Composite Cold-Formed Steel Beams with Diagonal Rebars for Earthquake-Resistant Buildings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Cold-Formed Steel and Rebars

2.2. Fly-Ash Concrete

2.3. Fabrication of CFS Beams

3. Experimental Investigation

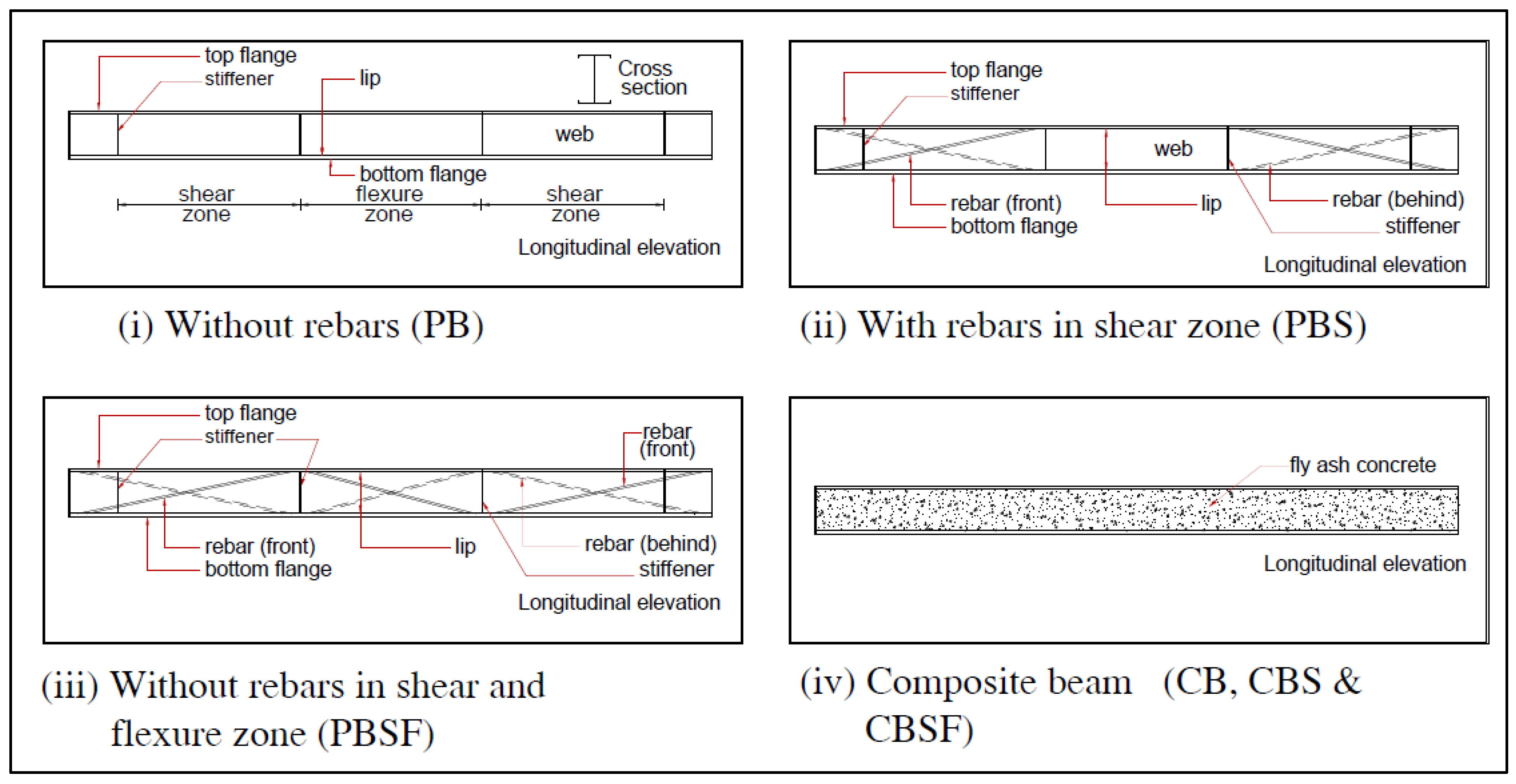

3.1. Specimen Details

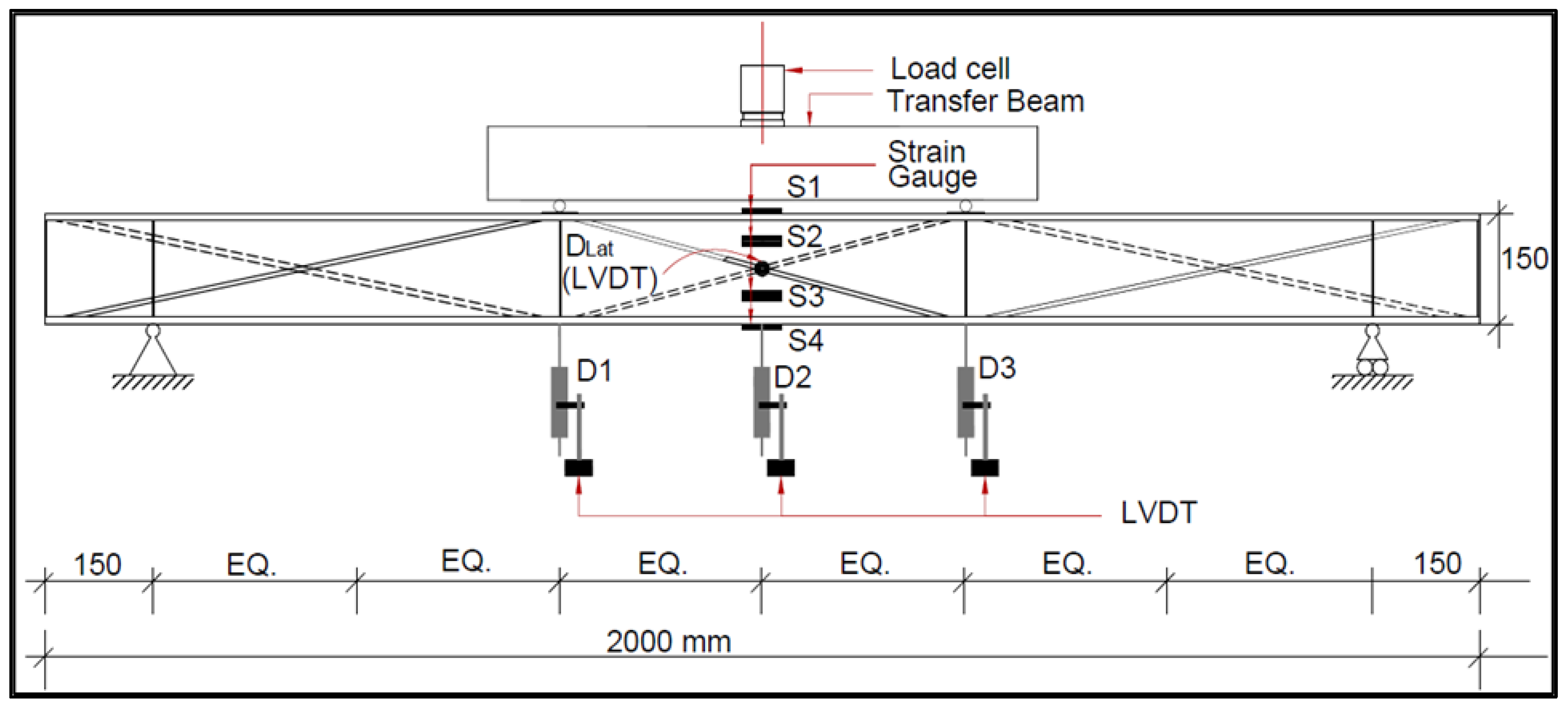

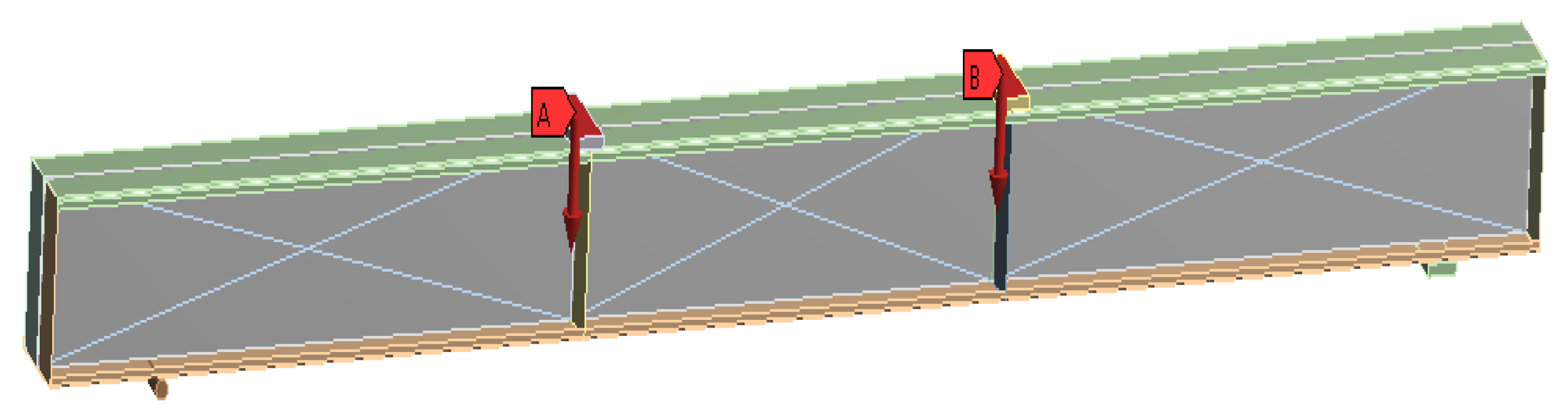

3.2. Test Set-Up

4. Results and Discussion

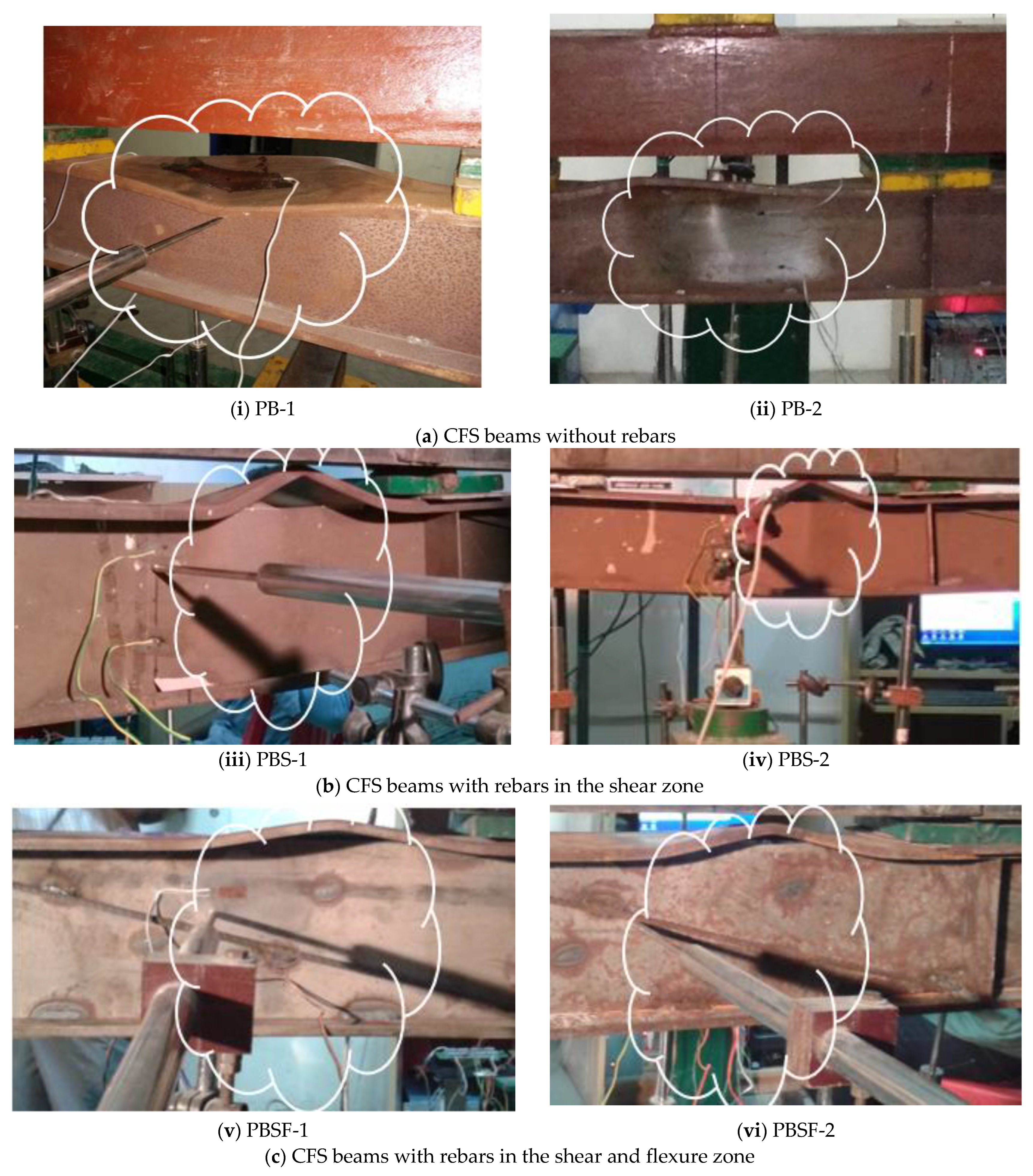

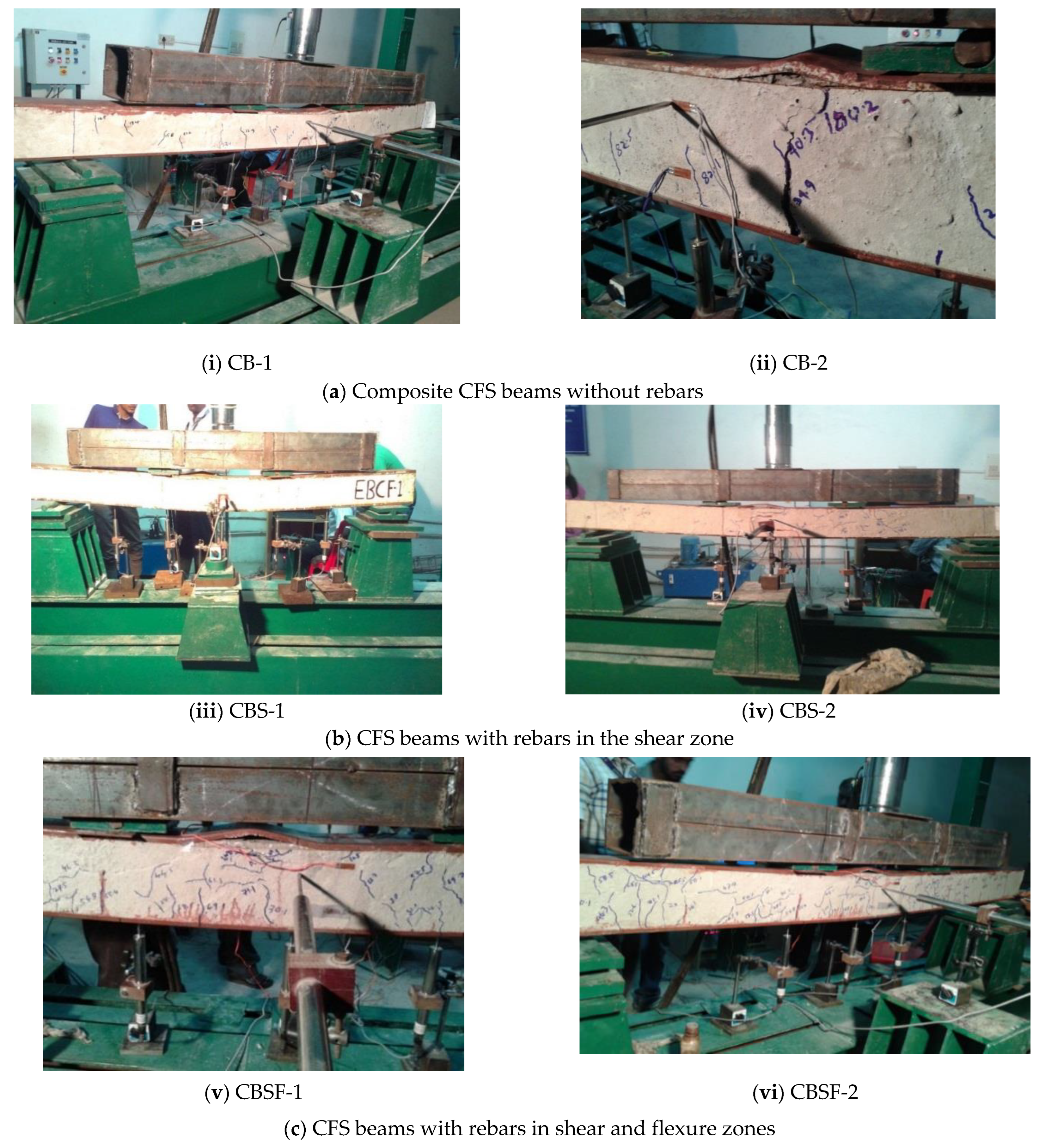

4.1. Failure Modes

