Preparation and Properties of Low-Carbon Foamed Lightweight Soil with High Resistance to Sulphate Erosion Environments

Abstract

:1. Introduction

2. Materials and Methods

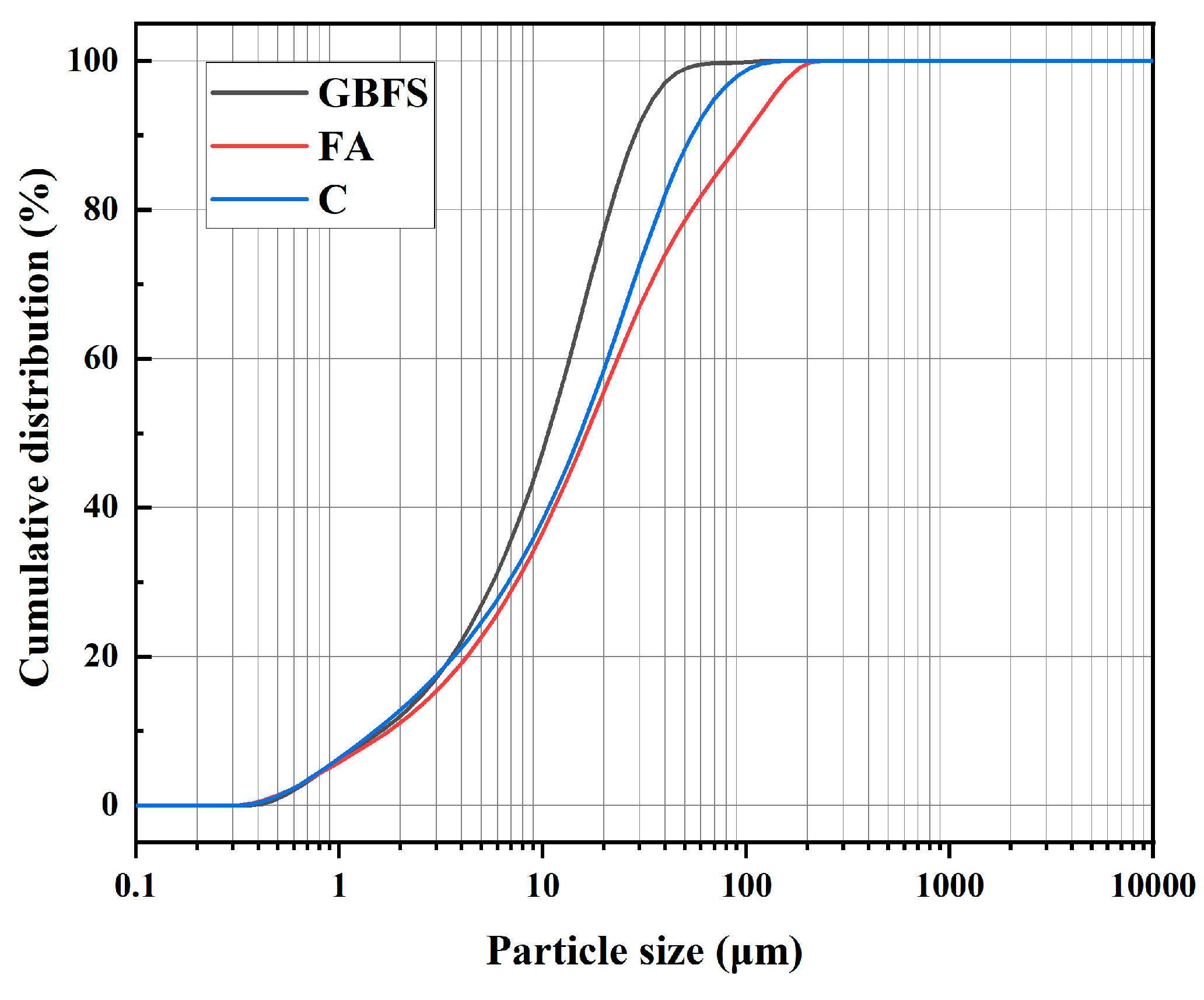

2.1. Materials

2.2. Mix Design

2.3. Specimen Preparation

2.3.1. Fabrication of Corrosion Resistance Specimens for Gelling Material Systems

2.3.2. Fabrication of FLS Cube Specimens

2.4. Test Methods

2.4.1. Corrosion Resistance Coefficients of Cementitious Materials

2.4.2. Flow Factor (Fluidity), Wet Density, Compressive Strength and Resistance to Sulphate Attacks of FLS

3. Results and Discussion

3.1. Resistance of Cementitious Materials to Sulphate Attacks

3.2. Physical Properties of FLS

3.3. Low Carbon Emission of FLS

3.4. Resistance of FLS to Sulphate Attacks

4. Conclusions

- (1)

