Comparative Study on Passive Film Formation Mechanism of Cast and PBF-LB/M-TC4 in Simulated Physiological Solution

Abstract

:1. Introduction

2. Experimental Section

2.1. Material and Sample Preparation

2.2. Electrochemical Tests

2.3. X-ray Photoelectron Spectroscopy Analysis

2.4. Auger Electron Spectroscopy Analysis

3. Results and Discussion

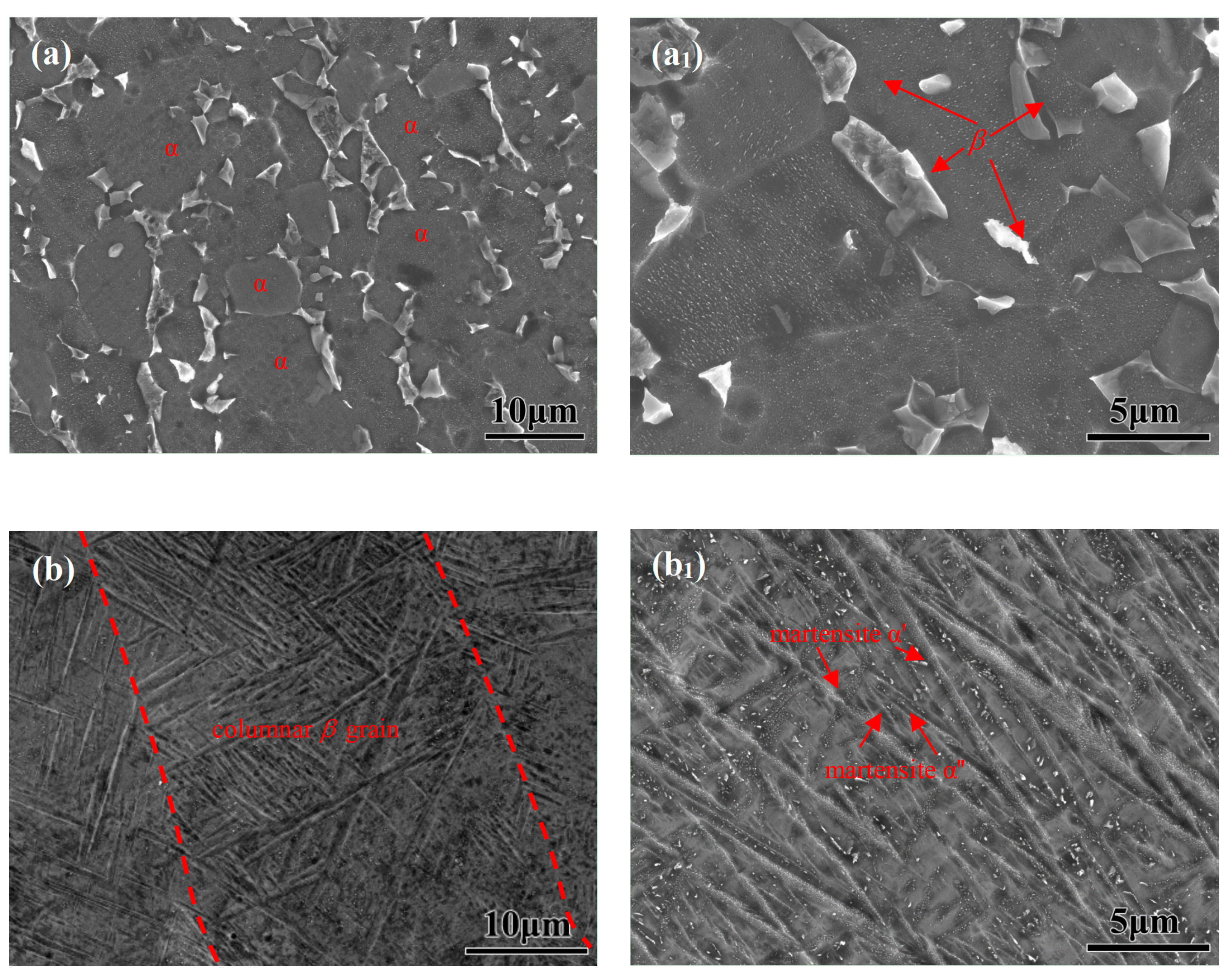

3.1. Microstructure Analysis

3.2. Electrochemical Analysis

3.2.1. Open Circuit Potential

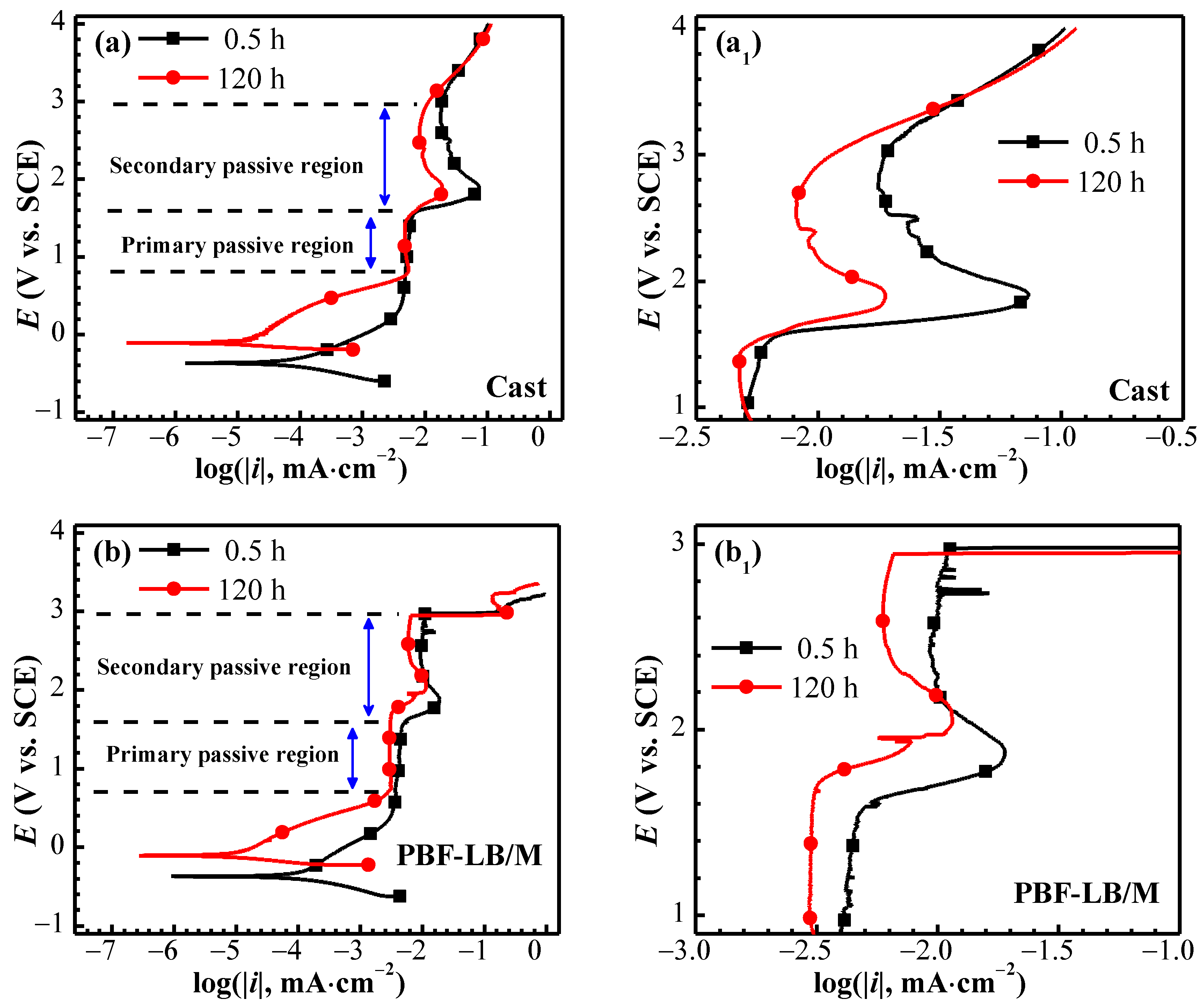

3.2.2. Potentiodynamic Polarization

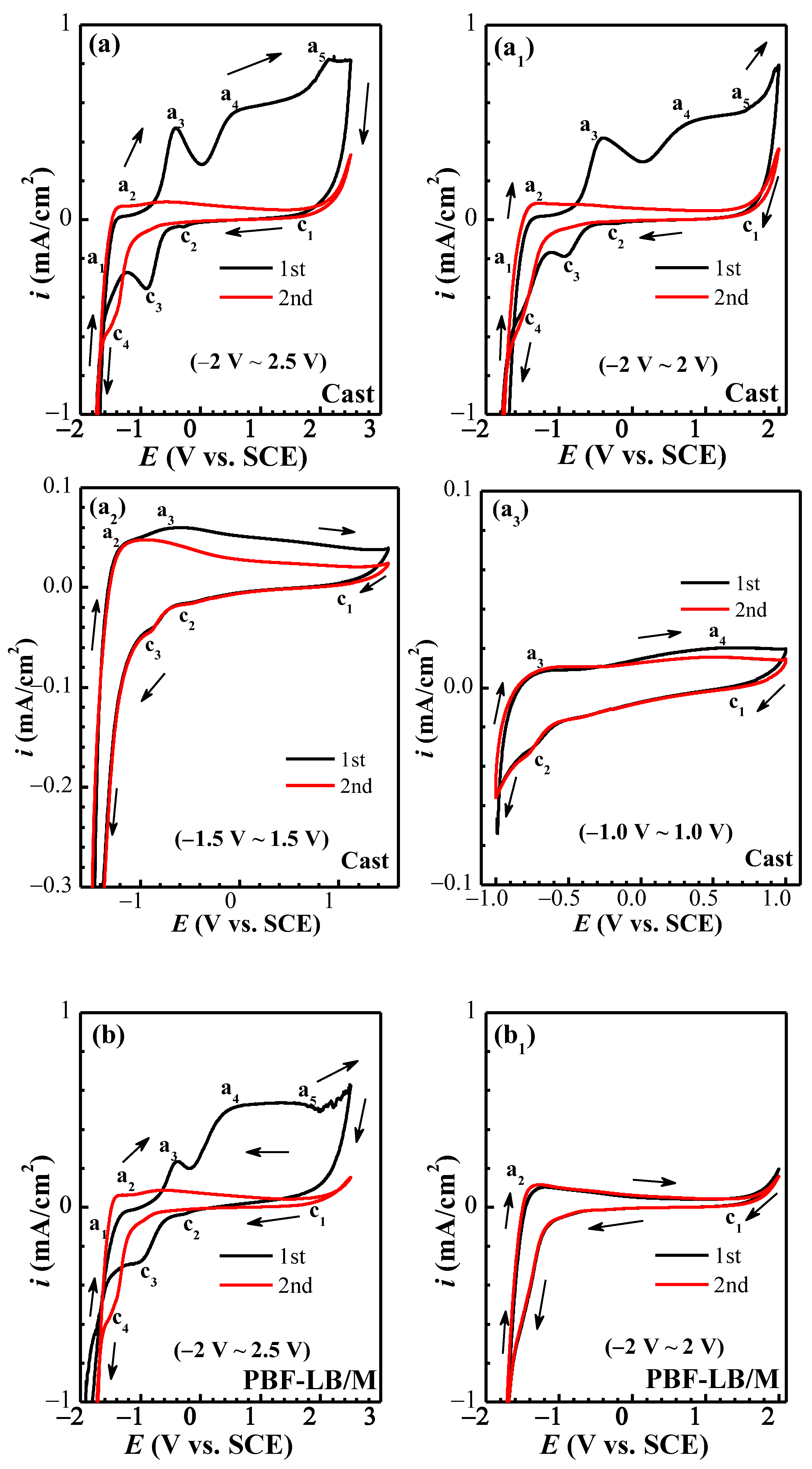

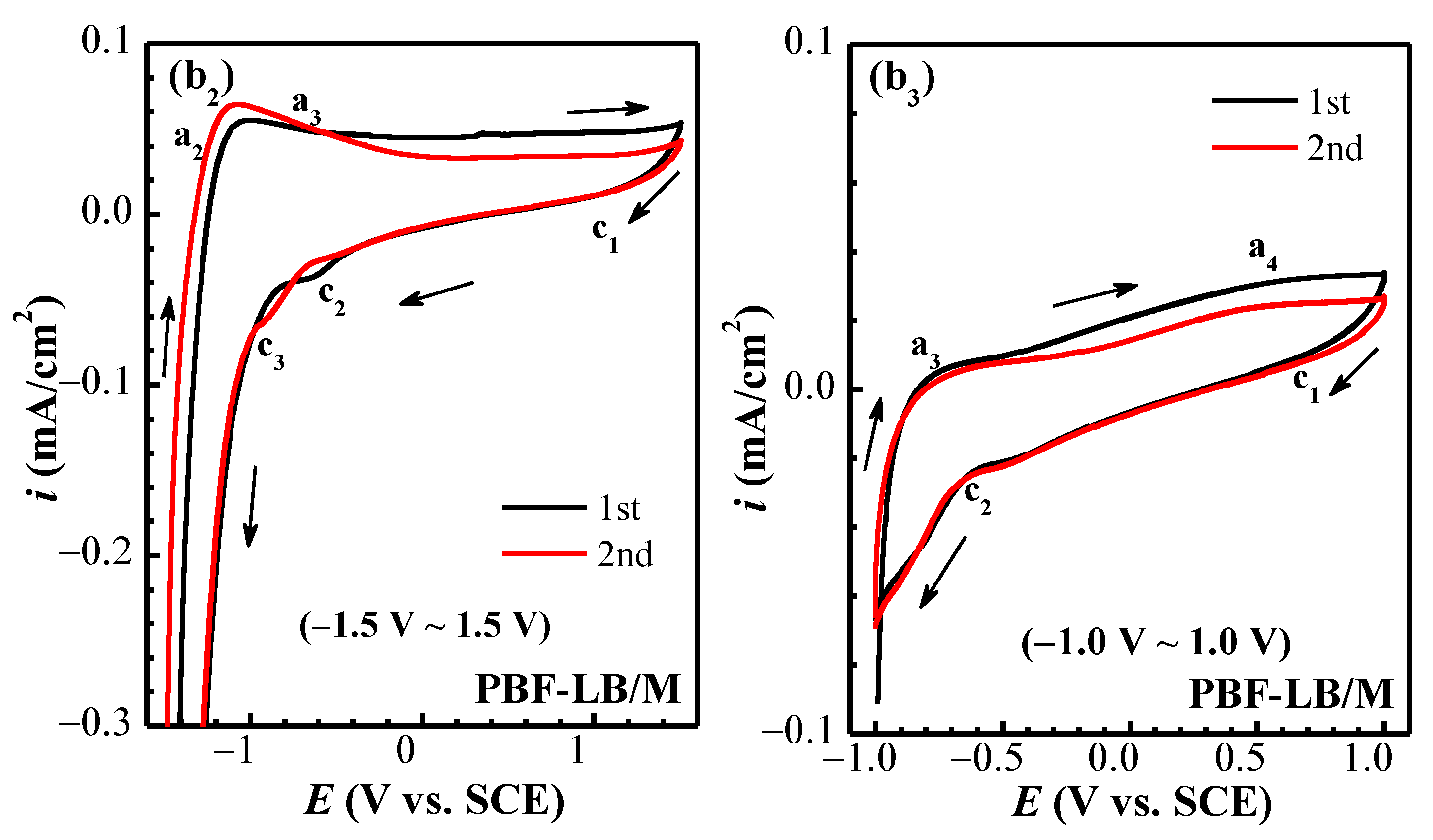

3.2.3. Cyclic Voltammetry

