Asymmetric Extrusion Technology of Mg Alloy: A Review

Abstract

1. Introduction

2. Processing Extrusion Technologies of Mg Alloy

2.1. Normal-Direction Asymmetric Extrusion Technology of Mg Alloy

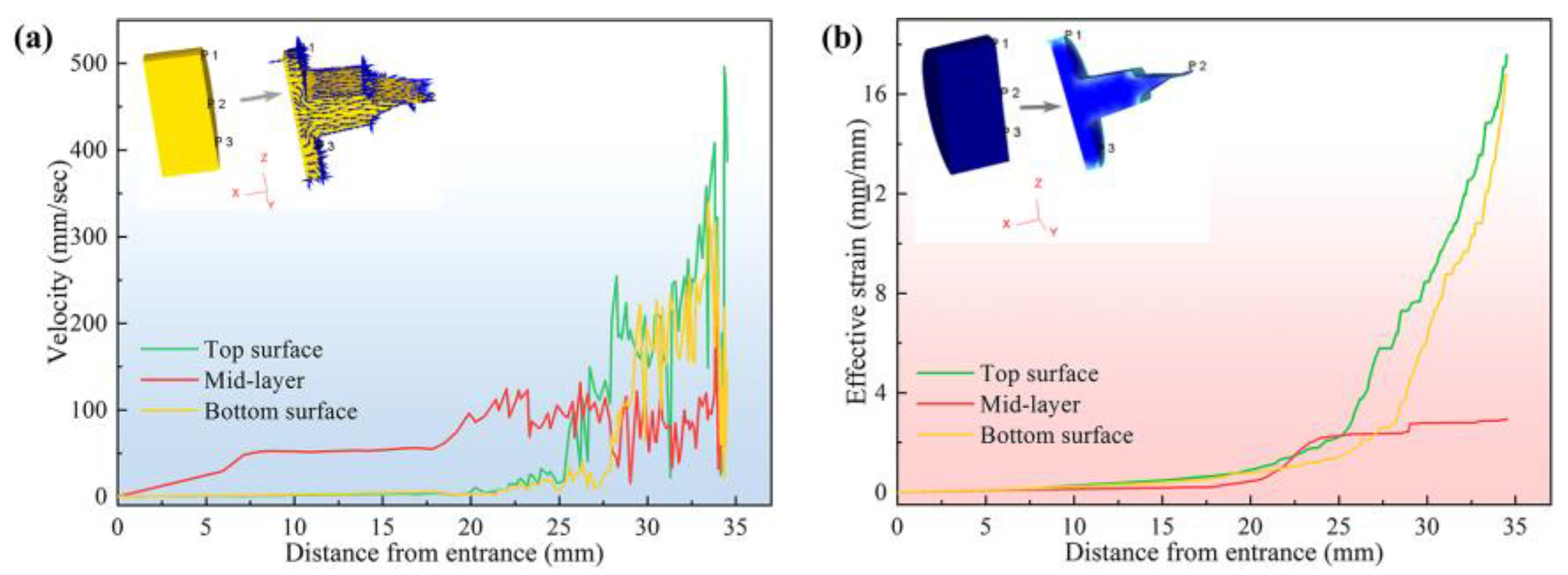

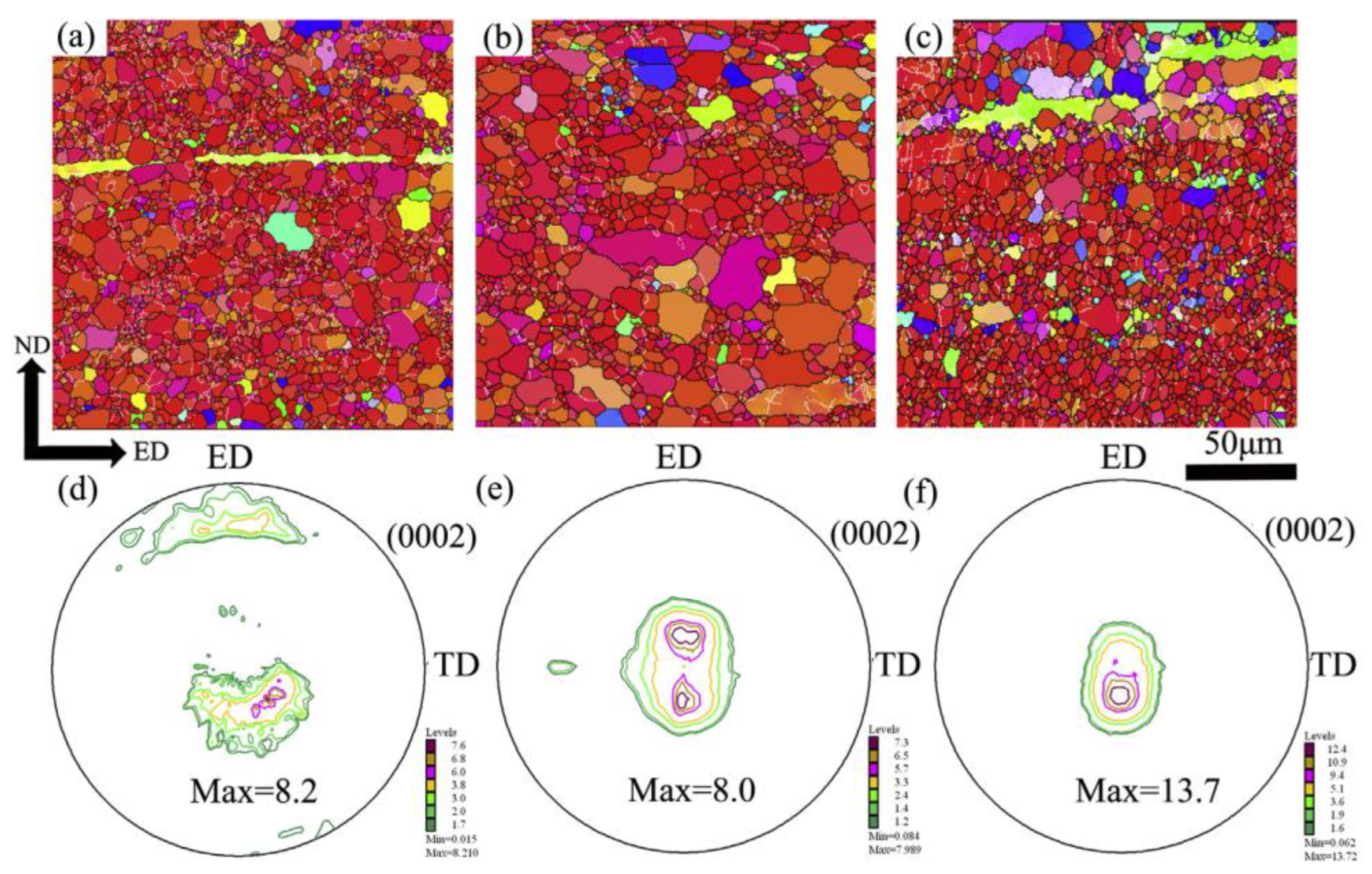

2.1.1. Asymmetric Extrusion (ASE)

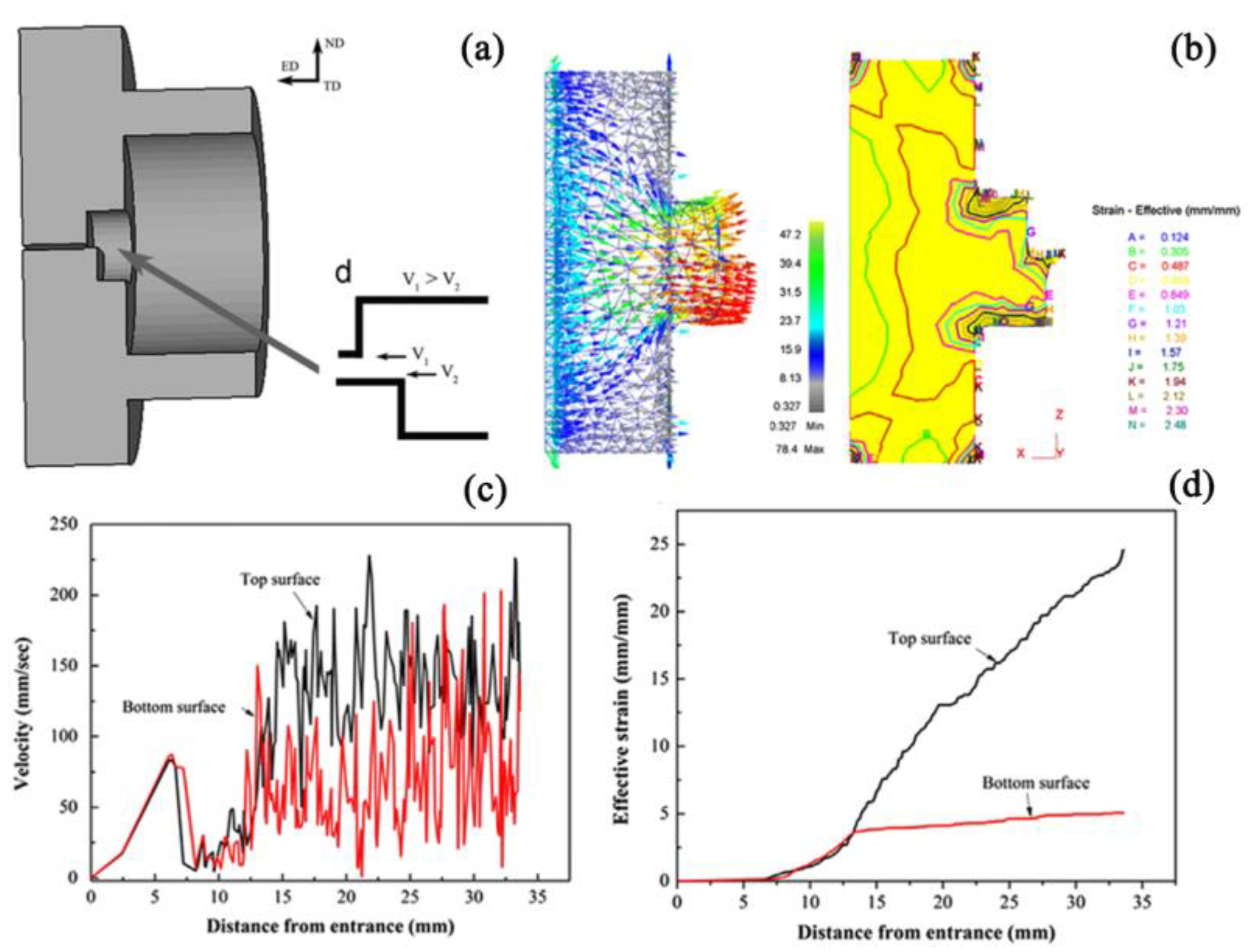

2.1.2. Differential Speed Extrusion (DSE)

2.1.3. Normal Gradient Extrusion (NGE)

2.2. Normal Direction Asymmetric Divergent Die Extrusion Technologies of Mg Alloy

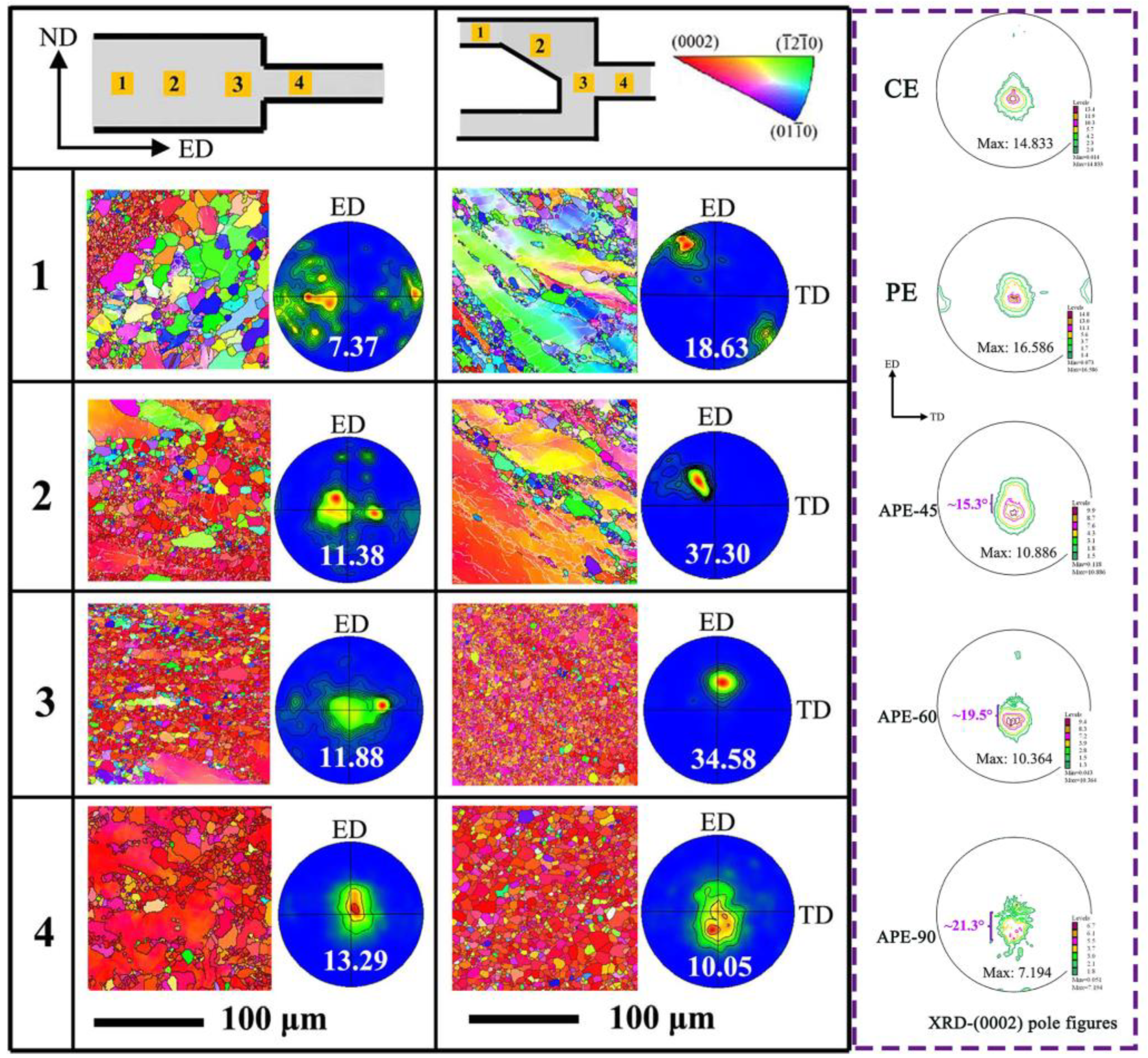

2.2.1. Asymmetric Porthole Die Extrusion (APE)

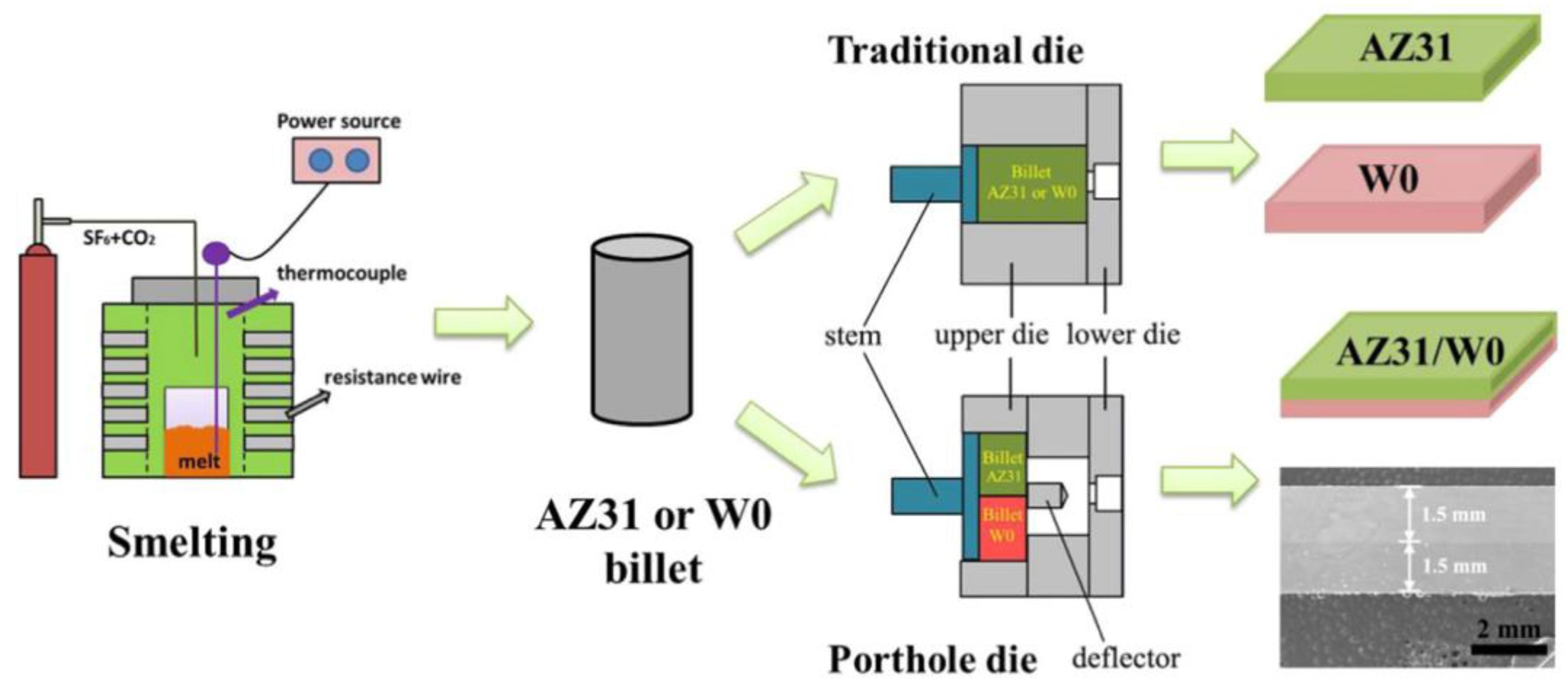

2.2.2. Asymmetric Billet Split Flow Die Extrusion

2.3. Transverse Direction Asymmetric Extrusion Technology for Mg Alloy

2.3.1. Asymmetric Extrusion (ASE)

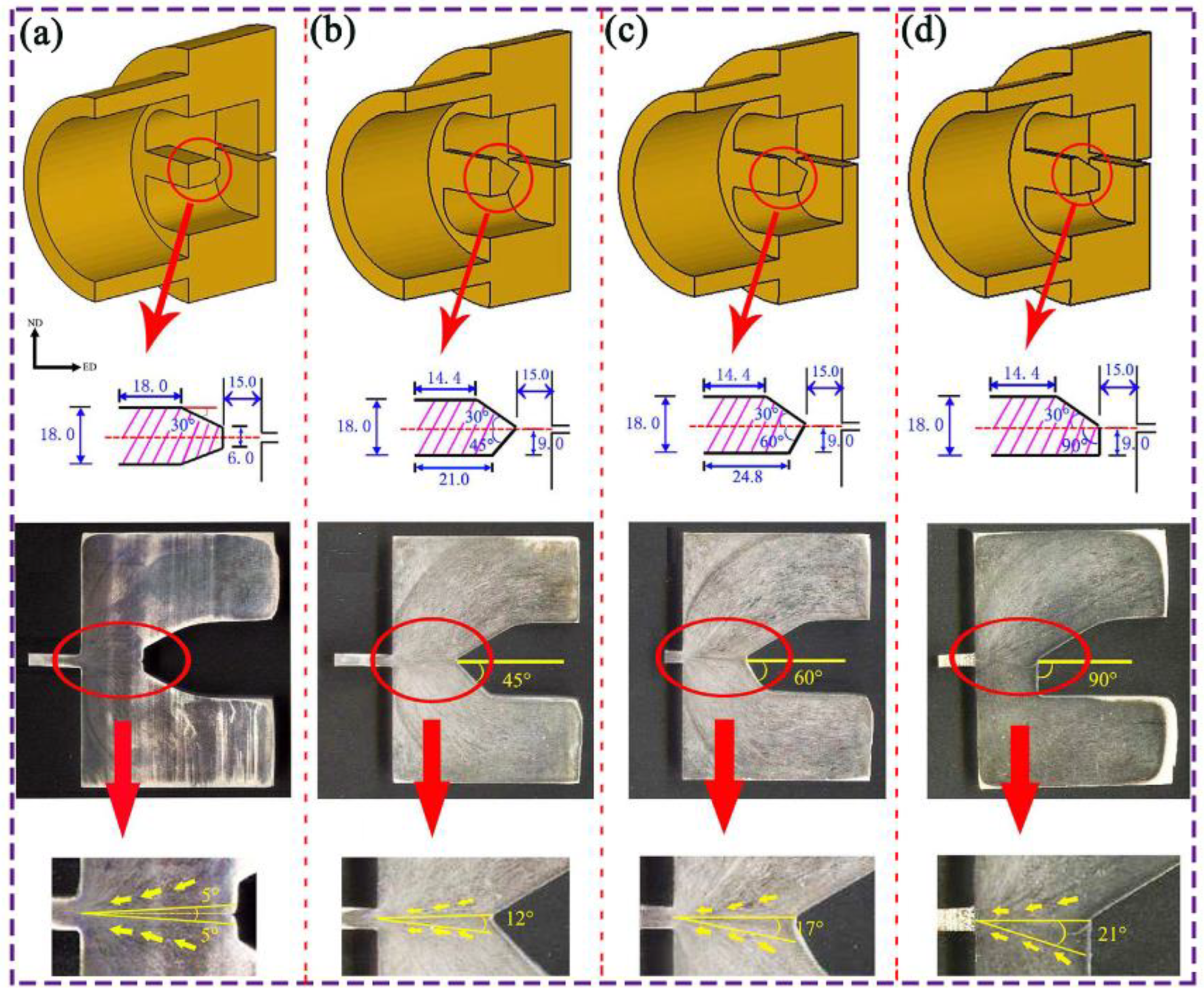

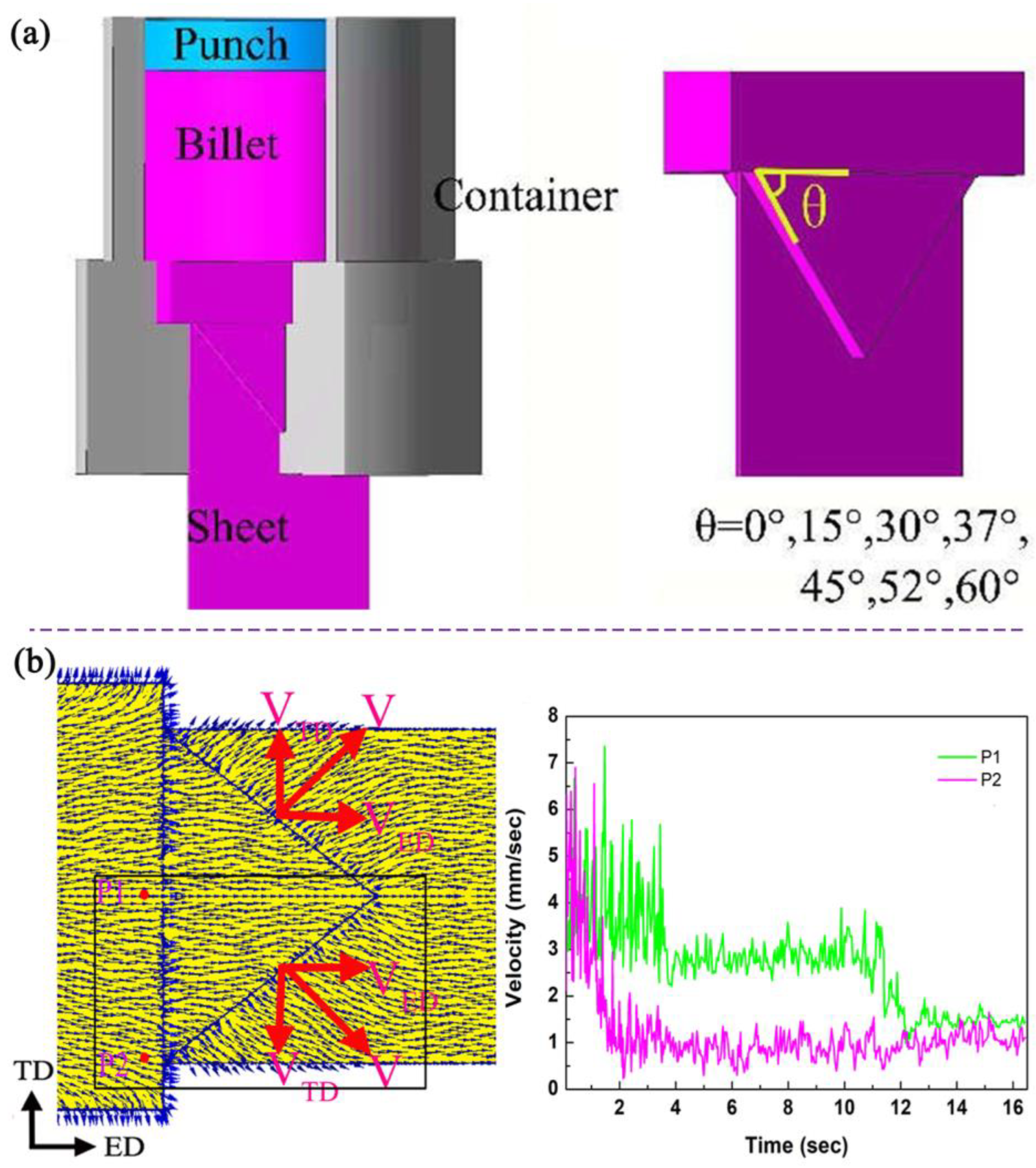

2.3.2. Asymmetric Curve Extrusion (ACE)

3. Conclusions and Outlooks

- (1)

- Mg-Al-Ca-Mn series microalloyed Mg alloys have been developed, whereby adding rare earth elements such as Ce, Y, and Gd, even at low concentrations, strongly weakens the basal textures.

- (2)

