Influence of Nb and Mo Substitution on the Structure and Magnetic Properties of a Rapidly Quenched Fe79.4Co5Cu0.6B15 Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

- Successive Nb substitution enhances thermal stability more efficiently than Mo, which is beneficial for crystallisation heat treatment.

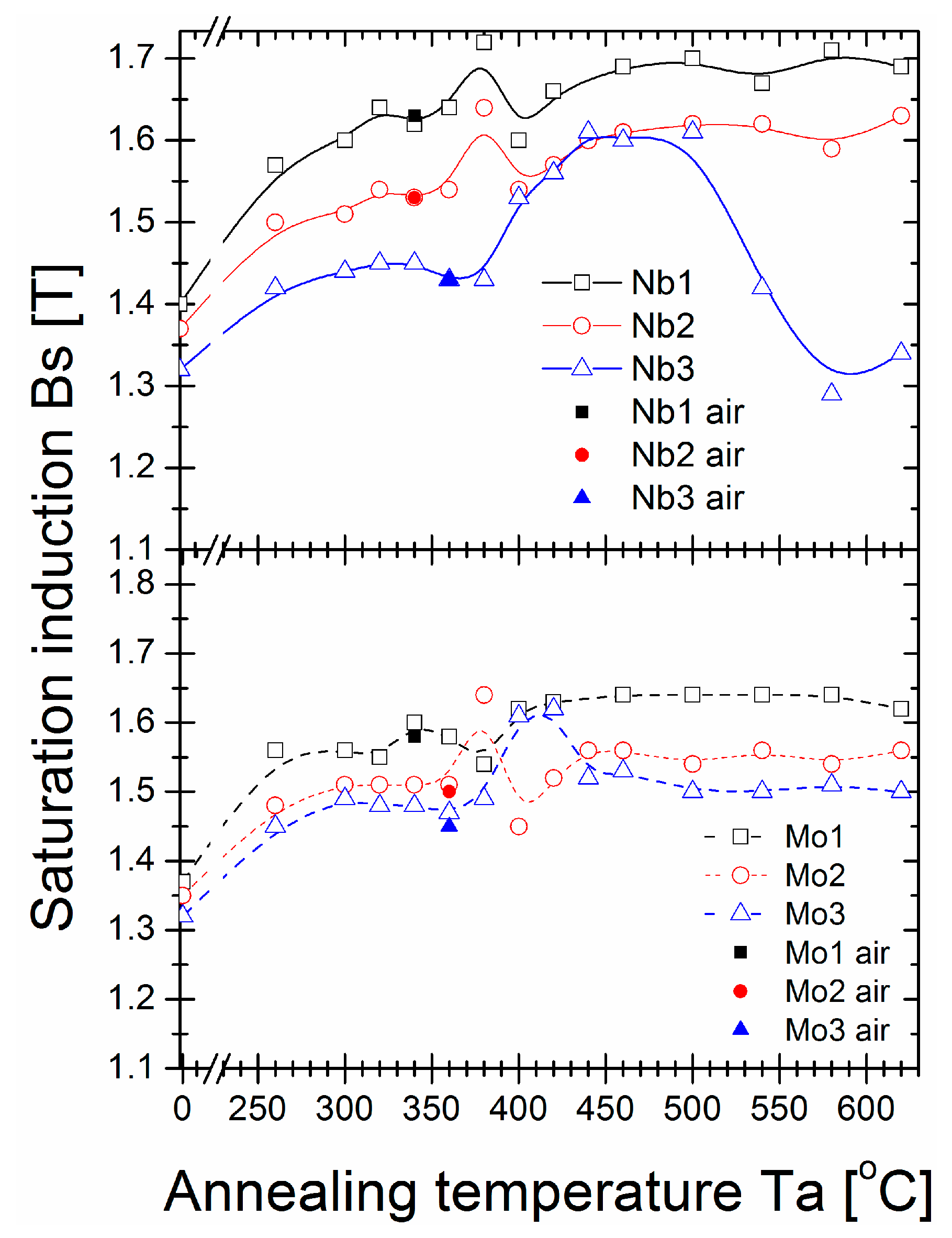

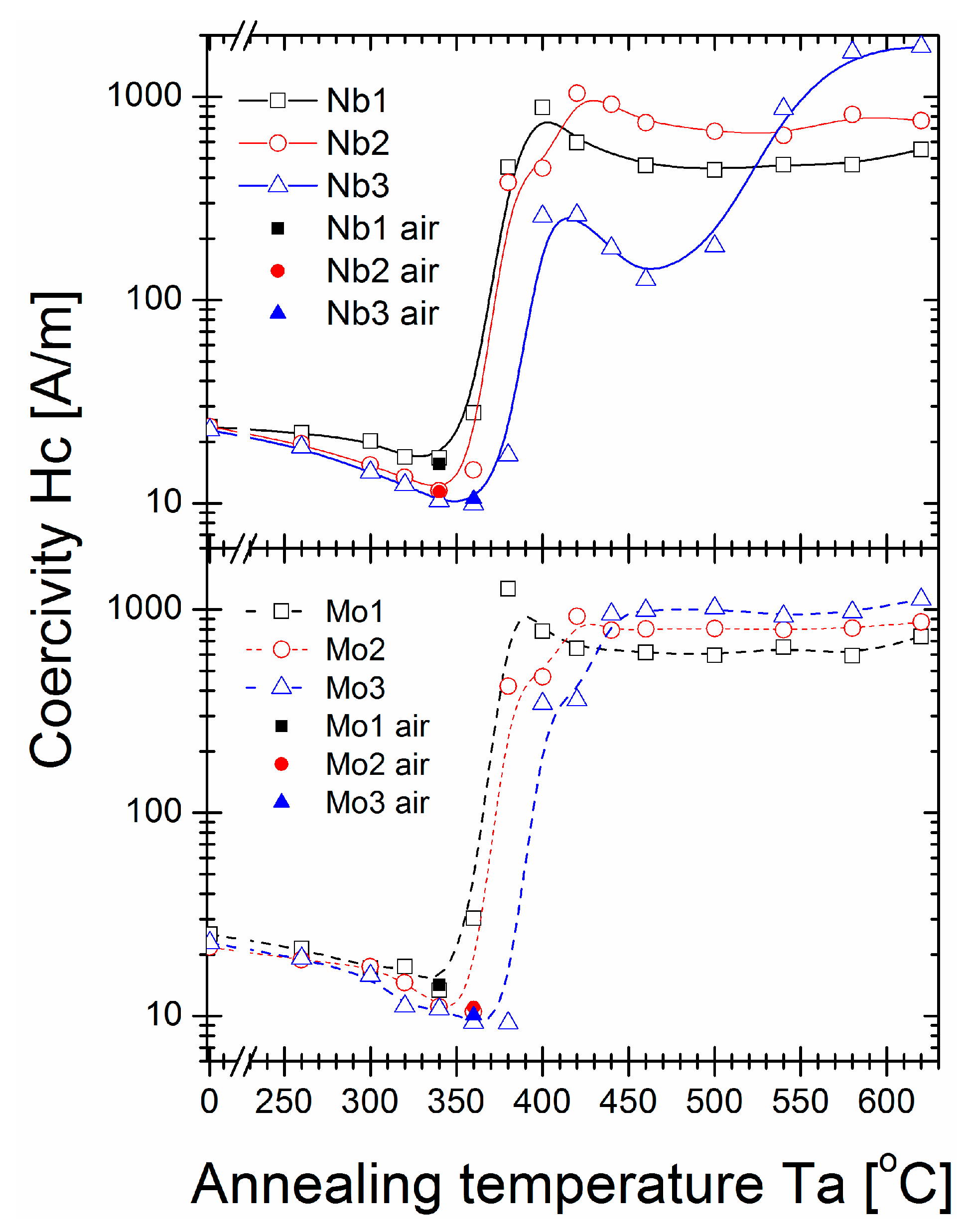

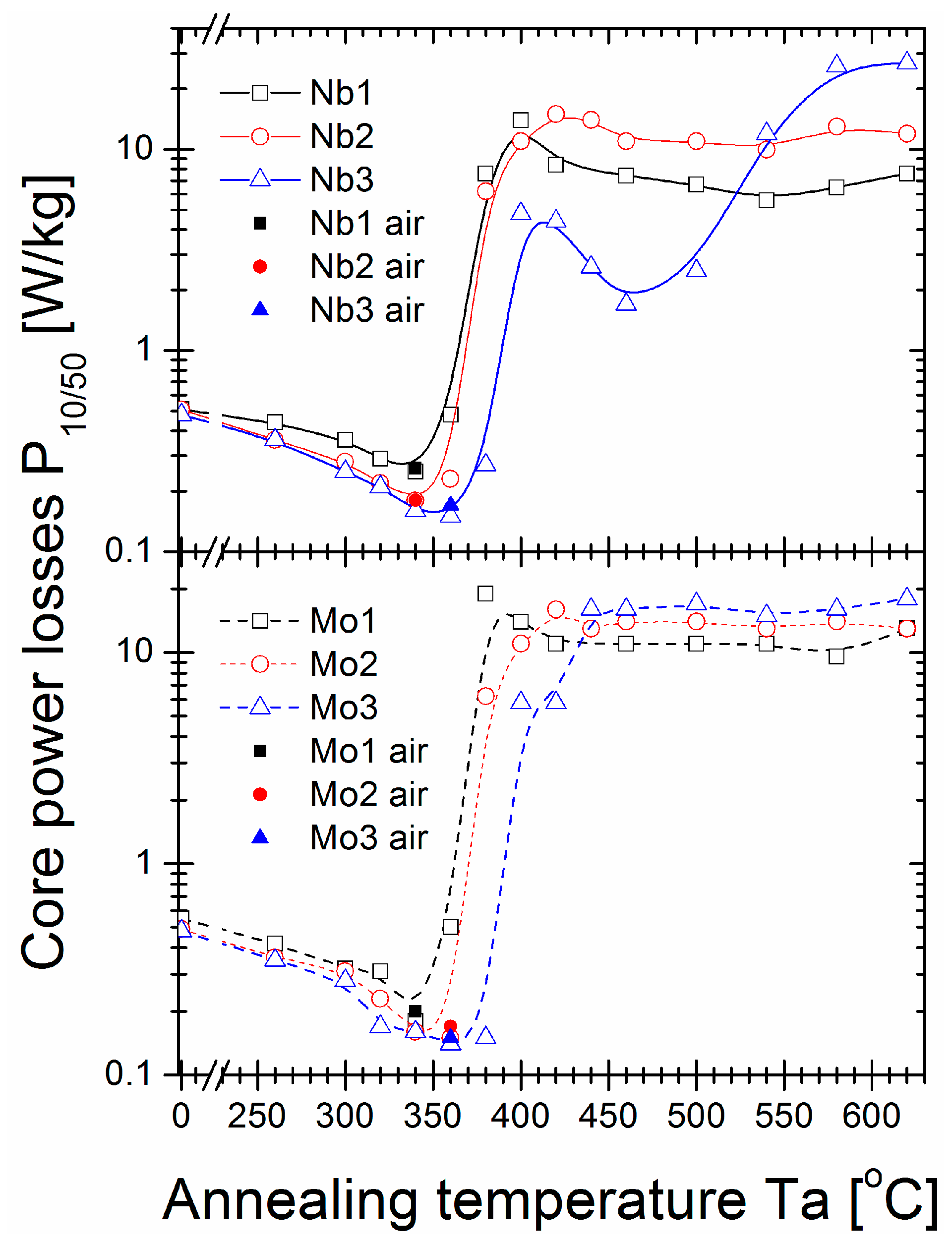

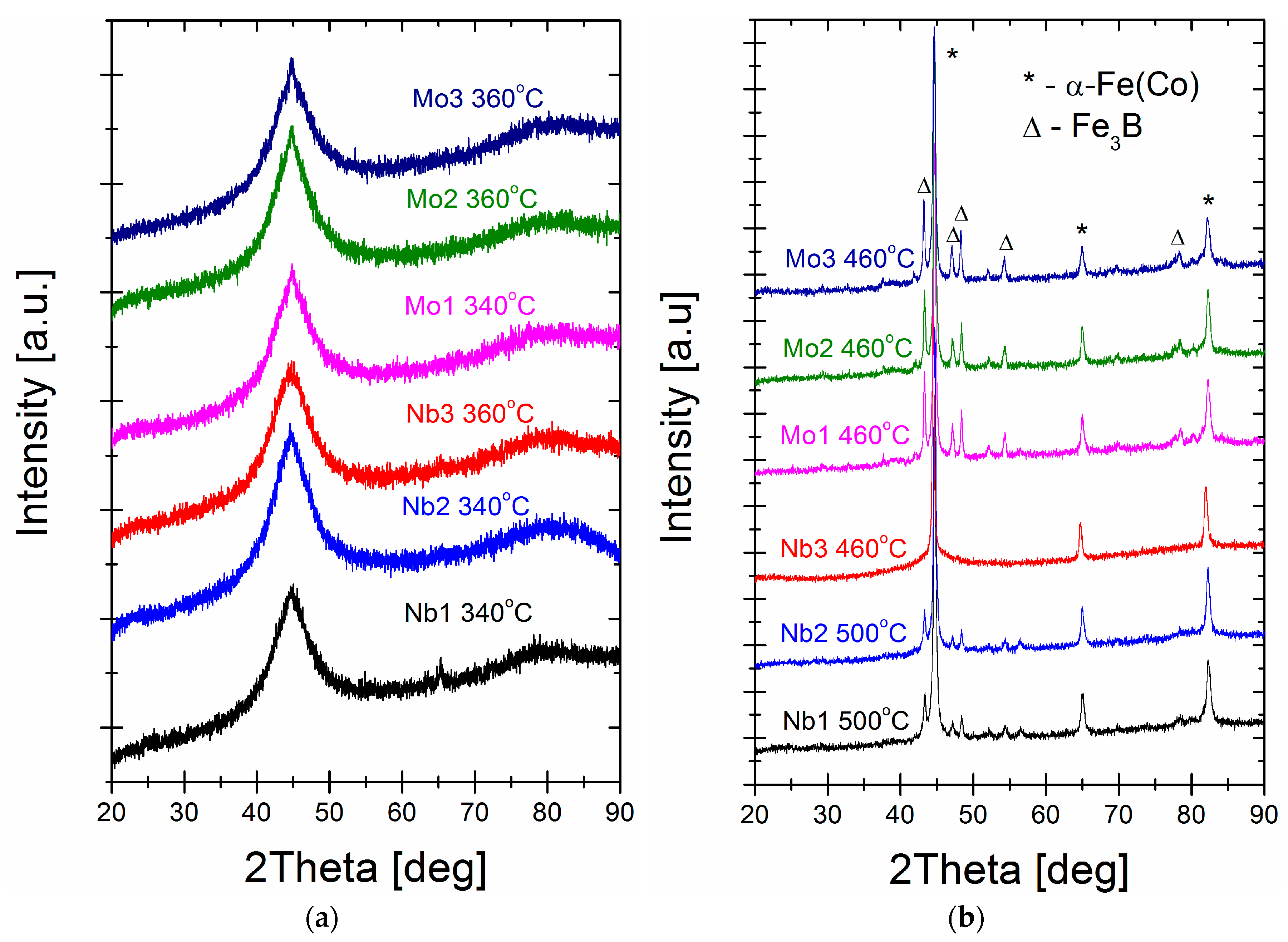

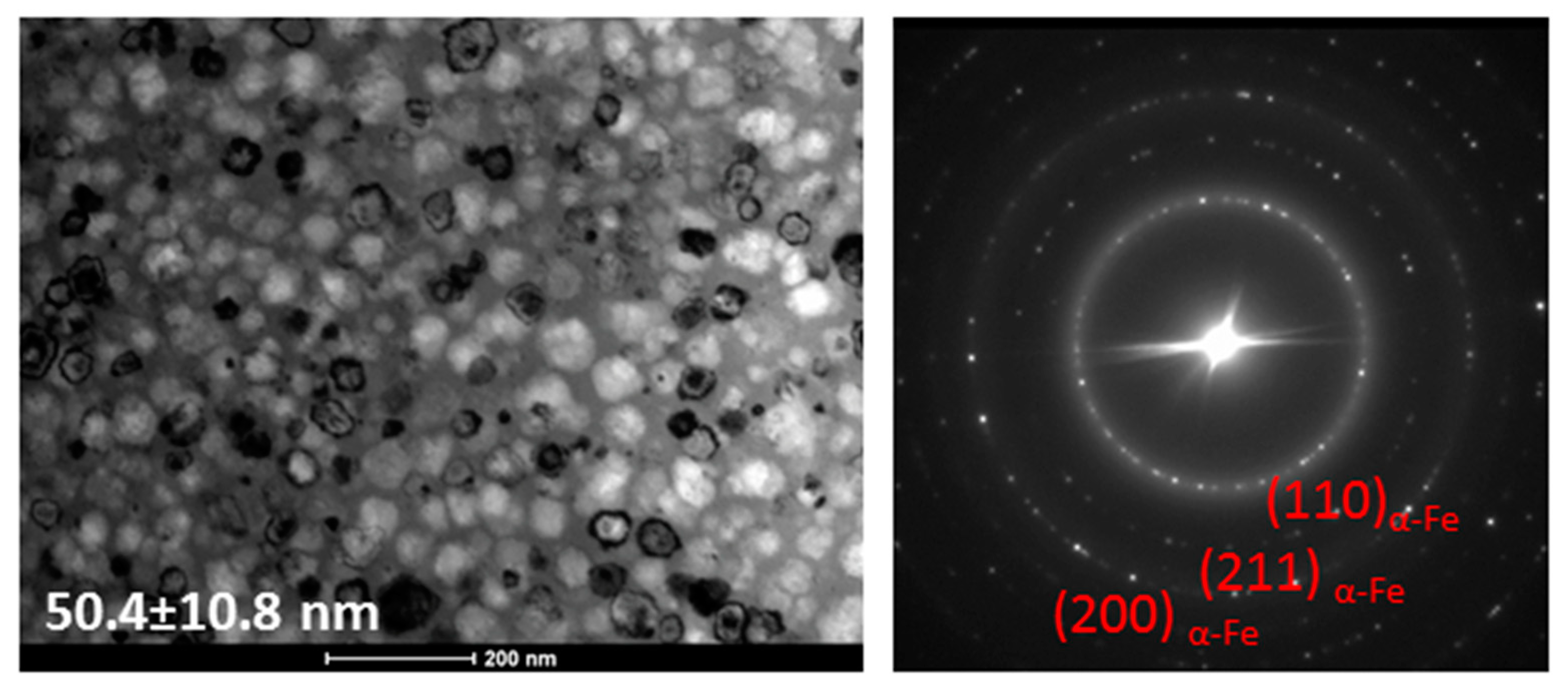

- The 20-min vacuum-annealing process was optimised for a wide temperature range from 260 to 640 °C. For the Nb = 3% alloy, the highest thermal stability favours the precipitation of only α-Fe(Co) nanograins