Calibration of Acousto-Optic Interaction Geometry Based on the Analysis of AOTF Angular Performance

Abstract

:1. Introduction

2. Methods

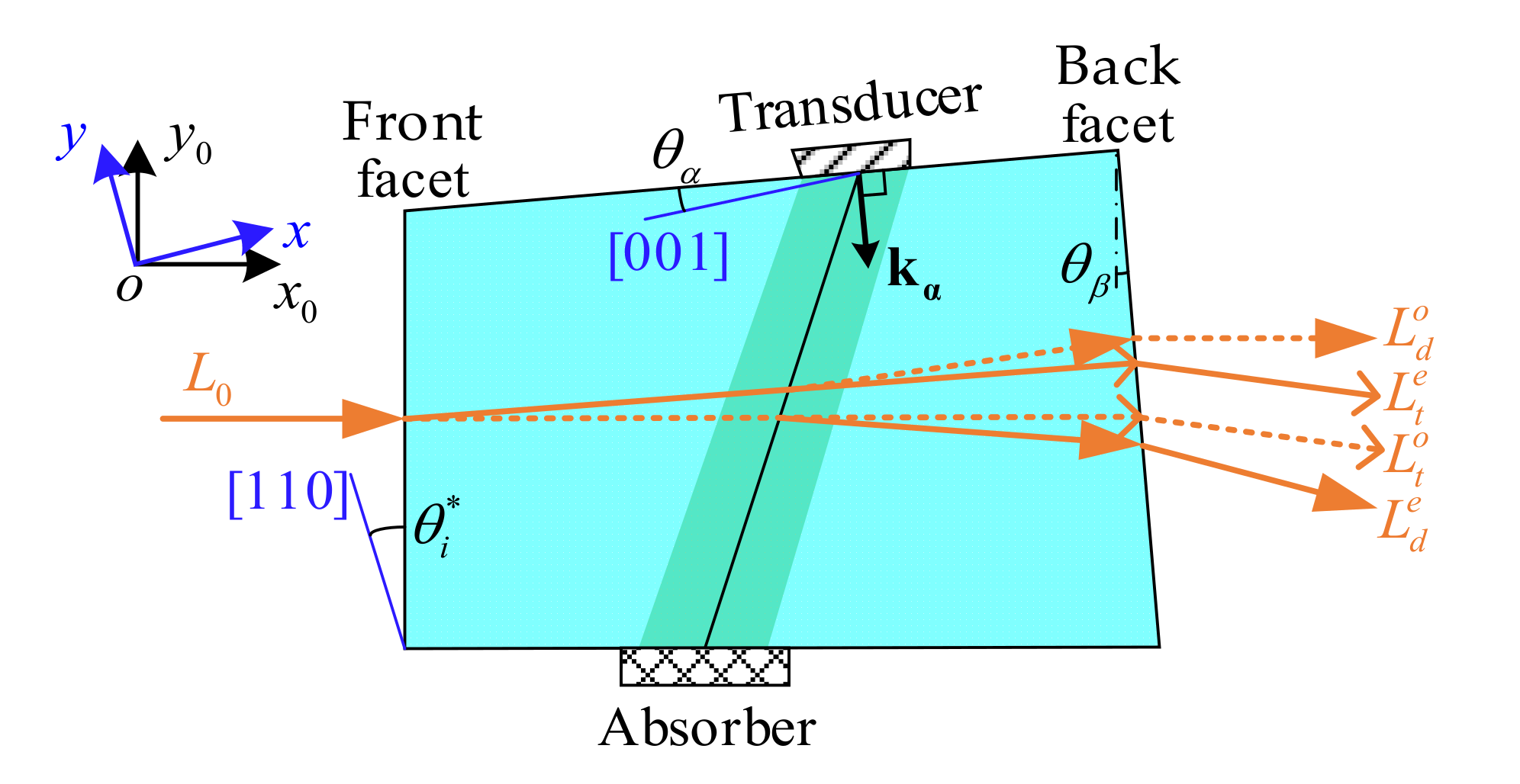

2.1. Refraction at the Plane of Incidence

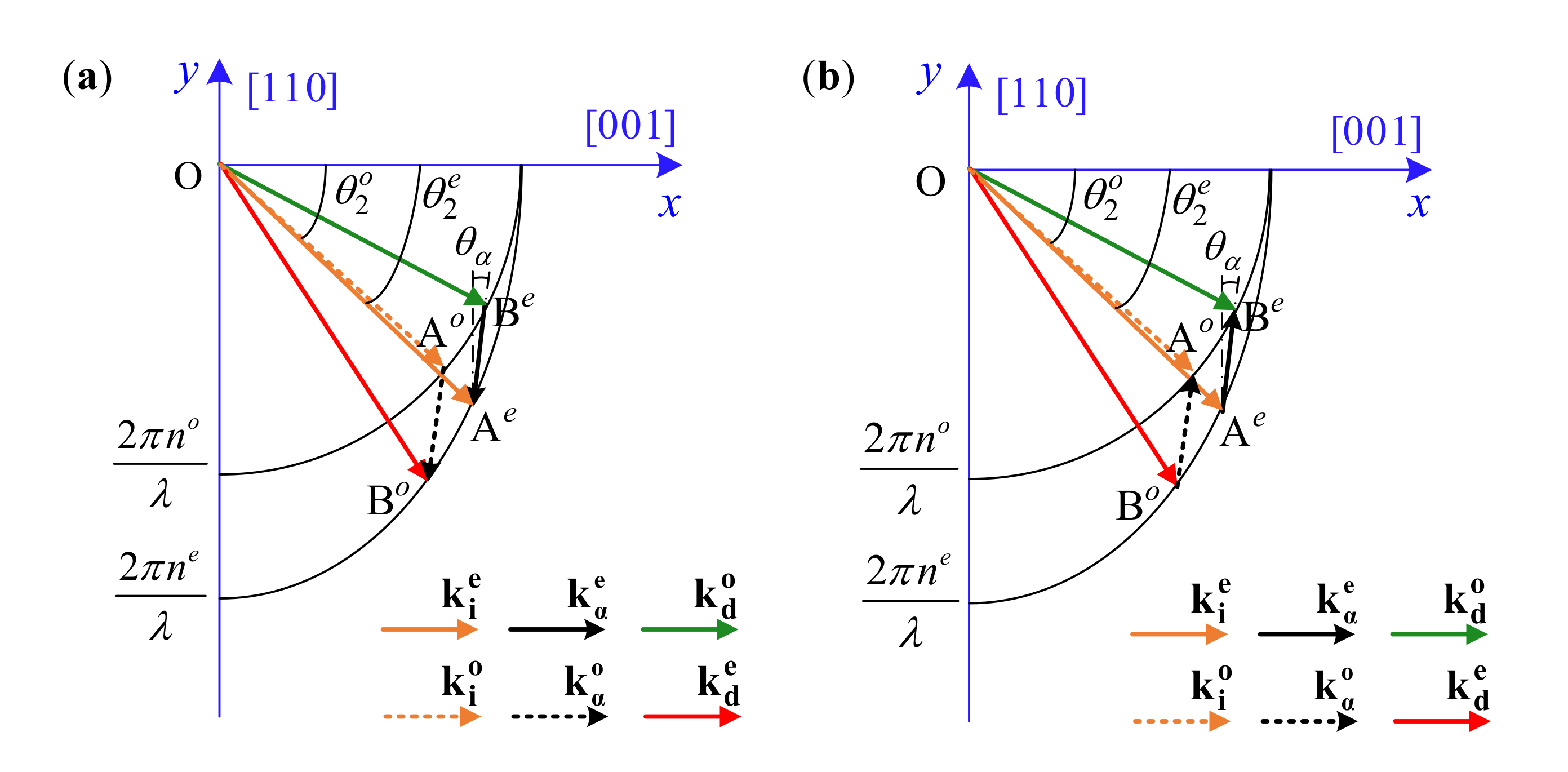

2.2. Wave Vector Analysis of Acousto-Optic Interaction

