Deformation Behavior and Processing Maps of 7075 Aluminum Alloy under Large-Strain Thermal Compression

Abstract

:1. Introduction

2. Materials and Experimental Methods

3. The Theory for Construction of Processing Map

4. Results and Discussion

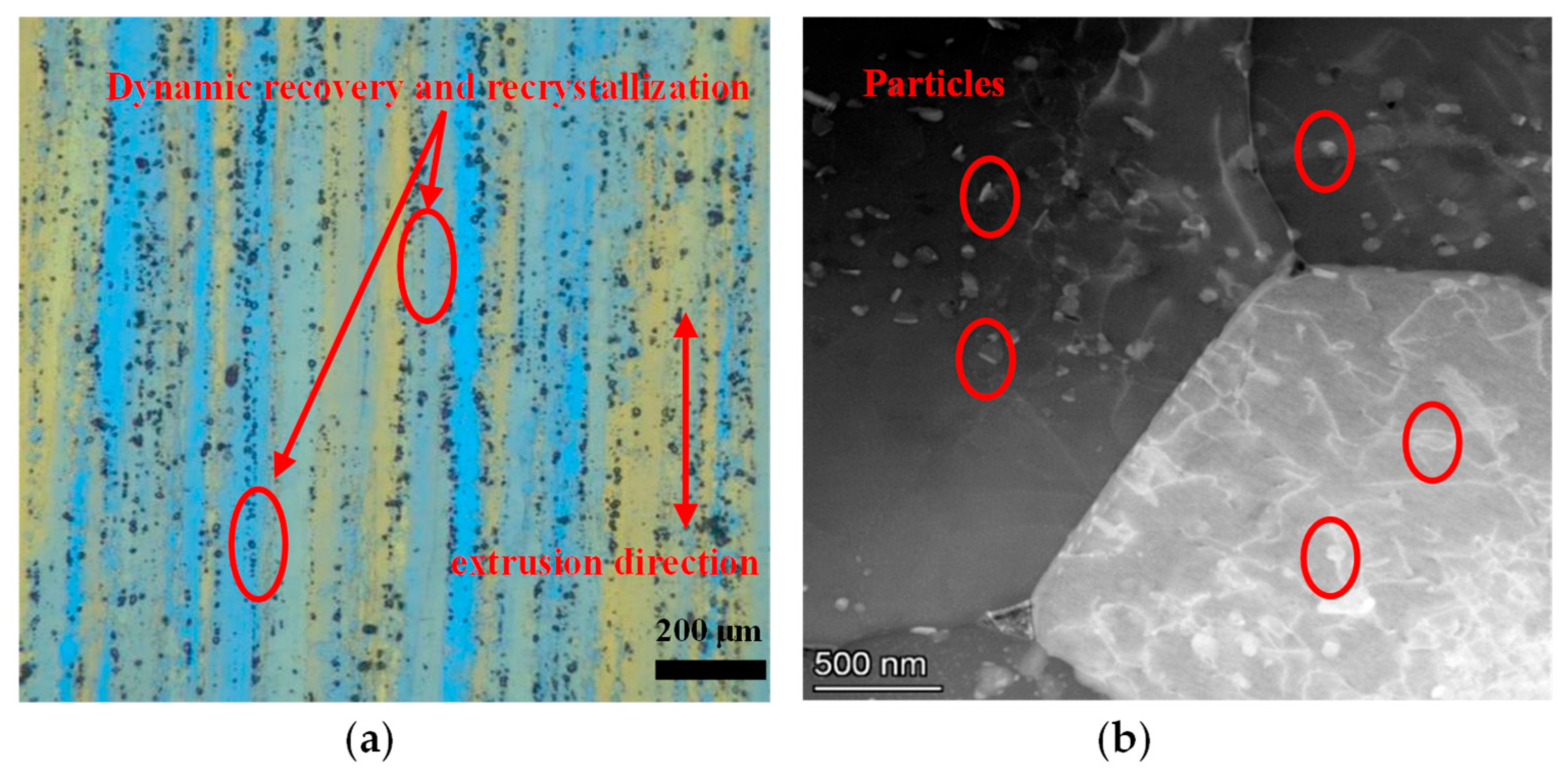

4.1. Initial Microstructure

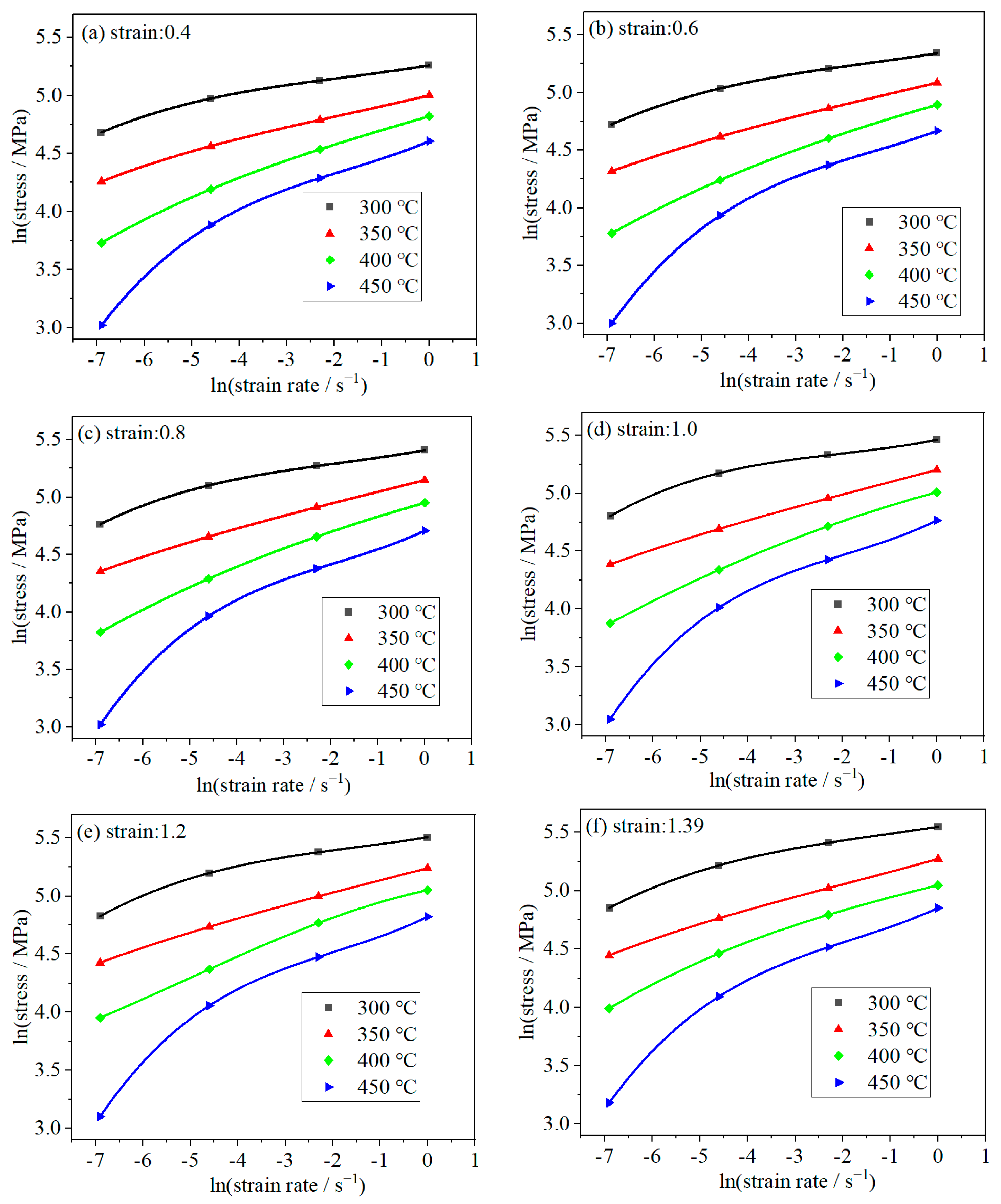

4.2. The True Stress–strain Curve

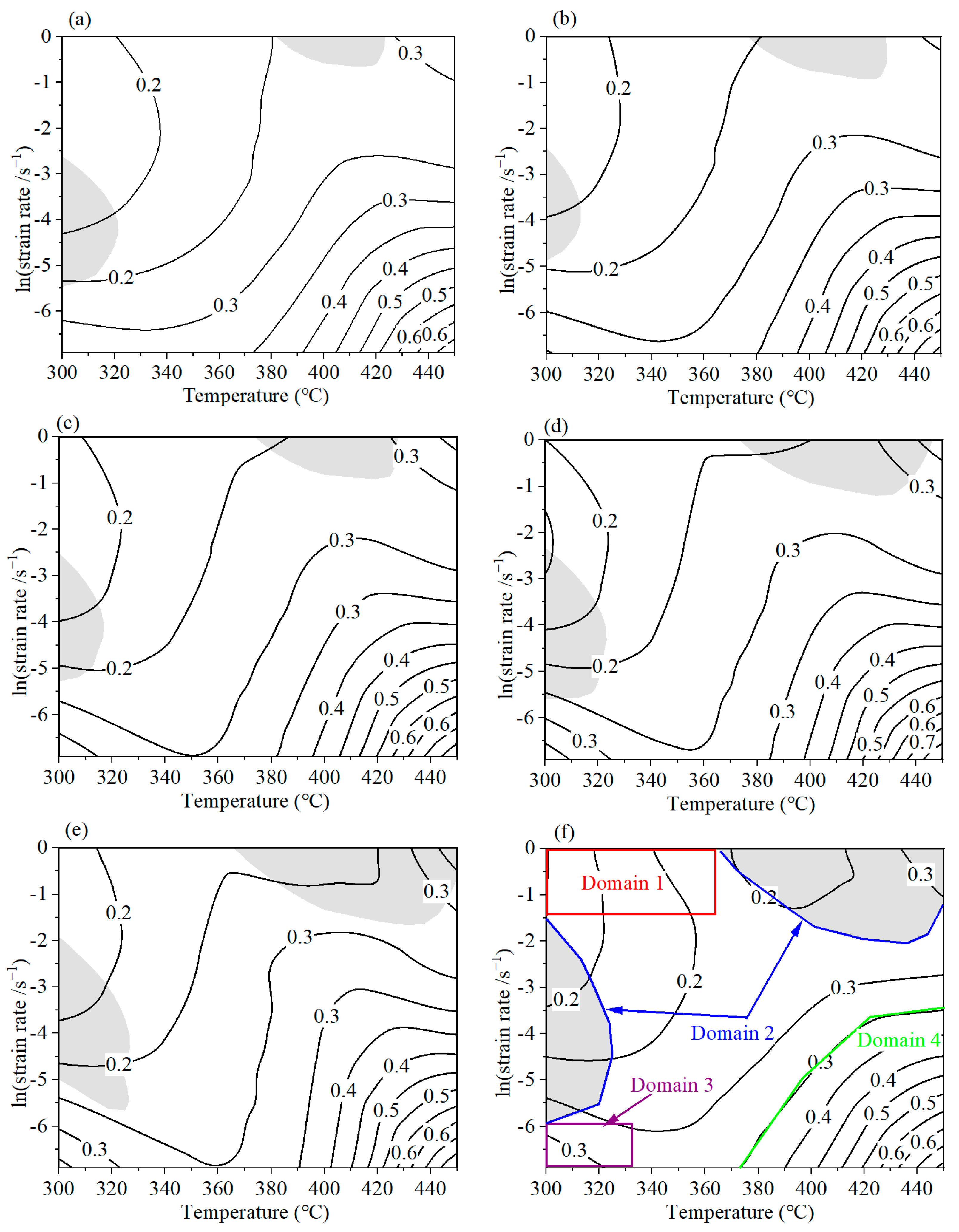

4.3. Processing Map

