The Influence of Cryogenic Treatment on the Microstructure and Mechanical Characteristics of Aluminum Silicon Carbide Matrix Composites

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Hardness and Tensile Properties

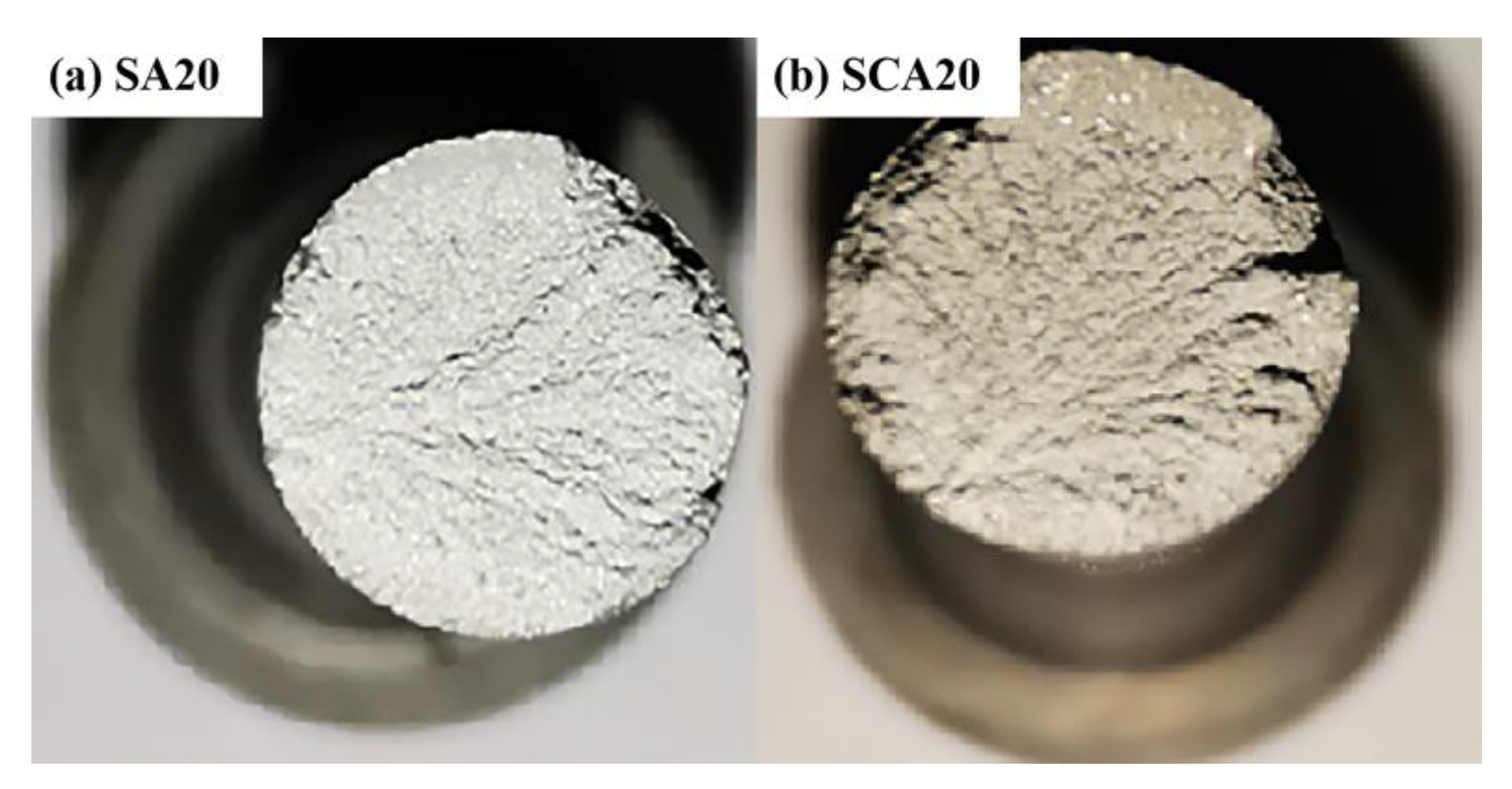

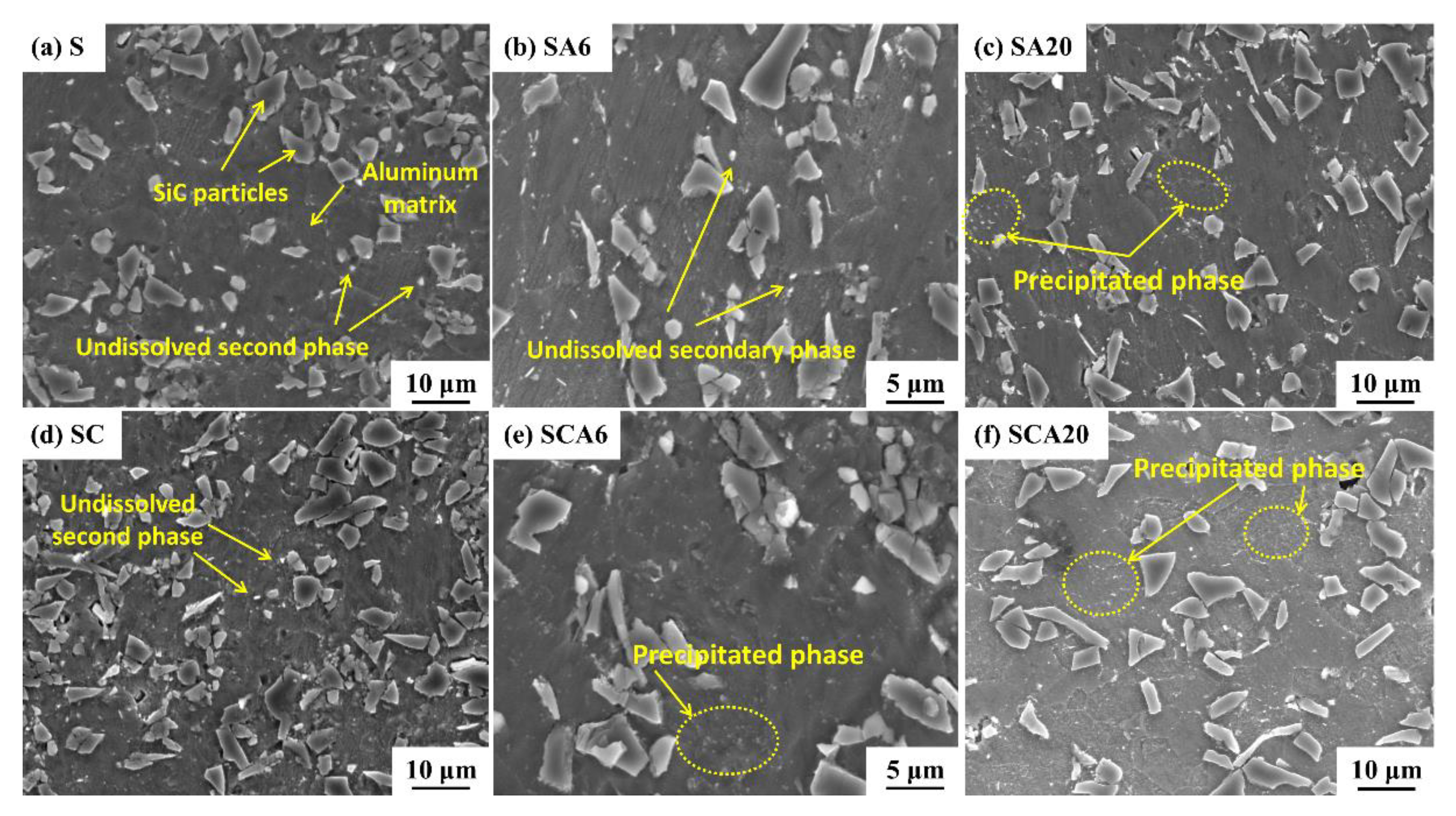

3.2. Microstructure Evolution by SEM

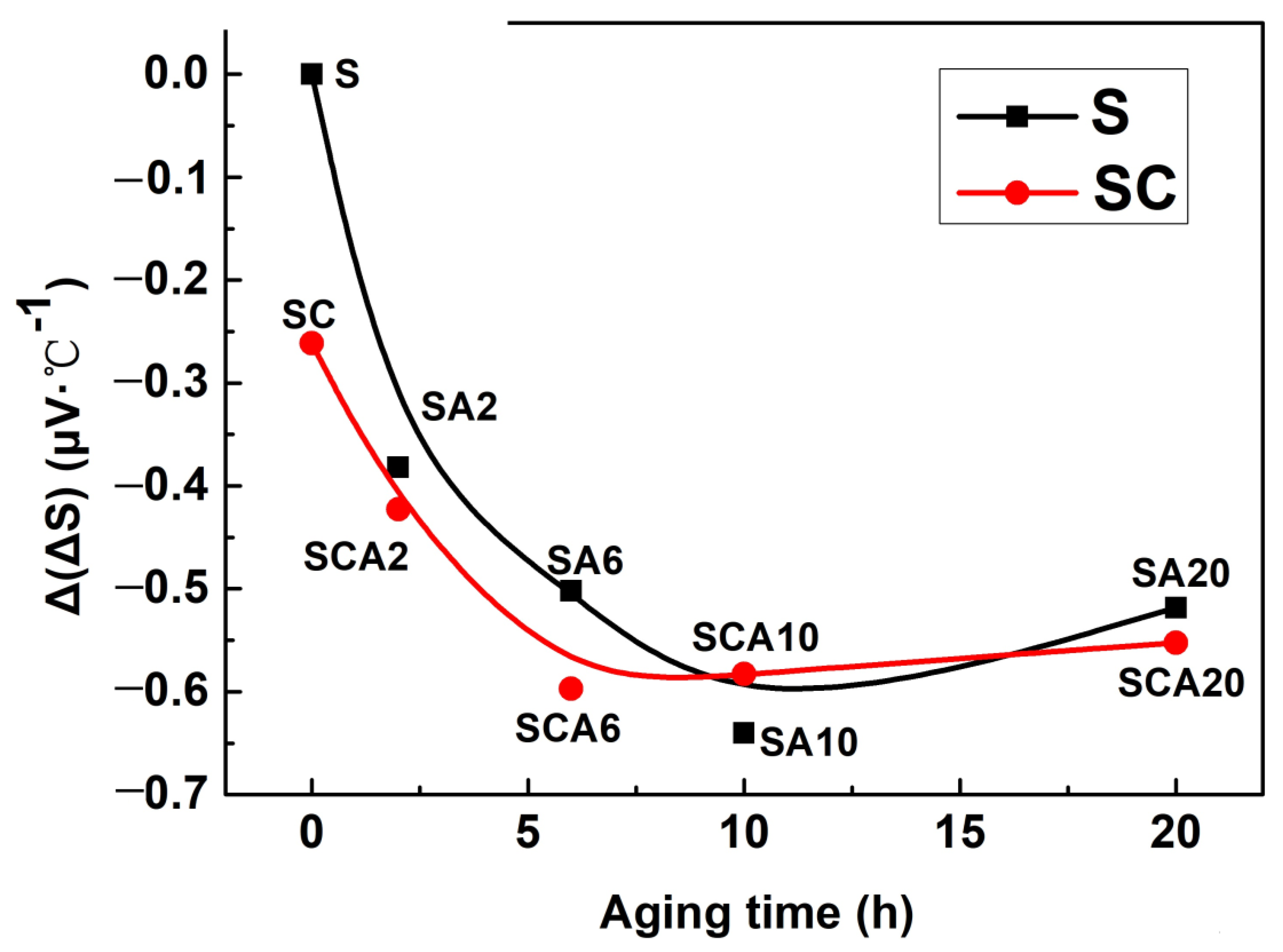

3.3. ThermoElectric Power Measurement

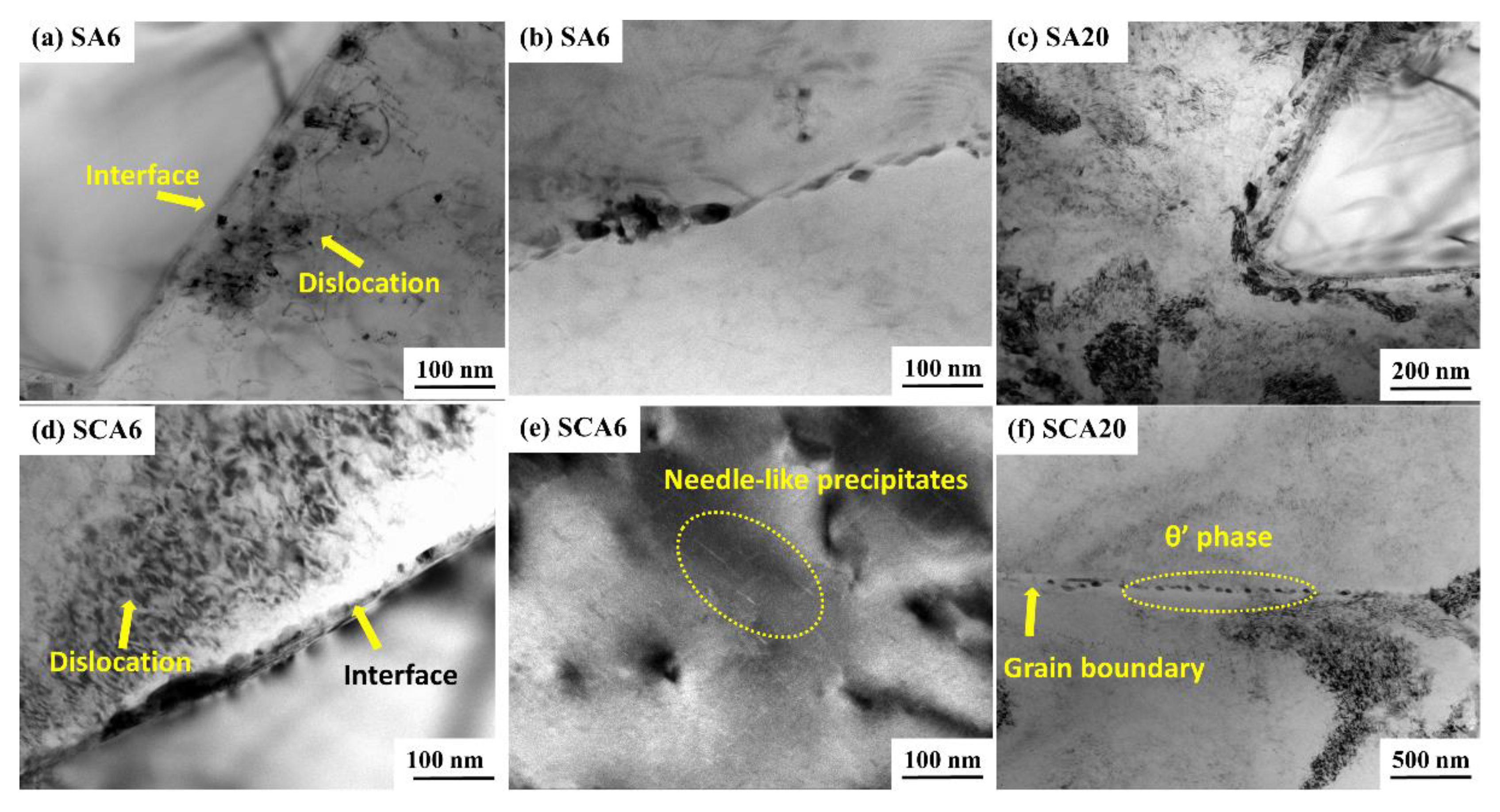

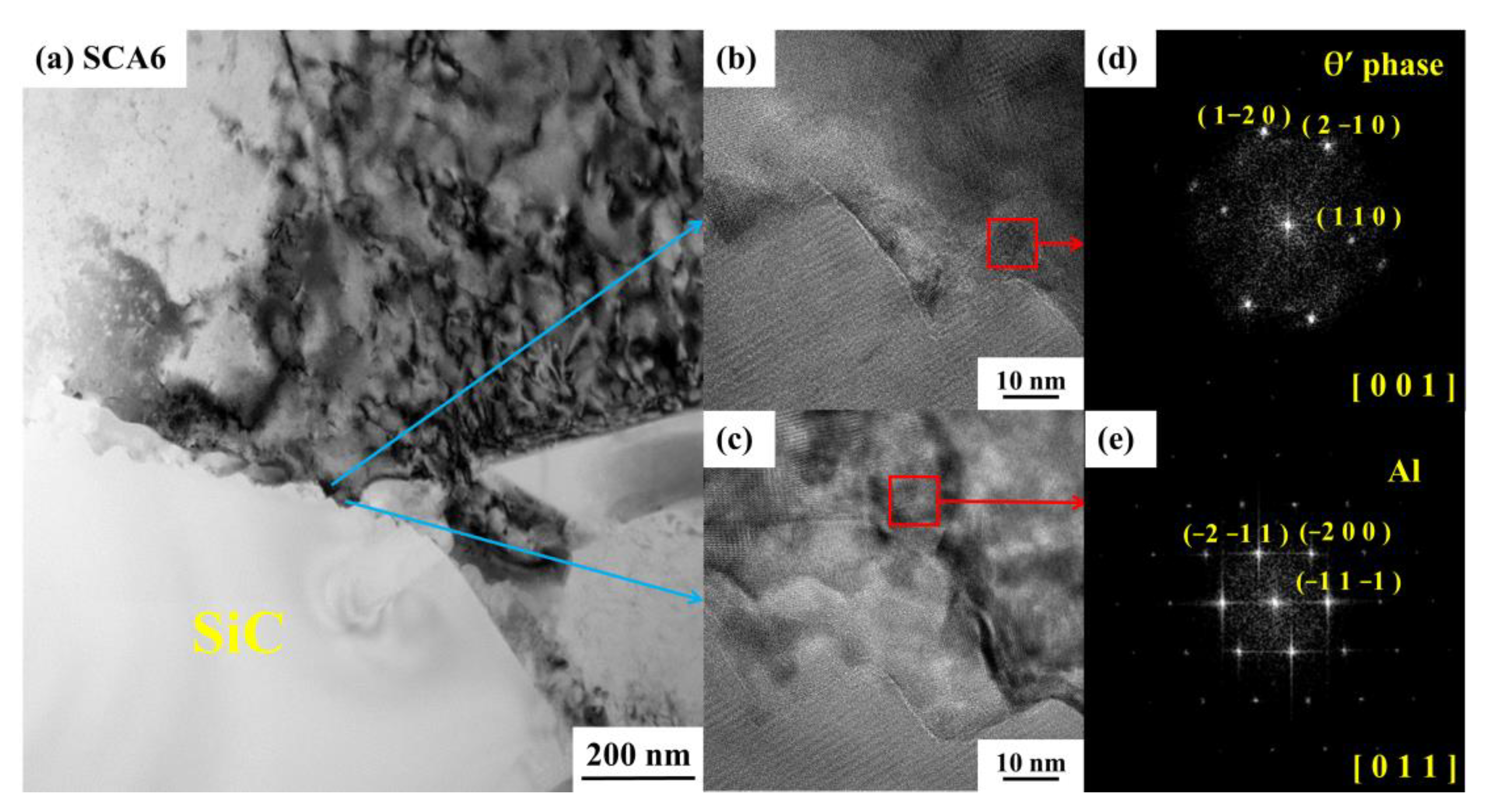

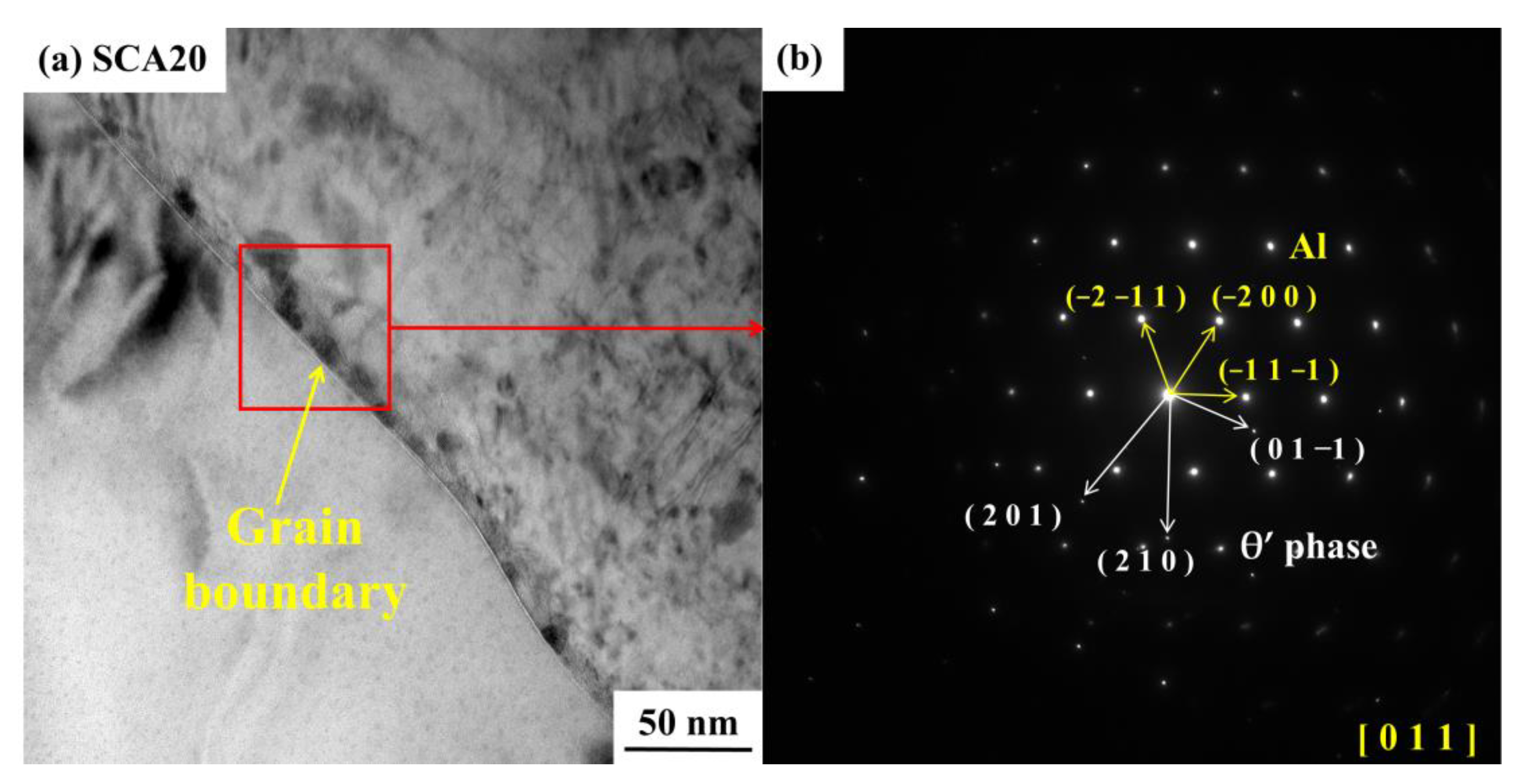

3.4. Microstructure Detection by TEM

4. Discussion

5. Conclusions

- (1)

