The Effect of Few-Layer Graphene on the Complex of Hardness, Strength, and Thermo Physical Properties of Polymer Composite Materials Produced by Digital Light Processing (DLP) 3D Printing

Abstract

:1. Introduction

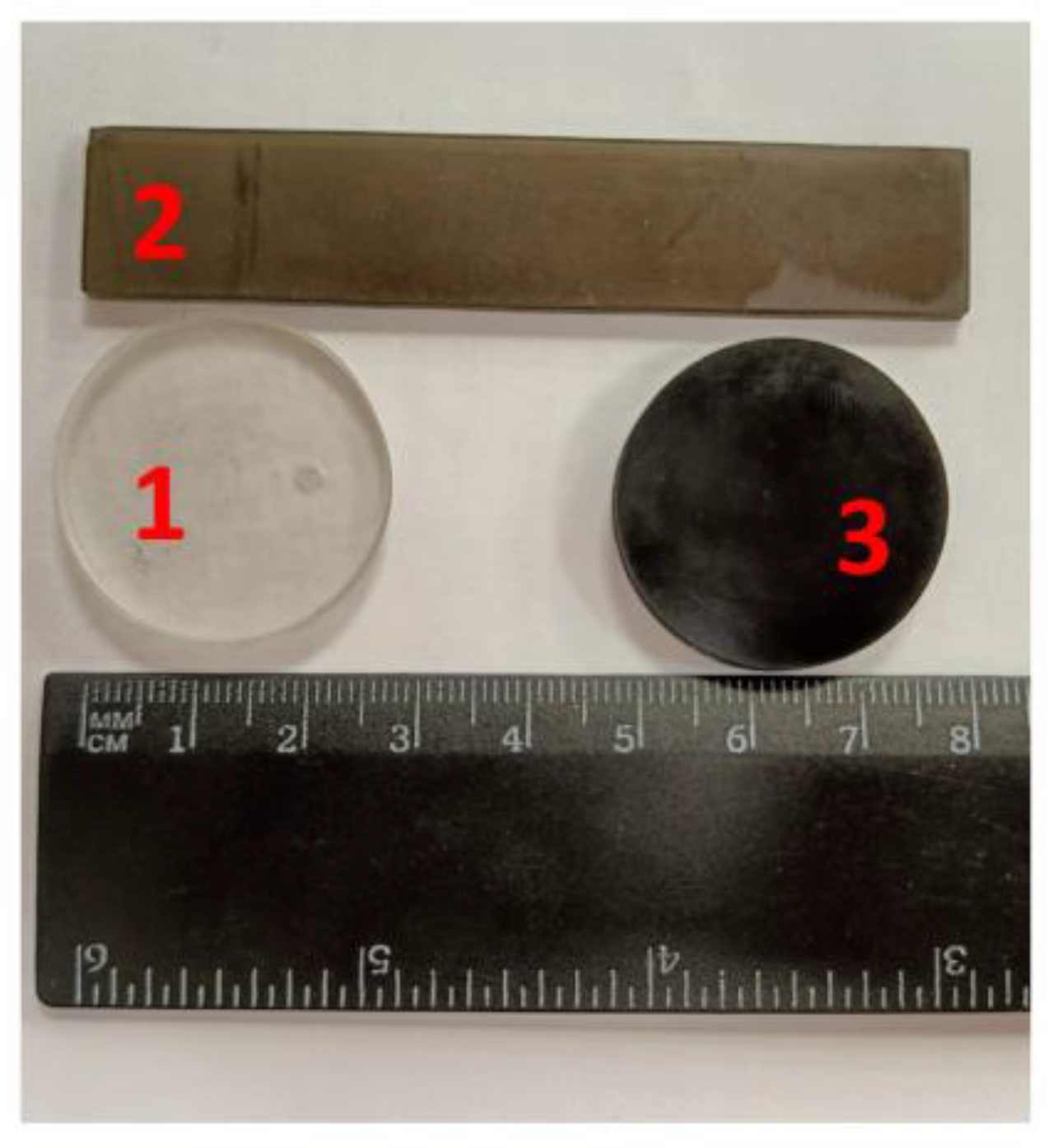

2. Materials and Methods

2.1. Raw Materials

2.2. Stone–Wales Defects Concentration Measurement

2.3. Specific Surface Area Measurement

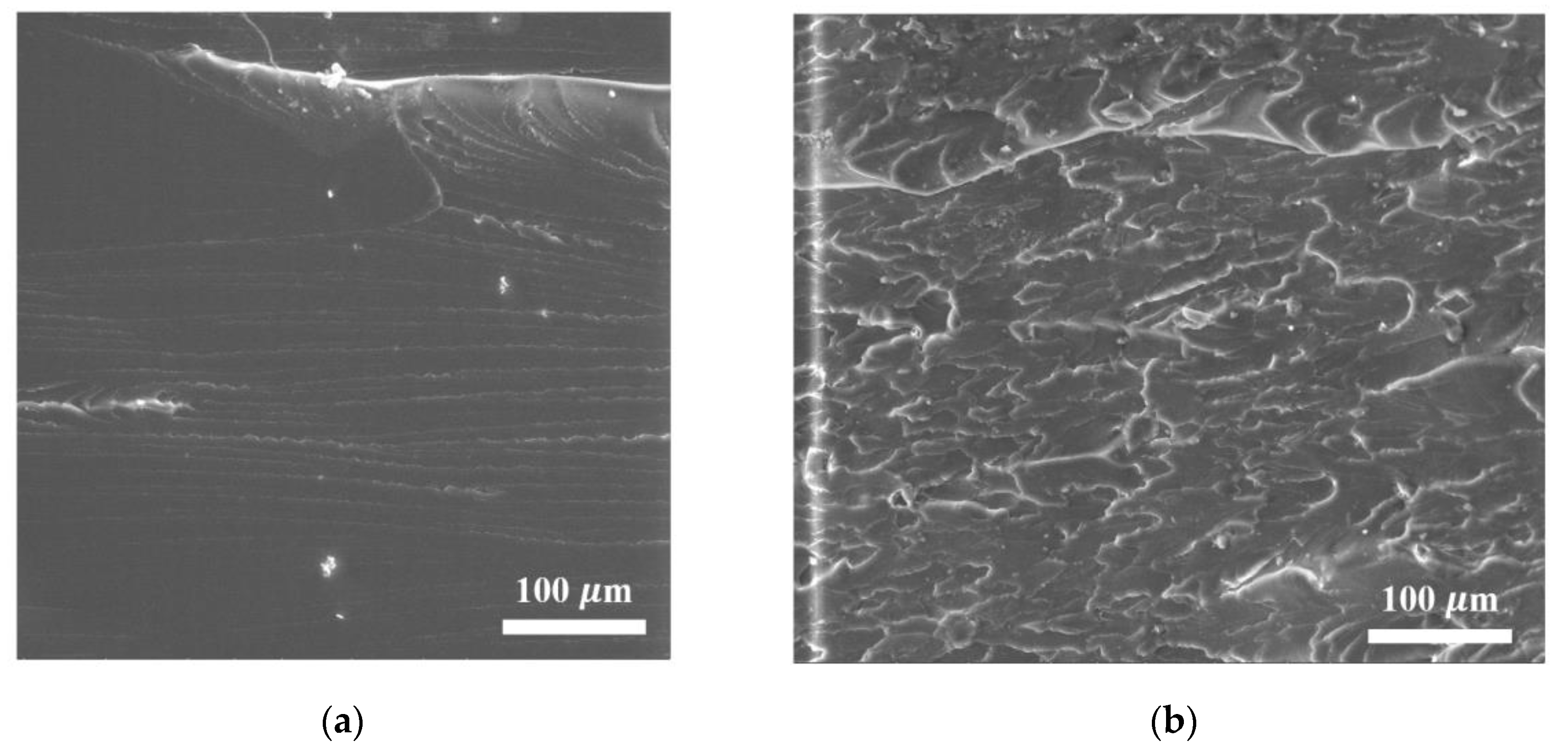

2.4. SEM Studies

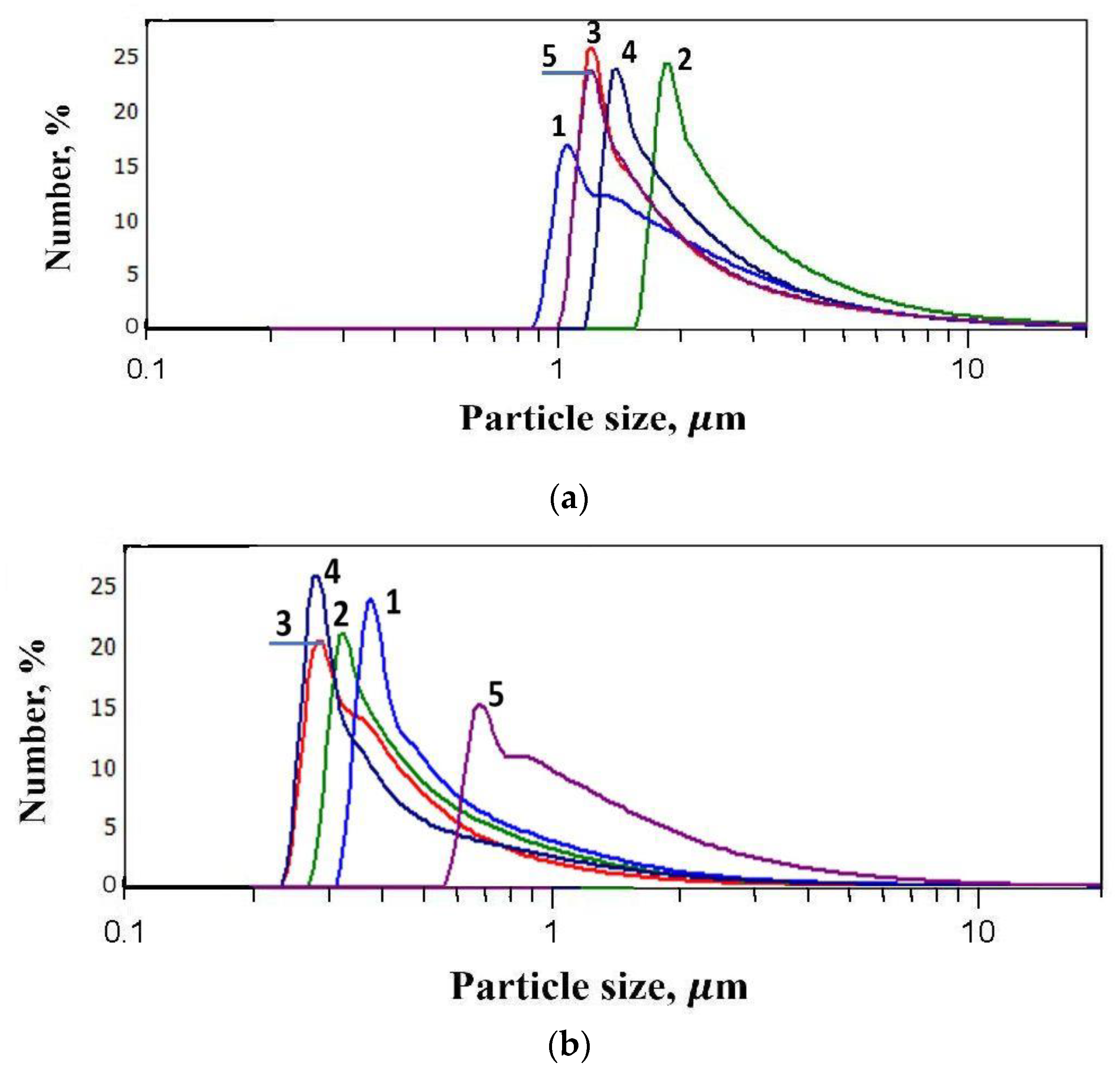

2.5. Measurement of Dispersion of FLG Particles

2.6. Obtaining Products from Photopolymer Resins with the Addition of FLG

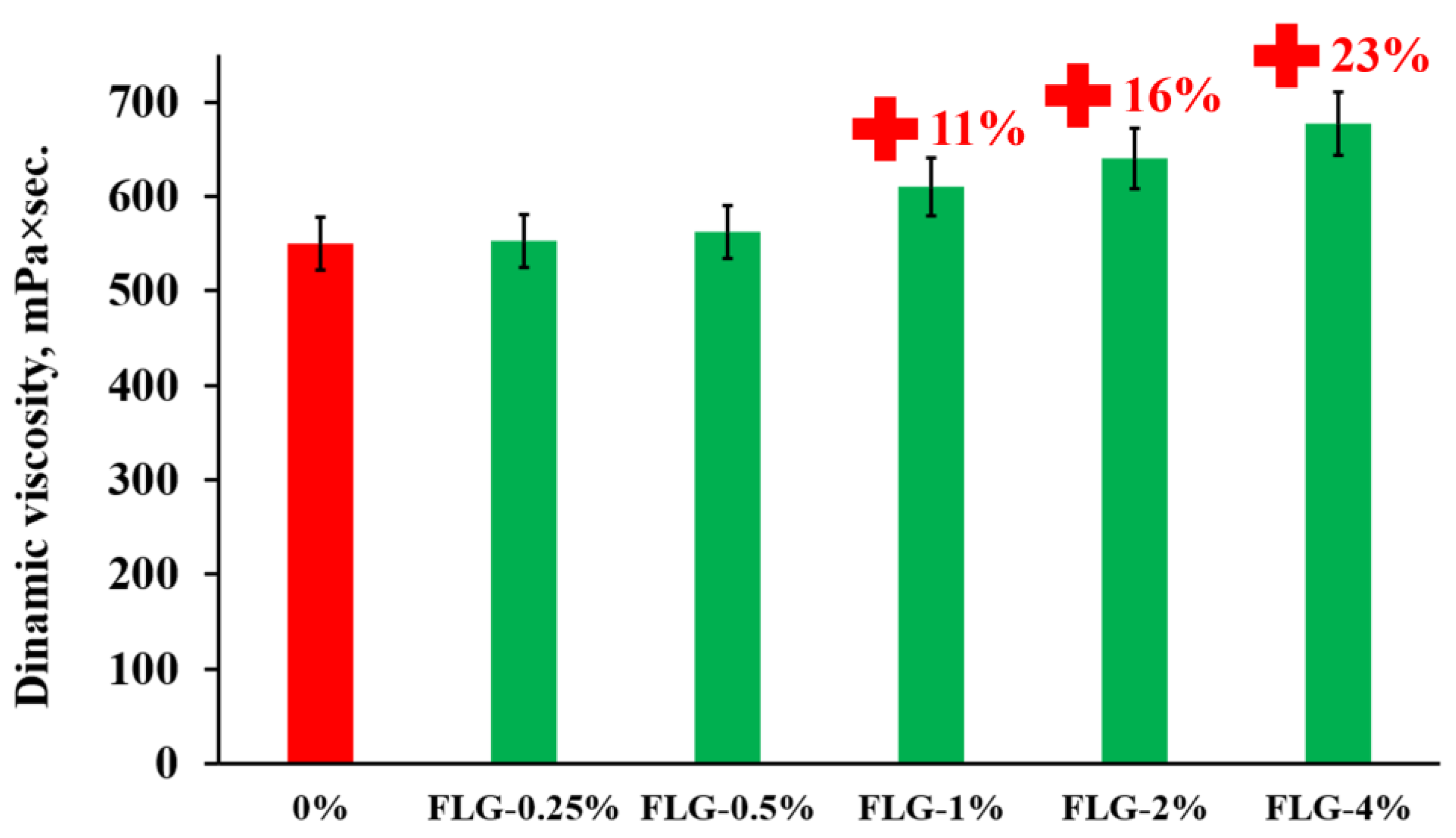

2.7. Viscosity Measurement

2.8. Hardness Test

2.9. Measurement of Flexural Strength