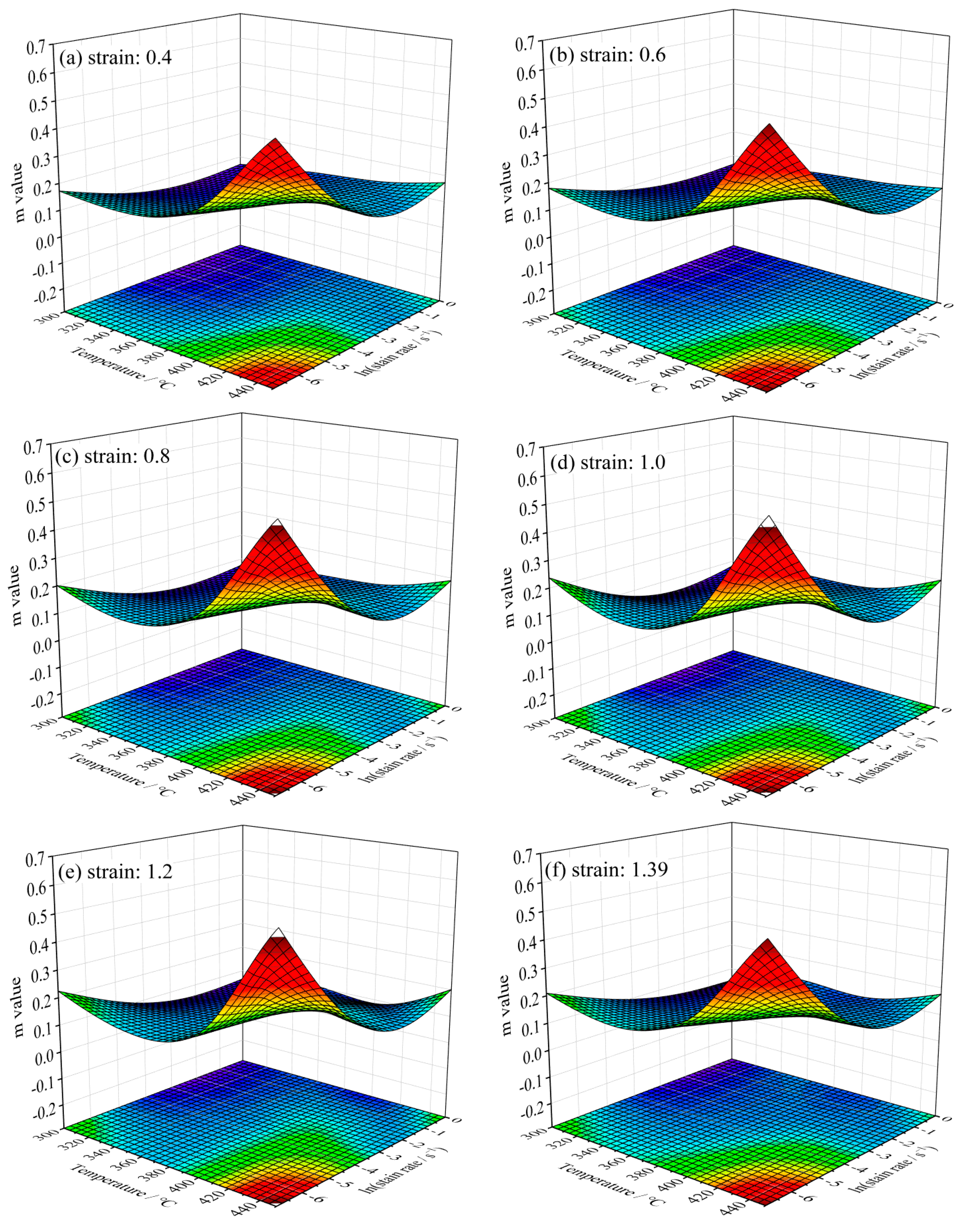

4.3.1. The Analysis of Strain Rate Sensitivity Factor m

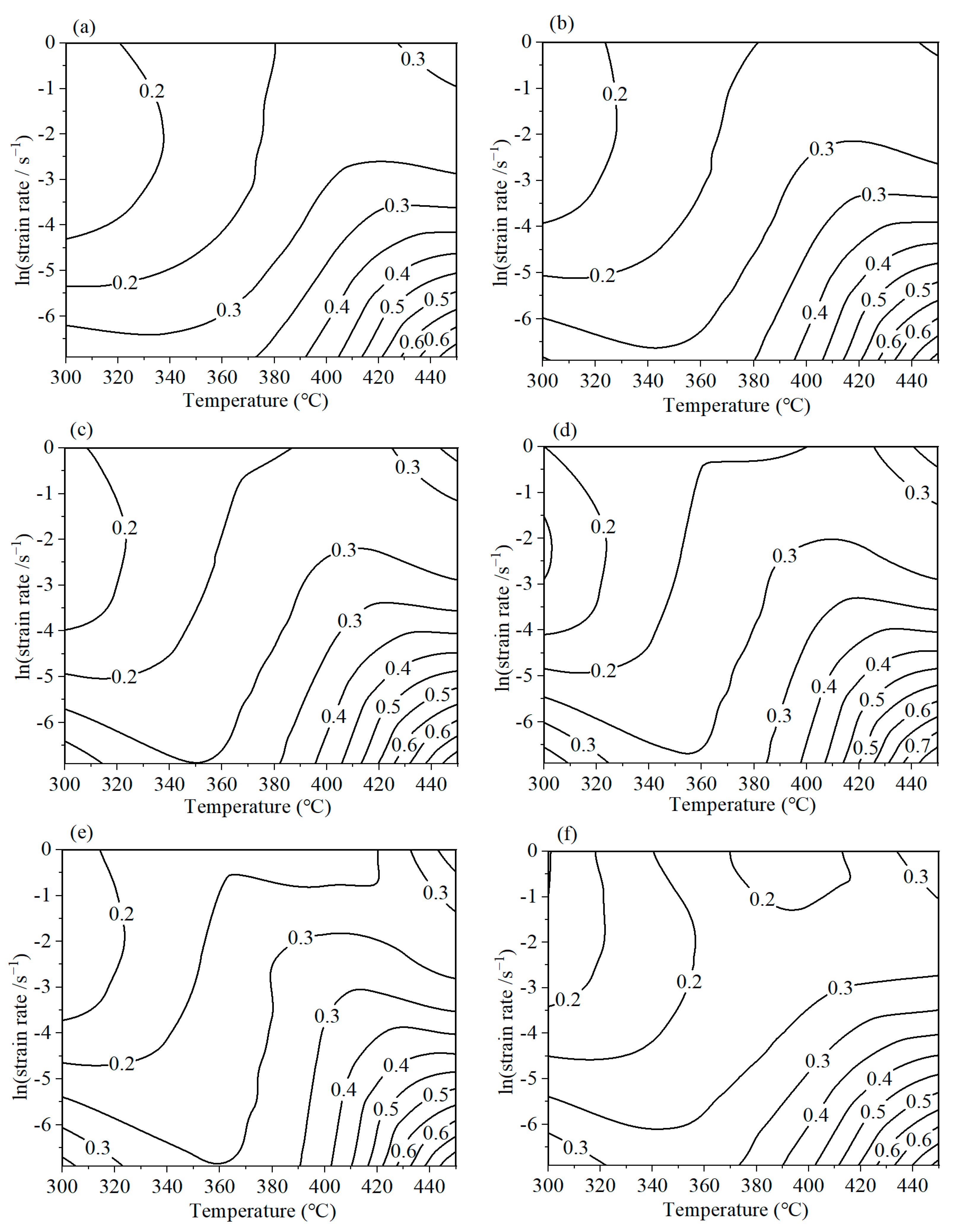

4.3.2. The Analysis of Power Dissipation Efficiency η

4.3.3. The Analysis of Instability Parameter ξ

4.3.4. The Analysis of Processing Map

4.4. Microstructure Examination

5. Conclusions

- The flow stress level of 7075 aluminum alloy under isothermal compression increased significantly with an increasing strain rate or decreasing deformation temperature.

- In the construction of the processing map, the determination of the instability region should consider both the negative dissipation efficiency and instability parameters.