3. Experiments and Discussions

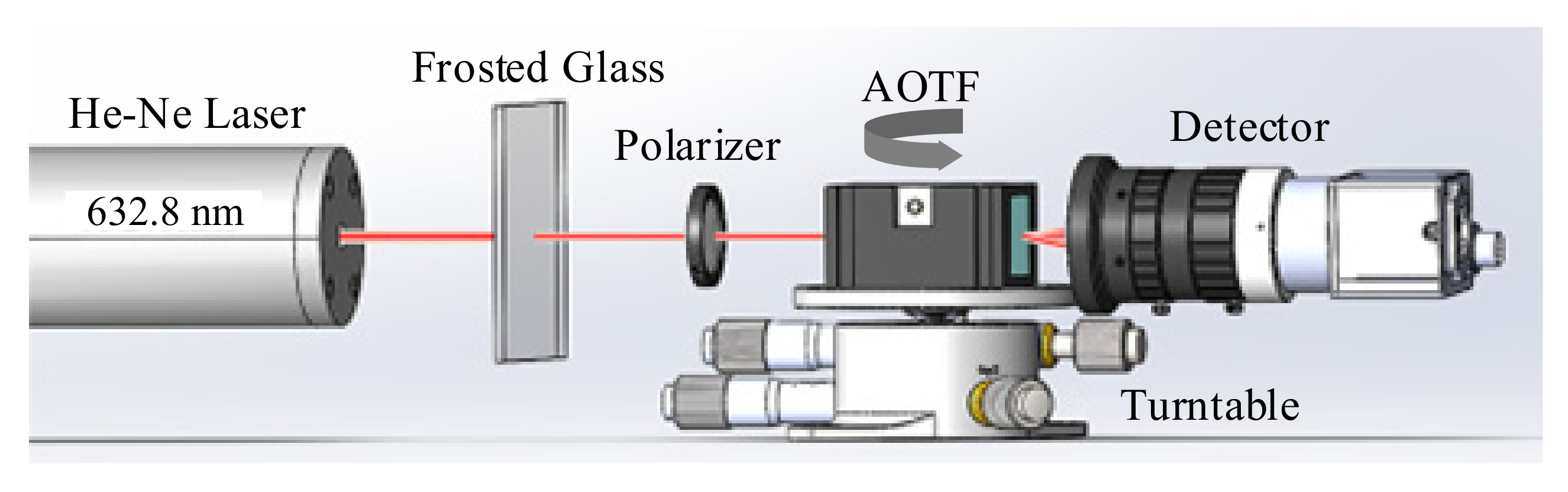

3.1. Experimental Setup

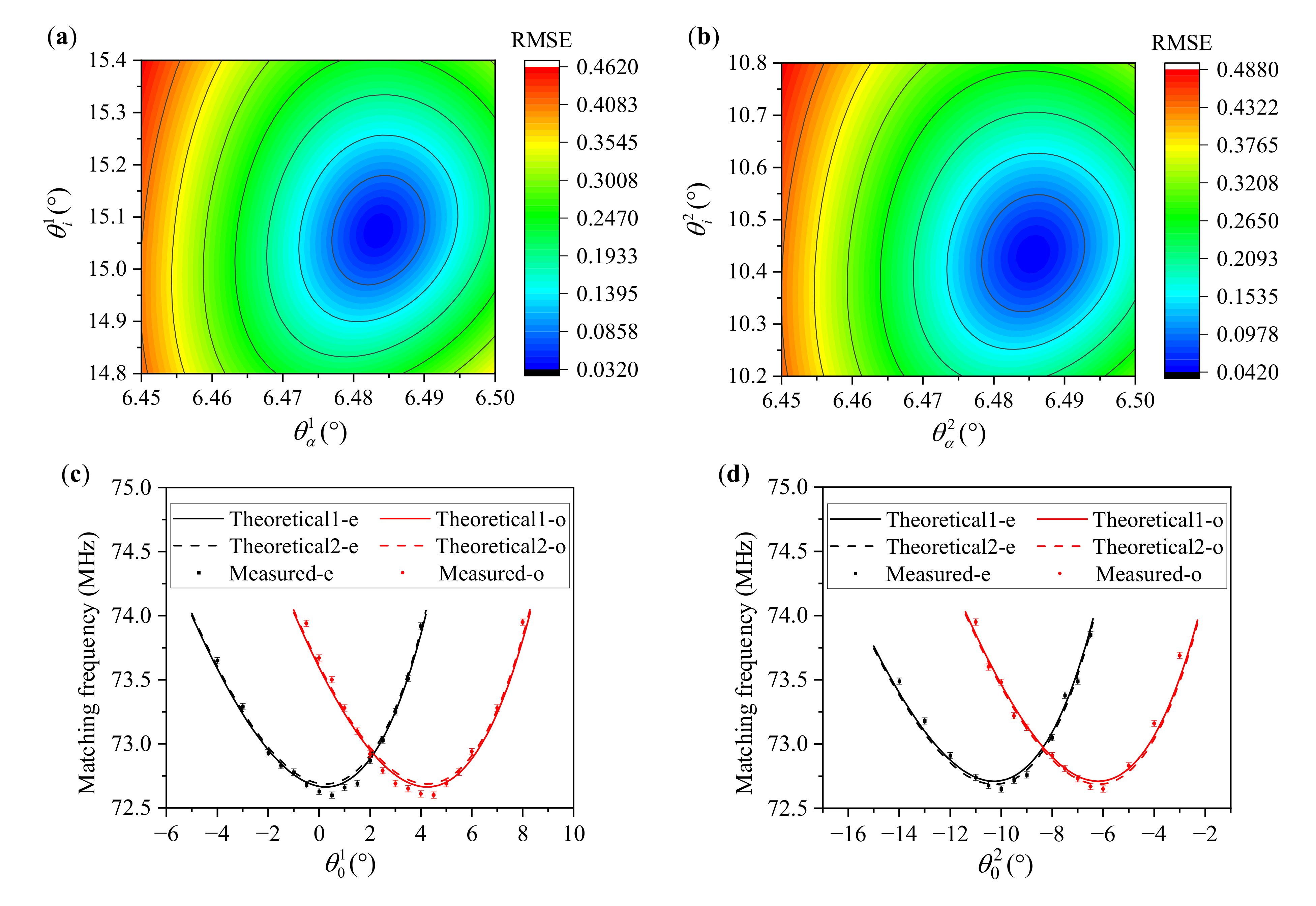

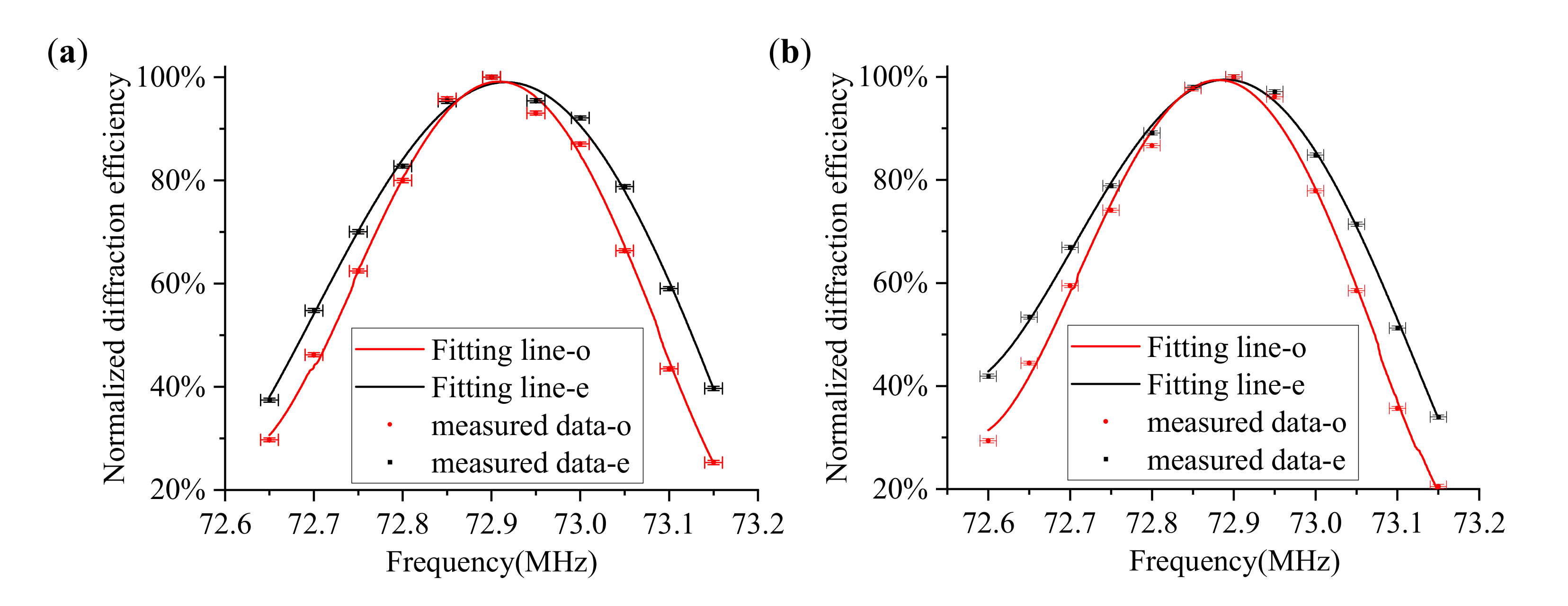

3.2. Results and Discussions

- Step 1: Adjust the polar angle of the AOTF by using the turntable and make sure that the incident plane of the AOTF is perpendicular to the incident light. This step can be judged by whether the reflected laser point coincides with the exit point. We recorded the scale of the turntable at this point as the “0” scale, and the other incident polar angles were able to be adjusted with this scale.

