A Review of Computational Approaches to the Microstructure-Informed Mechanical Modelling of Metals Produced by Powder Bed Fusion Additive Manufacturing

Abstract

:1. Introduction

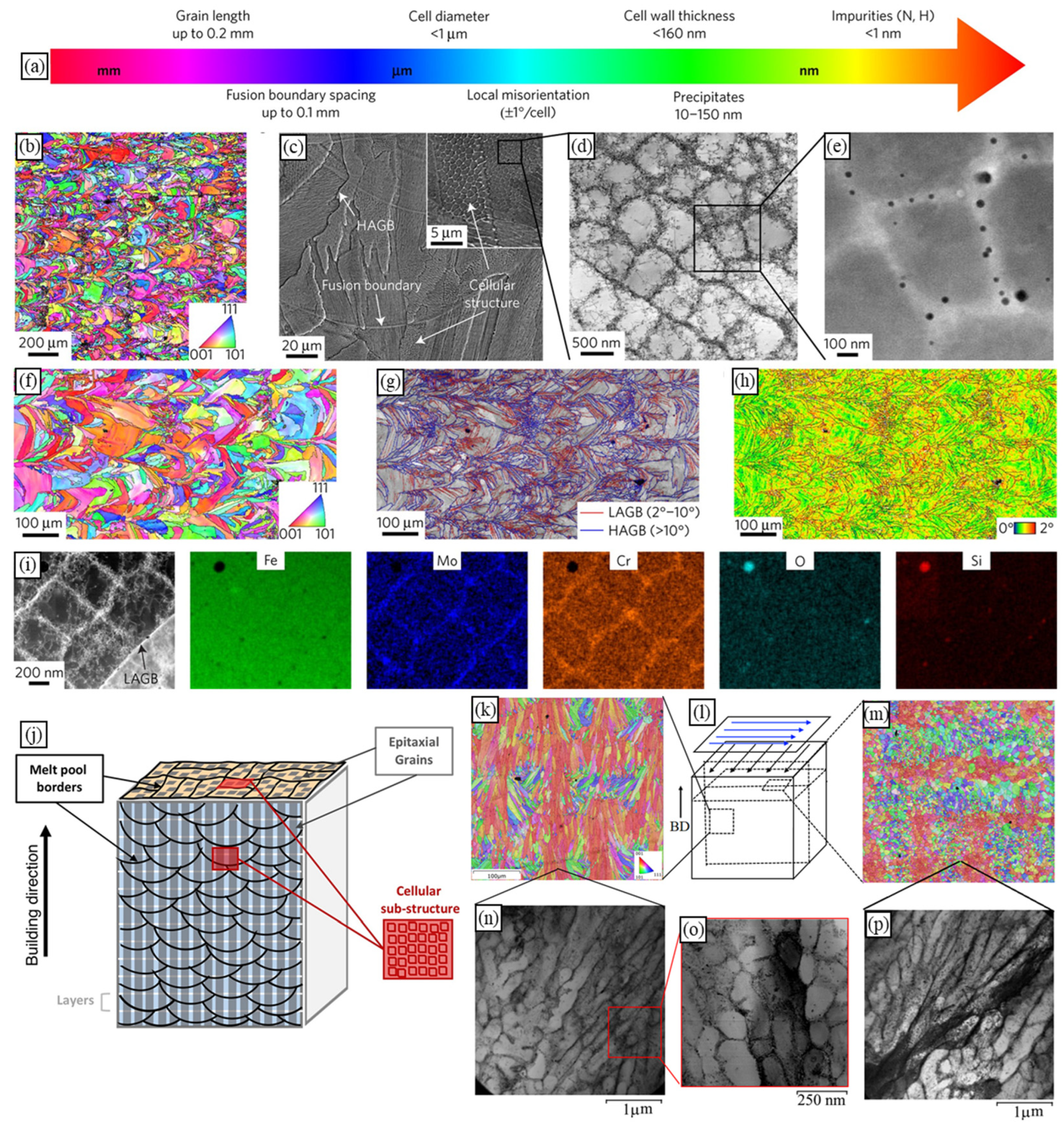

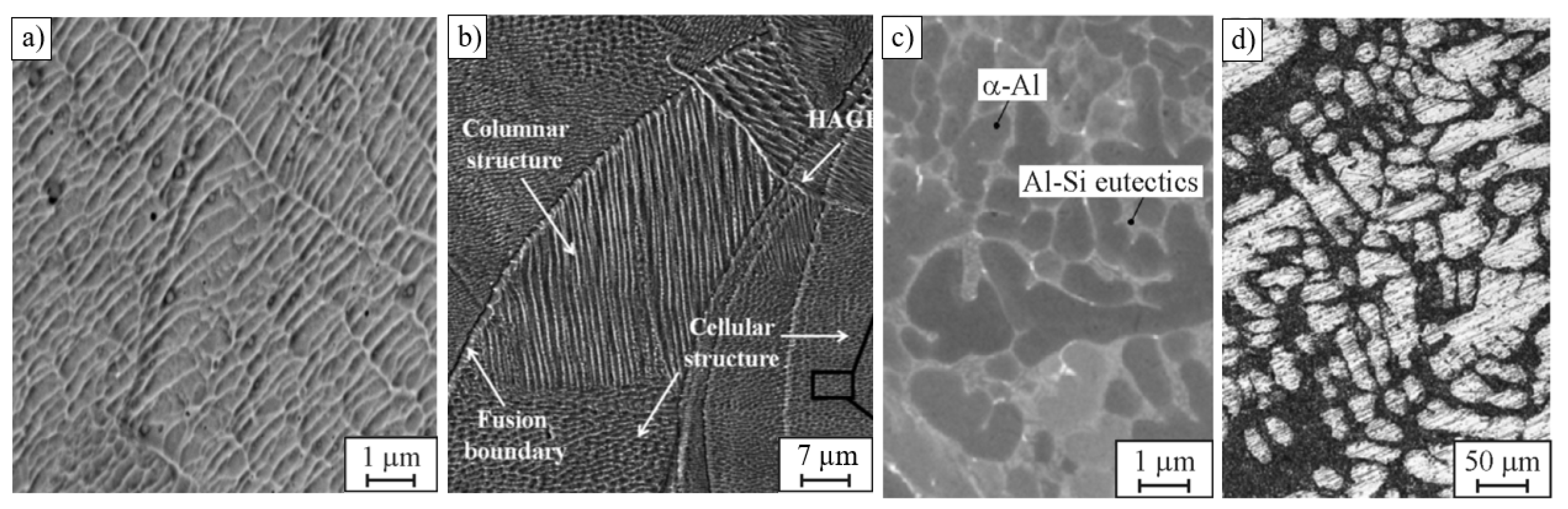

2. Microstructural Features of Materials Fabricated by PBF

2.1. Melt Pool Pattern

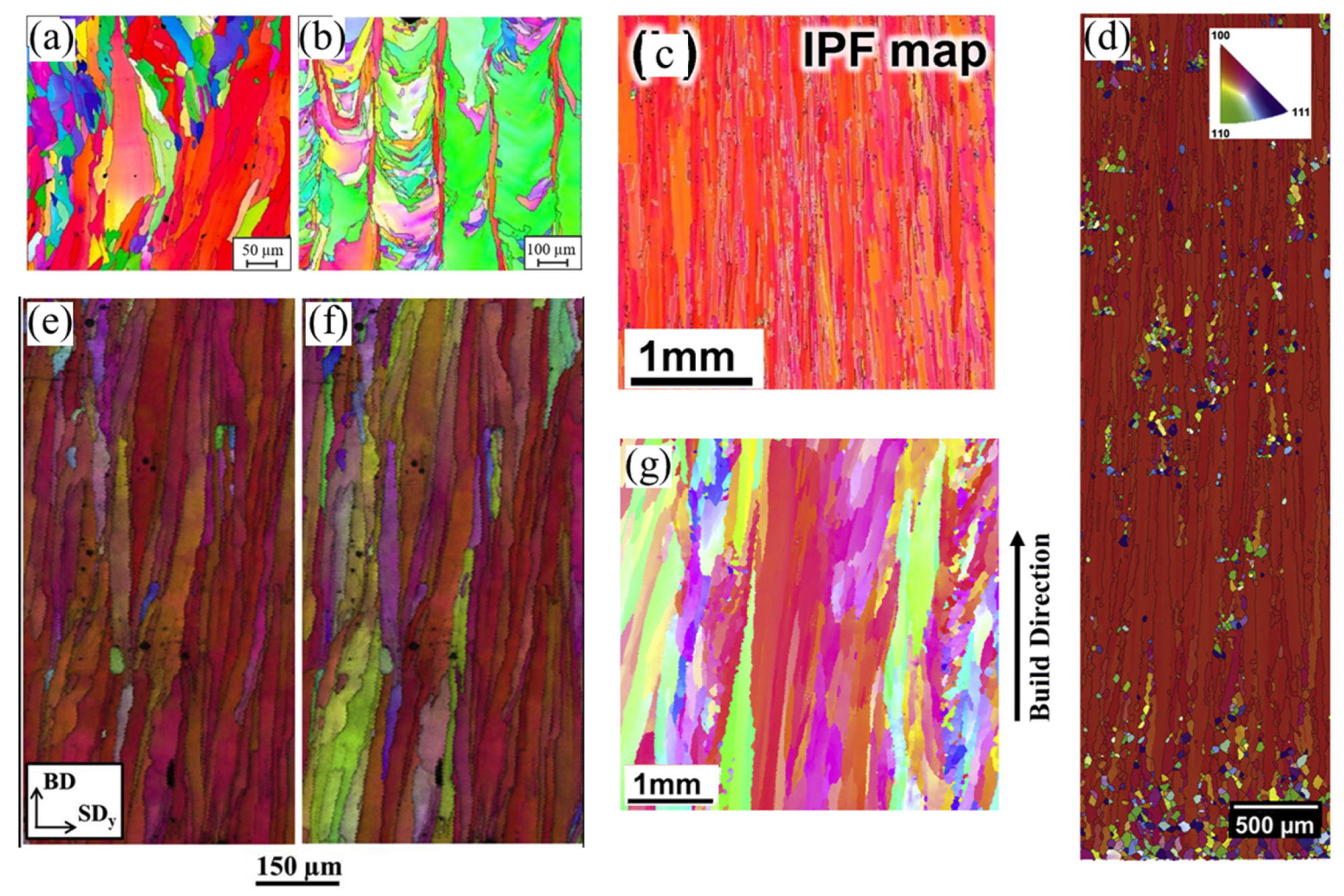

2.2. Grains

2.3. Cellular–Dendritic Substructure

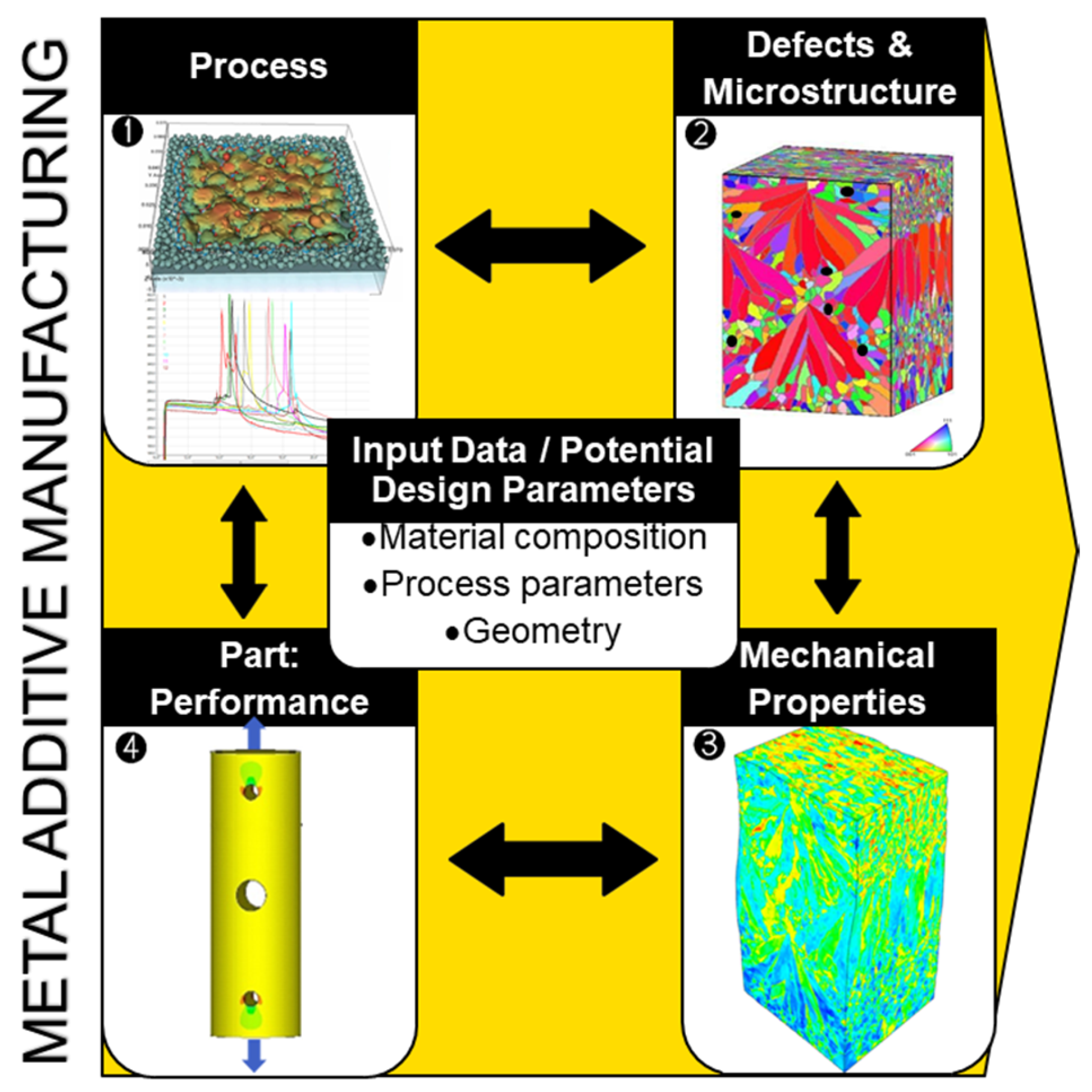

3. Process-Structure-Properties-Performance Concept

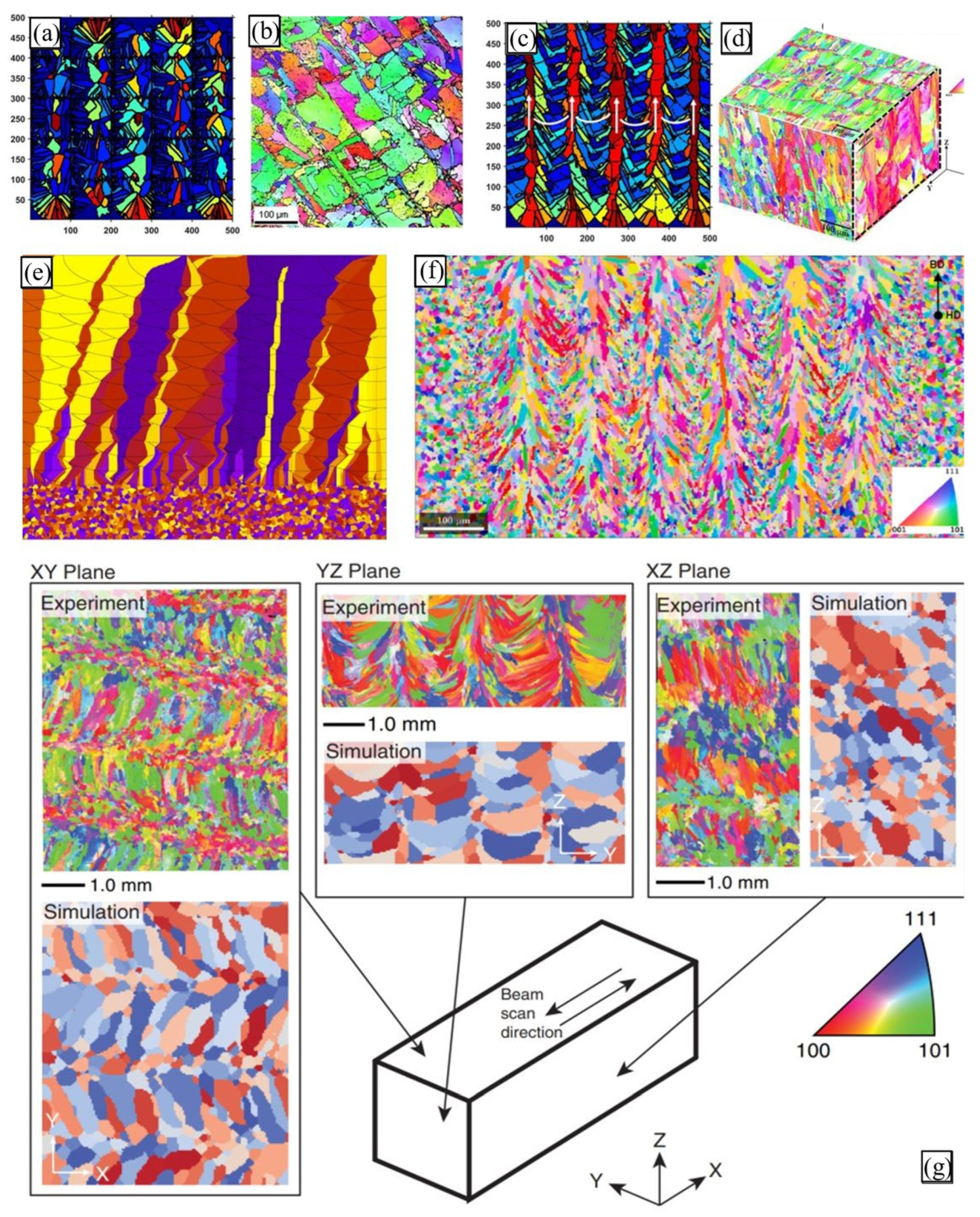

4. Microstructure Modelling in AM

4.1. Physically Based Microstructure Modelling