- FLS prepared using 30% C, 30% GBFS, 40% FA and a small amount of CA as a cementitious material has excellent resistance to sulphate erosion, low carbon emission and a corrosion resistance coefficient reaching 0.97. Compared with FLS prepared using pure cement, it can reduce CO2 by 70% and has obvious low carbon characteristics.

- (2)

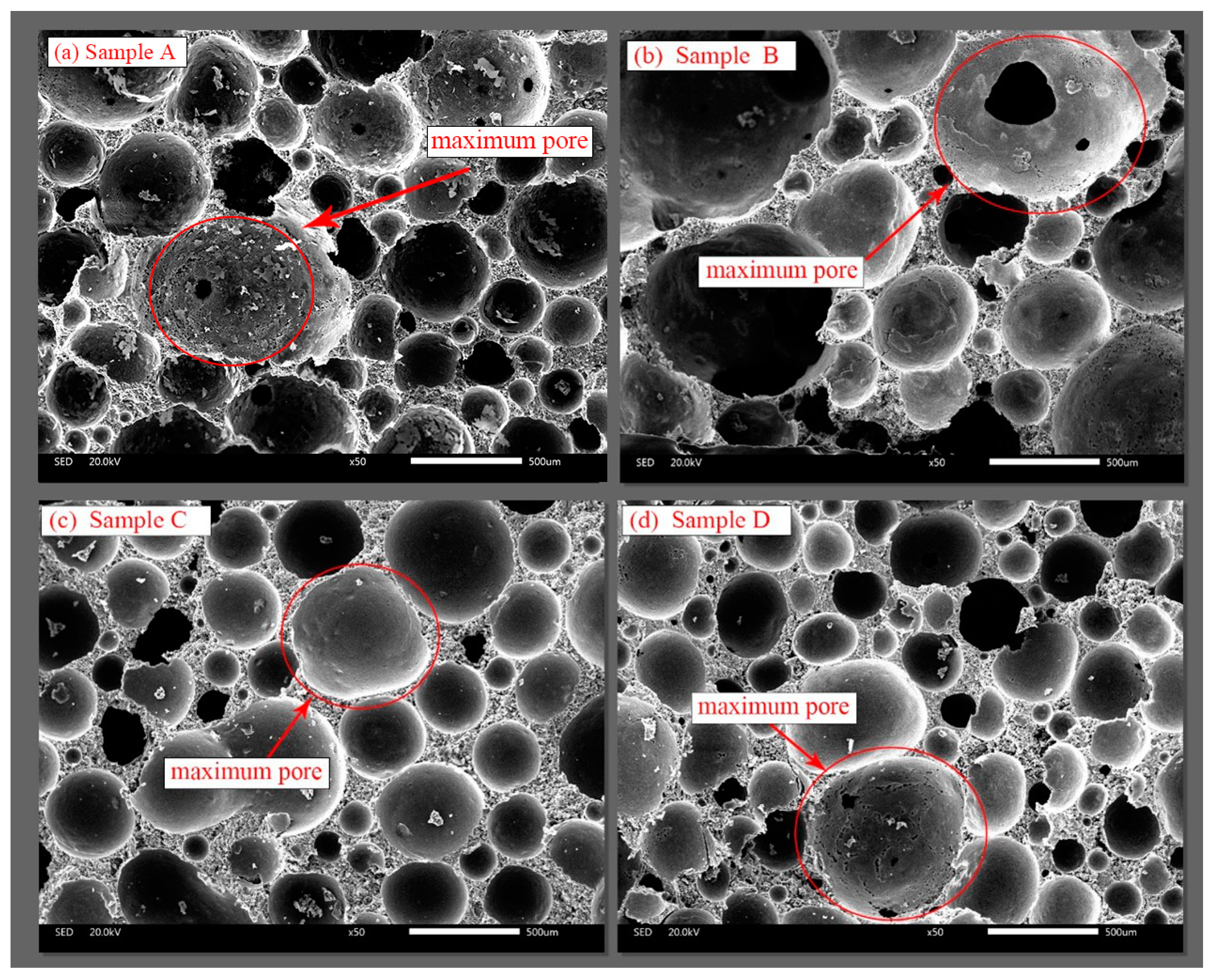

- FLS with a flow factor of about 170 mm and a wet density of about 600 kg/m3 can be prepared using 30% C, 30% GBFS, 40% FA, a water–binder ratio of 0.65 and a foam density of 50 kg/m3. Its compressive strengths at 7 and 28 d reached 0.8 and 1.9 MPa, respectively. After sulphate attacking, its compressive strength decreased the least, which is related to its pore size distribution and its own material composition.

- (3)

- For areas where the groundwater contains high concentrations of sulphate ions, pure C should not be utilised as a cementitious material to prepare FLS. For an erosion medium environment with SO42− concentrations of less than 1000 mg/L (moderate), GBFS or FA can be used to partially replace C. For SO42− concentrations of under 4000 mg/L (severe), only a small quantity of C should be used, and large amounts of GBFS and FA should be added as cementitious materials, preferably in combination with an appropriate amount of CA.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Watabe, Y.; Noguchi, T. Site-Investigation and Geotechnical Design of D-Runway Construction in Tokyo Haneda Airport. Soils Found. 2011, 51, 1003–1018. [Google Scholar] [CrossRef] [Green Version]

