A Molecular Dynamics Simulation Study of In- and Cross-Plane Thermal Conductivity of Bilayer Graphene

Abstract

:1. Introduction

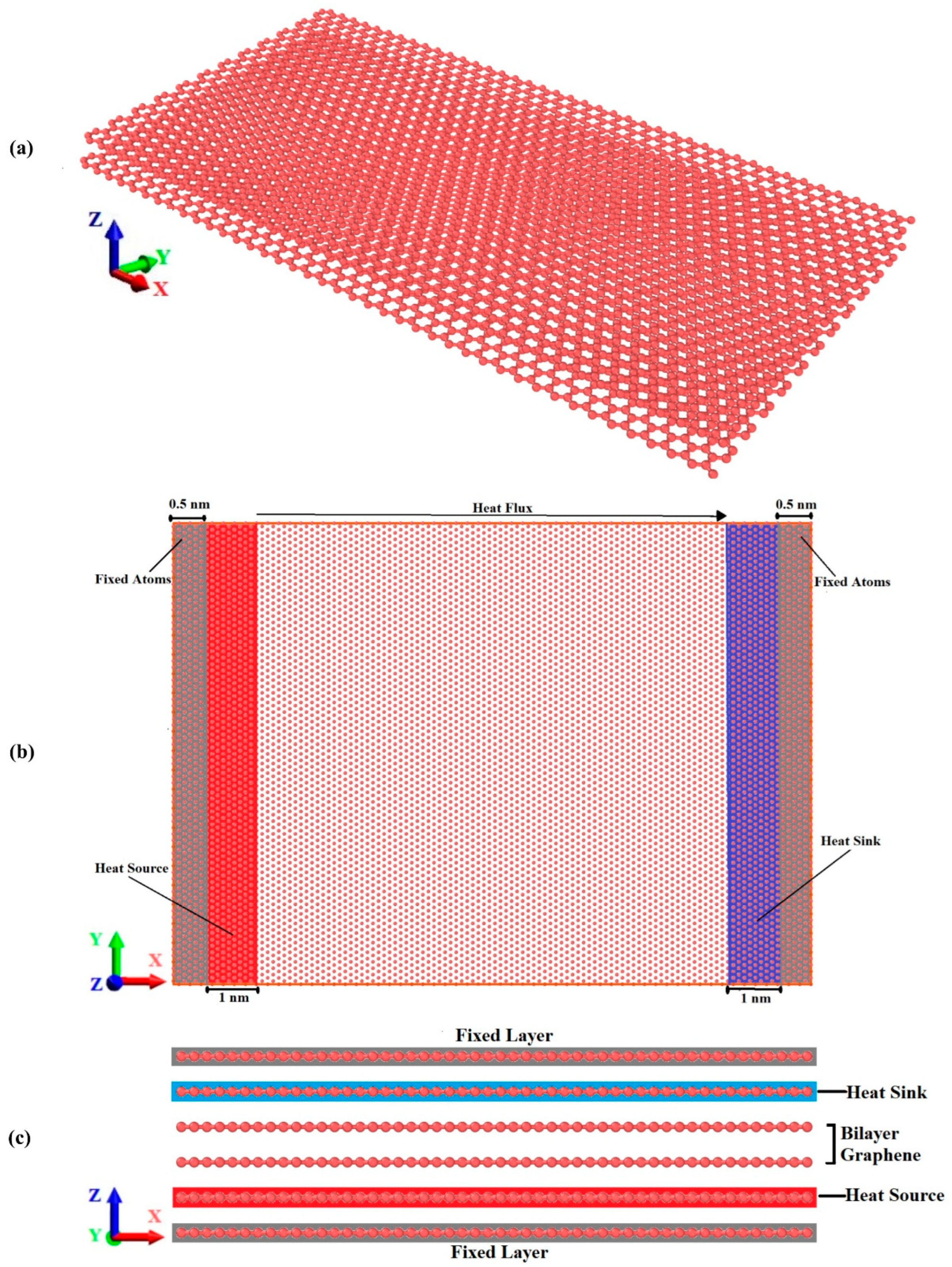

2. Simulation Procedures

3. Results and Discussion

3.1. In-Plane Thermal Conductivity

| Temperature (K) | Nie et al. [38] (W/m·K) | Current study (W/m·K) |

|---|---|---|

| 200 | 648 ± 25 | 653.2 ± 8 |

| 300 | 529 ± 25 | 520.4 ± 8 |

| 400 | 450 ± 25 | 465.6 ± 8 |

| 500 | 400 ± 25 | 406.1 ± 8 |

| 600 | 360 ± 25 | 368.7 ± 8 |

3.2. Cross-Plane Thermal Conductivity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Interatomic Potentials

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| (eV) | 1393.6 | n | 0.72751 |

| (eV) | 430.0 | (Å) | 1.95 |

| c | 38,049.0 | 1.5724 × 10−7 | |

| d | 4.3484 | (1/Å) | 3.4879 |

| (Å) | 0.15 | (1/Å) | 2.2119 |

| h | −0.930 | (1/Å) | 0.0000 |

| Parameter | (eV) | (Å) | ||

| Value | 15.12 | 24.1 × 103 | 2.39 × 10−3 | 3.41 |

References

- Garimella, S.V.; Fleischer, A.S.; Murthy, J.Y.; Keshavarzi, A.; Prasher, R.; Patel, C.; Bhavnani, S.H.; Venkatasubramanian, R.; Mahajan, R.; Joshi, Y.; et al. Thermal Challenges in Next-Generation Electronic Systems. IEEE Trans. Compon. Packag. Manuf. Technol. 2008, 31, 801–815. [Google Scholar] [CrossRef]

- Iradukunda, A.C.; Huitink, D.R.; Luo, F. A Review of Advanced Thermal Management Solutions and the Implications for Integration in High-Voltage Packages. IEEE J. Emerg. Sel. Top. Power Electron. 2019, 8, 256–271. [Google Scholar] [CrossRef]