in the amorphous matrix at a broadened annealing temperature range of up to 460 °C. Hc(Ta) and P10/50(Ta) dependences correlate strongly with crystal structure evolution. For example, the α-Fe(Co) grain growth and Fe3B phase precipitation significantly increase the magneto-crystalline anisotropy, leading to an increase in the Hc value. A double minimum of Hc(Ta) dependence exists with different α-Fe(Co) nanograin contents. The first minimum is related to a relaxed amorphous state, while the second is related to a relaxed α-Fe(Co)/amorphous nanocomposite.

- For all alloys except Nb = 3%, the limited thermal stability of <150 °C does not only allow for α-Fe(Co) nanograins to precipitate at higher temperatures. Rather, the fast co-precipitation of the hard magnetic Fe3B phase also substantially increases magnetic saturation while stabilising Hc and P10/50.

- Optimally vacuum-annealed alloys (when the P10/50 is at a minimum) exhibit excellent magnetic properties with high saturation induction up to 1.7 T and low coercivity below 10 A/m. Optimally vacuum-annealed Mo-containing alloys are 20% less lossy than Nb-containing alloys in the whole B (up to 0.8 T) and f (up to 400 kHz) ranges.

- The air-annealing process may be an alternative and effective heat treatment process for use on an industrial scale. There are no significant differences in magnetic properties between the vacuum- and air-annealed materials under optimal annealing conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Naitoh, Y.; Bitoh, T.; Hatanai, T.; Makino, A.; Inoue, A. Application of nanocrystalline soft magnetic Fe–M–B (M = Zr,Nb) alloys to choke coils. J. Appl. Phys. 1998, 83, 6332–6334. [Google Scholar] [CrossRef]

- Hasegawa, R. Advances in amorphous and nanocrystalline materials. J. Magn. Magn. Mater. 2012, 324, 3555–3557. [Google Scholar] [CrossRef]

- Masumoto, T.; Egami, T. Designing the composition and heat treatment of magnetic amorphous alloys. Mater. Sci. Eng. 1981, 48, 147–165. [Google Scholar] [CrossRef]

- Herzer, G. Modern soft magnets: Amorphous and nanocrystalline materials. Acta Mater. 2013, 61, 718–734. [Google Scholar] [CrossRef]