- Kim, T.-H.; Kim, T.-H.; Kang, G.-C. Performance Evaluation of Road Embankment Constructed Using Lightweight Soils on an Unimproved Soft Soil Layer. Eng. Geol. 2013, 160, 34–43. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Suddeepong, A.; Chinkulkijniwat, A.; Liu, M.D. Strength and Compressibility of Lightweight Cemented Clays. Appl. Clay Sci. 2012, 69, 11–21. [Google Scholar] [CrossRef] [Green Version]

- Suksiripattanapong, C.; Horpibulsuk, S.; Boongrasan, S.; Udomchai, A.; Chinkulkijniwat, A.; Arulrajah, A. Unit Weight, Strength and Microstructure of a Water Treatment Sludge–Fly Ash Lightweight Cellular Geopolymer. Constr. Build. Mater. 2015, 94, 807–816. [Google Scholar] [CrossRef]

- Shah, S.N.; Mo, K.H.; Yap, S.P.; Yang, J.; Ling, T.-C. Lightweight Foamed Concrete as a Promising Avenue for Incorporating Waste Materials: A Review. Resour. Conserv. Recycl. 2021, 164, 105103. [Google Scholar] [CrossRef]

- Ramamurthy, K.; Nambiar, E.K.; Ranjani, G.I.S. A Classification of Studies on Properties of Foam Concrete. Cem. Concr. Compos. 2009, 31, 388–396. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Farzadnia, N.; Abang Ali, A.A. Properties and Applications of Foamed Concrete; a Review. Constr. Build. Mater. 2015, 101, 990–1005. [Google Scholar] [CrossRef]

- Tian, T.; Yan, Y.; Hu, Z.; Xu, Y.; Chen, Y.; Shi, J. Utilization of Original Phosphogypsum for the Preparation of Foam Concrete. Constr. Build. Mater. 2016, 115, 143–152. [Google Scholar] [CrossRef]

- Ling, X.; Zhang, F.; Zhu, Z.; Ding, L.; Hu, Q. Field Experiment of Subgrade Vibration Induced by Passing Train in a Seasonally Frozen Region of Daqing. Earthq. Eng. Eng. Vib. 2009, 8, 149. [Google Scholar] [CrossRef]

- Yang, K.-H.; Lee, K.-H.; Song, J.-K.; Gong, M.-H. Properties and Sustainability of Alkali-Activated Slag Foamed Concrete. J. Clean. Prod. 2014, 68, 226–233. [Google Scholar] [CrossRef]

