Effective Platform Heating for Laser Powder Bed Fusion of an Al-Mn-Sc-Based Alloy

Abstract

:1. Introduction

2. Methods

2.1. Specimen Preparation

2.2. Residual Stress Measurement

2.3. Mechanical Testing

2.4. Microstructure Characterisation

2.5. Powder Temperature Measurement

3. Results

4. Discussion

5. Conclusions

- The residual stresses inherent to LPBF have been measured and compared for parts built on 35 °C and 200 °C platforms. The measurements confirm the presence of high tensile residual stress, reaching up to 40% of the yield stress. These residual stresses have been alleviated and reduced by more than half through platform heating at 200 °C.

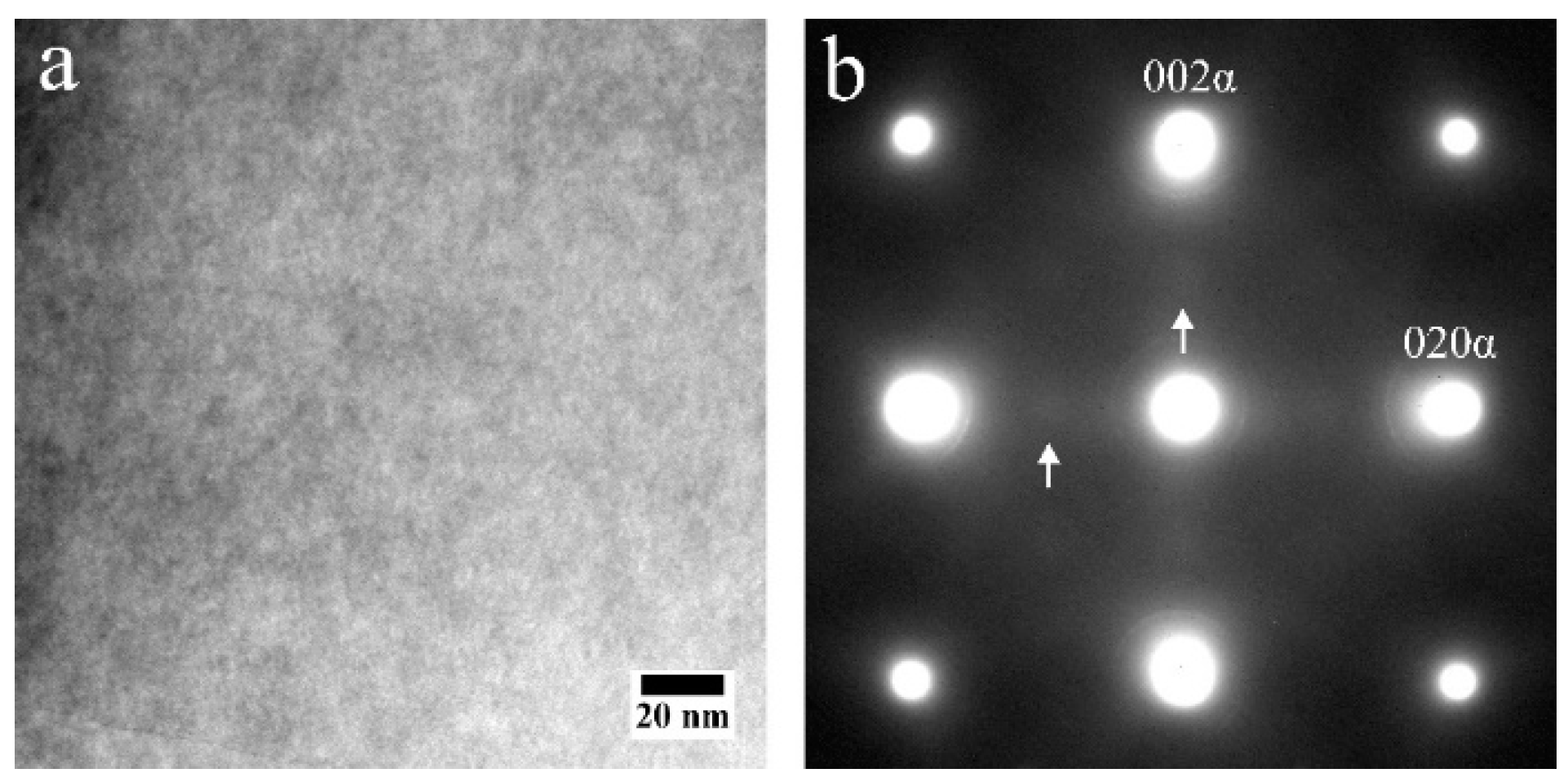

- The evolution of Sc-rich nano-clusters during in situ aging using a 200 °C platform was captured via an atom probe tomography study, from which a high number density (~1.75 × 1024 m−3) of uniformly dispersed Al3Sc nanoparticles (1–2 nm) was estimated.

- The precipitation and evolution of the nano-scale Al3Sc phase formed from the effect of platform heating improved the tensile strength (yielding strength beyond 520 MPa) and excellent ductility (~18%, compared to the 440 MPa achieved using an unheated platform).

- An in situ measurement study revealed that the temperatures attained within parts built using a 200 °C platform are within the aging temperature regime of Al-Sc alloys. However, the in situ heating effect based on the parameters employed in this work has not been found sufficient to precipitate all the Sc from the matrix and achieve the maximum strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lathabai, S. Additive Manufacturing of Aluminium-Based Alloys and Composites. In Fundamentals of Aluminium Metallurgy: Recent Advances; Lumley, R.N., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 47–92. [Google Scholar]

- Zhang, J.; Song, B.; Wei, Q.; Bourell, D.; Shi, Y. A review of selective laser melting of aluminum alloys: Processing, microstructure, property and developing trends. J. Mater. Sci. Technol. 2019, 35, 270–284. [Google Scholar] [CrossRef]