- TEP measurement can be an effective method for evaluating the precipitation characteristics of 15%SiCp/2009 aluminum matrix composites during aging. Cryogenic treatment after solution promotes the precipitation from the start-stage of aging, which can advance the precipitation time of a stable, non-coherent phase. Cryogenic treatment increases dislocation density, which provides a greater driving force for precipitation during the aging process. It can also promote the precipitation of θ′ phases after aging for 6 h. As a result, the content of the equilibrium precipitates formed after aging at the same time is higher than that of samples without cryogenic treatment.

- (2)

- After cryogenic treatment, the hardness of 15%SiCp/2009 aluminum matrix composites is improved. The change in hardness induced by cryogenic treatment becomes more significant with the extension of aging time, which is improved by 4% after artificial aging treatment for 20 h.

- (3)

- The cryogenic treatment combined with traditional heat treatment has little effect on the tensile strength and elongation of 15%SiCp/2009 aluminum matrix composites. Cryogenic treatment after solution and aging treatment (SAC) also has little effect on yield strength, while the conduction of cryogenic treatment after solution and prior to aging treatment (SCA) can increase the yield strength by 16 MPa.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rathod, N.; Menghani, J. A Consequence of Reinforcements In Aluminum-based Metal Matrix Composites: A Literature Review. Metall. Mater. Eng. 2019, 25, 195–208. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lakshmikanthan, A.; Angadi, S.; Malik, V.; Saxena, K.; Prakash, C.; Dixit, S.; Mohammed, K.A. Mechanical and Tribological Properties of Aluminum-Based Metal-Matrix Composites. Materials 2022, 15, 6111. [Google Scholar] [CrossRef] [PubMed]

