Optimization and Microstructural Studies on the Machining of Inconel 600 in WEDM Using Untreated and Cryogenically Treated Zinc Electrodes

Abstract

:1. Introduction

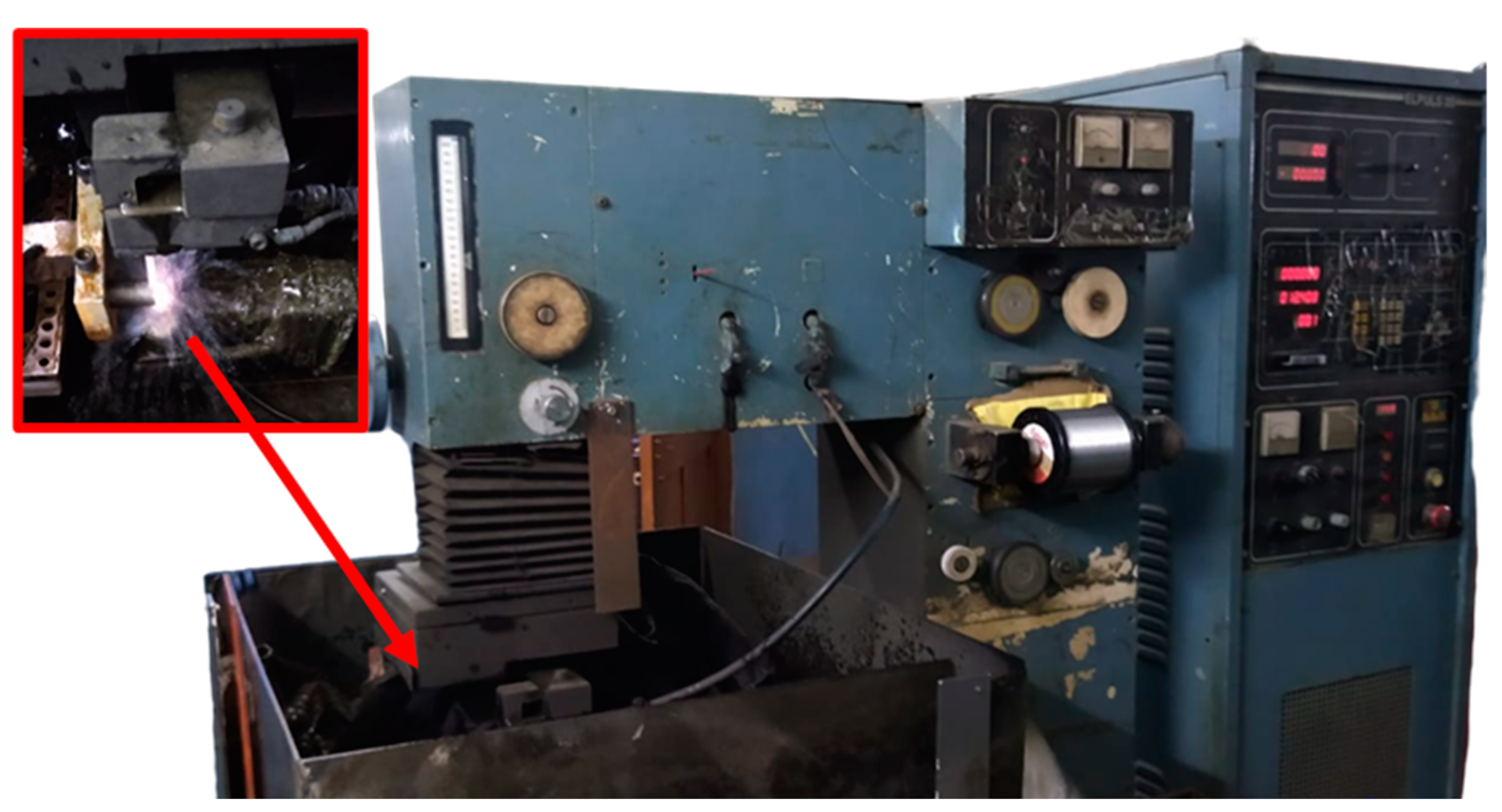

2. Materials and Methods

3. Results

3.1. S/N Ratio Analysis

3.2. Analysis of Variance

3.3. Microstructural Analysis

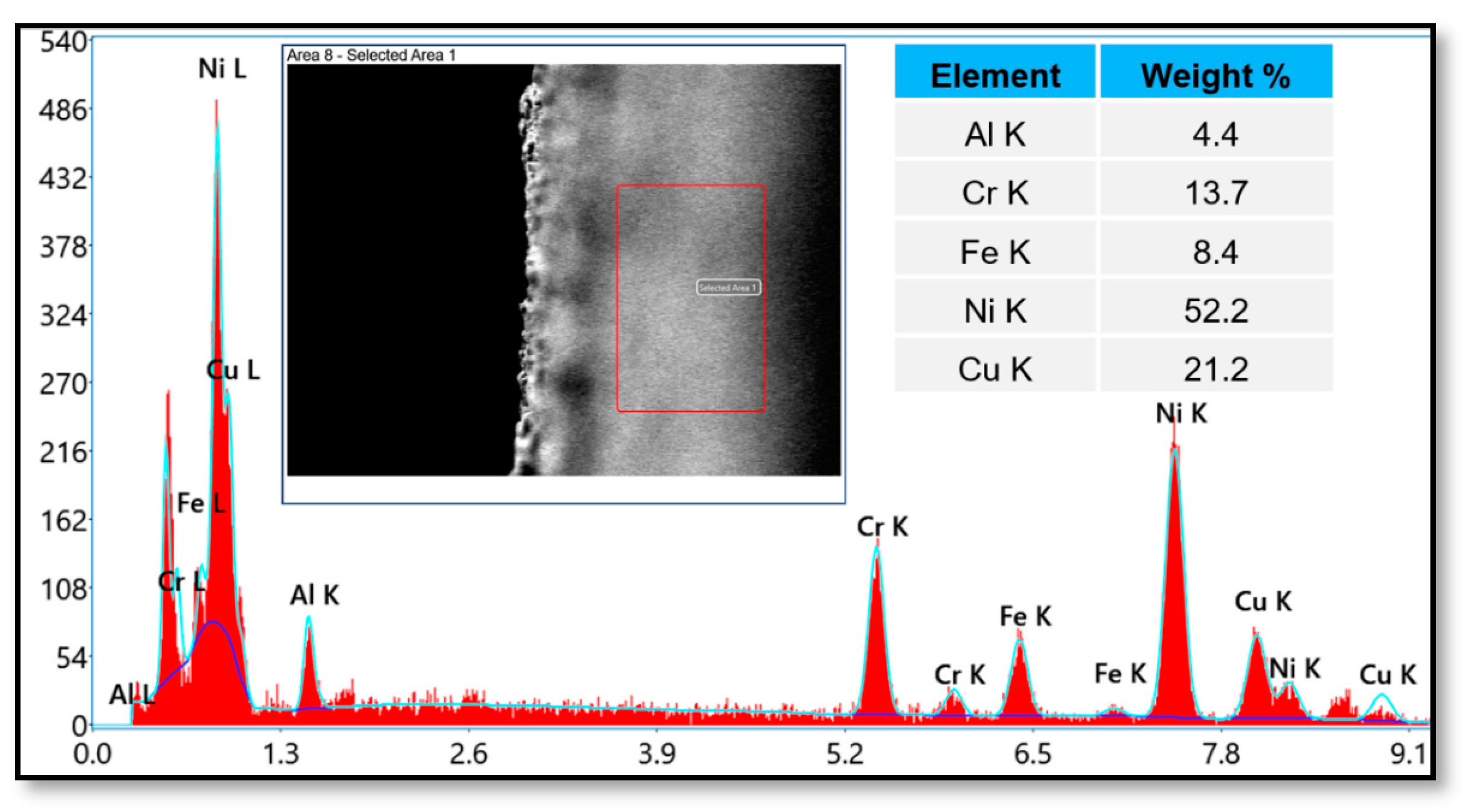

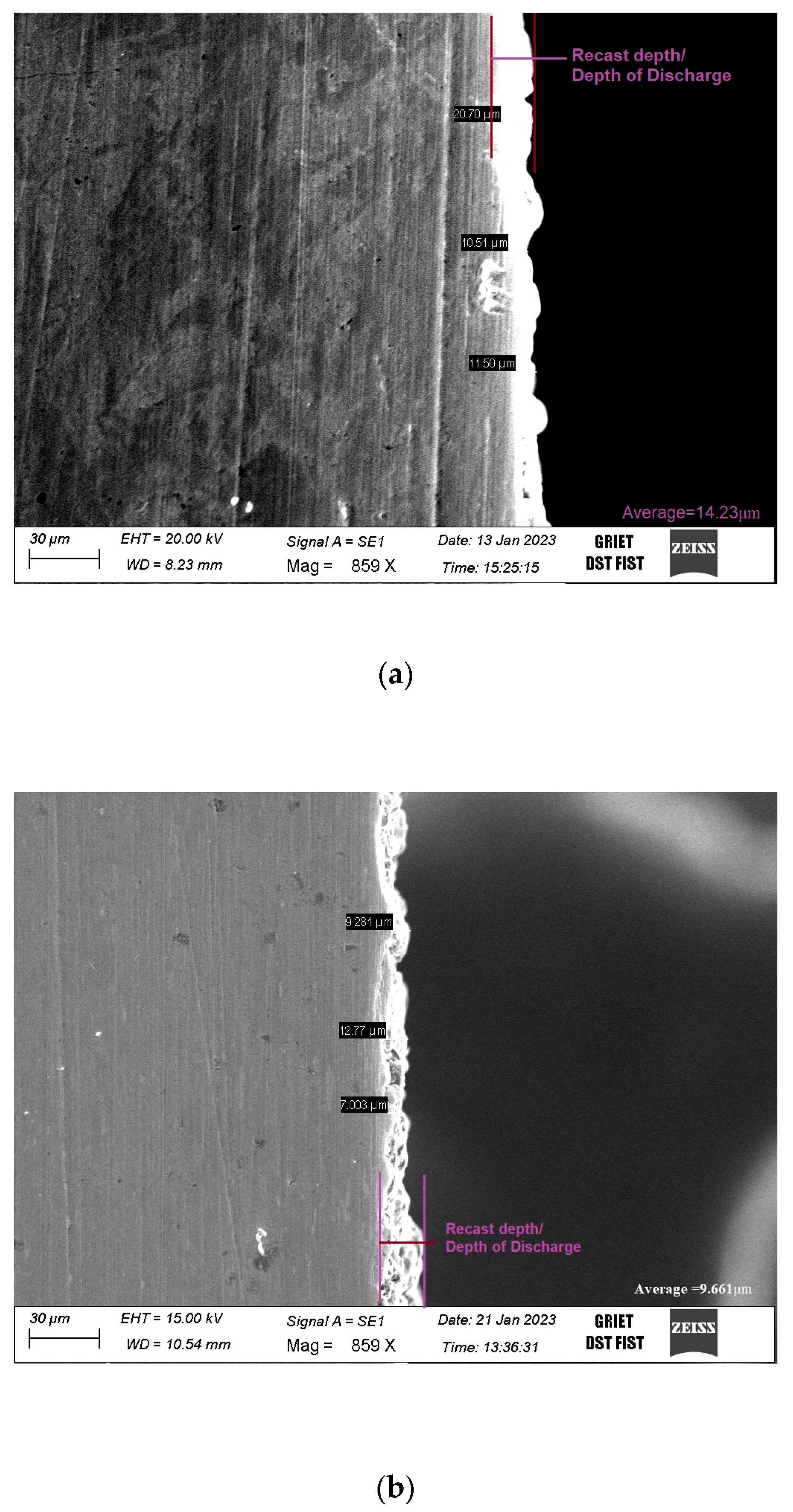

3.3.1. SEM/EDS Examination of the Work Surfaces

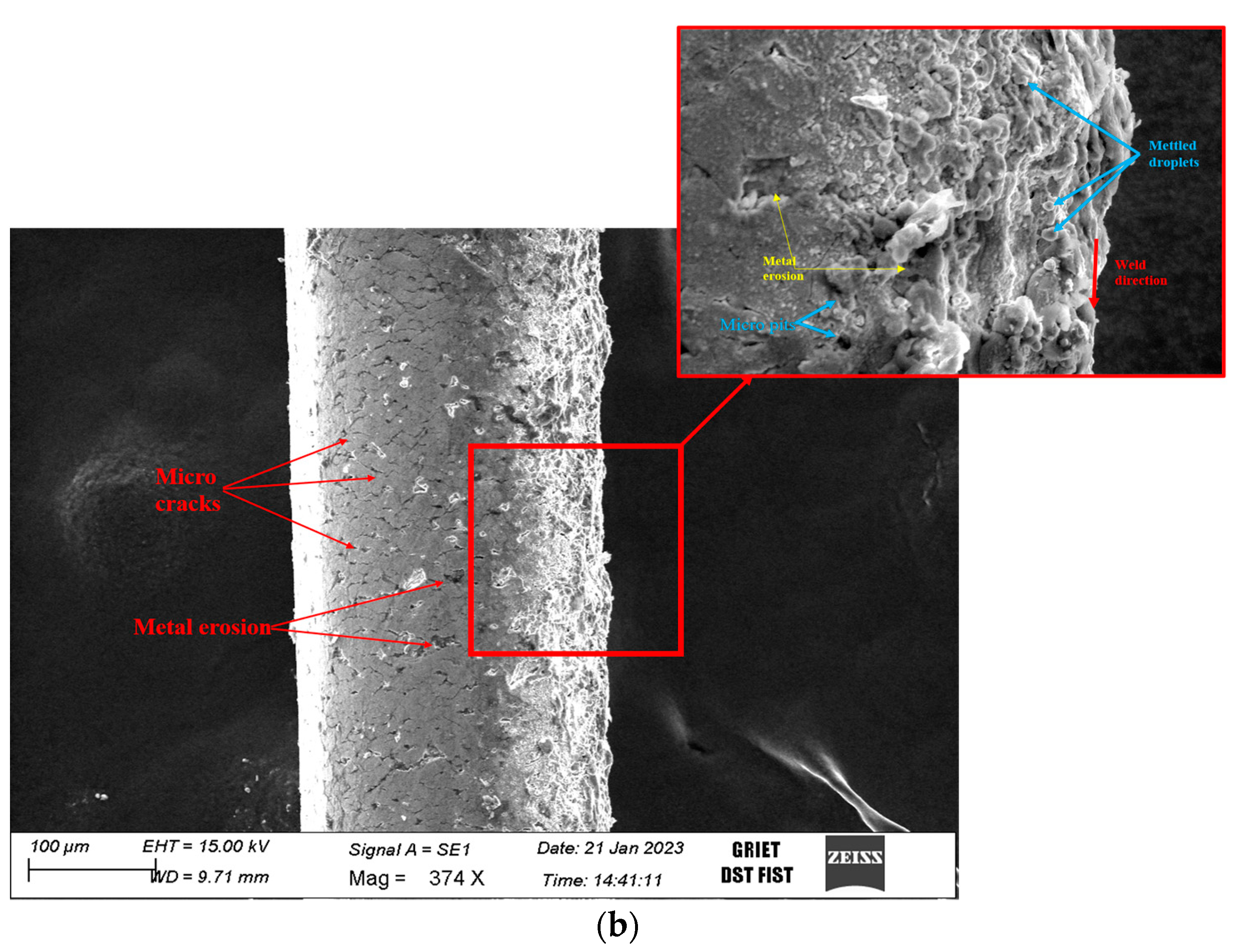

3.3.2. Examination of the Electrode with SEM

4. Conclusions

- In WEDM, the use of IP at 5 amps, Ton at 2 micro sec, and Toff at 9 micro sec is recommended to obtain a higher MRR in untreated and treated conditions;