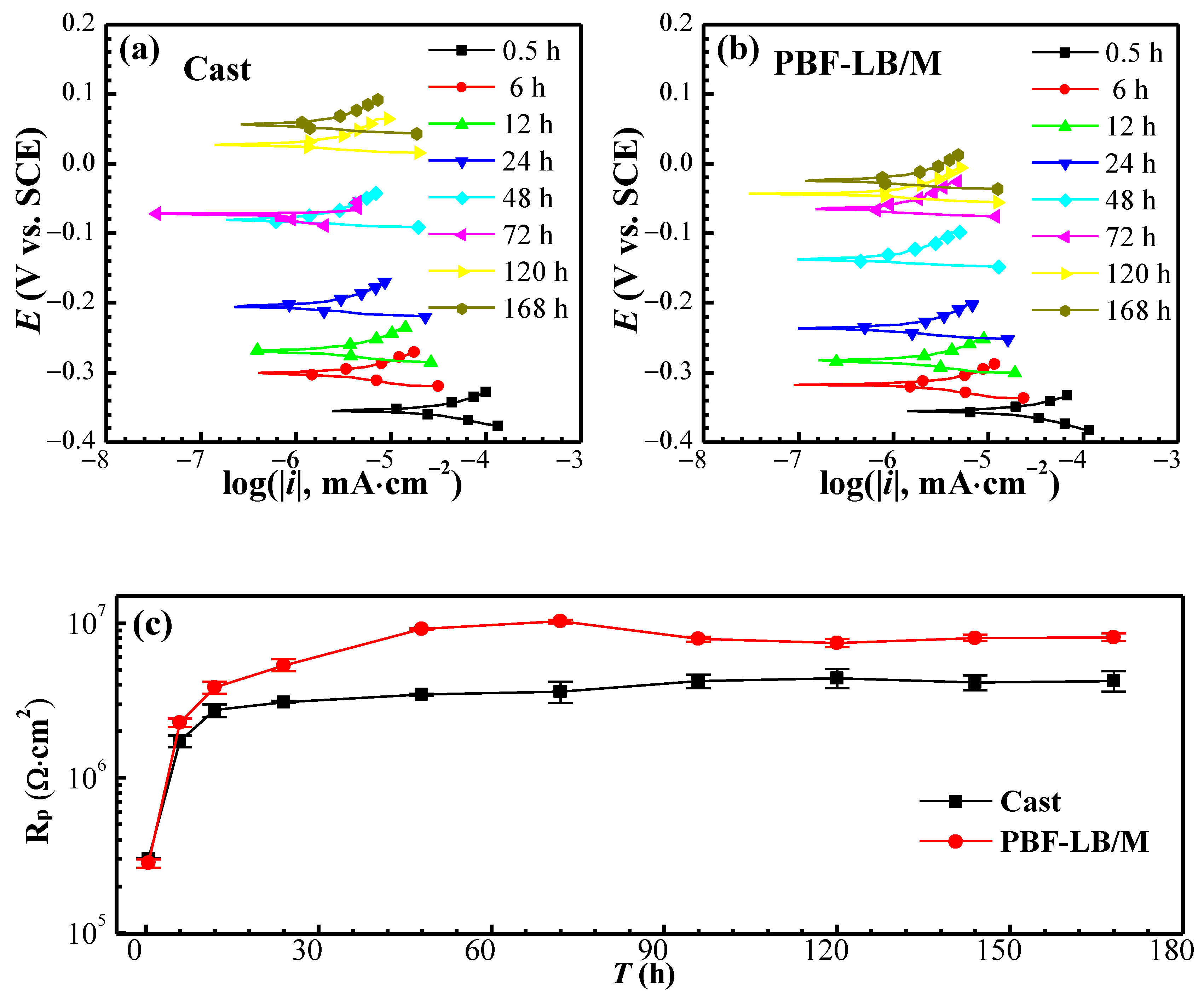

3.2.4. Linear Polarization Curve

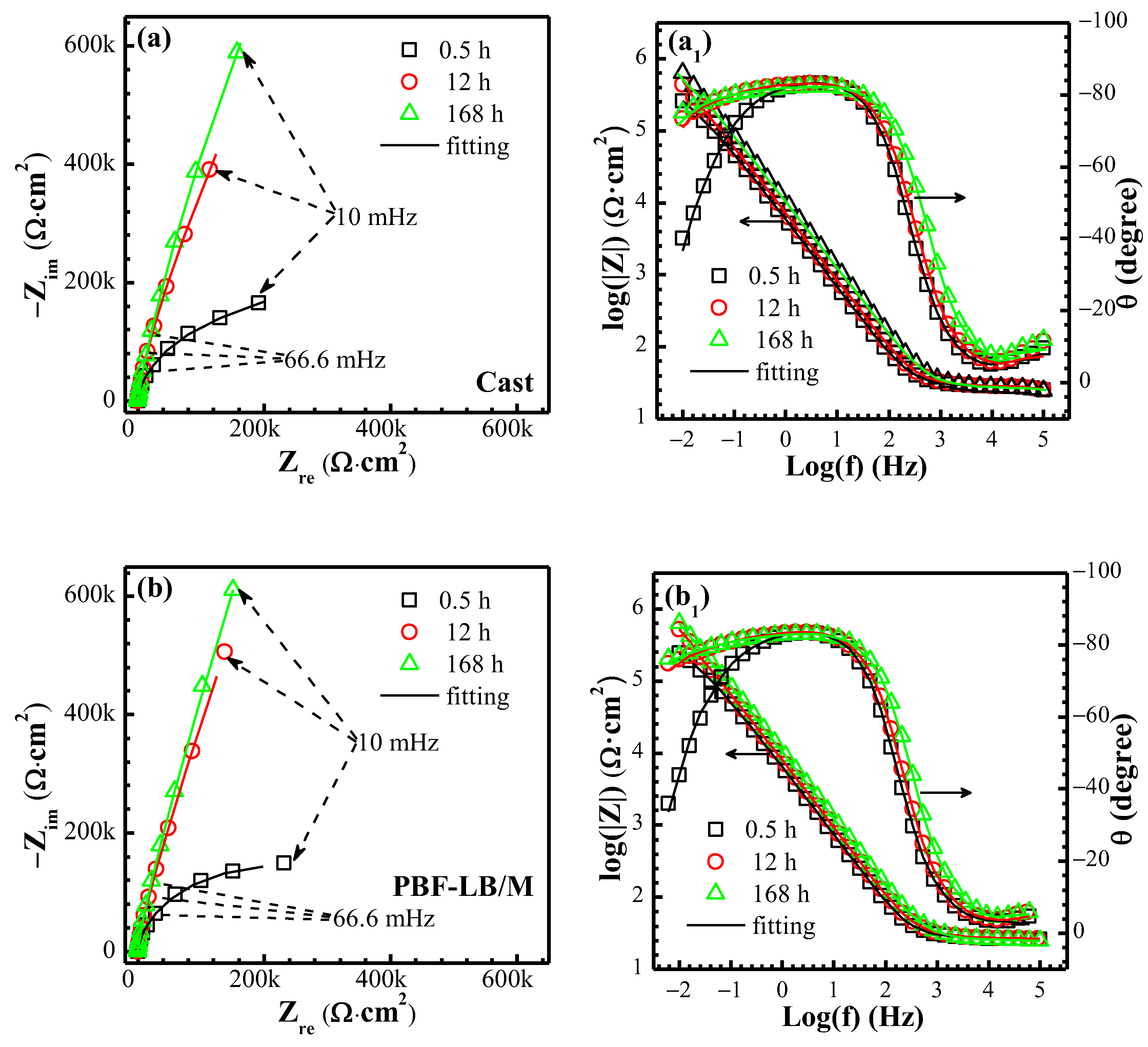

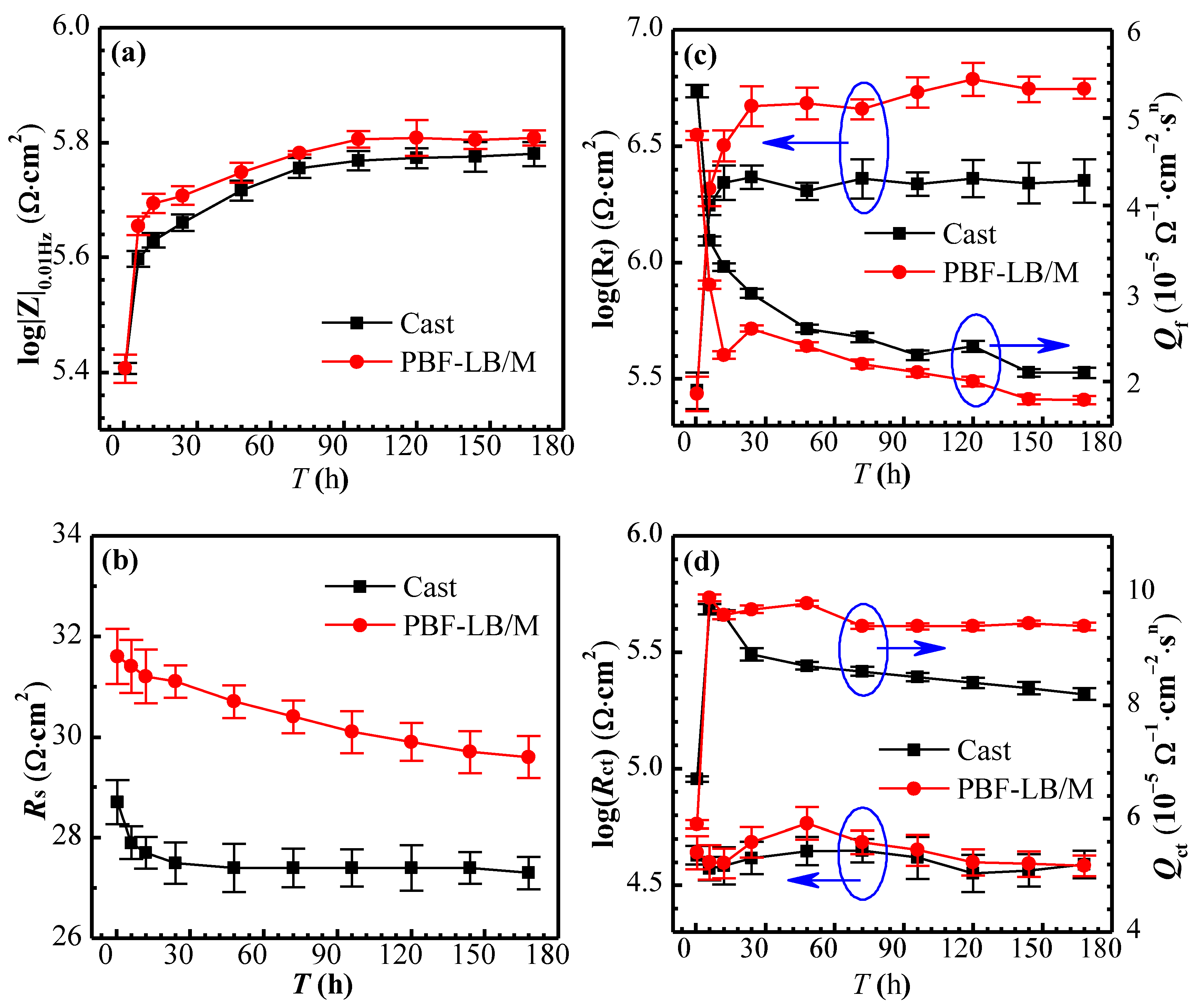

3.2.5. Electrochemical Impedance Spectroscopy

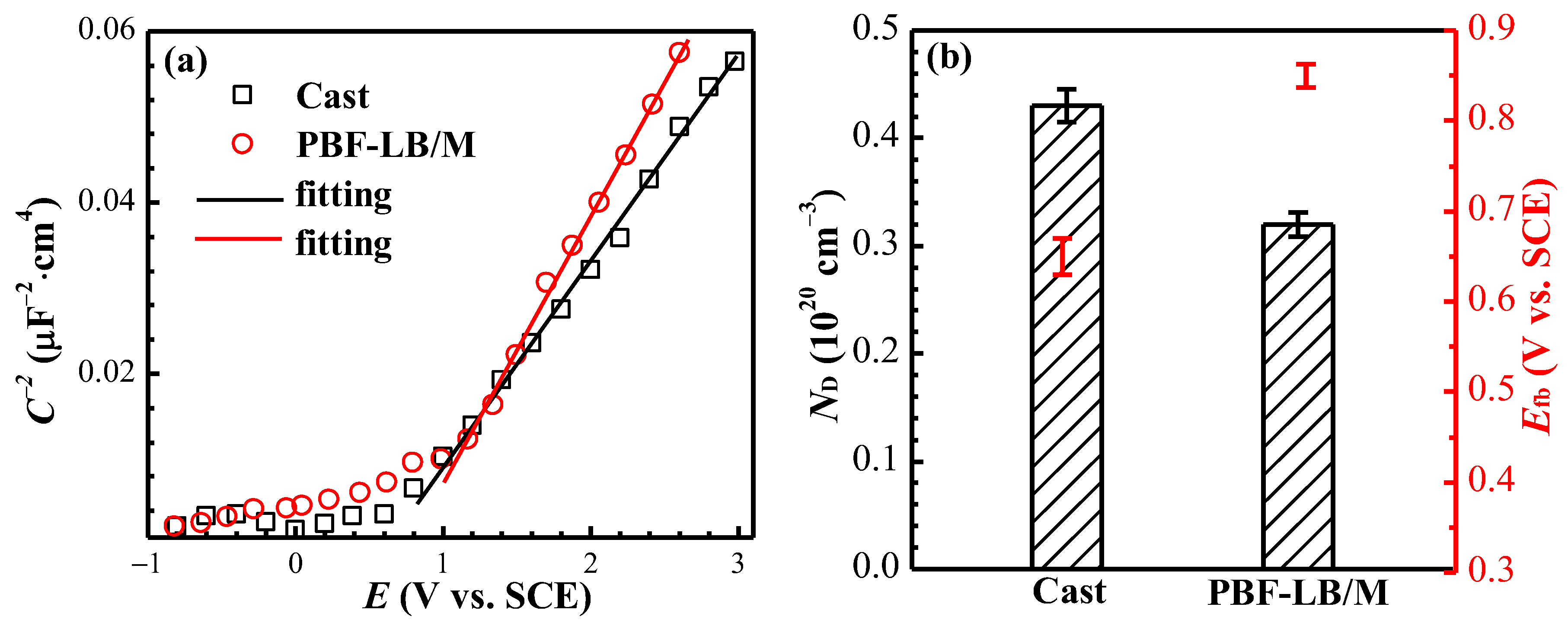

3.2.6. Mott–Schottky Analysis

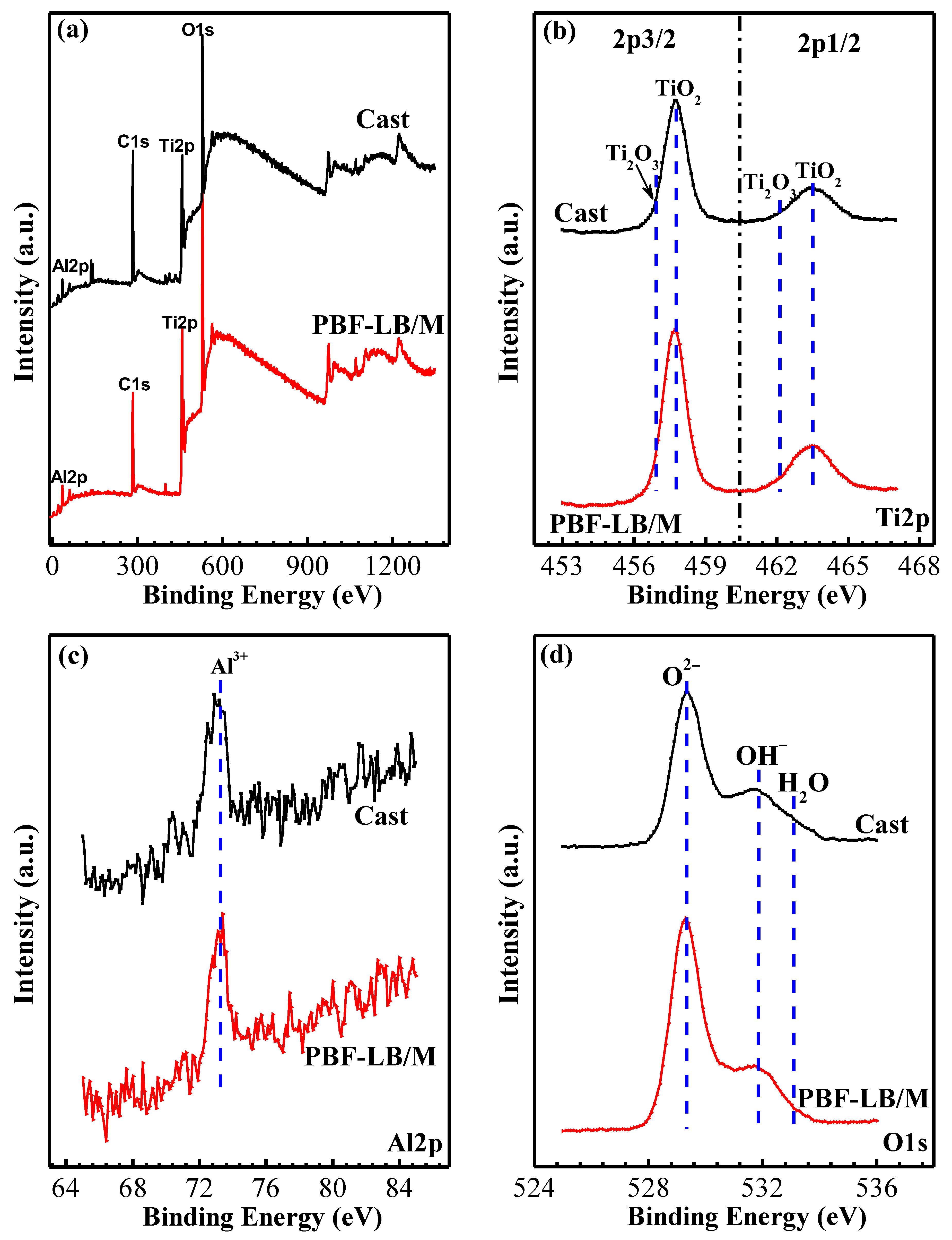

3.3. XPS Analysis