4.2. Geometrically Based Microstructure Modelling and Image Reconstruction

5. BVP Formulation for Microstructure-Based Mechanical Simulations of Additively Manufactured Metallic Materials

5.1. FE Implementation of a Boundary-Value Problem

5.2. Kinematics and Constitutive Laws

5.3. Constitutive Models of the Plastic Behaviour of Grains

5.4. Description of Hardening Mechanisms in PBF-Produced Materials

6. Microstructure-Informative Mechanical Simulations of Additively Manufactured Metallic Materials

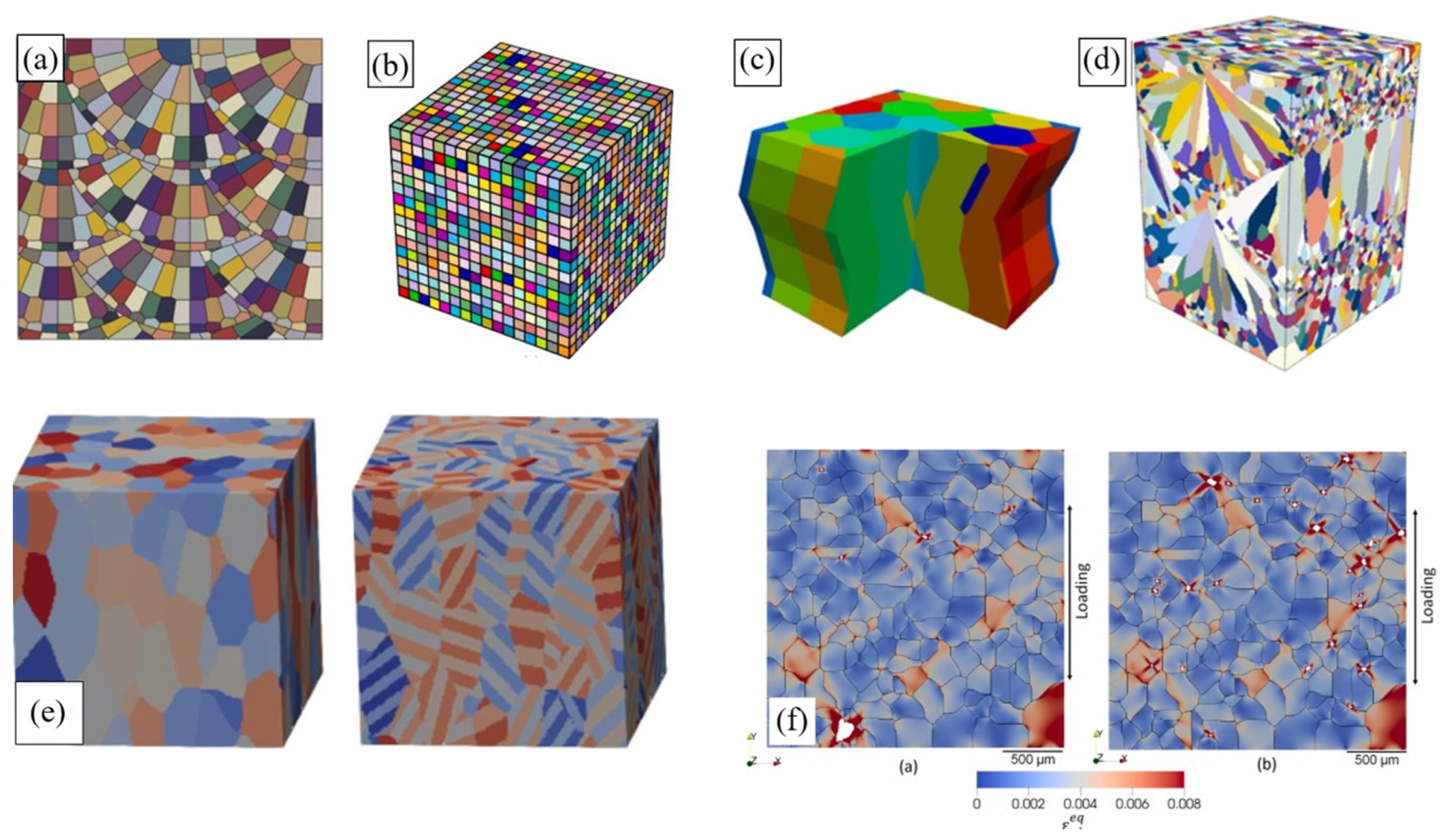

6.1. Two-Dimensional Microstructure-Based Mechanical Simulations

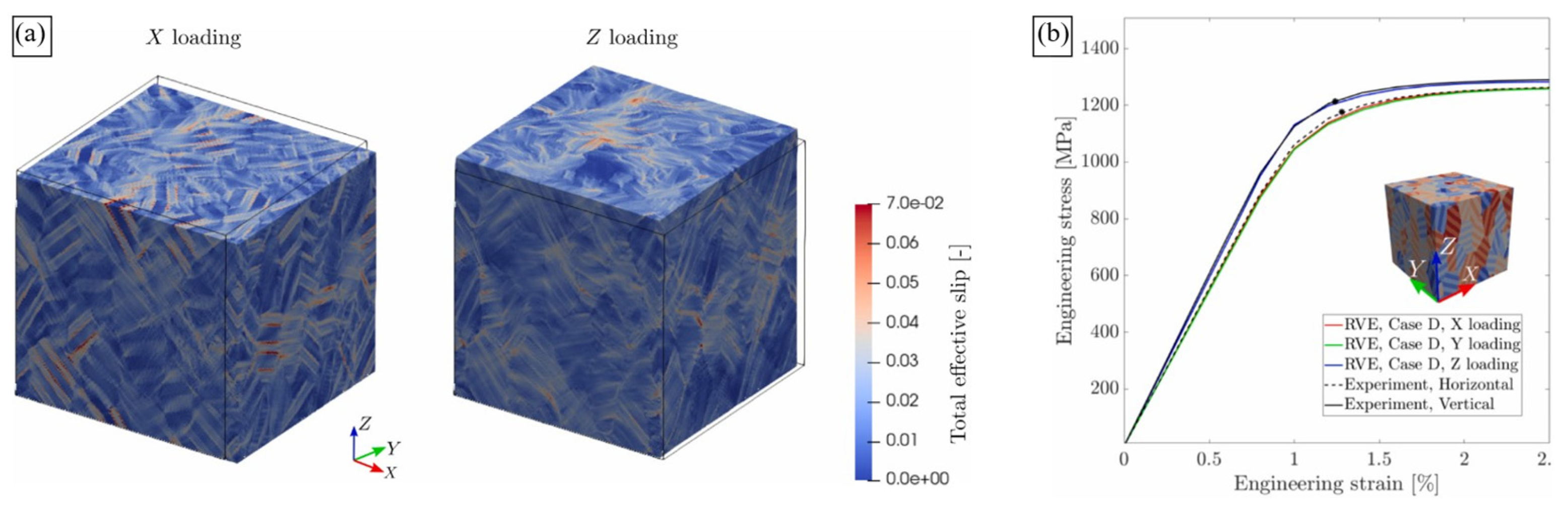

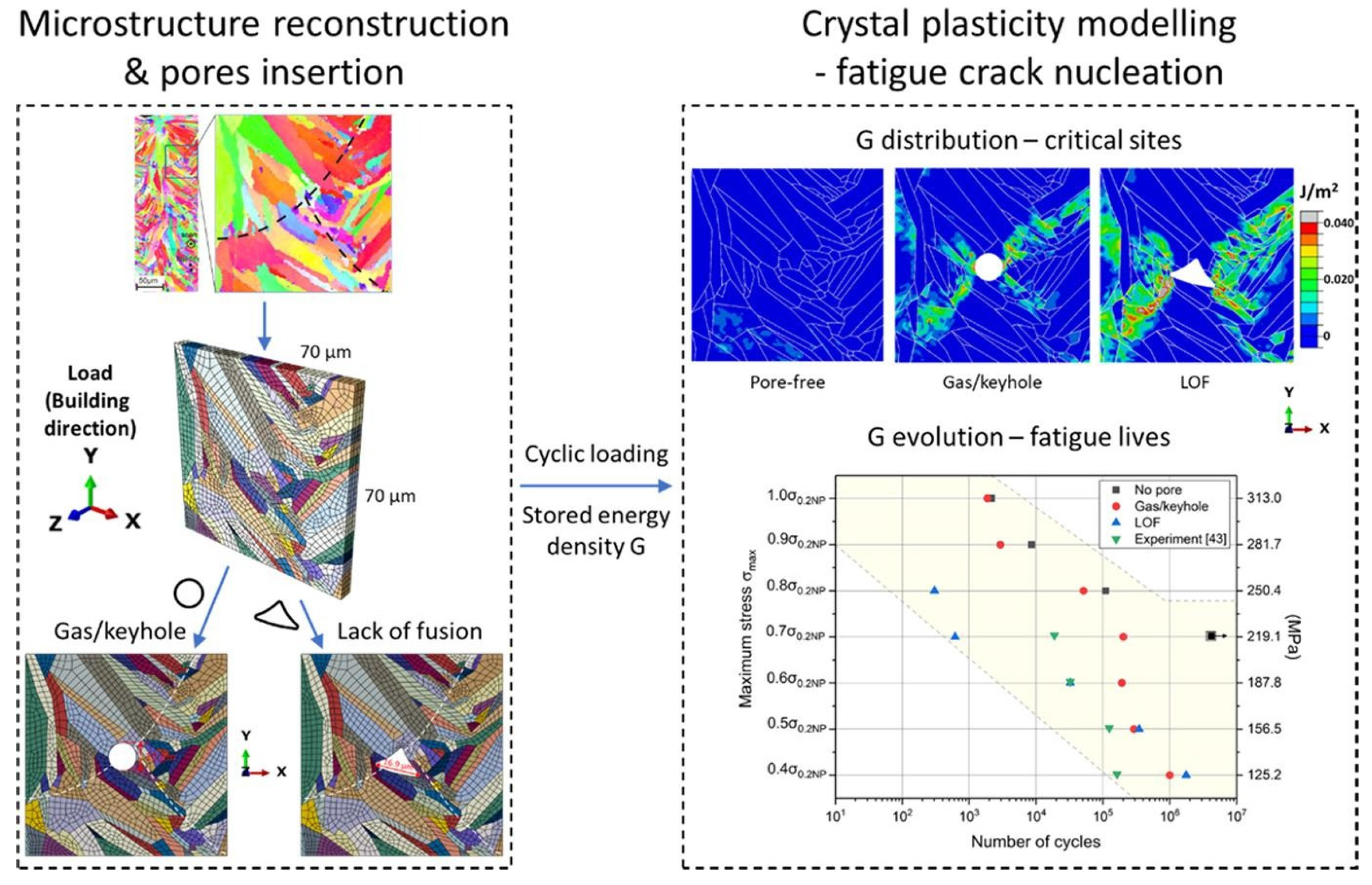

