Performance Improvement and Microstructure Characterization of Cement-Stabilized Roadbase Materials Containing Phosphogypsum/Recycled Concrete Aggregate

Abstract

:1. Introduction

2. Materials and Methods

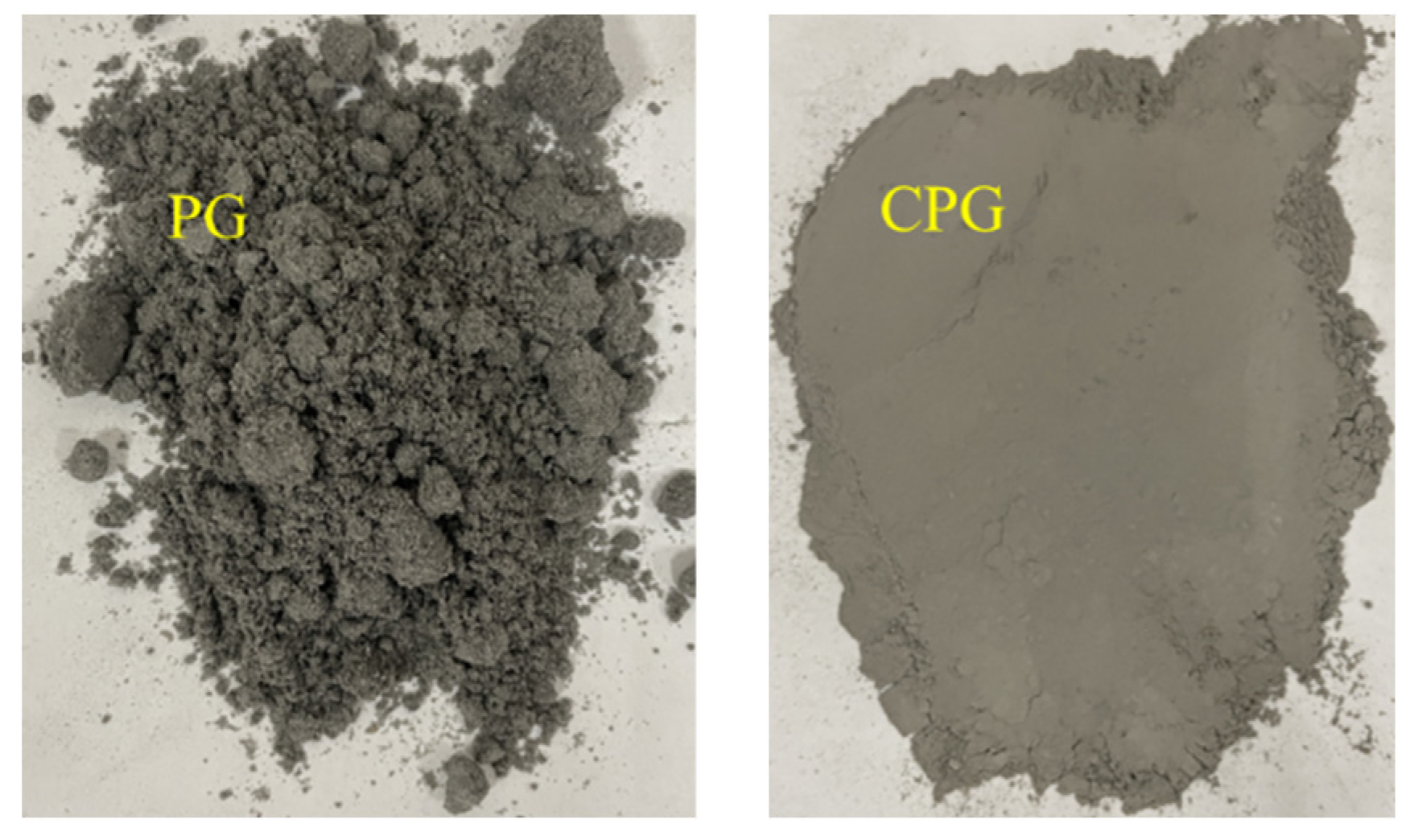

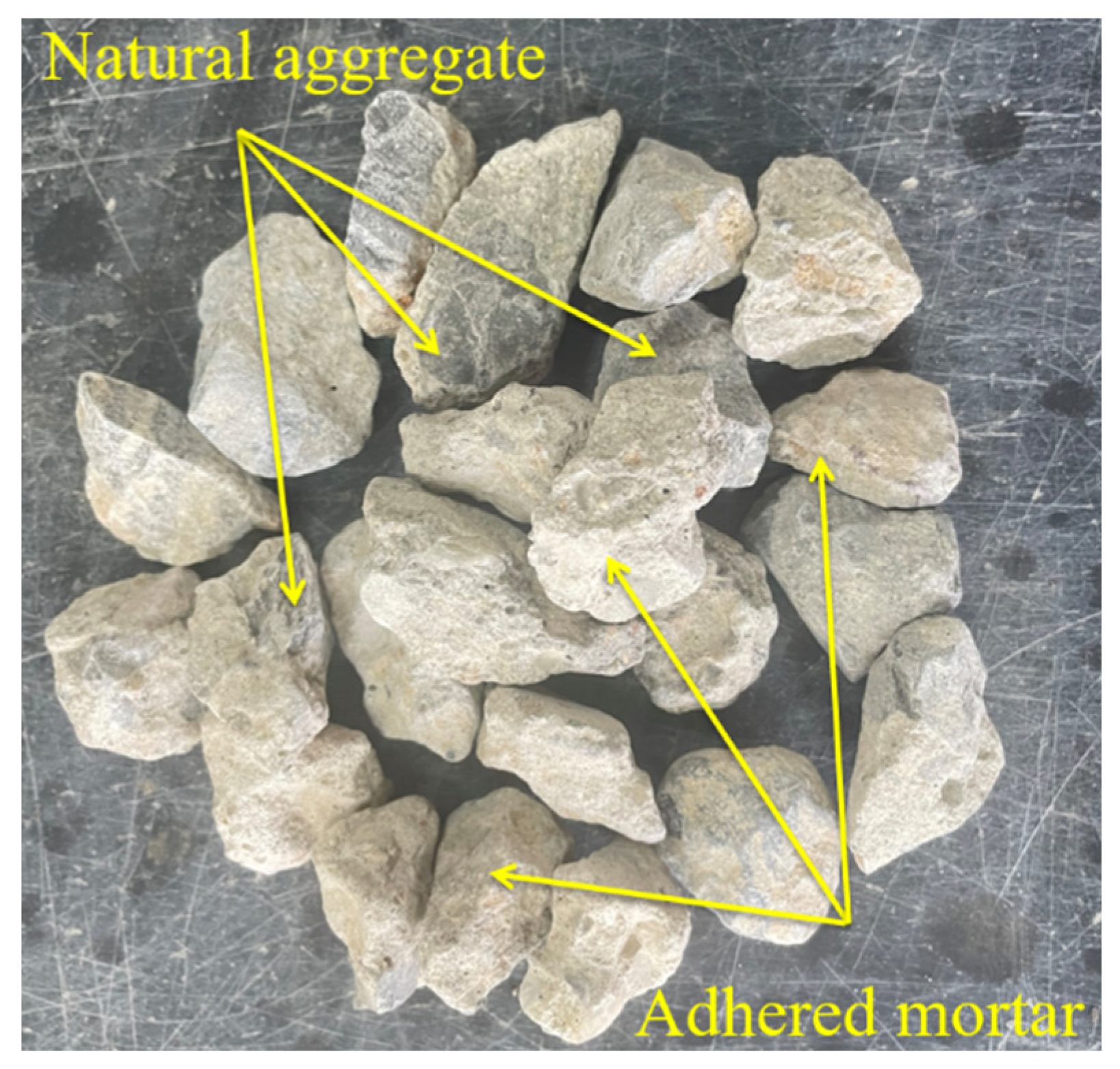

