Effect of Basalt Fiber on Uniaxial Compression-Related Constitutive Relation and Compressive Toughness of Recycled Aggregate Concrete

Abstract

:1. Introduction

2. Test Scheme

2.1. Materials

2.2. Mix Proportion

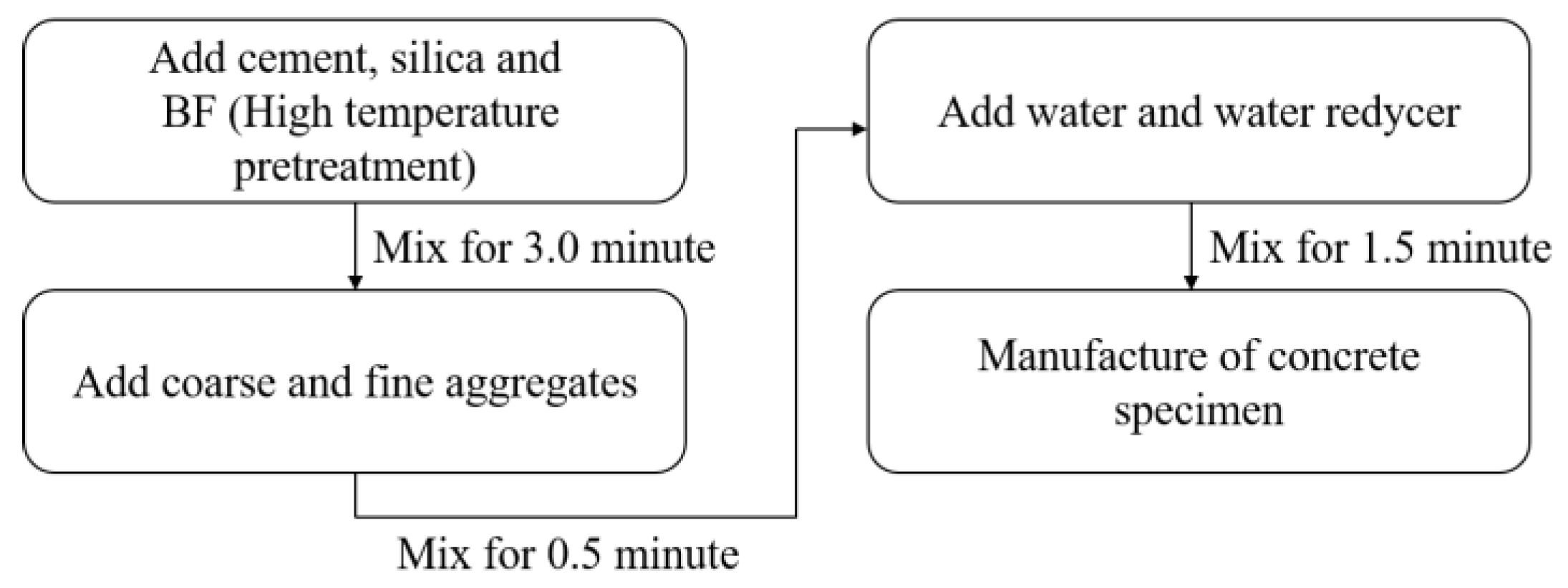

2.3. Specimen Making

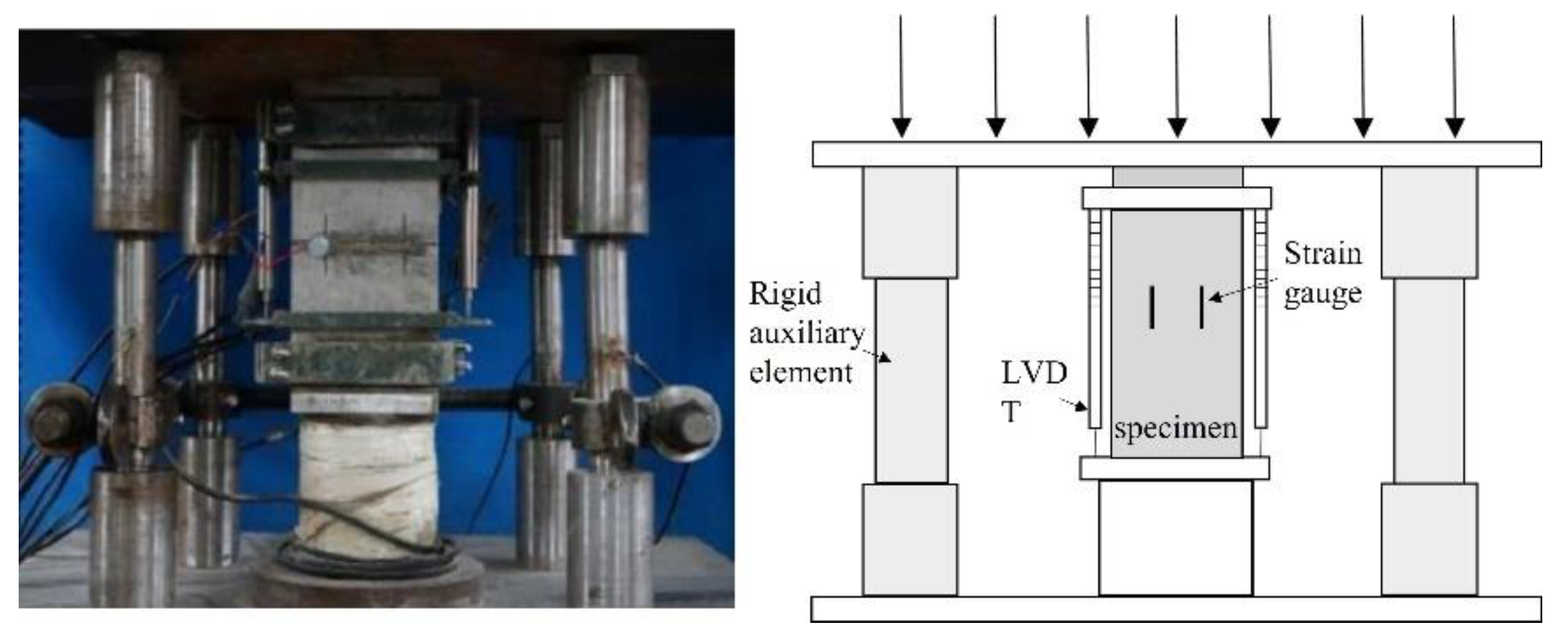

2.4. Test Method

3. Test Results and Analysis

3.1. Basic Mechanical Properties

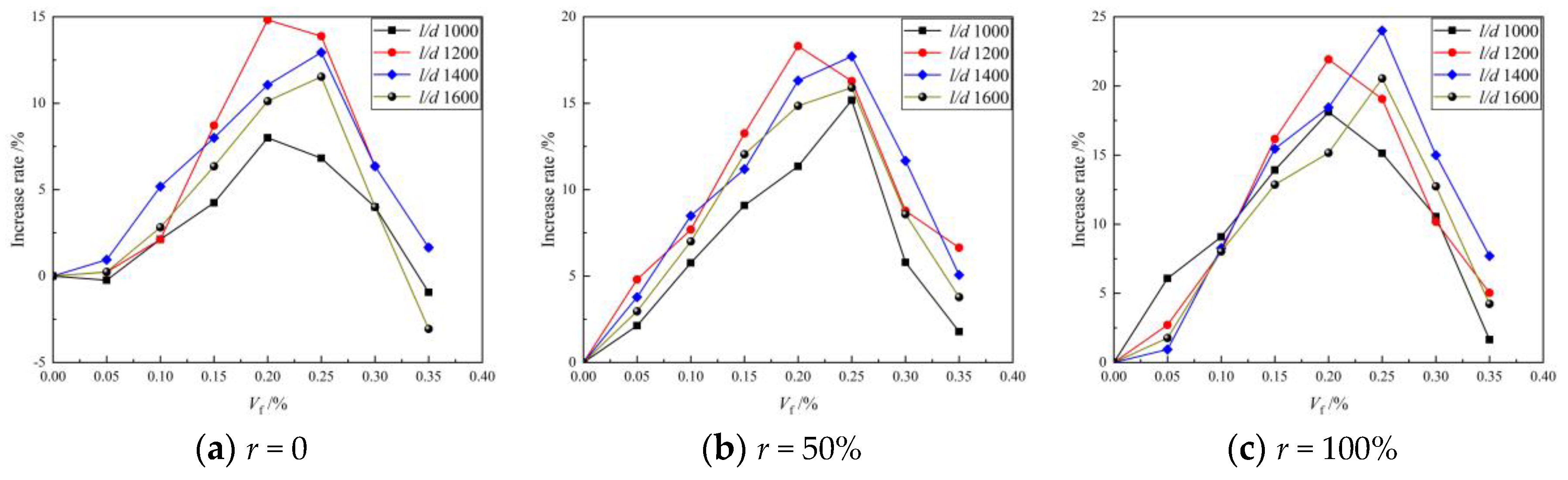

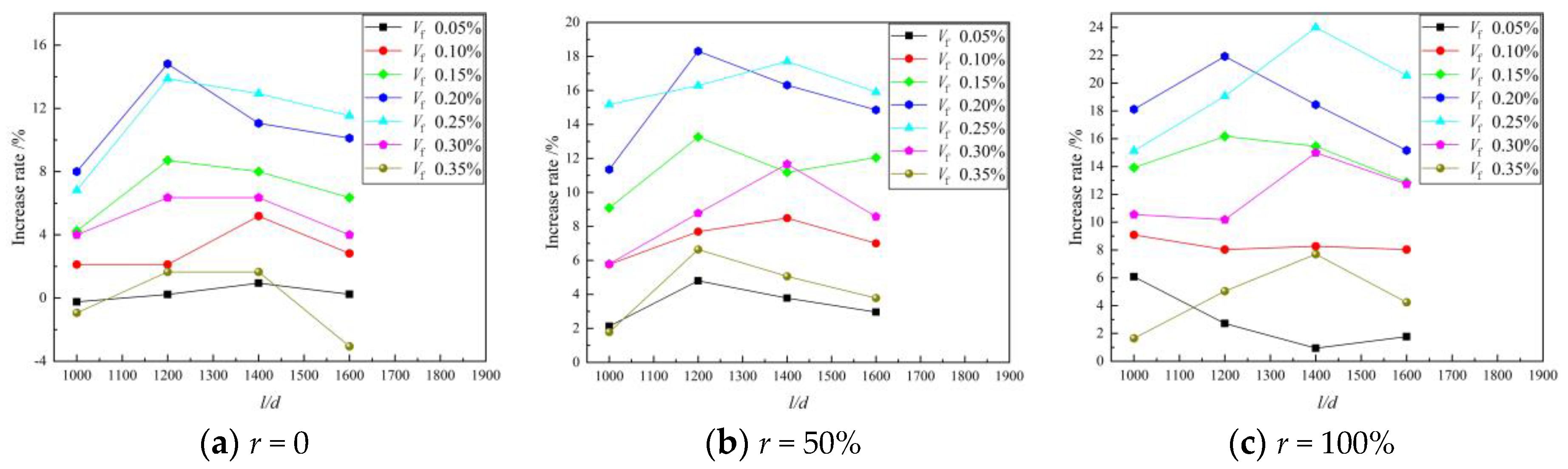

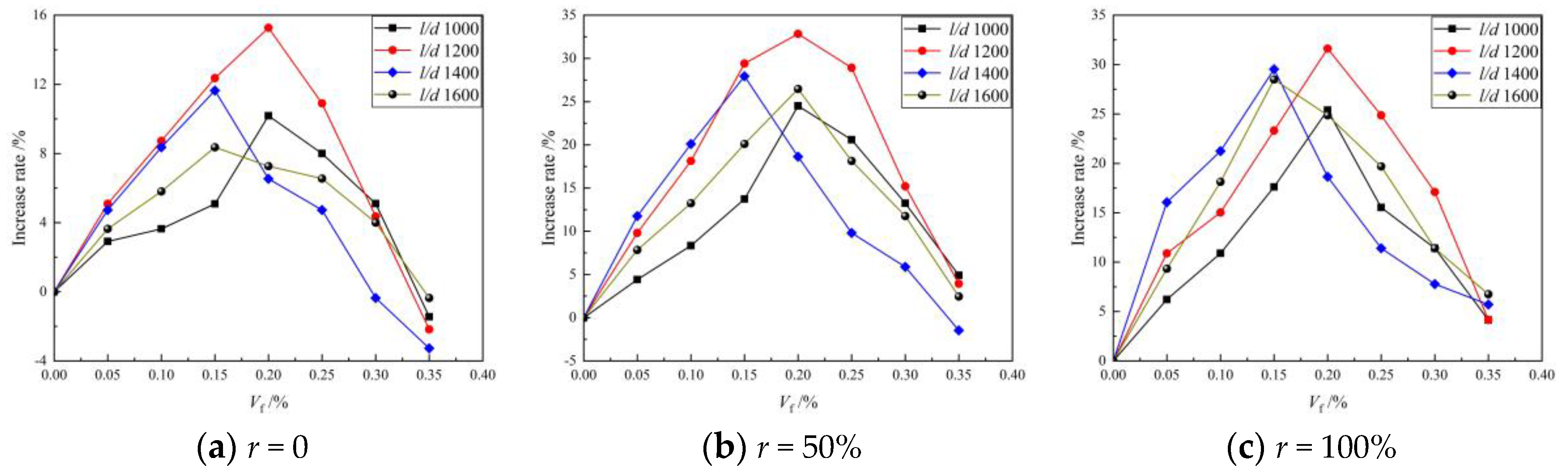

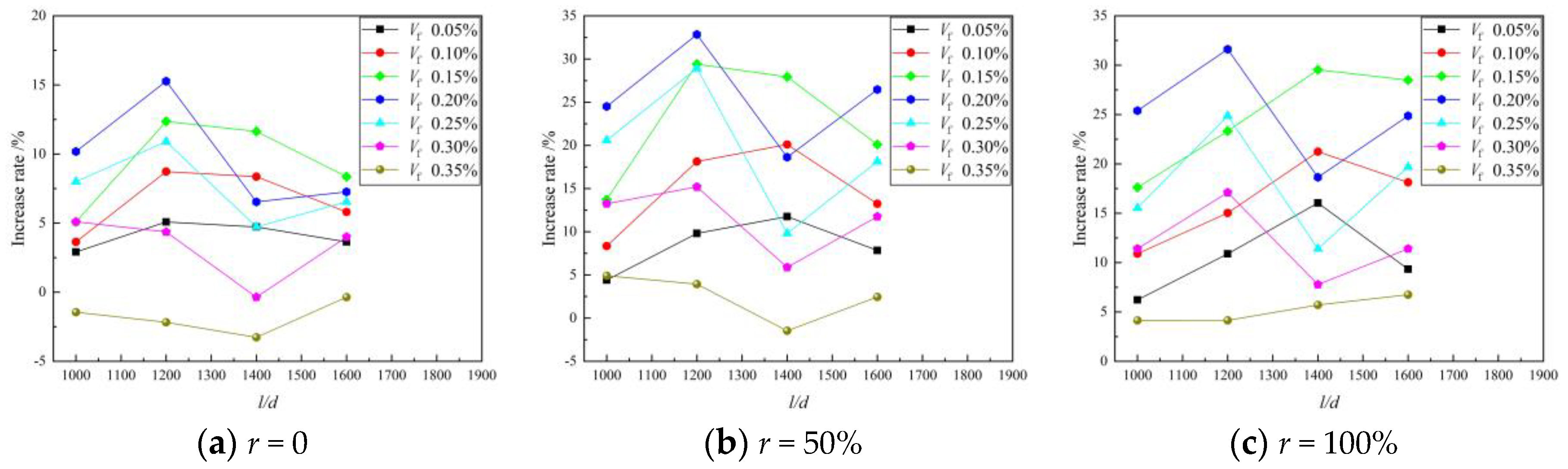

3.1.1. Compressive Strength

3.1.2. Splitting Tensile Strength

3.1.3. Tension–Compression Ratio

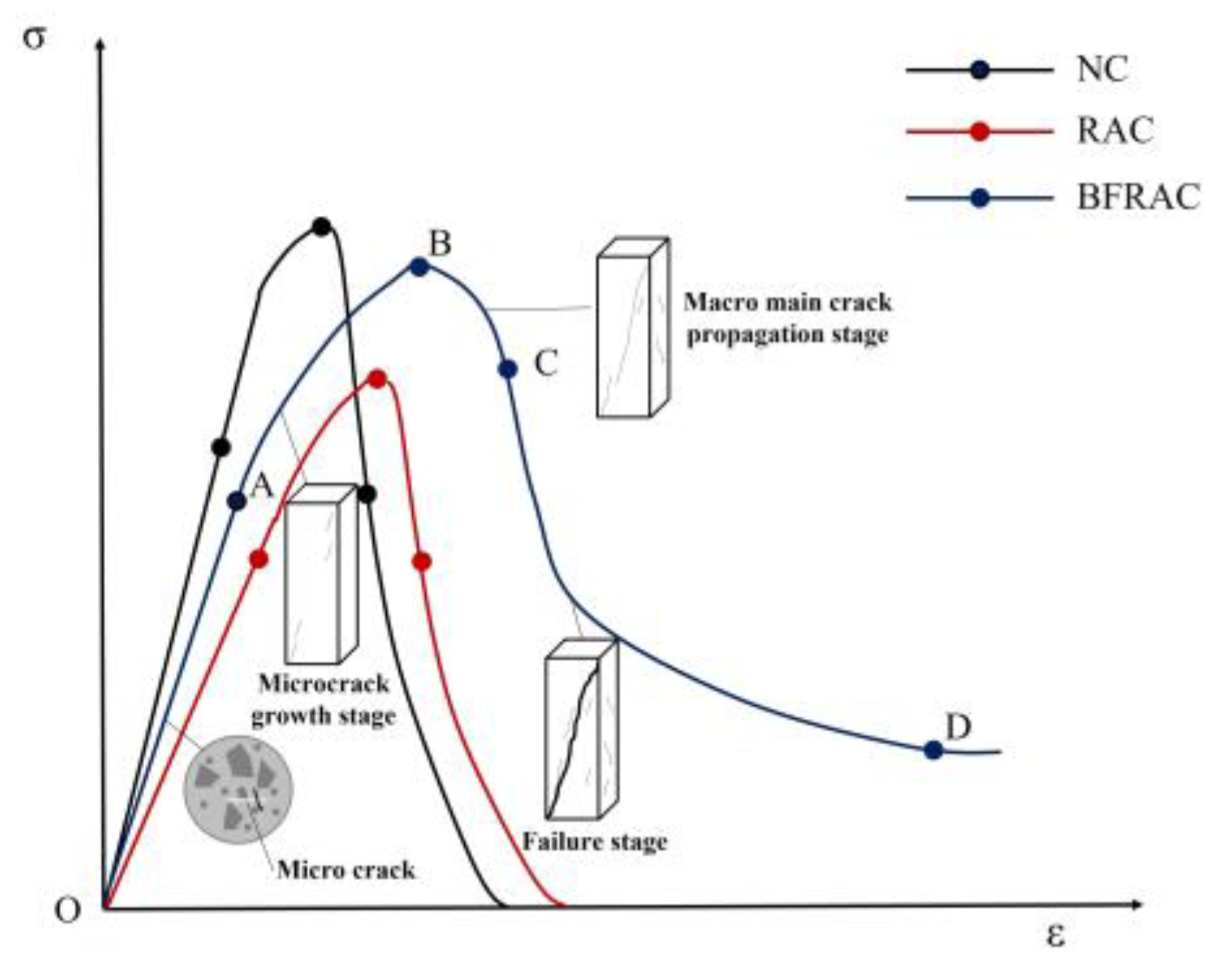

3.2. Characteristic Analysis of the Complete Stress–Strain Curve under Uniaxial Compression