- In WEDM, the use of IP at 7 amp, Ton at 2 micro sec, and Toff at 5 micro sec is recommended to obtain the minimum Ra in untreated and treated conditions;

- Through ANOVA, the Toff and the interaction of Toff parameters are the parameters that most affect the MRR and Ra in untreated and treated conditions;

- The recast depth for the untreated electrode was observed to be on average 14.23 μm, and with treated electrode it was 9.661 μm;

- The bonding of the elements in the case of the treated electrode improved due to the fact that the cryogenic treatment leads to a reduction in the number of pores and microcracks compared to the untreated electrode;

- The untreated electrode had high electrode erosion and pitching on the surface compared to the treated electrode.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Van Rooyen, D. Review of the stress corrosion cracking of Inconel 600. Corrosion 1975, 31, 327–337. [Google Scholar] [CrossRef]

- Yin, Q.; Liu, Z.; Wang, B.; Song, Q.; Cai, Y. Recent progress of machinability and surface integrity for mechanical machining Inconel 718: A review. Int. J. Adv. Manuf. Technol. 2020, 109, 215–245. [Google Scholar] [CrossRef]

- Antar, M.T.; Soo, S.L.; Aspinwall, D.K.; Jones, D.; Perez, R. Productivity and workpiece surface integrity when WEDM aerospace alloys using coated wires. Procedia Eng. 2011, 19, 3–8. [Google Scholar] [CrossRef]

- Sharma, V.S.; Sharma, N.; Singh, G.; Gupta, M.K.; Singh, G. Optimization of WEDM Parameters While Machining Biomedical Materials Using EDAS-PSO. Materials 2023, 16, 114. [Google Scholar] [CrossRef]

- Nani, V.-M. Complex phenomena study in dielectric fluid from gap during the W-EDM processing in ultrasonic field. Int. J. Adv. Manuf. Technol. 2017, 92, 197–215. [Google Scholar] [CrossRef]

- Mouralova, K.; Benes, L.; Bednar, J.; Zahradnicek, R.; Prokes, T.; Fiala, Z.; Fries, J. Precision Machining of Nimonic C 263 Super AlloyUsing WEDM. Coatings 2020, 10, 590. [Google Scholar] [CrossRef]

- Straka, Ľ.; Čorný, I.; Piteľ, J. Prediction of the Geometrical Accuracy of the Machined Surface of the Tool Steel EN X30WCrV9-3 after Electrical Discharge Machining with CuZn37 Wire Electrode. Metals 2017, 7, 462. [Google Scholar] [CrossRef]

- Sałaciński, T.; Przesmycki, A.; Chmielewski, T. Technological Aspects in Manufacturing of Non-Circular Gears. Appl. Sci. 2020, 10, 3420. [Google Scholar] [CrossRef]