2.1. Materials

2.2. Mix Design and Preparation Method

2.2.1. Mix Design

2.2.2. Preparation Method

2.3. Testing and Characterization

2.3.1. Unconfined Compressive Strength

2.3.2. Wet-Dry Cycle Test

2.3.3. Freeze–Thaw Cycle Test

2.3.4. Scanning Electron Microscope Test

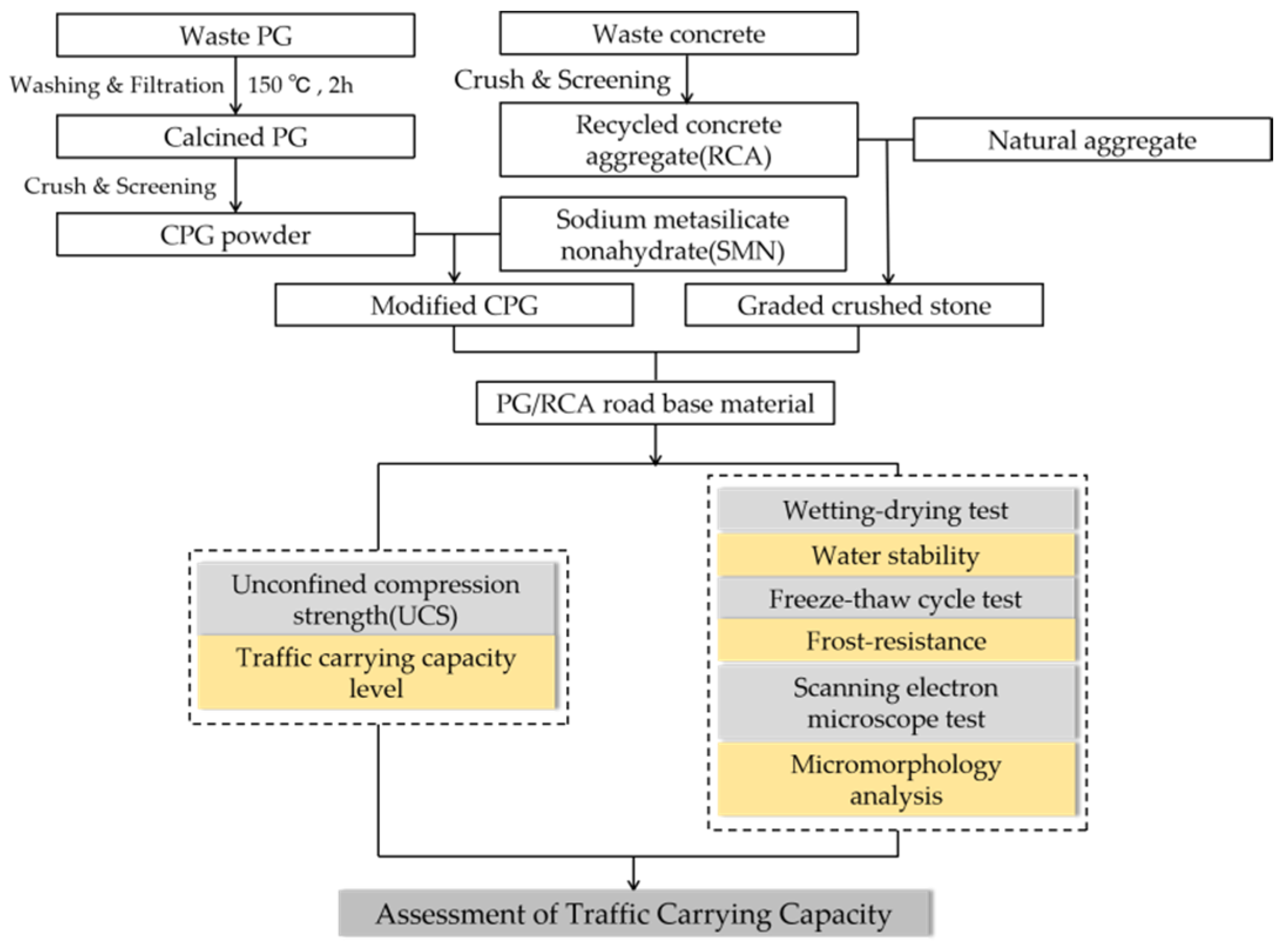

2.4. Research Flowchart

3. Results and Discussion

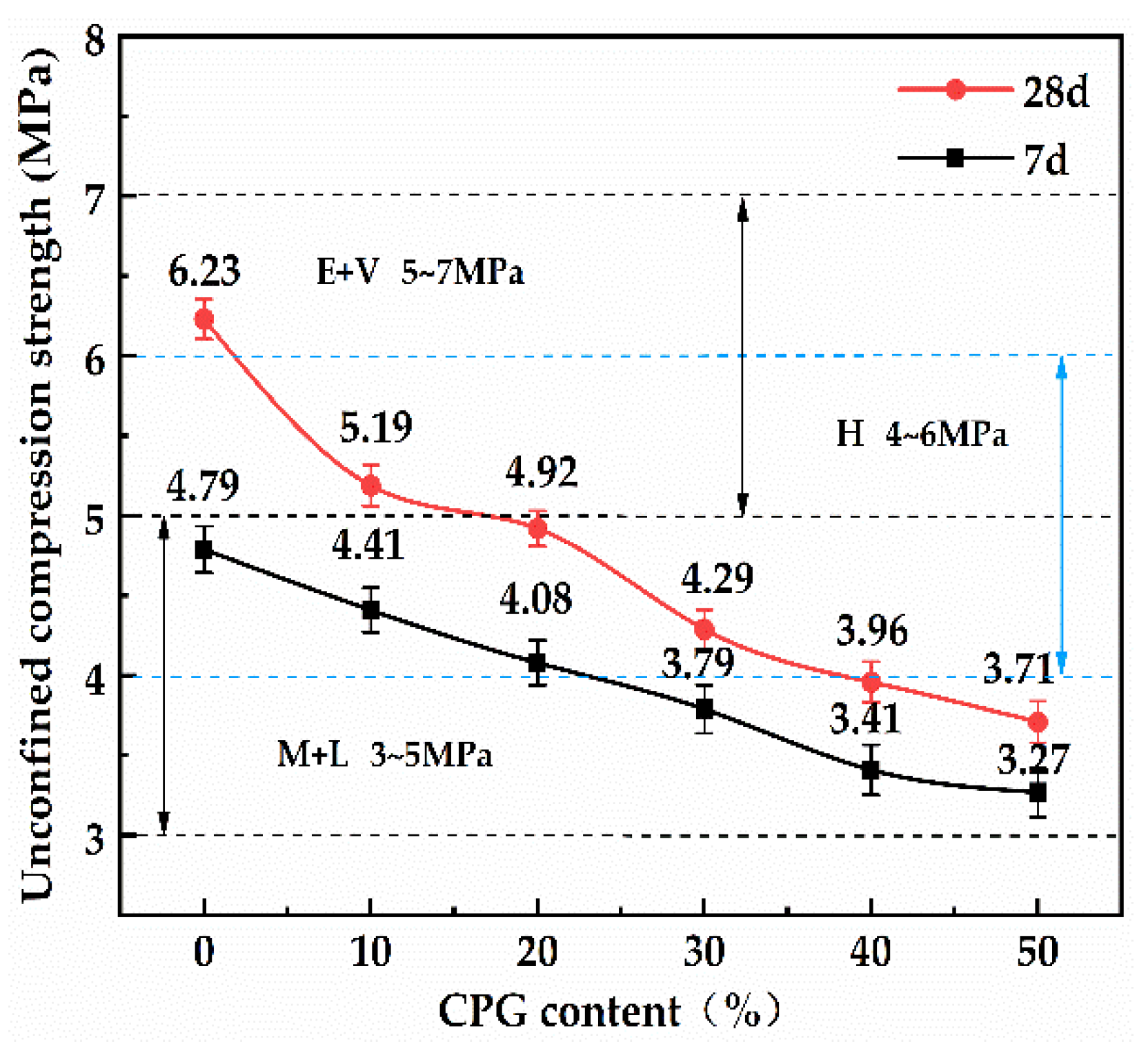

3.1. Unconfined Compressive Strength Results

3.1.1. Effect of Different CPG Contents

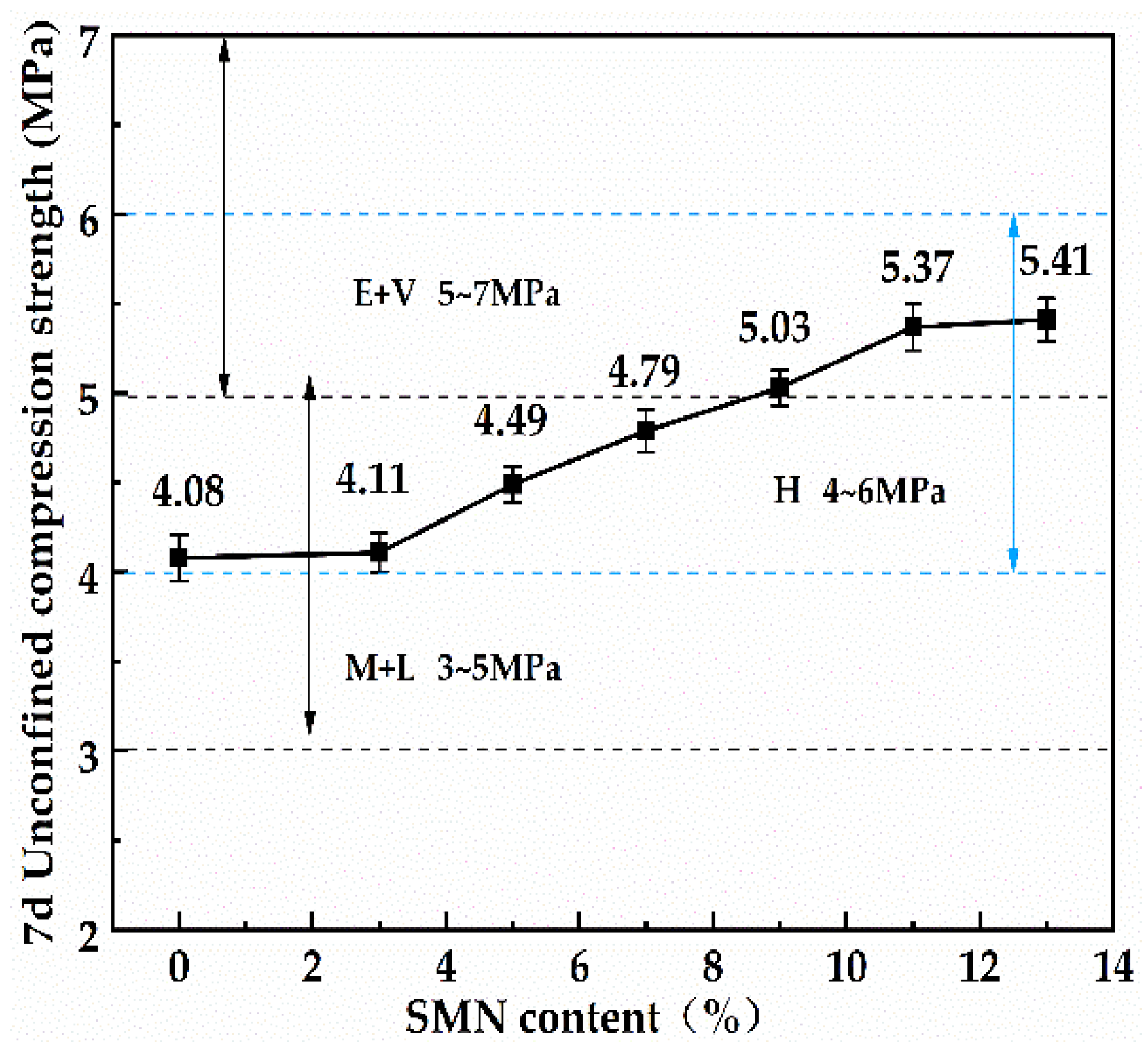