2.10. Measurement of Charpy Impact Strength

2.11. Measurement of Thermal Conductivity and Heat Capacity

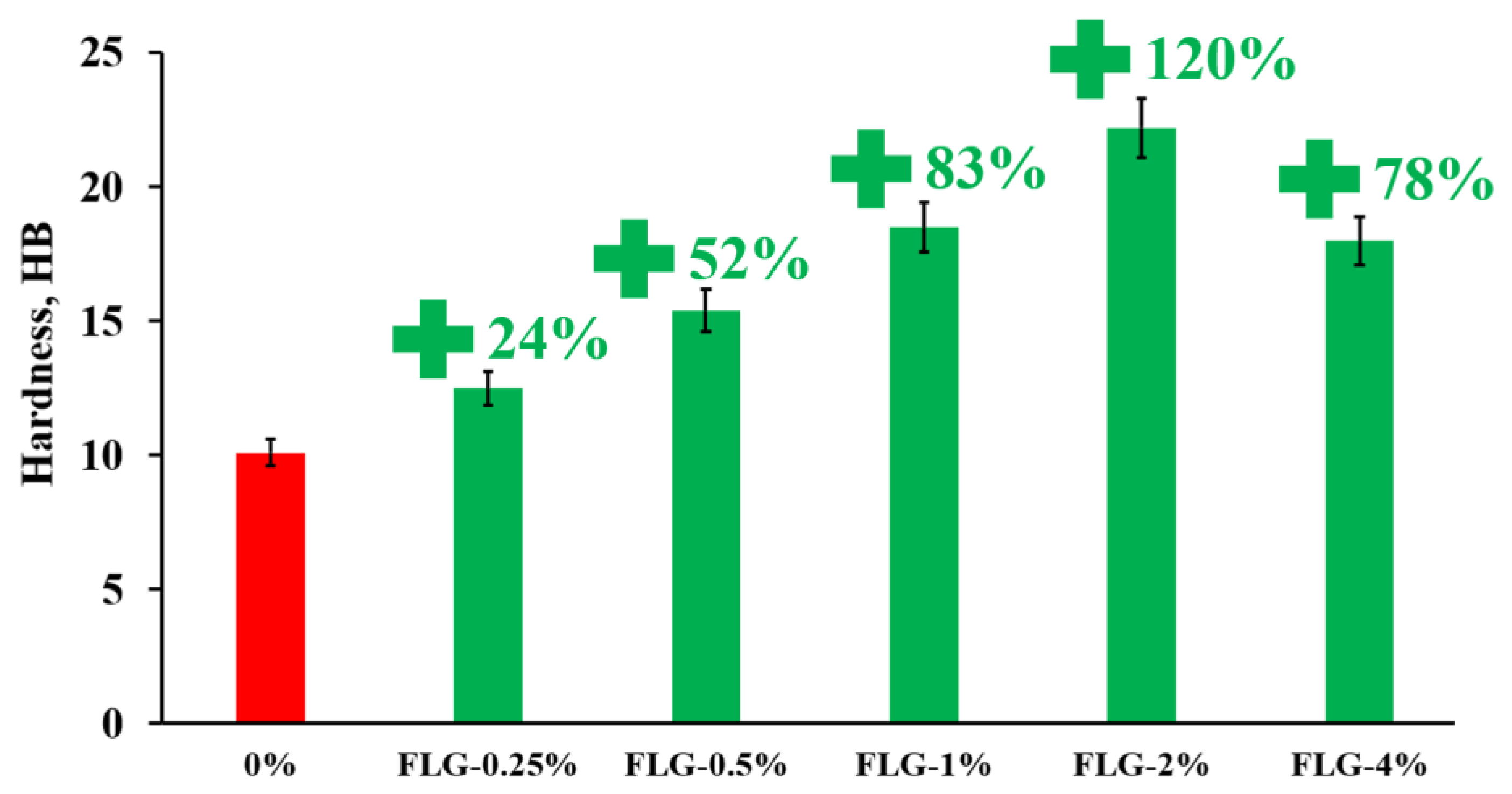

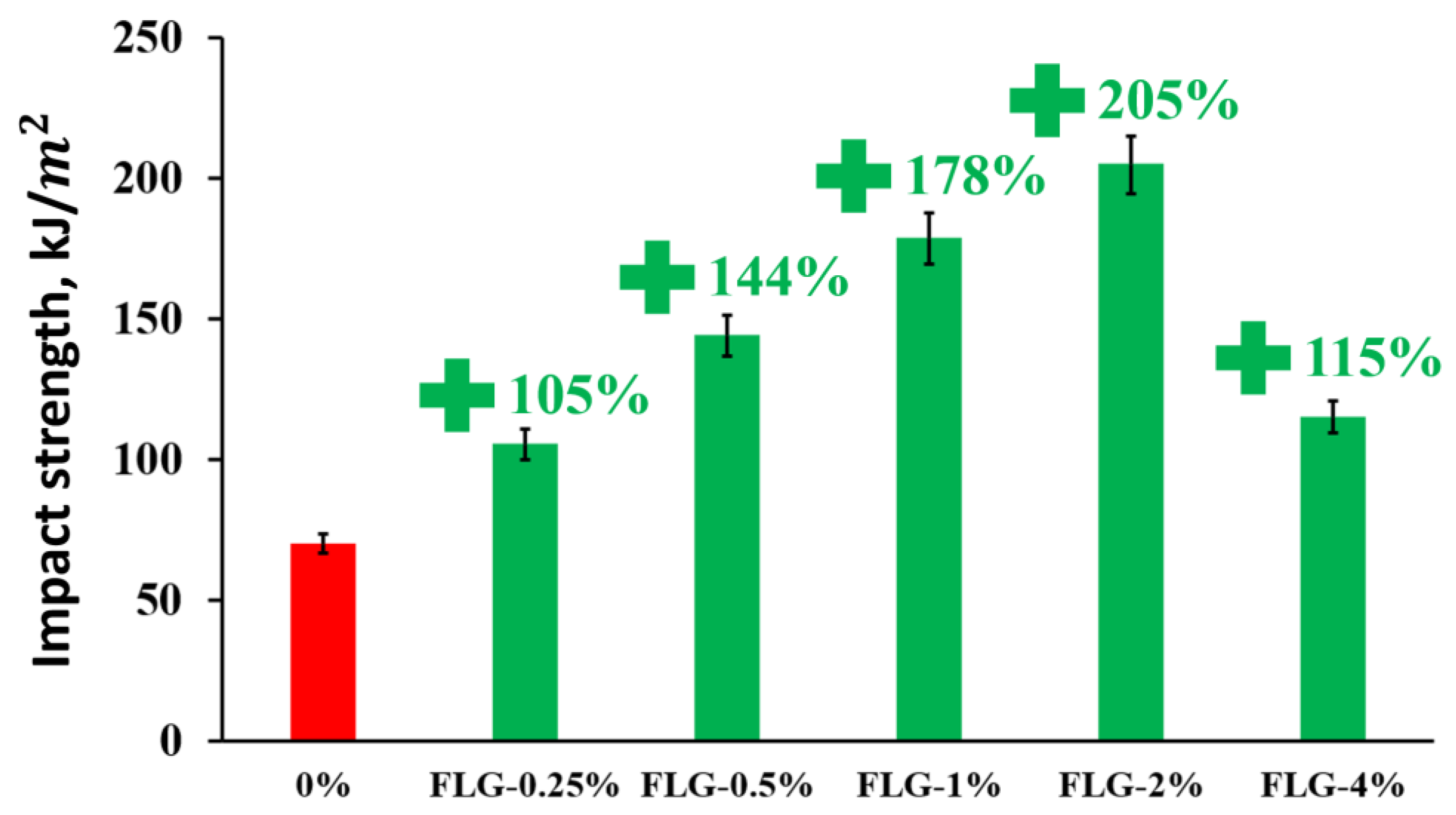

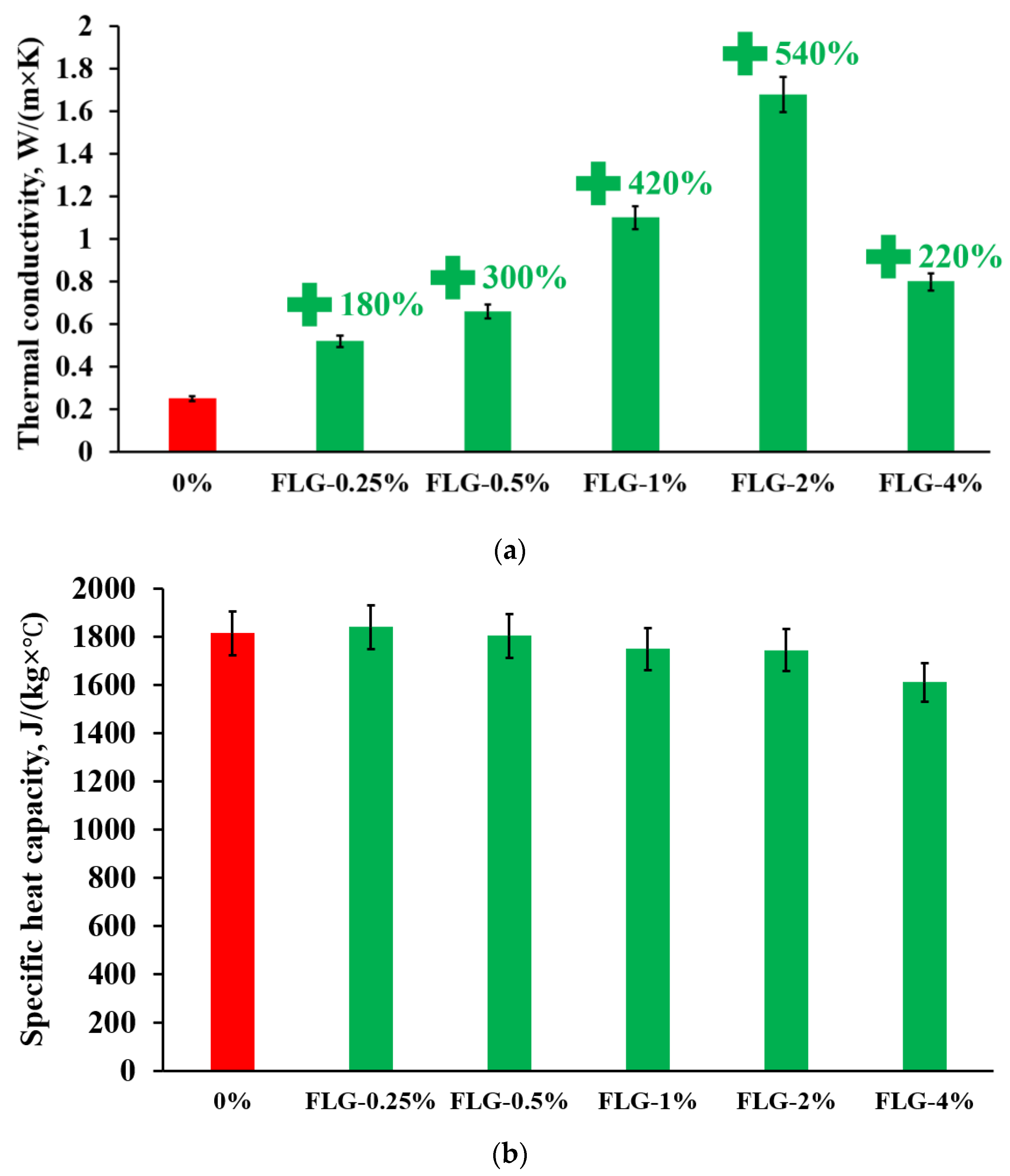

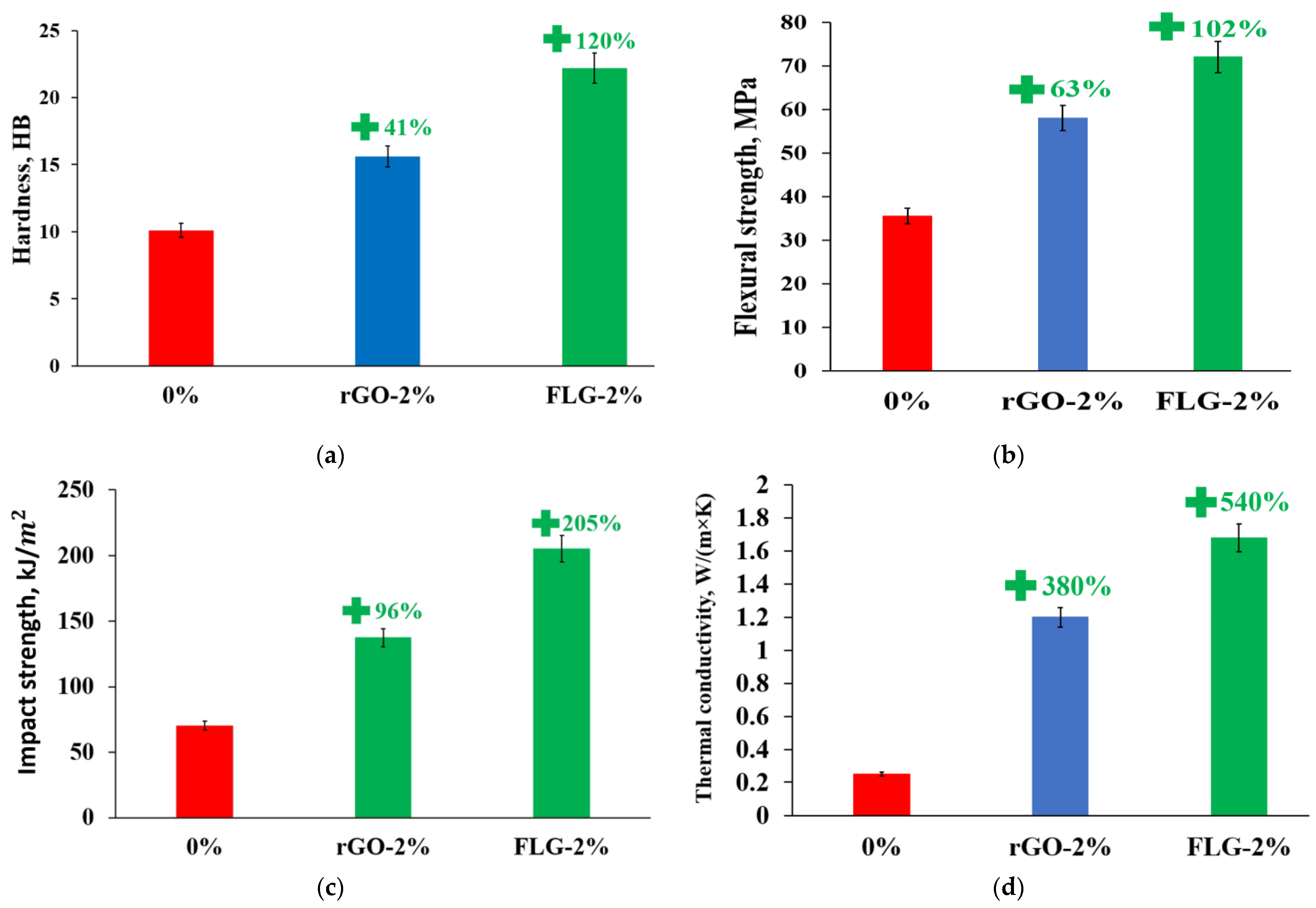

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hull, C.W. Apparatus for Production of Three-Dimensional Objects by Stereolithography. U.S. Patent 4575330A, 11 March 1986. [Google Scholar]

- Crump, S.S. Rapid prototyping using FDM. Mod. Cast. 1992, 82, 36–38. [Google Scholar]

- Blanco, I. The use of composite materials in 3D printing. J. Compos. Sci. 2020, 4, 42. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.; Kim, Y.; Park, D.; Kim, J. The thermal properties of a UV curable acrylate composite prepared by digital light processing 3D printing. Compos. Commun. 2021, 26, 100796. [Google Scholar] [CrossRef]

- Chaudhary, R.; Fabbri, P.; Leoni, E.; Mazzanti, F.; Akbari, R.; Antonini, C. Additive manufacturing by digital light processing: A review. Prog. Addit. Manuf. 2022, 7, 1–21. [Google Scholar] [CrossRef]

- Zheng, Y.; Huang, X.; Chen, J.; Wu, K.; Wang, J.; Zhang, X. A review of conductive carbon materials for 3D printing: Materials, technologies, properties, and applications. Materials 2021, 14, 3911. [Google Scholar] [CrossRef] [PubMed]

- Arias-Ferreiro, G.; Lasagabáster-Latorre, A.; Ares-Pernas, A.; Ligero, P.; García-Garabal, S.M.; Dopico-García, M.S.; Abad, M.J. Lignin as a High-Value Bioaditive in 3D-DLP Printable Acrylic Resins and Polyaniline Conductive Composite. Polymers 2022, 14, 4164. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, F.; Mohan, D.; Sajab, M.S.; Bakarudin, S.B.; Kaco, H. Evaluation of the compatibility of organosolv lignin-graphene nanoplatelets with photo-curable polyurethane in stereolithography 3D printing. Polymers 2019, 11, 1544. [Google Scholar] [CrossRef] [Green Version]

- Ponnamma, D.; Yin, Y.; Salim, N.; Parameswaranpillai, J.; Thomas, S.; Hameed, N. Recent progress and multifunctional applications of 3D printed graphene nanocomposites. Compos. Part B 2021, 204, 108493. [Google Scholar] [CrossRef]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior thermal conductivity of single-layer graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Joo, H.; Cho, S. Comparative Studies on Polyurethane Composites Filled with Polyaniline and Graphene for DLP-Type 3D Printing. Polymers 2020, 12, 67. [Google Scholar] [CrossRef]

- Feng, Z.; Li, Y.; Xin, C.; Tang, D.; Xiong, W.; Zhang, H. Fabrication of Graphene-reinforced nanocomposites with improved fracture toughness in net shape for complex 3D structures via digital light processing. C 2019, 5, 25. [Google Scholar] [CrossRef] [Green Version]

- Hanon, M.M.; Ghaly, A.; Zsidai, L.; Szakál, Z.; Szabó, I.; Kátai, L. Investigations of the mechanical properties of DLP 3d printed graphene/resin composites. Acta Polytech. Hung. 2021, 18, 143–161. [Google Scholar] [CrossRef]

- Xu, T.; Sun, L. Structural defects in graphene. In Defects in Advanced Electronic Materials and Novel Low Dimensional Structures; Stehr, J., Buyanova, I., Chen, W., Eds.; Woodhead Publishing: Cambridge, UK, 2018; pp. 137–160. [Google Scholar] [CrossRef]

- Bhatt, M.D.; Kim, H.; Kim, G. Various defects in graphene: A review. RSC Adv. 2022, 12, 21520–21547. [Google Scholar] [CrossRef]

- Hao, F.; Fang, D.; Xu, Z. Mechanical and thermal transport properties of graphene with defects. Appl. Phys. Lett. 2011, 99, 041901. [Google Scholar] [CrossRef]

- Li, M.; Deng, T.; Zheng, B.; Zhang, Y.; Liao, Y.; Zhou, H. Effect of Defects on the mechanical and thermal properties of graphene. Nanomaterials 2019, 9, 347. [Google Scholar] [CrossRef] [Green Version]