- Chaudhari, R.; Vora, J.J.; Patel, V.; Lacalle LL, D.; Parikh, D.M. Effect of WEDM process parameters on surface morphology of nitinol shape memory alloy. Materials 2020, 13, 4943. [Google Scholar] [CrossRef]

- Sonawane, S.A.; Kulkarni, M. Optimization of machining parameters of WEDM for Nimonic-75 alloy using principal component analysis integrated with taguchi method. J. King Saud Univ. Eng. Sci. 2018, 30, 250–258. [Google Scholar] [CrossRef]

- Dauw, D.F.; Albert, L. About the evolution of wire tool performance in wire EDM. CIRP Annals 1992, 41, 221–225. [Google Scholar] [CrossRef]

- Liu, L.; Thangaraj, M.; Karmiris-Obratański, P.; Zhou, Y.; Annamalai, R.; Machnik, R.; Elsheikh, A.; Markopoulos, A.P. Optimization of Wire EDM Process Parameters on Cutting Inconel 718 Alloy with Zinc-Diffused Coating Brass Wire Electrode Using Taguchi-DEAR Technique. Coatings 2022, 12, 1612. [Google Scholar] [CrossRef]

- Abdallah, R.; Hood, R.; Soo, S.L. The Machinability Characteristics of Multidirectional CFRP Composites Using High-Performance Wire EDM Electrodes. J. Compos. Sci. 2022, 6, 159. [Google Scholar] [CrossRef]

- Reolon, L.W.; Laurindo, C.A.H.; Torres, R.D.; Amorim, F.L. WEDM performance and surface integrity of Inconel alloy IN718 with coated and uncoated wires. Int. J. Adv. Manuf. Technol. 2019, 100, 1981–1991. [Google Scholar] [CrossRef]

- Chen, Z.; Zhou, H.; Wu, C.; Zhang, G.; Yan, H. A new wire electrode for improving the machining characteristics of high-volume fraction SiCp/Al composite in WEDM. Materials 2022, 15, 4098. [Google Scholar] [CrossRef]

- Sen, R.; Choudhuri, B.; Barma, J.D.; Chakraborti, P. An investigation on the effect of different coated electrodes on the surface quality of WEDM by varying discharge energy level. Int. J. Adv. Manuf. Technol. 2020, 106, 3285–3299. [Google Scholar] [CrossRef]

- Eldridge, E.; Deem, H. Physical Properties of Metals and Alloys from Cryogenic to Elevated Temperatures. In Report on Physical Properties of Metals and Alloys from Cryogenic to Elevated Temperatures; ASTM International: West Conshohocken, PA, USA, 1960. [Google Scholar]

- Voglar, J.; Novak, ž.; Jovičević-Klug, P.; Podgornik, B.; Kosec, T. Effect of deep cryogenic treatment on corrosion properties of various high-speed steels. Metals 2020, 11, 14. [Google Scholar] [CrossRef]

- Nas, E.; Kara, F. Optimization of EDM Machinability of Hastelloy C22 Super Alloys. Machines 2022, 10, 1131. [Google Scholar] [CrossRef]

- Kogbara, R.; Iyengar, S.; Grasley, Z.C.; Masad, E.A.; Zollinger, D.G. A review of concrete properties at cryogenic temperatures: Towards direct LNG containment. Constr. Build. Mater. 2013, 47, 760–770. [Google Scholar] [CrossRef]

- Dhande, S.; Kane, V.; Dhobe, M.; Gogte, C. Influence of soaking periods in cryogenic treatment of tungsten carbide. Procedia Manuf. 2018, 20, 318–328. [Google Scholar] [CrossRef]

- Tahir, W.; Jahanzaib, M.; Ahmad, W.; Hussain, S. Surface morphology evaluation of hardened HSLA steel using cryogenic-treated brass wire in WEDM process. Int. J. Adv. Manuf. Technol. 2019, 104, 4445–4455. [Google Scholar] [CrossRef]

- Yildiz, Y.; Nalbant, M. A review of cryogenic cooling in machining processes. Int. J. Mach. Tools Manuf. 2008, 48, 947–964. [Google Scholar] [CrossRef]

- Gill, S.S.; Singh, J. Effect of deep cryogenic treatment on machinability of titanium alloy (Ti-6246) in electric discharge drilling. Mater. Manuf. Process. 2010, 25, 378–385. [Google Scholar] [CrossRef]

- Corruccini, R.J.; Gniewek, J.J. Thermal Expansion of Technical solids at Low Temperatures: A Compilation from the Literature; US Department of Commerce, National Bureau of Standards: Washington, DC, USA, 1961; p. 29.