- Wu, R.R.; Yuan, Z.; Li, Q.S. Microstructure and mechanical properties of 7075 Al alloy based composites with Al2O3 nanoparticles. Int. J. Cast Met. Res. 2017, 30, 337–340. [Google Scholar]

- Wu, W.G.; Zeng, T.C.; Hao, W.F.; Jiang, S.P. Microstructure and Mechanical Properties of Aluminum Matrix Composites Reinforced With In-Situ TiB2 Particles. Front. Mater. 2022, 9, 1–9. [Google Scholar] [CrossRef]

- Galyshev, S.; Bulat, A. The Dependence of the Strength of a Carbon Fiber/Aluminum Matrix Composite on the Interface Shear Strength between the Matrix and Fiber. Materials 2022, 12, 1753–1771. [Google Scholar] [CrossRef]

- Bhat, R.; Hegde, A.; Sharma, S.; Shankar, G.; Murthy, G. Hybrid Heat Treatment for Conventionally Treatable Steel Powder Reinforced Age Hardenable Aluminium Alloy Matrix Composites and Mechanical Property Evaluation. Mater. Res. 2021, 25, e20210429. [Google Scholar] [CrossRef]

- Sagar, S.R.; Srikanth, K.M.; Jayasimha, R. Effect of cryogenic treatment and heat treatment on mechanical and tribological properties of A356 reinforced with SiC. Mater. Today Proc. 2021, 45, 184–190. [Google Scholar] [CrossRef]

- Xiao, B.L.; Zhang, W.Y.; Zuo, T.; Fan, J.Z.; Shi, L.K. Effect of Heat Treatment on Mechanical Properties and Fracture Behavior of 15% SiCp/2009Al Composite. Aerosp. Mater. Technol. 2005, 3, 34–37. [Google Scholar]