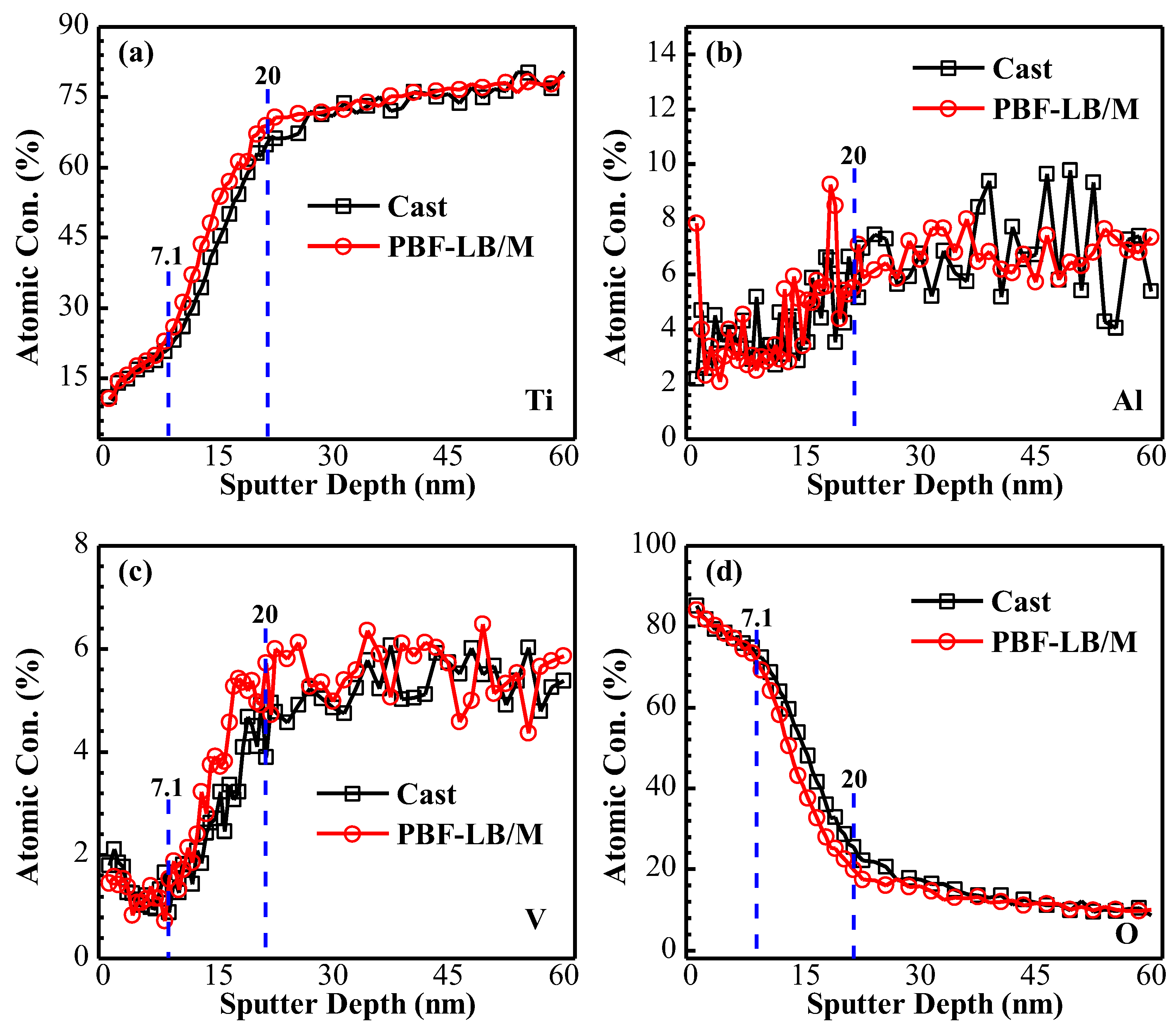

3.4. AES Analysis

4. Conclusions

- The OCP of cast- and PBF-LB/M-TC4 conforms to the power function and increases rapidly with an extension of immersion time. Due to the large grain size of cast-TC4, the passive film formation rate shows the following order: cast-TC4 > PBF-LB/M-TC4.

- The early-stage formed passive film shows a lower corrosion resistance. The metastable β phase and the equiaxial α phase of cast-TC4 promotes the passive film formation rate. A corrosion-resistant passive film could be formed during a longer period of immersion. The martensitic-based PBF-LB/M-TC4 shows better corrosion resistance than that of cast-TC4 after 120 h of immersion.

- The RP of LPR immersed for 168 h of PBF-LB/M-TC4 (8.2 × 106 Ω·cm2) is twice of that cast-TC4 (4.1 × 106 Ω·cm2), indicating the formed passive film of PBF-LB/M-TC4 has excellent corrosion resistance. The two TC4 passive film shows a typical n-type semiconductor, and the defect density in cast-TC4 is 139% times that of PBF-LB/M-TC4.