- Ren, Y.; Cao, G. Effect of geometrical defects on the tensile properties of graphene. Carbon 2016, 103, 125–133. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Chen, P.; Zheng, B.; Deng, T.; Zhang, Y.; Liao, Y.; Zhou, H. Effect of stone-wales defect on mechanical properties of Gr/epoxy nanocomposites. Polymers 2019, 11, 1116. [Google Scholar] [CrossRef] [Green Version]

- Voznyakovskii, A.; Vozniakovskii, A.; Kidalov, S. New Way of synthesis of few-layer graphene nanosheets by the self propagating high-temperature synthesis method from biopolymers. Nanomaterials 2022, 12, 657. [Google Scholar] [CrossRef]

- Voznyakovskii, A.; Neverovskaya, A.; Vozniakovskii, A.; Kidalov, S. A Quantitative chemical method for determining the surface concentration of stone–Wales defects for 1D and 2D carbon nanomaterials. Nanomaterials 2022, 12, 883. [Google Scholar] [CrossRef] [PubMed]

- Vozniakovskii, A.A.; Vozniakovskii, A.P.; Kidalov, S.V.; Otvalko, J.; Yu Neverovskaia, A. Characteristics and mechanical properties of composites based on nitrile butadiene rubber using graphene nanoplatelets. J. Compos. Mater. 2020, 54, 3351–3364. [Google Scholar] [CrossRef]

- Vozniakovskii, A.A.; Voznyakovskii, A.P.; Kidalov, S.V.; Osipov, V.Y. Structure and paramagnetic properties of graphene nanoplatelets prepared from biopolymers using self-propagating high-temperature synthesis. J. Struct. Chem. 2020, 65, 869–878. [Google Scholar] [CrossRef]

- Dideykin, A.; Aleksenskiy, A.E.; Kirilenko, D.; Brunkov, P.; Goncharov, V.; Baidakova, M.; Sakseev, D.; Vul, A.Y. Monolayer graphene from graphite oxide. Diam. Relat. Mater. 2011, 20, 105–108. [Google Scholar] [CrossRef]

- Parente, J.M.; Simões, R.; Reis PN, B. Effect of graphene nanoparticles on suspension viscosity and mechanical properties of epoxy-based nanocomposites. Procedia Struct. Integr. 2022, 37, 820–825. [Google Scholar] [CrossRef]

- Zhao, R.; Jing, F.; Li, C.; Wang, R.; Xi, Z.; Cai, J.; Wang, Q.; Xie, H. Viscosity-curing time behavior, viscoelastic properties, and phase separation of graphene oxide/epoxy asphalt composites. Polym. Compos. 2022, 43, 5454–5464. [Google Scholar] [CrossRef]

- Li, Q.Y.; Xia, K.; Zhang, J.; Zhang, Y.; Li, Q.; Takahashi, K.; Zhang, X. Measurement of specific heat and thermal conductivity of supported and suspended graphene by a comprehensive Raman optothermal method. Nanoscale 2017, 9, 10784–10793. [Google Scholar] [CrossRef]

- Lee, S.J.; Yoon, S.J.; Jeon, I.-Y. Graphene/Polymer nanocomposites: Preparation, mechanical properties, and application. Polymers 2022, 14, 4733. [Google Scholar] [CrossRef]

- Manapat, J.Z.; Mangadlao, J.D.; Tiu BD, B.; Tritchler, G.C.; Advincula, R.C. High-strength stereolithographic 3D printed nanocomposites: Graphene oxide metastability. ACS Appl. Mater. Interfaces 2017, 9, 10085–10093. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Sharma, K.; Dixit, A.R. Carbon nanotube-and graphene-reinforced multiphase polymeric composites: Review on their properties and applications. J. Mater. Sci. 2020, 55, 2682–2724. [Google Scholar] [CrossRef]

- Progelnof, R.C.; Throne, J.L.; Reutsch, R.R. Methods of predicting the thermal conductivity of composite systems: A review. Polym Eng Sci. 1976, 16, 615–625. [Google Scholar] [CrossRef]

- Zhai, S.; Zhang, P.; Xian, Y.; Zeng, J.; Shi, B. Effective thermal conductivity of polymer composites: Theoretical models and simulation models. Int. J. Heat Mass Transfer. 2018, 117, 358–374. [Google Scholar] [CrossRef]

- Baranovskii, V.M.; Temnikova, S.V.; Cherenkov, A.V.; Zeleneva, T.P.; Zelenev, Y.V. Predicting the thermophysical properties of polymer composites using model representations. Int. Polym. Sci. Technol. 2004, 31, 5–12. [Google Scholar] [CrossRef]

- Colonna, S.; Battegazzore, D.; Eleuteri, M.; Arrigo, R.; Fina, A. Properties of Graphene-Related Materials Controlling the Thermal Conductivity of Their Polymer Nanocomposites. Nanomaterials 2020, 10, 2167. [Google Scholar] [CrossRef] [PubMed]

- Li, A.; Zhang, C.; Zhang, Y.-F. Thermal Conductivity of Graphene-Polymer Composites: Mechanisms, Properties, and Applications. Polymers 2017, 9, 437. [Google Scholar] [CrossRef] [PubMed]