- Plastic processing technologies such as equal channel angular rolling (ECAR) and pre-deformation control have been developed, introducing gradient strain into the sheet plane, which is conducive to a large amount of basal slip and tensile twinning opening. As a result, forming a c-axis//RD texture orientation feature with a certain {10-12} twin structure significantly enhances the room temperature formability of Mg alloy sheets.

- (3)

- Wide-width Mg sheet near-isothermal rolling technology has been developed, realizing high-precision rolling of large coil weight wide-width Mg alloy sheets rolls and significantly improving the rolling formability, organization, and performance uniformity of Mg alloy sheets.

- (1)

- The development of low-cost, low-content Mg-Al series Mg alloys and their sheet processing and preparation technology is crucial. This can be achieved by regulating crystal orientation through alloy elements to improve the balance between Mg alloy strength and formability.

- (2)

- Optimizing the plastic deformation strain path and prefabricating the twinning orientation of Mg alloy sheets is necessary. Coupling with Mg alloy recrystallization behavior can form crystal orientations favorable for Mg alloy plastic deformation, ultimately controlling the isotropy and formability of Mg alloy sheets.

- (3)

- Exploring the activity of non-basal <a> dislocations and <c+a> dislocations through plastic deformation strain, further systematically theorizing and experimentally verifying, quantitatively analyzing the relationship between dislocation activity and plastic deformation mechanism, and predicting the formability of Mg alloys.