- The microstructure analysis matches the processing map results very well. Based on the processing maps, the optimum hot processing domain of 7075 aluminum alloy at a strain of 1.39 is located at (375–450 °C, 0.001–0.03 s−1), in which the maximum efficiency reaches 0.6. The most unfavorable areas are located at (365–450 °C, 0.132–1 s−1) and (300–325 °C, 0.003–0.2332 s−1), which should be avoided in the hot working process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guo, Y.; Zhang, J.; Zhao, H. Microstructure evolution and mechanical responses of Al-Zn-Mg-Cu alloys during hot deformation process. J. Mater. Sci. 2021, 56, 13429–13478. [Google Scholar] [CrossRef]

- Zhao, J.; Deng, Y.; Tang, J.; Zhang, J. Influence of strain rate on hot deformation behavior and recrystallization behavior under isothermal compression of Al-Zn-Mg-Cu alloy. J. Alloys Compd. 2019, 809, 151788. [Google Scholar] [CrossRef]

- Liu, M.; Shan, Z.; Li, X.; Zang, Y. Hot tensile deformation behavior and microstructure evolution of 7075 aluminum alloy sheet. J. Mater. Res. Technol. 2023, 24, 724–736. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Z.; Lang, Q.; Song, G.; Liu, L. Microstructure evolution and deformation behavior of TIG welded 7075-T6 aluminum alloy followed by partial hot rolling. J. Manuf. Process. 2023, 94, 524–538. [Google Scholar] [CrossRef]

- Zhao, J.; Deng, Y.; Tan, J.; Zhang, J. Effect of strain rate on the recrystallization mechanism during isothermal compression in 7050 aluminum alloy. Mater. Sci. Eng. A 2018, 734, 120–128. [Google Scholar] [CrossRef]

- Le, W.; Chen, Z.; Naseem, S.; Yan, K.; Zhao, Y.; Zhang, H.; Lv, Q. Study on the microstructure evolution and dynamic recrystallization mechanism of selective laser melted Inconel 718 alloy during hot deformation. Vacuum 2023, 209, 111799. [Google Scholar] [CrossRef]

- Ma, Z.; Li, G.; Su, Z.; Wei, G.; Huang, Y.; Hort, N.; Hadadzadeh, A.; Wells, M.A. Hot deformation behavior and microstructural evolution for dual-phase Mg–9Li–3Al alloys. J. Mater. Res. Technol. 2022, 19, 3536–3545. [Google Scholar] [CrossRef]

- Prasad, Y.; Gegel, H.; Doraivelu, S.; Malas, J.; Morgan, J.; Lark, K.; Barker, D. Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242. Metall. Mater. Trans. A 1984, 15, 1883–1892. [Google Scholar] [CrossRef]

- Prasad, Y.; Seshacharyulu, T. Modelling of hot deformation for microstructural control. Int. Mater. Rev. 1998, 43, 243–258. [Google Scholar] [CrossRef]

- Kang, F.; Wei, S.; Zhang, J.; Wang, E.; Fan, D.; Wang, S. Hot processing maps and microstructural characteristics of A357 alloy. J. Mater. Eng. Perform. 2020, 29, 7352–7360. [Google Scholar] [CrossRef]

- Liu, F.; Ma, J.; Peng, L.; Huang, G.; Zhang, W.; Xie, H.; Mi, X. Hot deformation behavior and microstructure evolution of Cu-Ni-Co-Si alloys. Materials 2020, 13, 2042. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, S.; Hamada, A.; Patnamsetty, M.; Borek, W.; Gouda, M.; Chiba, A.; Ebied, S. Constitutive modeling and hot deformation processing map of a new biomaterial Ti–14Cr alloy. J. Mater. Res. Technol. 2022, 20, 4097–4113. [Google Scholar] [CrossRef]

- Wu, H.; Wen, S.; Huang, H.; Gao, K.; Wu, X.; Wang, W.; Nie, Z. Hot deformation behavior and processing map of a new type Al-Zn-Mg-Er-Zr alloy. J. Alloys Compd. 2016, 685, 869–880. [Google Scholar] [CrossRef]

- Long, S.; Xia, Y.; Hu, J.; Zhang, J.; Zhou, J.; Zhang, P.; Cui, M. Hot deformation behavior and microstructure evolution of Ti-6Cr-5Mo-5V-4Al alloy during hot compression. Vacuum 2019, 160, 171–180. [Google Scholar] [CrossRef]

