Comparative Study of FSW, MIG, and TIG Welding of AA5083-H111 Based on the Evaluation of Welded Joints and Economic Aspect

Abstract

1. Introduction

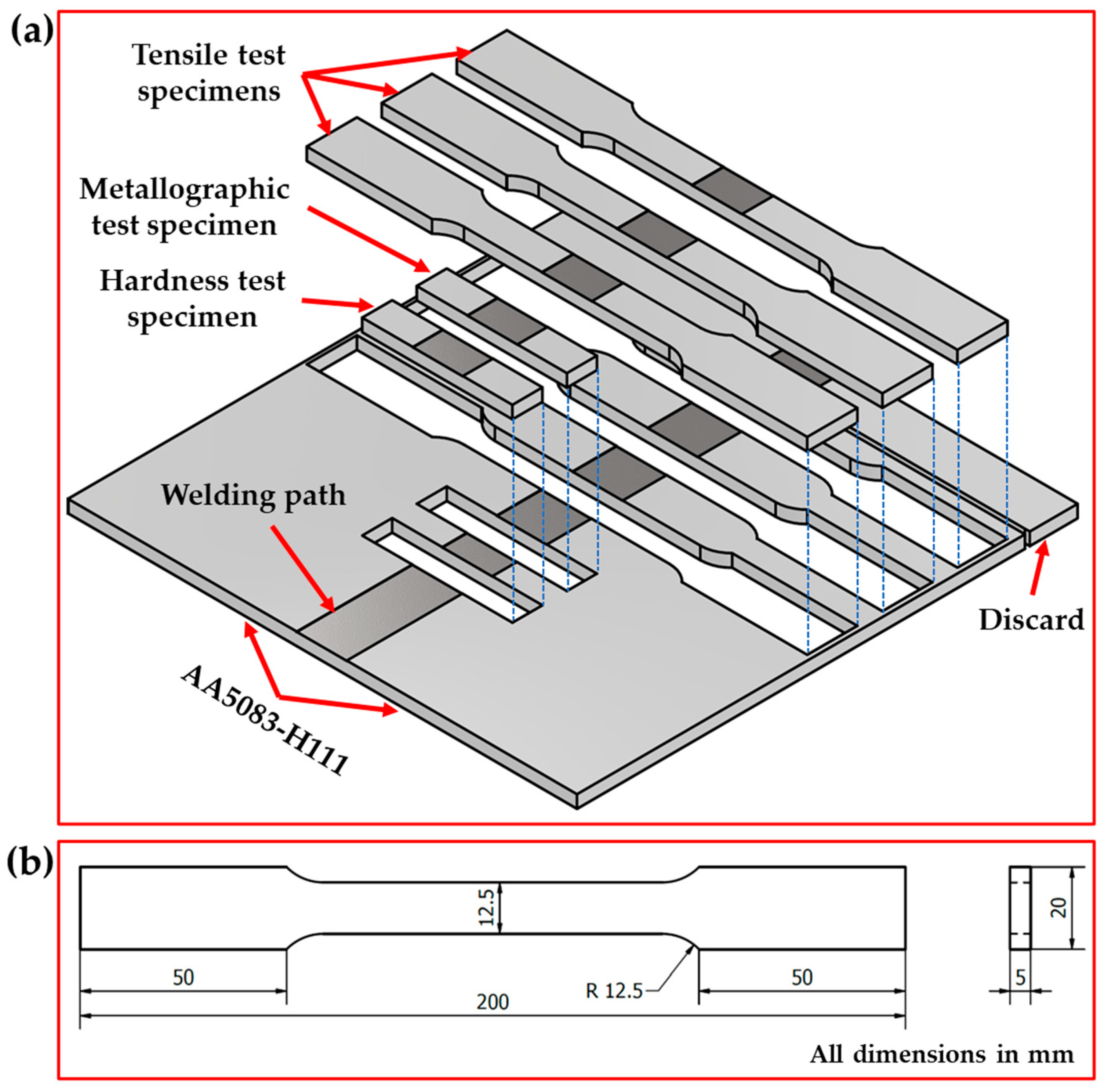

2. Materials and Methods

2.1. Material

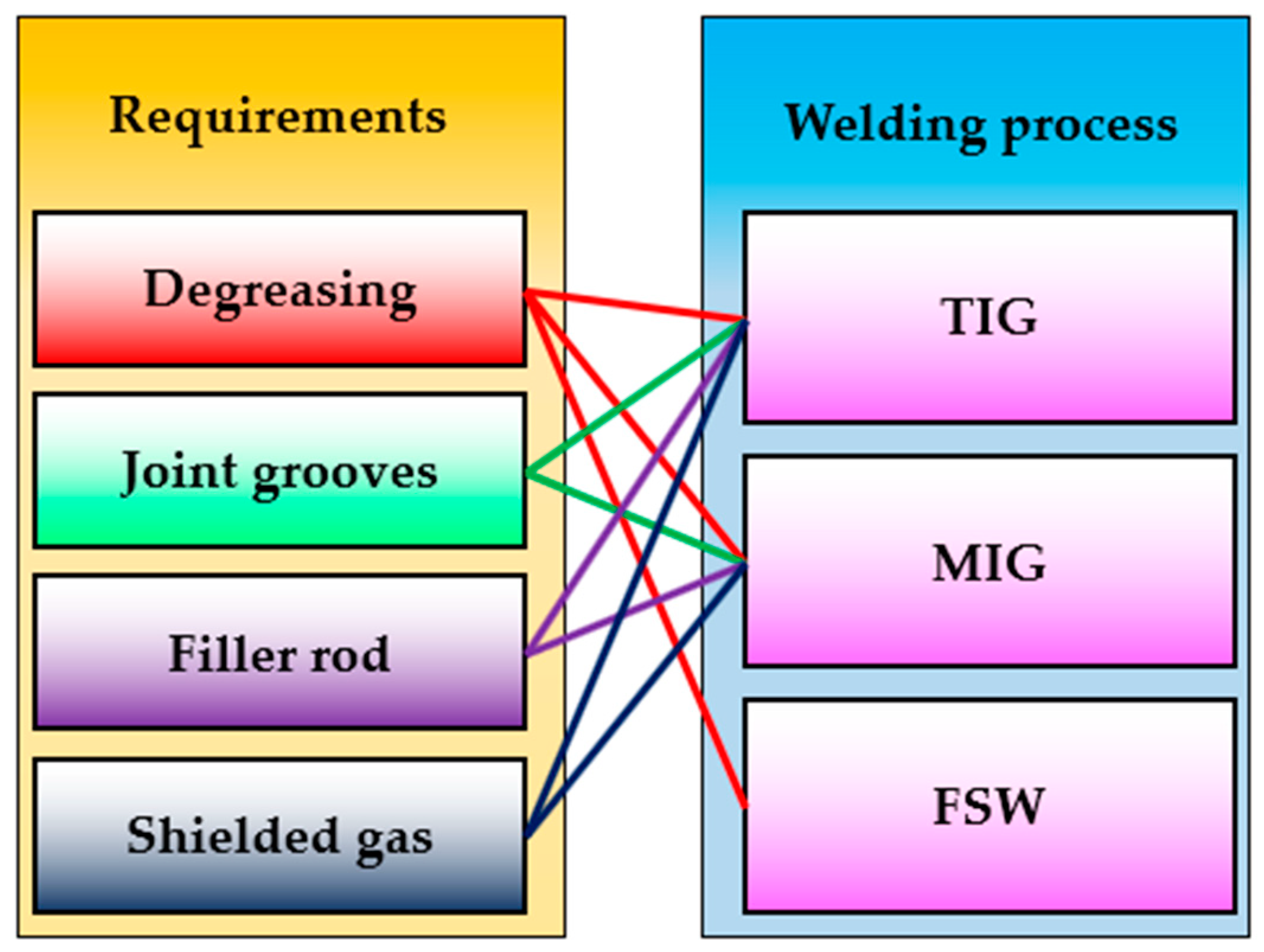

2.2. Fusion Welding of AA5083-H111

2.3. FSW of AA5083-H111