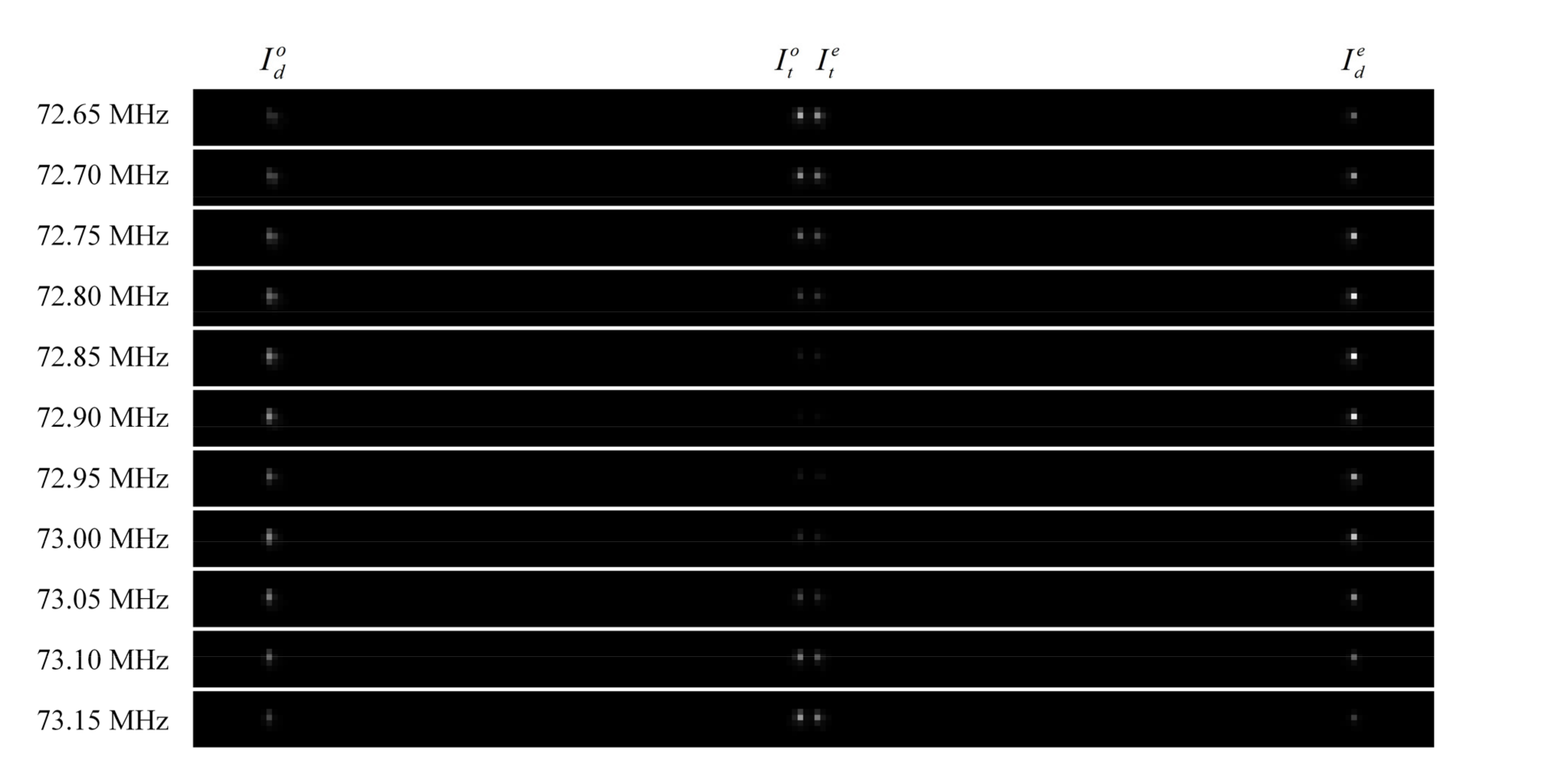

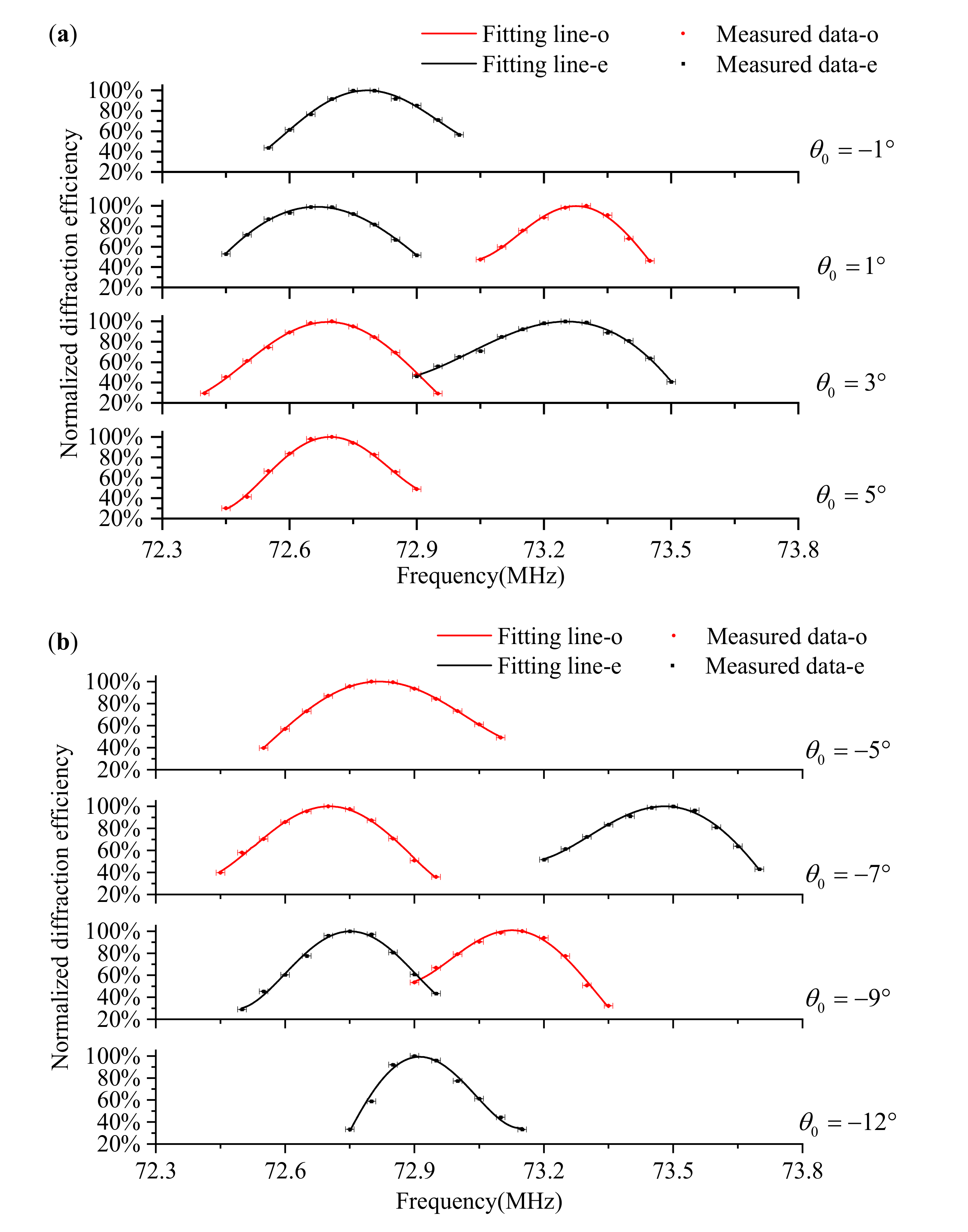

- Step 2: After adjusting the AOTF incident polar angle, the laser, AOTF and detector must be switched on. Then a montage of images, including transmitted and diffracted light, can be taken by scanning the acoustic frequencies, as shown in Figure 6. For each image, both transmitted and diffracted light can be captured, or only o-polarized and e-polarized light can be measured separately by adjusting the polarizer. Given that, in some cases, the AOTFs do not have the wedge angle compensation, the directions of transmitted o-polarized and e-polarized light are coincident. In these experiments, the frequency step was 0.05 MHz.

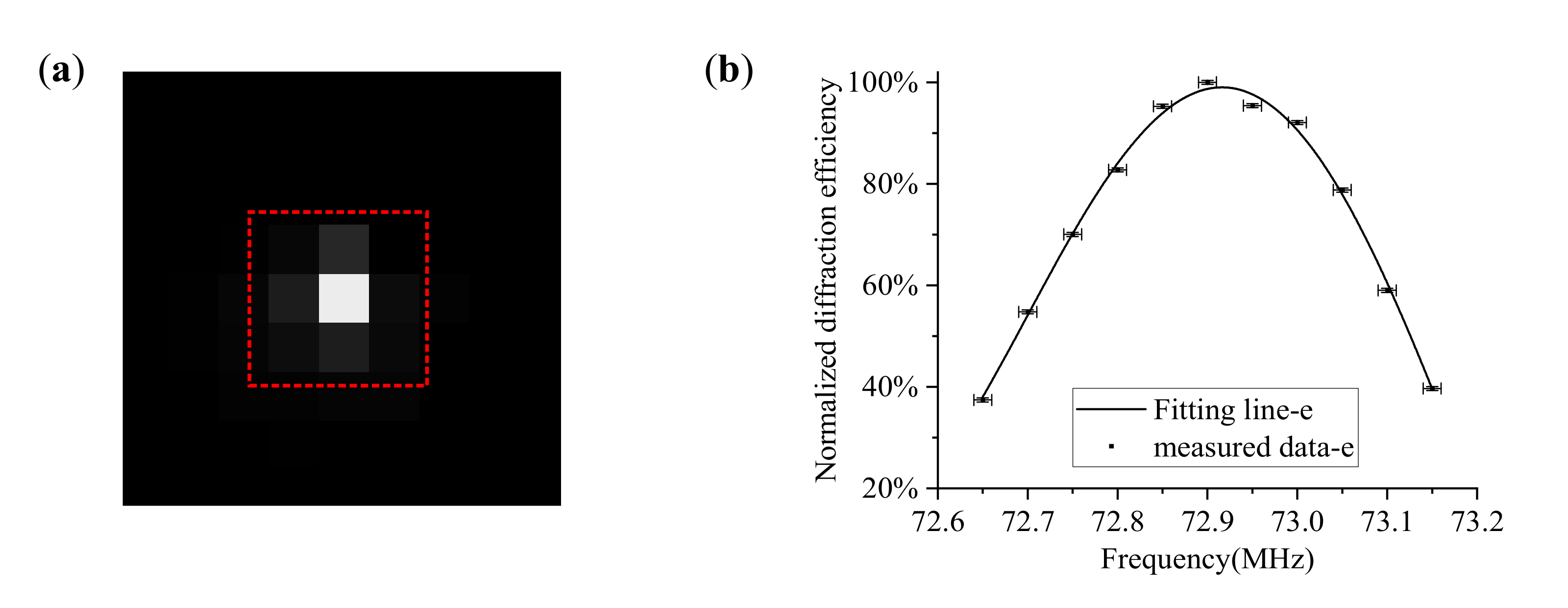

- Step 3: To find the matching frequency corresponding to the peak diffraction intensity, use the relative diffraction efficiency to evaluate as:where and are the light intensity values for the transmitted and diffracted light from the same incident light. The intensity values are quantified by the digital number (DN) values with 8-bit digitization. For each order of emitted light, we used the sum of DN values in the effective area, where nine adjacent pixels were selected for calculation, as shown in Figure 7a.

- Step 4: The matching frequencies were able to be solved by quartic polynomial fitting, as shown in Figure 7b, and at least five frequency points are required for each incident polar angle.

- Step 5: In order to ensure that the temperature of each measurement is close to the room temperature, the AOTF needs to be switched off for a few minutes because the temperature of the AOTF rises during operation, which would affect its polar angular performance.

- Step 6: Adjust another incident polar angle of the AOTF, switch on the AOTF and repeat Steps 2–6 again.