- (4)

- The development of advanced deformation Mg alloy extrusion die design and comprehensive processing technology, focusing on high strength and toughness, is of paramount importance. It is crucial to establish efficient production and processing technologies for wide-width Mg alloy profiles, along with the refinement of high-precision profile heat treatment, straightening, and other finishing techniques and equipment. Furthermore, the exploration of ultra-wide and high-precision deformation Mg alloy profiles should also be a significant area of investigation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zemkova, M.; Minarik, P.; Dittrich, J.; Bohlen, J.; Kral, R. Individual effect of Y and Nd on the microstructure formation of Mg-Y-Nd alloys processed by severe plastic deformation and their effect on the subsequent mechanical and corrosion properties. J. Magn. Alloys 2023, 11, 509–521. [Google Scholar] [CrossRef]

- Wang, S.; Pan, J.; Xie, W.; Yang, J.; Zhang, W.; Chen, W. Effects of Extrusion Ratio on the Microstructure, Texture and Mechanical Properties of Mg-2.5Nd-0.5Zn-0.5Zr Alloy Sheets. J. Mater. Eng. Perform. 2023, 32, 4834–4845. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, Y.; Geng, L.; Lu, C. Effects of calcium on texture and mechanical properties of hot-extruded Mg-Zn-Ca alloys. Mater. Sci. Eng. A 2012, 539, 56–60. [Google Scholar] [CrossRef]

- Yang, Q.; Jiang, B.; Song, B.; Yu, Z.; He, D.; Chai, Y.; Zhang, J.; Pan, F. The effects of orientation control via tension-compression on microstructural evolution and mechanical behavior of AZ31 Mg alloy sheet. J. Magn. Alloys 2022, 10, 411–422. [Google Scholar] [CrossRef]

- Bian, M.Z.; Sasaki, T.T.; Suh, B.C.; Nakata, T.; Kamado, S.; Hono, K. A heat-treatable Mg-Al-Ca-Mn-Zn sheet alloy with good room temperature formability. Scr. Mater. 2017, 138, 151–155. [Google Scholar] [CrossRef]

- Jin, H.; Amirkhiz, B.S.; Lloyd, D.J. Improvement of Superplasticity in High-Mg Aluminum Alloys by Sacrifice of Some Room Temperature Formability. Metall. Mater. Trans. A 2018, 49, 1962–1979. [Google Scholar] [CrossRef]

- Yu, H.; Li, C.; Xin, Y.; Chapuis, A.; Huang, X.; Liu, Q. The mechanism for the high dependence of the Hall-Petch slope for twinning/slip on texture in Mg alloys. Acta Mater. 2017, 128, 313–326. [Google Scholar] [CrossRef]

- Sabokpa, O.; Zarei-Hanzaki, A.; Abedi, H.R. An investigation into the hot ductility behavior of AZ81 magnesium alloy. Mater. Sci. Eng. A 2012, 550, 31–38. [Google Scholar] [CrossRef]