2.4. Characterization of AA5083-H111 Welds

3. Results and Discussion

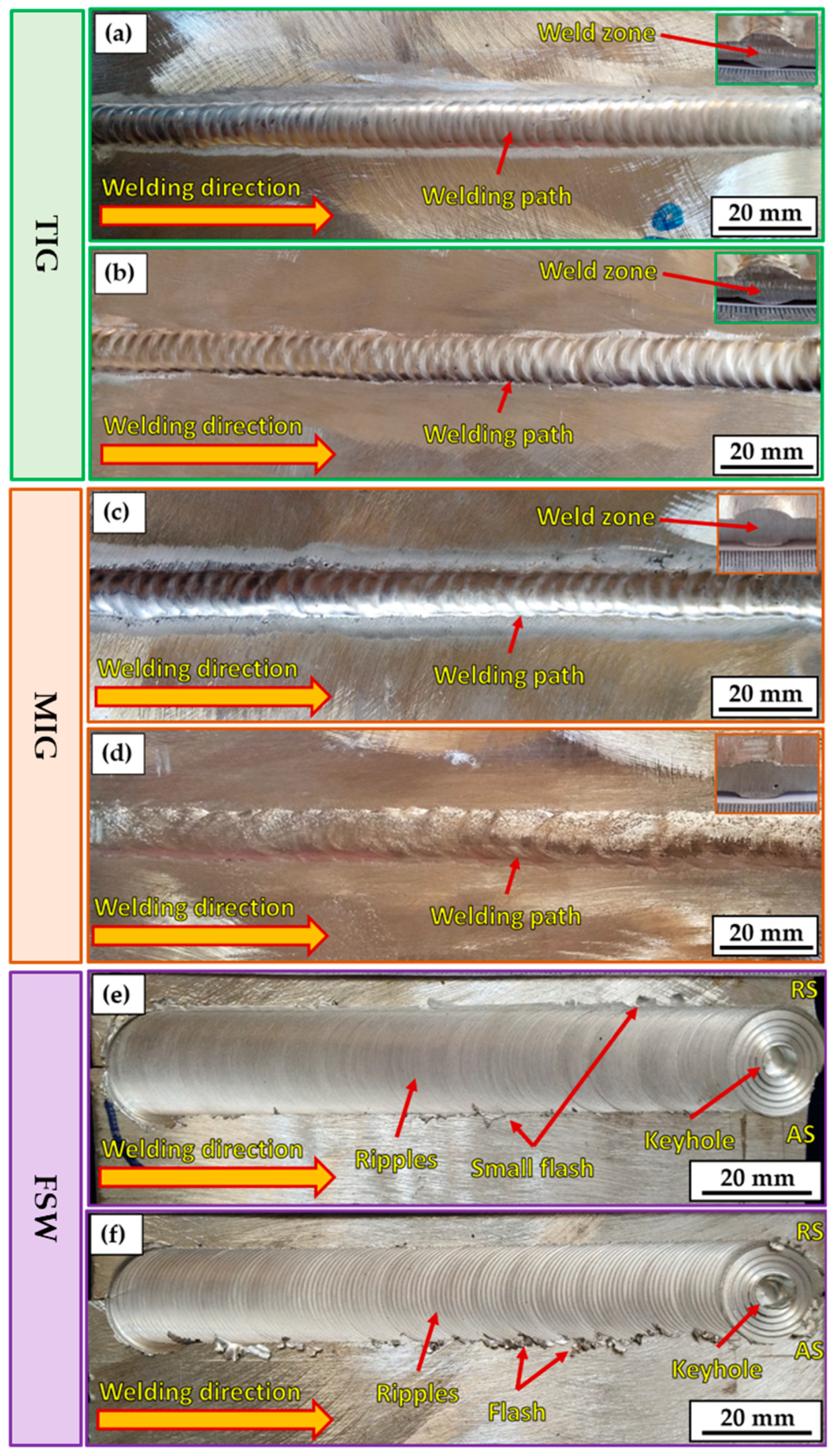

3.1. Visual Inspections

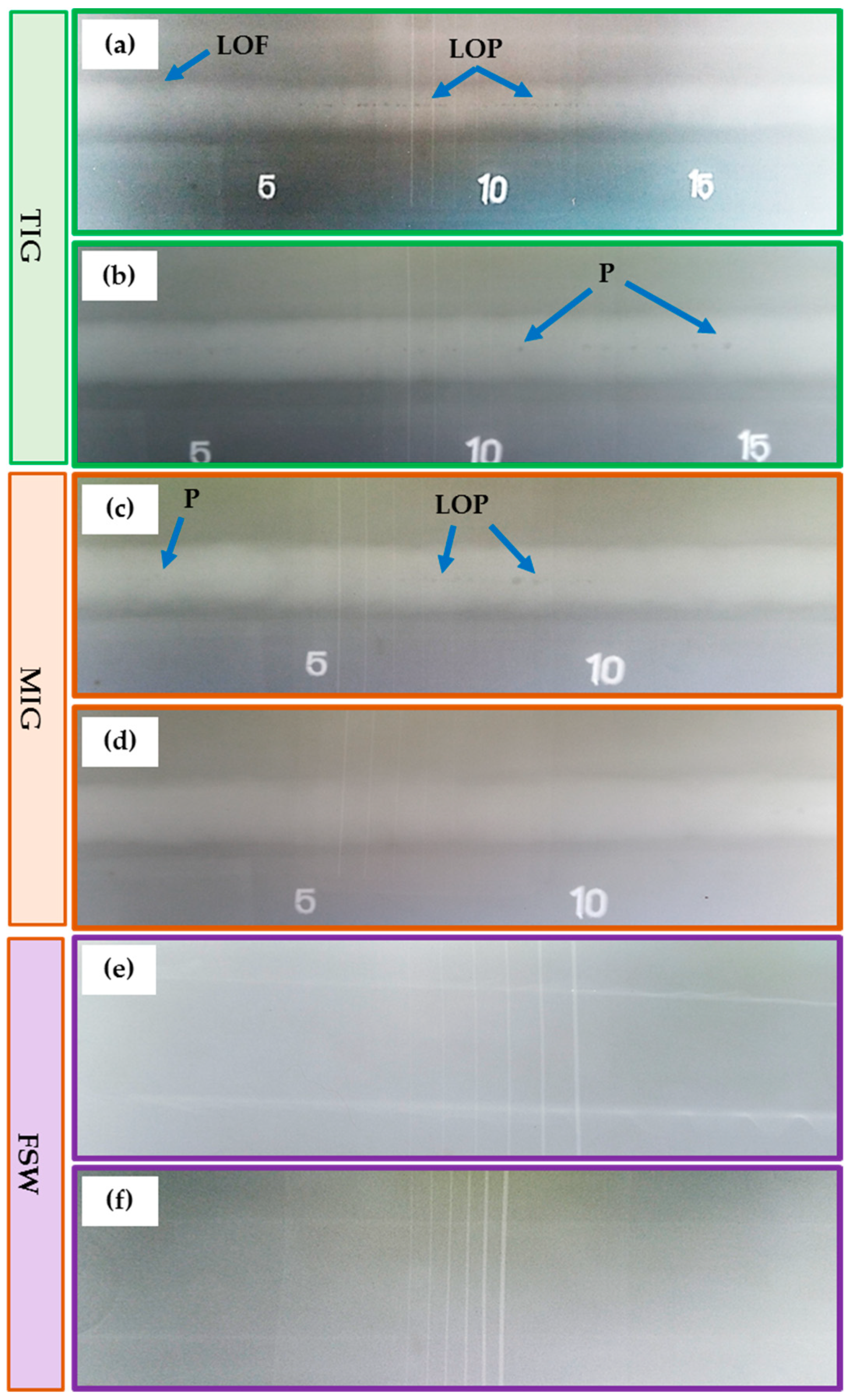

3.2. Radiographic Inspection

3.3. Macrostructure

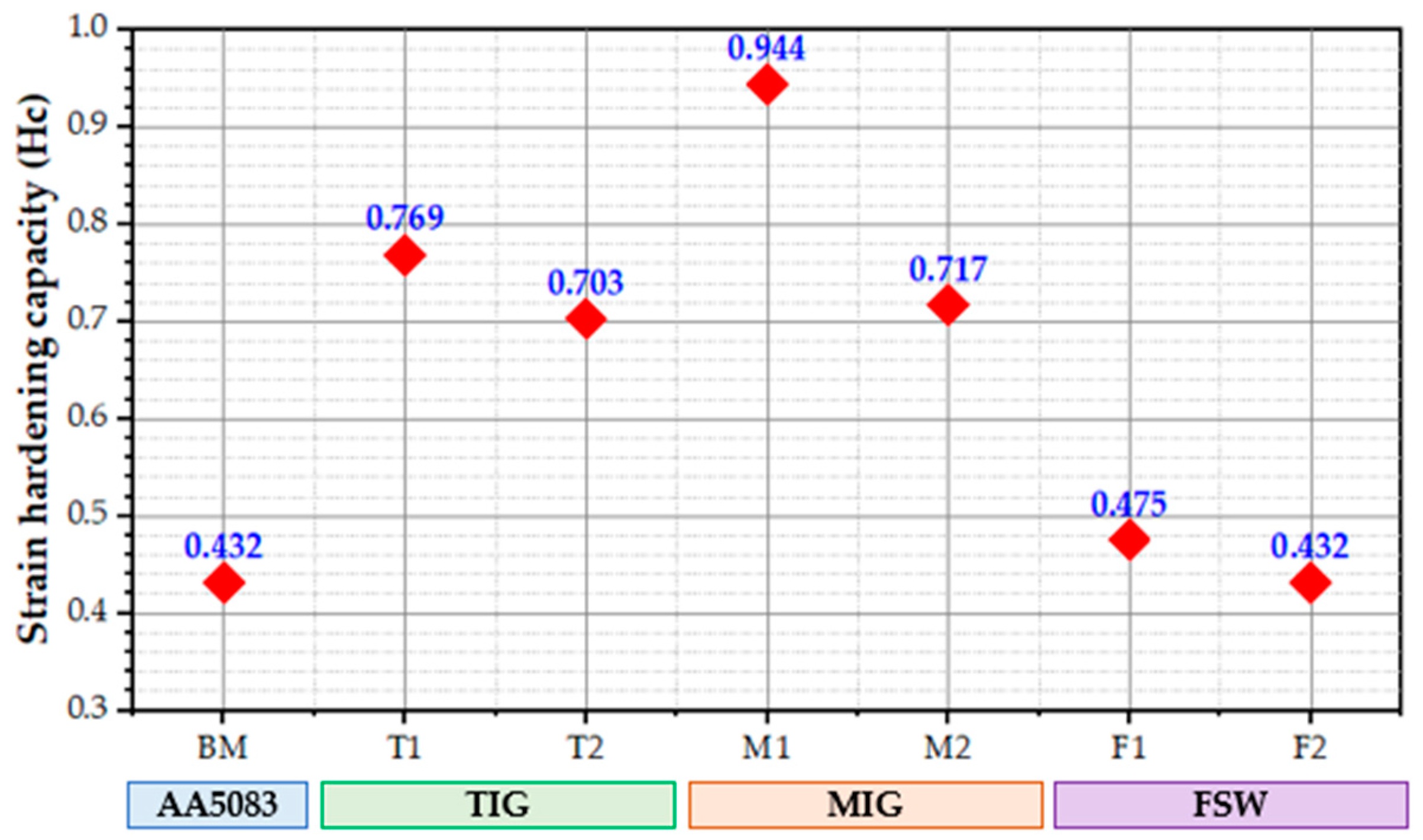

3.4. Mechanical Properties

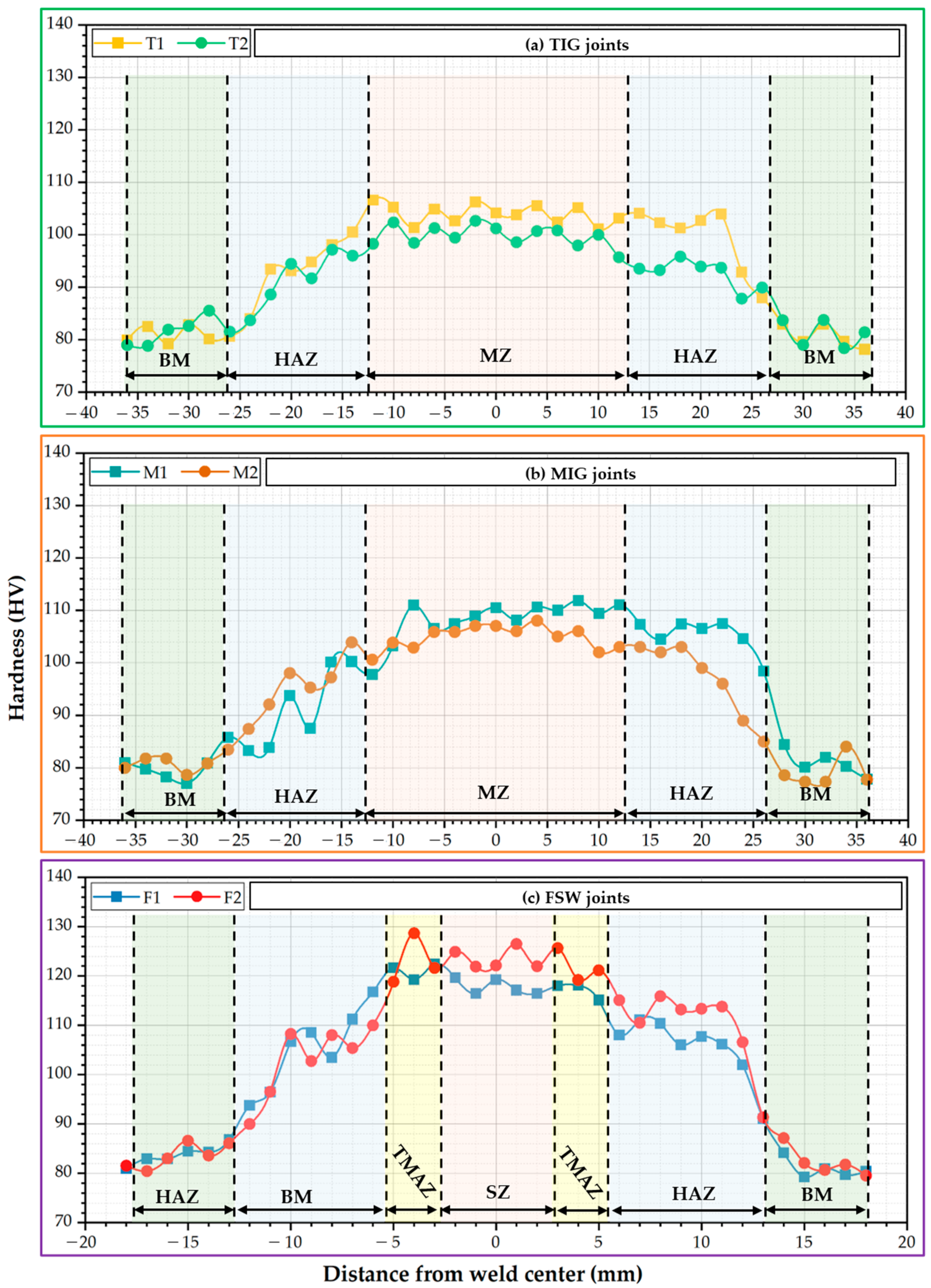

3.4.1. Hardness of the Produced Joints