3.1.2. Effect of Different SMN Contents

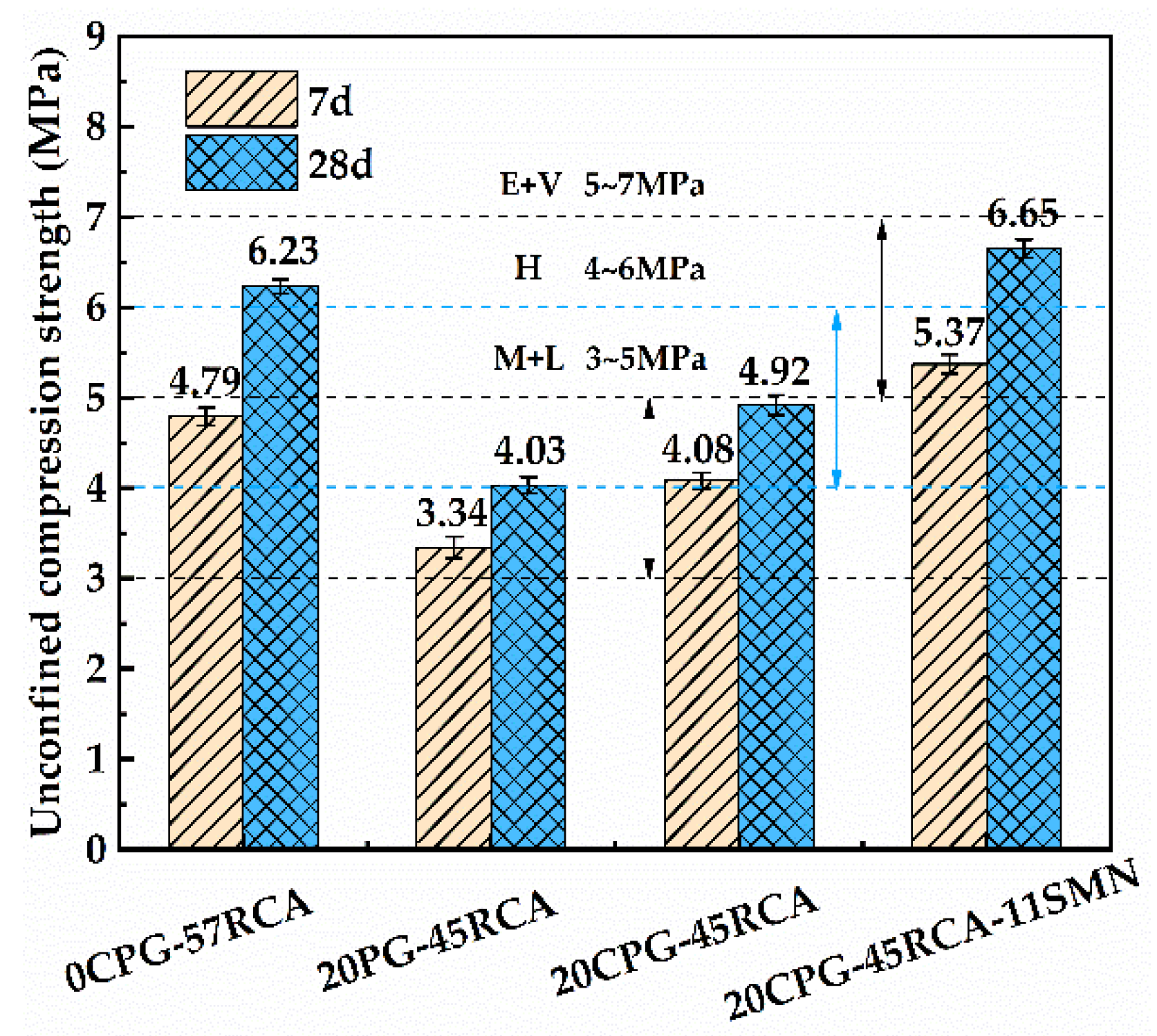

3.1.3. Compressive Strength Comparison of Different PG/RCA Roadbase Materials

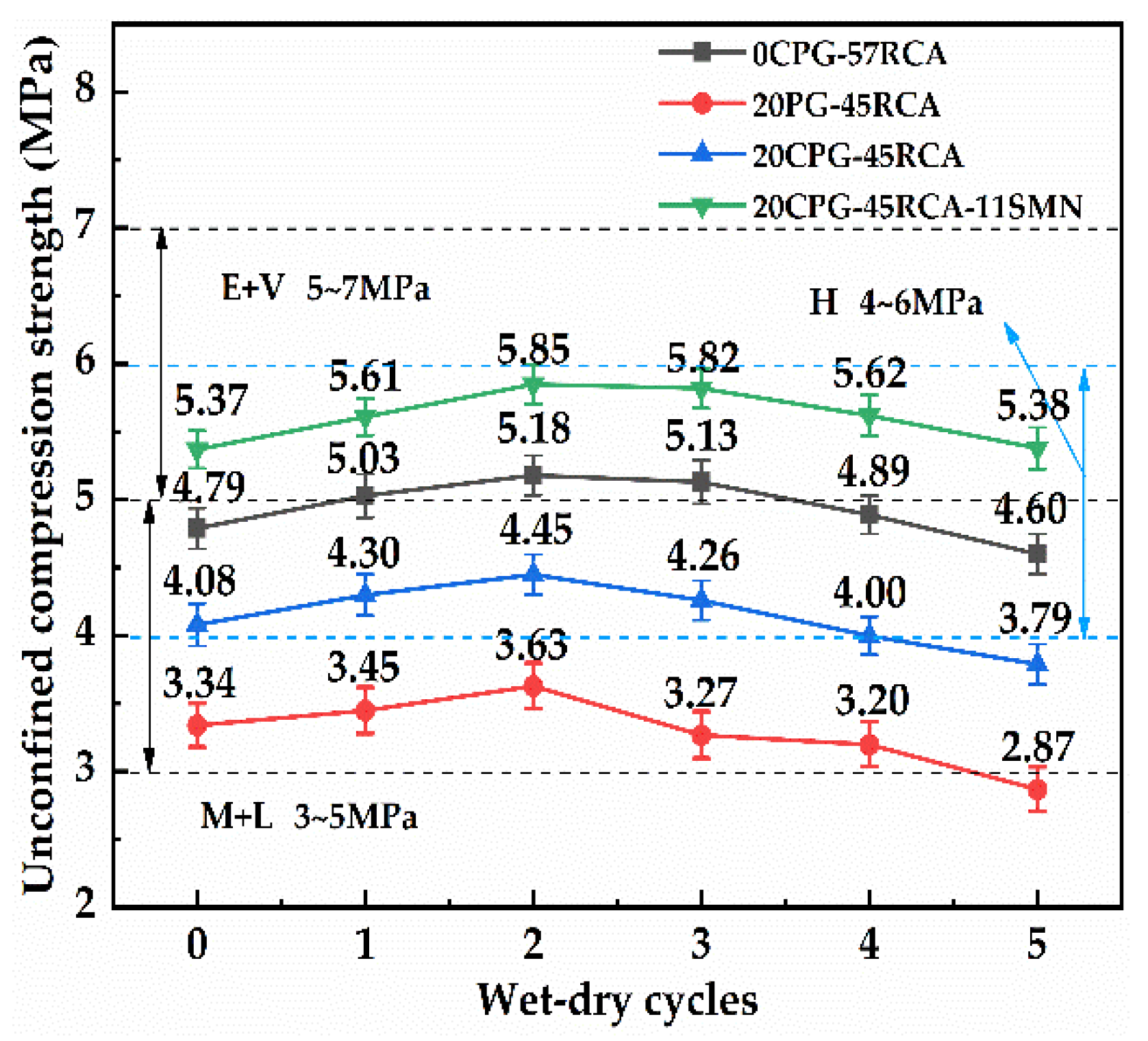

3.2. Water Stability

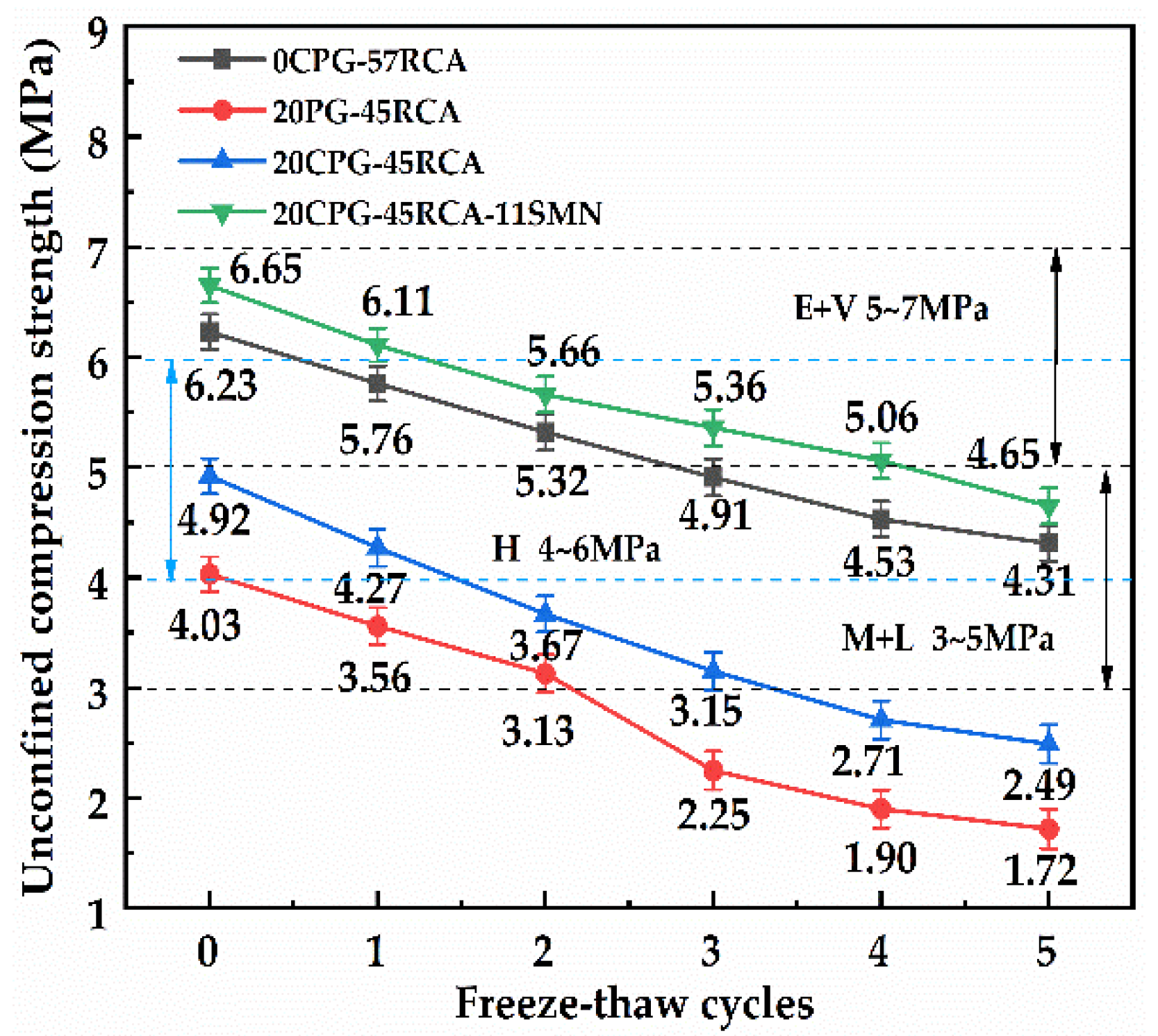