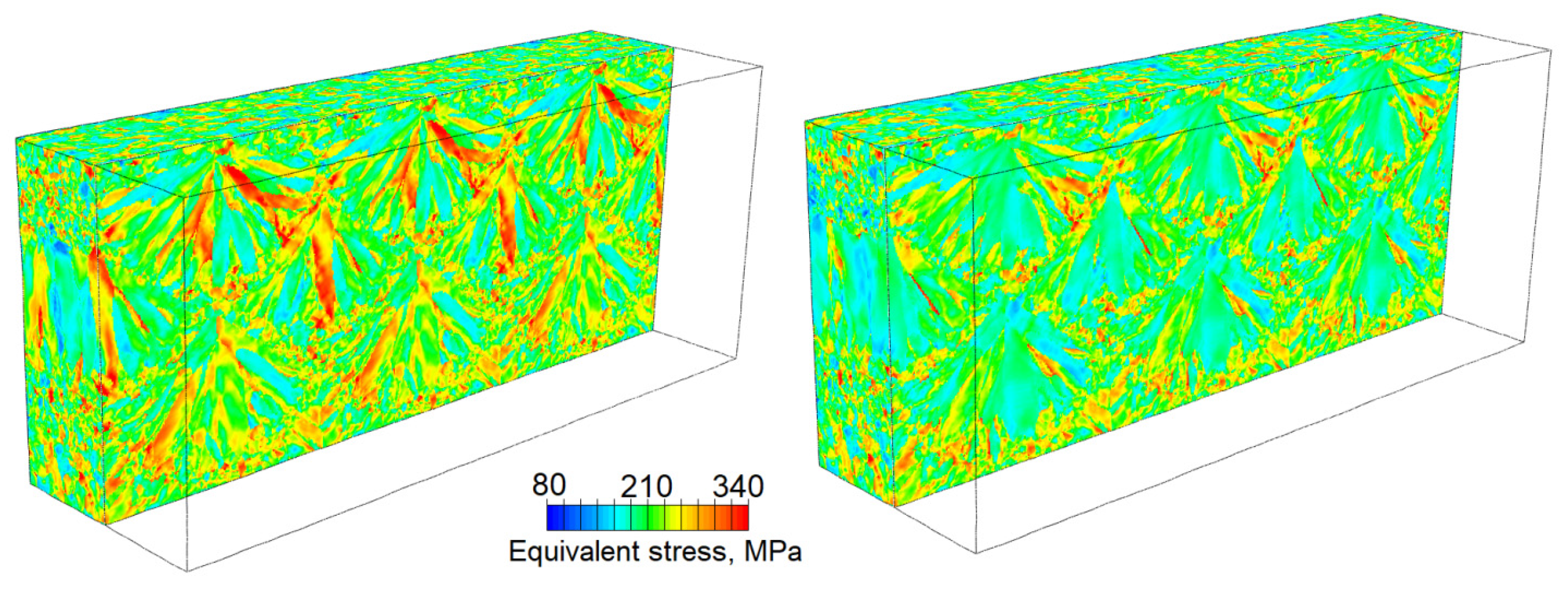

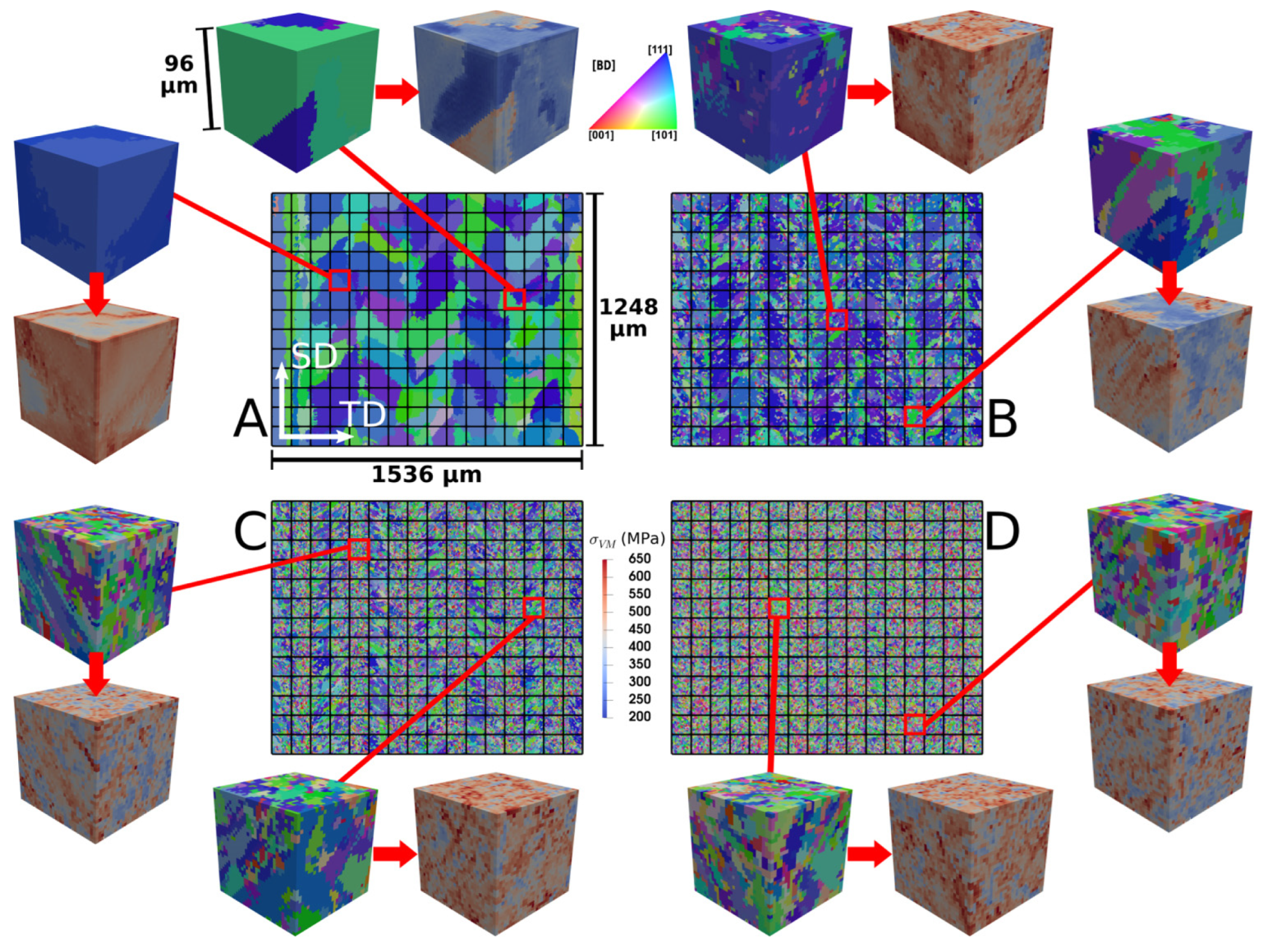

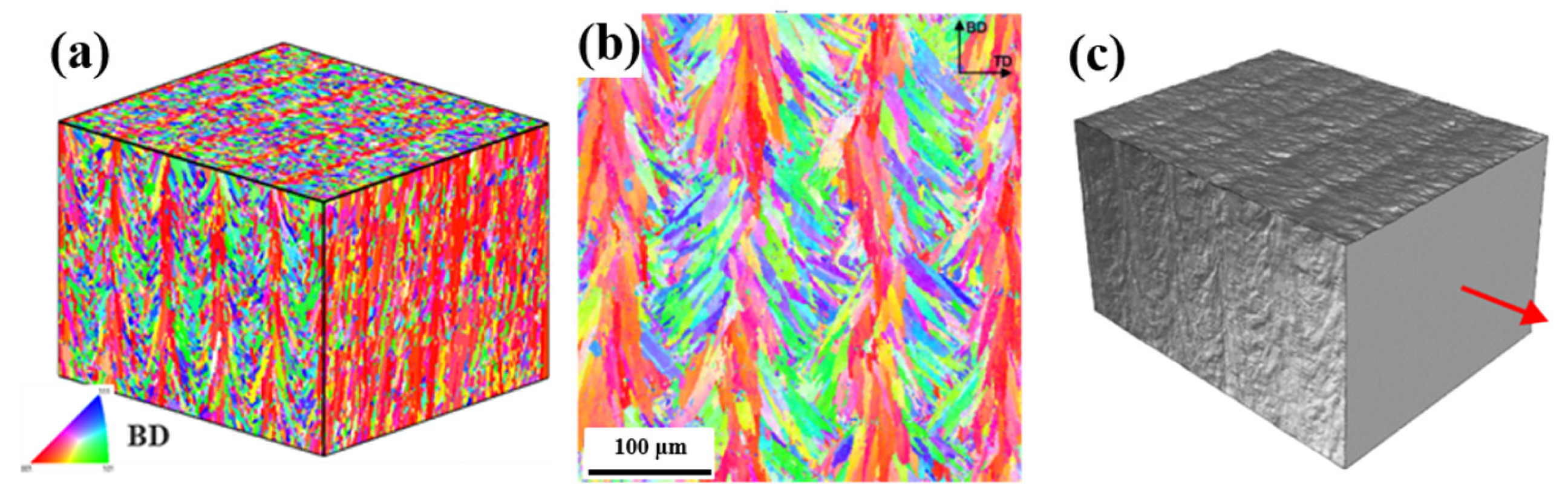

6.2. Three-Dimensional Mechanical Simulations for Synthetic Microstructures

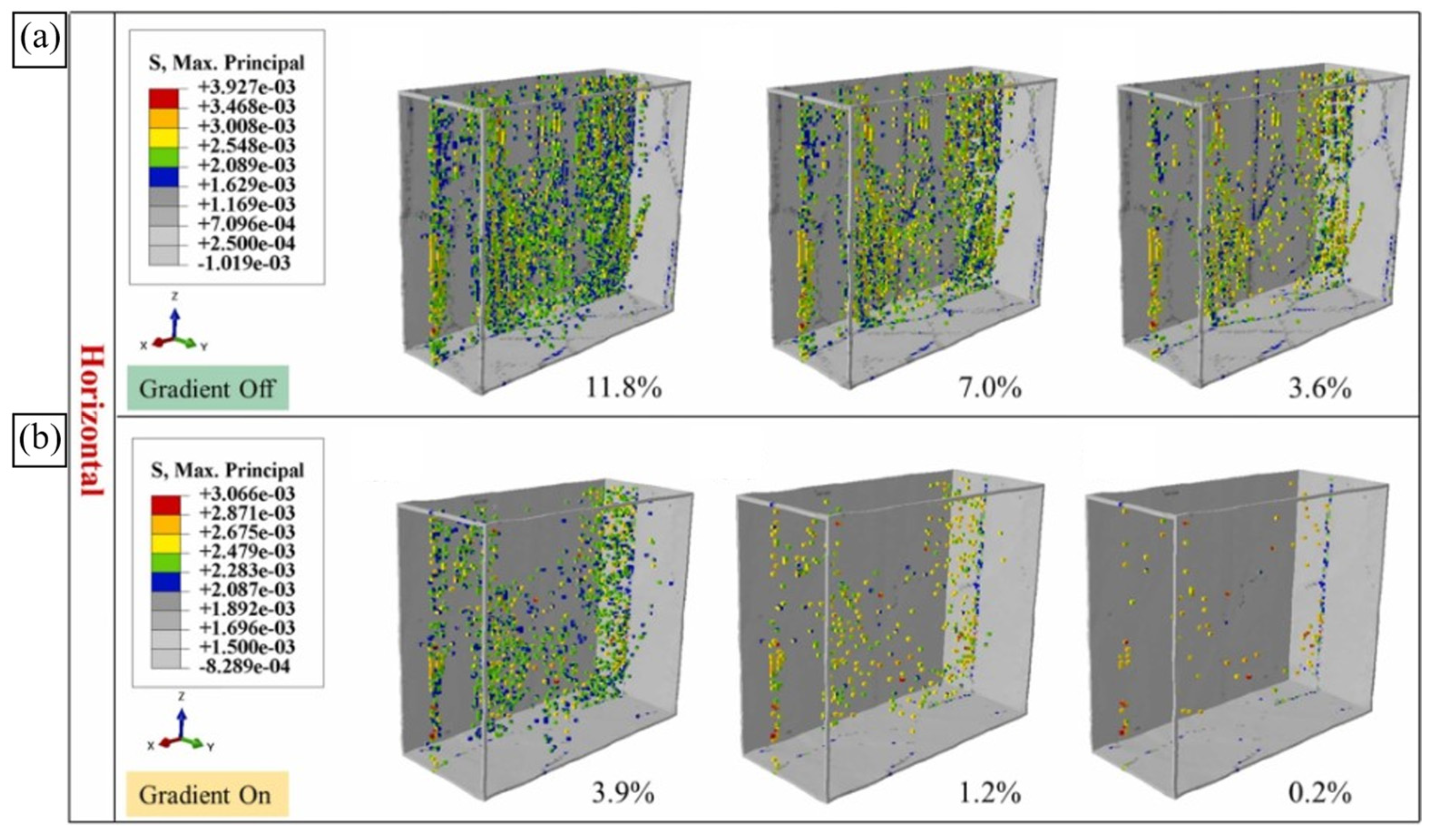

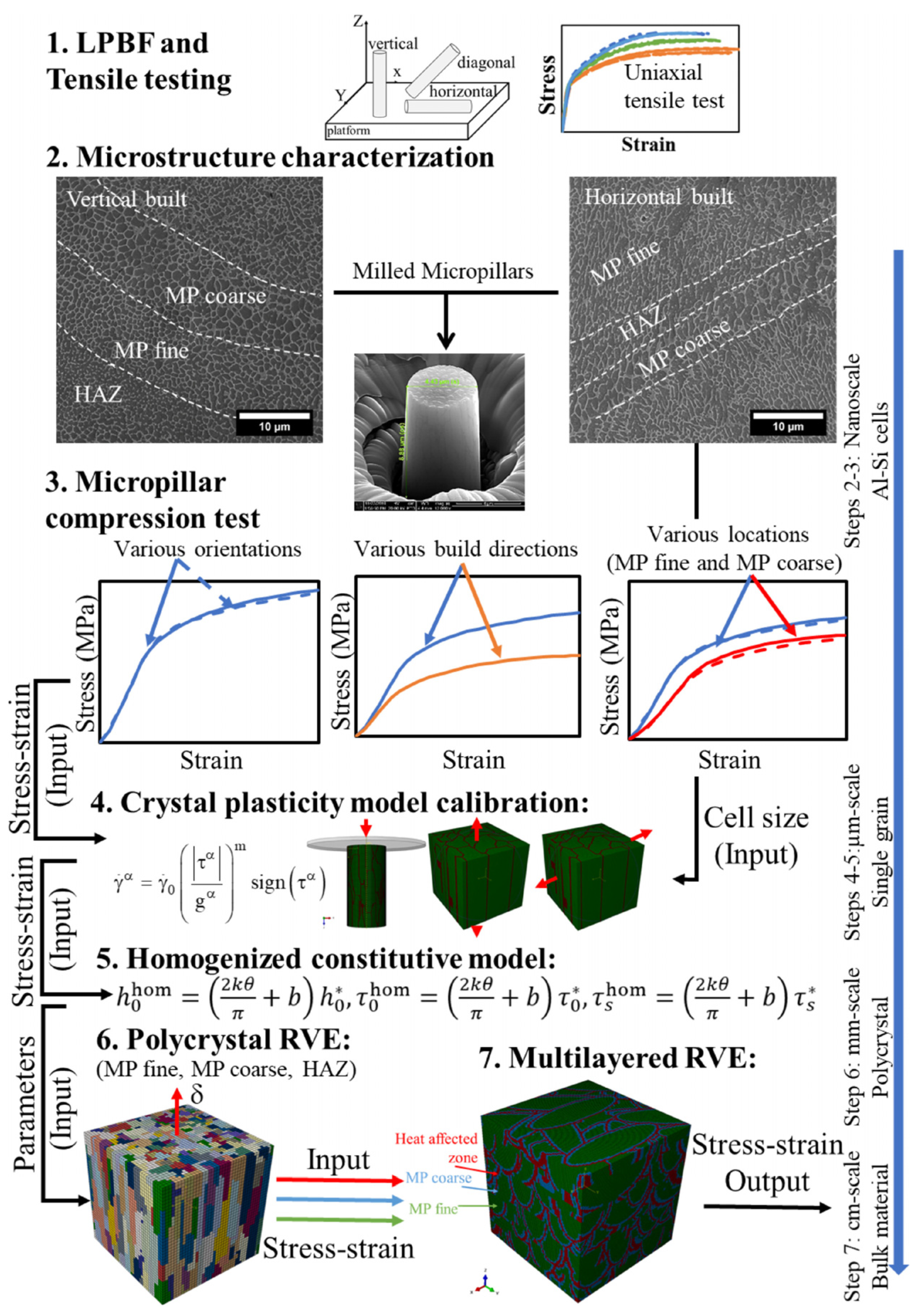

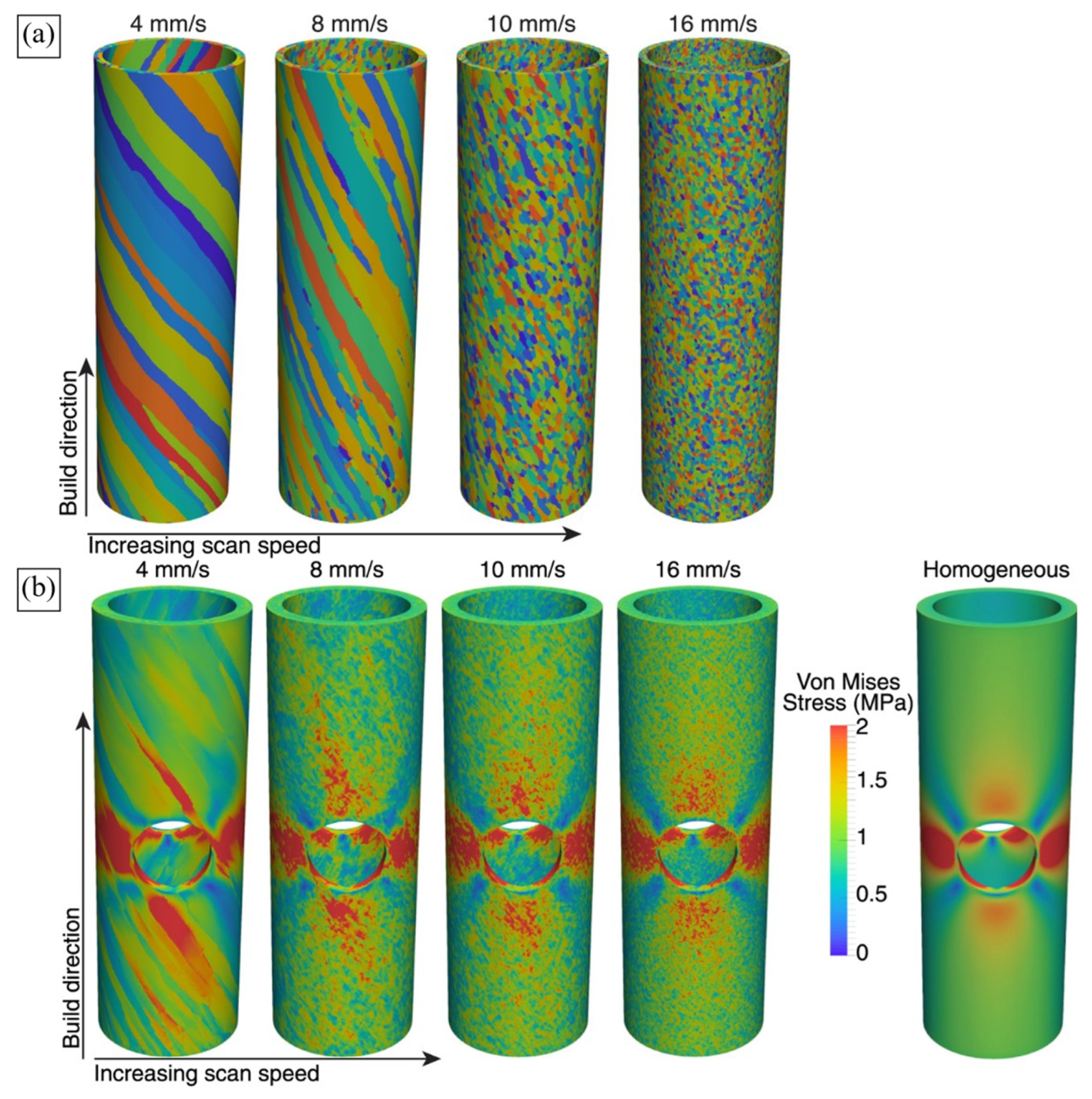

6.3. Process–Structure–Property–Performance Computational Analysis

7. Summary and Future Directions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yadroitsev, I.; Yadroitsava, I.; du Plessis, A.; MacDonald, E. (Eds.) Fundamentals of Laser Powder Bed Fusion of Metals; Elsevier: Amsterdam, The Netherlands, 2021; ISBN 9780128240908. [Google Scholar]