- Wu, Z.; Ahmad, R.; Yin, B.; Sandlöbes, S.; Curtin, W.A. Mechanistic origin and prediction of enhanced ductility in magnesium alloys. Science 2018, 359, 447–452. [Google Scholar] [CrossRef]

- Basu, S.; Dogan, E.; Kondori, B.; Karaman, I.; Benzerga, A.A. Towards designing anisotropy for ductility enhancement: A theory-driven investigation in Mg-alloys. Acta Mater. 2017, 131, 349–362. [Google Scholar] [CrossRef]

- Yi, S.B.; Davies, C.H.J.; Brokmeier, H.G.; Bolmaro, R.E.; Kainer, K.U.; Homeyer, J. Deformation and texture evolution in AZ31 magnesium alloy during uniaxial loading. Acta Mater. 2006, 54, 549–562. [Google Scholar] [CrossRef]

- Agnew, S.R.; Duygulu, Ö. Plastic anisotropy and the role of non-basal slip in magnesium alloy AZ31B. Int. J. Plast. 2005, 21, 1161–1193. [Google Scholar] [CrossRef]

- Agnew, S.R.; Singh, A.; Calhoun, C.A.; Mulay, R.P.; Bhattacharyya, J.J.; Somekawa, H.; Mukai, T.; Clausen, B.; Wu, P.D. In-situ neutron diffraction of a quasicrystal-containing Mg alloy interpreted using a new polycrystal plasticity model of hardening due to {10.2} tensile twinning. Int. J. Plast. 2018, 100, 34–51. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, D.; Xu, T.; Chen, S.; Zhang, Y.; Li, X.; Zhang, J. Achieving high-strength in Mg-0.8Zn-0.2Zr (wt.%) alloy extruded at low temperature. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2021, 822, 141657. [Google Scholar] [CrossRef]

- Yang, Q.; Jiang, B.; Song, B.; Yu, D.; Chai, S.; Zhang, J.; Pan, F. Mechanical behavior and microstructure evolution for extruded AZ31 sheet under side direction strain. Prog. Nat. Sci.-Mater. Int. 2020, 30, 270–277. [Google Scholar] [CrossRef]

- Zhou, C.; Liang, G.; Liu, Y.; Zhang, H.; Chen, X.; Li, Y. Pore structure of porous Mg-1Mn-xZn alloy fabricated by metal-gas eutectic unidirectional solidification. J. Magn. Alloys 2022, 10, 2137–2146. [Google Scholar] [CrossRef]

- Zhu, S.Q.; Ringer, S.P. On the role of twinning and stacking faults on the crystal plasticity and grain refinement in magnesium alloys. Acta Mater. 2018, 144, 365–375. [Google Scholar] [CrossRef]

- Zhang, X.; Kevorkov, D.; Jung, I.-H.; Pekguleryuz, M. Phase equilibria on the ternary Mg-Mn-Ce system at the Mg-rich corner. J. Alloys Compd. 2009, 482, 420–428. [Google Scholar] [CrossRef]

- Ji, H.; Wu, G.; Liu, W.; Sun, J.; Ding, W. Role of extrusion temperature on the microstructure evolution and tensile properties of an ultralight Mg-Li-Zn-Er alloy. J. Alloys Compd. 2021, 876, 160181. [Google Scholar] [CrossRef]

- Li, R.G.; Li, H.R.; Pan, H.C.; Xie, D.S.; Zhang, J.H.; Fang, D.Q.; Dai, Y.Q.; Zhao, D.Y.; Zhang, H. Achieving exceptionally high strength in binary Mg-13Gd alloy by strong texture and substantial precipitates. Scr. Mater. 2021, 193, 142–146. [Google Scholar] [CrossRef]

- Li, Y.; Nie, K.; Deng, K.; Yang, A. Microstructures and Mechanical Properties of Low-Alloyed Mg-Zn-Y Magnesium Alloy. Rare Metall. Mater. Eng. 2021, 50, 1425–1432. [Google Scholar]

- Wang, S.; Zhang, W.; Yang, J.; Pan, J.; Wang, H.; Chen, W.; Cui, G. Evolution of Microstructures, Texture, Damping and Mechanical Properties of Hot Extruded Mg-Nd-Zn-Zr Alloy. J. Mater. Eng. Perform. 2021, 30, 8872–8882. [Google Scholar] [CrossRef]

- Zhang, C.; Peng, C.; Huang, J.; Zhao, Y.; Han, T.; Wang, G.; Wu, L.; Huang, G. Improving Mechanical Properties of Mg-Sc Alloy by Surface AZ31 Layer. Metals 2021, 11, 2021. [Google Scholar] [CrossRef]

- Zhuang, Y.; Zhang, Y.; Zeng, Q.; Li, J. Coupling the semi-solid treatment and hot extrusion to strengthen a Mg-Zn-Gd alloy containing I-phase. Mater. Lett. 2021, 287, 129294. [Google Scholar] [CrossRef]

- Bairagi, D.; Mandal, S. A comprehensive review on biocompatible Mg-based alloys as temporary orthopaedic implants: Current status, challenges, and future prospects. J. Magn. Alloys 2022, 10, 627–669. [Google Scholar] [CrossRef]

- Suzuki, A.; Saddock, N.; Jones, J.; Pollock, T. Structure and transition of eutectic (Mg,Al)Ca Laves phase in a die-cast Mg-Al-Ca base alloy. Scr. Mater. 2004, 51, 1005–1010. [Google Scholar] [CrossRef]

- Che, B.; Lu, L.; Kang, W.; Zhong, Y.; Ma, M.; Liu, L.; Wu, Z. Effect of Expansion Sphere Diameter on Deformation Behavior of AZ31 Mg Alloy during Extrusion. J. Mater. Eng. Perform. 2022, 31, 8512–8521. [Google Scholar] [CrossRef]

- Du, P.; Mei, D.; Furushima, T.; Zhu, S.; Wang, L.; Zhou, Y.; Guan, S. In vitro corrosion properties of HTHEed Mg-Zn-Y-Nd alloy microtubes for stent applications: Influence of second phase particles and crystal orientation. J. Magn. Alloys 2022, 10, 1286–1295. [Google Scholar] [CrossRef]

- Zhang, D.; Pan, H.; Li, J.; Xie, D.; Zhang, D.; Che, C.; Meng, J.; Qin, G. Fabrication of exceptionally high-strength Mg-4Sm-0.6Zn-0.4Zr alloy via low-temperature extrusion. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2022, 833, 142565. [Google Scholar] [CrossRef]

- Xu, Y.; Li, J.; Qi, M.; Guo, W.; Deng, Y. A newly developed Mg-Zn-Gd-Mn-Sr alloy for degradable implant applications: Influence of extrusion temperature on microstructure, mechanical properties and in vitro corrosion behavior. Mater. Charact. 2022, 188, 111867. [Google Scholar] [CrossRef]

- Zhai, Y.; Hou, X.; Yuan, Z.; Zhang, P.; Guan, Q. Analysis of Crystallographic Texture and Mechanical Anisotropy of an Extruded Mg-RE Alloy. Rare Metall. Mater. Eng. 2018, 47, 1341–1346. [Google Scholar] [CrossRef]

- Meng, S.J.; Yu, H.; Fan, S.D.; Kim, Y.M.; Park, S.H.; Zhao, W.M.; You, B.S.; Shin, K.S. A high-ductility extruded Mg-Bi-Ca alloy. Mater. Lett. 2020, 261, 127066. [Google Scholar] [CrossRef]

- Bian, M.; Huang, X.; Mabuchi, M.; Chino, Y. Compositional optimization of Mg-Zn-Sc sheet alloys for enhanced room temperature stretch formability. J. Alloys Compd. 2020, 818, 152891. [Google Scholar] [CrossRef]