- Li, P.; Li, H.; Huang, L.; Liang, X.; Zhu, Z. Characterization of hot deformation behavior of AA2014 forging aluminum alloy using processing map. Trans. Nonferrous Met. Soc. China 2017, 27, 1677–1688. [Google Scholar] [CrossRef]

- He, H.; Yi, Y.; Cui, J.; Huang, S. Hot deformation characteristics and processing parameter optimization of 2219 Al alloy using constitutive equation and processing map. Vacuum 2019, 160, 293–302. [Google Scholar] [CrossRef]

- Wu, R.; Liu, Y.; Geng, C.; Lin, Q.; Xiao, Y.; Xu, J.; Kang, W. Study on hot deformation behavior and intrinsic workability of 6063 aluminum alloys using 3D processing map. J. Alloys Compd. 2017, 713, 212–221. [Google Scholar] [CrossRef]

- Sun, Y.; Cao, Z.; Wan, Z.; Hu, L.; Ye, W.; Li, N.; Fan, C. 3D processing map and hot deformation behavior of 6A02 aluminum alloy. J. Alloys Compd. 2018, 742, 356–368. [Google Scholar] [CrossRef]

- Shi, G.; Zhang, Y.; Liu, H.; Li, X.; Wang, G.; Li, Z.; Yan, L.; Wen, K.; Xiong, B. Constructing processing maps for hot deformation and microstructural evolution of Al-Zn-Mg-Cu alloys. Mater. Res. Express 2019, 6, 096566. [Google Scholar] [CrossRef]

- Jin, J.; Wang, X.; Hu, H.; Xia, J. High-temperature deformation behavior and processing map of 7050 aluminum alloy. Met. Mater. Int. 2012, 18, 69–75. [Google Scholar] [CrossRef]

- Lin, Y.; Li, L.; Xia, Y.; Jiang, Y. Hot deformation and processing map of a typical Al-Zn-Mg-Cu alloy. J. Alloys Compd. 2013, 550, 438–445. [Google Scholar] [CrossRef]

- Guo, L.; Yang, S.; Yang, H.; Zhang, J. Processing map of as-cast 7075 aluminum alloy for hot working. Chin. J. Aeronaut. 2015, 28, 1774–1783. [Google Scholar] [CrossRef]

- Luo, L.; Liu, Z.; Bai, S.; Zhao, J.; Zeng, D.; Wang, J.; Cao, J.; Hu, Y. Hot Deformation Behavior Considering Strain Effects and Recrystallization Mechanism of an Al-Zn-Mg-Cu Alloy. Materials 2020, 13, 1743. [Google Scholar] [CrossRef] [PubMed]

- Bembalge, O.; Panigrahi, S. Hot deformation behavior and processing map development of cryorolled AA6063 alloy under compression and tension. Int. J. Mech. Sci. 2021, 191, 106100. [Google Scholar] [CrossRef]

- Zhang, Y.; Fan, Z.; Li, Y.; Zhong, J.; Pang, S.; Nagaumi, H. Intermediate temperature tensile behavior and processing map of a spray formed 7075 aluminum alloy. J. Mater. Res. Technol. 2023, 26, 4534–4550. [Google Scholar] [CrossRef]

- Chen, P.; Li, X.; Yao, Y.; Shi, G.; Wen, K.; Li, Z.; Zhang, Y.; Xiong, B. Hot Deformation Analysis and Microstructure Evolution of a Novel Al-Cu-Li Alloy by Isothermal Compression. Adv. Eng. Mater. 2023, 25, 157655. [Google Scholar] [CrossRef]

- Wang, J.; Xiao, G.; Zhang, J. A New, Precise Constitutive Model and Thermal Processing Map Based on the Hot Deformation Behavior of 2219 Aluminum Alloy. Crystals 2023, 13, 732. [Google Scholar] [CrossRef]

- Wang, H.; Wang, C.; Mo, Y.; Wang, H.; Xu, J. Hot deformation and processing maps of Al-Zn-Mg-Cu alloy under coupling-stirring casting. J. Mater. Res. Technol. 2019, 8, 1224–1234. [Google Scholar] [CrossRef]