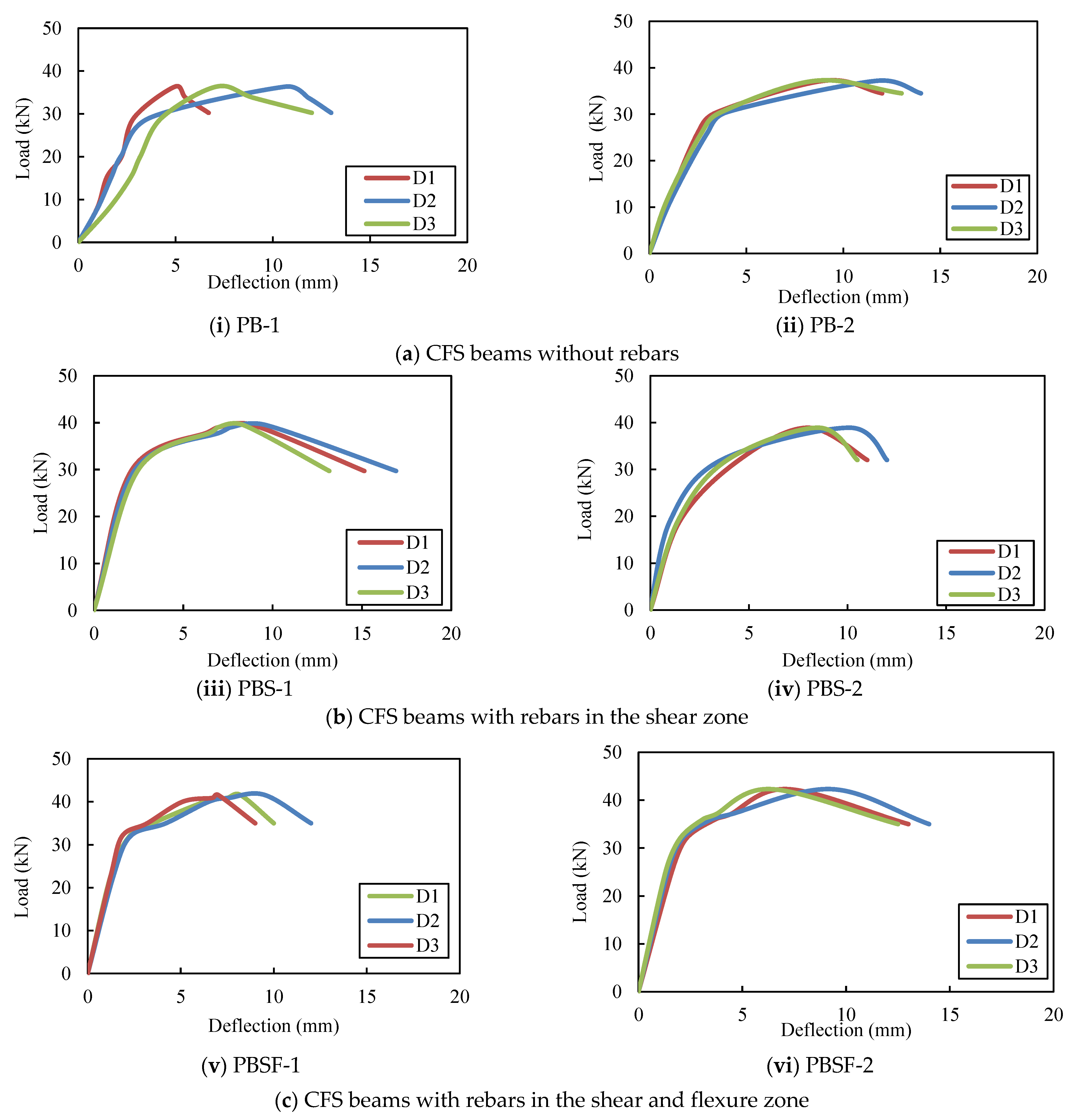

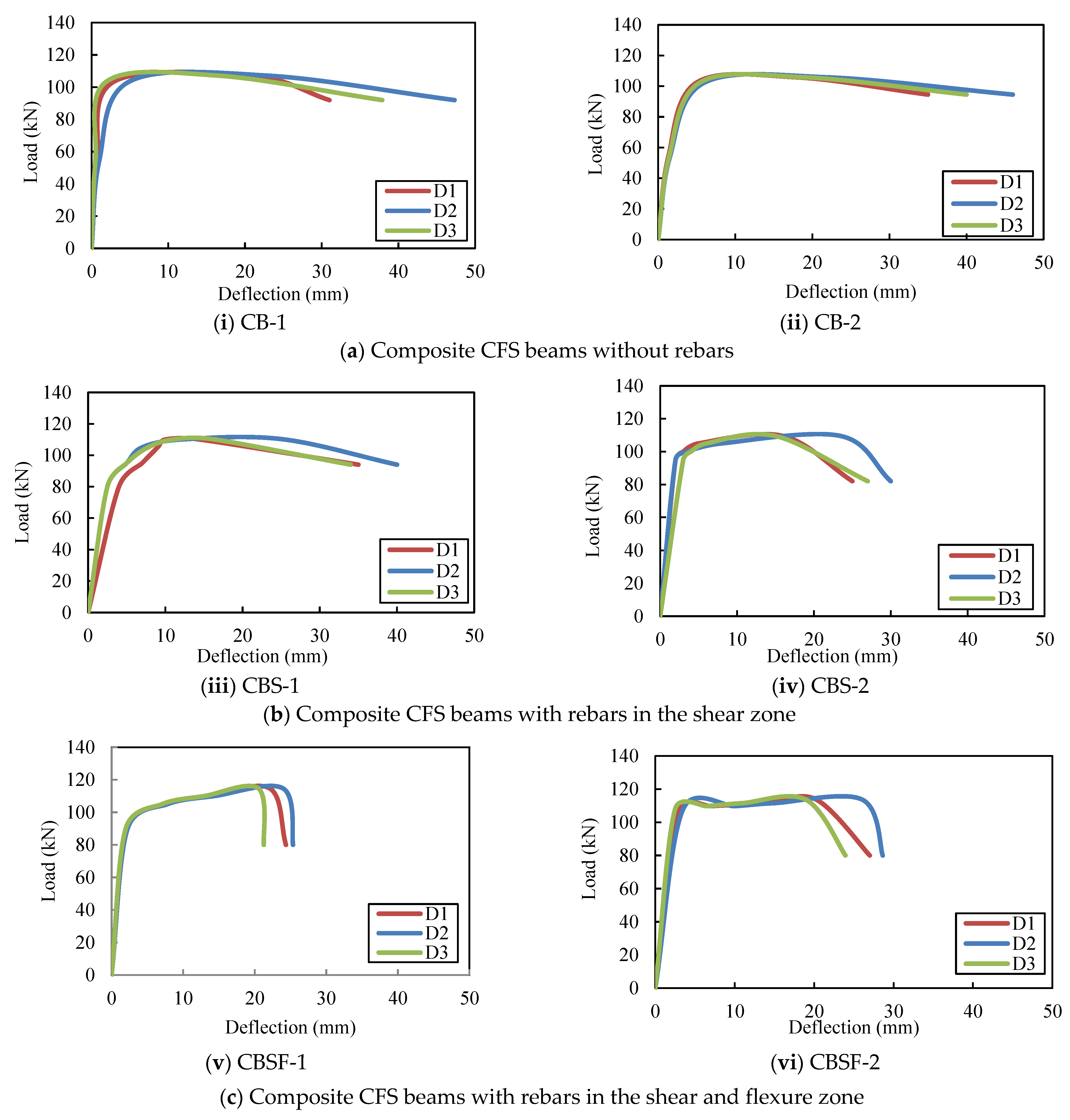

4.2. Load–Deflection Relationships

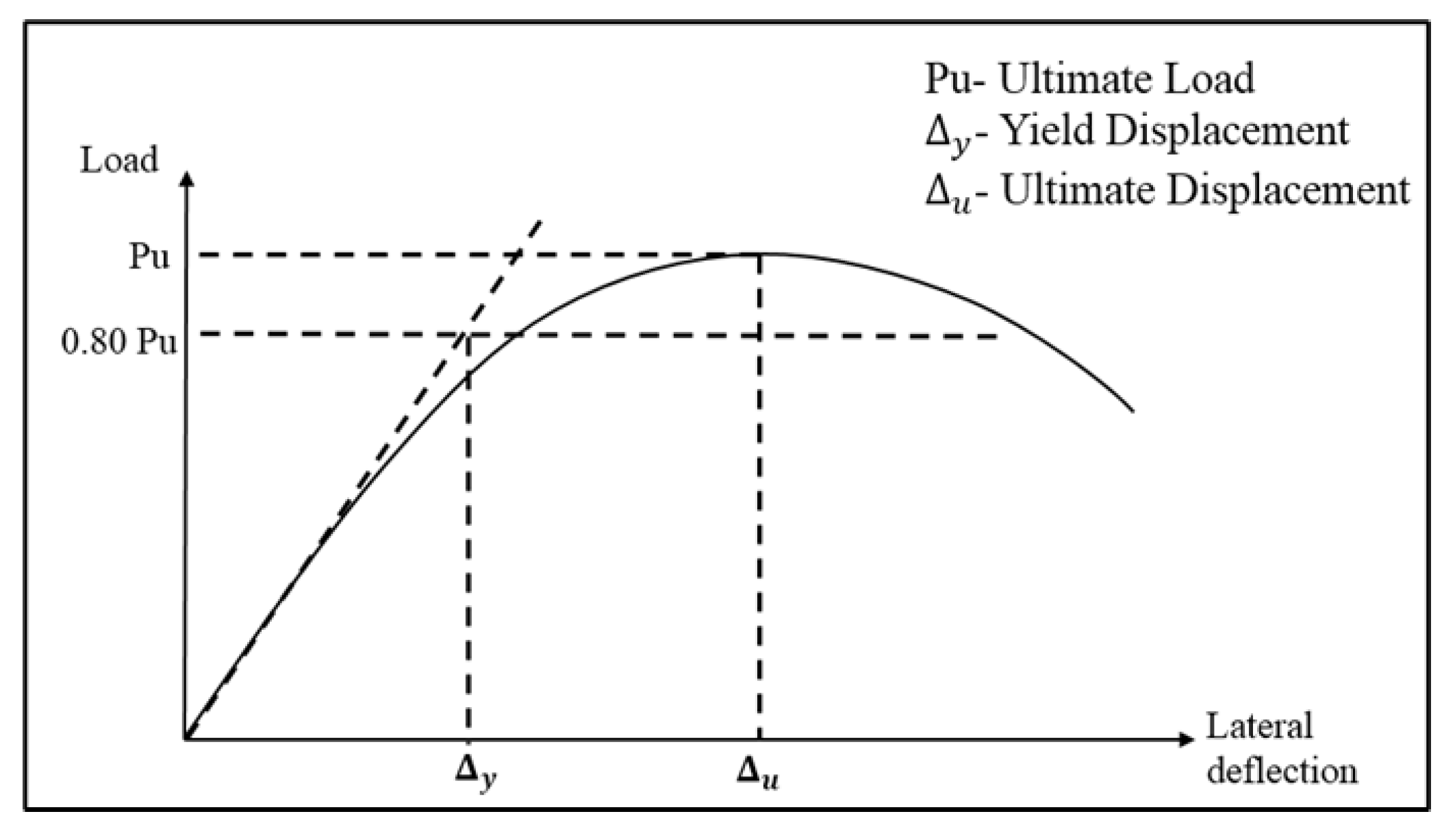

4.3. Ductility of CFS Beams

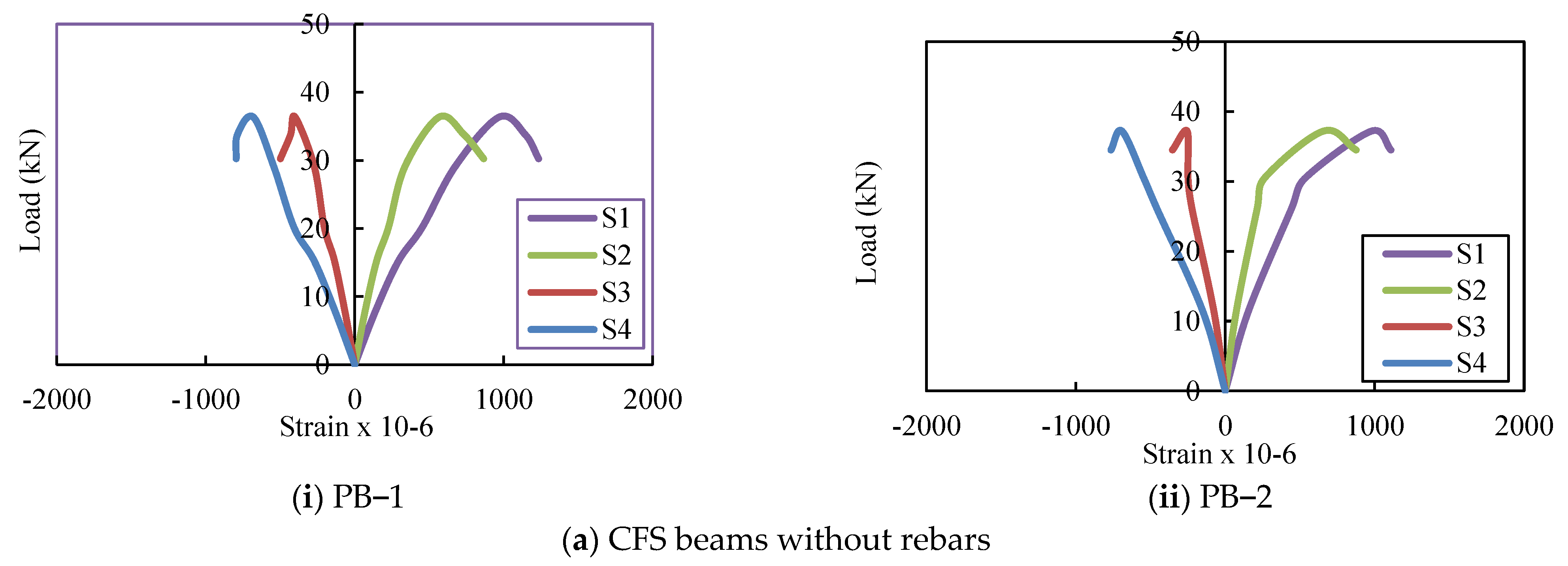

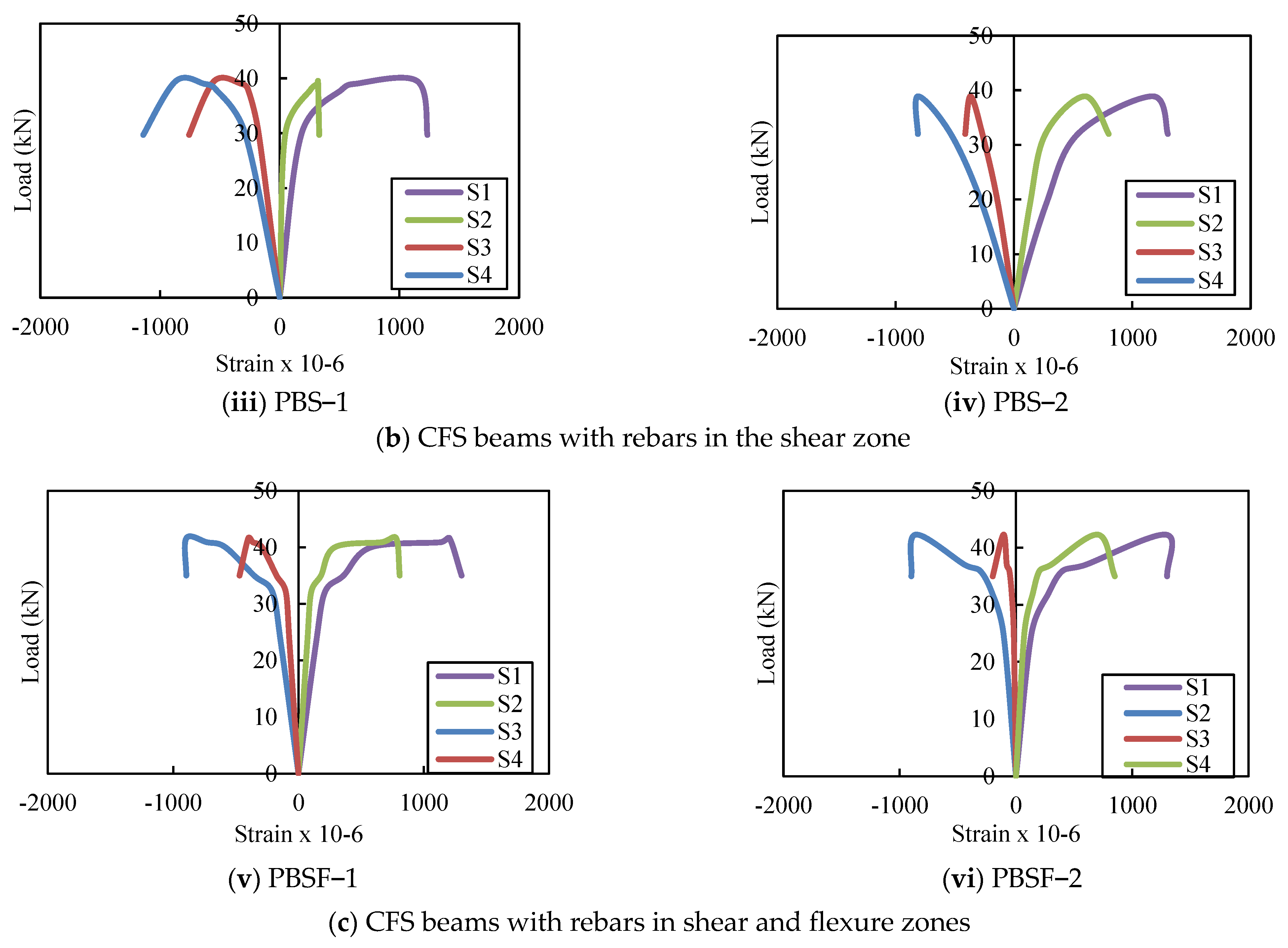