- Jiang, M.G.; Xu, C.; Nakata, T.; Yan, H.; Chen, R.S.; Kamado, S. Enhancing strength and ductility of Mg-Zn-Gd alloy via slow-speed extrusion combined with pre-forging. J. Alloys Compd. 2017, 694, 1214–1223. [Google Scholar] [CrossRef]

- Wang, H.Y.; Yu, Z.P.; Zhang, L.; Liu, C.G.; Zha, M.; Wang, C.; Jiang, Q.C. Achieving high strength and high ductility in magnesium alloy using hard-plate rolling (HPR) process. Sci. Rep. 2015, 5, 17100. [Google Scholar] [CrossRef] [PubMed]

- Kim, W.J.; Hong, S.I.; Lee, J.M.; Kim, S.H. Dispersion of TiC particles in an in situ aluminum matrix composite by shear plastic flow during high-ratio differential speed rolling. Mater. Sci. Eng. A 2013, 559, 325–332. [Google Scholar] [CrossRef]

- Chang, L.L.; Kang, S.B.; Cho, J.H. Influence of strain path on the microstructure evolution and mechanical properties in AM31 magnesium alloy sheets processed by differential speed rolling. Mater. Des. 2013, 44, 144–148. [Google Scholar] [CrossRef]

- Naghdi, F.; Mahmudi, R.; Kang, J.Y.; Kim, H.S. Contributions of different strengthening mechanisms to the shear strength of an extruded Mg-4Zn-0.5Ca alloy. Philos. Mag. 2015, 95, 3452–3466. [Google Scholar] [CrossRef]

- Mao, B.; Li, B.; Lin, D.; Liao, Y. Enhanced room temperature stretch formability of AZ31B magnesium alloy sheet by laser shock peening. Mater. Sci. Eng. A 2019, 756, 219–225. [Google Scholar] [CrossRef]

- Lee, J.U.; Kim, S.-H.; Kim, Y.J.; Park, S.H. Improvement in bending formability of rolled magnesium alloy through precompression and subsequent annealing. J. Alloys Compd. 2019, 787, 519–526. [Google Scholar] [CrossRef]

- Apachitei, I.; Fratila-Apachitei, L.E.; Duszczyk, J. Microgalvanic activity of an Mg-Al-Ca-based alloy studied by scanning Kelvin probe force microscopy. Scr. Mater. 2007, 57, 1012–1015. [Google Scholar] [CrossRef]

- Barnett, M.R. Importance of propagation in controlling the twinning stress in Mg. Scr. Mater. 2019, 162, 447–450. [Google Scholar] [CrossRef]

- Liu, X.-Y.; Lu, L.-W.; Sheng, K.; Zhou, T. Microstructure and Texture Evolution during the Direct Extrusion and Bending–Shear Deformation of AZ31 Magnesium Alloy. Acta Metall. Sin.-Engl. Lett. 2018, 32, 710–718. [Google Scholar] [CrossRef]

- Beygelzimer, Y.; Kulagin, R.; Estrin, Y.; Toth, L.S.; Kim, H.S.; Latypov, M.I. Twist Extrusion as a Potent Tool for Obtaining Advanced Engineering Materials: A Review. Adv. Eng. Mater. 2017, 19, 1600873. [Google Scholar] [CrossRef]

- Wang, F.; Zheng, R.; Chen, J.; Lyu, S.; Li, Y.; Xiao, W.; Ma, C. Significant improvement in the strength of Mg-Al-Zn-Ca-Mn extruded alloy by tailoring the initial microstructure. Vacuum 2019, 161, 429–433. [Google Scholar] [CrossRef]

- Zheng, L.; Nie, H.; Zhang, W.; Liang, W.; Wang, Y. Microstructural refinement and improvement of mechanical properties of hot-rolled Mg-3Al-Zn alloy sheets subjected to pre-extrusion and Al-Si alloying. Mater. Sci. Eng. A 2018, 722, 58–68. [Google Scholar] [CrossRef]

- Zhao, L.; Xin, Y.; Wu, Y.; Liu, Q. The texture dependence of strength in slip and twinning predominant deformations of Mg-3Al-1Zn alloy. Mater. Sci. Eng. A 2018, 717, 34–40. [Google Scholar] [CrossRef]

- Yang, H.W.; Widiantara, I.P.; Ko, Y.G. Effect of deformation path on texture and tension properties of submicrocrystalline Al-Mg-Si alloy fabricated by differential speed rolling. Mater. Lett. 2018, 213, 54–57. [Google Scholar] [CrossRef]

- Jin, S.-C.; Cha, J.W.; Lee, J.H.; Lee, T.; Han, S.H.; Park, S.H. Improvement in tensile strength of extruded Mg-5Bi alloy through addition of Sn and its underlying strengthening mechanisms. J. Magn. Alloys 2022, 10, 3100–3112. [Google Scholar] [CrossRef]

- Jeong, H.T.; Kim, W.J. Critical review of superplastic magnesium alloys with emphasis on tensile elongation behavior and deformation mechanisms. J. Magn. Alloys 2022, 10, 1133–1153. [Google Scholar] [CrossRef]

- Jafari, H.; Tehrani, A.H.M.; Tehrani, M.; Heydari, M. Effect of extrusion process on microstructure and mechanical and corrosion properties of biodegradable Mg-5Zn-1.5Y magnesium alloy. Int. J. Miner. Metall. Mater. 2022, 29, 490–502. [Google Scholar] [CrossRef]

- Zhou, M.; Huang, X.; Morisada, Y.; Fujii, H.; Chino, Y. Effects of Ca and Sr additions on microstructure, mechanical properties, and ignition temperature of hot-rolled Mg-Zn alloy. Mater. Sci. Eng. A 2020, 769, 138474. [Google Scholar] [CrossRef]

- Zhou, X.; Ha, C.; Yi, S.; Bohlen, J.; Schell, N.; Chi, Y.; Zheng, M.; Brokmeier, H.-G. Texture and Lattice Strain Evolution during Tensile Loading of Mg-Zn Alloys Measured by Synchrotron Diffraction. Metals 2020, 10, 124. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, S.; Wu, R.; Hou, L.; Zhang, M. Recent developments in high-strength Mg-RE-based alloys: Focusing on Mg-Gd and Mg-Y systems. J. Magn. Alloys 2018, 6, 277–291. [Google Scholar] [CrossRef]

- Yang, Q.; Jiang, B.; Tian, Y.; Liu, W.; Pan, F. A tilted weak texture processed by an asymmetric extrusion for magnesium alloy sheets. Mater. Lett. 2013, 100, 29–31. [Google Scholar] [CrossRef]

- Yang, Q.; Jiang, B.; Zhou, G.; Dai, J.; Pan, F. Influence of an asymmetric shear deformation on microstructure evolution and mechanical behavior of AZ31 magnesium alloy sheet. Mater. Sci. Eng. A 2014, 590, 440–447. [Google Scholar] [CrossRef]

- Yang, Q.-S.; Jiang, B.; Yu, Z.-J.; Dai, Q.-W.; Luo, S.-Q. Effect of Extrusion Strain Path on Microstructure and Properties of AZ31 Magnesium Alloy Sheet. Acta Metall. Sin.-Engl. Lett. 2015, 28, 1257–1263. [Google Scholar] [CrossRef]

- Yang, Q.; Jiang, B.; He, J.; Song, B.; Liu, W.; Dong, H.; Pan, F. Tailoring texture and refining grain of magnesium alloy by differential speed extrusion process. Mater. Sci. Eng. A 2014, 612, 187–191. [Google Scholar] [CrossRef]