- Ladani, L.; Sadeghilaridjani, M. Review of Powder Bed Fusion Additive Manufacturing for Metals. Metals 2021, 11, 1391. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys using selective laser melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- Bayoumy, D.; Kan, W.; Wu, X.; Zhu, Y.; Huang, A. The latest development of Sc -strengthened aluminum alloys by laser powder b e d fusion. J. Mater. Sci. Technol. 2023, 149, 1–17. [Google Scholar] [CrossRef]

- Leirmo, J.L. High Strength Aluminium Alloys in Laser-Based Powder Bed Fusion—A Review. Procedia CIRP 2021, 104, 1747–1752. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Everitt, N.M.; Maskery, I.; Ashcroft, I.; Tuck, C. Selective laser melting of aluminum alloys. MRS Bull. 2017, 42, 311–319. [Google Scholar] [CrossRef]

- Spierings, A.B.; Dawson, K.; Heeling, T.; Uggowitzer, P.J.; Schäublin, R.; Palm, F.; Wegener, K. Microstructural features of Sc- and Zr-modified Al-Mg alloys processed by selective laser melting. Mater. Des. 2017, 115, 52–63. [Google Scholar] [CrossRef]

- Rao, J.H.; Zhang, Y.; Zhang, K.; Wu, X.; Huang, A. Selective laser melted Al-7Si-0.6Mg alloy with in-situ precipitation via platform heating for residual strain removal. Mater. Des. 2019, 182, 108005. [Google Scholar] [CrossRef]

- Siddique, S.; Imran, M.; Wycisk, E.; Emmelmann, C.; Walther, F. Influence of process-induced microstructure and imperfections on mechanical properties of AlSi12 processed by selective laser melting. J. Mater. Process. Technol. 2015, 221, 205–213. [Google Scholar] [CrossRef]

- Muhammad, M.; Nezhadfar, P.D.; Thompson, S.; Saharan, A.; Phan, N.; Shamsaei, N. A comparative investigation on the microstructure and mechanical properties of additively manufactured aluminum alloys. Int. J. Fatigue 2021, 146, 106165. [Google Scholar] [CrossRef]

- Brandl, E.; Heckenberger, U.; Holzinger, V.; Buchbinder, D. Additive manufactured AlSi10Mg samples using Selective Laser Melting (SLM): Microstructure, high cycle fatigue, and fracture behavior. Mater. Des. 2012, 34, 159–169. [Google Scholar] [CrossRef]