3.2.1. Failure Mode

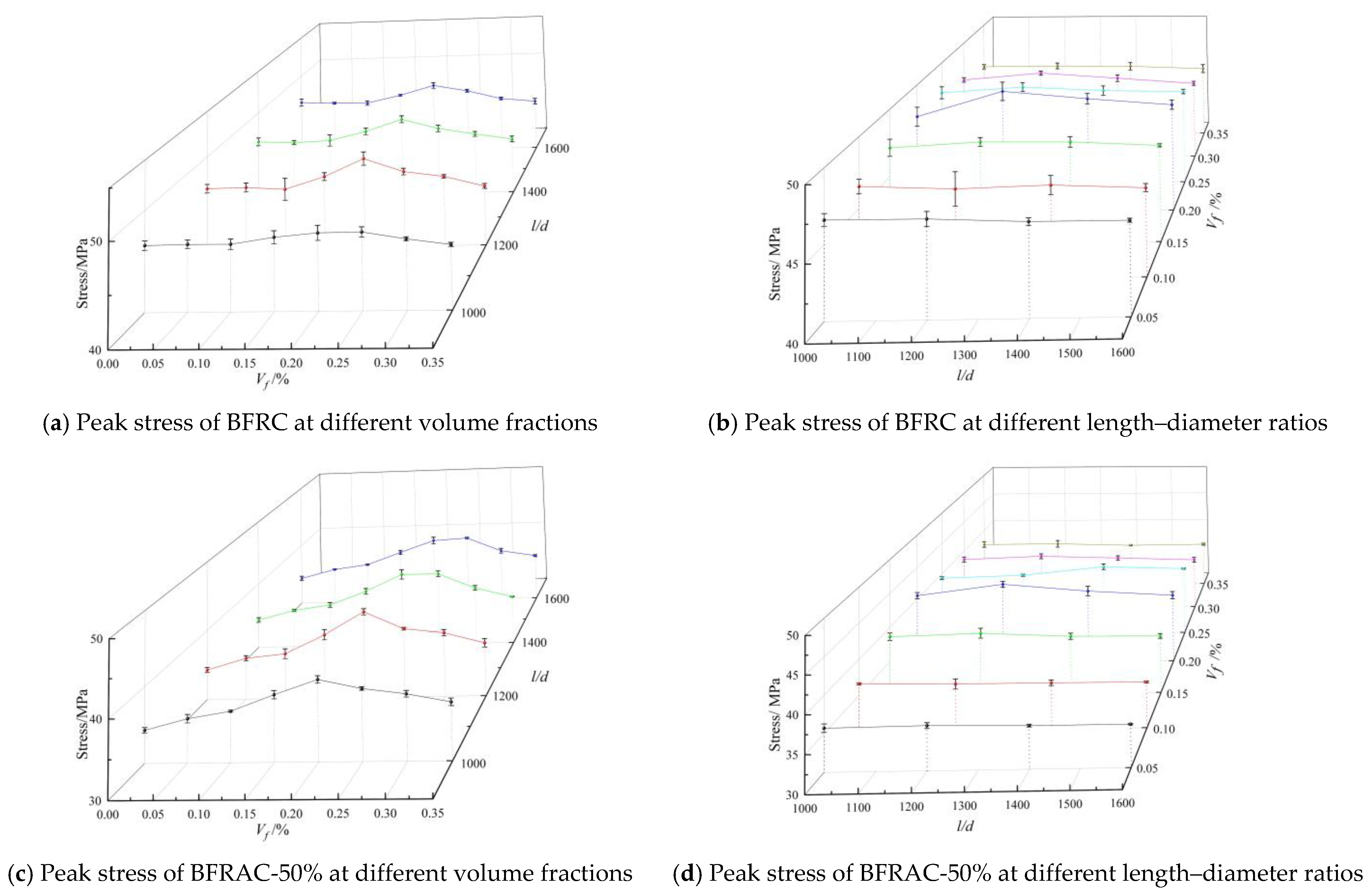

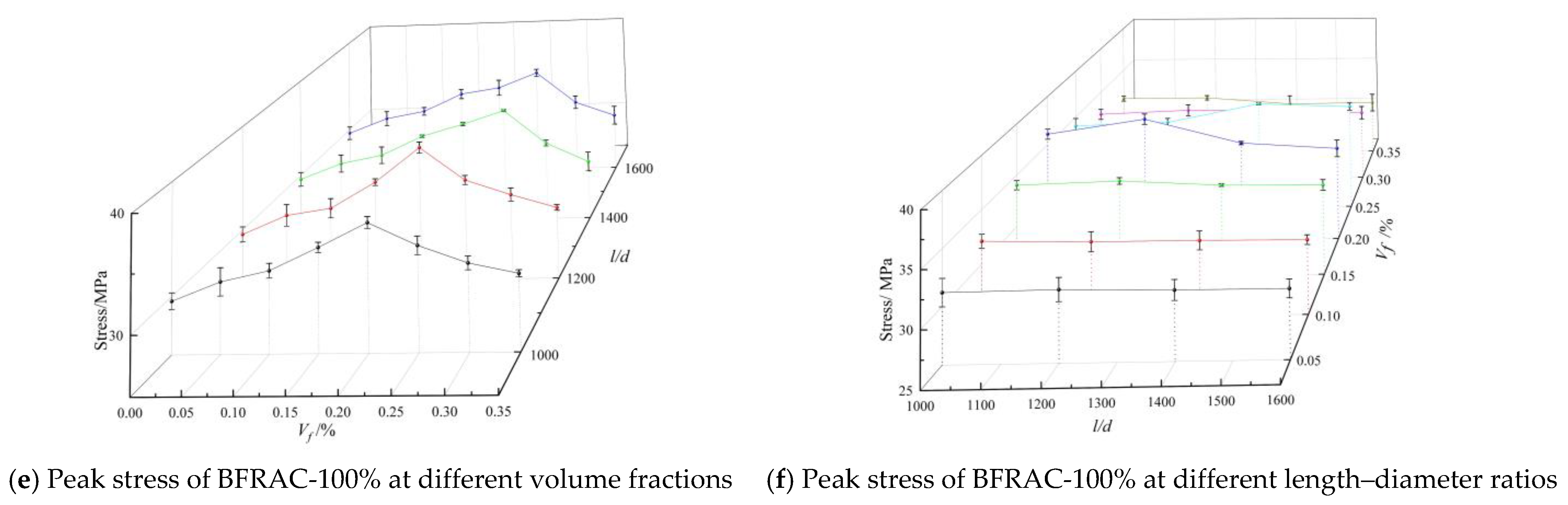

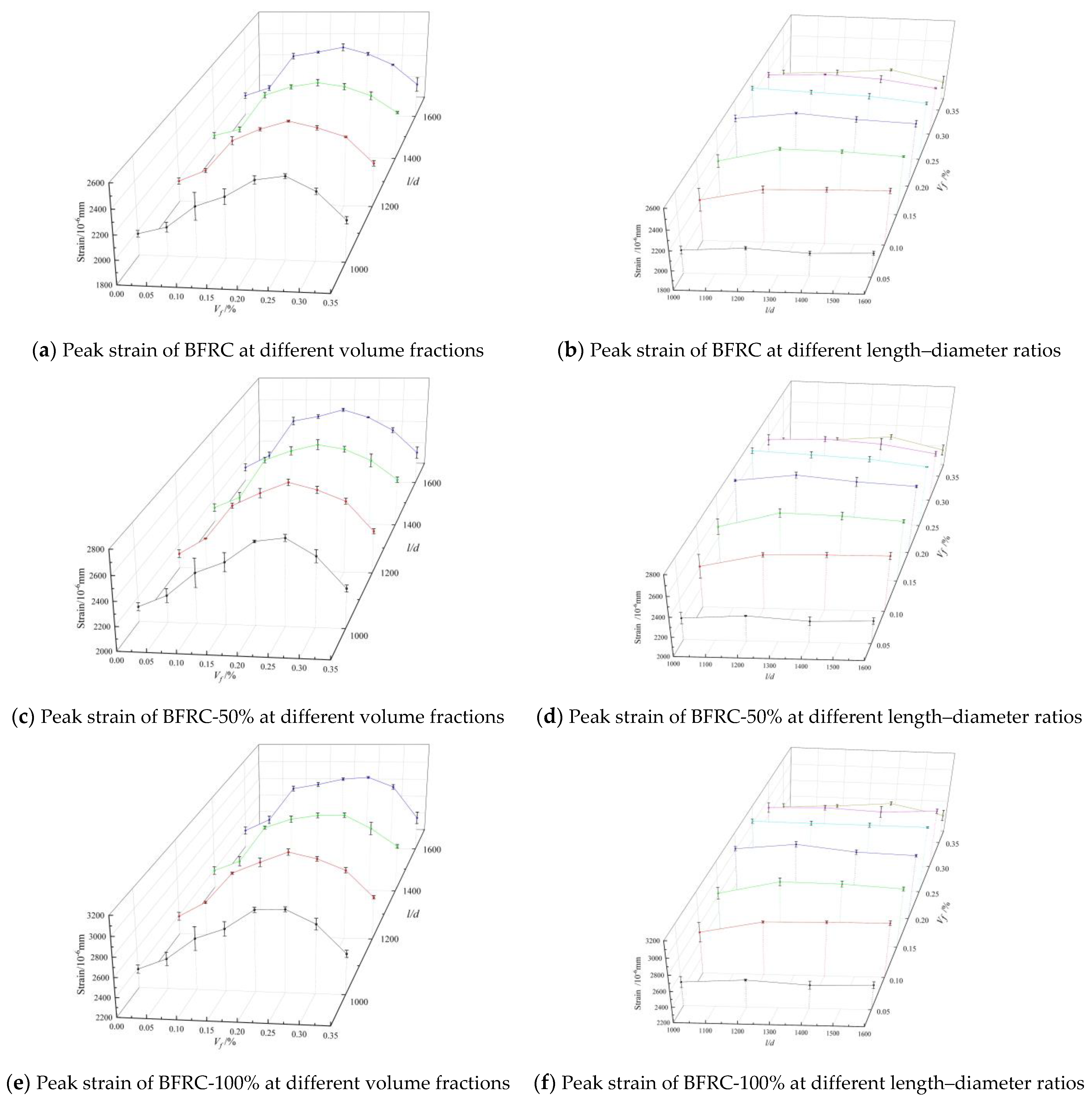

3.2.2. Feature Points of the Complete Curve

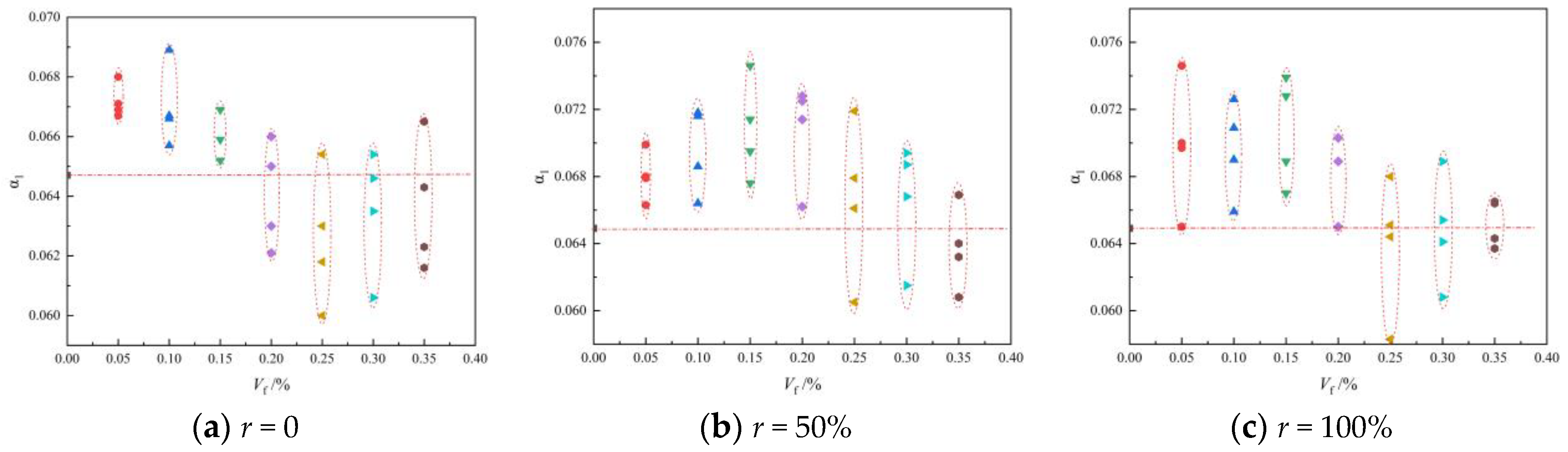

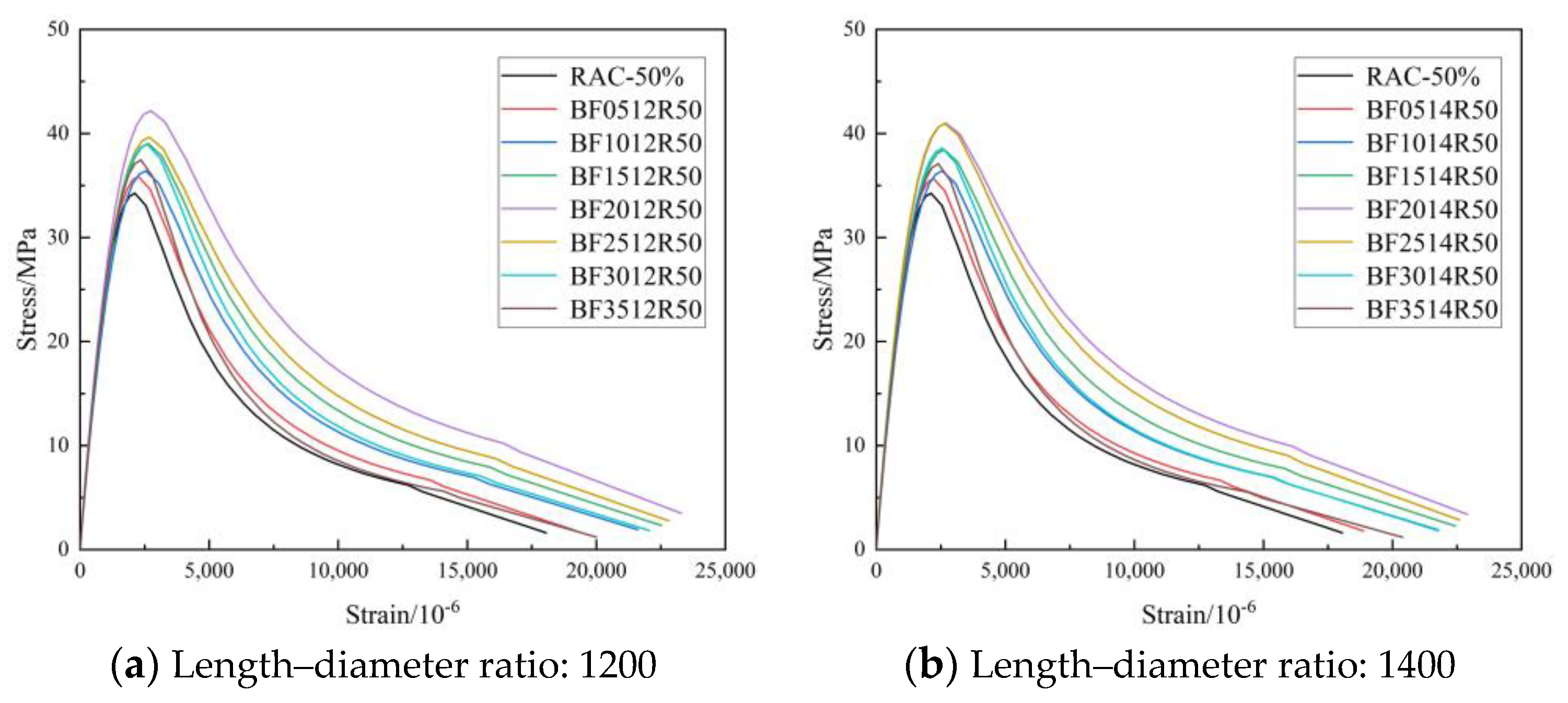

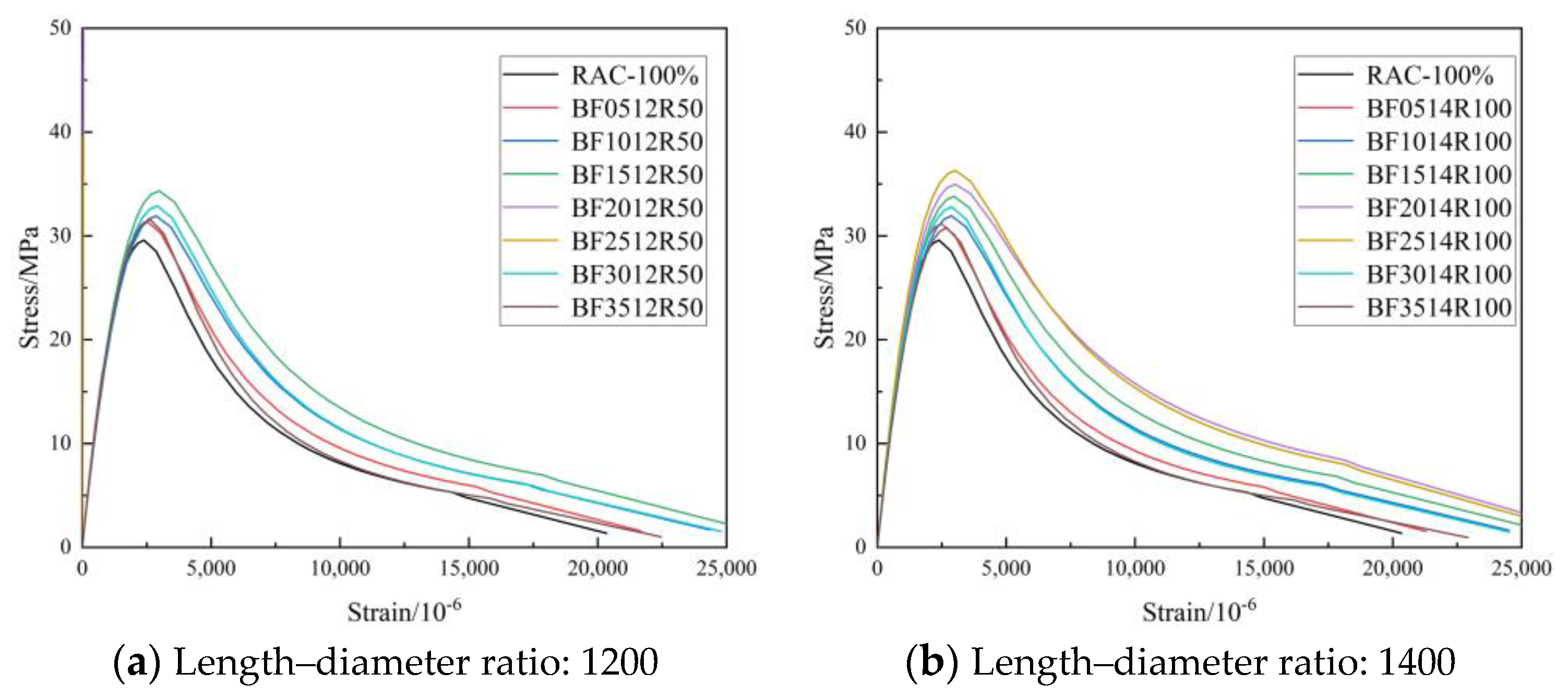

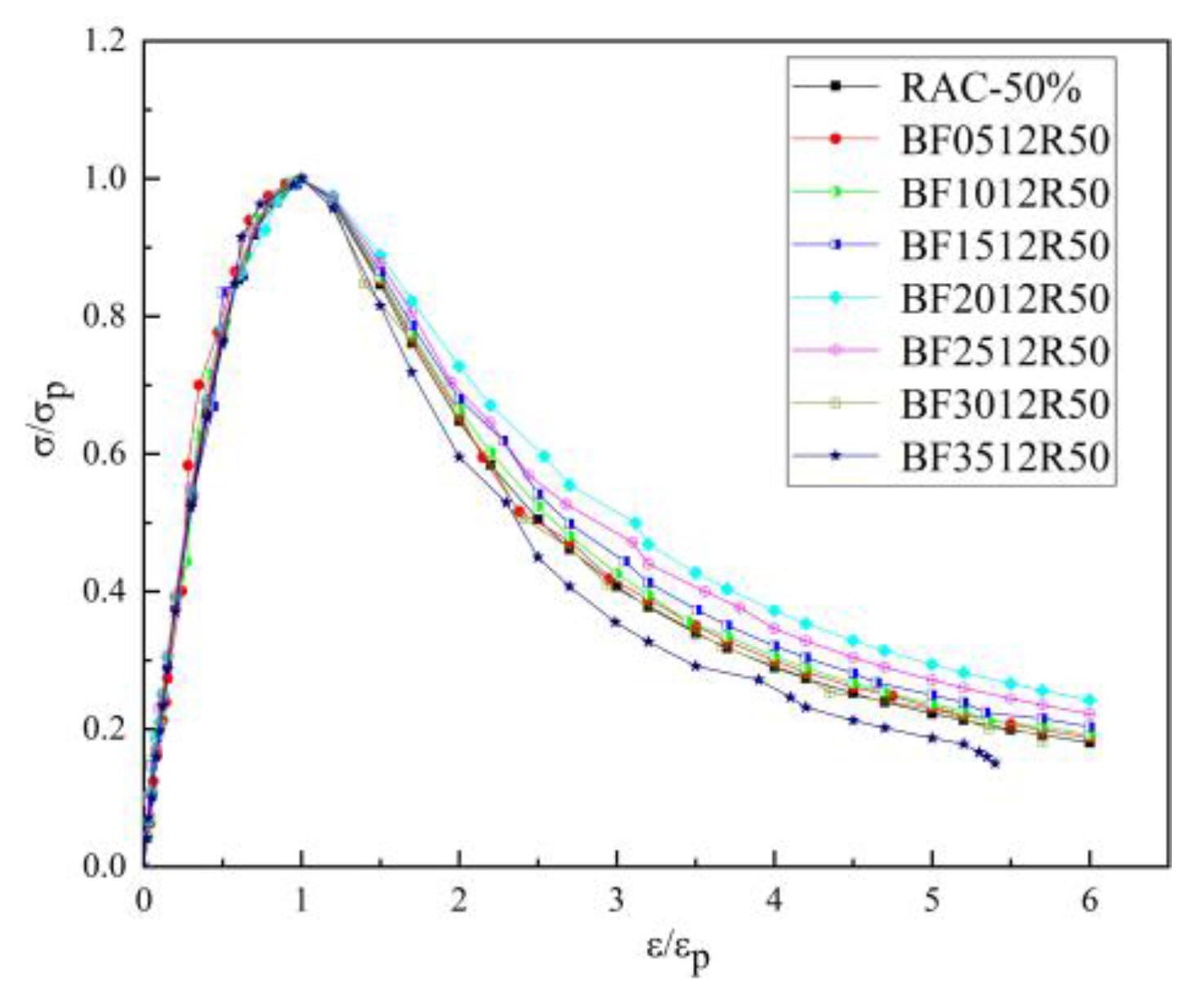

3.2.3. Curve of Feature

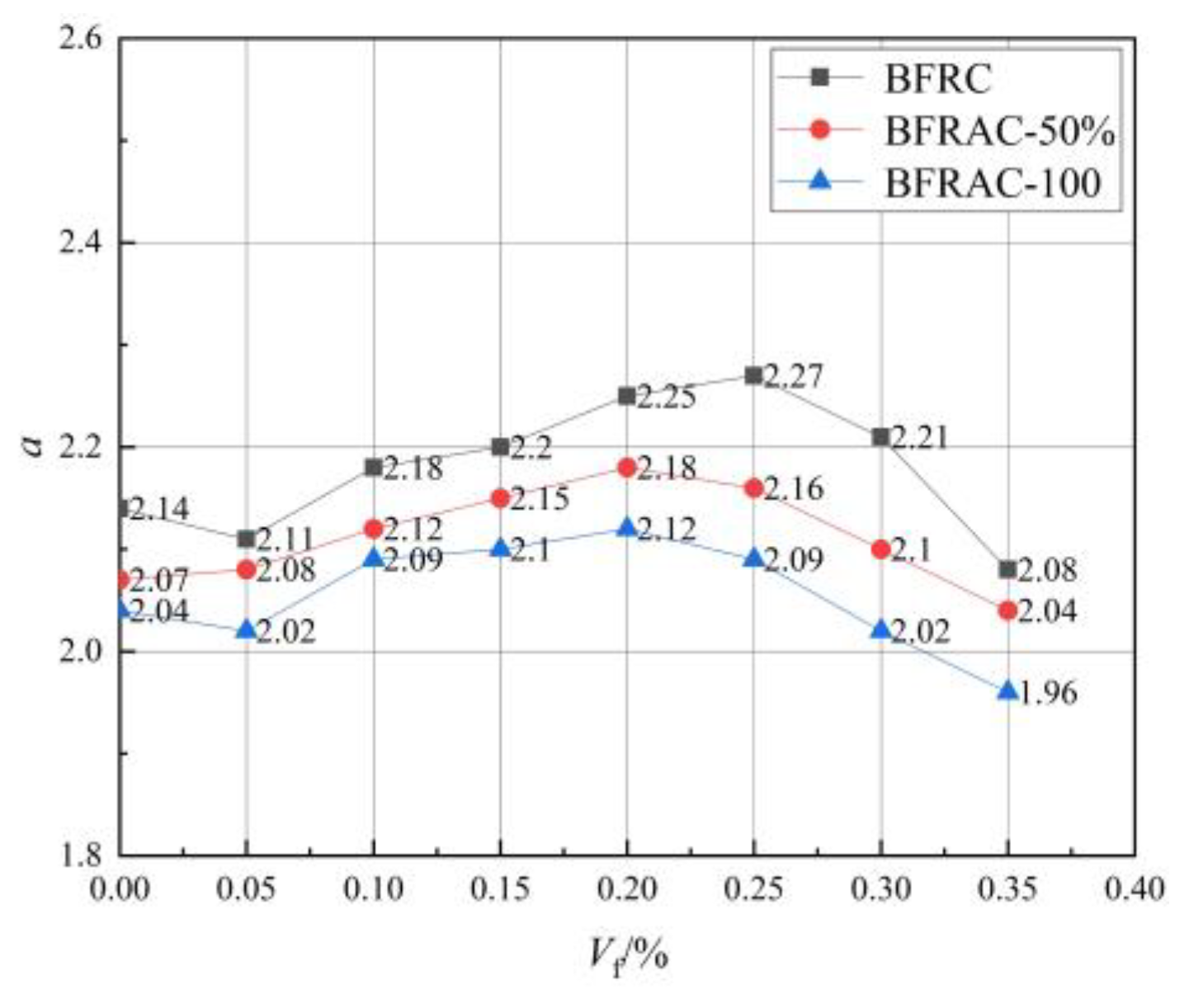

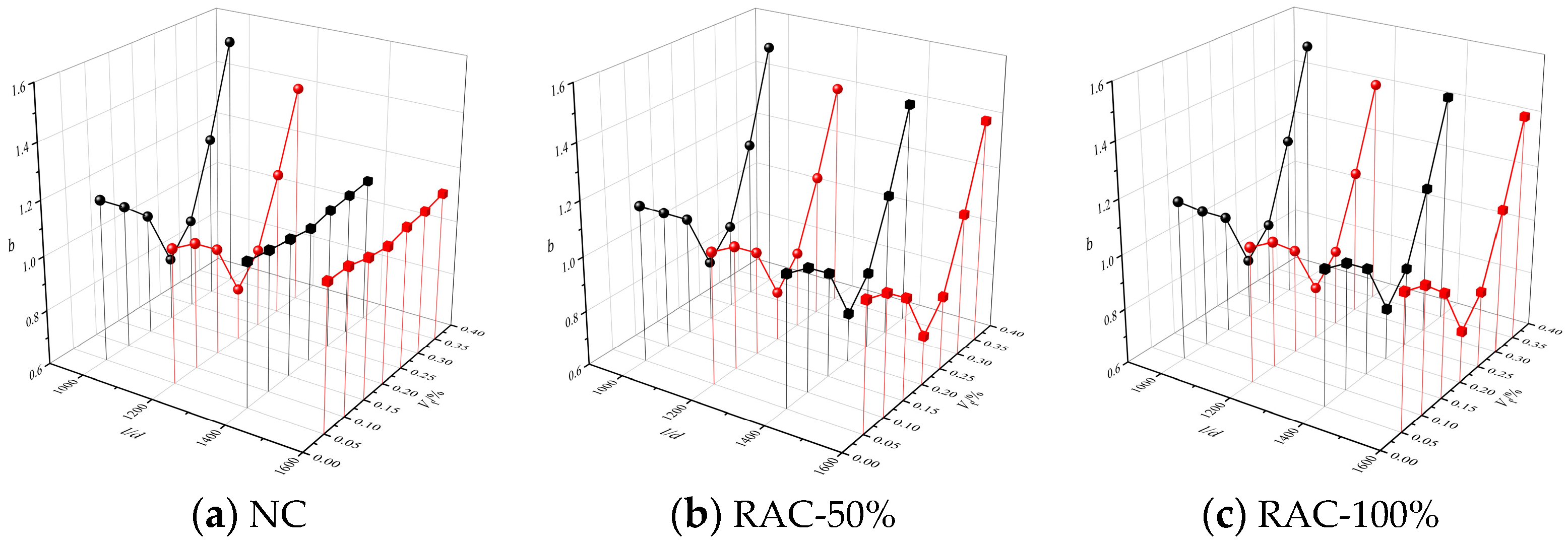

3.3. Establishment of a Complete Stress–Strain Curve Model

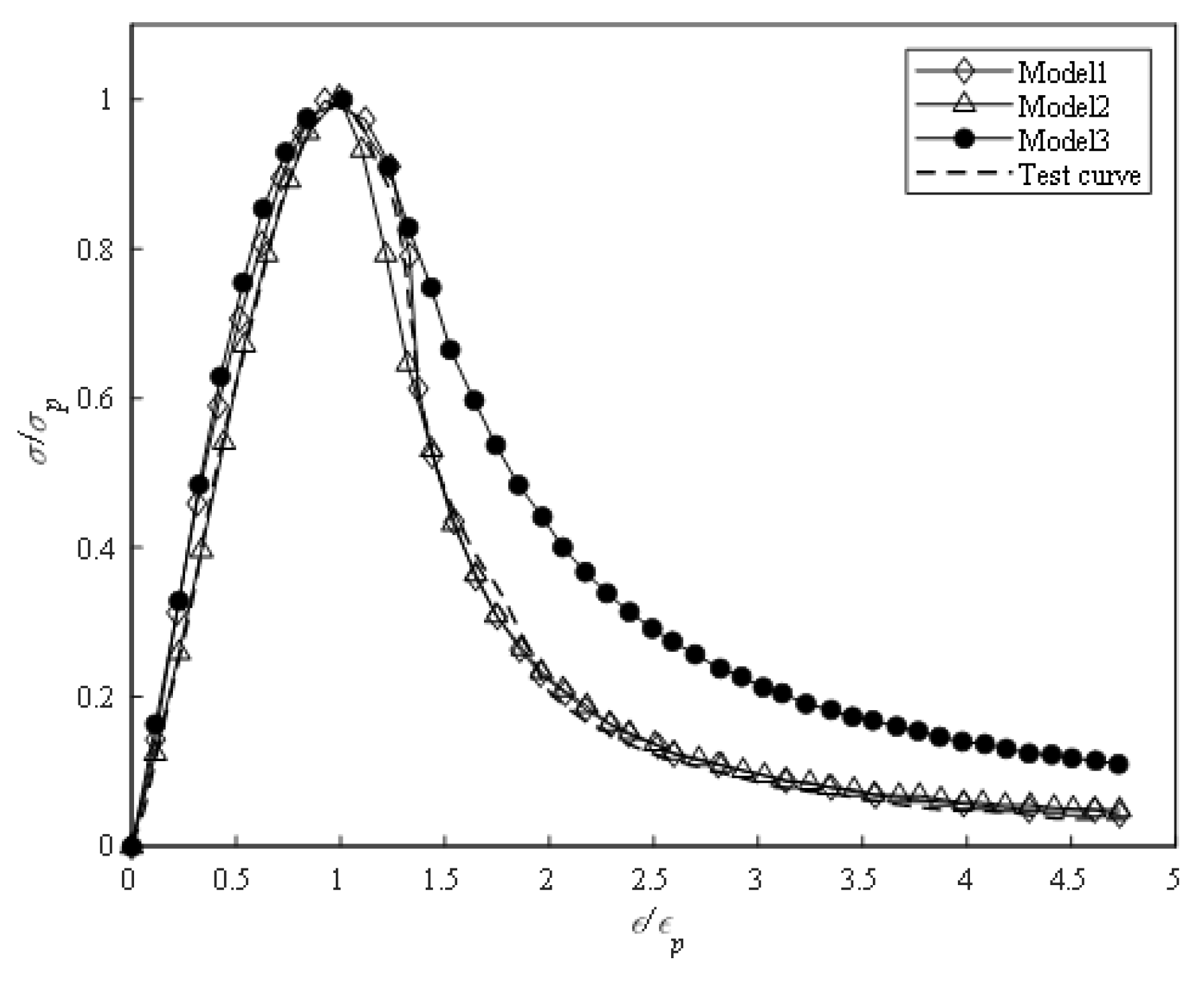

3.3.1. Classical Model

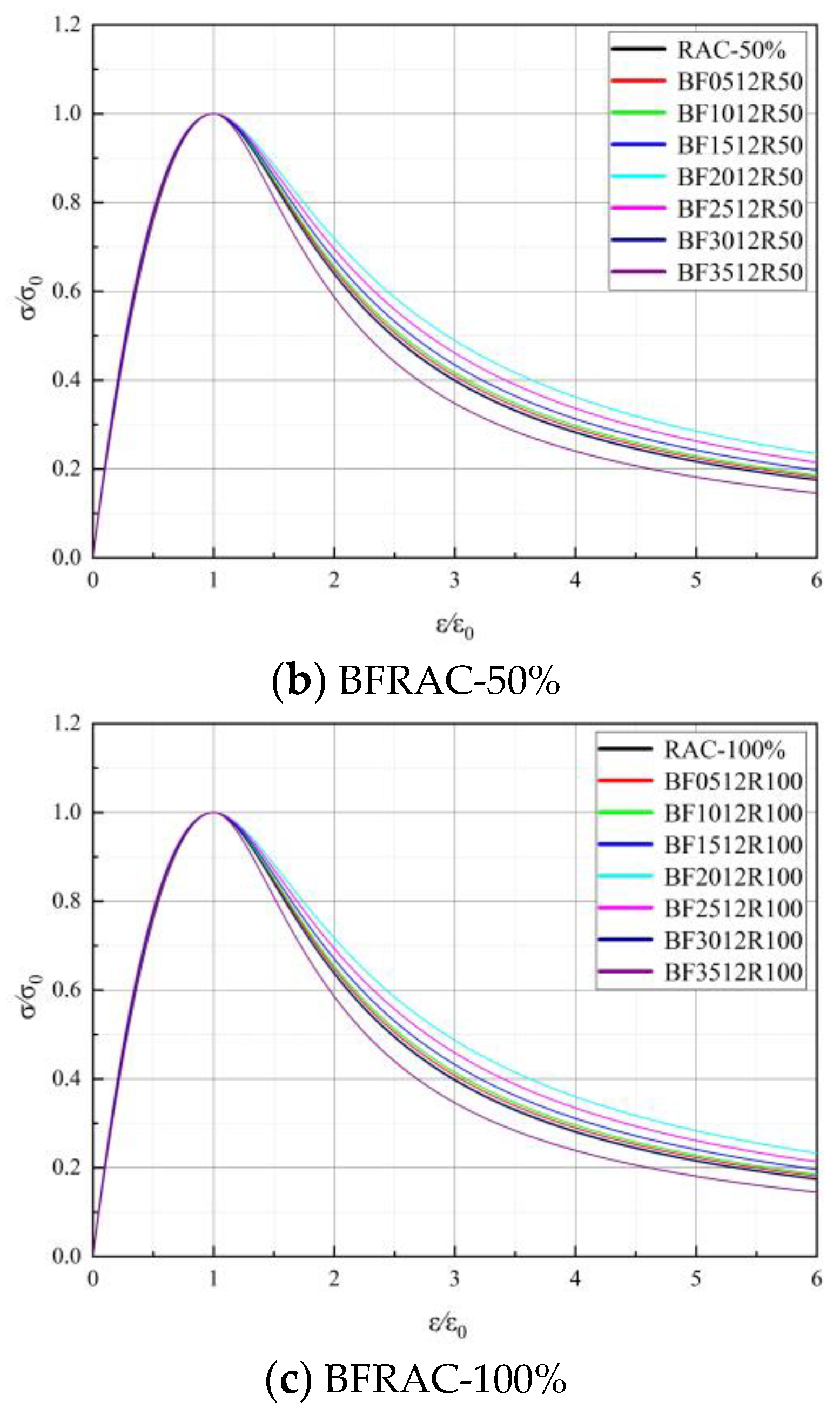

3.3.2. Establishment of Models

- (1)

- The curve passes through the origin and point of coordinates.

- (2)