- Francois, M.M.; Sun, A.; King, W.E.; Henson, N.J.; Tourret, D.; Bronkhorst, C.A.; Carlson, N.N.; Newman, C.K.; Haut, T.; Bakosi, J.; et al. Modeling of Additive Manufacturing Processes for Metals: Challenges and Opportunities. Curr. Opin. Solid State Mater. Sci. 2017, 21, 198–206. [Google Scholar] [CrossRef]

- Kotadia, H.R.; Gibbons, G.; Das, A.; Howes, P.D. A Review of Laser Powder Bed Fusion Additive Manufacturing of Aluminium Alloys: Microstructure and Properties. Addit. Manuf. 2021, 46, 102155. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive Manufacturing of Metallic Components—Process, Structure and Properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Fernandez-Zelaia, P.; Kirka, M.M.; Dryepondt, S.N.; Gussev, M.N. Crystallographic Texture Control in Electron Beam Additive Manufacturing via Conductive Manipulation. Mater. Des. 2020, 195, 109010. [Google Scholar] [CrossRef]

- Gokcekaya, O.; Ishimoto, T.; Hibino, S.; Yasutomi, J.; Narushima, T.; Nakano, T. Unique Crystallographic Texture Formation in Inconel 718 by Laser Powder Bed Fusion and Its Effect on Mechanical Anisotropy. Acta Mater. 2021, 212, 116876. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Yadroitsava, I. A Step-by-Step Guide to the L-PBF Process. In Fundamentals of Laser Powder Bed Fusion of Metals; Yadroitsev, I., Yadroitsava, I., du Plessis, A., MacDonald, E., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 39–77. [Google Scholar]

- Fotovvati, B.; Rauniyar, S.; Jobe, A.A.; Chou, K. Experimental, Computational, and Data-Driven Study of the Effects of Selective Laser Melting (SLM) Process Parameters on Single-Layer Surface Characteristics. Int. J. Adv. Manuf. Technol. 2022, 123, 119–144. [Google Scholar] [CrossRef]

- Rehme, O.; Emmelmann, C. Reproducibility for Properties of Selective Laser Melting Products. In Proceedings of the Third International WLT-Conference on Lasers in Manufacturing, Munich, Germany, 13–16 June 2005; Beyer, E., Ed.; AT-Verlag: Stuttgart, Germany, 2005; pp. 1–6. [Google Scholar]

- Kahlen, F.-J.; Kar, A. Tensile Strengths for Laser-Fabricated Parts and Similarity Parameters for Rapid Manufacturing. J. Manuf. Sci. Eng. 2001, 123, 38–44. [Google Scholar] [CrossRef]

- Samuel, M.P.; Mishra, A.K.; Mishra, R.K. Additive Manufacturing of Ti-6Al-4V Aero Engine Parts: Qualification for Reliability. J. Fail. Anal. Prev. 2018, 18, 136–144. [Google Scholar] [CrossRef]

- Lowther, M.; Louth, S.; Davey, A.; Hussain, A.; Ginestra, P.; Carter, L.; Eisenstein, N.; Grover, L.; Cox, S. Clinical, Industrial, and Research Perspectives on Powder Bed Fusion Additively Manufactured Metal Implants. Addit. Manuf. 2019, 28, 565–584. [Google Scholar] [CrossRef]

- DebRoy, T.; Mukherjee, T.; Milewski, J.O.; Elmer, J.W.; Ribic, B.; Blecher, J.J.; Zhang, W. Scientific, Technological and Economic Issues in Metal Printing and Their Solutions. Nat. Mater. 2019, 18, 1026–1032. [Google Scholar] [CrossRef]

- Zinovieva, O.; Romanova, V.; Balokhonov, R. Predictive Simulation of Microstructural Pattern in AM for Metals in Powder Bed Fusion. In Quality Analysis of Additively Manufactured Metals; Kadkhodapour, J., Schmauder, S., Sajadi, F., Eds.; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Wang, F.; Williams, S.; Rush, M. Morphology Investigation on Direct Current Pulsed Gas Tungsten Arc Welded Additive Layer Manufactured Ti6Al4V Alloy. Int. J. Adv. Manuf. Technol. 2011, 57, 597–603. [Google Scholar] [CrossRef]

- Garibaldi, M.; Ashcroft, I.; Simonelli, M.; Hague, R. Metallurgy of High-Silicon Steel Parts Produced Using Selective Laser Melting. Acta Mater. 2016, 110, 207–216. [Google Scholar] [CrossRef]

- Zinovieva, O.; Romanova, V.; Balokhonov, R. Effects of Scanning Pattern on the Grain Structure and Elastic Properties of Additively Manufactured 316L Austenitic Stainless Steel. Mater. Sci. Eng. A 2022, 832, 142447. [Google Scholar] [CrossRef]

- Wang, Y.M.; Voisin, T.; McKeown, J.T.; Ye, J.; Calta, N.P.; Li, Z.; Zeng, Z.; Zhang, Y.; Chen, W.; Roehling, T.T.; et al. Additively Manufactured Hierarchical Stainless Steels with High Strength and Ductility. Nat. Mater. 2018, 17, 63–70. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Z.; Sun, J.; Berto, F.; Wang, X.; Qian, G. Fatigue and Fracture Behavior of AlSi10Mg Manufactured by Selective Laser Melting: A Review. Phys. Mesomech. 2023, 26, 367–390. [Google Scholar] [CrossRef]

- Mukherjee, T.; DebRoy, T. A Digital Twin for Rapid Qualification of 3D Printed Metallic Components. Appl. Mater. Today 2019, 14, 59–65. [Google Scholar] [CrossRef]

- Wei, H.L.; Mukherjee, T.; Zhang, W.; Zuback, J.S.; Knapp, G.L.; De, A.; DebRoy, T. Mechanistic Models for Additive Manufacturing of Metallic Components. Prog. Mater. Sci. 2021, 116, 100703. [Google Scholar] [CrossRef]

- King, W.E.; Anderson, A.T.; Ferencz, R.M.; Hodge, N.E.; Kamath, C.; Khairallah, S.A.; Rubenchik, A.M. Laser Powder Bed Fusion Additive Manufacturing of Metals; Physics, Computational, and Materials Challenges. Appl. Phys. Rev. 2015, 2, 41304. [Google Scholar] [CrossRef]

- Gunasegaram, D.R.; Murphy, A.B.; Barnard, A.; DebRoy, T.; Matthews, M.J.; Ladani, L.; Gu, D. Towards Developing Multiscale-Multiphysics Models and Their Surrogates for Digital Twins of Metal Additive Manufacturing. Addit. Manuf. 2021, 46, 102089. [Google Scholar] [CrossRef]

- Trusov, P.V.; Shveykin, A.I.; Kondratyev, N.S.; Yants, A.Y. Multilevel Models in Physical Mesomechanics of Metals and Alloys: Results and Prospects. Phys. Mesomech. 2021, 24, 391–417. [Google Scholar] [CrossRef]

- Costas, M.; Morin, D.; de Lucio, M.; Langseth, M. Testing and Simulation of Additively Manufactured AlSi10Mg Components under Quasi-Static Loading. Eur. J. Mech. A/Solids 2020, 81, 103966. [Google Scholar] [CrossRef]

- Liu, J.; Xiong, W.; Behera, A.; Thompson, S.; To, A.C. Mean-Field Polycrystal Plasticity Modeling with Grain Size and Shape Effects for Laser Additive Manufactured FCC Metals. Int. J. Solids Struct. 2017, 112, 35–42. [Google Scholar] [CrossRef]

- Gribov, D.S.; Trusov, P.V. Three-Level Dislocation-Based Model for Describing the Deformation of Polycrystals: Structure, Implementation Algorithm, Examples for Studying Nonproportional Cyclic Loading. Phys. Mesomech. 2022, 25, 557–567. [Google Scholar] [CrossRef]

- Babu, B.; Lundbäck, A.; Lindgren, L.-E. Simulation of Ti-6Al-4V Additive Manufacturing Using Coupled Physically Based Flow Stress and Metallurgical Model. Materials 2019, 12, 3844. [Google Scholar] [CrossRef]

- Romanova, V.; Balokhonov, R.; Zinovieva, O.; Emelianova, E.; Dymnich, E.; Pisarev, M.; Zinoviev, A. Micromechanical Simulations of Additively Manufactured Aluminum Alloys. Comput. Struct. 2021, 244, 106412. [Google Scholar] [CrossRef]

- Romanova, V.; Zinovieva, O.; Balokhonov, R.; Dymnich, E.; Moskvichev, E.; Filippov, A.; Lychagin, D. Effects of the Grain Shape and Crystallographic Texture on the Grain-Scale Mechanical Behavior of Additively Manufactured Aluminum Alloys. Addit. Manuf. 2021, 48, 102415. [Google Scholar] [CrossRef]

- Kergaßner, A.; Mergheim, J.; Steinmann, P. Modeling of Additively Manufactured Materials Using Gradient-Enhanced Crystal Plasticity. Comput. Math. Appl. 2019, 78, 2338–2350. [Google Scholar] [CrossRef]

- Zinovieva, O.; Zinoviev, A.; Ploshikhin, V.; Romanova, V.; Balokhonov, R. Strategy of Computational Predictions for Mechanical Behaviour of Additively Manufactured Materials. Mater. Sci. Technol. 2018, 34, 1591–1605. [Google Scholar] [CrossRef]

- Bagheri, A.; Yadollahi, A.; Mahtabi, M.J.; Paudel, Y.; Vance, E.; Shamsaei, N.; Horstemeyer, M.F. Microstructure-Based Multistage Fatigue Modeling of NiTi Alloy Fabricated via Direct Energy Deposition (DED). J. Mater. Eng. Perform. 2022, 31, 4761–4775. [Google Scholar] [CrossRef]

- Wu, S.; Song, H.Y.; Peng, H.Z.; Hodgson, P.D.; Wang, H.; Wu, X.H.; Zhu, Y.M.; Lam, M.C.; Huang, A.J. A Microstructure-Based Creep Model for Additively Manufactured Nickel-Based Superalloys. Acta Mater. 2022, 224, 117528. [Google Scholar] [CrossRef]

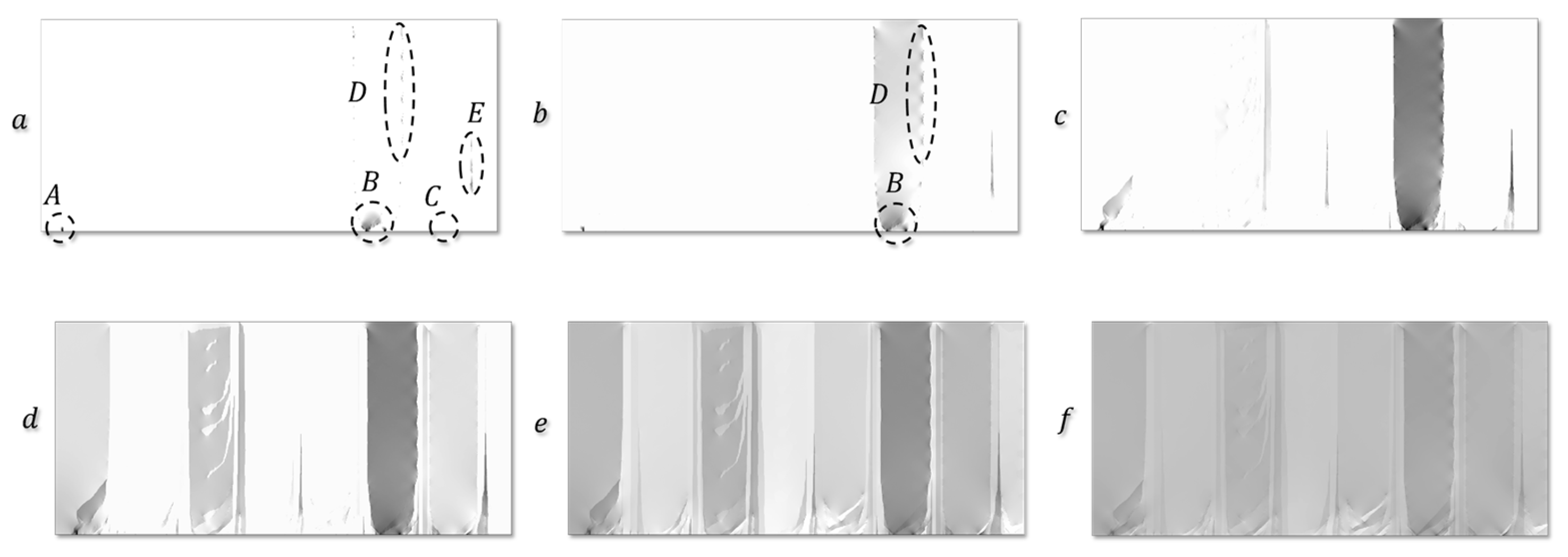

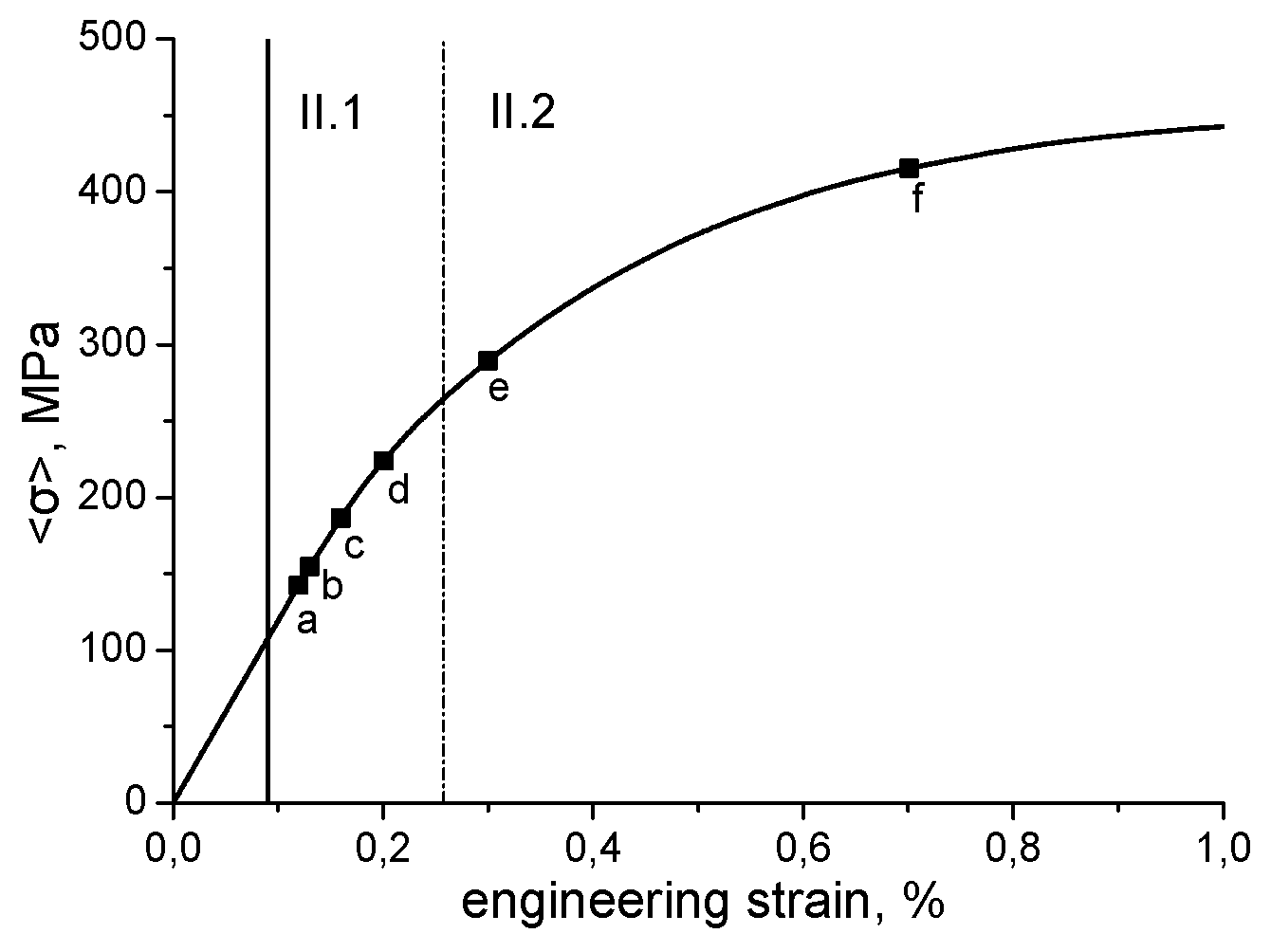

- Romanova, V.; Balokhonov, R.; Emelianova, E.; Zinovieva, O.; Zinoviev, A. Microstructure-Based Simulations of Quasistatic Deformation Using an Explicit Dynamic Approach. Facta Univ. Ser. Mech. Eng. 2019, 17, 243–254. [Google Scholar] [CrossRef]