- Yoshizawa, Y.A.; Oguma, S.; Yamauchi, K. New Fe-based soft magnetic alloys composed of ultrafine grain structure. J. Appl. Phys. 1988, 64, 6044–6046. [Google Scholar] [CrossRef]

- Suzuki, K.; Makino, A.; Inoue, A.; Masumoto, T. Soft magnetic properties of bcc Fe-MB-Cu (M = Ti, Nb or Ta) alloys with nanoscale grain size. Jpn. J. Appl. Phys. 1991, 30, L1729. [Google Scholar] [CrossRef]

- Willard, M.A.; Laughlin, D.E.; McHenry, M.E.; Thoma, D.; Sickafus, K.; Cross, J.O.; Harris, V.G. Structure and magnetic properties of (Fe0.5Co0.5)88Zr7B4Cu1 nanocrystalline alloys. J. Appl. Phys. 1998, 84, 6773–6777. [Google Scholar] [CrossRef]

- Blázquez, J.S.; Franco, V.; Conde, C.F.; Conde, A. Microstructure and magnetic properties of Fe78−xCoxNb6B15Cu1 (x = 18, 39, 60) alloys. J. Magn. Magn. Mater. 2003, 254, 460–462. [Google Scholar] [CrossRef]

- Zhang, Y.; Sharma, P.; Makino, A. Effects of Cobalt Addition in Nanocrystalline Fe83.3Si4B8P4Cu0.7 Soft Magnetic Alloy. IEEE Trans. Magn. 2014, 50, 2003004. [Google Scholar] [CrossRef]

- Hawelek, L.; Warski, T.; Wlodarczyk, P.; Polak, M.; Zackiewicz, P.; Radon, A.; Wojcik, A.; Kolano-Burian, A. Effect of Co Substitution on Crystallization and Magnetic Behavior of Fe85.45−xCoxCu0.55B14 Metallic Glass. Materials 2020, 13, 919. [Google Scholar] [CrossRef]

- Hawelek, L.; Polak, M.; Wlodarczyk, P.; Zackiewicz, P.; Radon, A.; Lukowiec, D.; Hreczka, M.; Kolano-Burian, A. Influence of Co substitution for Fe on magnetic properties and crystal structure of soft magnetic Fe81.3Mo0.2Cu0.5Si4B14 alloy. J. Magn. Magn. Mater. 2020, 512, 166681. [Google Scholar] [CrossRef]

- Victora, R.H.; Falicov, L.M. Calculated magnetization of iron-cobalt disordered alloys. Phys. Rev. B 1984, 30, 259. [Google Scholar] [CrossRef]

- Slater, J.C. Electronic structure of alloys. J. Appl. Phys. 1937, 8, 385–390. [Google Scholar] [CrossRef]

- Pauling, L. The nature of the interatomic forces in metals. Phys. Rev. 1938, 54, 899. [Google Scholar] [CrossRef]

- Warski, T.; Wlodarczyk, P.; Polak, M.; Zackiewicz, P.; Radon, A.; Wojcik, A.; Szlezynger, M.; Kolano-Burian, A.; Hawelek, L. Influence of Cu content on structure and magnetic properties in Fe86-xCuxB14 alloys. Materials 2020, 13, 1451. [Google Scholar] [CrossRef] [PubMed]

- Warski, T.; Radon, A.; Zackiewicz, P.; Wlodarczyk, P.; Polak, M.; Wojcik, A.; Maziarz, W.; Kolano-Burian, A.; Hawelek, L. Influence of Cu Content on Structure, Thermal Stability and Magnetic Properties in Fe72−xNi8Nb4CuxSi2B14 Alloys. Materials 2021, 14, 726. [Google Scholar] [CrossRef]

- Ohta, M.; Yoshizawa, Y. Recent progress in high Bs Fe-based nanocrystalline soft magnetic alloys. J. Phys. D Appl. Phys. 2011, 44, 064004. [Google Scholar] [CrossRef]

- Lashgari, H.R.; Chu, D.; Xie, S.; Sun, H.; Ferry, M.; Li, S. Composition dependence of the microstructure and soft magnetic properties of Fe-based amorphous/nanocrystalline alloys: A review study. J. Non Cryst. Solids 2014, 391, 61–82. [Google Scholar] [CrossRef]

- Lu, W.; Fan, J.; Wang, Y.; Yan, B. Microstructure and magnetic properties of Fe72.5Cu1M2V2Si13.5B9 (M = Nb, Mo,(NbMo),(MoW)) nanocrystalline alloys. J. Magn. Magn. Mater. 2010, 322, 2935–2937. [Google Scholar] [CrossRef]

- Yoshizawa, Y.; Yamauchi, K. Magnetic properties of Fe Cu M Si B (M = Cr, V, Mo, Nb, Ta, W) alloys. Mater. Sci. Eng. A 1991, 133, 176–179. [Google Scholar] [CrossRef]

- Tsepelev, V.S.; Starodubtsev, Y.N. Nanocrystalline soft magnetic iron-based materials from liquid state to ready product. Nanomaterials 2021, 11, 108. [Google Scholar] [CrossRef] [PubMed]

- Li, H.X.; Kim, K.B.; Yi, S. Enhanced glass-forming ability of Fe-based bulk metallic glasses prepared using hot metal and commercial raw materials through the optimization of Mo content. Scr. Mater. 2007, 56, 1035–1038. [Google Scholar] [CrossRef]