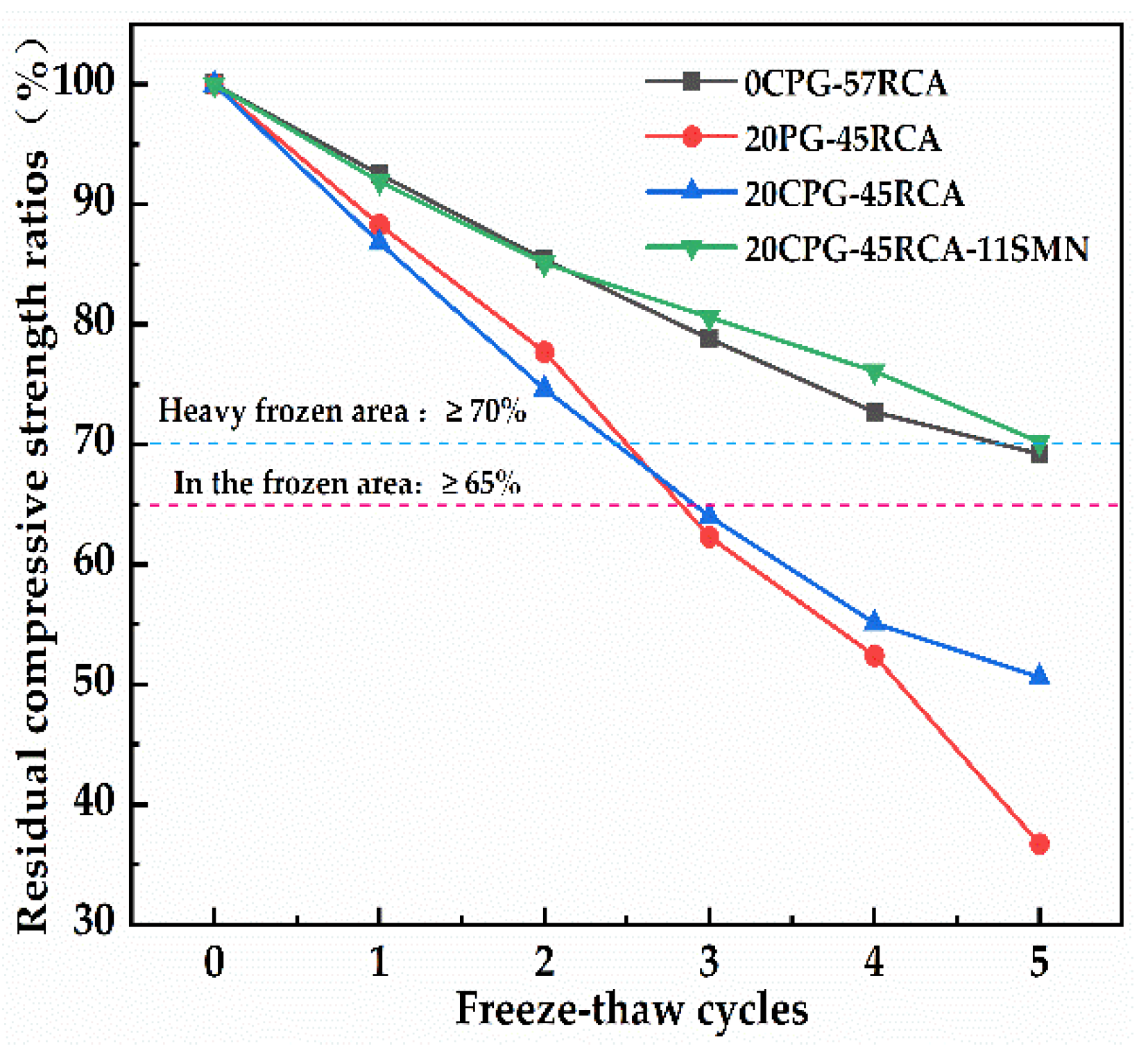

3.3. Frost Resistance

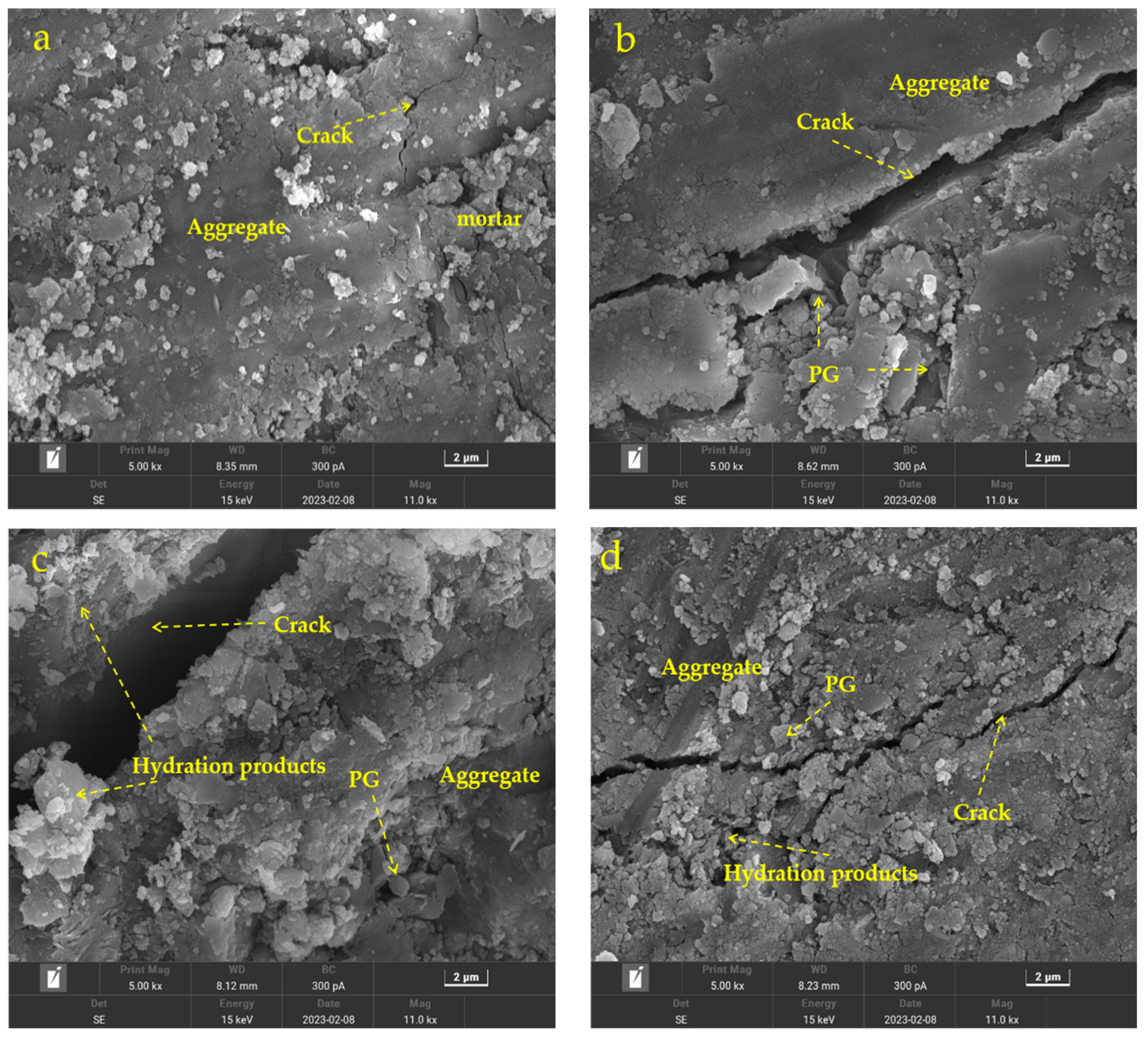

3.4. Microstructure Analysis

4. Conclusions

- (1)

- The results of compressive strength show that pretreated PG can slightly reduce its adverse impact on the compressive strength of roadbase materials containing RCA. As 11% SMN is considered, its compressive strength can be significantly increased to 5.37 MPa, reaching the requirement of an extremely and very heavy traffic grade for application in the expressway and first-class highway.