- Somlo, K.; Poulios, K.; Funch, C.V.; Niordson, C.F. Anisotropic Tensile Behaviour of Additively Manufactured Ti-6Al-4V Simulated with Crystal Plasticity. Mech. Mater. 2021, 162, 104034. [Google Scholar] [CrossRef]

- Saeb, S.; Steinmann, P.; Javili, A. Aspects of Computational Homogenization at Finite Deformations: A Unifying Review from Reuss’ to Voigt’s Bound. Appl. Mech. Rev. 2016, 68, 050801. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, Y.; Ge, P. A Review on Modelling and Simulation of Laser Additive Manufacturing: Heat Transfer, Microstructure Evolutions and Mechanical Properties. Coatings 2022, 12, 1277. [Google Scholar] [CrossRef]

- Tan, Z.; Li, J.; Zhang, Z. Experimental and Numerical Studies on Fabrication of Nanoparticle Reinforced Aluminum Matrix Composites by Friction Stir Additive Manufacturing. J. Mater. Res. Technol. 2021, 12, 1898–1912. [Google Scholar] [CrossRef]

- Gatsos, T.; Elsayed, K.A.; Zhai, Y.; Lados, D.A. Review on Computational Modeling of Process–Microstructure–Property Relationships in Metal Additive Manufacturing. JOM 2020, 72, 403–419. [Google Scholar] [CrossRef]

- Zhao, L.; Song, L.; Santos Macías, J.G.; Zhu, Y.; Huang, M.; Simar, A.; Li, Z. Review on the Correlation between Microstructure and Mechanical Performance for Laser Powder Bed Fusion AlSi10Mg. Addit. Manuf. 2022, 56, 102914. [Google Scholar] [CrossRef]

- Bajaj, P.; Hariharan, A.; Kini, A.; Kürnsteiner, P.; Raabe, D.; Jägle, E.A. Steels in Additive Manufacturing: A Review of Their Microstructure and Properties. Mater. Sci. Eng. A 2020, 772, 138633. [Google Scholar] [CrossRef]

- Karthik, G.M.; Kim, H.S. Heterogeneous Aspects of Additive Manufactured Metallic Parts: A Review. Met. Mater. Int. 2021, 27, 1–39. [Google Scholar] [CrossRef]

- Tonelli, L. Revealing the Hierarchical Microstructure of Innovative Additively Manufactured Metal Parts with Conventional Light Microscopy. Metallogr. Microstruct. Anal. 2021, 10, 278–282. [Google Scholar] [CrossRef]

- Haines, M.P.; Rielli, V.V.; Primig, S.; Haghdadi, N. Powder Bed Fusion Additive Manufacturing of Ni-Based Superalloys: A Review of the Main Microstructural Constituents and Characterization Techniques. J. Mater. Sci. 2022, 57, 14135–14187. [Google Scholar] [CrossRef]

- Zinovieva, O.; Romanova, V.; Balokhonov, R.; Emelyanova, T. A Review of Microstructure and Mechanical Properties of Additively Manufactured Aluminum Alloys. AIP Conf. Proc. 2020, 2310, 020364. [Google Scholar] [CrossRef]

- Yin, Y.; Tan, Q.; Bermingham, M.; Mo, N.; Zhang, J.; Zhang, M.-X. Laser Additive Manufacturing of Steels. Int. Mater. Rev. 2022, 67, 487–573. [Google Scholar] [CrossRef]

- Delahaye, J.; Tchuindjang, J.T.; Lecomte-Beckers, J.; Rigo, O.; Habraken, A.M.; Mertens, A. Influence of Si Precipitates on Fracture Mechanisms of AlSi10Mg Parts Processed by Selective Laser Melting. Acta Mater. 2019, 175, 160–170. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, H.; Qi, T.; Hu, Z.; Zeng, X. Selective Laser Melting of High Strength Al–Cu–Mg Alloys: Processing, Microstructure and Mechanical Properties. Mater. Sci. Eng. A 2016, 656, 47–54. [Google Scholar] [CrossRef]

- Karayagiz, K.; Johnson, L.; Seede, R.; Attari, V.; Zhang, B.; Huang, X.; Ghosh, S.; Duong, T.; Karaman, I.; Elwany, A.; et al. Finite Interface Dissipation Phase Field Modeling of Ni–Nb under Additive Manufacturing Conditions. Acta Mater. 2020, 185, 320–339. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.P.; Van Humbeeck, J. Microstructure and Mechanical Properties of a Novel β Titanium Metallic Composite by Selective Laser Melting. Acta Mater. 2014, 68, 150–158. [Google Scholar] [CrossRef]

- Sato, K.; Takagi, S.; Ichikawa, S.; Ishimoto, T.; Nakano, T. Microstructure and Solute Segregation around the Melt-Pool Boundary of Orientation-Controlled 316L Austenitic Stainless Steel Produced by Laser Powder Bed Fusion. Materials 2023, 16, 218. [Google Scholar] [CrossRef]

- Wei, H.L.; Mazumder, J.; Debroy, T. Evolution of Solidification Texture during Additive Manufacturing. Sci. Rep. 2015, 5, 16446. [Google Scholar] [CrossRef]

- Pantawane, M.V.; Sharma, S.; Dasari, S.; Mantri, S.A.; Sharma, A.; Banerjee, R.; Banerjee, S.; Dahotre, N.B. Spatial Variation of Thermokinetics and Associated Microstructural Evolution in Laser Surface Engineered IN718: Precursor to Additive Manufacturing. Metall. Mater. Trans. A 2021, 52, 2344–2360. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; van Humbeeck, J.; Kruth, J.P. A Study of the Microstructural Evolution during Selective Laser Melting of Ti-6Al-4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Li, W.; Li, S.; Liu, J.; Zhang, A.; Zhou, Y.; Wei, Q.; Yan, C.; Shi, Y. Effect of Heat Treatment on AlSi10Mg Alloy Fabricated by Selective Laser Melting: Microstructure Evolution, Mechanical Properties and Fracture Mechanism. Mater. Sci. Eng. A 2016, 663, 116–125. [Google Scholar] [CrossRef]

- Okugawa, M.; Ohigashi, Y.; Furishiro, Y.; Koizumi, Y.; Nakano, T. Equiaxed Grain Formation by Intrinsic Heterogeneous Nucleation via Rapid Heating and Cooling in Additive Manufacturing of Aluminum-Silicon Hypoeutectic Alloy. J. Alloys Compd. 2022, 919, 165812. [Google Scholar] [CrossRef]

- Liu, Y.J.; Liu, Z.; Jiang, Y.; Wang, G.W.; Yang, Y.; Zhang, L.C. Gradient in Microstructure and Mechanical Property of Selective Laser Melted AlSi10Mg. J. Alloys Compd. 2018, 735, 1414–1421. [Google Scholar] [CrossRef]

- Jiang, Z.; Li, Y.; Luo, H.; Zhou, B.; Liang, Y.; Liang, Y. Effect of the Boundary Orientation of Melt Pool on Mechanical Property and Fracture Path in Selective-Laser-Melted AlSi10Mg Alloy. Met. Mater. Int. 2022, 28, 2934–2946. [Google Scholar] [CrossRef]

- Shifeng, W.; Shuai, L.; Qingsong, W.; Yan, C.; Sheng, Z.; Yusheng, S. Effect of Molten Pool Boundaries on the Mechanical Properties of Selective Laser Melting Parts. J. Mater. Process Technol. 2014, 214, 2660–2667. [Google Scholar] [CrossRef]

- Xiong, Z.H.; Liu, S.L.; Li, S.F.; Shi, Y.; Yang, Y.F.; Misra, R.D.K. Role of Melt Pool Boundary Condition in Determining the Mechanical Properties of Selective Laser Melting AlSi10Mg Alloy. Mater. Sci. Eng. A 2019, 740–741, 148–156. [Google Scholar] [CrossRef]

- Zhang, S.; Hou, P.; Mooraj, S.; Chen, W. Printability of Zr41.2Ti13.8Cu12.5Ni10.0Be22.5 Metallic Glass on Steel by Laser Additive Manufacturing: A Single-Track Study. Surf. Coat. Technol. 2021, 428, 127882. [Google Scholar] [CrossRef]

- Kudzal, A.; McWilliams, B.; Hofmeister, C.; Kellogg, F.; Yu, J.; Taggart-Scarff, J.; Liang, J. Effect of Scan Pattern on the Microstructure and Mechanical Properties of Powder Bed Fusion Additive Manufactured 17-4 Stainless Steel. Mater. Des. 2017, 133, 205–215. [Google Scholar] [CrossRef]

- Antonysamy, A.A.; Meyer, J.; Prangnell, P.B. Effect of Build Geometry on the β-Grain Structure and Texture in Additive Manufacture of Ti6Al4V by Selective Electron Beam Melting. Mater. Charact. 2013, 84, 153–168. [Google Scholar] [CrossRef]

- Ghorbanpour, S.; Alam, M.E.; Ferreri, N.C.; Kumar, A.; McWilliams, B.A.; Vogel, S.C.; Bicknell, J.; Beyerlein, I.J.; Knezevic, M. Experimental Characterization and Crystal Plasticity Modeling of Anisotropy, Tension-Compression Asymmetry, and Texture Evolution of Additively Manufactured Inconel 718 at Room and Elevated Temperatures. Int. J. Plast. 2020, 125, 63–79. [Google Scholar] [CrossRef]

- Koepf, J.A.; Gotterbarm, M.R.; Markl, M.; Körner, C. 3D Multi-Layer Grain Structure Simulation of Powder Bed Fusion Additive Manufacturing. Acta Mater. 2018, 152, 119–126. [Google Scholar] [CrossRef]

- Raghavan, N.; Dehoff, R.; Pannala, S.; Simunovic, S.; Kirka, M.; Turner, J.; Carlson, N.; Babu, S.S. Numerical Modeling of Heat-Transfer and the Influence of Process Parameters on Tailoring the Grain Morphology of IN718 in Electron Beam Additive Manufacturing. Acta Mater. 2016, 112, 303–314. [Google Scholar] [CrossRef]

- Guan, K.; Wang, Z.; Gao, M.; Li, X.; Zeng, X. Effects of Processing Parameters on Tensile Properties of Selective Laser Melted 304 Stainless Steel. Mater. Des. 2013, 50, 581–586. [Google Scholar] [CrossRef]

- Yin, Y.J.; Sun, J.Q.; Guo, J.; Kan, X.F.; Yang, D.C. Mechanism of High Yield Strength and Yield Ratio of 316 L Stainless Steel by Additive Manufacturing. Mater. Sci. Eng. A 2019, 744, 773–777. [Google Scholar] [CrossRef]

- Andreau, O.; Koutiri, I.; Peyre, P.; Penot, J.D.; Saintier, N.; Pessard, E.; De Terris, T.; Dupuy, C.; Baudin, T. Texture Control of 316L Parts by Modulation of the Melt Pool Morphology in Selective Laser Melting. J. Mater. Process Technol. 2019, 264, 21–31. [Google Scholar] [CrossRef]

- Niendorf, T.; Leuders, S.; Riemer, A.; Richard, H.A.; Tröster, T.; Schwarze, D. Highly Anisotropic Steel Processed by Selective Laser Melting. Metall. Mater. Trans. B 2013, 44B, 794–796. [Google Scholar] [CrossRef]

- Liu, X.; Liu, Y.; Zhou, Z.; Wang, K.; Zhan, Q.; Xiao, X. Grain Refinement and Crack Inhibition of Selective Laser Melted AA2024 Aluminum Alloy via Inoculation with TiC–TiH2. Mater. Sci. Eng. A 2021, 813, 141171. [Google Scholar] [CrossRef]

- Liu, X.; Liu, Y.; Zhou, Z.; Luo, W.; Zeng, Z. Enhanced Printability and Strength of Unweldable AA2024-Based Nanocomposites Fabricated by Laser Powder Bed Fusion via Nano-TiC-Induced Grain Refinement. Mater. Sci. Eng. A 2022, 856, 144010. [Google Scholar] [CrossRef]

- Tarafder, P.; Rock, C.; Horn, T. Quasi-Static Tensile Properties of Unalloyed Copper Produced by Electron Beam Powder Bed Fusion Additive Manufacturing. Materials 2021, 14, 2932. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J.; Tan, Q.; Yin, Y.; Liu, S.; Li, M.; Li, M.; Liu, Q.; Zhou, Y.; Wu, T.; et al. Additive Manufacturing of High Strength Copper Alloy with Heterogeneous Grain Structure through Laser Powder Bed Fusion. Acta Mater. 2021, 220, 117311. [Google Scholar] [CrossRef]

- Ramirez, D.A.; Murr, L.E.; Martinez, E.; Hernandez, D.H.; Martinez, J.L.; MacHado, B.I.; Medina, F.; Frigola, P.; Wicker, R.B. Novel Precipitate–Microstructural Architecture Developed in the Fabrication of Solid Copper Components by Additive Manufacturing Using Electron Beam Melting. Acta Mater. 2011, 59, 4088–4099. [Google Scholar] [CrossRef]

- Raffeis, I.; Adjei-Kyeremeh, F.; Vroomen, U.; Westhoff, E.; Bremen, S.; Hohoi, A.; Bührig-Polaczek, A. Qualification of a Ni-Cu Alloy for the Laser Powder Bed Fusion Process (LPBF): Its Microstructure and Mechanical Properties. Appl. Sci. 2020, 10, 3401. [Google Scholar] [CrossRef]

- Sun, S.H.; Koizumi, Y.; Kurosu, S.; Li, Y.P.; Chiba, A. Phase and Grain Size Inhomogeneity and Their Influences on Creep Behavior of Co–Cr–Mo Alloy Additive Manufactured by Electron Beam Melting. Acta Mater. 2015, 86, 305–318. [Google Scholar] [CrossRef]

- Chae, H.; Huang, E.W.; Woo, W.; Kang, S.H.; Jain, J.; An, K.; Lee, S.Y. Unravelling Thermal History during Additive Manufacturing of Martensitic Stainless Steel. J. Alloys Compd. 2021, 857, 157555. [Google Scholar] [CrossRef] [PubMed]

- Piette, T.D.; Warren, R.J.; Spangenberger, A.G.; Hummelt, E.J.; Lados, D.A. Microstructure Evolution, Fatigue Crack Growth, and Ultrasonic Fatigue in As-Fabricated Laser Powder Bed and Conventionally Cast Al–10Si-0.4Mg: A Mechanistic Understanding and Integrated Flaw-Sensitive Fatigue Design Methods. Mater. Sci. Eng. A 2021, 825, 141892. [Google Scholar] [CrossRef]

- Bartlett, J.L.; Li, X. An Overview of Residual Stresses in Metal Powder Bed Fusion. Addit. Manuf. 2019, 27, 131–149. [Google Scholar] [CrossRef]

- Salmi, A.; Atzeni, E. History of Residual Stresses during the Production Phases of AlSi10Mg Parts Processed by Powder Bed Additive Manufacturing Technology. Virtual Phys. Prototyp. 2017, 12, 153–160. [Google Scholar] [CrossRef]

- Li, C.; Liu, Z.Y.; Fang, X.Y.; Guo, Y.B. Residual Stress in Metal Additive Manufacturing. Procedia CIRP 2018, 71, 348–353. [Google Scholar] [CrossRef]

- Tradowsky, U.; White, J.; Ward, R.M.; Read, N.; Reimers, W.; Attallah, M.M. Selective Laser Melting of AlSi10Mg: Influence of Post-Processing on the Microstructural and Tensile Properties Development. Mater. Des. 2016, 105, 212–222. [Google Scholar] [CrossRef]

- Liu, M.; Wada, T.; Suzuki, A.; Takata, N.; Kobashi, M.; Kato, M. Effect of Annealing on Anisotropic Tensile Properties of Al-12%Si Alloy Fabricated by Laser Powder Bed Fusion. Crystals 2020, 10, 1007. [Google Scholar] [CrossRef]