- Jiao, Z.; Li, H.; Wu, Y.; Gao, J.; Wang, S.; Yi, S.; Lu, Z. Effects of Mo additions on the glass-forming ability and magnetic properties of bulk amorphous Fe-C-Si-BP-Mo alloys. Sci. China Phys. Mech. Astron. 2010, 53, 430–434. [Google Scholar] [CrossRef]

- Kumar, A.; Murugaiyan, P.; Panda, A.K.; Roy, R.K. Effect of compositional elements and processing routes on structural and thermal response in Fe-based metallic glasses. J. Alloys Compd. 2020, 821, 153279. [Google Scholar] [CrossRef]

- Ramasamy, P.; Stoica, M.; Bera, S.; Calin, M.; Eckert, J. Effect of replacing Nb with (Mo and Zr) on glass forming ability, magnetic and mechanical properties of FeCoBSiNb bulk metallic glass. J. Alloys Compd. 2017, 707, 78–81. [Google Scholar] [CrossRef]

- Kraus, L.; Hašlar, V.; Duhaj, P.; Švec, P.; Studnička, V. The structure and magnetic properties of nanocrystalline Co21Fe64− xNbxB15 alloys. Mater. Sci. Eng. A 1997, 226, 626–630. [Google Scholar] [CrossRef]

- Tinh, N.H.; Dung, N.V.; Nghi, N.H.; Phan, M.H. Influence of Nb substitution for Fe on the magnetic and magneto-impedance properties of amorphous and annealed Fe76.5−xSi13.5B9Cu1Nbx (x = 0–7) ribbons. Phys. B Condens. 2012, 407, 3790–3796. [Google Scholar] [CrossRef]

- Kissinger, H.E. Reaction kinetics in differential thermal analysis. Anal. Chem. 1957, 29, 1702–1706. [Google Scholar] [CrossRef]

- Hawelek, L.; Warski, T.; Radon, A.; Pilsniak, A.; Maziarz, W.; Szlezynger, M.; Kolano-Burian, A. Structure and magnetic properties of thermodynamically predicted rapidly quenched Fe85-xCuxB15 alloys. Materials 2021, 14, 7807. [Google Scholar] [CrossRef]

- Stoica, M.; Kumar, S.; Roth, S.; Ram, S.; Eckert, J.; Vaughan, G.; Yavari, A.R. Crystallization kinetics and magnetic properties of Fe66Nb4B30 bulk metallic glass. J. Alloys Compd. 2009, 483, 632–637. [Google Scholar] [CrossRef]

- Xue, L.; Liu, H.; Dou, L.; Yang, W.; Chang, C.; Inoue, A.; Wang, X.; Li, R.-W.; Shen, B. Soft magnetic properties and microstructure of Fe84−xNb2B14Cux nanocrystalline alloys. Mater. Des. 2014, 56, 227–231. [Google Scholar] [CrossRef]

- Herzer, G. Grain size dependence of coercivity and permeability in nanocrystalline ferromagnets. IEEE Trans. Magn. 1990, 26, 1397–1402. [Google Scholar] [CrossRef]

- Hoque, S.M.; Hakim, M.A.; Dhar, U.; Saha, D.K.; Nordblad, P.; Paul, D.P. Detailed study of ultra-soft magnetic properties of Fe74Cu0.8Nb2.7Si15.5B7. Philos. Mag. 2011, 91, 2117–2139. [Google Scholar] [CrossRef]