- Li, G.; Tan, H.; He, X.; Zhang, J.; Deng, X.; Zheng, Z.; Guo, Y. The Influence of Wet Ground Fly Ash on the Performance of Foamed Concrete. Constr. Build. Mater. 2021, 304, 124676. [Google Scholar] [CrossRef]

- Wu, J.; Lv, C.; Pi, R.; Zhang, H.; Bi, Y.; Song, X.; Wang, Z. The Stability and Durability of Silt-Based Foamed Concrete: A New Type of Road Engineering Material. Constr. Build. Mater. 2021, 304, 124674. [Google Scholar] [CrossRef]

- Huang, J.; Su, Q.; Zhao, W.; Li, T.; Zhang, X. Experimental Study on Use of Lightweight Foam Concrete as Subgrade Bed Filler of Ballastless Track. Constr. Build. Mater. 2017, 149, 911–920. [Google Scholar] [CrossRef]

- Kikuchi, Y.; Nagatome, T.; Mizutani, T.; Yoshino, H. The Effect of Air Foam Inclusion on the Permeability and Absorption Properties of Light Weight Soil. Soils Found. 2011, 51, 151–165. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Liu, G.; Wang, H.; Wan, H.; Xu, X.; Shen, C.; Xuan, J.; He, Q. Preparation and Performance Study of Large Volume Foamed Lightweight Soil for an Intelligent Networked Vehicle Test Site. Materials 2022, 15, 5382. [Google Scholar] [CrossRef]

- Oh, J.S.; Kim, D.-Y.; Kim, T.H.; Kim, H.Y.; Lee, S.H.; Choi, K.Y. Numerical Prediction of the Viscoelastic Deformation of Seat Foam in Response to Long-Term Driving. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2015, 229, 214–225. [Google Scholar] [CrossRef]

- Falliano, D.; De Domenico, D.; Ricciardi, G.; Gugliandolo, E. Experimental Investigation on the Compressive Strength of Foamed Concrete: Effect of Curing Conditions, Cement Type, Foaming Agent and Dry Density. Constr. Build. Mater. 2018, 165, 735–749. [Google Scholar] [CrossRef]

- Watabe, Y.; Noguchi, T.; Mitarai, Y. Use of Cement-Treated Lightweight Soils Made from Dredged Clay. J. ASTM Int. JAI 2012, 9, JAI104219. [Google Scholar] [CrossRef]

- Tarasov, A.; Kearsley, E.P.; Kolomatskiy, A.; Mostert, H. Heat Evolution Due to Cement Hydration in Foamed Concrete. Mag. Concr. Res. 2010, 62, 895–906. [Google Scholar] [CrossRef] [Green Version]

- Jones, M.; McCarthy, A. Behaviour and Assessment of Foamed Concrete for Construction Applications. In Proceedings of the Use of Foamed Concrete in Construction: Proceedings of the International Conference held at the University of Dundee, Scotland, UK, 5 July 2005; Thomas Telford Publishing: London, UK, 2005; pp. 61–88. [Google Scholar]

- Panesar, D.K. Cellular Concrete Properties and the Effect of Synthetic and Protein Foaming Agents. Constr. Build. Mater. 2013, 44, 575–584. [Google Scholar] [CrossRef]

- Kan, A.; Demirboğa, R. A Novel Material for Lightweight Concrete Production. Cem. Concr. Compos. 2009, 31, 489–495. [Google Scholar] [CrossRef]

- Shen, C.; Liu, H.; Wan, H.; Li, J.; Liu, P.; He, Q.; Xuan, J. Effect of Cementitious Material Composition on the Performance of Low-Carbon Foamed Lightweight Soil. Buildings 2023, 13, 759. [Google Scholar] [CrossRef]

- Huang, Y.; Gong, L.; Shi, L.; Cao, W.; Pan, Y.; Cheng, X. Experimental Investigation on the Influencing Factors of Preparing Porous Fly Ash-Based Geopolymer for Insulation Material. Energy Build. 2018, 168, 9–18. [Google Scholar] [CrossRef]

- Tikalsky, P.J.; Pospisil, J.; MacDonald, W. A Method for Assessment of the Freeze–Thaw Resistance of Preformed Foam Cellular Concrete. Cem. Concr. Res. 2004, 34, 889–893. [Google Scholar] [CrossRef]