- Huang, P.; Li, Y.; Yang, G.; Li, Z.X.; Li, Y.Q.; Hu, N.; Fu, S.Y.; Novoselov, K.S. Graphene film for thermal management: A review. Nano Mater. Sci. 2021, 3, 1–16. [Google Scholar] [CrossRef]

- Khan, J.; Momin, S.A.; Mariatti, M. A review on advanced carbon-based thermal interface materials for electronic devices. Carbon 2020, 168, 65–112. [Google Scholar] [CrossRef]

- Joshi, S.N.; Zhou, F.; Liu, Y.; Lohan, D.J.; Ukegawa, H.; Lee, J.; Dede, E.M. A review of select patented technologies for cooling of high heat flux power semiconductor devices. IEEE Trans. Power Electron. 2023, 38, 6790–6794. [Google Scholar] [CrossRef]

- Goktas, N.I.; Wilson, P.; Ghukasyan, A.; Wagner, D.; McNamee, S.; LaPierre, R.R. Nanowires for energy: A review. Appl. Phys. Rev. 2018, 5, 041305. [Google Scholar] [CrossRef]

- Galdámez-Martinez, A.; Santana, G.; Güell, F.; Martínez-Alanis, P.R.; Dutt, A. Photoluminescence of ZnO nanowires: A review. Nanomaterials 2020, 10, 857. [Google Scholar] [CrossRef]

- Gupta, N.; Gupta, S.M.; Sharma, S.K. Carbon nanotubes: Synthesis, properties, and engineering applications. Carbon Lett. 2019, 29, 419–447. [Google Scholar] [CrossRef]

- Yang, H.; Valenzuela, S.O.; Chshiev, M.; Couet, S.; Dieny, B.; Dlubak, B.; Fert, A.; Garello, K.; Jamet, M.; Jeong, D.E.; et al. Two-dimensional materials prospects for non-volatile spintronic memories. Nature 2022, 606, 663–673. [Google Scholar] [CrossRef]