- Chen, S.; Tan, Q.; Gao, W.; Wu, G.; Fan, J.; Feng, Z.; Huang, T.; Godfrey, A.W.; Zhang, M.; Huang, X. Effect of Heat Treatment on the Anisotropy in Mechanical Properties of Selective Laser Melted AlSi10Mg. Mater. Sci. Eng. A 2022, 858, 144130. [Google Scholar] [CrossRef]

- Ch, S.R.; Raja, A.; Nadig, P.; Jayaganthan, R.; Vasa, N.J. Influence of Working Environment and Built Orientation on the Tensile Properties of Selective Laser Melted AlSi10Mg Alloy. Mater. Sci. Eng. A 2019, 750, 141–151. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Klauss, H.J.; Surreddi, K.B.; Löber, L.; Wang, Z.; Chaubey, A.K.; Kühn, U.; Eckert, J. Microstructure and Mechanical Properties of Al–12Si Produced by Selective Laser Melting: Effect of Heat Treatment. Mater. Sci. Eng. A 2014, 590, 153–160. [Google Scholar] [CrossRef]

- Popovich, V.A.; Borisov, E.V.; Popovich, A.A.; Sufiiarov, V.S.; Masaylo, D.V.; Alzina, L. Functionally Graded Inconel 718 Processed by Additive Manufacturing: Crystallographic Texture, Anisotropy of Microstructure and Mechanical Properties. Mater. Des. 2017, 114, 441–449. [Google Scholar] [CrossRef]

- Shamsujjoha, M.; Agnew, S.R.; Fitz-Gerald, J.M.; Moore, W.R.; Newman, T.A. High Strength and Ductility of Additively Manufactured 316L Stainless Steel Explained. Metall. Mater. Trans. A 2018, 49A, 3011–3027. [Google Scholar] [CrossRef]

- Maeshima, T.; Oh-ishi, K. Solute Clustering and Supersaturated Solid Solution of AlSi10Mg Alloy Fabricated by Selective Laser Melting. Heliyon 2019, 5, e01186. [Google Scholar] [CrossRef]

- Zyguła, K.; Pasiowiec, H.; Nosek, B.; Szysiak, N. Mechanical Properties and Microstructure of AlSi10Mg Alloy Obtained by Casting and SLM Technique. World Sci. News 2018, 104, 462–472. [Google Scholar]

- Ghassemali, E.; Riestra, M.; Bogdanoff, T.; Kumar, B.S.; Seifeddine, S. Hall-Petch Equation in a Hypoeutectic Al-Si Cast Alloy: Grain Size vs. Secondary Dendrite Arm Spacing. Procedia Eng. 2017, 207, 19–24. [Google Scholar] [CrossRef]

- Riemer, A.; Leuders, S.; Thöne, M.; Richard, H.A.; Tröster, T.; Niendorf, T. On the Fatigue Crack Growth Behavior in 316L Stainless Steel Manufactured by Selective Laser Melting. Eng. Fract. Mech. 2014, 120, 15–25. [Google Scholar] [CrossRef]

- Saeidi, K.; Gao, X.; Zhong, Y.; Shen, Z.J. Hardened Austenite Steel with Columnar Sub-Grain Structure Formed by Laser Melting. Mater. Sci. Eng. A 2015, 625, 221–229. [Google Scholar] [CrossRef]

- Kong, D.; Dong, C.; Ni, X.; Zhang, L.; Yao, J.; Man, C.; Cheng, X.; Xiao, K.; Li, X. Mechanical Properties and Corrosion Behavior of Selective Laser Melted 316L Stainless Steel after Different Heat Treatment Processes. J. Mater. Sci. Technol. 2019, 35, 1499–1507. [Google Scholar] [CrossRef]

- Tolosa, I.; Garciandía, F.; Zubiri, F.; Zapirain, F.; Esnaola, A. Study of Mechanical Properties of AISI 316 Stainless Steel Processed by “Selective Laser Melting”, Following Different Manufacturing Strategies. Int. J. Adv. Manuf. Technol. 2010, 51, 639–647. [Google Scholar] [CrossRef]

- Bayat, M.; Zinovieva, O.; Ferrari, F.; Ayas, C.; Langelaar, M.; Spangenberg, J.; Salajeghe, R.; Poulios, K.; Mohanty, S.; Sigmund, O.; et al. Holistic Computational Design within Additive Manufacturing through Topology Optimization Combined with Multiphysics Multi-Scale Materials and Process Modelling. Prog. Mater. Sci. 2023, 138, 101129. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, F.; Huang, Z.; Jia, M.; Chen, G.; Ye, Y.; Lin, Y.; Liu, W.; Chen, B.; Shen, Q.; et al. Additive Manufacturing of Functionally Graded Materials: A Review. Mater. Sci. Eng. A 2019, 764, 138209. [Google Scholar] [CrossRef]

- Reichardt, A.; Shapiro, A.A.; Otis, R.; Dillon, R.P.; Borgonia, J.P.; Mcenerney, B.W.; Hosemann, P.; Beese, A.M. Advances in Additive Manufacturing of Metal-Based Functionally Graded Materials. Int. Mater. Rev. 2021, 66, 1–29. [Google Scholar] [CrossRef]

- Fomin, V.M.; Malikov, A.G.; Golyshev, A.A.; Bulina, N.V.; Ancharov, A.I.; Vitoshkin, I.E.; Brusentseva, T.A.; Filippov, A.A. In-Situ Reactions during Direct Laser Deposition of a Functionally Gradient Ti64-B Composite. Phys. Mesomech. 2022, 25, 505–513. [Google Scholar] [CrossRef]

- Wu, X.; Su, Y.; Shi, J. Perspective of Additive Manufacturing for Metamaterials Development. Smart Mater. Struct. 2019, 28, 093001. [Google Scholar] [CrossRef]

- Li, Z.; Gao, W.; Yu Wang, M.; Luo, Z. Design of Multi-Material Isotropic Auxetic Microlattices with Zero Thermal Expansion. Mater. Des. 2022, 222, 111051. [Google Scholar] [CrossRef]

- Siddique, S.H.; Hazell, P.J.; Wang, H.; Escobedo, J.P.; Ameri, A.A.H. Lessons from Nature: 3D Printed Bio-Inspired Porous Structures for Impact Energy Absorption—A Review. Addit. Manuf. 2022, 58, 103051. [Google Scholar] [CrossRef]

- Islam, M.K.; Hazell, P.J.; Escobedo, J.P.; Wang, H. Biomimetic Armour Design Strategies for Additive Manufacturing: A Review. Mater. Des. 2021, 205, 109730. [Google Scholar] [CrossRef]

- Seifi, M.; Shamsaei, N. Perspectives on Advancing Qualification and Certification for Additive Manufacturing. In Proceedings of the International Conference on Materials for Advanced Technologies 2023, Singapore, 26–30 June 2023. [Google Scholar]

- Pauza, J.; Rollett, A. Simulation Study of Hatch Spacing and Layer Thickness Effects on Microstructure in Laser Powder Bed Fusion Additive Manufacturing Using a Texture-Aware Solidification Potts Model. J. Mater. Eng. Perform. 2021, 30, 7007–7018. [Google Scholar] [CrossRef]

- Yan, W.; Lian, Y.; Yu, C.; Kafka, O.L.; Liu, Z.; Liu, W.K.; Wagner, G.J. An Integrated Process–Structure–Property Modeling Framework for Additive Manufacturing. Comput. Methods Appl. Mech. Eng. 2018, 339, 184–204. [Google Scholar] [CrossRef]

- Romanova, V.; Mohebbi, M.S.; Dymnich, E.; Balokhonov, R.; Ploshikhin, V. A Physically-Based Computational Approach for Processing-Microstructure-Property Linkage of Materials Additively Manufactured by Laser Powder Bed Fusion. Int. J. Mech. Sci. 2022, 219, 107103. [Google Scholar] [CrossRef]

- Raabe, D.; Roters, F.; Barlat, F.; Chen, L. (Eds.) Continuum Scale Simulation of Engineering Materials; Wiley: Hoboken, NJ, USA, 2004; ISBN 9783527307609. [Google Scholar]

- Horstemeyer, M.F. Integrated Computational Materials Engineering (ICME) for Metals; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012; ISBN 9781118342664. [Google Scholar]

- Schmauder, S.; Schäfer, I. (Eds.) Multiscale Materials Modeling. Approaches to Full Multiscaling; De Gruyter: Berlin, Germany, 2016; ISBN 9783110412451. [Google Scholar]

- Kwon, Y.W. Multiphysics and Multiscale Modeling; CRC Press: Boca Raton, FL, USA, 2015; ISBN 9780429154423. [Google Scholar]

- Ghafouri, M.; Amraei, M.; Gopaluni, A.; Piili, H.; Björk, T.; Hämäläinen, J. Simulation and Its Use in Additive Manufacturing. In Impact of Scientific Computing on Science and Society; Neittaanmäki, P., Rantalainen, M.-L., Eds.; Springer: Cham, Switzerland, 2023; Volume 58, pp. 111–126. [Google Scholar]

- Lammens, N.; Gallego-Bordallo, F.; Ni, J.; Zinoviev, A.; de Weer, T.; Erdelyi, H. The Role of Simulation in the Industrialization of Additive Manufacturing. Procedia Struct. Integr. 2021, 34, 247–252. [Google Scholar] [CrossRef]

- Wimler, D.; Käsznar, K.; Musi, M.; Breuning, C.; Markl, M.; Keckes, J.; Clemens, H.; Körner, C.; Mayer, S. How Electron Beam Melting Tailors the Al-Sensitive Microstructure and Mechanical Response of a Novel Process-Adapted γ-TiAl Based Alloy. Mater. Des. 2021, 212, 110187. [Google Scholar] [CrossRef]

- Gouge, M.; Denlinger, E.; Irwin, J.; Li, C.; Michaleris, P. Experimental Validation of Thermo-Mechanical Part-Scale Modeling for Laser Powder Bed Fusion Processes. Addit. Manuf. 2019, 29, 100771. [Google Scholar] [CrossRef]

- Roehling, J.D.; Khairallah, S.A.; Shen, Y.; Bayramian, A.; Boley, C.D.; Rubenchik, A.M.; DeMuth, J.; Duanmu, N.; Matthews, M.J. Physics of Large-Area Pulsed Laser Powder Bed Fusion. Addit. Manuf. 2021, 46, 102186. [Google Scholar] [CrossRef]

- Zinovieva, O.; Romanova, V.; Balokhonov, R. Predictive Simulation of Microstructural Pattern in Additively Manufactured Metallic Materials. In Quality Analysis of Additively Manufactured Metals; Kadkhodapour, J., Schmauder, S., Sajadi, F., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 547–582. [Google Scholar]

- Tunay, M.; Baykasoğlu, C.; Akyildiz, O.; To, A.C. A Fully Coupled Thermal–Microstructural–Mechanical Finite Element Process Model for Directed Energy Deposition Additive Manufacturing of Ti–6Al–4V. Sci. Technol. Weld. Join. 2023, 28, 118–127. [Google Scholar] [CrossRef]

- Malmelöv, A.; Lundbäck, A.; Lindgren, L.-E. History Reduction by Lumping for Time-Efficient Simulation of Additive Manufacturing. Metals 2019, 10, 58. [Google Scholar] [CrossRef]

- Körner, C.; Attar, E.; Heinl, P. Mesoscopic Simulation of Selective Beam Melting Processes. J. Mater. Process Technol. 2011, 211, 978–987. [Google Scholar] [CrossRef]

- Haeri, S.; Wang, Y.; Ghita, O.; Sun, J. Discrete Element Simulation and Experimental Study of Powder Spreading Process in Additive Manufacturing. Powder Technol. 2017, 306, 45–54. [Google Scholar] [CrossRef]

- Megahed, M.; Mindt, H.-W.; Duan, H.; Desmaison, O. Metal Additive-Manufacturing Process and Residual Stress Modeling. Integr. Mater. Manuf. Innov. 2016, 5, 61–93. [Google Scholar] [CrossRef]

- Bayat, M.; Dong, W.; Thorborg, J.; To, A.C.; Hattel, J.H. A Review of Multi-Scale and Multi-Physics Simulations of Metal Additive Manufacturing Processes with Focus on Modeling Strategies. Addit. Manuf. 2021, 47, 102278. [Google Scholar] [CrossRef]

- Zinovieva, O.; Zinoviev, A.; Ploshikhin, V. Three-Dimensional Modeling of the Microstructure Evolution during Metal Additive Manufacturing. Comput. Mater. Sci. 2018, 141, 207–220. [Google Scholar] [CrossRef]

- Rodgers, T.M.; Moser, D.; Abdeljawad, F.; Jackson, O.D.U.; Carroll, J.D.; Jared, B.H.; Bolintineanu, D.S.; Mitchell, J.A.; Madison, J.D. Simulation of Powder Bed Metal Additive Manufacturing Microstructures with Coupled Finite Difference-Monte Carlo Method. Addit. Manuf. 2021, 41, 101953. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser Powder-Bed Fusion Additive Manufacturing: Physics of Complex Melt Flow and Formation Mechanisms of Pores, Spatter, and Denudation Zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef]

- Zakirov, A.; Belousov, S.; Bogdanova, M.; Korneev, B.; Stepanov, A.; Perepelkina, A.; Levchenko, V.; Meshkov, A.; Potapkin, B. Predictive Modeling of Laser and Electron Beam Powder Bed Fusion Additive Manufacturing of Metals at the Mesoscale. Addit. Manuf. 2020, 35, 101236. [Google Scholar] [CrossRef]

- Dorussen, B.J.A.; Geers, M.G.D.; Remmers, J.J.C. An Efficient Ray Tracing Methodology for the Numerical Analysis of Powder Bed Additive Manufacturing Processes. Addit. Manuf. 2023, 73, 103706. [Google Scholar] [CrossRef]

- Bayat, M.; Mohanty, S.; Hattel, J.H. A Systematic Investigation of the Effects of Process Parameters on Heat and Fluid Flow and Metallurgical Conditions during Laser-Based Powder Bed Fusion of Ti6Al4V Alloy. Int. J. Heat. Mass. Transf. 2019, 139, 213–230. [Google Scholar] [CrossRef]

- Zhavoronok, S.I.; Kurbatov, A.S.; Rabinskiy, L.N.; Solyaev, Y.O. Recent Problems of Heat-Transfer Simulation in Technological Processes of Selective Laser Melting and Fusion. High Temp. 2019, 57, 916–943. [Google Scholar] [CrossRef]

- Keller, T.; Lindwall, G.; Ghosh, S.; Ma, L.; Lane, B.M.; Zhang, F.; Kattner, U.R.; Lass, E.A.; Heigel, J.C.; Idell, Y.; et al. Application of Finite Element, Phase-Field, and CALPHAD-Based Methods to Additive Manufacturing of Ni-Based Superalloys. Acta Mater. 2017, 139, 244–253. [Google Scholar] [CrossRef] [PubMed]

- Lu, L.X.; Sridhar, N.; Zhang, Y.W. Phase Field Simulation of Powder Bed-Based Additive Manufacturing. Acta Mater. 2018, 144, 801–809. [Google Scholar] [CrossRef]

- Yang, M.; Wang, L.; Yan, W. Phase-Field Modeling of Grain Evolutions in Additive Manufacturing from Nucleation, Growth, to Coarsening. NPJ Comput. Mater. 2021, 7, 56. [Google Scholar] [CrossRef]

- Agius, D.; O’Toole, P.; Wallbrink, C.; Sterjovski, Z.; Wang, C.-H.; Schaffer, G.B. Integrating Phase Field and Crystal Plasticity Finite Element Models for Simulations of Titanium Alloy Ti-5553. J. Phys. Mater. 2021, 4, 44014. [Google Scholar] [CrossRef]

- Akram, J.; Chalavadi, P.; Pal, D.; Stucker, B. Understanding Grain Evolution in Additive Manufacturing through Modeling. Addit. Manuf. 2018, 21, 255–268. [Google Scholar] [CrossRef]

- Zinoviev, A.; Zinovieva, O.; Ploshikhin, V.; Romanova, V.; Balokhonov, R. Evolution of Grain Structure during Laser Additive Manufacturing. Simulation by a Cellular Automata Method. Mater. Des. 2016, 106, 321–329. [Google Scholar] [CrossRef]

- Mohebbi, M.S.; Ploshikhin, V. Implementation of Nucleation in Cellular Automaton Simulation of Microstructural Evolution during Additive Manufacturing of Al Alloys. Addit. Manuf. 2020, 36, 101726. [Google Scholar] [CrossRef]

- Rodgers, T.M.; Madison, J.D.; Tikare, V. Simulation of Metal Additive Manufacturing Microstructures Using Kinetic Monte Carlo. Comput. Mater. Sci. 2017, 135, 78–89. [Google Scholar] [CrossRef]