3.4.2. Tensile Properties

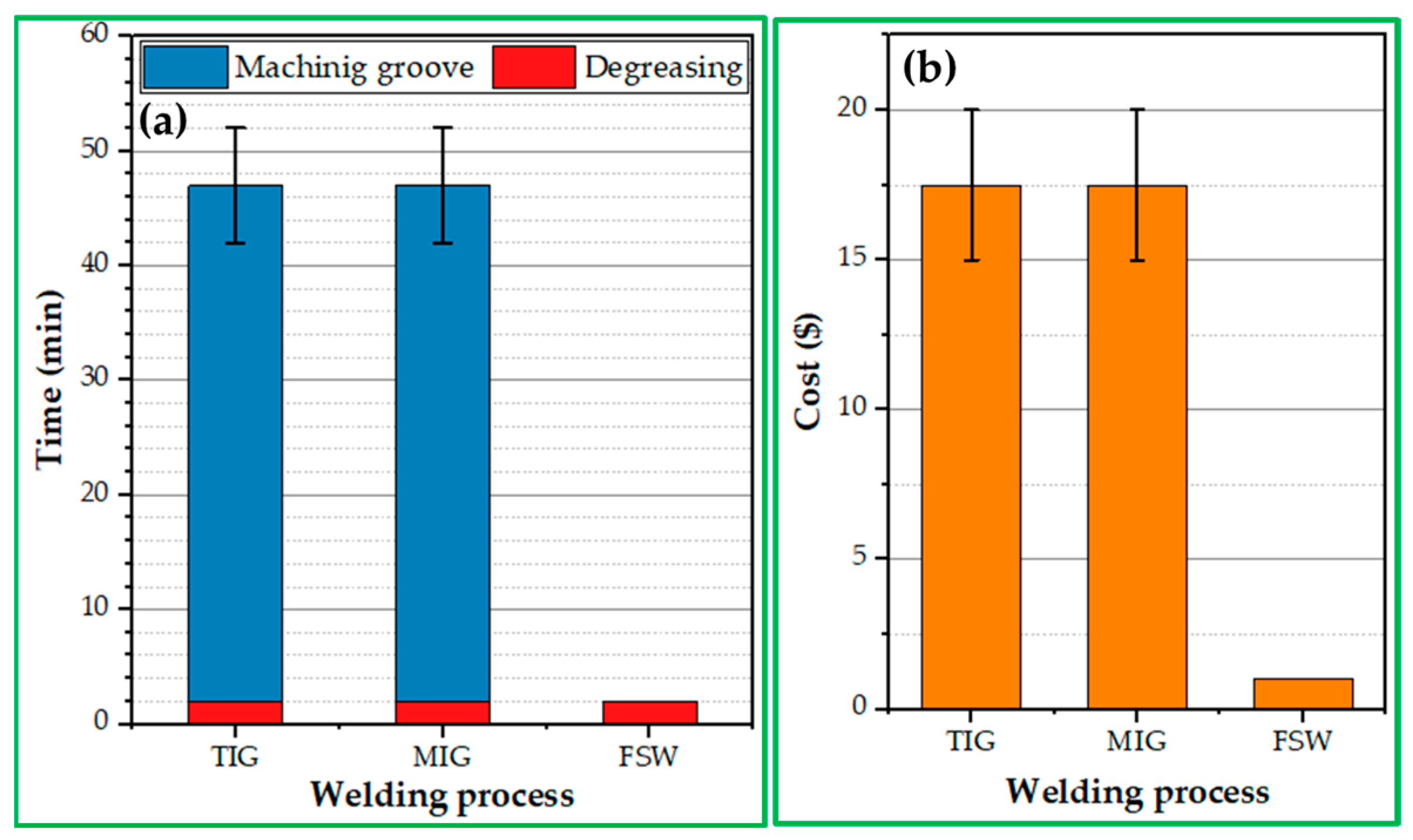

3.5. Economic Analysis

3.5.1. Time of Preparation and Welding Processes

3.5.2. Cost Items

4. Conclusions

- The MIG joint processed at a welding current of 170 Amp, with a 19 L/min flow rate of pure argon and the FSW joints processed at a constant tool rotation speed of 400 rpm and two travel speeds of 100 and 400 mm/min using a cylindrical pin geometry revealed defect-free joints among all the welded AA5083-H111 butt joints.

- The average hardness values of all the produced AA5083-H111 butt joints showed a notable enhancement over the hardness of AA5083-H111 BM by 25, 30, and 50% for the MIG, TIG, and FSW joints, respectively.