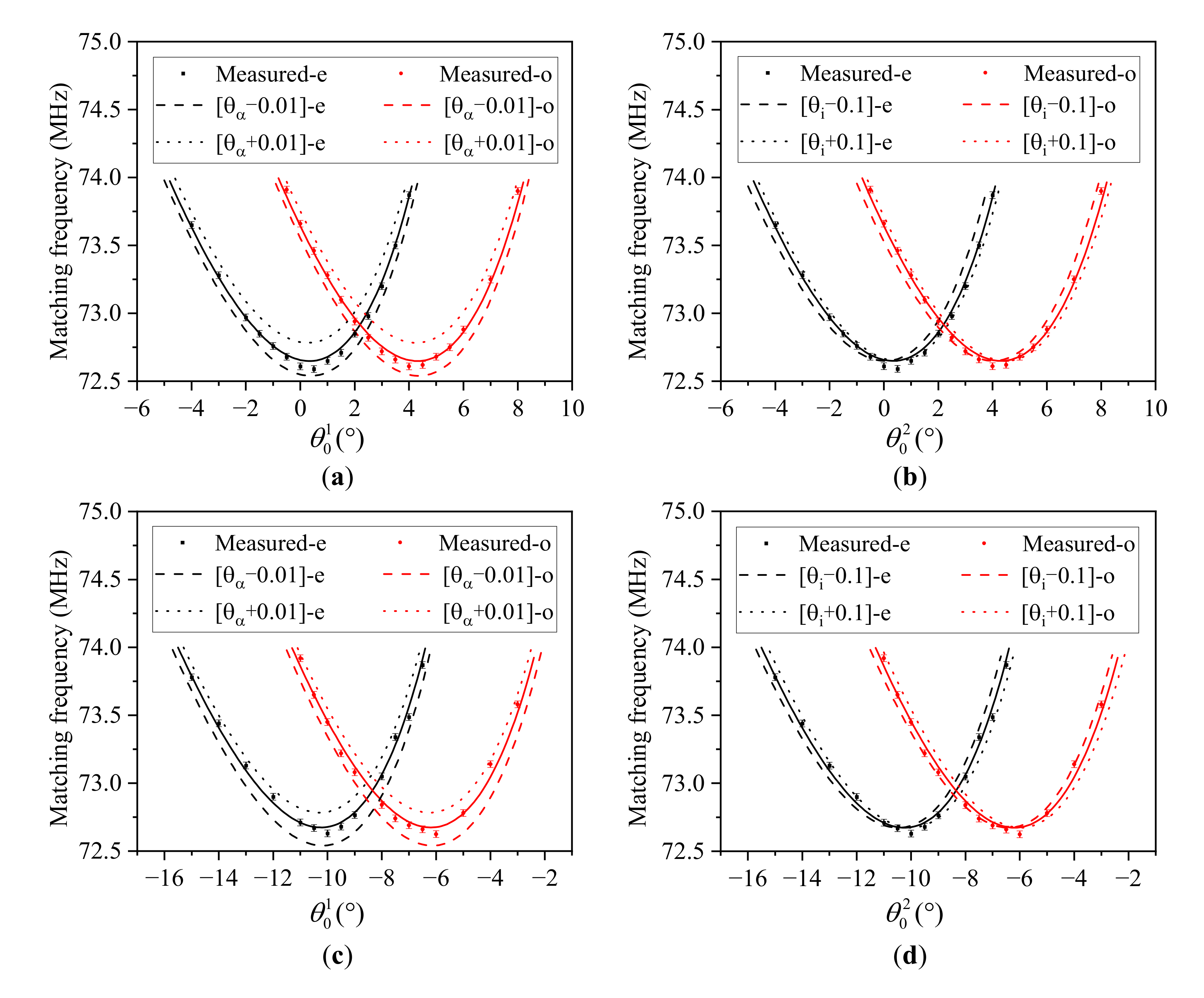

3.3. Tolerance Analysis

4. Conclusions

- (a)

- We established a model of the AOTF angular frequency relationship that can be solved analytically.

- (b)

- We proposed a novel and easy-to-perform method for calibrating the acousto-optic interaction geometry of an actual AOTF device. Furthermore, the experimental results showed a high precision with the acoustic cut angle, within results falling within 0.01°.

- (c)

- We analyzed the polar angular performance with the acousto-optic interaction geometry of the AOTF and the results showed that the acoustic cut angle of the AOTF is more sensitive than the front facet angle. Specifically speaking, changing the acoustic cut angle makes the angular frequency curves shift up and down, and the larger acoustic cut angle corresponds to the state of shifting up. In comparison, changing the front facet angle makes the angular frequency curves shift left and right, and the larger front facet angle corresponds to the state of shifting right.

- (d)

- We calculated and tested the equivalent points for the o-polarized and e-polarized lights in both positive and reserve modes, which is vital to the non-polarization applications of AOTFs.

- (e)

