Effect of Organic Matter Components on the Mechanical Properties of Cemented Soil

Abstract

:1. Introduction

2. Materials and Methods

2.1. Test Materials

2.2. Experimental Design and Sample Preparation

2.3. Unconfined Compressive Strength Test

2.4. Resistivity Test

3. Results

3.1. Uniaxial Strength and Deformation Characteristics

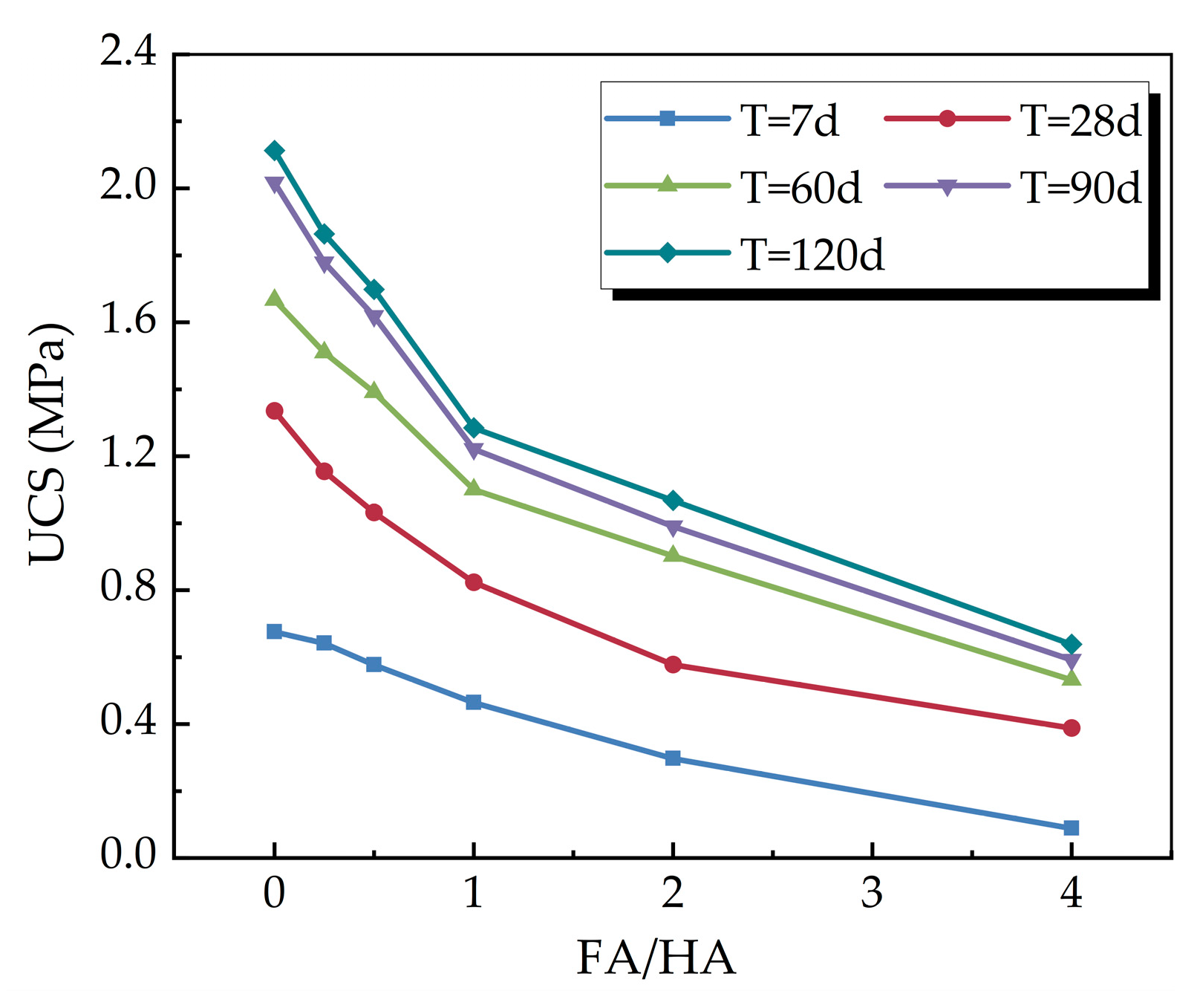

3.1.1. Unconfined Compressive Strength

3.1.2. Stress-Strain Relationship

3.1.3. Deformation Characteristics

(1) Relationship between FA/HA and Failure Strain

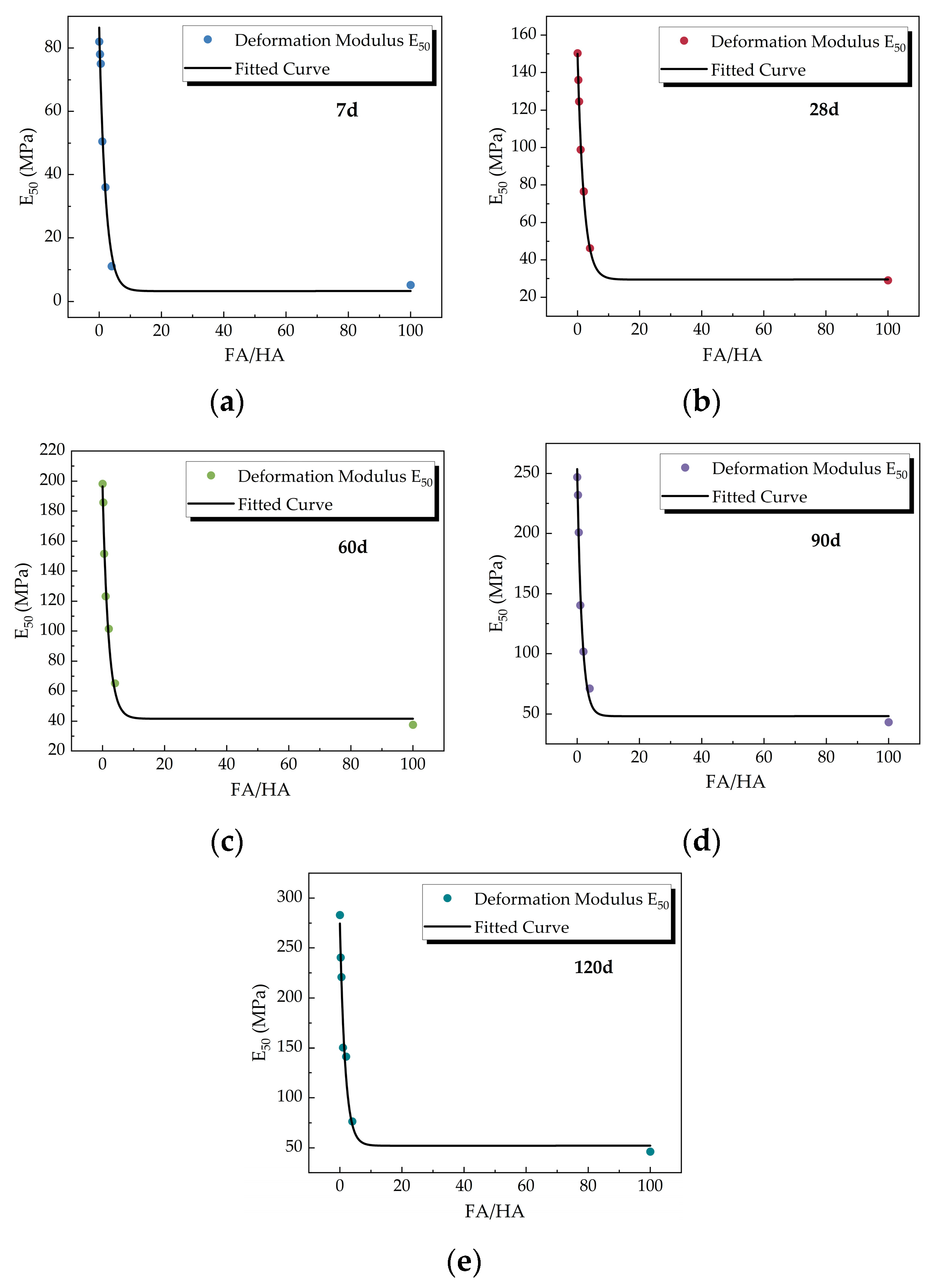

(2) Relationship between FA/HA and Deformation Modulus E50

3.2. Structural Analysis of Cemented Soil Based on Resistivity Theory