- At (1,1) the slope is 0.

- (3)

- .

- (4)

- .

3.4. BFRAC Toughness Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xiao, J. Recycled Aggregate Concrete; China Architecture & Building Press: Beijing, China, 2008. [Google Scholar]

- Gao, D.Y.; Zhu, Q.; Liu, J. Experiments on stress-strain curve of steel fiber reinforced geopolymer recycled concrete under uniaxial compression. J. Build. Struct. 2022, 43, 255–265. [Google Scholar]

- Gao, D.Y.; Zhu, Q.; Liu, J. Constitutive Model of SFRCAC Under Uniaxial Compression. J. Basic Sci. Eng. 2020, 28, 396–406. [Google Scholar]

- Le, H.B.; Bui, Q.B. Recycled Aggregate Concretes—A State-of-the-Art from the Microstructure to the Structural Performance; Elsevier BV: Amsterdam, The Netherlands, 2020; p. 119522. [Google Scholar]

- Liu, C.; Bai, G.; Jia, S. Experimental study on seismic behavior of recycled concrete frame joints with different axial compression ratios. China Civ. Eng. J. 2013, 46, 21–28. [Google Scholar]

- Liu, K.; Yan, J.; Zou, C. Experimental study on behavior of reinforced recycled aggregate concrete beams subjected to combined shear and torsion. J. Build. Struct. 2016, 37, 9–15. [Google Scholar]

- Liu, J.; Tang, J.; Han, F. Toughening and crack prevention of modern concrete: Mechanisms and applications. China Civ. Eng. J. 2021, 54, 47–54. [Google Scholar]

- Shi, X.; Park, P.; Rew, Y.; Huang, K.; Sim, C. Constitutive behaviors of steel fiber reinforced concrete under uniaxial compression and tension—ScienceDirect. Constr. Build. Mater. 2020, 233, 117316. [Google Scholar] [CrossRef]