- Jones, M.R.; McCarthy, A. Heat of Hydration in Foamed Concrete: Effect of Mix Constituents and Plastic Density. Cem. Concr. Res. 2006, 36, 1032–1041. [Google Scholar] [CrossRef]

- Que, Y.; Zhang, H.; Zhu, T.; Kwan Leung, A.; Lu, D.; Jiang, Z. Amending Foamed Lightweight Soil with Tailings Sand for Embankment Applications: Physical Properties, Durability, and Microstructure. Constr. Build. Mater. 2022, 350, 128912. [Google Scholar] [CrossRef]

- Peng, Y.; Ou, X.; Chen, X.; Lin, X.; Shen, X. Utilization of Discarded Bauxite Tailings into Eco-Friendly Foamed Mixture Lightweight Soil. J. Clean. Prod. 2022, 333, 130167. [Google Scholar] [CrossRef]

- Yuan, X.; Lu, Z.; Yao, H.; Tan, X.; Zhao, Y.; Tang, C.; Cheng, M.; Gao, Y. Engineering Properties and Applications of Air-Foamed Lightweight Soil. Adv. Mater. Sci. Eng. 2022, 2022, 4967037. [Google Scholar] [CrossRef]

- Ou, X.; Zeng, Y.; Jiang, J.; Lyu, Z.; Chen, H.; Chen, G. Experimental Research on the Properties of Foamed Mixture Lightweight Soil with Red Mud. Case Stud. Constr. Mater. 2022, 17, e01673. [Google Scholar] [CrossRef]

- Ho Minh Le, T.; Lee, S.-H.; Park, D.-W.; Lee, D.-W. Evaluation on the Full-Scale Testbed Performance of Lightweight Foamed Soil Using Railroad Loading System. Constr. Build. Mater. 2022, 330, 127249. [Google Scholar] [CrossRef]

- GB/T 749-2008; Test Method for Determing Capability of Resisting Sulfate Corrode of Cement. China Standard Publishing House: Beijing, China, 2008.

- Sun, J.; Ma, Y.; Li, J.; Zhang, J.; Ren, Z.; Wang, X. Machine Learning-Aided Design and Prediction of Cementitious Composites Containing Graphite and Slag Powder. J. Build. Eng. 2021, 43, 102544. [Google Scholar] [CrossRef]

- Sun, J.; Wang, X.; Zhang, J.; Xiao, F.; Sun, Y.; Ren, Z.; Zhang, G.; Liu, S.; Wang, Y. Multi-Objective Optimisation of a Graphite-Slag Conductive Composite Applying a BAS-SVR Based Model. J. Build. Eng. 2021, 44, 103223. [Google Scholar] [CrossRef]

- Feng, W.; Wang, Y.; Sun, J.; Tang, Y.; Wu, D.; Jiang, Z.; Wang, J.; Wang, X. Prediction of Thermo-Mechanical Properties of Rubber-Modified Recycled Aggregate Concrete. Constr. Build. Mater. 2022, 318, 125970. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, Y.; Li, G.; Wang, Y.; Sun, J.; Li, J. Machine-Learning-Assisted Shear Strength Prediction of Reinforced Concrete Beams with and without Stirrups. Eng. Comput. 2022, 38, 1293–1307. [Google Scholar] [CrossRef]

- Sun, J.; Wang, J.; Zhu, Z.; He, R.; Peng, C.; Zhang, C.; Huang, J.; Wang, Y.; Wang, X. Mechanical Performance Prediction for Sustainable High-Strength Concrete Using Bio-Inspired Neural Network. Buildings 2022, 12, 65. [Google Scholar] [CrossRef]