- Sun, C.; Wang, L.; Zhao, W.; Xie, L.; Wang, J.; Li, J.; Li, B.; Liu, S.; Zhuang, Z.; Zhao, Q. Atomic-Level Design of Active Site on Two-Dimensional MoS2 toward Efficient Hydrogen Evolution: Experiment, Theory, and Artificial Intelligence Modelling. Adv. Funct. Mater. 2022, 32, 2206163. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Yang, K.; Liu, G.; Chen, Y.; Wang, M.; Li, S.; Li, R. Recent Advances on Graphene: Synthesis, Properties, and Applications. Compos. Part A Appl. Sci. Manuf. 2022, 160, 107051. [Google Scholar] [CrossRef]

- Moser, J.; Barreiro, A.; Bachtold, A. Current-induced cleaning of graphene. Appl. Phys. Lett. 2007, 91, 163513. [Google Scholar] [CrossRef]

- Zhu, Y.; Murali, S.; Cai, W.; Li, X.; Suk, J.W.; Potts, J.R.; Ruoff, R.S. Graphene and Graphene Oxide: Synthesis, Properties, and Applications. Adv. Mater. 2010, 22, 3906–3924. [Google Scholar] [CrossRef]

- Ibrahim, A.; Klopocinska, A.; Horvat, K.; Abdel Hamid, Z. Graphene-based nanocomposites: Synthesis, mechanical properties, and characterizations. Polymers 2021, 13, 2869. [Google Scholar] [CrossRef]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior thermal conductivity of single-layer graphene. Nano Lett. 2008, 8, 902. [Google Scholar] [CrossRef]

- Ghosh, S.; Nika, D.L.; Pokatilov, E.P.; Balandin, A.A. Heat conduction in graphene: Experimental study and theoretical interpretation. New J. Phys. 2009, 11, 095012. [Google Scholar] [CrossRef]

- Cai, W.; Moore, A.L.; Zhu, Y.; Li, X.; Chen, S.; Shi, L.; Ruoff, R.S. Thermal Transport in Suspended and Supported Monolayer Graphene Grown by Chemical Vapor Deposition. Nano Lett. 2010, 10, 1645–1651. [Google Scholar] [CrossRef]

- Xu, X.; Pereira, L.F.C.; Wang, Y.; Wu, J.; Zhang, K.; Zhao, X.; Bae, S.; Bui, C.T.; Xie, R.; Thong, J.T.L.; et al. Length-dependent thermal conductivity in suspended single-layer graphene. Nature 2014, 5, 3689. [Google Scholar] [CrossRef]

- Guo, M.; Qian, Y.; Qi, H.; Bi, K.; Chen, Y. Experimental Measurements on the Thermal Conductivity of Strained Monolayer Graphene. Carbon 2019, 157, 185–190. [Google Scholar] [CrossRef]

- Zhang, H.; Fonseca, A.F.; Cho, K. Tailoring Thermal Transport Property of Graphene through Oxygen Functionalization. J. Phys. Chem. C 2014, 118, 1436–1442. [Google Scholar] [CrossRef]

- Ghosh, S.; Bao, W.; Nika, D.L.; Subrina, S.; Pokatilov, E.P.; Lau, C.N.; Balandin, A.A. Dimensional crossover of thermal transport in few-layer graphene. Nat. Mater. 2010, 9, 555. [Google Scholar] [CrossRef] [PubMed]

- Sood, A.; Sievers, C.; Shin, Y.C.; Chen, V.; Chen, S.; Smithe, K.K.; Chatterjee, S.; Donadio, D.; Goodson, K.E.; Pop, E. Engineering Thermal Transport across Layered Graphene–MoS2 Superlattices. ACS Nano 2021, 15, 19503–19512. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Qiu, B.; Ruan, X. Edge effect on thermal transport in graphene nanoribbons: A phonon localization mechanism beyond edge roughness scattering. Appl. Phys. Lett. 2012, 101, 013101. [Google Scholar] [CrossRef]