| Post-Processing Technique | Brinell Hardness | Change, % |

|---|---|---|

| No processing | 5.6 0.3 | 0 |

| 1 h UV | 7.4 0.4 | 32 |

| 1 h annealing | 6.1 0.3 | 9 |

| 1 h UV + 1 h annealing | 10.6 0.5 | 89 |

| 1 h UV + 2 h annealing | 8.8 0.4 | 57 |

| 2 h UV + 1 h annealing | 10.2 0.5 | 82 |

| 2 h UV + 2 h annealing | 8.2 0.4 | 46 |

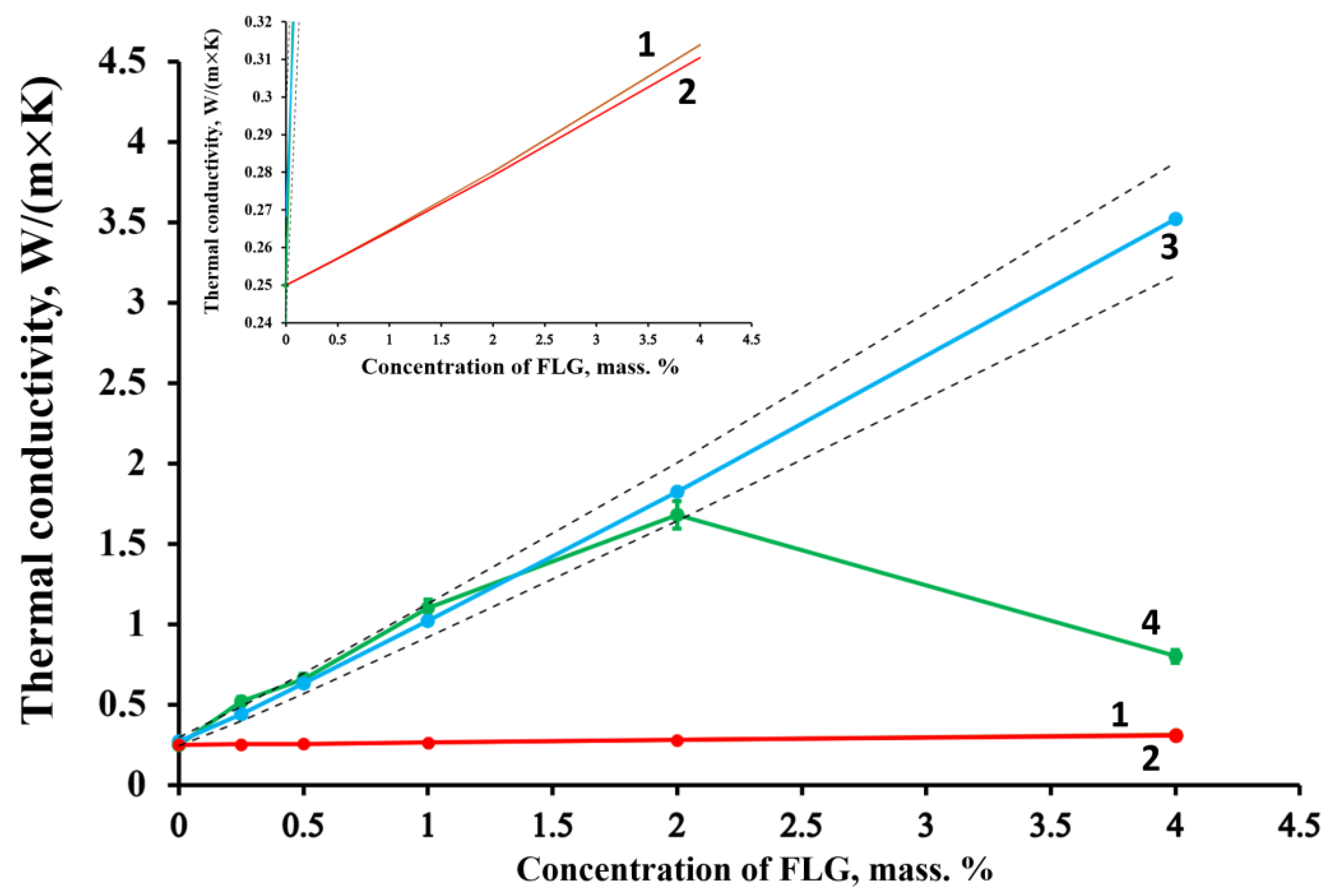

| vm, % | vf, % | λm, | λf, | λc, Geometric Model | λc, Maxwell Model | λc, MBE Model | λc, Experimental Value |

|---|---|---|---|---|---|---|---|

| % | % | W/(m K) | |||||

| 0.981 | 0.019 | 0.25 | 0.5 | 0.265 | 0.254 | 0.27 | 1.1 ± 0.05 |

| 0.981 | 0.019 | 0.25 | 5 | 0.265 | 0.263 | 0.41 | |

| 0.981 | 0.019 | 0.25 | 50 | 0.265 | 0.264 | 0.86 | |

| 0.981 | 0.019 | 0.25 | 500 | 0.265 | 0.265 | 1.86 | |

| 0.981 | 0.019 | 0.25 | 5000 | 0.265 | 0.265 | 10.12 | |

| Sample | Surface Area, m2/g | Stone–Wales Defects Concentration (mol/m2) |

|---|---|---|

| FLG | 660 | 0 |

| rGO | 580 | 3.6 × 10−5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kidalov, S.; Voznyakovskii, A.; Vozniakovskii, A.; Titova, S.; Auchynnikau, Y. The Effect of Few-Layer Graphene on the Complex of Hardness, Strength, and Thermo Physical Properties of Polymer Composite Materials Produced by Digital Light Processing (DLP) 3D Printing. Materials 2023, 16, 1157. https://doi.org/10.3390/ma16031157

Kidalov S, Voznyakovskii A, Vozniakovskii A, Titova S, Auchynnikau Y. The Effect of Few-Layer Graphene on the Complex of Hardness, Strength, and Thermo Physical Properties of Polymer Composite Materials Produced by Digital Light Processing (DLP) 3D Printing. Materials. 2023; 16(3):1157. https://doi.org/10.3390/ma16031157

Chicago/Turabian StyleKidalov, Sergey, Alexander Voznyakovskii, Aleksei Vozniakovskii, Sofia Titova, and Yvgenii Auchynnikau. 2023. "The Effect of Few-Layer Graphene on the Complex of Hardness, Strength, and Thermo Physical Properties of Polymer Composite Materials Produced by Digital Light Processing (DLP) 3D Printing" Materials 16, no. 3: 1157. https://doi.org/10.3390/ma16031157

APA StyleKidalov, S., Voznyakovskii, A., Vozniakovskii, A., Titova, S., & Auchynnikau, Y. (2023). The Effect of Few-Layer Graphene on the Complex of Hardness, Strength, and Thermo Physical Properties of Polymer Composite Materials Produced by Digital Light Processing (DLP) 3D Printing. Materials, 16(3), 1157. https://doi.org/10.3390/ma16031157