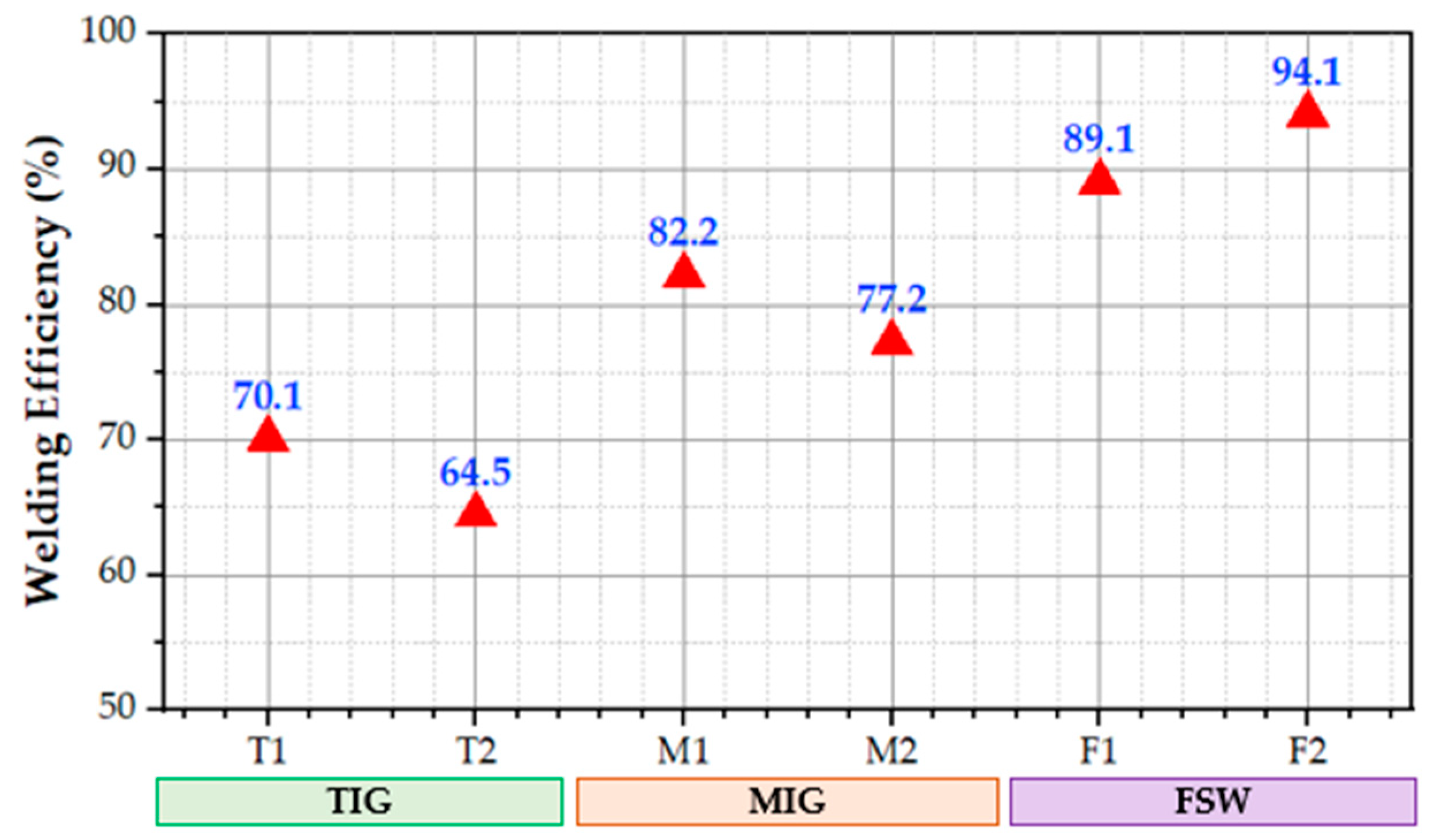

- The FSW joints exhibit the highest efficiency, around 89%, compared with 70 and 83% for the MIG and TIG joints, respectively.

- The highest joint tensile strength was obtained for the FSW joint produced at a travel speed of 400 mm/min and a 400 rpm rotation speed.

- The FSW has an advantage over TIG and MIG welding techniques, including the time required to prepare specimens for the welding process, the welding time, and the number of welding passes. In contrast, TIG and MIG technologies require mechanical preparation, high heat input, and high occupational safety precautions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Muñoz, A.C.; Rückert, G.; Huneau, B.; Sauvage, X.; Marya, S. Comparison of TIG Welded and Friction Stir Welded Al-4.5Mg-0.26Sc Alloy. J. Mater. Process. Technol. 2008, 197, 337–343. [Google Scholar] [CrossRef]

- Jaume, J.; Marques, M.J.F.; Délia, M.L.; Basséguy, R. Surface Modification of 5083 Aluminum-Magnesium Induced by Marine Microorganisms. Corros. Sci. 2022, 194, 109934. [Google Scholar] [CrossRef]

- Wahid, M.A.; Siddiquee, A.N.; Khan, Z.A. Aluminum Alloys in Marine Construction: Characteristics, Application, and Problems from a Fabrication Viewpoint. Mar. Syst. Ocean Technol. 2020, 15, 70–80. [Google Scholar] [CrossRef]

- Wu, R.Z.; Qu, Z.K.; Zhang, M.L. Reviews on the Influences of Alloying Elements on the Microstructure and Mechanical Properties of Mg-Li Base Alloys. Rev. Adv. Mater. Sci. 2010, 24, 35–43. [Google Scholar]

- Amini, S.; Amiri, M.R.; Barani, A. Investigation of the Effect of Tool Geometry on Friction Stir Welding of 5083-O Aluminum Alloy. Int. J. Adv. Manuf. Technol. 2015, 76, 255–261. [Google Scholar] [CrossRef]

- Jannet, S.; Mathews, K.; Raja, R. Comparative Investigation of Friction Stir Welding and Fusion Welding of 6061 T6-5083 O Aluminum Alloy Based on Mechanical Properties and Microstructure. Bull. Pol. Acad. Sci. Tech. Sci. 2014, 62, 791–795. [Google Scholar] [CrossRef]

- Kumar, L.; Yazar, K.U.; Pramanik, S. Effect of Fusion and Friction Stir Welding Techniques on the Microstructure, Crystallographic Texture and Mechanical Properties of Mild Steel. Mater. Sci. Eng. A 2019, 754, 400–410. [Google Scholar] [CrossRef]

- Jeyaprakash, N.; Haile, A.; Arunprasath, M. The Parameters and Equipments Used in TIG Welding: A Review. Int. J. Eng. Sci. 2015, 4, 11–20. [Google Scholar]

- Singh, A.K.; Dey, V.; Rai, R.N. Techniques to Improveweld Penetration in TIG Welding (A Review). Mater. Today Proc. 2017, 4, 1252–1259. [Google Scholar] [CrossRef]

- Kanemaru, S.; Sasaki, T.; Sato, T.; Mishima, H.; Tashiro, S.; Tanaka, M. Study for TIG-MIG Hybrid Welding Process. Weld. World 2014, 58, 11–18. [Google Scholar] [CrossRef]

- Patil, S.R.; Waghmare, C.A. Research Paper Optimization of Mig Welding Parameters for Improving Strength of Welded Joints Address for Correspondence. Int. J. Adv. Eng. Res. Stud. 2013, 14–16. [Google Scholar]

- Madavi, K.R.; Jogi, B.F.; Lohar, G.S. Metal Inert Gas (MIG) Welding Process: A Study of Effect of Welding Parameters. Mater. Today Proc. 2021, 51, 690–698. [Google Scholar] [CrossRef]

- Karpagarajan, S.; Balamurugan, C.; Vigneshwaran, S.; Abdel Aziz, E.S.I. Effect of Volume Fraction on Microstructure and Wear Behavior of Dual-Phase Brass/W Surface Composites Fabricated via Friction Stir Processing. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2023. [Google Scholar] [CrossRef]

- Darzi Bourkhani, R.; Eivani, A.R.; Nateghi, H.R.; Jafarian, H.R. Effects of Pin Diameter and Number of Cycles on Microstructure and Tensile Properties of Friction Stir Fabricated AA1050-Al2O3 Nanocomposite. J. Mater. Res. Technol. 2020, 9, 4506–4517. [Google Scholar] [CrossRef]