- Körner, C.; Markl, M.; Koepf, J.A. Modeling and Simulation of Microstructure Evolution for Additive Manufacturing of Metals: A Critical Review. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2020, 51, 4970–4983. [Google Scholar] [CrossRef]

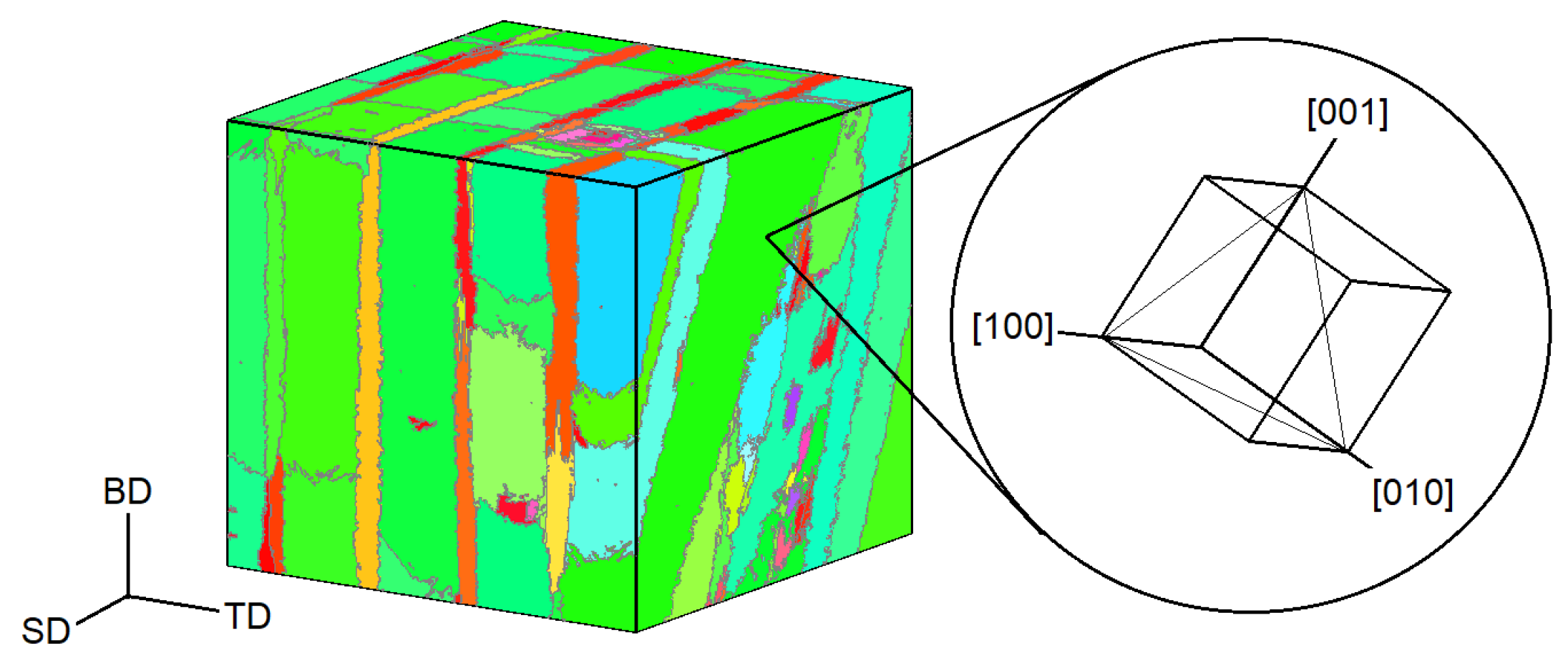

- Zinovieva, O.; Zinoviev, A.; Romanova, V.; Balokhonov, R. Three-Dimensional Analysis of Grain Structure and Texture of Additively Manufactured 316L Austenitic Stainless Steel. Addit. Manuf. 2020, 36, 101521. [Google Scholar] [CrossRef]

- Wang, X.; Chou, K. Electron Backscatter Diffraction Analysis of Inconel 718 Parts Fabricated by Selective Laser Melting Additive Manufacturing. JOM 2017, 69, 402–408. [Google Scholar] [CrossRef]

- Choi, J.P.; Shin, G.H.; Yang, S.; Yang, D.Y.; Lee, J.S.; Brochu, M.; Yu, J.H. Densification and Microstructural Investigation of Inconel 718 Parts Fabricated by Selective Laser Melting. Powder Technol. 2017, 310, 60–66. [Google Scholar] [CrossRef]

- Parimi, L.L.; Ravi, G.; Clark, D.; Attallah, M.M. Microstructural and Texture Development in Direct Laser Fabricated IN718. Mater. Charact. 2014, 89, 102–111. [Google Scholar] [CrossRef]

- Taheri Andani, M.; Ghodrati, M.; Karamooz-Ravari, M.R.; Mirzaeifar, R.; Ni, J. Damage Modeling of Metallic Alloys Made by Additive Manufacturing. Mater. Sci. Eng. A 2019, 743, 656–664. [Google Scholar] [CrossRef]

- Charmi, A.; Falkenberg, R.; Ávila, L.; Mohr, G.; Sommer, K.; Ulbricht, A.; Sprengel, M.; Saliwan Neumann, R.; Skrotzki, B.; Evans, A. Mechanical Anisotropy of Additively Manufactured Stainless Steel 316L: An Experimental and Numerical Study. Mater. Sci. Eng. A 2021, 799, 140154. [Google Scholar] [CrossRef]

- Yeratapally, S.R.; Lang, C.G.; Cerrone, A.R.; Niebur, G.L.; Cronberger, K. Effect of Defects on the Constant-Amplitude Fatigue Behavior of as-Built Ti-6Al-4V Alloy Produced by Laser Powder Bed Fusion Process: Assessing Performance with Metallographic Analysis and Micromechanical Simulations. Addit. Manuf. 2022, 52, 102639. [Google Scholar] [CrossRef]

- Romanova, V.; Balokhonov, R. A Method of Step-by-Step Packing and Its Application in Generating 3D Microstructures of Polycrystalline and Composite Materials. Eng. Comput. 2021, 37, 241–250. [Google Scholar] [CrossRef]

- Mandal, S.; Lao, J.; Donegan, S.; Rollett, A.D. Generation of Statistically Representative Synthetic Three-Dimensional Microstructures. Scr. Mater. 2018, 146, 128–132. [Google Scholar] [CrossRef]

- Dionyssopoulos, C.; Wallbrink, C.; Agius, D.; Qiu, D.; Easton, M.; Barter, S.; Das, R. A Comparison of Length Scale Dependent Classical Crystal Plasticity Models for Modelling the Deformation of Additively Manufactured Ti-6Al-4V. In Proceedings of the AIAC 2023: 20th Australian International Aerospace Congress, Engineers Australia, Melbourne, Australia, 27 February–1 March 2023; pp. 266–271. [Google Scholar]

- Tang, H.; Huang, H.; Liu, C.; Liu, Z.; Yan, W. Multi-Scale Modelling of Structure-Property Relationship in Additively Manufactured Metallic Materials. Int. J. Mech. Sci. 2021, 194, 106185. [Google Scholar] [CrossRef]

- Wang, P.; Lei, H.; Zhu, X.; Chen, H.; Fang, D. Influence of Manufacturing Geometric Defects on the Mechanical Properties of AlSi10Mg Alloy Fabricated by Selective Laser Melting. J. Alloys Compd. 2019, 789, 852–859. [Google Scholar] [CrossRef]

- Dymnich, E.; Romanova, V.A.; Balokhonov, R.R.; Zinovieva, O.S.; Zinoviev, A.V. A Numerical Study of the Stress-Strain Behavior of Additively Manufactured Aluminum-Silicon Alloy at the Scale of Dendritic Structure. Phys. Mesomech. 2021, 24, 51–60. [Google Scholar] [CrossRef]

- Cocke, C.K.; Rollett, A.D.; Lebensohn, R.A.; Spear, A.D. The AFRL Additive Manufacturing Modeling Challenge: Predicting Micromechanical Fields in AM IN625 Using an FFT-Based Method with Direct Input from a 3D Microstructural Image. Integr. Mater. Manuf. Innov. 2021, 10, 157–176. [Google Scholar] [CrossRef]

- Furushima, T.; Masuda, T.; Manabe, K.; Alexandrov, S. Prediction of Free Surface Roughening by 2D and 3D Model Considering Material Inhomogeneity. J. Solid Mech. Mater. Eng. 2011, 5, 978–990. [Google Scholar] [CrossRef]

- Roters, F.; Diehl, M.; Shanthraj, P.; Eisenlohr, P.; Reuber, C.; Wong, S.L.; Maiti, T.; Ebrahimi, A.; Hochrainer, T.; Fabritius, H.-O.; et al. DAMASK—The Düsseldorf Advanced Material Simulation Kit for Modeling Multi-Physics Crystal Plasticity, Thermal, and Damage Phenomena from the Single Crystal up to the Component Scale. Comput. Mater. Sci. 2019, 158, 420–478. [Google Scholar] [CrossRef]

- Romanova, V.A.; Balokhonov, R.R.; Batukhtina, E.E.; Emelianova, E.S.; Sergeev, M.V. On the Solution of Quasi-Static Micro- and Mesomechanical Problems in a Dynamic Formulation. Phys. Mesomech. 2019, 22, 296–306. [Google Scholar] [CrossRef]

- Balokhonov, R.; Romanova, V.; Batukhtina, E.; Martynov, S.; Zinoviev, A.; Zinovieva, O. A Mesomechanical Analysis of the Stress–Strain Localisation in Friction Stir Welds of Polycrystalline Aluminium Alloys. Meccanica 2016, 51, 319–328. [Google Scholar] [CrossRef]

- Pham, C.H.; Thuillier, S.; Manach, P.Y. Prediction of Flow Stress and Surface Roughness of Stainless Steel Sheets Considering an Inhomogeneous Microstructure. Mater. Sci. Eng. A 2016, 678, 377–388. [Google Scholar] [CrossRef]

- Hollomon, J.H. Tensile Deformation. Trans. AIME 1945, 112, 268. [Google Scholar]

- Sufiiarov, V.S.; Orlov, A.V.; Borisov, E.V.; Polozov, I.A.; Popovich, A.A.; Chukovenkova, M.O.; Soklakov, A.V.; Mikhaluk, D.S. Computer Modelling of Uniaxial Tension of Functionally Gradient Material Produced by Additive Manufacturing. Tech. Phys. 2021, 66, 23–27. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D Printing of High-Strength Aluminium Alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef]

- Hofer, A.K.; Kocjan, A.; Bermejo, R. High-Strength Lithography-Based Additive Manufacturing of Ceramic Components with Rapid Sintering. Addit. Manuf. 2022, 59, 103141. [Google Scholar] [CrossRef]

- Ng, C.H.; Bermingham, M.J.; Yuan, L.; Dargusch, M.S. Towards β-Fleck Defect Free Additively Manufactured Titanium Alloys by Promoting the Columnar to Equiaxed Transition and Grain Refinement. Acta Mater. 2022, 224, 117511. [Google Scholar] [CrossRef]

- Zinovieva, O.; Romanova, V.; Zinoviev, A.; Nekhorosheva, O.; Balokhonov, R. Elastic Properties of Additively Manufactured Steel Produced with Different Scan Strategies. Int. J. Mech. Sci. 2023, 244, 108089. [Google Scholar] [CrossRef]

- Musienko, A. Plasticité Cristalline En Présence de Grandes Déformations et D’endommagement. Ph.D. Thesis, Centre des Matériaux P.M. FOURT de l’Ecole des Mines de Paris, Evry, France, 2005. [Google Scholar]

- Motaman, S.A.H.; Roters, F.; Haase, C. Anisotropic Polycrystal Plasticity Due to Microstructural Heterogeneity: A Multi-Scale Experimental and Numerical Study on Additively Manufactured Metallic Materials. Acta Mater. 2020, 185, 340–369. [Google Scholar] [CrossRef]

- Kalidindi, S.R. Incorporation of Deformation Twinning in Crystal Plasticity Models. J. Mech. Phys. Solids 1998, 46, 267–290. [Google Scholar] [CrossRef]

- Ji, H.; Song, Q.; Wang, R.; Cai, W.; Liu, Z. Evaluation and Prediction of Pore Effects on Single-Crystal Mechanical and Damage Properties of Selective Laser Melted Inconel-718. Mater. Des. 2022, 219, 110807. [Google Scholar] [CrossRef]

- Prithivirajan, V.; Sangid, M.D. The Role of Defects and Critical Pore Size Analysis in the Fatigue Response of Additively Manufactured IN718 via Crystal Plasticity. Mater. Des. 2018, 150, 139–153. [Google Scholar] [CrossRef]

- Cheng, J.; Fernandez-Zelaia, P.; Hu, X.; Kirka, M. Effect of Microstructure on Fatigue Crack Propagation in Additive Manufactured Nickel-Based Superalloy Haynes 282: An Experiment and Crystal Plasticity Study. J. Mater. Sci. 2022, 57, 9741–9768. [Google Scholar] [CrossRef]

- Cailletaud, G.; Chaboche, J.-L.; Forest, S.; Rémy, L. On the Design of Single Crystal Turbine Blades. Rev. Métallurgie 2003, 100, 165–172. [Google Scholar] [CrossRef]

- Yalcinkaya, T. Microstructure Evolution in Crystal Plasticity: Strain Path Effects and Dislocation Slip Patterning. Ph.D. Thesis, Technische Universiteit Eindhoven, Eindhoven, The Netherlands, 2011. [Google Scholar]

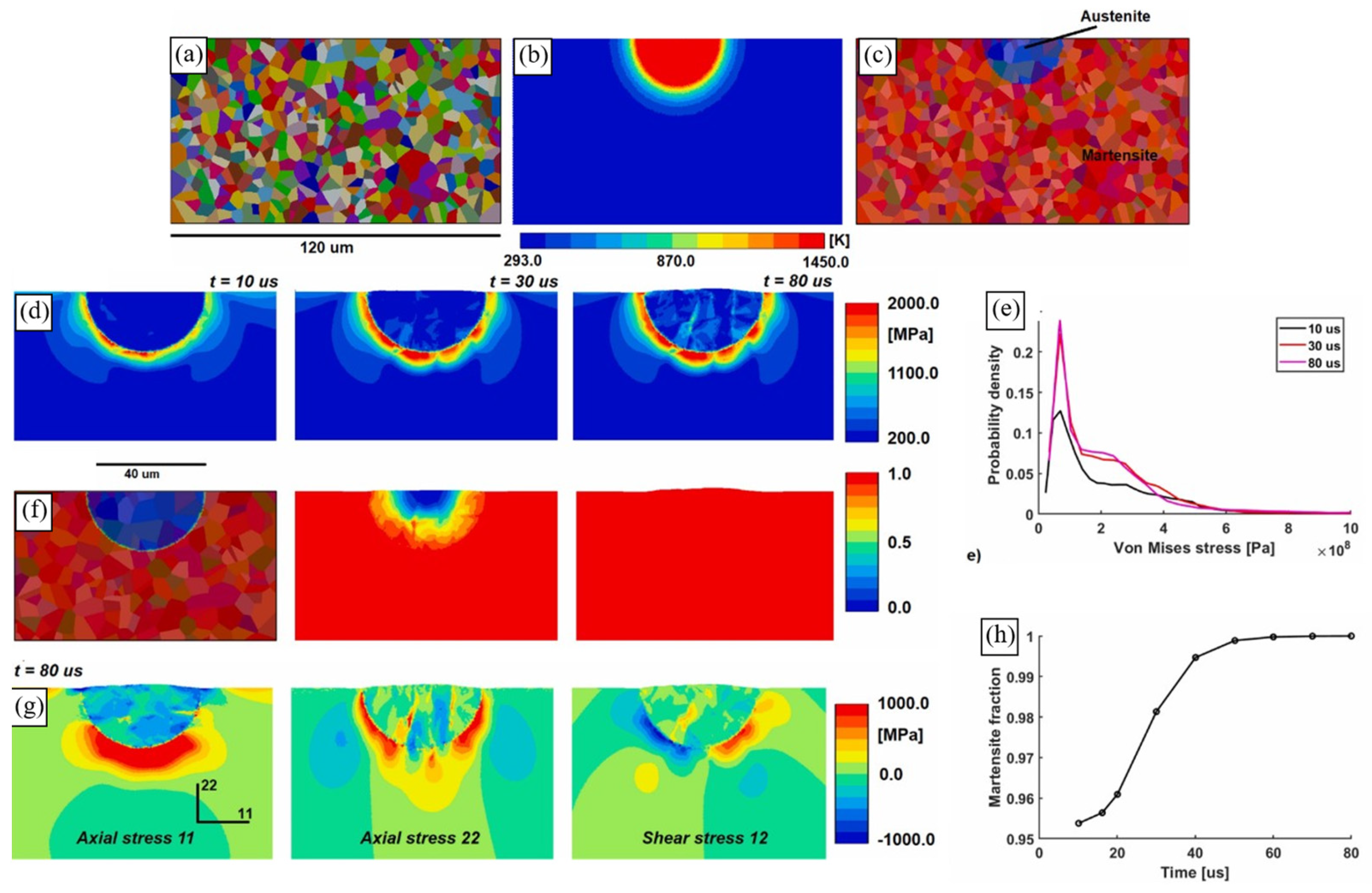

- Lindroos, M.; Pinomaa, T.; Antikainen, A.; Lagerbom, J.; Reijonen, J.; Lindroos, T.; Andersson, T.; Laukkanen, A. Micromechanical Modeling Approach to Single Track Deformation, Phase Transformation and Residual Stress Evolution during Selective Laser Melting Using Crystal Plasticity. Addit. Manuf. 2021, 38, 101819. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Baxter, C.; Amirkhiz, B.S.; Mohammadi, M. Strengthening Mechanisms in Direct Metal Laser Sintered AlSi10Mg: Comparison between Virgin and Recycled Powders. Addit. Manuf. 2018, 23, 108–120. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Tuck, C.; Ashcroft, I.; Maskery, I.; Everitt, N.M. On the Precipitation Hardening of Selective Laser Melted AlSi10Mg. Metall. Mater. Trans. A 2015, 46, 3337–3341. [Google Scholar] [CrossRef]