- Zhang, C.; Hao, X.L.; Wang, C.X.; Wei, N.; Rabczuk, T. Experimental measurements on the under shear deformation: A molecular dynamics simulation. Sci. Rep. 2017, 7, 1–8. [Google Scholar]

- Kipper, A.C.; da Silva, L.B. Non equilibrium molecular dynamics simulation study of thermal conductivity in doped graphene nanoribbons. Phys. B Condens. Matter 2019, 556, 1–5. [Google Scholar] [CrossRef]

- Fang, T.H.; Lee, Z.W.; Chang, W.J.; Huang, C.C. Determining porosity effect on the thermal conductivity of single-layer graphene using a molecular dynamics simulation. Phys. E Low Dimens. Syst. Nanostruct. 2019, 106, 90–94. [Google Scholar] [CrossRef]

- Yousefi, F.; Khoeini, F.; Rajabpour, A. Thermal conductivity and thermal rectification of nanoporous graphene: A molecular dynamics simulation. Int. J. Heat Mass Transf. 2020, 146, 118884. [Google Scholar] [CrossRef]

- Kim, J.C.; Wi, J.H.; Ri, N.C.; Ri, S.I. Thermal conductivity of graphene/graphane/graphene heterostructure nanoribbons: Non-equilibrium molecular dynamics simulations. Solid State Commun. 2021, 328, 114249. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, F.; Hong, Y.; Xiong, Q.; Pan, J. A comprehensive review on the molecular dynamics simulation of the novel thermal properties of graphene. RSC Adv. 2015, 5, 89415–89426. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, K.; Dixit, A.R. A review on the mechanical and thermal properties of graphene and graphene-based polymer nanocomposites: Understanding of modelling and MD simulation. Mol. Simul. 2020, 46, 136–154. [Google Scholar] [CrossRef]

- Wei, Z.; Ni, Z.; Bi, K.; Chen, M.; Chen, Y. In-plane lattice thermal conductivities of multilayer graphene films. Carbon 2011, 49, 2653–2658. [Google Scholar] [CrossRef]

- Cao, H.Y.; Guo, Z.X.; Xiang, H.; Gong, X.G. Layer and size dependence of thermal conductivity in multilayer graphene nanoribbons. Phys. Lett. A 2012, 376, 525–528. [Google Scholar] [CrossRef]

- Guo, T.; Sha, Z.; Liu, X.; Zhang, G.; Guo, T.; Pei, Q.; Zhang, Y. Tuning the thermal conductivity of multi-layer graphene with interlayer bonding and tensile strain. Appl. Phys. A 2015, 120, 1275–1281. [Google Scholar] [CrossRef]

- Zhan, H.; Zhang, Y.; Bell, J.M.; Gu, Y. Suppressed thermal conductivity of bilayer graphene with vacancy-initiated linkages. J. Phys. Chem. C 2015, 119, 1748–1752. [Google Scholar] [CrossRef]

- Si, C.; Wang, X.; Fan, Z.; Feng, Z.; Cao, B. Impacts of potential models on calculating the thermal conductivity of graphene using non-equilibrium molecular dynamics simulations. Int. J. Heat Mass Transf. 2017, 107, 450–460. [Google Scholar] [CrossRef]

- Li, C.; Debnath, B.; Tan, X.; Su, S.; Xu, K.; Ge, S.; Neupane, M.R.; Lake, R.K. Commensurate lattice constant dependent thermal conductivity of misoriented bilayer graphene. Carbon 2018, 138, 451–457. [Google Scholar] [CrossRef]