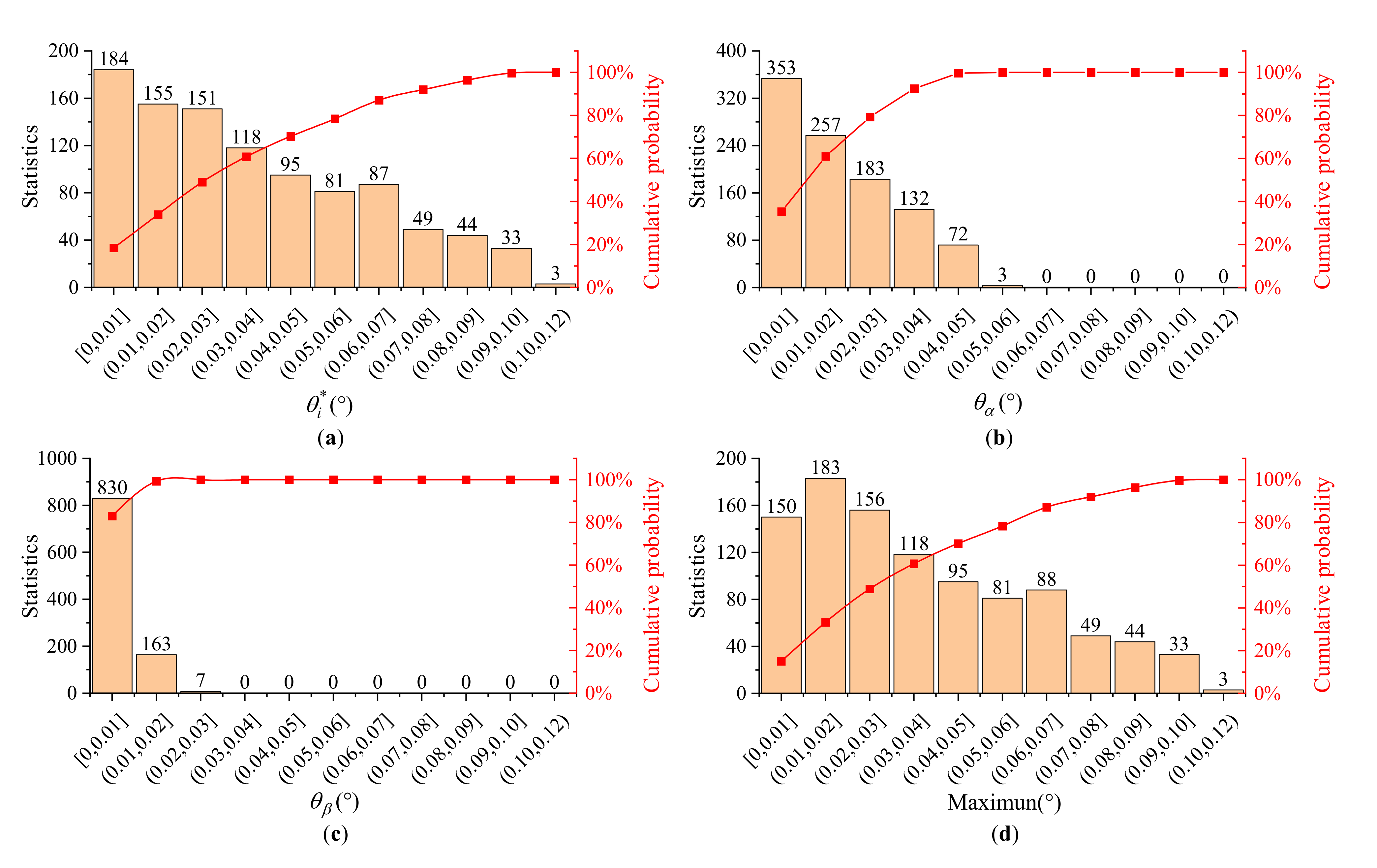

- We analyzed the parameter sensitivity and Monte Carlo tolerance of the calibration method. The results of the parameter sensitivity analysis showed that the principal refractive index of the crystal has a large influence on the calibration results, while other factors have little influence. The results of the Monte Carlo tolerance analysis showed that the cumulative probability of the results falling within 0.1° with this method is greater than 99.7%. Moreover, the probability of falling within 0.01°, for the front facet angle is greater than 18.4%. In comparison, the acoustic cut angle and the back facet angle are greater than 35.3% and 83.0%, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dixon, R. Acoustic diffraction of light in anisotropic media. IEEE J. Quantum Electron. 1967, 3, 85–93. [Google Scholar] [CrossRef]

- Chang, I.C. Tunable Acousto-Optic Filters: An Overview. Opt. Eng. 1977, 16, 455–460. [Google Scholar] [CrossRef]

- Tran, C.D. Principles and analytical applications of acousto-optic tunable filters, an overview. Talanta 1997, 45, 237–248. [Google Scholar] [CrossRef] [PubMed]

- Calpe-Maravilla, J. 400– to 1000–nm imaging spectrometer based on acousto-optic tunable filters. J. Electron. Imaging 2006, 15, 023001. [Google Scholar] [CrossRef]

- Li, J.; Gui, Y.; Xu, R.; Zhang, Z.; Liu, W.; Lv, G.; Wang, M.; Li, C.; He, Z. Applications of AOTF Spectrometers in In Situ Lunar Measurements. Materials 2021, 14, 3454. [Google Scholar] [CrossRef]

- Gupta, N.; Suhre, D.R. Acousto-optic tunable filter imaging spectrometer with full Stokes polarimetric capability. Appl. Opt. 2007, 46, 2632–2637. [Google Scholar] [CrossRef]

- Anchutkin, V.S.; Bel’skii, A.B.; Voloshinov, V.B.; Yushkov, K.B. Acoustooptical method of spectral-polarization image analysis. J. Opt. Technol. 2009, 76, 473–477. [Google Scholar] [CrossRef]

- Machikhin, A.; Batshev, V.; Pozhar, V.; Naumov, A. Single-volume dual-channel acousto-optical tunable filter. Opt. Express 2020, 28, 1150–1157. [Google Scholar] [CrossRef]

- Gupta, N.; Suhre, D.R. Notch filtering using a multiple passband AOTF in the SWIR region. Appl. Opt. 2016, 55, 7855–7860. [Google Scholar] [CrossRef] [PubMed]

- Yushkov, K.B.; Molchanov, V.Y.; Belousov, P.V.; Abrosimov, A.Y. Contrast enhancement in microscopy of human thyroid tumors by means of acousto-optic adaptive spatial filtering. J. Biomed. Opt. 2016, 21, 16003. [Google Scholar] [CrossRef] [PubMed]

- Chu, Y.; Chen, L.; Wang, H.; ZHang, C.; Liu, W.; Wang, P.; Fan, S.; Yan, B.; Li, Z. Research on edge enhancement of optical image based on acousto-optic filtering. In Proceedings of the Twelfth International Conference on Information Optics and Photonics, Xi’an, China, 23–26 July 2021; pp. 1084–1088. [Google Scholar]

- Harris, S.E.; Wallace, R.W. Acousto-Optic Tunable Filter*. J. Opt. Soc. Am. 1969, 59, 744–747. [Google Scholar] [CrossRef]

- Chang, I.C. Noncollinear acousto-optic filter with large angular aperture. Appl. Phys. Lett. 1974, 25, 370–372. [Google Scholar] [CrossRef]

- Gupta, N. Materials for imaging acousto-optic tunable filters. In Proceedings of the Image Sensing Technologies: Materials, Devices, Systems, and Applications, Baltimore, MD, USA, 7–8 May 2014; pp. 41–50. [Google Scholar]

- Gupta, N.; Voloshinov, V. Hyperspectral imaging performance of a TeO2 acousto-optic tunable filter in the ultraviolet region. Opt. Lett. 2005, 30, 985–987. [Google Scholar] [CrossRef]