- Fiocchi, J.; Tuissi, A.; Biffi, C.A. Heat treatment of aluminium alloys produced by laser powder bed fusion: A review. Mater. Des. 2021, 204, 109651. [Google Scholar] [CrossRef]

- Shiomi, M.; Osakada, K.; Nakamura, K.; Yamashita, T.; Abe, F. Residual stress within metallic model made by selective laser melting process. CIRP Ann.—Manuf. Technol. 2004, 53, 195–198. [Google Scholar] [CrossRef]

- Salmi, A.; Atzeni, E.; Iuliano, L.; Galati, M. Experimental Analysis of Residual Stresses on AlSi10Mg Parts Produced by Means of Selective Laser Melting (SLM). Procedia CIRP 2017, 62, 458–463. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, Y.; Wang, D. A study on the residual stress during selective laser melting (SLM) of metallic powder. Int. J. Adv. Manuf. Technol. 2016, 87, 647–656. [Google Scholar] [CrossRef]

- Kempen, K.; Vrancken, B.; Thijs, L. Lowering thermal gradients in Selective Laser melting by pre-heating the baseplate. In Proceedings of the Solid Freeform Fabrication Symposium Proceedings, Austin, TX, USA, 12–15 August 2013. [Google Scholar]

- Buchbinder, D.; Meiners, W.; Pirch, N.; Wissenbach, K.; Schrage, J. Investigation on reducing distortion by preheating during manufacture of aluminum components using selective laser melting. J. Laser Appl. 2014, 26, 012004. [Google Scholar] [CrossRef]

- Bosio, F.; Shen, H.; Liu, Y.; Lombardi, M.; Rometsch, P.; Wu, X.; Zhu, Y.; Huang, A. Production Strategy for Manufacturing Large-Scale AlSi10Mg Components by Laser Powder Bed Fusion. JOM 2021, 73, 770–780. [Google Scholar] [CrossRef]

- Casati, R.; Nasab, M.H.; Coduri, M.; Tirelli, V.; Vedani, M. Effects of Platform Pre-Heating and Thermal-Treatment Strategies on Properties of AlSi10Mg Alloy Processed by Selective Laser Melting. Metals 2018, 8, 954. [Google Scholar] [CrossRef]

- Tan, Q.; Liu, Y.; Fan, Z.; Zhang, J.; Yin, Y.; Zhang, M.X. Effect of processing parameters on the densification of an additively manufactured 2024 Al alloy. J. Mater. Sci. Technol. 2020, 58, 34–45. [Google Scholar] [CrossRef]

- Koutny, D.; Palousek, D.; Pantelejev, L.; Hoeller, C.; Pichler, R.; Tesicky, L.; Kaiser, J. Influence of scanning strategies on processing of aluminum alloy EN AW 2618 using selective laser melting. Materials 2018, 11, 298. [Google Scholar] [CrossRef]

- Ahuja, B.; Karg, M.; Nagulin, K.Y.; Schmidt, M. Fabrication and characterization of high strength Al-Cu alloys processed using Laser Beam Melting in metal powder bed. Phys. Procedia 2014, 56, 135–146. [Google Scholar] [CrossRef]

- Raffeis, I.; Adjei-Kyeremeh, F.; Vroomen, U.; Richter, S.; Bührig-Polaczek, A. Characterising the microstructure of an additively built Al-Cu-Li alloy. Materials 2020, 13, 5188. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Li, R.; Yuan, T.; Chen, C.; Zhang, Z.; Li, X. Microstructures and tensile properties of a selective laser melted Al–Zn–Mg–Cu (Al7075) alloy by Si and Zr microalloying. Mater. Sci. Eng. A 2020, 787, 139492. [Google Scholar] [CrossRef]

- Stopyra, W.; Gruber, K.; Smolina, I.; Kurzynowski, T.; Kuźnicka, B. Laser powder bed fusion of AA7075 alloy: Influence of process parameters on porosity and hot cracking. Addit. Manuf. 2020, 35, 101270. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef]

- Spierings, A.B.; Dawson, K.; Dumitraschkewitz, P.; Pogatscher, S.; Wegener, K. Microstructure characterization of SLM-processed Al-Mg-Sc-Zr alloy in the heat treated and HIPed condition. Addit. Manuf. 2018, 20, 173–181. [Google Scholar] [CrossRef]