- Kapoor, J.; Singh, S.; Khamba, J.S. Effect of cryogenic treated brass wire electrode on material removal rate in wire electrical discharge machining. Proc. Inst. Mech. Eng. Part C: J. Mech. Eng. Sci. 2012, 226, 2750–2758. [Google Scholar] [CrossRef]

- Zaman, U.K.U.; Khan, U.A.; Aziz, S.; Baqai, A.A.; Butt, S.U.; Hussain, D.; Siadat, A.; Jung, D.W. Optimization of Wire Electric Discharge Machining (WEDM) Process Parameters for AISI 1045 Medium Carbon Steel Using Taguchi Design of Experiments. Materials 2022, 15, 7846. [Google Scholar] [CrossRef] [PubMed]

- Abdudeen, A.; Abu Qudeiri, J.E.; Kareem, A.; Ahammed, T.; Ziout, A. Recent advances and perceptive insights into powder-mixed dielectric fluid of EDM. Micromachines 2020, 11, 754. [Google Scholar] [CrossRef]

- Vora, J.; Shah, Y.; Khanna, S.; Chaudhari, R. Effect of Near-Dry WEDM Process Variables through Taguchi-Based-GRA Approach on Performance Measures of Nitinol. J. Manuf. Mater. Process. 2022, 6, 131. [Google Scholar] [CrossRef]

- Dzionk, S.; Siemiątkowski, M.S. Studying the effect of working conditions on WEDM machining performance of super alloy Inconel 617. Machines 2020, 8, 54. [Google Scholar] [CrossRef]

- Usman, M.; Ishfaq, K.; Rehan, M.; Raza, A.; Mumtaz, J. An in-depth evaluation of surface characteristics and key machining responses in WEDM of aerospace alloy under varying electric discharge environments. Int. J. Adv. Manuf. Technol. 2023, 124, 2437–2449. [Google Scholar] [CrossRef]

- Asgar, E.; Singholi, A.K.S. Parameter study and optimization of WEDM process: A Review. In Iop Conference Series, Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 404. [Google Scholar]

- Yuan, J.; Wang, K.; Yu, T.; Fang, M. Reliable multi-objective optimization of high-speed WEDM process based on Gaussian process regression. Int. J. Mach. Tools Manuf. 2008, 48, 47–60. [Google Scholar] [CrossRef]

- Alkahlan, B.; Tabbakh, T.; Kurdi, A.; Pramanik, A.; Basak, A.K. Formation and Characterization of the Recast Layer Formed on Inconel 718 during Wire Electro Discharge Machining. Materials 2023, 16, 930. [Google Scholar] [CrossRef]

- Kumar, P.; Gupta, M.; Kumar, V. Microstructural analysis and multi response optimization of WEDM of Inconel 825 using RSM based desirability approach. J. Mech. Behav. Mater. 2019, 28, 39–61. [Google Scholar] [CrossRef]

- Benes, L.; Mouralova, K.; Midula, P.; Snow, J.; Lysonkova, I.; Pilnaj, D.; Burdova, H.; Prokes, T.; Zahradnicek, R.; Fries, J.; et al. The Corrosion Behavior of WEDM Machined Stainless Steels in a Pyrolysis Environment. Metals 2023, 13, 144. [Google Scholar] [CrossRef]

- Sharma, P.; Chakradhar, D.; Narendranath, S. Effect of wire diameter on surface integrity of wire electrical discharge machined Inconel 706 for gas turbine application. J. Manuf. Process. 2016, 24, 170–178. [Google Scholar] [CrossRef]

- Mouralova, K.; Zahradnicek, R.; Benes, L.; Prokes, T.; Hrdy, R.; Fries, J. Study of Micro Structural Material Changes after WEDM Based on TEM Lamella Analysis. Metals 2020, 10, 949. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Pivkin, P.M.; Kozochkin, M.P.; Volosova, M.A.; Okunkova, A.A.; Porvatov, A.N.; Zelensky, A.A.; Nadykto, A.B. Physicomechanical Nature of Acoustic Emission Preceding Wire Breakage during Wire Electrical Discharge Machining (WEDM) of Advanced Cutting Tool Materials. Metals 2021, 11, 1865. [Google Scholar] [CrossRef]

- Edwards, A.W. RA Fischer, statistical methods for research workers, (1925). In Landmark Writings in Western Mathematics; Elsevier Science: Amsterdam, The Netherlands, 2005; pp. 856–870. [Google Scholar]