- Nie, X.; Zhao, L.; Deng, S.; Zhang, Y.; Du, Z. How interlayer twist angles affect in-plane and cross-plane thermal conduction of multilayer graphene: A non-equilibrium molecular dynamics study. Int. J. Heat Mass Transf. 2019, 137, 161–173. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Z.; Chen, H.; Xu, L. Comparative studies of thermal conductivity for bilayer graphene with different potential functions in molecular dynamic simulations. Results Phys. 2021, 22, 103894. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short–range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO–the open visualization tool. Modell. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Humphrey, W.; Dalke, A.; Schulten, K. VMD: Visual molecular dynamics. J. Mol. Graphics 1996, 14, 33–38. [Google Scholar] [CrossRef] [PubMed]

- Lindsay, L.; Broido, D.A. Optimized Tersoff and Brenner empirical potential parameters for lattice dynamics and phonon thermal transport in carbon nanotubes and graphene. Phys. Rev. B 2010, 81, 205441. [Google Scholar] [CrossRef]

- Girifalco, L.A.; Hodak, M.; Lee, R.S. Carbon nanotubes, buckyballs, ropes, and a universal graphitic potential. Phys. Rev. B 2000, 62, 13104. [Google Scholar] [CrossRef]

- Jiang, J.W.; Chen, J.; Wang, J.S.; Li, B. Edge states induce boundary temperature jump in molecular dynamics simulation of heat conduction. Phys. Rev. B 2009, 80, 052301. [Google Scholar] [CrossRef]

- Yarifard, M.; Davoodi, J.; Rafii-Tabar, H. Computation of the thermal resistance in graphene sheets with a rectangular hole. Comput. Mater. Sci. 2017, 126, 29–34. [Google Scholar] [CrossRef]

- Pop, E.; Varshney, V.; Roy, A.K. Thermal properties of graphene: Fundamentals and applications. MRS Bull. 2012, 37, 1273–1281. [Google Scholar] [CrossRef]

- Bae, M.H.; Aksamija, Z.; Martin, P.N.; Xiong, F.; Ong, Z.Y.; Knezevic, I.; Pop, E. Ballistic to Diffusive Crossover of Heat Flow in Graphene Ribbons. Nat. Commun. 2013, 4, 1734. [Google Scholar] [CrossRef]

- Hu, J.; Ruan, X.; Chen, Y.P. Thermal conductivity and thermal rectification in graphene nanoribbons: A molecular dynamics study. Nano Lett. 2009, 9, 2730–2735. [Google Scholar] [CrossRef]

- Khan, A.I.; Navid, I.A.; Hossain, F.F.; Noshin, M.; Subrina, S. A molecular dynamics study on thermal conductivity of armchair graphene nanoribbon. In Proceedings of the 2016 IEEE Region 10 Conference (TENCON), Singapore, 22–25 November 2016; pp. 2775–2778. [Google Scholar]

- Xu, Y.; Chen, X.; Gu, B.L.; Duan, W. Intrinsic anisotropy of thermal conductance in graphene nanoribbons. Appl. Phys. Lett. 2009, 95, 233116. [Google Scholar] [CrossRef]

- Aksamija, Z.; Knezevic, I. Lattice thermal conductivity of graphene nanoribbons: Anisotropy and edge roughness scattering. Appl. Phys. Lett. 2011, 98, 141919. [Google Scholar] [CrossRef]

- Khan, A.I.; Paul, R.; Subrina, S. Characterization of thermal and mechanical properties of stanene nanoribbons: A molecular dynamics study. RSC Adv. 2017, 7, 50485–50495. [Google Scholar] [CrossRef]

- Rahman, M.H.; Chowdhury, E.H.; Shahadat, M.R.B.; Islam, M.M. Engineered defects to modulate the phonon thermal conductivity of Silicene: A nonequilibrium molecular dynamics study. Comput. Mater. Sci. 2021, 191, 110338. [Google Scholar] [CrossRef]

- Ng, T.Y.; Yeo, J.; Liu, Z. Molecular dynamics simulation of the thermal conductivity of shorts strips of graphene and silicene: A comparative study. Int. J. Mech. Mater. Des. 2013, 9, 105–114. [Google Scholar] [CrossRef]