- Spierings, A.B.; Dawson, K.; Kern, K.; Palm, F.; Wegener, K. SLM-processed Sc- and Zr- modified Al-Mg alloy: Mechanical properties and microstructural effects of heat treatment. Mater. Sci. Eng. A 2017, 701, 264–273. [Google Scholar] [CrossRef]

- Bayoumy, D.; Kwak, K.; Boll, T.; Dietrich, S.; Schliephake, D.; Huang, J.; Yi, J.; Takashima, K.; Wu, X.; Zhu, Y.; et al. Origin of non-uniform plasticity in a high-strength Al-Mn-Sc based alloy produced by laser powder bed fusion. J. Mater. Sci. Technol. 2022, 103, 121–133. [Google Scholar] [CrossRef]

- Lu, J.; Lin, X.; Kang, N.; Huang, W. Characterizations of micro-nano structure and tensile properties of a Sc modified Al Mn alloy fabricated by selective laser melting. Mater. Charact. 2021, 178, 111305. [Google Scholar] [CrossRef]

- Jägle, E.A.; Sheng, Z.; Wu, L.; Lu, L.; Risse, J.; Weisheit, A.; Raabe, D. Precipitation Reactions in Age-Hardenable Alloys During Laser Additive Manufacturing. JOM 2016, 68, 943–949. [Google Scholar] [CrossRef]

- Spierings, A.B.; Dawson, K.; Uggowitzer, P.J.; Wegener, K. Influence of SLM scan-speed on microstructure, precipitation of Al3Sc particles and mechanical properties in Sc- and Zr-modified Al-Mg alloys. Mater. Des. 2018, 140, 134–143. [Google Scholar] [CrossRef]

- Shi, Y.; Yang, K.; Kairy, S.K.; Palm, F.; Wu, X.; Rometsch, P.A. Effect of platform temperature on the porosity, microstructure and mechanical properties of an Al-Mg-Sc-Zr alloy fabricated by selective laser melting. Mater. Sci. Eng. A 2018, 732, 41–52. [Google Scholar] [CrossRef]

- Li, R.; Chen, H.; Zhu, H.; Wang, M.; Chen, C.; Yuan, T. Effect of aging treatment on the microstructure and mechanical properties of Al-3.02Mg-0.2Sc-0.1Zr alloy printed by selective laser melting. Mater. Des. 2019, 168, 107668. [Google Scholar] [CrossRef]

- Tang, H.; Geng, Y.; Bian, S.; Xu, J.; Zhang, Z. An Ultra-High Strength Over 700 MPa in Al-Mn-Mg-Sc-Zr Alloy Fabricated by Selective Laser Melting. Acta Metall. Sin. English Lett. 2022, 35, 466–474. [Google Scholar] [CrossRef]

- Knipling, K.E.; Karnesky, R.A.; Lee, C.P.; Dunand, D.C.; Seidman, D.N. Precipitation evolution in Al-0.1Sc, Al-0.1Zr and Al-0.1Sc-0.1Zr (at.%) alloys during isochronal aging. Acta Mater. 2010, 58, 5184–5195. [Google Scholar] [CrossRef]

- Bayoumy, D.; Schliephake, D.; Dietrich, S.; Wu, X.H.; Zhu, Y.M.; Huang, A.J. Intensive processing optimization for achieving strong and ductile Al-Mn-Mg-Sc-Zr alloy produced by selective laser melting. Mater. Des. 2021, 198, 109317. [Google Scholar] [CrossRef]

- Kürnsteiner, P.; Bajaj, P.; Gupta, A.; Wilms, M.B.; Weisheit, A.; Li, X.; Leinenbach, C.; Gault, B.; Jägle, E.A.; Raabe, D. Control of thermally stable core-shell nano-precipitates in additively manufactured Al-Sc-Zr alloys. Addit. Manuf. 2020, 32, 100910. [Google Scholar] [CrossRef]

- Mercelis, P.; Kruth, J.P. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

- Zaeh, M.F.; Branner, G. Investigations on residual stresses and deformations in selective laser melting. Prod. Eng. 2010, 4, 35–45. [Google Scholar] [CrossRef]