- Wang, Z.X.; Chen, J.; Liu, B.S.; Pan, R.; Guo, Y.; Li, Y. Effect of Deep Cryogenic Treatment on the Artificial Ageing Behavior of SiCp-AA2009 Composite. Materials 2022, 12, 1767–1781. [Google Scholar] [CrossRef]

- Pal, S.; Mitra, R.; Bhanuprasad, V.V. Aging behaviour of Al-Cu-Mg alloy-SiC composites. Mater. Sci. Eng. A 2008, 480, 496–505. [Google Scholar] [CrossRef]

- Jin, P.; Xiao, Q.Z.; Wang, Q.Z.; Ma, Z.Y.; Liu, Y.; Li, S. Effect of solution temperature on aging behavior and properties of SiCp/Al-Cu-Mg composites. Mater. Sci. Eng. A 2011, 528, 1504–1511. [Google Scholar] [CrossRef]

- Araghchi, M.; Mansouri, H.; Vafaei, R.; Guo, Y. Optimization of the Mechanical Properties and Residual Stresses in 2024 Aluminum Alloy Through Heat Treatment. J. Mater. Eng. Perform. 2018, 27, 3234–3238. [Google Scholar] [CrossRef]

- Steier, V.F.; Ashiuchi, E.S.; Reißig, L.; Araújo, J.A. Effect of a Deep Cryogenic Treatment on Wear and Microstructure of a 6101 Aluminum Alloy. Adv. Mater. Sci. Eng. 2016, 2016, 1582490. [Google Scholar]

- Koklu, U. The drilling machinability of 5083 aluminum under shallow and deep cryogenic treatment. Emerg. Mater. Res. 2020, 9, 323–330. [Google Scholar] [CrossRef]

- Gao, W.L.; Wang, X.J.; Chen, J.Z.; Ban, C.Y.; Cui, J.Z.; Liu, Z. Influence of Deep Cryogenic Treatment on Microstructure and Properties of 7A99 Ultra-High Strength Aluminum Alloy. Metals 2019, 9, 631. [Google Scholar] [CrossRef] [Green Version]

- Park, K.; Ko, D.H.; Kim, B.M.; Lim, H.J.; Lee, J.M.; Cho, Y.R. Effects of Cryogenic Treatment on Residual Stress and Tensile Properties for 6061 Al Alloy. Korean J. Met. Mater. 2011, 49, 9–16. [Google Scholar] [CrossRef] [Green Version]

- Araghchi, M.; Mansouri, H.; Vafaei, R.; Guo, Y. A novel cryogenic treatment for reduction of residual stresses in 2024 aluminum alloy. Mater. Sci. Eng. A 2017, 689, 48–52. [Google Scholar] [CrossRef]

- Jovičević-Klug, M.; Rezar, R.; Jovičević-Klug, P.; Podgornik, B. Influence of deep cryogenic treatment on natural and artificial aging of Al-Mg-Si alloy EN AW 6026. J. Alloys Compd. 2022, 899, 163323. [Google Scholar] [CrossRef]

- Zhou, C.; Sun, Q.; Qian, D.; Liu, J.; Sun, J.; Sun, Z. Effect of deep cryogenic treatment on mechanical properties and residual stress of AlSi10Mg alloy fabricated by laser powder bed fusion. J. Mater. Process. Technol. 2022, 303, 117543. [Google Scholar] [CrossRef]

- Li, G.R.; Cheng, J.F.; Wang, H.M.; Li, C.Q. The influence of cryogenic-aging circular treatment on the microstructure and properties of aluminum matrix composites. J. Alloys Compd. 2017, 695, 1930–1945. [Google Scholar] [CrossRef]

- Hong, T.R.; Shen, Y.W.; Geng, J.W.; Chen, D.; Li, X.F.; Zhou, C. Effect of cryogenic pre-treatment on aging behavior of in-situ TiB2/Al–Cu–Mg composites. Mater. Charact. 2016, 119, 40–46. [Google Scholar] [CrossRef]

- Pelletier, J.M.; Borrelly, R. Temperature and concentration dependences of thermoelectric power at high temperatures in some aluminium alloys. Mater. Sci. Eng. 1982, 55, 191–202. [Google Scholar] [CrossRef]

- Bakare, F.; Alsubhi, Y.; Ragkousis, A.; Ebomwony, O.; Damisa, J.; Okunzuwa, S. The effect of pre-straining and pre-ageing on a novel thermomechanical treatment for improving the mechanical properties of AA2139 aerospace aluminium alloys. Mater. Res. Express 2017, 4, 076506. [Google Scholar] [CrossRef]