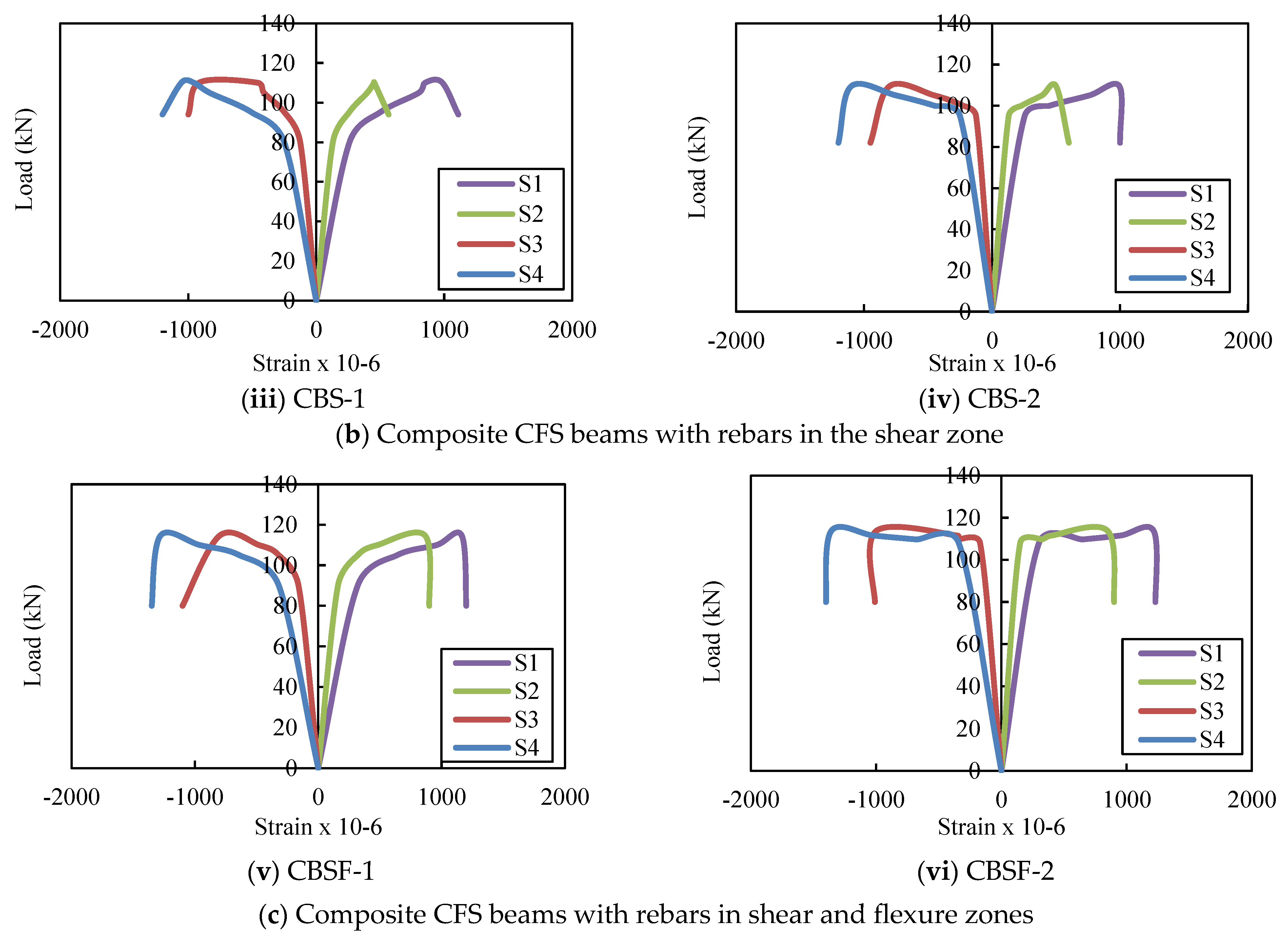

4.4. Load–Strain Relationship

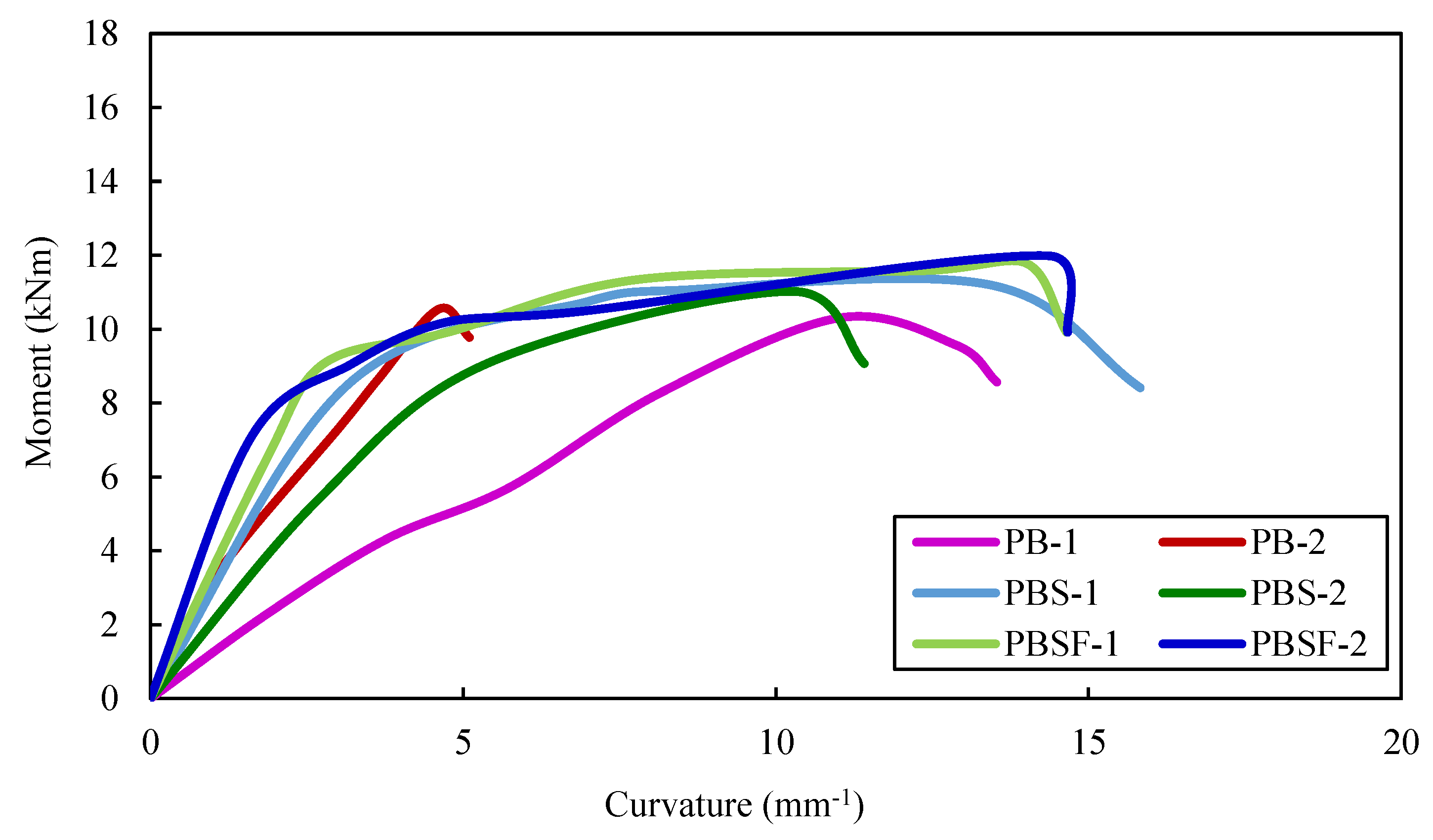

4.5. Moment vs. Curvature Relationships

- εc—compressive strain at the top flange,

- εt—tensile strain at the bottom flange,

- d—depth of the beam.