- Xu, J.; Yang, T.; Jiang, B.; Song, J.; He, J.; Wang, Q.; Chai, Y.; Huang, G.; Pan, F. Improved mechanical properties of Mg-3Al-1Zn alloy sheets by optimizing the extrusion die angles: Microstructural and texture evolution. J. Alloys Compd. 2018, 762, 719–729. [Google Scholar] [CrossRef]

- Xu, J.; Liu, W.; Jiang, B.; Yang, H.; Li, X.; Kang, Y.; Zhou, N.; Zhang, W.; Zheng, K.; Pan, F. Forming novel texture and enhancing the formability in Mg-3Al-Zn alloy sheets fabricated by transverse gradient extrusion. J. Mater. Res. Technol. 2022, 18, 3143–3149. [Google Scholar] [CrossRef]

- Wang, Q.; Song, J.; Jiang, B.; Tang, A.; Chai, Y.; Yang, T.; Huang, G.; Pan, F. An investigation on microstructure, texture and formability of AZ31 sheet processed by asymmetric porthole die extrusion. Mater. Sci. Eng. A 2018, 720, 85–97. [Google Scholar] [CrossRef]

- Wang, Q.; Shen, Y.; Jiang, B.; Tang, A.; Song, J.; Jiang, Z.; Yang, T.; Huang, G.; Pan, F. Enhanced stretch formability at room temperature for Mg-Al-Zn/Mg-Y laminated composite via porthole die extrusion. Mater. Sci. Eng. A 2018, 731, 184–194. [Google Scholar] [CrossRef]

- Xu, J.; Jiang, B.; Kang, Y.; Zhao, J.; Zhang, W.; Zheng, K.; Pan, F. Tailoring microstructure and texture of Mg-3Al-1Zn alloy sheets through curve extrusion process for achieving low planar anisotropy. J. Mater. Sci. Technol. 2022, 113, 48–60. [Google Scholar] [CrossRef]

- Wang, Z.; Gu, R.; Chen, S.; Wang, W.; Wei, X. Effect of upper-die temperature on the formability of AZ31B magnesium alloy sheet in stamping. J. Mater. Process. Technol. 2018, 257, 180–190. [Google Scholar] [CrossRef]

- Wang, W.; Ma, L.; Chai, S.; Zhang, W.; Chen, W.; Feng, Y.; Cui, G. Role of one direction strong texture in stretch formability for ZK60 magnesium alloy sheet. Mater. Sci. Eng. A 2018, 730, 162–167. [Google Scholar] [CrossRef]

- Sun, J.; Yang, Z.; Liu, H.; Han, J.; Wu, Y.; Zhuo, X.; Song, D.; Jiang, J.; Ma, A.; Wu, G. Tension-compression asymmetry of the AZ91 magnesium alloy with multi-heterogenous microstructure. Mater. Sci. Eng. A 2019, 759, 703–707. [Google Scholar] [CrossRef]

- Xu, J.; Song, J.; Jiang, B.; He, J.; Wang, Q.; Liu, B.; Huang, G.; Pan, F. Effect of effective strain gradient on texture and mechanical properties of Mg-3Al-1Zn alloy sheets produced by asymmetric extrusion. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2017, 706, 172–180. [Google Scholar] [CrossRef]

- Jin, Z.-Z.; Zha, M.; Wang, S.-Q.; Wang, S.-C.; Wang, C.; Jia, H.-L.; Wang, H.-Y. Alloying design and microstructural control strategies towards developing Mg alloys with enhanced ductility. J. Magn. Alloys 2022, 10, 1191–1206. [Google Scholar] [CrossRef]

- Yang, Q.S.; Jiang, B.; Dai, J.H.; Xiang, Q.; Pan, F.S. Microstructure and mechanical behaviour of asymmetric extruded Mg-3Al-1Zn alloy sheets. Mater. Sci. Technol. 2013, 29, 710–714. [Google Scholar] [CrossRef]

- Kim, W.J.; Yoo, S.J.; Chen, Z.H.; Jeong, H.T. Grain size and texture control of Mg-3Al-1Zn alloy sheet using a combination of equal-channel angular rolling and high-speed-ratio differential speed-rolling processes. Scr. Mater. 2009, 60, 897–900. [Google Scholar] [CrossRef]

- Huang, X.; Suzuki, K.; Watazu, A.; Shigematsu, I.; Saito, N. Microstructural and textural evolution of AZ31 magnesium alloy during differential speed rolling. J. Alloys Compd. 2009, 479, 726–731. [Google Scholar] [CrossRef]

- Stanford, N.; Sha, G.; Xia, J.H.; Ringer, S.P.; Barnett, M.R. Solute segregation and texture modification in an extruded magnesium alloy containing gadolinium. Scr. Mater. 2011, 65, 919–921. [Google Scholar] [CrossRef]

- Stanford, N.; Taylor, A.S.; Cizek, P.; Siska, F.; Ramajayam, M.; Barnett, M.R. Twinning in magnesium-based lamellar microstructures. Scr. Mater. 2012, 67, 704–707. [Google Scholar] [CrossRef]

- Suzuki, A.; Saddock, N.D.; Jones, J.W.; Pollock, T.M. Solidification paths and eutectic intermetallic phases in Mg-Al-Ca ternary alloys. Acta Mater. 2005, 53, 2823–2834. [Google Scholar] [CrossRef]

- Tekumalla, S.; Bibhanshu, N.; Suwas, S.; Gupta, M. Superior ductility in magnesium alloy-based nanocomposites: The crucial role of texture induced by nanoparticles. J. Mater. Sci. 2019, 54, 8711–8718. [Google Scholar] [CrossRef]

- Pan, H.; Wang, F.; Feng, M.; Jin, L.; Dong, J.; Wu, P. Mechanical behavior and microstructural evolution in rolled Mg-3Al-1Zn-0.5Mn alloy under large strain simple shear. Mater. Sci. Eng. A 2018, 712, 585–591. [Google Scholar] [CrossRef]

- Guan, D.; Rainforth, W.M.; Gao, J.; Sharp, J.; Wynne, B.; Ma, L. Individual effect of recrystallisation nucleation sites on texture weakening in a magnesium alloy: Part 1—Double twins. Acta Mater. 2017, 135, 14–24. [Google Scholar] [CrossRef]

- Cepeda-Jiménez, C.M.; Prado-Martínez, C.; Pérez-Prado, M.T. Understanding the high temperature reversed yield asymmetry in a Mg-rare earth alloy by slip trace analysis. Acta Mater. 2018, 145, 264–277. [Google Scholar] [CrossRef]

- Shi, H.; Xu, C.; Hu, X.; Gan, W.; Wu, K.; Wang, X. Improving the Young’s modulus of Mg via alloying and compositing—A short review. J. Magn. Alloys 2022, 10, 2009–2024. [Google Scholar] [CrossRef]

- Pulido-Gonzalez, N.; Hidalgo-Manrique, P.; Garcia-Rodriguez, S.; Torres, B.; Rams, J. Effect of heat treatment on the mechanical and biocorrosion behaviour of two Mg-Zn-Ca alloys. J. Magn. Alloys 2022, 10, 540–554. [Google Scholar] [CrossRef]

- Liu, J.C.; Hu, J.; Nie, X.Y.; Li, H.X.; Du, Q.; Zhang, J.S.; Zhuang, L.Z. The interface bonding mechanism and related mechanical properties of Mg/Al compound materials fabricated by insert molding. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2015, 635, 70–76. [Google Scholar] [CrossRef]

- Zhao, K.N.; Li, H.X.; Luo, J.R.; Liu, Y.J.; Du, Q.; Zhang, J.S. Interfacial bonding mechanism and mechanical properties of novel AZ31/WE43 bimetal composites fabricated by insert molding method. J. Alloys Compd. 2017, 729, 344–353. [Google Scholar] [CrossRef]