3.2.1. Influence of FA/HA on Resistivity

3.2.2. The Variation Pattern of Resistivity Structural Property Parameters

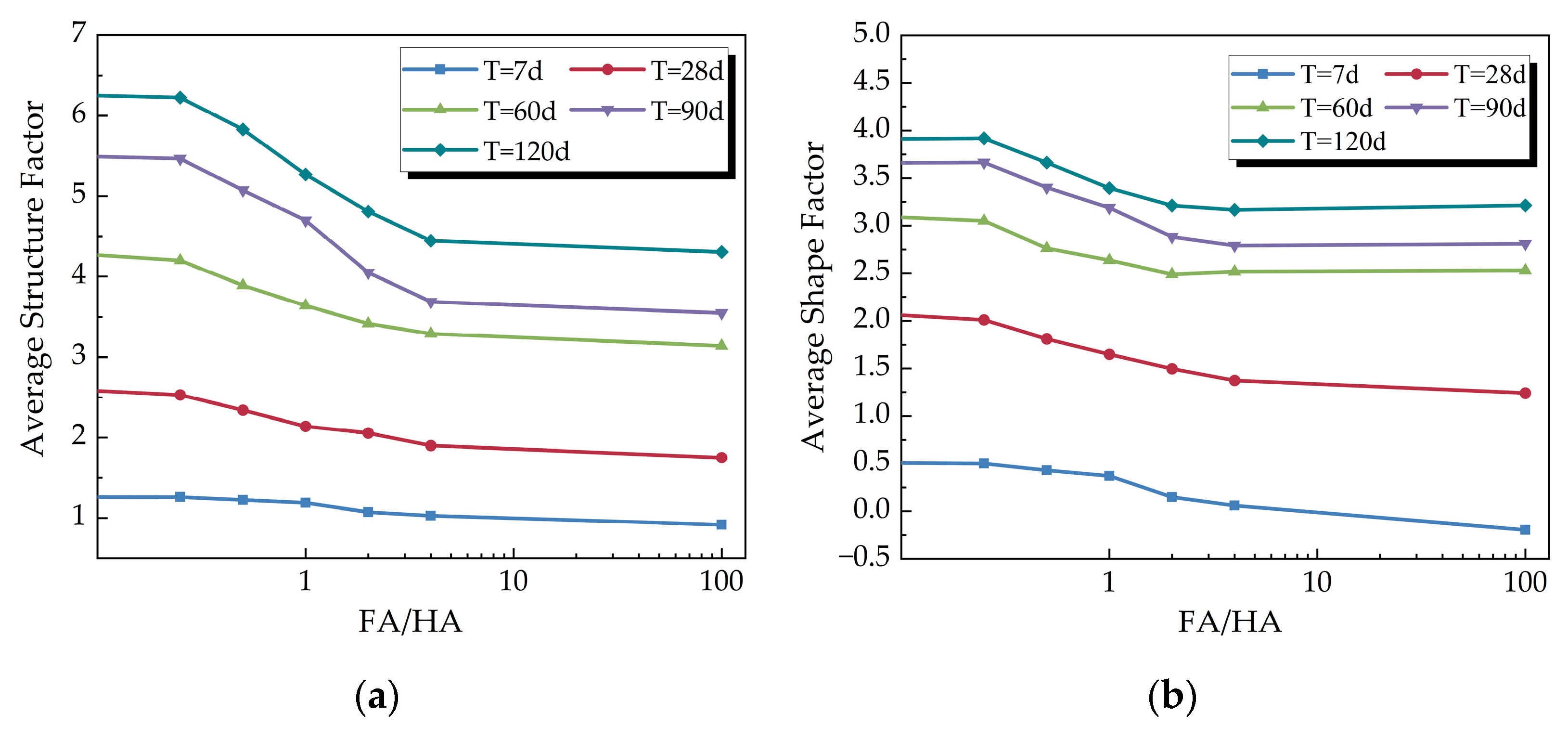

(1) Influence of FA/HA on Resistivity Structural Property Parameters

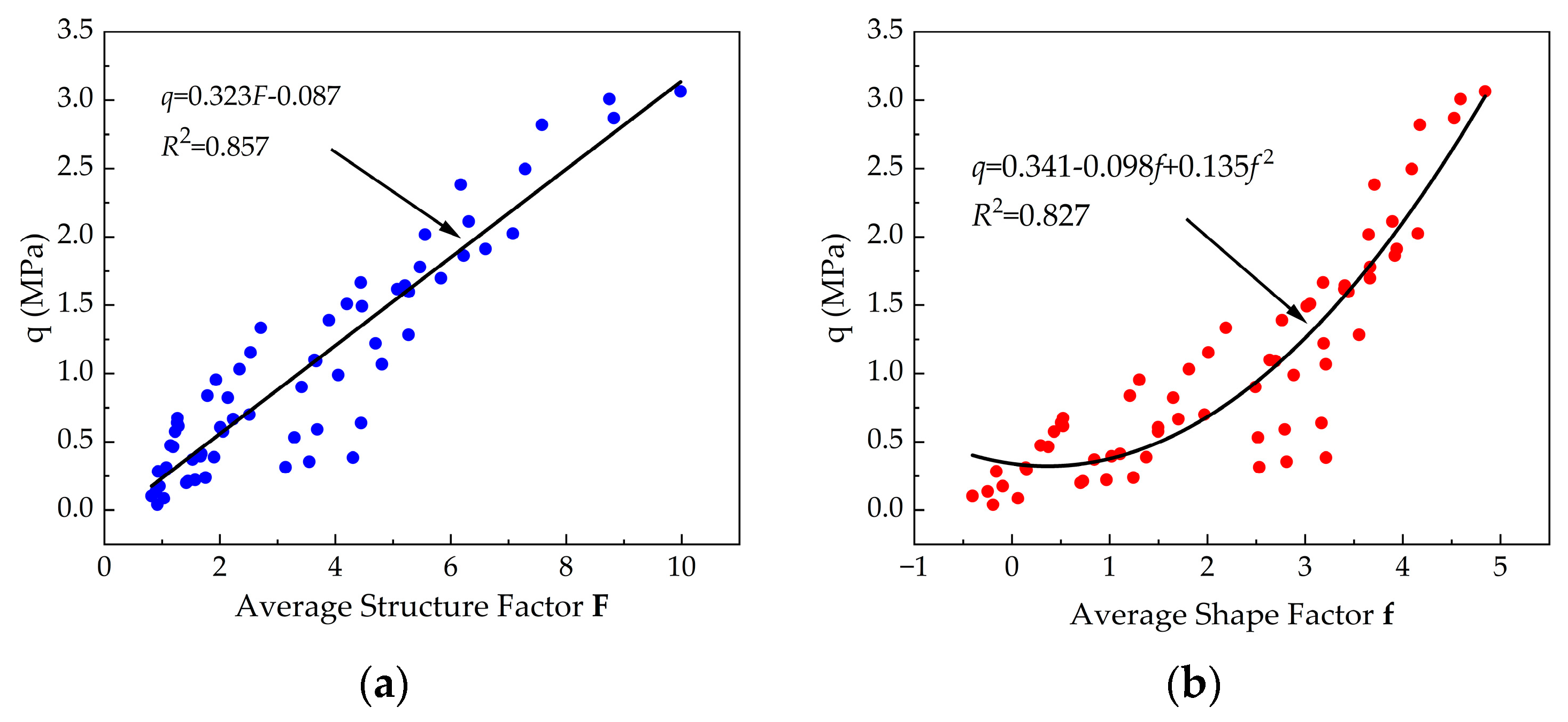

(2) Relationships between Unconfined Compressive Strength and Resistivity Structural Property Parameters

(3) Mechanism of Variation of Resistivity Structural Property Parameters

4. Conclusions

- (1)

- As FA/HA increased, the uniaxial compressive strength and resistance to deformation of cemented soil with a certain amount of total organic matter gradually decreased, while its compressibility improved. The increase in curing time led to further development of the cement hydration reaction and an increase in strength. Fulvic acid had a greater impact on the strength and deformation properties of cemented soil compared to humic acid.

- (2)

- The initial resistivity and structural property parameters of the cemented soil decreased gradually with increasing FA/HA and increased gradually with age. The unconfined compressive strength and resistivity structural property parameters of the cemented soil exhibited similar growth characteristics. The presence of organic matter hindered cement hydration and limited the role of agglomeration. Fulvic acid had a more pronounced destructive effect on the cemented soil structure, and its decomposition disrupted the cement hydration products, resulting in a less compact soil pore structure, which affected inter-particle cementation and, consequently, the strength and deformation properties of the cemented soil.

- (3)

- The results of the unconfined compressive strength test were used to establish quantitative relationships between unconfined compressive strength, failure strain, deformation modulus, FA/HA, and curing time. The results of the resistivity test were used to establish quantitative relationships between unconfined compressive strength, resistivity, and structural property parameters. These relationships serve as the basis for designing soil mixing piles with organic matter.