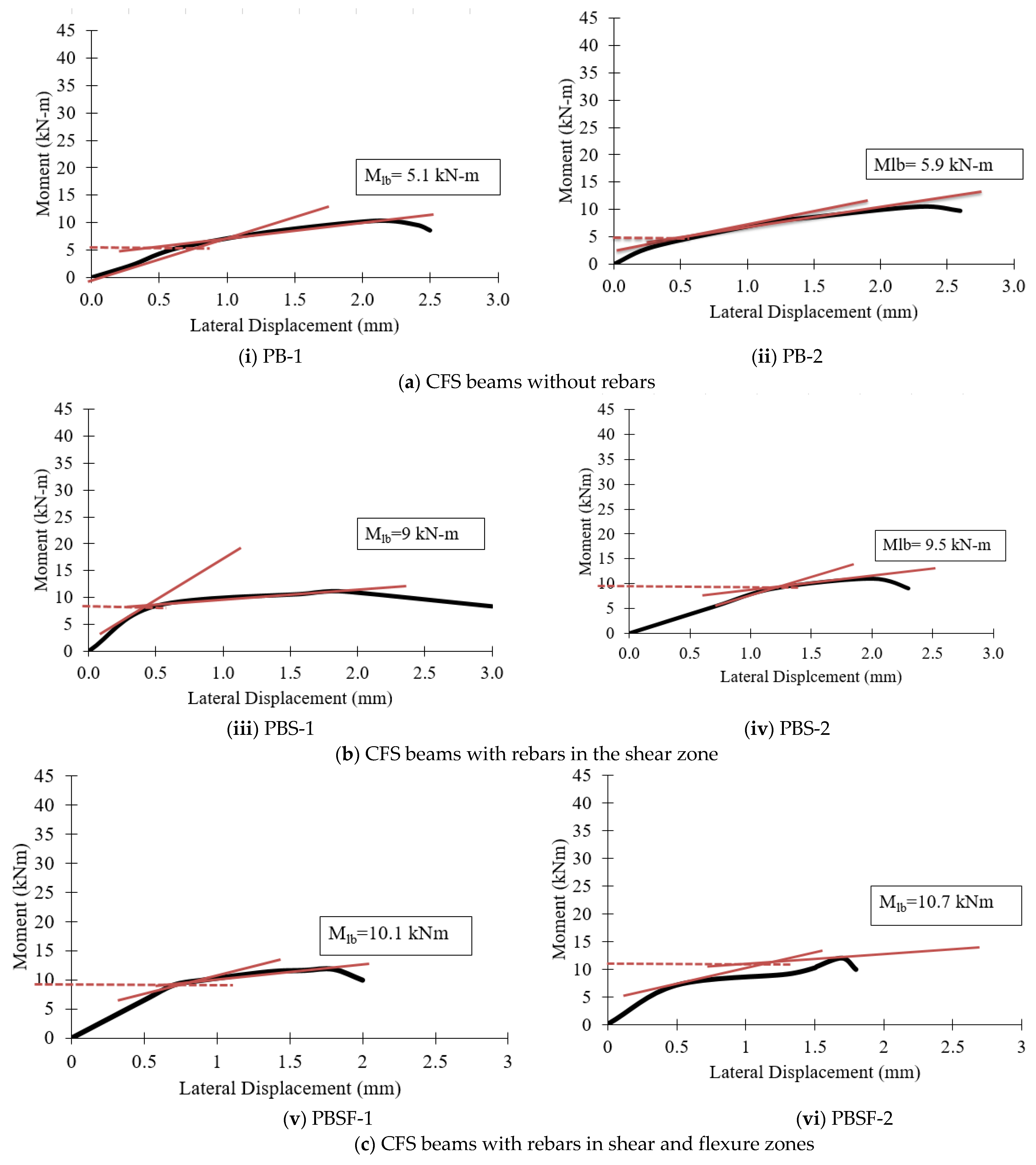

4.6. Lateral Buckling Resistance

5. Finite Element Analysis of CFS Beams

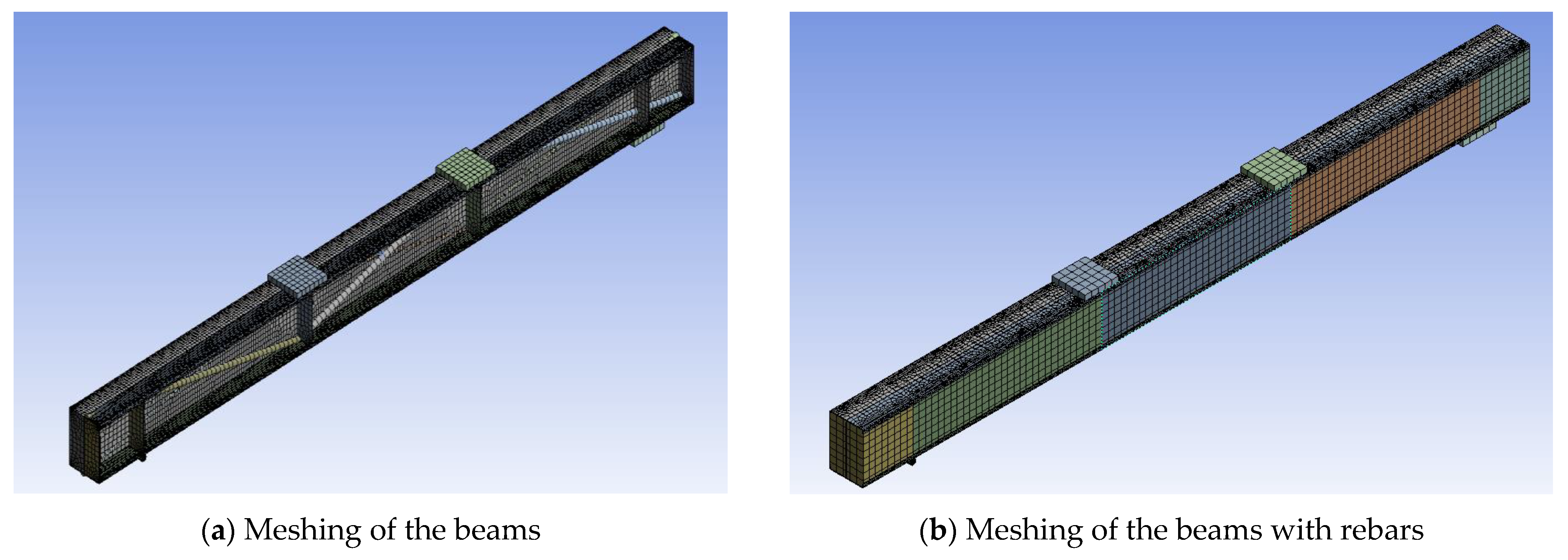

5.1. Details of the Model

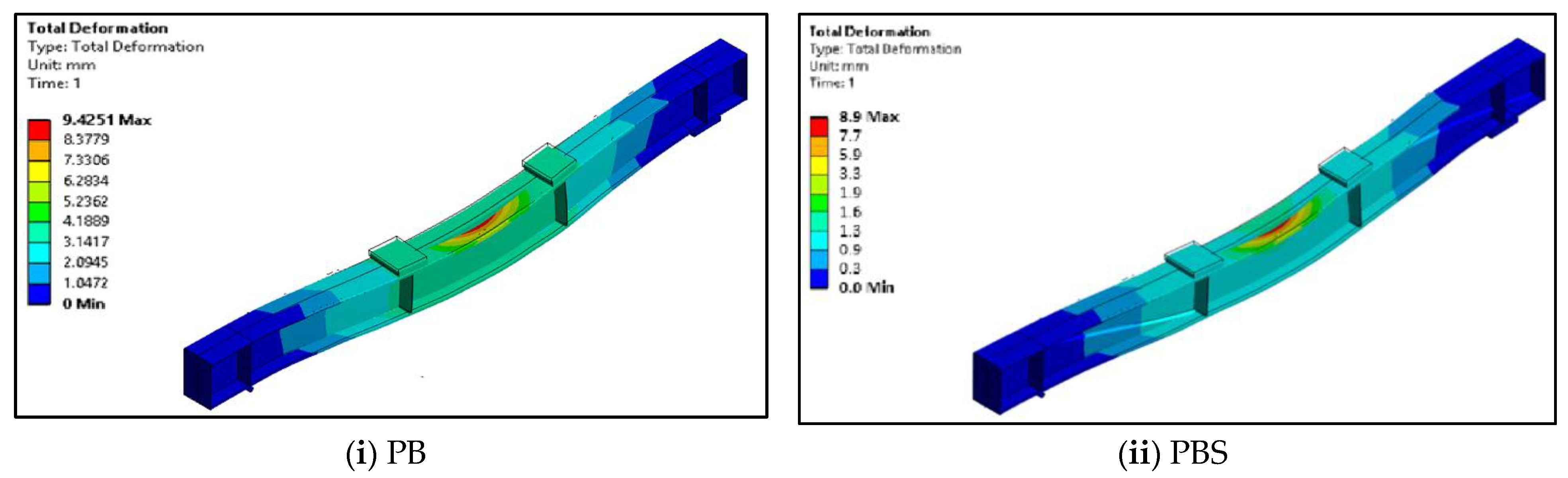

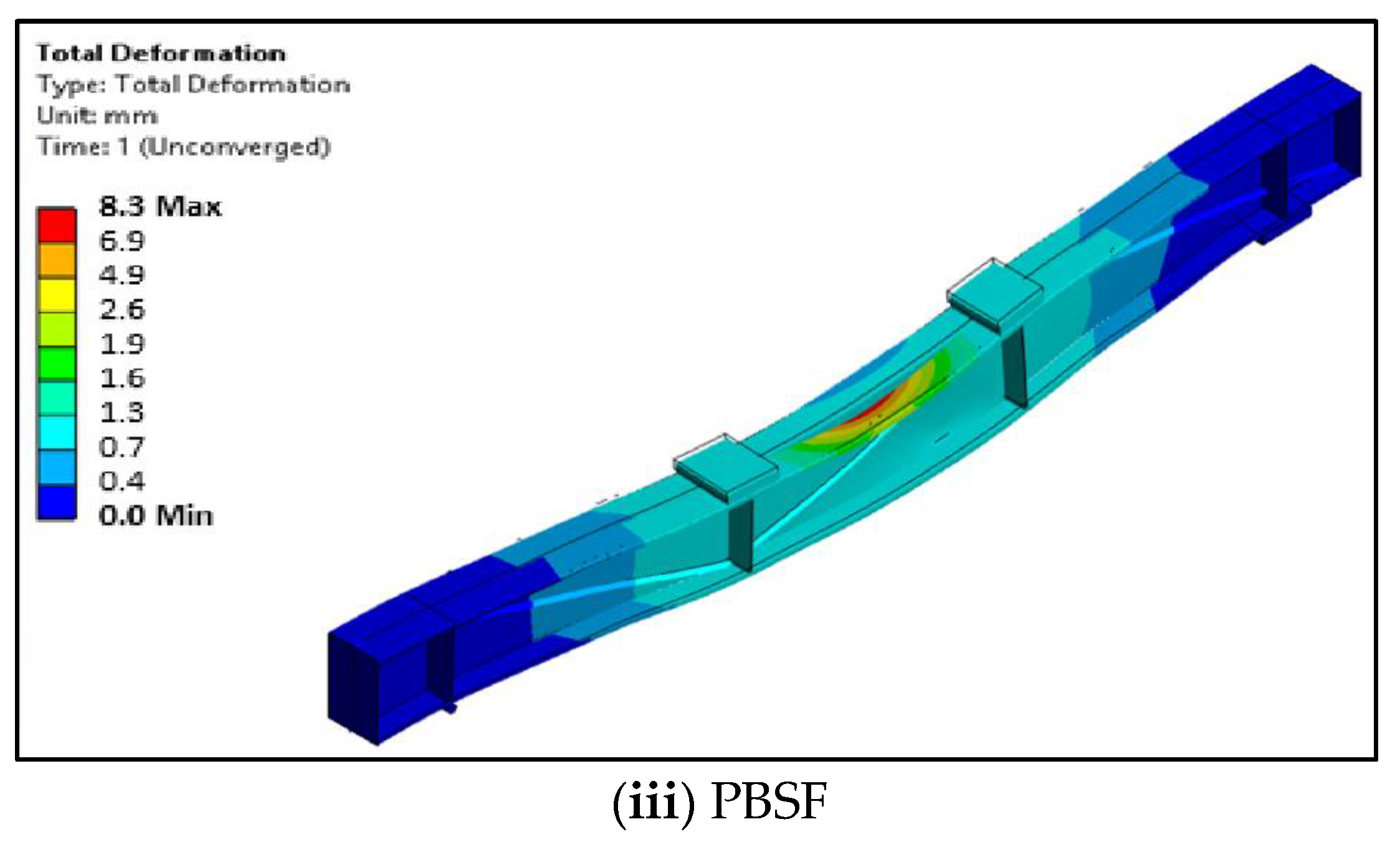

5.2. Deformed Shapes of CFS Beams

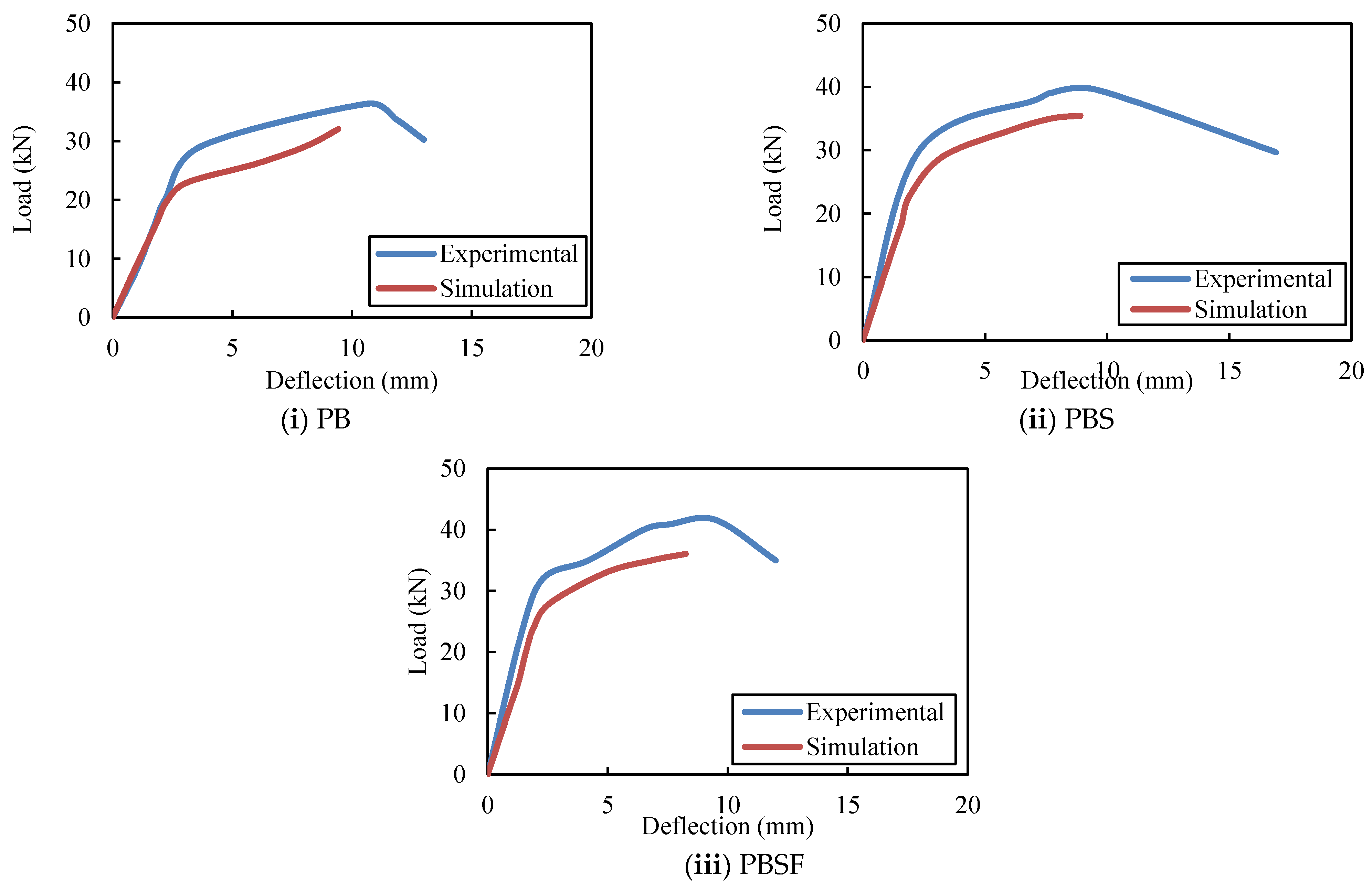

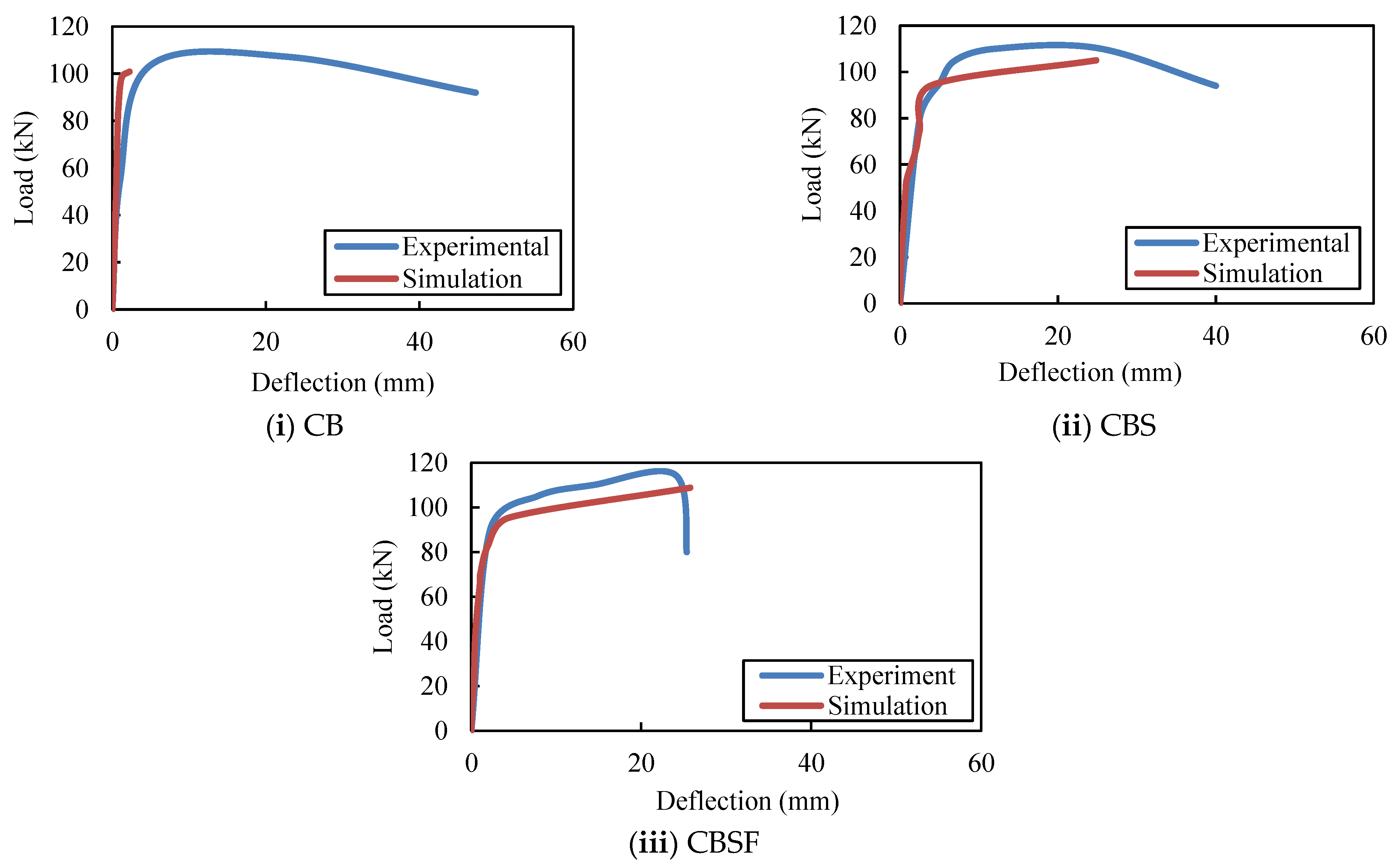

5.3. Comparison of the Experimental Results with the FE Results

5.4. Performance Assessment of the Composite CFS Beams

6. Conclusions

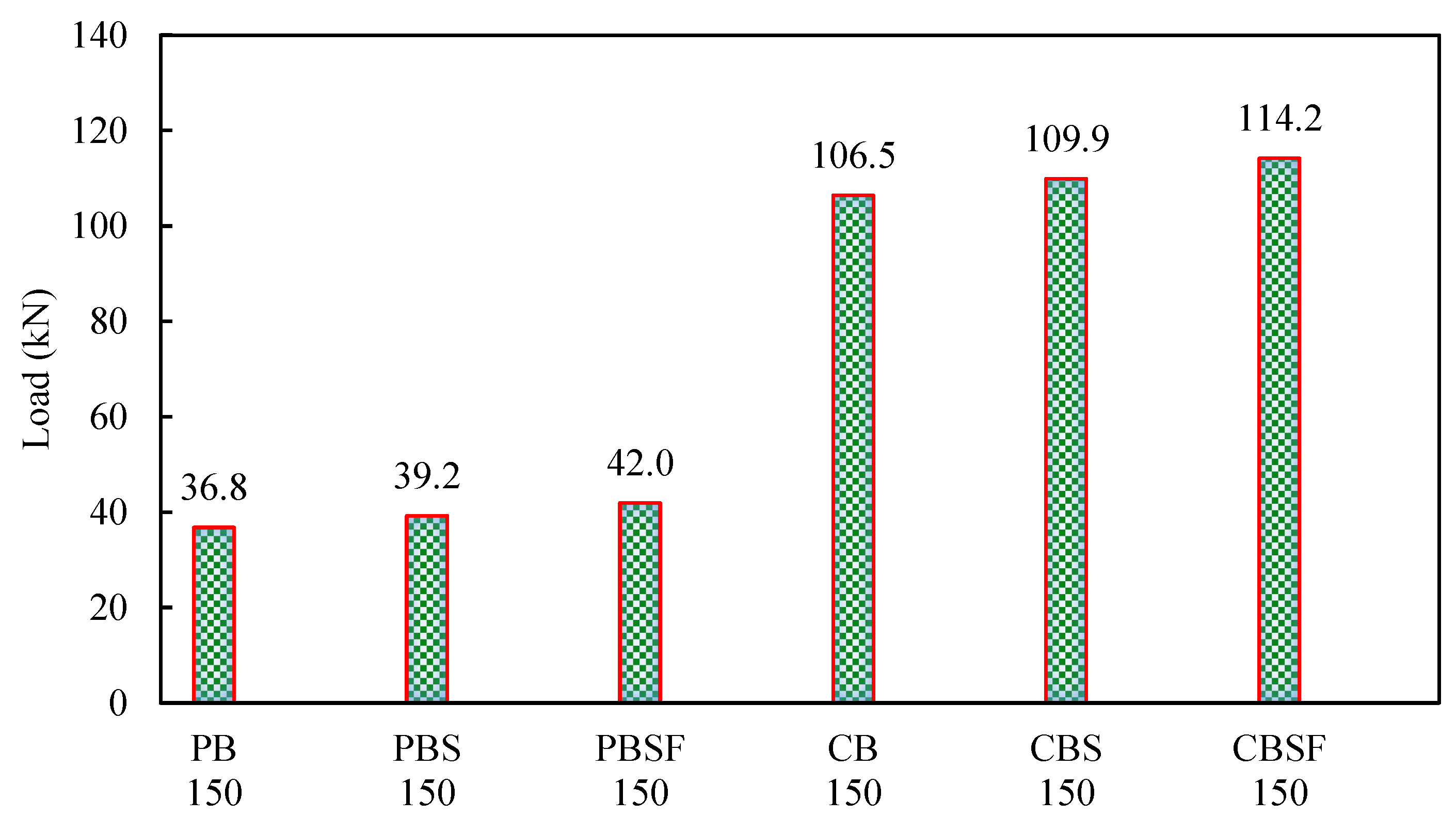

- When compared to plain beams without diagonal rebars, the ultimate load-carrying capacity of plain beams with diagonal rebars in the shear and flexure zones (PBSF) increased by 14% (PB).

- The addition of rebars to the PBSF beams’ shear and flexure zones increased ductility by 1.2 times that of the PB beam.

- When compared to PB beams, the lateral buckling capacity of PBSF beams increased by 66%.

- When compared to the composite beam without diagonal rebars, the ultimate load-carrying capacity of the composite beams with diagonal rebars in the shear and flexure zones (CBSF) increased by 7% (CB).

- The addition of rebars to the CBSF beams’ shear and flexure zones increased its ductility by 1.1 times that of the CB beam.

- When compared to CB beams, the lateral buckling capacity of CBSF beams increased by 10%.

- The beam CBSF’s ultimate load-carrying capacity was 2.7 times that of the beam PBSF.

- The finite element analysis results were in good agreement with the experimental investigation.

- Finally, it can be concluded that using the composite CFS beam, the building’s floor height can be reduced, earthquake-resistant structures can be built, and significant sustainability in the industry can be practised.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Irwan, J.; Hanizah, A.; Azmi, I.; Koh, H. Large-scale test of symmetric cold-formed steel (CFS)–concrete composite beams with BTTST enhancement. J. Constr. Steel Res. 2011, 67, 720–726. [Google Scholar] [CrossRef]

- Roy, K.; Ting, T.; Lau, H.H.; Lim, J. Experimental Investigation into the Behaviour of Back-to-Back Gapped Built-Up Cold-Formed Steel Channel Sections under Compression. In Proceedings of the Wei-Wen Yu International Specialty Conference on Cold-Formed Steel Structures 2018, Missouri University of Science and Technology, St. Louis, MI, USA, 7–8 November 2018. [Google Scholar]