- The passive film of two TC4 alloy is mainly Ti oxide. Ti4+ plays a dominant role, and the passive film’s stability from high to low is PBF-LB/M-TC4 > cast-TC4. Compared to the passive film thickness, the content of TiO2 in the passive film is a good criterion to evaluate corrosion resistance. A higher TiO2 concentration and fewer defects promote better corrosion protection of martensite-based PBF-LB/M-TC4.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclatures

| PBF-LB/M | laser powder bed fusion of metals |

| TC4 | Ti-6Al-4V |

| SCE | saturated calomel reference electrode |

| OCP | open circuit potential |

| CV | cyclic voltammetry |

| EIS | electrochemical impedance spectroscopy |

| M-S | Mott–Schottky |

| XPS | X-ray photoelectron spectroscopy |

| AES | Auger electron spectroscopy |

| SEM | scanning electron microscopy |

| passivation film formation rate | |

| α | charge transfer coefficient |

| energy accumulation width | |

| Ecorr | self-corrosion potential |

| icorr | self-corrosion current density |

| ipass | maintaining passivity current density |

| LPR | linear polarization |

| EEC | equivalent circuit |

| Rs | solution resistance |

| Rf | passive film resistance |

| Qf | passive film double-layer constant phase element |

| Rct | charge transfer resistance |

| Qdl | charge transfer double-layer constant phase element |

| C | space charge layer capacitance |

| ε | dielectric constant of passive film |

| ε0 | dielectric constant of vacuum (ε0 = 8.85 × 10−12 F/m) |

| e | number of electrons (e = 1.602×10−19 C) |

| E | applied potential |

| Efb | flat-band potential |

| k | Boltzmann constant (k = 1.38 × 10−23 J/K) |

| T | thermodynamic temperature |

References

- Du, H.; To, S.; Yin, T.; Zhu, Z. Microstructured surface generation and cutting force prediction of pure titanium TA2. Precis. Eng. 2022, 75, 101–110. [Google Scholar] [CrossRef]

- Huang, G.; Fan, Z.; Li, L.; Lu, Y.; Lin, J. Corrosion Resistance of Selective Laser Melted Ti6Al4V3Cu Alloy Produced Using Pre-Alloyed and Mixed Powder. Materials 2022, 15, 2487. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Chen, G.; Wang, A.; Wang, Y.; Qiao, Y.; Liu, Z.; Qi, Z.; Liu, C.T. Corrosion behavior of single-and poly-crystalline dual-phase TiAl-Ti3Al alloy in NaCl solution. Int. J. Miner. Metall. Mater. 2023, 30, 689–696. [Google Scholar]

- Hattingh, D.G.; Botha, S.; Bernard, D.; James, M.N.; du Plessis, A. Corrosion fatigue of Ti-6Al-4V coupons manufactured by directed energy deposition. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 1969–1980. [Google Scholar] [CrossRef]

- Chen, L.-Y.; Zhang, H.-Y.; Zheng, C.; Yang, H.-Y.; Qin, P.; Zhao, C.; Lu, S.; Liang, S.-X.; Chai, L.; Zhang, L.-C. Corrosion behavior and characteristics of passive films of laser powder bed fusion produced Ti–6Al–4V in dynamic Hank’s solution. Mater. Des. 2021, 208, 109907. [Google Scholar] [CrossRef]

- Feng, J.; Wang, J.; Yang, K.; Rong, J. Microstructure and performance of YTaO4 coating deposited by atmospheric plasma spraying on TC4 titanium alloy surface. Surf. Coatings Technol. 2022, 431, 128004. [Google Scholar] [CrossRef]

- Liu, M.; Zhu, J.-N.; Popovich, V.; Borisov, E.; Mol, J.; Gonzalez-Garcia, Y. Passive film formation and corrosion resistance of laser-powder bed fusion fabricated NiTi shape memory alloys. J. Mater. Res. Technol. 2023, 23, 2991–3006. [Google Scholar] [CrossRef]

- Cao, J.; Zhao, W.; Wang, X.; Zhao, Y.; Ma, P.; Jiang, W.; Song, G. The Microstructure and tribological behavior of ultrasonic electroless Ni-P plating on TC4 titanium alloy with heat-Treatment. Ferroelectrics 2022, 589, 1–11. [Google Scholar] [CrossRef]

- Huo, W.; Zhao, L.; Zhang, W.; Lu, J.; Zhao, Y.; Zhang, Y. In vitro corrosion behavior and biocompatibility of nanostructured Ti6Al4V. Mater. Sci. Eng. C 2018, 92, 268–279. [Google Scholar] [CrossRef]

- Kazemi, M.; Ahangarani, S.; Esmailian, M.; Shanaghi, A. Investigation on the corrosion behavior and biocompatibility of Ti-6Al-4V implant coated with HA/TiN dual layer for medical applications. Surf. Coatings Technol. 2020, 397, 126044. [Google Scholar] [CrossRef]

- Ilani, M.A.; Khoshnevisan, M. An evaluation of the surface integrity and corrosion behavior of Ti-6Al-4 V processed thermodynamically by PM-EDM criteria. Int. J. Adv. Manuf. Technol. 2022, 120, 5117–5129. [Google Scholar] [CrossRef]

- Liao, Y.; Bai, J.; Chen, F.; Xu, G.; Cui, Y. Microstructural strengthening and toughening mechanisms in Fe-containing Ti-6Al-4V: A comparison between homogenization and aging treated states. J. Mater. Sci. Technol. 2022, 99, 114–126. [Google Scholar] [CrossRef]

- Cheng, R.; Luo, X.; Huang, G.; Li, C.J. Corrosion and wear resistant WC17Co-TC4 composite coatings with fully dense microstructure enabled by in-situ forging of the large-sized WC17Co particles in cold spray. J. Am. Acad. Dermatol. 2021, 296, 117231. [Google Scholar] [CrossRef]

- Yao, J.; Wang, Y.; Wu, G.; Sun, M.; Wang, M.; Zhang, Q. Growth characteristics and properties of micro-arc oxidation coating on SLM-produced TC4 alloy for biomedical applications. Appl. Surf. Sci. 2019, 479, 727–737. [Google Scholar] [CrossRef]

- Dai, N.; Zhang, L.-C.; Zhang, J.; Chen, Q.; Wu, M. Corrosion behavior of selective laser melted Ti-6Al-4 V alloy in NaCl solution. Corros. Sci. 2016, 102, 484–489. [Google Scholar] [CrossRef]

- Zhang, H.; Man, C.; Dong, C.; Wang, L.; Li, W.; Kong, D.; Wang, L.; Wang, X. The corrosion behavior of Ti-6Al-4V fabricated by selective laser melting in theartificial saliva with different fluoride concentrations and pH values. Corros. Sci. 2021, 179, 109097. [Google Scholar] [CrossRef]

- Zhao, B.; Wang, H.; Qiao, N.; Wang, C.; Hu, M. Corrosion resistance characteristics of a Ti-6Al-4V alloy scaffold that is fabricated by electron beam melting and selective laser melting for implantation in vivo. Mater. Sci. Eng. C 2017, 70, 832–841. [Google Scholar] [CrossRef] [PubMed]

- Hamza, H.M.; Deen, K.M.; Haider, W. Microstructural examination and corrosion behavior of selective laser melted and conventionally manufactured Ti6Al4V for dental applications. Mater. Sci. Eng. C 2020, 113, 110980. [Google Scholar] [CrossRef] [PubMed]