- (4)

- In this paper, the organic matter with artificially prepared soil cannot consider the historical interaction of organic matter and soft soil, which will reduce the influence of organic matter on the curing effect of cement. At the same time, the research only studied the changing pattern of the mechanical and microscopic characteristics of the cemented soil with the change of FA/HA when the organic matter content is 10%. Therefore, quantitative equations are somewhat restrictive. The characteristics of cemented soil with different content and composition of organic matter need further study.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lorenzo, G.; Bergado, D. Fundamental parameters of cement-admixed clay—New approach. J. Geotech. Geoenviron. Eng. 2004, 130, 1042–1050. [Google Scholar] [CrossRef]

- Muñoz, Y.O. The role of rice husk ash, cement and polypropylene fibers on the mechanical behavior of a soil from Guabirotuba formation. Transp. Geotech. 2021, 31, 100673. [Google Scholar] [CrossRef]

- Ghorbani, A.; Salimzadehshooiili, M. Dynamic characterization of sand stabilized with cement and RHA and reinforced with polypropylene fiber. J. Mater. Civ. Eng. 2019, 31, 04019095. [Google Scholar] [CrossRef]

- Tran, K.Q.; Satomi, T.; Takahashi, H. Tensile behaviors of natural fiber and cement reinforced soil subjected to direct tensile test. J. Build. Eng. 2019, 24, 100748. [Google Scholar] [CrossRef]

- Deng, Y.; Meng, L.Q.; Cai, M.Z. Research on Stability of loess Roadbed Reinforced with Cement-soil Mixing piles. J. Zhengzhou Univ. Eng. Sci. 2022, 43, 59–66. [Google Scholar]

- Du, C.; Zhang, J.; Yang, G. The influence of organic matter on the strength development of cement-stabilized marine soft clay. Mar. Georesour. Geotechnol. 2021, 39, 983–993. [Google Scholar] [CrossRef]

- Liang, S.; Zhou, J.; Luo, Q. An Experimental Research on the Effect of Organic Matter on Mechanical Properties of Cementing Solidified Silt. J. Guangdong. Univ. Tech. 2019, 36, 86–91. [Google Scholar]

- Liu, X.; Zhao, J.; Yang, P. Study on compressive strength and micro-pore characteristics of organic cement soil under freeze-thaw cycle. J. For. Eng. 2022, 7, 169–176. [Google Scholar]

- Wang, S.; He, X.; Gong, S. Influence Mechanism of Fulvic Acid on the Strength of Cement-Solidified Dredged Sludge. Water 2022, 14, 2616. [Google Scholar] [CrossRef]

- Cao, Y.; Zhang, J.; Xu, G. Strength Properties and Prediction Model of Cement-Solidified Clay Considering Organic Matter and Curing Temperature. Front. Mater. 2022, 9, 965–975. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, Q.; Chen, J. Tests For Effect of Soil Humid Acid Components on Strength of Cemented Soft Soils. J. Eng. Geol. 2009, 17, 842–846. [Google Scholar]

- Beddaa, H.; Fraj, A.B.; Lavergne, F. Effect of potassium humate as humic substances from river sediments on the rheology, the hydration and the strength development of a cement paste. Cem. Concr. Compos. 2019, 104, 103400. [Google Scholar] [CrossRef]

- Ma, C.; Chen, B.; Chen, L. Effect of organic matter on strength development of self-compacting earth-based construction stabilized with cement-based composites. Constr. Build. Mater. 2016, 123, 414–423. [Google Scholar] [CrossRef]

- Yu, X.; Liu, S. Researches on application of electrical resistivity indices to the microstructure of expansive soils. Chin. J. Geotech. Eng. 2004, 3, 393–396. [Google Scholar]

- Han, L.; Liu, S.; Du, Y. New method for testing contaminated soil-electrical resistivity method. Chin. J. Geotech. Eng. 2006, 28, 1028. [Google Scholar]

- Archie, G. The electrical resistivity log as an aid in determining some reservoir characteristics. Trans. AIME 1942, 146, 54–62. [Google Scholar] [CrossRef]

- Zha, F.; Liu, J. Electrical resistivity of heavy metal contaminated soils solidified/stabilized with cement-fly ash. Rock. Soil. Mech. 2019, 40, 4573–4580. [Google Scholar]