- Sharma, P.; Chakradhar, D.; Narendranath, S. Measurement of WEDM performance characteristics of aero-engine alloy using RSM-based TLBO algorithm. Measurement 2021, 179, 109483. [Google Scholar] [CrossRef]

| S. No | Parameters | Symbol | Units | Level 1 | Level 2 | Level 3 |

|---|---|---|---|---|---|---|

| 1 | Current | I | A | 3 | 5 | 7 |

| 2 | Pulse-on time | Ton | micro sec | 2 | 4 | 6 |

| 3 | Pulse-off time | Toff | micro sec | 5 | 7 | 9 |

| S. No | IP | Ton | Toff | Untreated | Cryogenically Treated | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Weight (g) | Time (min) | MRR (g/min) | S/N Ratio MRR | Ra (µm) | S/N Ratio Ra | Weight (g) | Time (min) | MRR (g/min) | S/N Ratio MRR | Ra (µm) | S/N Ratio Ra | ||||||

| Before | After | Before | After | ||||||||||||||

| 1 | 3 | 2 | 5 | 177.25 | 158.24 | 43 | 0.442 | −7.09 | 1.31 | −2.37 | 240.12 | 222.00 | 41 | 0.442 | −7.09 | 1.29 | −2.23 |

| 2 | 3 | 4 | 7 | 158.24 | 140.98 | 48 | 0.360 | −8.87 | 1.92 | −5.69 | 222.00 | 205.42 | 45 | 0.368 | −8.68 | 1.75 | −4.84 |

| 3 | 3 | 6 | 9 | 140.98 | 121.20 | 43 | 0.460 | −6.74 | 3.03 | −9.61 | 205.42 | 186.30 | 42 | 0.455 | −6.84 | 2.91 | −9.27 |

| 4 | 5 | 2 | 7 | 121.20 | 103.45 | 41 | 0.433 | −7.27 | 2.72 | −8.70 | 186.30 | 167.80 | 40 | 0.463 | −6.69 | 2.11 | −6.47 |

| 5 | 5 | 4 | 9 | 103.45 | 82.95 | 38 | 0.539 | −5.36 | 3.46 | −10.78 | 167.80 | 148.22 | 36 | 0.544 | −5.29 | 3.37 | −10.54 |

| 6 | 5 | 6 | 5 | 82.95 | 64.80 | 37 | 0.491 | −6.18 | 1.45 | −3.25 | 148.22 | 130.12 | 38 | 0.476 | −6.45 | 1.31 | −2.33 |

| 7 | 7 | 2 | 9 | 64.80 | 46.78 | 36 | 0.501 | −6.00 | 1.49 | −3.46 | 130.12 | 112.54 | 33 | 0.533 | −5.47 | 1.34 | −2.53 |

| 8 | 7 | 4 | 5 | 46.78 | 26.58 | 45 | 0.449 | −6.95 | 1.32 | −2.41 | 112.54 | 94.99 | 38 | 0.462 | −6.71 | 1.27 | −2.08 |

| 9 | 7 | 6 | 7 | 26.58 | 17.01 | 35 | 0.274 | −11.24 | 1.99 | −5.99 | 94.99 | 86.75 | 32 | 0.258 | −11.77 | 1.78 | −4.98 |

| Level | MRR | Ra | ||||

|---|---|---|---|---|---|---|

| IP | Ton | Toff | IP | Ton | Toff | |

| 1 | −7.57 | −6.79 | −6.75 | −5.89 | −4.84 | −2.68 |

| 2 | −6.27 | −7.07 | −9.14 | −7.58 | −6.29 | −6.79 |

| 3 | −8.07 | −8.06 | −6.04 | −3.95 | −6.28 | −7.95 |

| Delta | 1.80 | 1.27 | 3.10 | 3.62 | 1.45 | 5.27 |

| Rank | 2 | 3 | 1 | 2 | 3 | 1 |

| Level | MRR | Ra | ||||

|---|---|---|---|---|---|---|

| IP | Ton | Toff | IP | Ton | Toff | |

| 1 | −7.53 | −6.42 | −6.75 | −5.44 | −3.74 | −2.21 |

| 2 | −6.14 | −6.89 | −9.05 | −6.45 | −5.82 | −5.43 |

| 3 | −7.99 | −8.35 | −5.87 | −3.20 | −5.53 | −7.45 |

| Delta | 1.85 | 1.93 | 3.19 | 3.25 | 2.08 | 5.28 |

| Rank | 3 | 2 | 1 | 2 | 3 | 1 |

| MRR | Ra | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Source | DF | Adj. SS | Adj. MS | F-Value | p-Value | % Con. | Source | DF | Adj. SS | Adj. MS | F-Value | p-Value | % Con. |

| Regression | 6 | 0.049 | 0.008 | 8.56 | 0.108 | Regression | 6 | 4.388 | 0.731 | 1.88 | 0.387 | ||

| IP | 1 | 0.010 | 0.010 | 10.8 | 0.081 | 12.32 | IP | 1 | 0.246 | 0.246 | 0.63 | 0.51 | 6.11 |

| Ton | 1 | 0.000 | 0.000 | 0.19 | 0.707 | 0.21 | Ton | 1 | 0.131 | 0.131 | 0.34 | 0.62 | 3.25 |