- Zhao, K.N.; Liu, J.C.; Nie, X.Y.; Li, Y.; Li, H.X.; Du, Q.; Zhuang, L.Z.; Zhang, J.S. Interface formation in magnesium-magnesium bimetal composites fabricated by insert molding method. Mater. Des. 2016, 91, 122–131. [Google Scholar] [CrossRef]

- Wu, D.; Chen, R.-S.; Han, E.-H. Bonding interface zone of Mg-Gd-Y/Mg-Zn-Gd laminated composite fabricated by equal channel angular extrusion. Trans. Nonferrous Met. Soc. China 2010, 20, S613–S618. [Google Scholar] [CrossRef]

- Thirumurugan, M.; Rao, S.A.; Kumaran, S.; Rao, T.S. Improved ductility in ZM21 magnesium-aluminium macrocomposite produced by co-extrusion. J. Mater. Process. Technol. 2011, 211, 1637–1642. [Google Scholar] [CrossRef]

- Liu, X.B.; Chen, R.S.; Han, E.H. Preliminary investigations on the Mg-Al-Zn/Al laminated composite fabricated by equal channel angular extrusion. J. Mater. Process. Technol. 2009, 209, 4675–4681. [Google Scholar] [CrossRef]

- Wu, H.; Wang, T.; Wu, R.; Hou, L.; Zhang, J.; Li, X.; Zhang, M. Effects of Annealing Process on the Interface of Alternate alpha/beta Mg-Li Composite Sheets Prepared by Accumulative Roll Bonding. J. Mater. Process. Technol. 2018, 254, 265–276. [Google Scholar] [CrossRef]

- Negendank, M.; Mueller, S.; Reimers, W. Coextrusion of Mg-Al macro composites. J. Mater. Process. Technol. 2012, 212, 1954–1962. [Google Scholar] [CrossRef]

- Mozaffari, A.; Manesh, H.D.; Janghorban, K. Evaluation of mechanical properties and structure of multilayered Al/Ni composites produced by accumulative roll bonding (ARB) process. J. Alloys Compd. 2010, 489, 103–109. [Google Scholar] [CrossRef]

- Xin, Y.; Hong, R.; Feng, B.; Yu, H.; Wu, Y.; Liu, Q. Fabrication of Mg/AL multilayer plates using an accumulative extrusion bonding process. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2015, 640, 210–216. [Google Scholar] [CrossRef]

- Meng, F.; Lv, S.; Yang, Q.; Qiu, X.; Yan, Z.; Duan, Q.; Meng, J. Multiplex intermetallic phases in a gravity die-cast Mg-6.0Zn-1.5Nd-0.5Zr (wt%) alloy. J. Magn. Alloys 2022, 10, 209–223. [Google Scholar] [CrossRef]

- Luginin, N.A.; Eroshenko, A.Y.; Legostaeva, E.V.; Schmidt, J.; Tolmachev, A.I.; Uvarkin, P.V.; Sharkeev, Y.P. Effect of Severe Plastic Deformation by Extrusion on Microstructure and Physical and Mechanical Properties of Mg-Y-Nd and Mg-Ca Alloys. Technol. Phys. 2022, 67, 791–797. [Google Scholar] [CrossRef]

- Ling, L.; Cai, S.; Li, Q.; Sun, J.; Bao, X.; Xu, G. Recent advances in hydrothermal modification of calcium phosphorus coating on magnesium alloy. J. Magn. Alloys 2022, 10, 62–80. [Google Scholar] [CrossRef]

- Guo, L.; Wang, J.; Yun, X.; Chen, Z. Fabrication of aluminum-magnesium clad composites by continuous extrusion. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2021, 802, 140670. [Google Scholar] [CrossRef]

- Bao, J.; Li, Q.; Chen, X.; Zhang, Q.; Chen, Z. Microstructure and texture evolution with Sm addition in extruded Mg-Gd-Sm-Zr alloy. Mater. Res. Express 2021, 8, 096523. [Google Scholar] [CrossRef]

| Composition (wt%) | Extrusion Technologies | Samples | Mechanical Properties | Ref. | ||||

|---|---|---|---|---|---|---|---|---|

| UTS (MPa) | YS (MPa) | FE (%) | r | n | ||||

| AZ31 | Conventional extrusion (CE) | 0° | 335.6 | 156.2 | 20.0 | 2.14 | 0.27 | [67] |

| 45° | 337.4 | 166.6 | 21.0 | 2.08 | 0.26 | |||

| 90° | 328.3 | 196.3 | 16.4 | 2.87 | 0.22 | |||

| AZ31 | Asymmetric extrusion (ASE) | 0° | 315.4 | 149.5 | 16.4 | 1.00 | 0.34 | [55] |

| 45° | 326.4 | 124.7 | 23.7 | |||||

| 90° | 344.3 | 135.7 | 22.1 | |||||

| AZ31 | Differential speed extrusion (DSE) | 0° | 352.8 | 179.9 | 20.1 | — | [58] | |

| 45° | 364.3 | 198.3 | 22.8 | |||||

| 90° | 341.5 | 225.0 | 18.7 | |||||

| AZ31 | Normal gradient extrusion(NGE, 45°) | 0° | 342.6 | 151.1 | 20.9 | 1.96 | 0.27 | [59] |

| 45° | 345.1 | 152.5 | 22.9 | 1.87 | 0.28 | |||

| 90° | 349.1 | 182.3 | 18.5 | 2.43 | 0.26 | |||

| AZ31 | Transverse gradient extrusion (TGE, 52°) | 0° | 350.1 | 210.3 | 22.1 | 2.85 | 0.26 | [60] |

| 45° | 356.9 | 102.1 | 30.0 | 1.15 | 0.53 | |||

| 90° | 350.7 | 117.2 | 26.5 | 1.30 | 0.45 | |||

| AZ31 | Asymmetric porthole die extrusion (APE, 45°) | 0° | 337.6 | 180.8 | 21.9 | 2.71 | 0.22 | [61] |

| 45° | 379.5 | 180.8 | 26.2 | 2.94 | 0.29 | |||

| 90° | 389.9 | 180.8 | 25.1 | 2.01 | 0.34 | |||

| AZ31/W0 | Asymmetric material composition extrusion | 0° | 300.9 | 160.3 | 18.7 | — | [62] | |

| AZ31 | Asymmetric curve extrusion (ACE) | 0° | 329.5 | 172.2 | 19.8 | 1.85 | 0.26 | [63] |

| 45° | 333.4 | 148.6 | 24.5 | 1.67 | 0.29 | |||

| 90° | 337.6 | 152.6 | 21.9 | 1.37 | 0.30 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Q.; Zhang, D.; Peng, P.; Wei, G.; Zhang, J.; Jiang, B.; Pan, F. Asymmetric Extrusion Technology of Mg Alloy: A Review. Materials 2023, 16, 5255. https://doi.org/10.3390/ma16155255

Yang Q, Zhang D, Peng P, Wei G, Zhang J, Jiang B, Pan F. Asymmetric Extrusion Technology of Mg Alloy: A Review. Materials. 2023; 16(15):5255. https://doi.org/10.3390/ma16155255

Chicago/Turabian StyleYang, Qingshan, Dan Zhang, Peng Peng, Guobing Wei, Jianyue Zhang, Bin Jiang, and Fusheng Pan. 2023. "Asymmetric Extrusion Technology of Mg Alloy: A Review" Materials 16, no. 15: 5255. https://doi.org/10.3390/ma16155255

APA StyleYang, Q., Zhang, D., Peng, P., Wei, G., Zhang, J., Jiang, B., & Pan, F. (2023). Asymmetric Extrusion Technology of Mg Alloy: A Review. Materials, 16(15), 5255. https://doi.org/10.3390/ma16155255