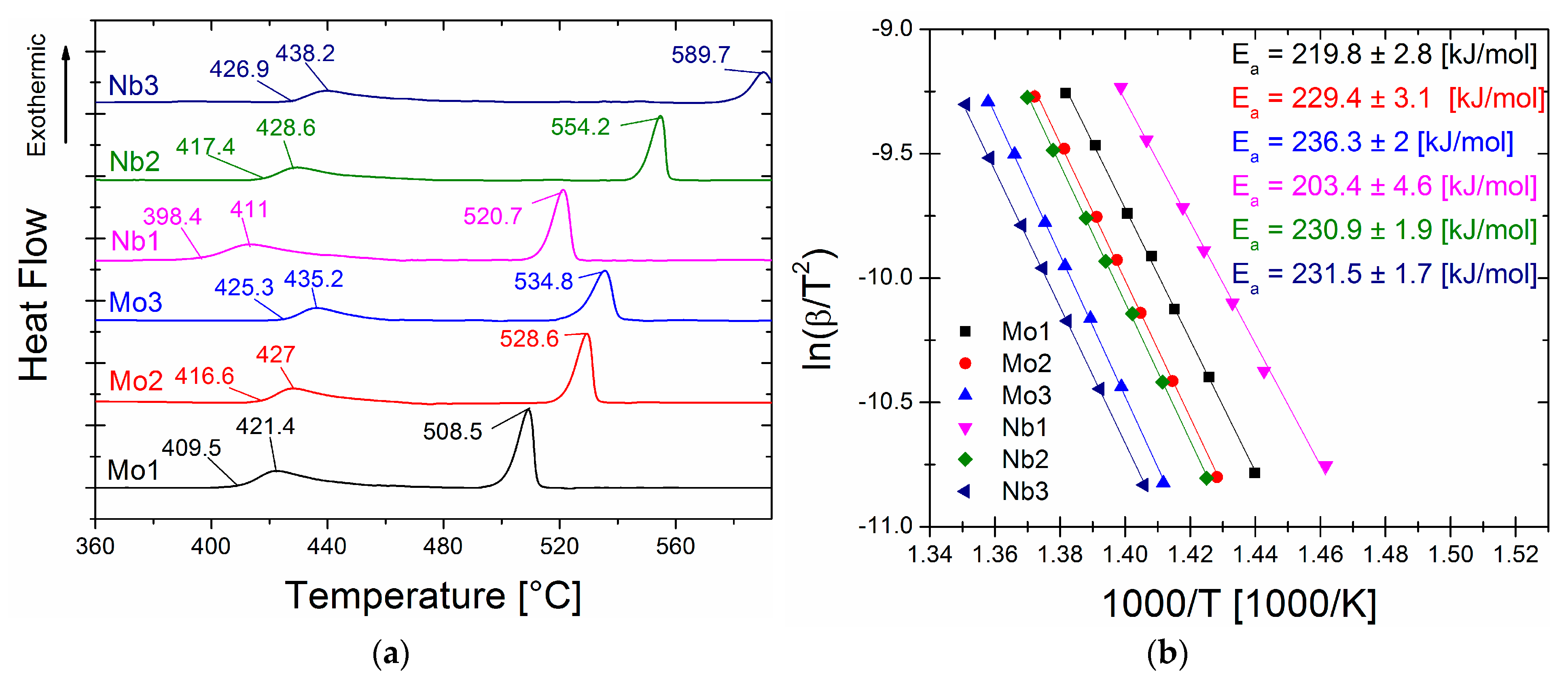

| Composition | Tx1 [°C] | Tp1 [°C] | Tx2 [°C] | Tp2 [°C] | ΔTx = Tx2 − Tx1 [°C] |