| Toff | 1 | 0.029 | 0.029 | 31.09 | 0.031 | 35.45 | Toff | 1 | 1.100 | 1.100 | 2.83 | 0.235 | 27.28 |

| IP * IP | 1 | 0.011 | 0.011 | 11.34 | 0.078 | 12.93 | IP * Ton | 1 | 0.857 | 0.857 | 2.2 | 0.276 | 21.25 |

| Ton * Ton | 1 | 0.001 | 0.001 | 0.53 | 0.543 | 0.60 | IP * Toff | 1 | 1.066 | 1.066 | 2.74 | 0.24 | 26.42 |

| Toff * Toff | 1 | 0.031 | 0.031 | 32.76 | 0.029 | 37.35 | Ton * Toff | 1 | 0.244 | 0.244 | 0.63 | 0.512 | 6.04 |

| Error | 2 | 0.002 | 0.001 | 1.14 | Error | 2 | 0.778 | 0.389 | 9.64 | ||||

| Total | 8 | 0.051 | 0.083 | 100.00 | Total | 8 | 5.166 | 4.033 | 100.00 | ||||

| MRR | Ra | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Source | DF | Adj. SS | Adj. MS | F-Value | p-Value | % Con. | Source | DF | Adj. SS | Adj. MS | F-Value | p-Value | % Con. |

| Regression | 6 | 0.056 | 0.009 | 4.65 | 0.188 | Regression | 6 | 3.971 | 0.662 | 1.83 | 0.394 | ||

| IP | 1 | 0.011 | 0.011 | 5.41 | 0.145 | 13.12 | IP | 1 | 0.134 | 0.134 | 0.37 | 0.604 | 5.23 |

| Ton | 1 | 0.000 | 0.000 | 0.09 | 0.789 | 0.23 | Ton | 1 | 0.158 | 0.158 | 0.44 | 0.576 | 6.15 |

| Toff | 1 | 0.028 | 0.028 | 13.92 | 0.065 | 33.74 | Toff | 1 | 0.645 | 0.645 | 1.79 | 0.313 | 25.11 |

| IP * IP | 1 | 0.011 | 0.011 | 5.55 | 0.143 | 13.44 | IP * Ton | 1 | 0.542 | 0.542 | 1.5 | 0.345 | 21.08 |

| Ton * Ton | 1 | 0.001 | 0.001 | 0.4 | 0.59 | 0.98 | IP * Toff | 1 | 0.649 | 0.649 | 1.8 | 0.312 | 25.25 |

| Toff * Toff | 1 | 0.030 | 0.030 | 14.89 | 0.061 | 36.07 | Ton * Toff | 1 | 0.081 | 0.081 | 0.22 | 0.683 | 3.14 |

| Error | 2 | 0.004 | 0.002 | 2.42 | Error | 2 | 0.721 | 0.361 | 14.04 | ||||

| Total | 8 | 0.060 | 0.083 | 100.00 | Total | 8 | 4.693 | 2.569 | 100.00 | ||||

| Electrode | Element | Cr K | Fe K | Ni K | Cu K | Zn K |

|---|---|---|---|---|---|---|

| Untreated | Weight% | 11.1 | 5.8 | 41.7 | 22.8 | 8.3 |

| Treated | Weight% | 14.3 | 8.5 | 54.2 | 17.7 | 4.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kosaraju, S.; Babu Bobba, P.; Salkuti, S.R. Optimization and Microstructural Studies on the Machining of Inconel 600 in WEDM Using Untreated and Cryogenically Treated Zinc Electrodes. Materials 2023, 16, 3181. https://doi.org/10.3390/ma16083181

Kosaraju S, Babu Bobba P, Salkuti SR. Optimization and Microstructural Studies on the Machining of Inconel 600 in WEDM Using Untreated and Cryogenically Treated Zinc Electrodes. Materials. 2023; 16(8):3181. https://doi.org/10.3390/ma16083181

Chicago/Turabian StyleKosaraju, Satyanarayana, Phaneendra Babu Bobba, and Surender Reddy Salkuti. 2023. "Optimization and Microstructural Studies on the Machining of Inconel 600 in WEDM Using Untreated and Cryogenically Treated Zinc Electrodes" Materials 16, no. 8: 3181. https://doi.org/10.3390/ma16083181

APA StyleKosaraju, S., Babu Bobba, P., & Salkuti, S. R. (2023). Optimization and Microstructural Studies on the Machining of Inconel 600 in WEDM Using Untreated and Cryogenically Treated Zinc Electrodes. Materials, 16(8), 3181. https://doi.org/10.3390/ma16083181