- Salih, O.S.; Ou, H.; Sun, W. Heat Generation, Plastic Deformation and Residual Stresses in Friction Stir Welding of Aluminium Alloy. Int. J. Mech. Sci. 2023, 238, 107827. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Habba, M.I.A.; Jouini, N.; Alzahrani, B.; El-Sayed Seleman, M.M.; El-Nikhaily, A. Bobbin Tool Friction Stir Welding of Aluminum Using Different Tool Pin Geometries: Mathematical Models for the Heat Generation. Metals 2021, 11, 438. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Habba, M.I.A.; El-Sayed Seleman, M.M.; Hajlaoui, K.; Ataya, S.; Latief, F.H.; EL-Nikhaily, A.E. Bobbin Tool Friction Stir Welding of Aluminum Thick Lap Joints: Effect of Process Parameters on Temperature Distribution and Joints’ Properties. Materials 2021, 14, 4585. [Google Scholar] [CrossRef]

- Liu, F.C.; Hovanski, Y.; Miles, M.P.; Sorensen, C.D.; Nelson, T.W. A Review of Friction Stir Welding of Steels: Tool, Material Flow, Microstructure, and Properties. J. Mater. Sci. Technol. 2018, 34, 39–57. [Google Scholar] [CrossRef]

- Gite, R.A.; Loharkar, P.K.; Shimpi, R. Friction Stir Welding Parameters and Application: A Review. Mater. Today Proc. 2019, 19, 361–365. [Google Scholar] [CrossRef]

- Mehta, K.P.; Badheka, V.J. Effects of Tilt Angle on the Properties of Dissimilar Friction Stir Welding Copper to Aluminum. Mater. Manuf. Process. 2016, 31, 255–263. [Google Scholar] [CrossRef]

- Haribalaji, V.; Boopathi, S.; Mohammed Asif, M. Optimization of Friction Stir Welding Process to Join Dissimilar AA2014 and AA7075 Aluminum Alloys. Mater. Today Proc. 2022, 50, 2227–2234. [Google Scholar] [CrossRef]

- Hashmi, F.A.; Mohamed Ali, H.B.; Lone, N.F.; Azma, R.; Siddiquee, A.N.; Ashraf Mir, M.; Ahmad, T.; Mir, F.A. Friction Stir Welds of Aluminium Alloy Pipes: An Investigation of Defects and Mechanical Properties. Adv. Mater. Process. Technol. 2023, 9, 169–185. [Google Scholar] [CrossRef]

- Moradi, M.M.; Jamshidi Aval, H.; Jamaati, R. Effect of Tool Pin Geometry and Weld Pass Number on Microstructural, Natural Aging and Mechanical Behaviour of SiC-Incorporated Dissimilar Friction-Stir-Welded Aluminium Alloys. Sadhana-Acad. Proc. Eng. Sci. 2019, 44, 9. [Google Scholar] [CrossRef]

- Datta, A.; Shrivastava, A.; Mandal, N.; Roy, H.; Chakraborty, S.S. A Comparative Investigation of Butt Friction Stir Welding of Aluminium Alloys, AA 1100 and AA 7075, with AISI 304 Stainless Steel. Weld. World 2023, 67, 1449–1465. [Google Scholar] [CrossRef]

- Murr, L.E. A Review of FSW Research on Dissimilar Metal and Alloy Systems. J. Mater. Eng. Perform. 2010, 19, 1071–1089. [Google Scholar] [CrossRef]

- Victor Christy, J.; Ismail Mourad, A.-H.; Sherif, M.M.; Shivamurthy, B. Review of Recent Trends in Friction Stir Welding Process of Aluminum Alloys and Aluminum Metal Matrix Composites. Trans. Nonferrous Met. Soc. China 2021, 31, 3281–3309. [Google Scholar] [CrossRef]

- Cabibbo, M.; Forcellese, A.; Santecchia, E.; Paoletti, C.; Spigarelli, S.; Simoncini, M. New Approaches to Friction Stir Welding of Aluminum Light-Alloys. Metals 2020, 10, 233. [Google Scholar] [CrossRef]

- Paik, J.K. Mechanical Properties of Friction Stir Welded Aluminum Alloys 5083 and 5383. Int. J. Nav. Archit. Ocean Eng. 2009, 1, 39–49. [Google Scholar] [CrossRef]

- Torzewski, J.; Grzelak, K.; Wachowski, M.; Kosturek, R. Microstructure and Low Cycle Fatigue Properties of AA5083 H111 Friction Stir Welded Joint. Materials 2020, 13, 2381. [Google Scholar] [CrossRef]

- Muhayat, N.; Zubaydi, A.; Sulistijono; Yuliadi, M.Z. Effect of Tool Tilt Angle and Tool Plunge Depth on Mechanical Properties of Friction Stir Welded AA 5083 Joints. Appl. Mech. Mater. 2014, 493, 709–714. [Google Scholar] [CrossRef]

- Anganan, K.; Ganesh Murali, J.; Muthu Krishnan, M.; Marimuthu, K. Study of Mechanical Properties and Experimental Comparison of MIG and Friction Stir Welding Processes for AA6082-T6 Aluminium Alloy. In Proceedings of the 2014 IEEE 8th International Conference on Intelligent Systems and Control (ISCO), Coimbatore, India, 10–11 January 2014; pp. 74–78. [Google Scholar] [CrossRef]

- Singh, G.; Kang, A.S.; Singh, K.; Singh, J. Experimental Comparison of Friction Stir Welding Process and TIG Welding Process for 6082-T6 Aluminium Alloy. Mater. Today Proc. 2017, 4, 3590–3600. [Google Scholar] [CrossRef]

- Dwivedi, U.; Tiwari, S.; Mishra, A.; Das, S. ScienceDirect Comparative Study of Weld Characteristics of Friction Stir Welded Joints on Aluminium 7075 with Autogenous TIG. Mater. Today Proc. 2020, 22, 2532–2538. [Google Scholar] [CrossRef]

- Nginda, S.; Pita, M. Investigation of the Mechanical Properties of Aluminum AA4007 Joints Using the MIG and FSW Processes. In Proceedings of the 2022 IEEE 13th International Conference on Mechanical and Intelligent Manufacturing Technologies (ICMIMT), Cape Town, South Africa, 25–27 May 2022; pp. 11–14. [Google Scholar] [CrossRef]

- Arunakumara, P.C.; Sagar, H.N.; Gautam, B.; George, R.; Rajeesh, S. A Review Study on Fatigue Behavior of Aluminum 6061 T-6 and 6082 T-6 Alloys Welded by MIG and FS Welding Methods. Mater. Today Proc. 2023, 74, 293–301. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, G.; Roy, A.; Sinha, R.S.; Hasnain, S.M.M.; Prakash, O.; Ahmad, A. A Comparative Analysis of Friction Stir and Tungsten Inert Gas Dissimilar AA5082-AA7075 Butt Welds. Mater. Sci. Energy Technol. 2022, 5, 74–80. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Fydrych, D.; Çam, G. Friction Stir Welding of Aluminum in the Aerospace Industry: The Current Progress and State-of-the-Art Review. Materials 2023, 16, 2971. [Google Scholar] [CrossRef]

- Seleman, M.M.E.; Ahmed, M.M.Z.; Rashad, M.; Zaki, B.A. Effect of FSW Parameters on the Microstructure and Mechanical Properties of T-Joints between Dissimilar Al-Alloys. Int. J. Integr. Eng. 2022, 14, 1–12. [Google Scholar] [CrossRef]

- ASTM-E8 04; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2010.