- Kong, D.; Dong, C.; Ni, X.; Li, X. Corrosion of metallic materials fabricated by selective laser melting. npj Mater. Degrad. 2019, 3, 24. [Google Scholar] [CrossRef]

- Zhou, L.; Yuan, T.; Tang, J.; He, J.; Li, R. Mechanical and corrosion behavior of titanium alloys additively manufactured by selective laser melting—A comparison between nearly b titanium, a titanium and a + b titanium. Opt. Laser Tech. 2019, 119, 105625. [Google Scholar] [CrossRef]

- Liu, M.; Zhu, J.-N.; Popovich, V.A.; Borisov, E.; Mol, J.M.C.; Gonzalez-Garcia, Y. Corrosion and passive film characteristics of 3D-printed NiTi shape memory alloys in artificial saliva. Rare Met. 2023, 42, 3114–3129. [Google Scholar] [CrossRef]

- Qin, P.; Chen, Y.; Liu, Y.J.; Zhang, J.; Chen, L.Y.; Li, Y.; Zhang, X.; Cao, C.; Sun, H.; Zhang, L.C. Resemblance in corrosion behavior of selective laser melted and traditional monolithic b Ti-24Nb-4Zr-8Sn alloy. ACS Biomater. Sci. Eng. 2019, 5, 1141–1149. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Zhang, J.; Dai, N.; Qin, P.; Attar, H.; Zhang, L.C. Corrosion behaviour of selective laser melted Ti-TiB biocomposite in simulated body fluid. Electrochim. Acta 2017, 232, 89–97. [Google Scholar] [CrossRef]

- Liu, M.; Cheng, X.; Li, X.; Pan, Y.; Li, J. Effect of Cr on the passive film formation mechanism of steel rebar in saturated calcium hydroxide solution. Appl. Surf. Sci. 2016, 389, 1182–1191. [Google Scholar] [CrossRef]

- El Haleem, S.A.; El Aal, E.A.; El Wanees, S.A.; Diab, A. Environmental factors affecting the corrosion behaviour of reinforcing steel: I. The early stage of passive film formation in Ca(OH)2 solutions. Corros. Sci. 2010, 52, 3875–3882. [Google Scholar] [CrossRef]

- Fischer, H.; Hauffe, K. Passivierende Filme und Deckschichten Anlaufschichten; Springer: Berlin/Heidelberg, Germany, 1956. [Google Scholar]

- Yang, X.; Du, C.; Wan, H.; Liu, Z.; Li, X. Influence of sulfides on the passivation behavior of titanium alloy TA2 in simulated seawater environments. Appl. Surf. Sci. 2018, 458, 198–209. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Z.; Sui, Q.; Xu, S.; Yuan, Q.; Zhang, D.; Liu, J. A Comparison of the Microstructure, Mechanical Properties, and Corrosion Resistance of the K213 Superalloy after Conventional Casting and Selective Laser Melting. Materials 2023, 16, 1331. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Wen, S.; Ma, J.; Sun, Z.; Lin, C.; Yue, Z.; Mol, J.; Liu, M. Optimization of intrinsic self-healing silicone coatings by benzotriazole loaded mesoporous silica. Surf. Coatings Technol. 2021, 421, 127388. [Google Scholar] [CrossRef]

- Jia, C.; Wang XHu, M.; Su, Y.; Li, S.; Gai, X.; Sheng, L. Corrosion Behavior of TiNi Alloy Fabricated by Selective Laser Melting in Simulated Saliva. Coatings 2022, 12, 840. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, X.; Li, X. Electrochemical behavior and compositions of passive films formed on the constituent phases of duplex stainless steel without coupling. Electrochem. Commun. 2015, 57, 56–60. [Google Scholar] [CrossRef]

- Chen, X.; Liao, Q.; Gong, M.; Fu, Q. Corrosion Performances of Selective Laser Melting Ti6Al4V Alloy in Different Solutions. Metals 2023, 13, 192. [Google Scholar] [CrossRef]

- Liu, M.; Cheng, X.; Li, X.; Lu, T.J. Corrosion behavior of low-Cr steel rebars in alkaline solutions with different pH in the presence of chlorides. J. Electroanal. Chem. 2017, 803, 40–50. [Google Scholar] [CrossRef]

- Luo, H.; Su, H.; Dong, C.; Xiao, K.; Li, X. Electrochemical and passivation behavior investigation of ferritic stainless steel in alkaline environment. Constr. Build. Mater. 2015, 96, 502–507. [Google Scholar] [CrossRef]

| Alloy | Fitting Result | R2 |

|---|---|---|

| Cast-TC4 | 0.9666 | |

| PBF-LB/M-TC4 | 0.9969 |

| Sample | Time (h) | Ecorr (mVSCE) | bc, mV·dec−1 | icorr, μA·cm−2 | ipass, μA·cm−2 |

|---|---|---|---|---|---|

| Cast-TC4 | 0.5 | −383 ± 12 | −144 ± 11 | 0.12 ± 0.03 | 6.5 ± 0.6 |

| 120 | −113 ± 8 | −127 ± 9 | 0.04 ± 0.02 | 4.6 ± 0.4 | |

| PBF-LB/M-TC4 | 0.5 | −385 ± 13 | −191 ± 14 | 0.17 ± 0.03 | 4.4 ± 0.5 |

| 120 | −118 ± 7 | −143 ± 6 | 0.02 ± 0.01 | 3.0 ± 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Liu, Z.; Wang, J.; Zhang, Y.; Gao, X. Comparative Study on Passive Film Formation Mechanism of Cast and PBF-LB/M-TC4 in Simulated Physiological Solution. Materials 2024, 17, 2583. https://doi.org/10.3390/ma17112583

Liu M, Liu Z, Wang J, Zhang Y, Gao X. Comparative Study on Passive Film Formation Mechanism of Cast and PBF-LB/M-TC4 in Simulated Physiological Solution. Materials. 2024; 17(11):2583. https://doi.org/10.3390/ma17112583

Chicago/Turabian StyleLiu, Ming, Zhang Liu, Jie Wang, Yongqiang Zhang, and Xin Gao. 2024. "Comparative Study on Passive Film Formation Mechanism of Cast and PBF-LB/M-TC4 in Simulated Physiological Solution" Materials 17, no. 11: 2583. https://doi.org/10.3390/ma17112583

APA StyleLiu, M., Liu, Z., Wang, J., Zhang, Y., & Gao, X. (2024). Comparative Study on Passive Film Formation Mechanism of Cast and PBF-LB/M-TC4 in Simulated Physiological Solution. Materials, 17(11), 2583. https://doi.org/10.3390/ma17112583