- Ananthi, G.B.G.; Roy, K.; Lim, J.B.P. Experimental and numerical study of an innovative 4-channels cold-formed steel built-up column under axial compression. Steel Compos. Struct. 2022, 42, 513–538. [Google Scholar]

- Roy, K.; Lau, H.H.; Lim, J.B.P. Finite element modelling of back-to-back built-up cold-formed stainless-steel lipped channels under axial compression. Steel Compos. Struct. 2019, 33, 37–66. [Google Scholar]

- Chi, Y.; Roy, K.; Chen, B.; Fang, Z.; Uzzaman, A.; Ananthi, G.B.G.; Lim, J.B.P. Effect of web hole spacing on axial capacity of back-to-back cold-formed steel channels with edge-stiffened holes. Steel Compos. Struct. 2021, 40, 287–305. [Google Scholar]

- Mathieson, C.; Roy, K.; Clifton, G.C.; Ahmadi, A.; Lim, J.B.P. Failure mechanism and bearing capacity of cold-formed steel trusses with HRC connectors. Eng. Struct. 2021, 201, 109741. [Google Scholar] [CrossRef]

- Krishnan, L.; Dineshraj, C.S.; Prema, S. Experimental investigation of cold-formed steel section-flexural member with triangular web. IOSR J. Mech. Civ. Eng. 2015, 12, 36–39. [Google Scholar]

- Ye, J.; Hajirasouliha, I.; Becque, J.; Pilakoutas, K. Development of more efficient cold-formed steel channel sections in bending. Thin-Walled Struct. 2016, 101, 1–13. [Google Scholar] [CrossRef]

- Wang, L.; Young, B. Behavior of cold-formed steel built-up sections with intermediate stiffeners under bending. I: Tests and numerical validation. J. Struct. Eng. 2016, 142, 04015150. [Google Scholar] [CrossRef]

- Ungureanu, V.; Both, I.; Burca, M.; Grosan, M.; Neagu, C.; Dubina, D. Experimental Investigations on Built-Up Cold-Formed Steel Beams Connected by Resistance Spot Welding. In Proceedings of the 12th International Conference on Advances in Steel-Concrete Composite Structures ASCCS 2018, Valencia, Spain, 27–29 June 2018. [Google Scholar]

- Roy, K.; Lau, H.H.; Ting, T.C.H.; Chen, B.; Lim, J.B. Flexural behaviour of back-to-back built-up cold-formed steel channel beams: Experiments and finite element modelling. Structures 2021, 29, 235–253. [Google Scholar] [CrossRef]

- Irwan, J.M.; Hanizah, A.; Azmi, I. Test of shear transfer enhancement in symmetric cold-formed steel–concrete composite beams. J. Constr. Steel Res. 2009, 65, 2087–2098. [Google Scholar] [CrossRef]

- Tahir, M.; Shek, P.N.; Tan, C.S. Push-off tests on pin-connected shear studs with composite steel–concrete beams. Constr. Build. Mater. 2009, 23, 3024–3033. [Google Scholar] [CrossRef]