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | K2O | Na2O | TiO2 | LOI | |

|---|---|---|---|---|---|---|---|---|---|---|

| Cement | 60.11 | 20.92 | 5.76 | 3.24 | 1.15 | 2.86 | 0.88 | 0.14 | 0.31 | 4.17 |

| Granulated Blast Furnace Slag | 39.92 | 31.23 | 14.12 | 0.78 | 7.34 | 2.23 | 0.61 | 0.72 | 0.76 | −0.29 |

| Fly Ash | 0.44 | 57.64 | 21.49 | 6.52 | 1.77 | 0.37 | 3.42 | 0.12 | 0.93 | 6.85 |

| Concrete Antiseptic | 0.18 | 58.63 | 37.91 | 0.24 | 0.58 | 0.07 | 0.55 | 0.25 | 0.04 | 0.64 |

| Density /(kg/m3) | Specific Surface Area/(m2/kg) | Soundness of Cement/mm | Setting Times/min | Flexural Strength /MPa | Compressive Strength/MPa | |||

|---|---|---|---|---|---|---|---|---|

| Initial | Final | 3 d | 28 d | 3 d | 28 d | |||

| 3100 | 340 | 2 | 170 | 235 | 5.6 | 8.7 | 28.1 | 50.4 |

| No. | Cementitious Material Systems | Water | Foam | |||

|---|---|---|---|---|---|---|

| C | GBFS | FA | CA | |||

| A | 345 | 0 | 0 | 0 | 224 | 33.2 |

| B | 207 | 138 | 0 | 0 | 224 | 33.0 |

| C | 207 | 0 | 138 | 0 | 224 | 32.3 |

| D | 103.5 | 103.5 | 138 | 0 | 224 | 32.1 |

| E | 103.5 | 103.5 | 138 | 5.2 | 224 | 31.9 |

| No. | A | B | C | D | E |

|---|---|---|---|---|---|

| Corrosion resistance coefficient | 0.83 | 0.89 | 0.87 | 0.95 | 0.97 |

| No. | A | B | C | D | E |

|---|---|---|---|---|---|

| Flow factor, mm | 170 | 175 | 178 | 175 | 165 |

| Wet density, kg/m3 | 601 | 597 | 596 | 593 | 608 |

| 7 d Compressive strength, MPa | 1.16 | 0.95 | 0.63 | 0.82 | 0.87 |

| 28 d Compressive strength, MPa | 2.18 | 2.12 | 1.34 | 1.90 | 2.05 |

| No. | A | B | C | D | E |

|---|---|---|---|---|---|

| Amount of cement, kg | 345 | 207 | 207 | 103.5 | 103.5 |

| CO2 emissions of cement manufacturing, kg | 241.5 | 144.9 | 144.9 | 72.5 | 72.5 |

| CO2 reduction rate, % | / | 40% | 40% | 70% | 70% |

| No. | A | B | C | D | E | |

|---|---|---|---|---|---|---|

| 56d compressive strength (contrast specimens), MPa | 2.36 | 2.72 | 1.78 | 2.41 | 2.58 | |

| 56d compressive strength (experimental specimens), MPa | 200 mg/L | 2.39 | 2.73 | 1.77 | 2.41 | 2.60 |

| 1000 mg/L | 2.08 | 2.55 | 1.62 | 2.29 | 2.53 | |

| 4000 mg/L | 1.80 | 2.35 | 1.47 | 2.23 | 2.47 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Wan, H.; Liu, H.; Zhang, G.; Xu, X.; Shen, C. Preparation and Properties of Low-Carbon Foamed Lightweight Soil with High Resistance to Sulphate Erosion Environments. Materials 2023, 16, 4604. https://doi.org/10.3390/ma16134604

Wang Y, Wan H, Liu H, Zhang G, Xu X, Shen C. Preparation and Properties of Low-Carbon Foamed Lightweight Soil with High Resistance to Sulphate Erosion Environments. Materials. 2023; 16(13):4604. https://doi.org/10.3390/ma16134604

Chicago/Turabian StyleWang, Yongsheng, Huiwen Wan, Hao Liu, Gaoke Zhang, Xiaoyang Xu, and Cong Shen. 2023. "Preparation and Properties of Low-Carbon Foamed Lightweight Soil with High Resistance to Sulphate Erosion Environments" Materials 16, no. 13: 4604. https://doi.org/10.3390/ma16134604

APA StyleWang, Y., Wan, H., Liu, H., Zhang, G., Xu, X., & Shen, C. (2023). Preparation and Properties of Low-Carbon Foamed Lightweight Soil with High Resistance to Sulphate Erosion Environments. Materials, 16(13), 4604. https://doi.org/10.3390/ma16134604