- Bayoumy, D.; Boll, T.; Schliephake, D.; Wu, X.; Zhu, Y.; Huang, A. On the Complex Intermetallics in an Al-Mn-Sc Based Alloy Produced by Laser Powder Bed Fusion. J. Alloys Compd. 2022, 901, 163571. [Google Scholar] [CrossRef]

- Taendl, J.; Orthacker, A.; Amenitsch, H.; Kothleitner, G.; Poletti, C. Influence of the degree of scandium supersaturation on the precipitation kinetics of rapidly solidified Al-Mg-Sc-Zr alloys. Acta Mater. 2016, 117, 43–50. [Google Scholar] [CrossRef]

- Wang, M.; Li, R.; Yuan, T.; Yang, H.; Niu, P.; Chen, C. Microstructure and Mechanical Properties of Selective Laser Melted Al–2.51Mn–2.71Mg–0.55Sc–0.29Cu–0.31Zn Alloy Designed by Supersaturated Solid Solution. Acta Metall. Sin. English Lett. 2022, 35, 354–368. [Google Scholar] [CrossRef]

- Li, R.; Wang, M.; Li, Z.; Cao, P.; Yuan, T.; Zhu, H. Developing a high-strength Al-Mg-Si-Sc-Zr alloy for selective laser melting: Crack-inhibiting and multiple strengthening mechanisms. Acta Mater. 2020, 193, 83–98. [Google Scholar] [CrossRef]

- Ma, R.; Peng, C.; Cai, Z.; Wang, R.; Zhou, Z.; Li, X.; Cao, X. Manipulating the microstructure and tensile properties of selective laser melted Al–Mg-Sc-Zr alloy through heat treatment. J. Alloys Compd. 2020, 831. [Google Scholar] [CrossRef]

- Hyer, H.; Zhou, L.; Park, S.; Huynh, T.; Mehta, A.; Thapliyal, S.; Mishra, R.S.; Sohn, Y. Elimination of extraordinarily high cracking susceptibility of aluminum alloy fabricated by laser powder bed fusion. J. Mater. Sci. Technol. 2022, 103, 50–58. [Google Scholar] [CrossRef]

- Zhou, L.; Pan, H.; Hyer, H.; Park, S.; Bai, Y.; McWilliams, B.; Cho, K.; Sohn, Y. Microstructure and tensile property of a novel AlZnMgScZr alloy additively manufactured by gas atomization and laser powder bed fusion. Scr. Mater. 2019, 158, 24–28. [Google Scholar] [CrossRef]

- Harada, Y.; Dunand, D.C. Microstructure of Al3Sc with ternary rare-earth additions. Mater. Sci. Eng. A 2002, 329, 686–695. [Google Scholar] [CrossRef]

- Marquis, E.A.; Vurpillot, F. Chromatic aberrations in the field evaporation behavior of small precipitates. Microsc. Microanal. 2008, 14, 561–570. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bayoumy, D.; Boll, T.; Karapuzha, A.S.; Wu, X.; Zhu, Y.; Huang, A. Effective Platform Heating for Laser Powder Bed Fusion of an Al-Mn-Sc-Based Alloy. Materials 2023, 16, 7586. https://doi.org/10.3390/ma16247586

Bayoumy D, Boll T, Karapuzha AS, Wu X, Zhu Y, Huang A. Effective Platform Heating for Laser Powder Bed Fusion of an Al-Mn-Sc-Based Alloy. Materials. 2023; 16(24):7586. https://doi.org/10.3390/ma16247586

Chicago/Turabian StyleBayoumy, Dina, Torben Boll, Amal Shaji Karapuzha, Xinhua Wu, Yuman Zhu, and Aijun Huang. 2023. "Effective Platform Heating for Laser Powder Bed Fusion of an Al-Mn-Sc-Based Alloy" Materials 16, no. 24: 7586. https://doi.org/10.3390/ma16247586

APA StyleBayoumy, D., Boll, T., Karapuzha, A. S., Wu, X., Zhu, Y., & Huang, A. (2023). Effective Platform Heating for Laser Powder Bed Fusion of an Al-Mn-Sc-Based Alloy. Materials, 16(24), 7586. https://doi.org/10.3390/ma16247586