- Zhu, D.; Liu, S.; Yao, Y.; Li, G.; Du, Y.; Shi, C. Effects of short fiber and pre-tension on the tensile behavior of basalt textile reinforced concrete. Cem. Concr. Compos. 2019, 96, 33–45. [Google Scholar] [CrossRef]

- High, C.; Seliem, H.M.; El-Safty, A.; Rizkalla, S.H. Use of basalt fibers for concrete structures. Constr. Build. Mater. 2015, 96, 37–46. [Google Scholar] [CrossRef]

- Wang, Y. Experimental Study on Mechanical Properties of Basalt Fiber Reinforced Concrete; Southwest Jiaotong University: Chengdu, China, 2018. [Google Scholar]

- Guo, Y.; Liu, Y.; Wang, W.; Zhang, Y.; Wang, K.; Liu, Y. Influence of basalt fiber characteristic parameters on uniaxial tensile properties of concrete. Acta Mater. Compos. Sin. 2022, 1–13. [Google Scholar] [CrossRef]

- Wang, Q.; Zhao, J.; Dong, H.; Zhang, Y. Analysis of Bending Failure Characteristics and Toughness of Basalt Fiber Reinforced Concrete. China Concr. Cem. Prod. 2021, 10, 48–51. [Google Scholar]

- Dias, D.P.; Thaumaturgo, C. Thaumaturgo. Fracture toughness of geopolymeric concretes reinforced with basalt fibers. Cem. Concr. Compos. 2005, 27, 49–54. [Google Scholar] [CrossRef]

- Chen, M. The Main Performance and Stress-Strain Relationship of Basalt Fiber Rubber Recycied Concrete; North China University of Water Resources and Electric Power: Zhengzhou, China, 2015. [Google Scholar]

- Elshafie, S. A review of the effect of basalt fibre lengths and proportions on the mechanical properties of concrete. Int. J. Res. Eng. Technol. 2015, 4, 458–465. [Google Scholar]

- Khan, M.; Rehman, A.; Ali, M. Efficiency of silica-fume content in plain and natural fiber reinforced concrete for concrete road. Constr. Build. Mater. 2020, 244, 118382. [Google Scholar] [CrossRef]

- Liu, H.; Yang, J.; Kong, X.; Xue, X. Basic Mechanical Properties of Basalt Fiber Reinforced Recycled Aggregate Concrete; Bentham Science Publishers Ltd.: Sharjah, United Arab, 2017; Volume 11, pp. 43–53. [Google Scholar]

- Gao, Y. Study on Basic Mechanical Properties of Basalt Fiber Recycled Concrete; Anhui University of Science and Technology: Huainan, China, 2019. [Google Scholar]

- Chen, Z.; Zhou, C.; Chen, Y.; Huang, J. Mechanical Properties of Recycled Pebble Aggregate Concrete. J. Build. Mater. 2014, 17, 465–469, 506. [Google Scholar]