- Khan, N.Z.; Khan, Z.A.; Siddiquee, A.N.; AL-Ahmari, A.M.; Abidi, M.H. Analysis of Defects in Clean Fabrication Process of Friction Stir Welding. Trans. Nonferrous Met. Soc. China (Engl. Ed.) 2017, 27, 1507–1516. [Google Scholar] [CrossRef]

- Kah, P.; Rajan, R.; Martikainen, J.; Suoranta, R. Investigation of Weld Defects in Friction-Stir Welding and Fusion Welding of Aluminium Alloys. Int. J. Mech. Mater. Eng. 2015, 10, 26. [Google Scholar] [CrossRef]

- Al-Moussawi, M.; Smith, A.J. Defects in Friction Stir Welding of Steel. Metallogr. Microstruct. Anal. 2018, 7, 194–202. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Hajlaoui, K.; El-Sayed Seleman, M.M.; Elkady, M.F.; Ataya, S.; Latief, F.H.; Habba, M.I.A. Microstructure and Mechanical Properties of Friction Stir Welded 2205 Duplex Stainless Steel Butt Joints. Materials 2021, 14, 6640. [Google Scholar] [CrossRef]

- Ramon, J.; Pal, M.; Das, B. Investigation of Induction Heating Process for Selective Melting of Aluminum Alloy for the Repair of Exit Hole Defect in Friction Stir Welding Process. Arab. J. Sci. Eng. 2023. [Google Scholar] [CrossRef]

- Tier, M.D.; Rosendo, T.S.; Dos Santos, J.F.; Huber, N.; Mazzaferro, J.A.; Mazzaferro, C.P.; Strohaecker, T.R. The Influence of Refill FSSW Parameters on the Microstructure and Shear Strength of 5042 Aluminium Welds. J. Mater. Process. Technol. 2013, 213, 997–1005. [Google Scholar] [CrossRef]

- Rajkumar, S.; Mageshkumar, K.; Arul, K.; Ravi, S.; Maridurai, T.; Subbiah, R. Effect of Welding Speed on the Mechanical Properties of AA6061 Al Alloy Joined by Friction Stir Welding. Mater. Today Proc. 2022, 59, 1544–1549. [Google Scholar] [CrossRef]

- Xu, N.; Qiu, Z.; Ren, Z.; Shen, J.; Wang, D.; Song, Q.; Zhao, J.; Jiang, Y.; Bao, Y. Enhanced Strength and Ductility of Rapid Cooling Friction Stir Welded Ultralight Mg–14Li–1Al Alloy Joint. J. Mater. Res. Technol. 2023, 23, 4444–4453. [Google Scholar] [CrossRef]

- Samiuddin, M.; Li, J.L.; Taimoor, M.; Siddiqui, M.N.; Siddiqui, S.U.; Xiong, J.T. Investigation on the Process Parameters of TIG-Welded Aluminum Alloy through Mechanical and Microstructural Characterization. Def. Technol. 2021, 17, 1234–1248. [Google Scholar] [CrossRef]

- Lee, H.K.; Chun, K.S.; Park, S.H.; Kang, C.Y. Control of Surface Defects on Plasma-MIG Hybrid Welds in Cryogenic Aluminum Alloys. Int. J. Nav. Archit. Ocean Eng. 2015, 7, 770–783. [Google Scholar] [CrossRef]

- Abima, C.S.; Akinlabi, S.A.; Madushele, N.; Akinlabi, E.T. Comparative Study between TIG-MIG Hybrid, TIG and MIG Welding of 1008 Steel Joints for Enhanced Structural Integrity. Sci. Afr. 2022, 17, e01329. [Google Scholar] [CrossRef]

- Celis, M.M.; Harcuba, P.; Veselý, J.; Moisy, F.; Picot, F.; Retoux, R.; Domenges, B.; Hug, E. Identification of a Pseudo-Ternary Intermetallic Compound in the Stirred Zone of Friction-Stir-Welded 5083 Aluminum Alloy with 316L Steel. J. Mater. Sci. 2023, 58, 5516–5529. [Google Scholar] [CrossRef]

- Gaurav, S.; Mishra, R.S.; Zunaid, M. Enhancement of Microstructure and Mechanical Properties of Similar and Dissimilar Aluminium Alloy by Friction Stir Welding/Processing Using Nanoparticles: A Review. J. Adhes. Sci. Technol. 2023, 1–42. [Google Scholar] [CrossRef]

- Aldanondo, E.; Vivas, J.; Álvarez, P.; Hurtado, I. Effect of Tool Geometry and Welding Parameters on Friction Stir Welded Lap Joint Formation with Aa2099-T83 and Aa2060-T8e30 Aluminium Alloys. Metals 2020, 10, 872. [Google Scholar] [CrossRef]

- Alzahrani, B.; El-Sayed Seleman, M.M.; Ahmed, M.M.Z.; Elfishawy, E.; Ahmed, A.M.Z.; Touileb, K.; Jouini, N.; Habba, M.I.A. The Applicability of Die Cast A356 Alloy to Additive Friction Stir Deposition at Various Feeding Speeds. Materials 2021, 14, 6018. [Google Scholar] [CrossRef] [PubMed]

- El-Sayed Seleman, M.M.; Ataya, S.; Ahmed, M.M.Z.; Hassan, A.M.M.; Latief, F.H.; Hajlaoui, K.; El-Nikhaily, A.E.; Habba, M.I.A. The Additive Manufacturing of Aluminum Matrix Nano Al2O3 Composites Produced via Friction Stir Deposition Using Different Initial Material Conditions. Materials 2022, 15, 2926. [Google Scholar] [CrossRef] [PubMed]

- Ataya, S.; Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Hajlaoui, K.; Latief, F.H.; Soliman, A.M.; Elshaghoul, Y.G.Y.; Habba, M.I.A. Effective Range of FSSW Parameters for High Load-Carrying Capacity of Dissimilar Steel A283M-C/Brass CuZn40 Joints. Materials 2022, 15, 1394. [Google Scholar] [CrossRef]

- Liu, J.; Guo, F.; Wang, T.; Duan, S.; Zou, Y. Study on Corrosion Resistance of HAZ and TMAZ in Friction Stir Welding Joint of 7075 Aluminum Alloy by Thermal Simulation. Mater. Res. Express 2023, 10, 016505. [Google Scholar] [CrossRef]

- Çam, G.; İpekoğlu, G. Recent Developments in Joining of Aluminum Alloys. Int. J. Adv. Manuf. Technol. 2017, 91, 1851–1866. [Google Scholar] [CrossRef]

- Liyakat, N.A.; Veeman, D. Improvement of Mechanical and Microstructural Properties of AA 5052-H32 TIG Weldment Using Friction Stir Processing Approach. J. Mater. Res. Technol. 2022, 19, 332–344. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Ataya, S.; El-Sayed Seleman, M.M.; Ammar, H.R.; Ahmed, E. Friction Stir Welding of Similar and Dissimilar AA7075 and AA5083. J. Mater. Process. Technol. 2017, 242, 77–91. [Google Scholar] [CrossRef]