- Tullini, N.; Minghini, F. Nonlinear analysis of composite beams with concrete-encased steel truss. J. Constr. Steel Res. 2013, 91, 1–13. [Google Scholar] [CrossRef]

- Laila, L.R.; Gurupatham, B.G.A.; Roy, K.; Lim, J.B.P. Effect of super absorbent polymer on microstructural and mechanical properties of concrete blends using granite pulver. Struct. Concr. 2020, 22, E898–E915. [Google Scholar] [CrossRef]

- Rajamony Laila, L.; Gurupatham, B.G.A.; Roy, K.; Lim, J.B.P. Influence of Super Absorbent Polymer on Mechanical, Rheological, Durability, and Microstructural Properties of Self-Compacting Concrete Using Non-Biodegradable Granite Pulver. Struct. Concr. 2020, 22, E1093–E1116. [Google Scholar] [CrossRef]

- Preetha, R.; Joanna, P.S.; Rooby, J.; Pillai, C.S. Ductility behavior of reinforced high volume flyash concrete beams. Int. J. Sci. Eng. Res. 2013, 4, 123–126. [Google Scholar]

- Soman, M.; Sobha, K. Strength and behaviour of high-volume fly ash concrete, International Journal of Innovative Research in Science. Eng. Technol. 2014, 3, 12416–12424. [Google Scholar]

- Arezoumandi, M.; Ortega, C.A.; Volz, J.S. Flexural behavior of high-volume fly ash concrete beams: Experimental Study. Transp. Res. Rec. 2015, 2508, 22–30. [Google Scholar] [CrossRef]

- Lisantono, A.; Wigroho, H.Y.; Purba, R.A. Shear Behavior of High-volume Fly Ash Concrete as Replacement of Portland Cement in RC Beam. Procedia Eng. 2017, 171, 80–87. [Google Scholar] [CrossRef]

- Krishna Teja, K.; Kameswara Rao, B. Strength and durability of high volume flyash concrete. Int. J. Civ. Eng. Technol. 2018, 9, 109–116. [Google Scholar]

- Parvati, T.S.; Namitha Jacob Samuel, J.; Joanna, P.S. Behavior of high volume fly ash concrete beams. Int. J. Civ. Eng. Technol. 2018, 9, 472–479. [Google Scholar]

- Hashmi, A.F.; Shariq, M.; Baqi, A. Flexural performance of high volume fly ash reinforced concrete beams and slabs. Structures 2020, 25, 868–880. [Google Scholar] [CrossRef]

- Lakkavalli, B.S.; Liu, Y. Experimental study of composite cold-formed steel C-section floor joists. J. Constr. Steel Res. 2006, 62, 995–1006. [Google Scholar] [CrossRef]

- Lee, Y.L.; Tan, C.S.; Lee, Y.H.; Mohammad, S.; Tahir, M.M.; Shek, P.N. Effective Steel Area of Fully Embedded Cold-Formed Steel Frame in Composite Slab System under Pure Bending. Appl. Mech. Mater. 2013, 284–287, 1300–1304. [Google Scholar] [CrossRef]