- Liu, X.; Huang, H.; Peng, S. Study on the strength, leachability, and electrical resistivity of lead-contaminated soil solidified with a slag-based binder. Bull. Eng. Geol. Environ. 2021, 80, 8553–8564. [Google Scholar] [CrossRef]

- Zhao, M.; Chen, S.; Wang, K. Analysis of Electrical Resistivity Characteristics and Damage Evolution of Soil–Rock Mixture under Triaxial Shear. Materials 2023, 16, 3698. [Google Scholar] [CrossRef]

- Yousuf, F.; Wei, X.; Tao, J. Evaluation of the influence of a superplasticizer on the hydration of varying composition cements by the electrical resistivity measurement method. Constr. Build. Mater. 2017, 144, 25–34. [Google Scholar] [CrossRef]

- Pan, Y.; Rossabi, J.; Pan, C. Stabilization/solidification characteristics of organic clay contaminated by lead when using cement. J. Hazard. Mater. 2019, 362, 132–139. [Google Scholar] [CrossRef]

- Du, Y.; Wei, M.; Reddy, K. Effect of acid rain pH on leaching behavior of cement stabilized lead-contaminated soil. J. Hazard. Mater. 2014, 271, 131–140. [Google Scholar] [CrossRef] [PubMed]

- Saride, S.; Puppala, A.J.; Chikyala, S.R. Swell-shrink and strength behaviors of lime and cement stabilized expansive organic clays. Appl. Clay Sci. 2013, 85, 39–45. [Google Scholar] [CrossRef]

- Eshwar, M.; Srilatha, M.; Rekha, K.B. Characterization of humic substances by functional groups and spectroscopic methods. Int. J. Curr. Microbiol. Appl. Sci. 2017, 6, 1768–1774. [Google Scholar] [CrossRef]

- Chen, H.; Wang, Q. The behaviour of organic matter in the process of soft soil stabilization using cement. Bull. Eng. Geol. Environ. 2006, 65, 445–448. [Google Scholar] [CrossRef]

- Arulanandan, K.; Muraleetharan, K.K. Level ground soil-liquefaction analysis using in situ properties: I. J. Geotech. Eng. 1988, 114, 753–770. [Google Scholar] [CrossRef]

- Rui, K.; Hongxing, W.; Yunzhi, T. Solidification of high organic matter content sludge by cement, lime and metakaolin. Period. Polytech. Civ. Eng. 2019, 63, 53–62. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Moisture content (%) | 82.8 |

| Density (g/cm3) | 1.53 |

| Specific gravity | 2.72 |

| Plastic limit | 37.4 |

| Liquid limit | 75.7 |

| Organic Matter (%) | 2.55 |

| pH | 7.94 |

| Chemical Composition (%) | Value |

|---|---|

| CaO | 49.18 |

| MgO | 1.62 |

| SiO2 | 26.01 |

| Al2O3 | 10.67 |

| Fe2O3 | 2.83 |

| K2O | 0.95 |

| SO3 | 3.76 |

| TiO2 | 0.51 |

| MnO | 0.38 |

| Loss of ignition | 3.54 |

| Test | FA/HA | Organic Matter Content (%) | Cement Content (%) | Moisture Content (%) | Curing Time (d) |

|---|---|---|---|---|---|

| Unconfined compressive strength test | 0.01, 0.25, 0.5, 2, 4, ∞ | 10 | 15 | 80 | 7, 28, 60, 90, 120 |

| Resistivity test |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, L.; Ding, Z.; Wang, S.; Pan, K.; Hu, C. Effect of Organic Matter Components on the Mechanical Properties of Cemented Soil. Materials 2023, 16, 5889. https://doi.org/10.3390/ma16175889

Shao L, Ding Z, Wang S, Pan K, Hu C. Effect of Organic Matter Components on the Mechanical Properties of Cemented Soil. Materials. 2023; 16(17):5889. https://doi.org/10.3390/ma16175889

Chicago/Turabian StyleShao, Li, Zhixuan Ding, Suran Wang, Kuashi Pan, and Chuxue Hu. 2023. "Effect of Organic Matter Components on the Mechanical Properties of Cemented Soil" Materials 16, no. 17: 5889. https://doi.org/10.3390/ma16175889

APA StyleShao, L., Ding, Z., Wang, S., Pan, K., & Hu, C. (2023). Effect of Organic Matter Components on the Mechanical Properties of Cemented Soil. Materials, 16(17), 5889. https://doi.org/10.3390/ma16175889