- Chamanfar, A.; Alamoudi, M.; Nanninga, N.; Misiolek, W. Analysis of flow stress and microstructure during hot compression of 6099 aluminum alloy (AA6099). Mater. Sci. Eng. A 2019, 743, 684–696. [Google Scholar] [CrossRef]

- Tang, J.; Wang, J.; Teng, J.; Wang, G.; Fu, D.; Zhang, H.; Jiang, F. Effect of Zn content on the dynamic softening of Al-Zn-Mg-Cu alloys during hot compression deformation. Vacuum 2021, 184, 109941. [Google Scholar] [CrossRef]

- Wang, J.; Xiao, G.; Zhang, J. A new constitutive model and hot processing map of 5A06 aluminum alloy based on high-temperature rheological behavior and higher-order gradients. Mater. Today Commun. 2023, 36, 106502. [Google Scholar] [CrossRef]

- Raja, N.; Daniel, B.S.S. Microstructural evolution of Al-7.3Zn-2.2Mg-2Cu (Al7068) alloy in T6 condition during isothermal compression using 3-dimensional processing map. J. Alloys Compd. 2022, 902, 163690. [Google Scholar]

- Deng, L.; Zhang, H.-D.; Li, G.-A.; Tang, X.-F.; Yi, P.-S.; Liu, Z.; Wang, X.-Y.; Jin, J.-S. Processing map and hot deformation behavior of squeeze cast 6082 aluminum alloy. Trans. Nonferrous Met. Soc. China 2022, 32, 2150–2163. [Google Scholar] [CrossRef]

- Zhao, H.; Ye, L.; Cheng, Q.; Kang, Y.; Zhang, W. Constitutive model and processing maps of 7055 aluminum alloy used for fasteners. Mater. Today Commun. 2022, 33, 104996. [Google Scholar] [CrossRef]

- Venkatraman, G.; Headings, L.M.; Dapino, M.J. Effect of Process Parameters on the Microstructure of Aluminum Alloys Made via Ultrasonic Additive Manufacturing. Crystals 2022, 12, 1696. [Google Scholar] [CrossRef]

| Composition | Zn | Mg | Cu | Si | Cr | Fe | Mn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| Content (wt.%) | 5.8 | 2.3 | 1.5 | 0.07 | 0.21 | 0.16 | 0.05 | 0.02 | Bal. |

| True Strain | 0.4 | 0.6 | 0.8 | 1.0 | 1.2 | 1.39 |

| Maximum m value | 0.5269 | 0.5652 | 0.5897 | 0.6073 | 0.5991 | 0.5598 |

| Minimum m value | 0.0540 | 0.0590 | 0.0567 | 0.0484 | 0.0567 | 0.0512 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, E.; Ye, T.; Qiu, S.; Liu, L.; Luo, F.; Yue, H.; Wu, Y. Deformation Behavior and Processing Maps of 7075 Aluminum Alloy under Large-Strain Thermal Compression. Materials 2023, 16, 7432. https://doi.org/10.3390/ma16237432

Xia E, Ye T, Qiu S, Liu L, Luo F, Yue H, Wu Y. Deformation Behavior and Processing Maps of 7075 Aluminum Alloy under Large-Strain Thermal Compression. Materials. 2023; 16(23):7432. https://doi.org/10.3390/ma16237432

Chicago/Turabian StyleXia, Erli, Tuo Ye, Sawei Qiu, Limei Liu, Fang Luo, Huanyu Yue, and Yuanzhi Wu. 2023. "Deformation Behavior and Processing Maps of 7075 Aluminum Alloy under Large-Strain Thermal Compression" Materials 16, no. 23: 7432. https://doi.org/10.3390/ma16237432

APA StyleXia, E., Ye, T., Qiu, S., Liu, L., Luo, F., Yue, H., & Wu, Y. (2023). Deformation Behavior and Processing Maps of 7075 Aluminum Alloy under Large-Strain Thermal Compression. Materials, 16(23), 7432. https://doi.org/10.3390/ma16237432