- Ji, G.; Ouyang, Z.; Li, G. Effects of bondline thickness on Mode-I nonlinear interfacial fracture of laminated composites: An experimental study. Compos. Part B Eng. 2013, 47, 1–7. [Google Scholar] [CrossRef]

- Xu, C.; Sugiura, K. Analytical investigation on failure development of group studs shear connector in push-out specimen under biaxial load action. Eng. Fail. Anal. 2014, 37, 75–85. [Google Scholar] [CrossRef]

- Sohel, K.; Liew, R.; Yan, J.-B.; Zhang, M.; Chia, K. Behavior of Steel–Concrete–Steel sandwich structures with lightweight cement composite and novel shear connectors. Compos. Struct. 2012, 94, 3500–3509. [Google Scholar] [CrossRef]

- Zhang, K.; Varma, A.H.; Malushte, S.R.; Gallocher, S. Effect of shear connectors on local buckling and composite action in steel concrete composite walls. Nucl. Eng. Des. 2014, 269, 231–239. [Google Scholar] [CrossRef]

- Qureshi, J.; Lam, D.; Ye, J. Effect of shear connector spacing and layout on the shear connector capacity in composite beams. J. Constr. Steel Res. 2011, 67, 706–719. [Google Scholar] [CrossRef]

- Nakamura, S.-I. Bending Behavior of Composite Girders with Cold Formed Steel U Section. J. Struct. Eng. 2002, 128, 1169–1176. [Google Scholar] [CrossRef]

- Kvočáka, V.; Drab, L. Partially-Encased Composite Thin-Walled Steel Beams. Procedia Eng. 2012, 40, 91–95. [Google Scholar] [CrossRef]

- Ipe, T.V.; Bai, H.S.; Vani, K.M.; Iqbal, M.M.Z. Flexural behavior of cold-formed steel concrete composite beams. Steel Compos. Struct. 2013, 14, 105–120. [Google Scholar] [CrossRef]

- Dar, M.A.; Subramanian, N.; Anbarasu, M.; Dar, A.R.; Lim, J.B. Structural performance of cold-formed steel composite beams. Steel Compos. Struct. 2018, 7, 545–554. [Google Scholar]

- Manikandan, P.; Arun, N. Behaviour of Partially Closed Stiffened Cold-Formed Steel Compression Member. Arab. J. Sci. Eng. 2016, 41, 3865–3875. [Google Scholar] [CrossRef]

- Anju, T.; Smitha, K. Finite Element Analysis of Composite Beam with Shear Connectors. Procedia Technol. 2016, 24, 179–187. [Google Scholar] [CrossRef]

- Turmo, J.; Lozano-Galant, J.; Mirambell, E.; Xu, D. Modeling composite beams with partial interaction. J. Constr. Steel Res. 2015, 114, 380–393. [Google Scholar] [CrossRef]

- Wehbe, N.; Wehbe, A.; Dayton, L.; Sigl, A. Development of Concrete/Cold Formed Steel Composite Flexural Members. In Proceedings of the Structures Congress 2011, Las Vegas, NV, USA, 14–16 April 2011; pp. 3099–3109. [Google Scholar] [CrossRef]

- Rethnasamy, C.; Rajagopal, T.; Muthuraj, H. Bending behavior, deformability and strength analysis of Prefabricated Cage Reinforced Composite beams. Constr. Build. Mater. 2013, 38, 482–490. [Google Scholar] [CrossRef]

- ASTM A370 Ed.2020; Standard Methods and Definitions for Mechanical Testing of Steel Products. ASTM International: West Conshohocken, PA, USA, 2020.

- IS 11384: 1985; Code of Practice for Composite Construction in Structural Steel and Concrete. Bureau of Indian Standards: New Delhi, India, 1985.

- IS 800: 2007; Indian Standard Code of Practice for General Construction in Steel. Bureau of Indian Standards: New Delhi, India, 2007.

- Park, R. Ductility evaluation from laboratory and analytical testing. In Proceedings of the Ninth World Conference on Earthquake Engineering, Tokyo-Kyoto, Japan, 2–9 August 1988. [Google Scholar]

- Divahar, R.; Joanna, P.S. Numerical simulation experimental investigation on static behavior of cold formed steel beam with trapezoidally corrugated web by varying depth-thickness ratio. Asian J. Civ. Eng. 2018, 19, 121–137. [Google Scholar] [CrossRef]

- Denan, F.; Osman, M.H.; Saad, S. The study of lateral torsional buckling behaviour of beam with trapezoid web steel section by experimental and finite element analysis. Int. J. Res. Rev. Appl. Sci. 2010, 2, 232–240. [Google Scholar]

- ANSYS 2022-R1, Manual Set; ANSYS Inc.: Canonsburg, PA, USA, 2022.

- Ravi, D.; Ponsubbiah, A.R.; Prabha, S.S.; Saratha, J.P. Experimental, analytical and numerical studies on concrete encased trapezoidally web profiled cold-formed steel beams by varying depth-thickness ratio. Front. Struct. Civ. Eng. 2020, 14, 930–946. [Google Scholar] [CrossRef]

- Chen, Y.; Fu, K.; Jiang, B. Modelling localised progressive failure of composite sandwich panels under in-plane compression. Thin-Walled Struct. 2023, 184, 110552. [Google Scholar] [CrossRef]

- Chen, Y.; Hou, S.; Fu, K.; Han, X.; Ye, L. Low-velocity impact response of composite sandwich structures: Modelling and experiment. Compos. Struct. 2017, 168, 322–334. [Google Scholar] [CrossRef]

| Designation | Description |

|---|---|

| PB-1 and 2 | Plain beams without diagonal rebars |

| PBS-1 and 2 | Plain beams with rebars in the flexure zone |

| PBSF-1 and 2 | Plain beams with rebars in shear and flexure zones |

| CB-1 and 2 | Composite beams without diagonal rebars |

| CBS-1 and 2 | Composite beams with rebars in the flexure zone |

| CBSF-1 and 2 | Composite beams with rebars in shear and flexure zones |

| Specification of CFS Beam Specimens | Ultimate Load (kN) | Deflection at Ultimate Load (mm) | Deflection at Yield Load (mm) |

|---|---|---|---|

| PB-1 | 36.4 | 10.7 | 4.3 |

| PB-2 | 37.2 | 11.7 | 3.7 |

| PBS-1 | 39.5 | 9.6 | 2.5 |

| PBS -2 | 38.9 | 10.1 | 3.1 |

| PBSF-1 | 41.6 | 9.5 | 2.3 |

| PBSF-2 | 42.3 | 9.3 | 2.0 |

| CB-1 | 107.1 | 23.0 | 2.5 |

| CB-2 | 105.8 | 22.0 | 3.2 |

| CBS-1 | 110.3 | 25.0 | 2.5 |

| CBS-2 | 109.5 | 23.5 | 2.9 |

| CBSF-1 | 114.6 | 24.0 | 2.0 |

| CBSF-2 | 113.7 | 26.0 | 2.3 |

| Sl. No. | Beam Number | Deflection at Yield Load (mm) | Deflection at Ultimate Load (mm) | Displacement Ductility Ratio | Average Displacement Ductility Ratio |

|---|---|---|---|---|---|

| 1 | PB-1 | 4 | 10.7 | 2.7 | 2.6 |

| 2 | PB-2 | 4.6 | 11.7 | 2.5 | |

| 3 | PBS-1 | 3.3 | 9.6 | 2.9 | 2.9 |

| 4 | PBS-2 | 3.6 | 10.1 | 2.8 | |

| 5 | PBSF-1 | 3 | 9.5 | 3.2 | 3.2 |

| 6 | PBSF-2 | 2.8 | 9.3 | 3.3 | |

| 7 | CB-1 | 3 | 23 | 7.7 | 7.5 |

| 8 | CB-2 | 3 | 22 | 7.3 | |

| 9 | CBS-1 | 3.2 | 25 | 7.8 | 7.7 |

| 10 | CBS-2 | 3.1 | 23.5 | 7.6 | |

| 11 | CBSF-1 | 2.9 | 24 | 8.3 | 8.1 |

| 12 | CBSF-2 | 3.25 | 26 | 8.0 |

| Beam | Ult. Moment (kNm) | Deflection at Max Load (mm) | Ultimate Compressive Strain (εc) % | Ultimate Tensile Strain (εt) % | Curvature at the Ultimate Moment (m−1) | Ductility Ratio |

|---|---|---|---|---|---|---|

| PB-1 | 36.4 | 10.7 | 970.3 | 681.1 | 11.0 | 2.7 |

| PB-2 | 37.2 | 11.7 | 978.9 | 691.3 | 9.6 | 2.5 |

| PBS-1 | 39.5 | 9.6 | 1148.4 | 868.2 | 13.4 | 2.9 |

| PBS-2 | 38.9 | 10.1 | 1170.1 | 810.3 | 10.3 | 2.8 |

| PBSF-1 | 41.6 | 9.5 | 1205.3 | 894.6 | 14.0 | 3.2 |

| PBSF-2 | 42.3 | 9.3 | 1289.4 | 863.6 | 14.4 | 3.3 |

| CB-1 | 107.1 | 23.0 | 710.6 | 1020.4 | 11.5 | 7.7 |

| CB-2 | 105.8 | 22.0 | 708.4 | 1015.6 | 11.4 | 7.3 |

| CBS-1 | 110.3 | 25.0 | 981.3 | 1047.7 | 13.5 | 7.8 |

| CBS-2 | 109.5 | 23.5 | 994.7 | 1098.6 | 14.0 | 7.6 |

| CBSF-1 | 114.6 | 24.0 | 1164.1 | 1279.5 | 16.3 | 8.3 |

| CBSF-2 | 113.7 | 26.0 | 1216.7 | 1358.6 | 17.2 | 8.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samuel, J.; Nair, S.R.; Joanna, P.S.; Gurupatham, B.G.A.; Roy, K.; Lim, J.B.P. Composite Cold-Formed Steel Beams with Diagonal Rebars for Earthquake-Resistant Buildings. Materials 2023, 16, 3002. https://doi.org/10.3390/ma16083002

Samuel J, Nair SR, Joanna PS, Gurupatham BGA, Roy K, Lim JBP. Composite Cold-Formed Steel Beams with Diagonal Rebars for Earthquake-Resistant Buildings. Materials. 2023; 16(8):3002. https://doi.org/10.3390/ma16083002

Chicago/Turabian StyleSamuel, James, Shalini Ramachandran Nair, Philip Saratha Joanna, Beulah Gnana Ananthi Gurupatham, Krishanu Roy, and James Boon Piang Lim. 2023. "Composite Cold-Formed Steel Beams with Diagonal Rebars for Earthquake-Resistant Buildings" Materials 16, no. 8: 3002. https://doi.org/10.3390/ma16083002