- Peirce, D.; Asaro, R.J.; Needleman, A. An Analysis of Nonuniform and Localized Deformation in Ductile Single Crystals. Acta Metall. 1982, 30, 1087–1119. [Google Scholar] [CrossRef]

- Taheri Andani, M.; Karamooz-Ravari, M.R.; Mirzaeifar, R.; Ni, J. Micromechanics Modeling of Metallic Alloys 3D Printed by Selective Laser Melting. Mater. Des. 2018, 137, 204–213. [Google Scholar] [CrossRef]

- Anand, L.; Kothari, M. A Computational Procedure for Rate-Independent Crystal Plasticity. J. Mech. Phys. Solids 1996, 44, 525–558. [Google Scholar] [CrossRef]

- Besson, J.; Foerch, R. Object-Oriented Programming Applied to the Finite Element Method Part I. General Concepts. Rev. Eur. Éléments Finis 1998, 7, 535–566. [Google Scholar] [CrossRef]

- Hu, Y.; Tian, J.; Xu, M.; Zhao, H.; Wang, M.; Wang, M.; Zhang, A. The Preparation of H13 Steel for TBM Cutter and the Performance Test Close to Working Condition. Appl. Sci. 2018, 8, 1877. [Google Scholar] [CrossRef]

- Song, D.; Xiao, X.; Xue, J.; Chu, H.; Duan, H. Mechanical Properties of Irradiated Multi-Phase Polycrystalline BCC Materials. Acta Mech. Sin. 2015, 31, 191–204. [Google Scholar] [CrossRef]

- Monnet, G.; Vincent, L.; Gélébart, L. Multiscale Modeling of Crystal Plasticity in Reactor Pressure Vessel Steels: Prediction of Irradiation Hardening. J. Nucl. Mater. 2019, 514, 128–138. [Google Scholar] [CrossRef]

- Ozturk, T.; Rollett, A.D. Effect of Microstructure on the Elasto-Viscoplastic Deformation of Dual Phase Titanium Structures. Comput. Mech. 2018, 61, 55–70. [Google Scholar] [CrossRef]

- Facchini, L.; Magalini, E.; Robotti, P.; Molinari, A. Microstructure and Mechanical Properties of Ti-6Al-4V Produced by Electron Beam Melting of Pre-alloyed Powders. Rapid Prototyp. J. 2009, 15, 171–178. [Google Scholar] [CrossRef]

- Zhang, X.X.; Andrä, H. Crystal Plasticity Simulation of the Macroscale and Microscale Stress–Strain Relations of Additively Manufactured AlSi10Mg Alloy. Comput. Mater. Sci. 2021, 200, 110832. [Google Scholar] [CrossRef]

- Zhang, X.X.; Lutz, A.; Andrä, H.; Lahres, M.; Gan, W.M.; Maawad, E.; Emmelmann, C. Evolution of Microscopic Strains, Stresses, and Dislocation Density during in-Situ Tensile Loading of Additively Manufactured AlSi10Mg Alloy. Int. J. Plast. 2021, 139, 102946. [Google Scholar] [CrossRef]

- Song, L.; Yuan, S.; Zhao, L.; Zhu, Y.; Liang, S.; Huang, M.; Simar, A.; Li, Z. Deciphering Phase Stress Partition and Its Correlation to Mechanical Anisotropy of Laser Powder Bed Fusion AlSi10Mg. Addit. Manuf. 2023, 71, 103594. [Google Scholar] [CrossRef]

- Song, L.; Zhao, L.; Ding, L.; Zhu, Y.; Huang, M.; Simar, A.; Li, Z. Microstructure and Loading Direction Dependent Hardening and Damage Behavior of Laser Powder Bed Fusion AlSi10Mg. Mater. Sci. Eng. A 2022, 832, 142484. [Google Scholar] [CrossRef]

- Huang, Y. A User-Material Subroutine Incorporating Single Crystal Plasticity in the Abaqus Finite Element Program; Harvard University: Cambridge, MA, USA, 1991. [Google Scholar]

- Han, C.S.; Gao, H.; Huang, Y.; Nix, W.D. Mechanism-Based Strain Gradient Crystal Plasticity—I. Theory. J. Mech. Phys. Solids 2005, 53, 1188–1203. [Google Scholar] [CrossRef]

- Kuo, C.N.; Chua, C.K.; Peng, P.C.; Chen, Y.W.; Sing, S.L.; Huang, S.; Su, Y.L. Microstructure Evolution and Mechanical Property Response via 3D Printing Parameter Development of Al-Sc Alloy. Virtual Phys. Prototyp. 2019, 15, 120–129. [Google Scholar] [CrossRef]

- Leicht, A.; Rashidi, M.; Klement, U.; Hryha, E. Effect of Process Parameters on the Microstructure, Tensile Strength and Productivity of 316L Parts Produced by Laser Powder Bed Fusion. Mater. Charact. 2020, 159, 110016. [Google Scholar] [CrossRef]

- Zinovieva, O.; Romanova, V.; Balokhonov, R. Effect of Hatch Distance on the Microstructure of Additively Manufactured 316 L Steel. AIP Conf. Proc. 2020, 2310, 020363. [Google Scholar] [CrossRef]

- Patel, M.N.; Qiu, D.; Wang, G.; Gibson, M.A.; Prasad, A.; StJohn, D.H.; Easton, M.A. Understanding the Refinement of Grains in Laser Surface Remelted Al–Cu Alloys. Scr. Mater. 2020, 178, 447–451. [Google Scholar] [CrossRef]

- Gong, X.; Lydon, J.; Cooper, K.; Chou, K. Beam Speed Effects on Ti–6Al–4V Microstructures in Electron Beam Additive Manufacturing. J. Mater. Res. 2014, 29, 1951–1959. [Google Scholar] [CrossRef]

- Cao, M.; Liu, Y.; Dunne, F.P.E. A Crystal Plasticity Approach to Understand Fatigue Response with Respect to Pores in Additive Manufactured Aluminium Alloys. Int. J. Fatigue 2022, 161, 106917. [Google Scholar] [CrossRef]

- Balokhonov, R.R.; Zinovyev, A.V.; Romanova, V.A.; Bakeev, R.A.; Zinovyeva, O.S. Numerical Simulation of Deformation and Fracture of a Material with a Polysilazane-Based Coating. Phys. Mesomech. 2016, 19, 430–440. [Google Scholar] [CrossRef]

- Konovalenko, I.S.; Shilko, E.V.; Sharkeev, Y.P. Computer-Aided Study of the Mechanical Behavior of the Porous Ceramic Based Composite with Plastic Pore Filler. AIP Conf. Proc. 2018, 2051, 020130. [Google Scholar] [CrossRef]

- Rodgers, T.M.; Bishop, J.E.; Madison, J.D. Direct Numerical Simulation of Mechanical Response in Synthetic Additively Manufactured Microstructures. Model. Simul. Mat. Sci. Eng. 2018, 26, 055010. [Google Scholar] [CrossRef]

- Li, P.; Kim, Y.; Bobel, A.C.; Hector, L.G.; Sachdev, A.K.; Kumar, S.; Bower, A.F. Microstructural Origin of the Anisotropic Flow Stress of Laser Powder Bed Fused AlSi10Mg. Acta Mater. 2021, 220, 117346. [Google Scholar] [CrossRef]

- Herriott, C.; Li, X.; Kouraytem, N.; Tari, V.; Tan, W.; Anglin, B.; Rollett, A.D.; Spear, A.D. A Multi-Scale, Multi-Physics Modeling Framework to Predict Spatial Variation of Properties in Additive-Manufactured Metals. Model. Simul. Mat. Sci. Eng. 2019, 27, 025009. [Google Scholar] [CrossRef]

- Upadhyay, M.V.; Capek, J.; Van Petegem, S.; Lebensohn, R.A.; Van Swygenhoven, H. Intergranular Strain Evolution during Biaxial Loading: A Multiscale FE-FFT Approach. JOM 2017, 69, 839–847. [Google Scholar] [CrossRef]

- Loginova, I.S.; Bykovskiy, D.P.; Solonin, A.N.; Prosviryakov, A.S.; Cheverikin, V.V.; Pozdniakov, A.V.; Petrovskiy, V.N. Peculiarities of the Microstructure and Properties of Parts Produced by the Direct Laser Deposition of 316L Steel Powder. Russ. J. Non-Ferr. Met. 2019, 60, 87–94. [Google Scholar] [CrossRef]

- Mendagaliev, R.V.; Evdokimov, D.D.; Firsov, A.M.; Vildanov, A.M.; Evstifeev, A.D.; Maksimochkin, V.I.; Grachev, R.A.; Dubinin, O.N.; Evlashin, S.A.; Klimova-Korsmik, O.G. Direct Laser Deposition of Austenitic and Martensitic Steel Gradient Layers. Met. Mater. Int. 2023, 29, 1555–1562. [Google Scholar] [CrossRef]

- Eliseeva, O.V. Utilizing the Structure-Property Relationship of Porosity and Composition in Additively Manufactured Metallic Systems. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 2021. [Google Scholar]

| Topic, Reference | Highlights | Hardening Law |

|---|---|---|

| Damage modelling of alloys produced by LPBF [146] | Two-dimensional FE structure–property model developed for uniaxial tensile loading of as-built LPBF 316L steel. Incorporates a simplistic synthetic grain structure that fits a melt pool (Figure 7a). Implemented in the FE commercial software Abaqus using a user material (UMAT) subroutine. Compared with an experimental stress–strain curve of the as-built LPBF 316L steel. | . (20) Here, areare the hardening moduli, including (no sum on ) and () which denote self and latent hardening moduli, respectively, as introduced by Peirce et al. [178], , . Here, is the initial hardening modulus; stands for accumulated shear strain; is the saturation stress; is the initial stress and denotes the ratio of latent to self-hardening. Latent hardening represents the increment of flow stress on the slip system due to a shear increment on the slip system . As pointed out by Peirce et al. [178], the components of the hardening matrix represent ‘the most elusive parameters’ in the constitutive equations. In a later study [179], Taheri Andani and coworkers adapted the model proposed in [180] where they considered the slip system hardening model as (no sum on ), where a single slip hardening rate ; is the Kronecker delta; and ; , are the slip system hardening parameters which were set to be identical for all slip systems. |

| Micromechanical modelling of single track deformation, phase transformation and residual stress evolution during laser surface remelting [175] | Two-dimensional FE structure–property model developed to estimate residual stresses that are formed due to the laser surface remelting of H13 tool steel. Incorporates a simplistic synthetic equiaxed grain structure and takes into account martensitic and austenitic phases. Implemented in the FE software Zset [181]. When determining single crystal model parameters, the authors compared a calculated macroscopic stress–strain curve with an experimental one for H13 samples that were cast and heat-treated [182]. | Martensite: . (21) Here, the self-hardening resistance which is usually defined as a constant, are considered. Here, is the hardening coefficient characterising the dislocation network interactions [183]; stands for the minimum length of the screw segment. is the effective stress, i.e., mean stress driving dislocation motion; the line tension model goes to the classical formulation proposed by Taylor. The average obstacle strength is a function of the densities of different defects, are the planar densities of carbides and solute clusters, respectively. A similar hardening model was adapted for austenite: . (22) Here, is the Hall–Petch term. Dislocation density evolution is estimated using a classical equation which describes the evolving mean free path during the accumulation of dislocations. The model is largely adopted from [184]. |

| Microstructural effects on the elasto-viscoplastic deformation of dual-phase Ti-6Al-4V produced by PBF [185] | laths. Equation (23) is calibrated with the experimental stress–strain curve of the as-built EPBF Ti-6Al-4V [186]. | A modified version of the Voce hardening model , (23) stands for the back-extrapolated CRSS. |

| CP modelling of the anisotropic tensile behaviour of LPBF Ti-6Al-4V [36] | laths. Implemented in the FFT software DAMASK [157]. Equation (24) is calibrated with experimental the stress–strain curves of the heat-treated LPBF Ti-6Al-4V ELI. | The slip resistance , (24) denotes the saturation value of the slip resistance. |

| CP modelling of the structure–property relationship in LPBF Ti-6A-4V [152] | ’ laths. Implemented in Abaqus using a UMAT subroutine. The results are compared with the experimental stress–strain curves obtained under tension, compression, and cyclic loading along the BD of LPBF Ti-6Al-4V. | , where (25) stands for CRSS. |

| Macroscale and microscale stress–strain relations of LPBF AlSi10Mg alloy [187] | Three-dimensional FFT structure–property model developed for the uniaxial tensile loading of as-built LPBF AlSi10Mg. Incorporates a synthetic grain structure (columnar or equiaxed), Si particles, and the porosity with a prescribed volume fraction. Implemented in DAMASK [157]. Compared the computationally obtained stress–strain curves with the experimental one from the in situ synchrotron X-ray diffraction experiment [188]. | (26) stands for the initial slip resistance. |

| Phase stress partition and its correlation with the mechanical anisotropy of LPBF AlSi10Mg [189] | Three-dimensional FE structure–property models developed for uniaxial tensile loading of the as-built LPBF AlSi10Mg in two different directions. Incorporate a synthetic Al-Si cellular substructure. Implemented in Abaqus using a UMAT subroutine. The results are compared with the experimental stress–strain curves obtained under tension along the BD and TD of LPBF AlSi10Mg [190]. | The traditional CP model 191 and the mechanism-based strain gradient crystal plasticity model (MSG-CP) [192] were employed. The former considered the hardening law suggested by Peirce et al. [178], as described in Equation (20). The MSG-CP defined the effective slip resistance following the Taylor hardening relation: , (27) ), in Equation (13). |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zinovieva, O.; Romanova, V.; Dymnich, E.; Zinoviev, A.; Balokhonov, R. A Review of Computational Approaches to the Microstructure-Informed Mechanical Modelling of Metals Produced by Powder Bed Fusion Additive Manufacturing. Materials 2023, 16, 6459. https://doi.org/10.3390/ma16196459

Zinovieva O, Romanova V, Dymnich E, Zinoviev A, Balokhonov R. A Review of Computational Approaches to the Microstructure-Informed Mechanical Modelling of Metals Produced by Powder Bed Fusion Additive Manufacturing. Materials. 2023; 16(19):6459. https://doi.org/10.3390/ma16196459

Chicago/Turabian StyleZinovieva, Olga, Varvara Romanova, Ekaterina Dymnich, Aleksandr Zinoviev, and Ruslan Balokhonov. 2023. "A Review of Computational Approaches to the Microstructure-Informed Mechanical Modelling of Metals Produced by Powder Bed Fusion Additive Manufacturing" Materials 16, no. 19: 6459. https://doi.org/10.3390/ma16196459

APA StyleZinovieva, O., Romanova, V., Dymnich, E., Zinoviev, A., & Balokhonov, R. (2023). A Review of Computational Approaches to the Microstructure-Informed Mechanical Modelling of Metals Produced by Powder Bed Fusion Additive Manufacturing. Materials, 16(19), 6459. https://doi.org/10.3390/ma16196459