- Abdala, M.R.W.S.; Garcia de Blas, J.C.; Barbosa, C.; Acselrad, O. Thermoelectrical power analysis of precipitation in 6013 aluminum alloy. Mater. Charact. 2008, 9, 271–277. [Google Scholar] [CrossRef]

- Massardier, V.; Epicier, T.; Merle, P. Correlation between the microstructural evolution of a 6061 aluminium alloy and the evolution of its thermoelectric power. Acta Mater. 2000, 48, 2911–2924. [Google Scholar] [CrossRef]

- LSenthilkumar, D. Encyclopedia of Iron, Steel, and Their Alloys; CRC Press-Taylor and Francis Group: New York, NY, USA, 2016; pp. 995–1007. [Google Scholar]

- Jovičević-Klug, P.; Tóth, L.; Podgornik, B. Comparison of K340 Steel Microstructure and Mechanical Properties Using Shallow and Deep Cryogenic Treatment. Coatings 2022, 12, 1296. [Google Scholar] [CrossRef]

- Chen, D.; Dong, J.F.; Ma, G.Z.; Ma, G.Z.; Wu, Z.; Zhang, X.L. The Research about Cryogenic Treatment Process of Nonferrous Alloys—A Review. Mater. Rep. 2010, 24, 1–4. [Google Scholar]

- Cai, H.K.; Weng, Z.J.; Gu, K.X.; Wang, K.K.; Zheng, J.P.; Wang, J.J. Advances in Deep Cryogenic Treatment of Cemented Carbide. Mater. Rep. 2019, 33, 175–182. [Google Scholar]

- Mochalova, M.V.; Avtokratova, E.V.; Kazakulov, I.Y.; Krymsky, S.V.; Mochalova, M.Y.; Murashkin, M.Y.; Sitdikov, O.S. Microstructure and Properties of an Aluminum D16 Alloy Subjected to Cryogenic Rolling. Russ. Metall. (Met.) 2011, 4, 364–369. [Google Scholar]

- Liu, C.H.; Ma, Z.Y.; Ma, P.P.; Zhan, L.H.; Huang, M.H. Multiple precipitation reactions and formation of θ’-phase in a pre-deformed Al-Cu alloy. Mater. Sci. Eng. A 2018, 733, 28–38. [Google Scholar] [CrossRef]

- Rodrigo, P.; Poza, P.; Utrilla, V.; Urena, A. Effect of reinforcement geometry on precipitation kinetics of powder metallurgy AA2009/SiC composites. J. Alloys Compd. 2009, 479, 451–456. [Google Scholar] [CrossRef]

- Jovicevic-Klug, M.; Tegg, L.; Jovicevic-Klug, P.; Drazic, G.; Almasy, L.; Lim, B.; Cairney, J.M.; Podgornik, B. Multiscale modification of aluminum alloys with deep cryogenic treatment for advanced properties. J. Mater. Res. Technol. 2022, 21, 3062–3073. [Google Scholar] [CrossRef]

| Cu | Mg | Si | Fe | Zn | O | Impurity | Al |

|---|---|---|---|---|---|---|---|

| 3.44 | 1.38 | 0.29 | 0.06 | 0.05 | 0.15 | 0.15 | Balance |

| Treatment | Sample Index |

|---|---|

| Solution–Aging treatment | SA2, SA6, SA10, SA20 |

| Solution–Cryogenic–Aging treatment | SCA2, SCA6, SCA10, SCA20 |

| Solution–Aging–Cryogenic treatment | SA20C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, M.; Pan, R.; Liu, B.; Gu, K.; Weng, Z.; Cui, C.; Wang, J. The Influence of Cryogenic Treatment on the Microstructure and Mechanical Characteristics of Aluminum Silicon Carbide Matrix Composites. Materials 2023, 16, 396. https://doi.org/10.3390/ma16010396

Zhang M, Pan R, Liu B, Gu K, Weng Z, Cui C, Wang J. The Influence of Cryogenic Treatment on the Microstructure and Mechanical Characteristics of Aluminum Silicon Carbide Matrix Composites. Materials. 2023; 16(1):396. https://doi.org/10.3390/ma16010396

Chicago/Turabian StyleZhang, Mingli, Ran Pan, Baosheng Liu, Kaixuan Gu, Zeju Weng, Chen Cui, and Junjie Wang. 2023. "The Influence of Cryogenic Treatment on the Microstructure and Mechanical Characteristics of Aluminum Silicon Carbide Matrix Composites" Materials 16, no. 1: 396. https://doi.org/10.3390/ma16010396