- (2)

- The water stability results indicate that, compared to 0CPG-57RCA, 20CPG-45RCA-11SMN has better resistance to moisture, and its compressive strength still exceeds 5 MPa after five wet–dry cycles and meets the requirement of an extremely and very heavy traffic grade for application in the expressway and first-class highway.

- (3)

- The freeze–thaw test results state that compared to 0CPG-57RCA, 20CPG-45RCA-11SMN has better frost resistance. Its compressive strength and residual compressive strength ratio can still reach 4.65 MPa and 70.2% after five freeze–thaw cycles, respectively, meeting the requirements of a heavy traffic grade and heavy frozen area.

- (4)

- Microstructural analysis demonstrates that 11% SMN can effectively promote the occurrence of hydration reactions to reduce the crack width and pore generation rate of roadbase materials containing CPG and RCA with improved compactness.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Meskini, S.; Mechnou, I. Environmental investigation on the use of a phosphogypsum-based road material: Radiological and leaching assessment. J. Environ. Manag. 2023, 345, 118597. [Google Scholar] [PubMed]

- Min, Y.; Jueshi, Q. Activation of fly ash–lime systems using calcined phosphogypsum. Constr. Build Mater. 2008, 22, 1004–1008. [Google Scholar] [CrossRef]

- Sun, T.; Li, W. A new eco-friendly concrete made of high content phosphogypsum based aggregates and binder: Mechanical properties and environmental benefits. J. Clean. Prod. 2023, 400, 136555. [Google Scholar]

- Murali, G.; Azab, M. Recent research in utilization of phosphogypsum as building materials: Review. J. Mater. Res. Technol. 2023, 25, 960–987. [Google Scholar]

- Wu, F.H.; Ren, Y.C. Utilization path of bulk industrial solid waste: A review on the multi-directional resource utilization path of phosphogypsum. J. Environ. Manag. 2022, 313, 114957. [Google Scholar] [PubMed]

- Tejas, S.; Pasla, D. Assessment of mechanical and durability properties of composite cement-based recycled aggregate concrete. Constr. Build Mater. 2023, 387, 131620. [Google Scholar]

- Sua-iam, G.; Makul, N. Self-compacting concrete produced with recycled concrete aggregate coated by a polymer-based agent: A case study. Case Stud. Constr. Mat. 2023, 19, e02351. [Google Scholar]

- Xu, X.; Luo, Y.; Anand, S. Potential use of recycled concrete aggregate (RCA) for sustainable asphalt pavements of the future: A state-of-the-art review. J. Clean Prod. 2022, 344, 130893. [Google Scholar]

- Hu, Q.; Yang, C. Study on the impermeability of recycled aggregate thermal insulation concrete. J. Build Eng. 2023, 77, 107400. [Google Scholar]

- Xie, D.Z.; Zhang, R. The influence of environmental factors and precipitation precursors on enzyme-induced carbonate precipitation (EICP) process and its application on modification of recycled concrete aggregates. J. Clean Prod. 2023, 395, 136444. [Google Scholar]

- Lal, C.B.; Jail, S.G. Sustainable development of recycled concrete aggregate through optimized acid-mechanical treatment: A simplified approach. Constr. Build Mater. 2023, 399, 132559. [Google Scholar]

- Xu, X.; Leng, Z. Sustainable practice in pavement engineering through value-added collective recycling of waste plastic and waste tyre rubber. Engineering 2021, 7, 857–867. [Google Scholar]

- Engelsen, C.J.; van der Sloot, H.A. Long-term leaching from recycled concrete aggregates applied as sub-base material in road construction. Sci. Tot. Environ. 2017, 587–588, 94–101. [Google Scholar]

- Gracioli, B.; Angulski da Luz, C. Influence of the calcination temperature of phosphogypsum on the performance of supersulfated cements. Constr. Build Mater. 2020, 262, 119961. [Google Scholar] [CrossRef]

- Cao, W.X.; Yi, W. Recycling of phosphogypsum to prepare gypsum plaster: Effect of calcination temperature. J. Build Eng. 2022, 45, 103511. [Google Scholar]

- Geraldo, R.H.; Costa, A.R.D. Calcination parameters on phosphogypsum waste recycling. Constr. Build Mater. 2020, 256, 119406. [Google Scholar]

- Bumanis, G.; Zorica, J. Technological properties of phosphogypsum binder obtained from fertilizer production waste. Energy Procedia. 2018, 147, 301–308. [Google Scholar] [CrossRef]

- Değirmenci, N. Utilization of phosphogypsum as raw and calcined material in manufacturing of building products. Constr Build Mater. 2008, 22, 1857–1862. [Google Scholar] [CrossRef]

- Mohammad, I.; Rana, A.S. Incorporation of phosphogypsum with cement in rigid Pavement: An approach towards sustainable development. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Ding, J.; Shi, M. Failure of Roadway Subbase Induced by Overuse of Phosphogypsum. J. Perform. Constr. Facil. 2019, 33, 04019013. [Google Scholar] [CrossRef]

- Zhang, H.; Cheng, Y.; Yang, L. Modification of lime-fly ash-crushed stone with phosphogypsum for road base. Adv. Civ. Eng. 2020, 2020, 1–7. [Google Scholar]

- Engelsen, C.J.; Wibetoe, G. Field site leaching from recycled concrete aggregates applied as sub-base material in road construction. Sci. Tot. Environ. 2012, 427–428, 86–97. [Google Scholar]

- Rahman, M.A.; Imteaz, M. Suitability of recycled construction and demolition aggregates as alternative pipe backfilling materials. J. Clean Prod. 2014, 66, 75–84. [Google Scholar]

- Kox, S.; Vanroelen, G.l. Experimental evaluation of the high-grade properties of recycled concrete aggregates and their application in concrete road pavement construction. Case Stud. Constr. Mat. 2019, 11, e00282. [Google Scholar] [CrossRef]

- Poon, C.S.; Chan, D. Feasible use of recycled concrete aggregates and crushed clay brick as unbound road sub-base. Constr. Build Mater. 2006, 20, 578–585. [Google Scholar] [CrossRef]

- Oliveira, F.D.; Gupta, N. pH attenuation by soils underlying recycled concrete aggregate road base. Resour. Conserv. Recy. 2020, 161, 104987. [Google Scholar]

- JGJ 52-2006; Standard for Technical Requirements and Test Method of Sand and Crushed Stone (or Gravel) for Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2006.

