Asian J. Civ. Eng. 2014, 15, 169–178. [Google Scholar]

- Suda, V.R.; Rao, P.S. Experimental studies on steel fiber reinforced short ternary columns under axial loading. Mater. Today Proc. 2021, 38, 2975–2980. [Google Scholar] [CrossRef]

- Kaloop, M.R.; Samui, P.; Iqbal, M.; Hu, J.W. Soft computing approaches towards tensile strength estimation of GFRP rebars subjected to alkaline-concrete environment. Case Stud. Constr. Mater. 2022, 16, e00955. [Google Scholar] [CrossRef]

- Iqbal, M.; Zhao, Q.; Zhang, D.; Jalal, F.E.; Jamal, A. Evaluation of tensile strength degradation of GFRP rebars in harsh alkaline conditions using non-linear genetic-based models. Mater. Struct. 2021, 54, 190. [Google Scholar] [CrossRef]

- Iqbal, M.; Elbaz, K.; Zhang, D.; Hu, L.; Jalal, F.E. Prediction of residual tensile strength of glass fiber reinforced polymer bars in harsh alkaline concrete environment using fuzzy metaheuristic models. J. Ocean. Eng. Sci. 2022, in press. [Google Scholar] [CrossRef]

- Khan, K.J.; Jalal, F.E.; Iqbal, M.; Khan, M.I.; Amin, M.N.; Al-Faiad, M.A. Predictive Modeling of Compression Strength of Waste PET/SCM Blended Cementitious Grout Using Gene Expression Programming. Materials 2022, 15, 3077. [Google Scholar] [CrossRef]

| Property | Specific Gravity | Fineness Modulus | Initial Setting Time | Final Setting Time |

|---|---|---|---|---|

| Value | 3.15 | 345 m2/kg | 45 min | 250 min |

| Specific Gravity | Bulk Density | Absorption Capacity | Max. Aggregate Size | Fineness Modulus | |

|---|---|---|---|---|---|

| Coarse aggregate | 2.63 | 1555.8 kg/m3 | 0.45% | 25 mm down | ------ |

| Fine aggregate | 2.30 | ------ | 1.50% | ------- | 2.40 |

| Property | Tensile Strength | Diameter | Length | Aspect Ratio |

|---|---|---|---|---|

| Value | 132 kg/mm2 | 1 mm | 75 mm | 75 |

| Water/Cement | Weight of Concrete Ingredient (lbs./yd3) | Proportions | Percentage of Steel Fibers | Number of Specimens | |||

|---|---|---|---|---|---|---|---|

| Water (lbs.) | Cement (lbs.) | Fine Aggregates (lbs.) | Coarse Aggregates (lbs.) | ||||

| 0.66 | 3.4 | 5.15 | 11.90 | 21.90 | 1:2.3:4.3 | 0 | 3 |

| 0.66 | 3.4 | 5.15 | 11.90 | 21.90 | 1:2.3:4.3 | 1 | 3 |

| 0.66 | 3.4 | 5.15 | 11.90 | 21.90 | 1:2.3:4.3 | 1.5 | 3 |

| 0.66 | 3.4 | 5.15 | 11.90 | 21.90 | 1:2.3:4.3 | 2 | 3 |

| 0.66 | 3.4 | 5.15 | 11.90 | 21.90 | 1:2.3:4.3 | 2.5 | 3 |

| 0.66 | 3.4 | 5.15 | 11.91 | 21.91 | 1:2.3:4.3 | 3 | 3 |

| Water/Cement | Slump Type | Slump Values (mm) | |

|---|---|---|---|

| Control Samples | Percentage of Steel Fibers | ||

| 0.65 | True | 89 | 0 |

| 0.65 | True | 76 | 1.5 |

| 0.65 | True | 64 | 2.0 |

| 0.65 | True | 50 | 2.5 |

| 0.65 | True | 41 | 3.0 |

| Designation of Cylinder | Ultimate Load (KN) | Axial Deformation (mm) | Toughness/Energy Absorption KN-mm |

|---|---|---|---|

| G1 | 327.12 | 1.804 | 590 |

| G2 | 354.24 | 3.174 | 1124 |

| G3 | 394.44 | 4.86 | 1917 |

| G4 | 408.5 | 5.36 | 2190 |

| G5 | 438.56 | 5.29 | 2320 |

| G6 | 320.26 | 5.04 | 1614 |

| Column Type | Ultimate Load (KN) | Axial Deformation (mm) | Toughness/Energy Absorption (KN-mm) |

|---|---|---|---|

| C1 | 398.96 | 7.248 | 2892 |

| C2 | 443.4 | 8.856 | 3927 |

| C3 | 620.76 | 7.786 | 4833 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, I.; Iqbal, M.; Abbas, A.; Badrashi, Y.I.; Jamal, A.; Ullah, S.; Yosri, A.M.; Hamad, M. Enhancement of Confinement in Scaled RC Columns using Steel Fibers Extracted from Scrap Tyres. Materials 2022, 15, 3219. https://doi.org/10.3390/ma15093219

Ahmad I, Iqbal M, Abbas A, Badrashi YI, Jamal A, Ullah S, Yosri AM, Hamad M. Enhancement of Confinement in Scaled RC Columns using Steel Fibers Extracted from Scrap Tyres. Materials. 2022; 15(9):3219. https://doi.org/10.3390/ma15093219

Chicago/Turabian StyleAhmad, Izaz, Mudasir Iqbal, Asim Abbas, Yasir Irfan Badrashi, Arshad Jamal, Shahid Ullah, Ahmed M. Yosri, and Moustafa Hamad. 2022. "Enhancement of Confinement in Scaled RC Columns using Steel Fibers Extracted from Scrap Tyres" Materials 15, no. 9: 3219. https://doi.org/10.3390/ma15093219