- Su, X.; Tao, W.; Chen, Y.; Fu, J. Microstructure and Tensile Property of the Joint of Laser-MIG Hybrid Welded Thick-Section TC4 Alloy. Metals 2018, 8, 1002. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Zidan, Z.A.; Ramadan, R.M.; Ataya, S.; Alsaleh, N.A. Microstructure and Mechanical Properties of Dissimilar Friction Stir Welded AA2024-T4/AA7075-T6 T-Butt Joints. Metals 2021, 11, 128. [Google Scholar] [CrossRef]

- Kang, J.; Si, M.; Wang, J.; Zhou, L.; Jiao, X.; Wu, A. Effect of Friction Stir Repair Welding on Microstructure and Corrosion Properties of 2219-T8 Al Alloy Joints. Mater. Charact. 2023, 196, 112634. [Google Scholar] [CrossRef]

- Yuan, L.; Zeng, X.; Zhao, X.; Xie, Y.; Gandra, J.; Guan, D. Microstructure Evolution and Tensile Behaviour of Fine-Grained 6082 Al Wire with High Ultimate Strength and High Work Hardening by Friction Stir Extrusion of Bulk Al Sheet. Mater. Sci. Eng. A 2023, 864, 144589. [Google Scholar] [CrossRef]

- Vinoth Kumar, M.; Balasubramanian, V.; Gourav Rao, A. Hot Tensile Properties and Strain Hardening Behaviour of Super 304HCu Stainless Steel. J. Mater. Res. Technol. 2017, 6, 116–122. [Google Scholar] [CrossRef]

- Xu, W.F.; Zhang, Z.L. Microstructure and Mechanical Properties of Laser Beam Welded TC4/TA15 Dissimilar Joints. Trans. Nonferrous Met. Soc. China (Engl. Ed.) 2016, 26, 3135–3146. [Google Scholar] [CrossRef]

- Su, M.; Qi, X.; Xu, L.; Feng, Q.; Han, Y.; Zhao, L. Microstructural and Mechanical Analysis of 6063-T6 Aluminum Alloy Joints Bonded by Friction Stir Welding. J. Mater. Sci. 2022, 57, 15078–15093. [Google Scholar] [CrossRef]

- Wang, Z.; Zhu, W.; Zhang, Z.; Wang, B.; Xue, P.; Ni, D.; Liu, F.; Xiao, B.; Ma, Z.; Wang, F.; et al. Dissimilar Friction Stir Welding of 2219-T8 and 2195-T8 Aluminum Alloys: Part I—Microstructure Evolution and Mechanical Properties. J. Mater. Sci. 2023, 58, 9737–9754. [Google Scholar] [CrossRef]

| No. | Welding Techniques | Joint Materials (Thickness) | Points of Comparison | Recommended Techniques | Ref. |

|---|---|---|---|---|---|

| 1 | FSW and TIG | AA7075 (4 mm) | Mechanical properties and microstructure | FSW | [33] |

| 2 | FSW and MIG | AA4007 (6 mm) | Mechanical properties | FSW | [34] |

| 3 | FSW and MIG | AA6061 T-6 (6 mm) and AA6082 T-6 (6 mm) | Mechanical properties and microstructure | MIG | [35] |

| 4 | FSW and TIG | AA5082 and AA7075 dissimilar joint (6 mm) | Mechanical properties | FSW | [36] |

| Alloying Element | Mg | Zn | Si | Fe | Ti | Cu | Al |

|---|---|---|---|---|---|---|---|

| Wt. % | 4.760 | 0.040 | 0.045 | 0.140 | 0.054 | 0.020 | Balance |

| Element | Cr | Cu | Fe | Mg | Mn | Si | Zn | Al |

|---|---|---|---|---|---|---|---|---|

| Wt. % | 0.12 | 0.01 | 0.13 | 4.90 | 0.13 | 0.05 | 0.01 | Balance |

| Sample Code | Welding Process | Electrode or Filler Wire | Ampere (A) | Shielding Gas | Gas Flow Rate (L/min) | Welding Speed (mm/min) | ||

|---|---|---|---|---|---|---|---|---|

| First Layer | Second Layer | Third Layer | ||||||

| T1 | TIG | R5356 | Back 100 A | Root 135 A | Cap 100 A | Pure argon (99.99%) | 19 | 240–300 |

| T2 | 130 | 135 | 130 | |||||

| M1 | MIG | ER5356 | Root 170 A | Cap 140 A | Back 140 A | Pure argon (99.99%) | 19 | 290–350 |

| M2 | 170 A | 170 A | 170 A | |||||

| Item | Sample No. | Welding Process | Joint Dimensions (L mm × W mm × T mm) | Evaluation | Remarks |

|---|---|---|---|---|---|

| 1 | T1 | TIG | 200 × 200 × 5 | Accepted both sides |

|

| 2 | T2 | 200 × 200 × 5 | Accepted both sides |

| |

| 3 | M1 | MIG | 200 × 200 × 5 | Accepted both sides |

|

| 4 | M2 | 200 × 200 × 5 | Accepted both sides |

| |

| 5 | F1 | FSW | 20 × 20 × 0.5 | Accepted both sides |

|

| 6 | F2 | 20 × 20 × 0.5 | Accepted both sides |

|

| Item | Sample No. | Welding Process | No. of Welding Passes | Evaluation | Remarks |

|---|---|---|---|---|---|

| 1 | T1 | TIG | 3 | (0–5) LOF | - |

| (5–18) LOP | |||||

| 2 | T2 | (2–15) P | - | ||

| 3 | M1 | MIG | (0 3) P | - | |

| (5–10) LOP | |||||

| 4 | M2 | 3 | Accepted | Fully welded | |

| 5 | F1 | FSW | 1 | Accepted | Fully welded |

| 6 | F2 | Accepted | Fully welded |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Habba, M.I.A.; Alsaleh, N.A.; Badran, T.E.; El-Sayed Seleman, M.M.; Ataya, S.; El-Nikhaily, A.E.; Abdul-Latif, A.; Ahmed, M.M.Z. Comparative Study of FSW, MIG, and TIG Welding of AA5083-H111 Based on the Evaluation of Welded Joints and Economic Aspect. Materials 2023, 16, 5124. https://doi.org/10.3390/ma16145124

Habba MIA, Alsaleh NA, Badran TE, El-Sayed Seleman MM, Ataya S, El-Nikhaily AE, Abdul-Latif A, Ahmed MMZ. Comparative Study of FSW, MIG, and TIG Welding of AA5083-H111 Based on the Evaluation of Welded Joints and Economic Aspect. Materials. 2023; 16(14):5124. https://doi.org/10.3390/ma16145124

Chicago/Turabian StyleHabba, Mohamed I. A., Naser A. Alsaleh, Takwa E. Badran, Mohamed M. El-Sayed Seleman, Sabbah Ataya, Ahmed E. El-Nikhaily, Akrum Abdul-Latif, and Mohamed M. Z. Ahmed. 2023. "Comparative Study of FSW, MIG, and TIG Welding of AA5083-H111 Based on the Evaluation of Welded Joints and Economic Aspect" Materials 16, no. 14: 5124. https://doi.org/10.3390/ma16145124

APA StyleHabba, M. I. A., Alsaleh, N. A., Badran, T. E., El-Sayed Seleman, M. M., Ataya, S., El-Nikhaily, A. E., Abdul-Latif, A., & Ahmed, M. M. Z. (2023). Comparative Study of FSW, MIG, and TIG Welding of AA5083-H111 Based on the Evaluation of Welded Joints and Economic Aspect. Materials, 16(14), 5124. https://doi.org/10.3390/ma16145124