- Cao, A. Molecular dynamics simulation study on heat transport in monolayer graphene sheet with various geometries. J. Appl. Phys. 2012, 111, 083528. [Google Scholar] [CrossRef]

- Li, H.; Ying, H.; Chen, X.; Nika, D.L.; Cocemasov, A.; Cai, W.; Balandin, A.A.; Chen, S. Thermal Conductivity of Twisted Bilayer Graphene. Nanoscale 2014, 6, 13402–13408. [Google Scholar] [CrossRef]

- Oh, J.; Yoo, H.; Choi, J.; Kim, J.Y.; Lee, D.S.; Kim, M.J.; Lee, J.; Kim, W.N.; Kim, J.C.; Son, J.G. Significantly reduced thermal conductivity and enhanced thermoelectric properties of single- and bi-layer graphene nanomeshes with sub-10 nm neck-width. Nano Energy 2017, 35, 26–35. [Google Scholar] [CrossRef]

- Guo, Z.; Zhang, D.; Gong, X. Thermal conductivity of graphene nanoribbons. Appl. Phys. Lett. 2009, 95, 163103. [Google Scholar] [CrossRef]

- Wei, N.; Xu, L.; Wang, H.Q.; Zheng, J.C. Strain engineering of thermal conductivity in graphene sheets and nanoribbons: A demonstration of magic flexibility. Nanotechnology 2011, 22, 105705. [Google Scholar] [CrossRef]

- Bergman, T.L.; Lavine, A.S.; Incropera, F.P.; DeWitt, D.P. Fundamentals of Heat and Mass Transfer, 7th ed.; Wiley: New York, NY, USA, 2011. [Google Scholar]

- Koh, Y.K.; Bae, M.H.; Cahill, D.G.; Pop, E. Heat Conduction across Monolayer and Few-Layer Graphenes. Nano Lett. 2010, 10, 4363–4368. [Google Scholar] [CrossRef]

- Wei, Z.; Ni, Z.; Bi, K.; Chen, M.; Chen, Y. Interfacial thermal resistance in multilayer graphene structures. Phys. Lett. A 2011, 375, 1195–1199. [Google Scholar] [CrossRef]

- Ni, Y.; Chalopin, Y.; Volz, S. Calculation of inter-plane thermal resistance of few-layer graphene from equilibrium molecular dynamics simulations. J. Phys. Conf. Ser. 2012, 395, 012106. [Google Scholar] [CrossRef]

- Ding, Z.; Pei, Q.X.; Jiang, J.W.; Huang, W.; Zhang, Y.W. Interfacial thermal conductance in graphene/MoS2 heterostructures. Carbon 2016, 96, 888–896. [Google Scholar] [CrossRef]

- Alofi, A.; Srivastava, G.P. Evolution of thermal properties from graphene to graphite. Appl. Phys. Lett. 2014, 104, 031903. [Google Scholar] [CrossRef]

- Sun, K.; Stroscio, M.A.; Dutta, M. Graphite C-axis thermal conductivity. Superlattices Microstruct. 2009, 45, 60–64. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammadi, R.; Ghaderi, M.R.; Hajian, E. A Molecular Dynamics Simulation Study of In- and Cross-Plane Thermal Conductivity of Bilayer Graphene. Materials 2023, 16, 6714. https://doi.org/10.3390/ma16206714

Mohammadi R, Ghaderi MR, Hajian E. A Molecular Dynamics Simulation Study of In- and Cross-Plane Thermal Conductivity of Bilayer Graphene. Materials. 2023; 16(20):6714. https://doi.org/10.3390/ma16206714

Chicago/Turabian StyleMohammadi, Rafat, Mohammad Reza Ghaderi, and Ebrahim Hajian. 2023. "A Molecular Dynamics Simulation Study of In- and Cross-Plane Thermal Conductivity of Bilayer Graphene" Materials 16, no. 20: 6714. https://doi.org/10.3390/ma16206714