- Zhang, L.; Shi, H.; Liu, B.; Ji, T. Experimental Study on Compressive Properties and Flexural Performance of Polyacrylonitrile Fiber Reinforced Concrete. J. Nantong Univ. (Nat. Sci. Ed.) 2012, 11, 39–42. [Google Scholar]

- Xu, L.; Mei, G.; Huang, L.; Lu, W. Study on uniaxial tensile stress-strain relationship of steel-polypropylene hybrid fiber reinforced concrete. China Civ. Eng. J. 2014, 47, 35–45. [Google Scholar]

- Guo, Z. Strength and Constitutive Relations of Concrete; China Architecture & Building Press: Beijing, China, 2004. [Google Scholar]

- Xiao, J. Experimental Investigation on Complete Stress-Strain Curve of Recycled Concrete Under Uniaxial Loading. J. Tongji Univ. (Nat. Sci.) 2007, 11, 1445–1449. [Google Scholar]

- Lin, J. Study on Mechanical Properties and Microstructure of BFRC Based on SEM. Constr. Technol. 2018, 47, 97–101. [Google Scholar]

- Zhong, G.; Zhou, Y.; Xiao, Y. Stress-strain behavior of steel-polyviny alcohol hybrid fiber reinforced concrete under axial compression and tension. Eng. Mech. 2020, 37, 111–120. [Google Scholar]

- Zhang, Y. Study on Uniaxial Compressive Constitutive Relationship and Uniaxial Tensile Behavior of Steel-Polypropylene Hybrid Fiber Reinforced Concrete; Wuhan University: Wuhan, China, 2010. [Google Scholar]

- Hui, W.; Tao, W.; Xue, Y.; Xi, L. Experimental study on stress-strain relationship of fiber reinforced lightweight aggregate concrete. Eng. Mech. 2019, 36, 126–135. [Google Scholar]

- Liu, B.; Zhou, J.; Wen, X.; Hu, X.; Deng, Z. Mechanical properties and constitutive model of carbon fiber reinforced coral concrete under uniaxial compression. Constr. Build. Mater. 2020, 263, 120649. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Xie, C.; Ali, M. Effectiveness of hybrid steel-basalt fiber reinforced concrete under compression. Case Stud. Constr. Mater. 2022, 16, e00941. [Google Scholar] [CrossRef]

- Xiao, J.; Li, J.; Zhang, C. Mechanical properties of recycled aggregate concrete under uniaxial loading. Cem. Concr. Res. 2005, 35, 1187–1194. [Google Scholar] [CrossRef]

- UNE-EN 1992-1-1-2013; Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings. Certification The-Spanish-Association-for-Standardization-and Spain: Madrid, Spain, 2013.

- Ning, X.; Ding, Y. Effect of Steel Fiber on the Damage Constitutive Model of Concrete under Uniaxial Compression. J. Build. Mater. 2015, 18, 214–220. [Google Scholar]

- Swamy, R.N.; Sa’ad, A. Deformation and ultimate strength in flexure of reinforced beams made with steel fibre concrete. J. Am. Concr. Inst. 1981, 78, 395–405. [Google Scholar]

- Narayanan, R.; Darwish IY, S. Use of steel fibers as shear reinforcement. Aci Struct. J. 1987, 84, 216–227. [Google Scholar]

- Cai, X.; Xu, S. Experimental measurement and evaluation indexes of toughness properties for UHTCC under uniaxial compression. Eng. Mech. 2010, 27, 218–224+239. [Google Scholar]

- Ye, P.; Chen, Z.; Su, W. Mechanical properties of fully recycled coarse aggregate concrete with polypropylene fiber. Case Stud. Constr. Mater. 2022, 17, e01352. [Google Scholar] [CrossRef]

- CECS 13: 2009; Standard Test Methods for Fiber Reinforced Concrete. China Planning Press: Beijing, China, 2010. (In Chinese)

| Index | Cement | SF |

|---|---|---|

| SiO2/% | 20.88 | 94.26 |

| Al2O3/% | 2.86 | 0.78 |

| Fe2O3/% | 4.66 | 0.66 |

| CaCl2/% | — | — |

| MgCl2/% | — | — |

| Na2O/% | 0.48 | 0.58 |

| MgO/% | 1.66 | 0.64 |

| K2O/% | 0.26 | 2.65 |

| CaO/% | 69.04 | 0.43 |

| MnO/% | 0.16 | — |

| Specific gravity/(kg·m−3) | 3120 | 2310 |

| Specific surface area/(m2·kg−1) | 334 | 18,954 |

| Loss on ignition/% | 1.5 | 2.28 |

| Parameters | NCA | RCA | S |

|---|---|---|---|

| Apparent density/(kg/m3) | 2660 | 2430 | 2720 |

| Bulk density/(kg/m3) | 1430 | 1170 | 1450 |

| Water absorption/% | 0.63 | 2.50 | 1.20 |

| Water absorption of 24 h/% | 1.19 | 5.24 | 2.80 |

| Crush index | 11.70 | 14.48 | — |

| Needle and flake particle content | 2.24 | 1.35 | — |

| Clay lump content | 0.6 | 0.2 | 0.12 |

| Fineness modulus | — | — | 2.6 |

| Length/mm | Density/(kg/m3) | Tensile Strength/MPa | Elasticity Modulus/GPa | Elongation at Break/% |

|---|---|---|---|---|

| 15~24 | 2650 | 3800~4840 | 79.3~93.1 | 3.1 |

| Mix | BF (%) | CA (kg/m3) | S (kg/m3) | Cement (kg/m3) | SF (kg/m3) | Water (kg/m3) | SP (kg/m3) |

| NC | 0 | 1211 | 682 | 364 | 27 | 195 | 1.5 |

| Specimen Number | Vf/% | l/d | r/% |

|---|---|---|---|

| BF0510R0 | 0.05 | 1000 | 0 |

| BF0510R50 | 0.10 | 1000 | 50 |

| BF0510R100 | 0.15 | 1000 | 100 |

| Constitutive Model | Type of Fiber | Parameters of Fiber | References |

|---|---|---|---|

| Ascending section: Descending section: | Steel–polypropylene fiber | Zhang Yuanyuan [27] | |

| Ascending section: Descending section: | Steel–carbon fiber | Vf | Wei Hui [28] |

| Ascending section: Descending section: | Steel fiber | - | Bing Liu [29] |

| Ascending section: Descending section: | Steel–basalt fiber | - | Mehran Khan [30] |

| Concrete | Fitted Equation | R2 | Equation No. |

|---|---|---|---|

| BFRC | 0.8859 | (4) | |

| BFRAC-50% | 0.8929 | (5) | |

| BFRAC-100% | 0.9006 | (6) |

| Specimen Number | T | Specimen Number | T | Specimen Number | T |

|---|---|---|---|---|---|

| NC | 2.828 | RAC-50% | 2.587 | RAC-100% | 2.478 |

| BFRC05-1200 | 2.826 | BFRC05-1200 | 2.832 | BFRC05-1200 | 2.818 |

| BFRC10-1200 | 2.858 | BFRC10-1200 | 2.862 | BFRC10-1200 | 2.850 |

| BFRC15-1200 | 2.924 | BFRC15-1200 | 2.930 | BFRC15-1200 | 2.926 |

| BFRC20-1200 | 3.148 | BFRC20-1200 | 3.155 | BFRC20-1200 | 3.137 |

| BFRC25-1200 | 3.033 | BFRC25-1200 | 3.035 | BFRC25-1200 | 3.029 |

| BFRC30-1200 | 2.800 | BFRC30-1200 | 2.799 | BFRC30-1200 | 2.784 |

| BFRC35-1200 | 2.588 | BFRC35-1200 | 2.585 | BFRC35-1200 | 2.572 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Y.; Liu, Y.; Wang, W.; Wang, K.; Zhang, Y.; Hou, J. Effect of Basalt Fiber on Uniaxial Compression-Related Constitutive Relation and Compressive Toughness of Recycled Aggregate Concrete. Materials 2023, 16, 1849. https://doi.org/10.3390/ma16051849

Guo Y, Liu Y, Wang W, Wang K, Zhang Y, Hou J. Effect of Basalt Fiber on Uniaxial Compression-Related Constitutive Relation and Compressive Toughness of Recycled Aggregate Concrete. Materials. 2023; 16(5):1849. https://doi.org/10.3390/ma16051849

Chicago/Turabian StyleGuo, Yaodong, Yuanzhen Liu, Wenjing Wang, Kaidi Wang, Yu Zhang, and Jingguang Hou. 2023. "Effect of Basalt Fiber on Uniaxial Compression-Related Constitutive Relation and Compressive Toughness of Recycled Aggregate Concrete" Materials 16, no. 5: 1849. https://doi.org/10.3390/ma16051849

APA StyleGuo, Y., Liu, Y., Wang, W., Wang, K., Zhang, Y., & Hou, J. (2023). Effect of Basalt Fiber on Uniaxial Compression-Related Constitutive Relation and Compressive Toughness of Recycled Aggregate Concrete. Materials, 16(5), 1849. https://doi.org/10.3390/ma16051849