- GB 175-1999; Portland Cement and Ordinary Portland Cement. Standards Press of China: Beijing, China, 1999.

- JTG E51-2009; Test Methods of Materials Stabilized with Inorganic Binders for Highway Engineering. China Communications Press: Beijing, China, 2009.

- JTGT F20-2015; Technical Guigelines for Construction of Highway RoadBases. China Communications Press: Beijing, China, 2015.

- Nasir, M.; Islam, A.B.M.S. Evolution of Arabic Gum-based green mortar towards enhancing the engineering properties—Fresh, mechanical, and microstructural investigation. Constr. Build Mater. 2023, 365, 130025. [Google Scholar] [CrossRef]

- Shen, W.G.; Zhou, M.K. Investigation on the application of steel slag–fly ash–phosphogypsum solidified material as road base material. J. Hazard Mater. 2009, 164, 99–104. [Google Scholar] [CrossRef]

- Wang, Z.H.; Bai, E. Microwave heating efficiency and frost resistance of concrete modified with powder absorbing materials. Constr. Build. Mater. 2023, 379, 131145. [Google Scholar]

- Ruan, W.; Liao, J. Effects of bauxite tailings and sodium silicate on mechanical properties and hydration mechanism of magnesium phosphate cement. Constr. Build. Mater. 2023, 366, 130055. [Google Scholar]

- JTG D50-2017; Specifications for Design of Highway Asphalt Pavement. China Communications Press: Beijing, China, 2017.

- Saberian, M.; Li, J. Effect of freeze–thaw cycles on the resilient moduli and unconfined compressive strength of rubberized recycled concrete aggregate as pavement base/subbase. Transp. Geotech. 2021, 27, 100477. [Google Scholar]

- Nasir, M.; Johari, M.A.M. Influence of heat curing period and temperature on the strength of silico-manganese fume-blast furnace slag-based alkali-activated mortar. Constr. Build. Mater. 2020, 251, 118961. [Google Scholar]

| Composition | CaO | SO3 | SiO2 | P2O5 | Al2O3 | MgO | As2O5 | Cr2O5 | BaO | F | Crystal Water |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Percentage/% | 30.72 | 40.20 | 4.63 | 1.51 | 2.25 | 0.01 | 0.59 | 0.01 | 0.04 | 0.15 | 18.29 |

| Particle Size/mm | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 |

|---|---|---|---|---|---|---|

| Passing percentage/% | 100 | 96.87 | 93.26 | 90.89 | 78.36 | 9.32 |

| Aggregates | Bulk Density (kg/m3) | Apparent Density (kg/m3) | Porosity (%) | Water Absorption Rate (%) | Crushing Value (%) | Mass Percent of Adhered Mortar to NA (%) | Fineness Modulus |

|---|---|---|---|---|---|---|---|

| RCA | 1190 | 2560 | 0.47 | 6.1 | 15.9 | 25~30 | — |

| NFA | 1240 | 2597 | — | — | — | — | 2.94 |

| Type | Standard Consistency Water Consumption (%) | Condensation Time (min) | Compressive Strength (MPa) | ||

|---|---|---|---|---|---|

| Initial Setting Time | Final Setting Time | 3 d | 28 d | ||

| P.O 42.5 | 25.9 | 215 | 279 | 24.5 | 48.2 |

| Item | Cement (%) | CPG (%) | Aggregates (%) | OMC (%) | MDD (g/cm3) | |

|---|---|---|---|---|---|---|

| RCA | NFA | |||||

| 0CPG-57RCA | 5 | 0 | 57 | 38 | 6.73 | 2.272 |

| 10CPG-51RCA | 5 | 10 | 51 | 34 | 5.97 | 2.059 |

| 20CPG-45RCA | 5 | 20 | 45 | 30 | 6.17 | 2.044 |

| 30CPG-39RCA | 5 | 30 | 39 | 26 | 6.65 | 1.999 |

| 40CPG-33RCA | 5 | 40 | 33 | 22 | 7.50 | 1.931 |

| 50CPG-27RCA | 5 | 50 | 27 | 18 | 8.44 | 1.869 |

| Structural Layer | Highway Level | Extremely and Very Heavy Traffic (E + V) | Heavy Traffic (H) | Medium and Light Traffic (M + L) |

|---|---|---|---|---|

| Roadbase | Expressway and first-class highway | 5.0~7.0 | 4.0~6.0 | 3.0~5.0 |

| Second-class and below highway | 4.0~6.0 | 3.0~5.0 | 2.0~4.0 |

| Name | Abbreviation |

|---|---|

| Phosphopypsum | PG |

| Calcination phosphopypsum | CPG |

| Sodium metasilicate nonahydrate | SMN |

| Rcycled concrete aggregate | RCA |

| Natural aggregate | NA |

| Natural coarse aggregate | NCA |

| Natural fine aggregate | NFA |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Bian, X.; Liu, J.; Chi, R.; Chen, X. Performance Improvement and Microstructure Characterization of Cement-Stabilized Roadbase Materials Containing Phosphogypsum/Recycled Concrete Aggregate. Materials 2023, 16, 6607. https://doi.org/10.3390/ma16196607

Wu Y, Bian X, Liu J, Chi R, Chen X. Performance Improvement and Microstructure Characterization of Cement-Stabilized Roadbase Materials Containing Phosphogypsum/Recycled Concrete Aggregate. Materials. 2023; 16(19):6607. https://doi.org/10.3390/ma16196607

Chicago/Turabian StyleWu, Yang, Xiaoya Bian, Jie Liu, Ruan Chi, and Xuyong Chen. 2023. "Performance Improvement and Microstructure Characterization of Cement-Stabilized Roadbase Materials Containing Phosphogypsum/Recycled Concrete Aggregate" Materials 16, no. 19: 6607. https://doi.org/10.3390/ma16196607

APA StyleWu, Y., Bian, X., Liu, J., Chi, R., & Chen, X. (2023). Performance Improvement and Microstructure Characterization of Cement-Stabilized Roadbase Materials Containing Phosphogypsum/Recycled Concrete Aggregate. Materials, 16(19), 6607. https://doi.org/10.3390/ma16196607