- Voloshinov, V.B. Anisotropic light diffraction on ultrasound in a tellurium dioxide single crystal. Ultrasonics 1993, 31, 333–338. [Google Scholar] [CrossRef]

- Voloshinov, V.B.; Yushkov, K.B.; Linde, B.B.J. Improvement in performance of a TeO2 acousto-optic imaging spectrometer. J. Opt. A-Pure Appl. Opt. 2007, 9, 341–347. [Google Scholar] [CrossRef]

- Yano, T.; Watanabe, A. Acoustooptic TeO2 tunable filter using far-off-axis anisotropic Bragg diffraction. Appl. Opt. 1976, 15, 2250–2258. [Google Scholar] [CrossRef]

- Gass, P.A.; Sambles, J.R. Accurate design of a noncollinear acousto-optic tunable filter. Opt. Lett. 1991, 16, 429–431. [Google Scholar] [CrossRef] [PubMed]

- Yushkov, K.B.; Kupreychik, M.I.; Obydennov, D.V.; Molchanov, V.Y. Acousto-optic k-space filtering for multifrequency laser beam shaping. J. Opt. 2023, 25, 014002. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, H.; Zhang, Z.; Yuan, J.; Shi, L.; Sheng, Z.; Zhang, X. Non-radio-frequency signal tuned acousto-optic tunable filter. Opt. Express 2018, 26, 1049–1054. [Google Scholar] [CrossRef]

- Knuteson, D.; Singh, N.; Gupta, N.; Gottlieb, M.; Suhre, D.; Berghmans, A.; Thomson, D.; Kahler, D.; Wagner, B.; Hawkins, J. Design and fabrication of mercurous bromide acousto-optic filters. In Proceedings of the Infrared and Photoelectronic Imagers and Detector Devices, San Diego, CA, USA, 31 July–1 August 2005; pp. 98–105. [Google Scholar]

- Li, C.; Zhao, H.; Zhang, Y.; Zhou, P. Crystal geometry measurement of an acousto-optic tunable filter using the tested tuning curves. In Proceedings of the 2012 8th IEEE International Symposium on Instrumentation and Control Technology (ISICT), London, UK, 11–13 July 2012; pp. 267–272. [Google Scholar]

- Georgiev, G.; Georgieva, E.; Konstantinov, L. Angular and power characteristics of noncollinear acousto-optic tunable filters. Opt. Lasers Eng. 1999, 31, 1–12. [Google Scholar] [CrossRef]

- Chang, I.C. Acousto-Optic Tunable Filters. Opt. Eng. 1981, 20, 824–829. [Google Scholar] [CrossRef]

- Goutzoulis, A.P.; Pape, D.R. Design and Fabrication of Acousto-Optic Devices; Marcel Dekker Inc.: New York, NY, USA, 1994. [Google Scholar]

- Uchida, N.; Ohmachi, Y. Elastic and Photoelastic Properties of TeO2 Single Crystal. J. Appl. Phys. 1969, 40, 4692–4695. [Google Scholar] [CrossRef]

- Gorevoy, A.V.; Machikhin, A.S.; Martynov, G.N.; Pozhar, V.E. Spatiospectral transformation of noncollimated light beams diffracted by ultrasound in birefringent crystals. Photonics Res. 2021, 9, 687–693. [Google Scholar] [CrossRef]

- Pozhar, V.; Machihin, A. Image aberrations caused by light diffraction via ultrasonic waves in uniaxial crystals. Appl. Opt. 2012, 51, 4513–4519. [Google Scholar] [CrossRef]

- Voloshinov, V.B.; Molchanov, V.Y.; Mosquera, J.C. Spectral and polarization analysis of optical images by means of acousto-optics. Opt. Laser Technol. 1996, 28, 119–127. [Google Scholar] [CrossRef]

- Xue, B.; Xu, K.; Yamamoto, H. Discussion to the equivalent point realized by the two polarized beams in AOTF system. Opt. Express 1999, 4, 139–146. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.S. Monte Carlo Strategies in Scientific Computing; Springer: Berlin/Heidelberg, Germany, 2001; Volume 75. [Google Scholar]

| Parameters | Values |

|---|---|

| 632.8 nm | |

| 2.2597 at 632.8 nm | |

| 2.4119 at 632.8 nm | |

| 616 m/s | |

| 2104 m/s |

| Parameters | Tolerances | Standard Deviation of Calibration Results | |||

|---|---|---|---|---|---|

| Principle refractive index | ±0.0006 | 0.066° | 0.032° | 0.001° | |

| ±0.0007 | |||||

| Acoustic wave velocity | ±0.5 m/s | 0.002° | 0.001° | 0.001° | |

| Incident polar angle | ±1′ | 0.003° | <0.001° | 0.006° | |

| Matching frequency | ±0.025 MHz | 0.004° | <0.001° | 0.005° | |

| Parameters | ≤0.01° | ≤0.1° |

|---|---|---|

| 18.4% | 99.7% | |

| 35.3% | 100% | |

| 83.0% | 100% | |

| Maximum | 15.0% | 99.7% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Zhao, H.; Guo, Q.; Xuan, Y. Calibration of Acousto-Optic Interaction Geometry Based on the Analysis of AOTF Angular Performance. Materials 2023, 16, 3708. https://doi.org/10.3390/ma16103708

Zhang H, Zhao H, Guo Q, Xuan Y. Calibration of Acousto-Optic Interaction Geometry Based on the Analysis of AOTF Angular Performance. Materials. 2023; 16(10):3708. https://doi.org/10.3390/ma16103708

Chicago/Turabian StyleZhang, Hao, Huijie Zhao, Qi Guo, and Yan Xuan. 2023. "Calibration of Acousto-Optic Interaction Geometry Based on the Analysis of AOTF Angular Performance" Materials 16, no. 10: 3708. https://doi.org/10.3390/ma16103708

APA StyleZhang, H., Zhao, H., Guo, Q., & Xuan, Y. (2023). Calibration of Acousto-Optic Interaction Geometry Based on the Analysis of AOTF Angular Performance. Materials, 16(10), 3708. https://doi.org/10.3390/ma16103708