|---|---|---|---|---|---|

| Fe78.4Co5Nb1Cu0.6B15 | 398.4 | 411 | 513 | 520.7 | 114.6 |

| Fe77.4Co5Nb2Cu0.6B15 | 417.4 | 428.6 | 546.4 | 554.2 | 129 |

| Fe76.4Co5Nb3Cu0.6B15 | 426.9 | 438.2 | 581.6 | 589.7 | 154.7 |

| Fe78.4Co5Mo1Cu0.6B15 | 409.5 | 421.4 | 500.3 | 508.5 | 90.8 |

| Fe77.4Co5Mo2Cu0.6B15 | 416.6 | 427 | 521 | 528.6 | 104.4 |

| Fe76.4Co5Mo3Cu0.6B15 | 425.3 | 435.2 | 525.5 | 534.8 | 100.2 |

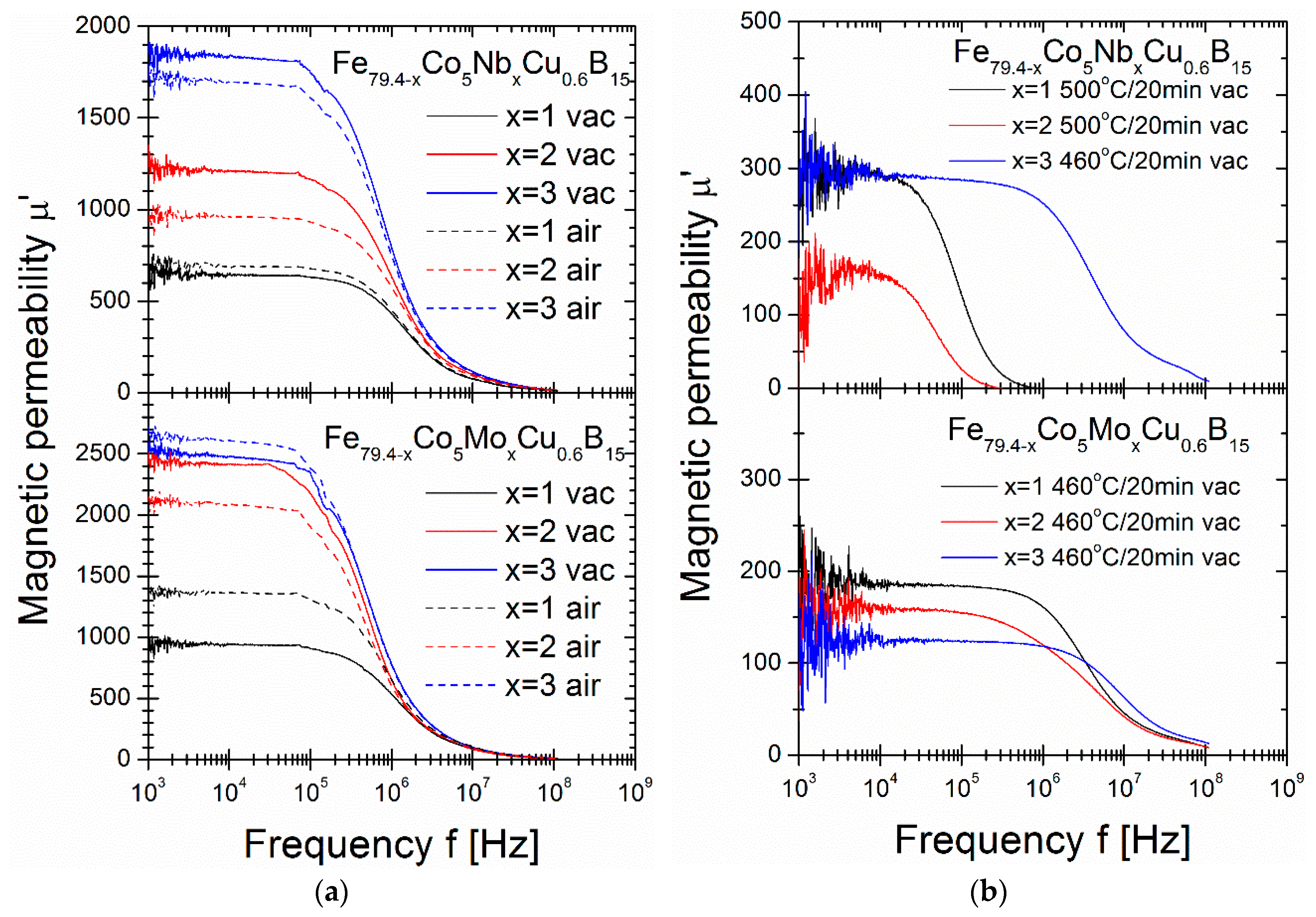

| Composition | Ta [°C] | Bs [T] | Hc [A/m] | P10/50[W/kg] | µ’ | fcut-off [kHz] |

|---|---|---|---|---|---|---|

| Fe78.4Co5Nb1Cu0.6B15 | 340 vac | 1.62 | 16.7 | 0.25 | 631 | 1472 |

| 340 air | 1.63 | 15.6 | 0.26 | 678 | 1394 | |

| 500 vac | 1.7 | 437 | 6.7 | 287 | 78 | |

| Fe77.4Co5Nb2Cu0.6B15 | 340 vac | 1.53 | 11.5 | 0.18 | 1165 | 1022 |

| 340 air | 1.53 | 11.4 | 0.18 | 932 | 1472 | |

| 500 vac | 1.62 | 675 | 11 | 150 | 45 | |

| Fe76.4Co5Nb3Cu0.6B15 | 360 vac | 1.43 | 9.9 | 0.15 | 1746 | 791 |

| 360 air | 1.43 | 10.5 | 0.17 | 1614 | 791 | |

| 460 vac | 1.6 | 126 | 1.7 | 291 | 3951 | |

| Fe78.4Co5Mo1Cu0.6B15 | 340 vac | 1.6 | 13.4 | 0.18 | 907 | 1182 |

| 340 air | 1.58 | 14.2 | 0.2 | 1306 | 867 | |

| 460 vac | 1.64 | 615 | 11 | 187 | 3351 | |

| Fe77.4Co5Mo2Cu0.6B15 | 360 vac | 1.51 | 10.5 | 0.15 | 2416 | 519 |

| 360 air | 1.5 | 11 | 0.17 | 1904 | 483 | |

| 460 vac | 1.56 | 801 | 14 | 159 | 3950 | |

| Fe76.4Co5Mo3Cu0.6B15 | 360 vac | 1.47 | 9.3 | 0.14 | 2543 | 529 |

| 360 air | 1.45 | 10.1 | 0.15 | 2681 | 483 | |

| 460 vac | 1.53 | 989 | 16 | 119 | 8993 |

| Composition | Ta [°C] | 50 Hz/0.8 T [W/kg] | 50 kHz/0.8 T [W/kg] | 100 kHz/0.4 T [W/kg] | 400 kHz/0.1 T [W/kg] |

|---|---|---|---|---|---|

| Fe78.4Co5Nb1Cu0.6B15 | 340 vac | 0.0025 | 15 | 13 | 7.3 |

| Fe77.4Co5Nb2Cu0.6B15 | 340 vac | 0.0018 | 13 | 11 | 6.6 |

| Fe76.4Co5Nb3Cu0.6B15 | 360 vac | 0.0015 | 11 | 8.8 | 4.7 |

| Fe78.4Co5Mo1Cu0.6B15 | 340 vac | 0.0018 | 12 | 10 | 5.5 |

| Fe77.4Co5Mo2Cu0.6B15 | 360 vac | 0.0014 | 9.1 | 7.6 | 5.0 |

| Fe76.4Co5Mo3Cu0.6B15 | 360 vac | 0.0012 | 7.4 | 5.9 | 3.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hawelek, L.; Zackiewicz, P.; Wojcik, A.; Hudecki, J.; Warski, T. Influence of Nb and Mo Substitution on the Structure and Magnetic Properties of a Rapidly Quenched Fe79.4Co5Cu0.6B15 Alloy. Materials 2023, 16, 6288. https://doi.org/10.3390/ma16186288

Hawelek L, Zackiewicz P, Wojcik A, Hudecki J, Warski T. Influence of Nb and Mo Substitution on the Structure and Magnetic Properties of a Rapidly Quenched Fe79.4Co5Cu0.6B15 Alloy. Materials. 2023; 16(18):6288. https://doi.org/10.3390/ma16186288

Chicago/Turabian StyleHawelek, Lukasz, Przemyslaw Zackiewicz, Anna Wojcik, Jacek Hudecki, and Tymon Warski. 2023. "Influence of Nb and Mo Substitution on the Structure and Magnetic Properties of a Rapidly Quenched Fe79.4Co5Cu0.6B15 Alloy" Materials 16, no. 18: 6288. https://doi.org/10.3390/ma16186288

APA StyleHawelek, L., Zackiewicz, P., Wojcik, A., Hudecki, J., & Warski, T. (2023). Influence of Nb and Mo Substitution on the Structure and Magnetic Properties of a Rapidly Quenched Fe79.4Co5Cu0.6B15 Alloy. Materials, 16(18), 6288. https://doi.org/10.3390/ma16186288