In Situ Study of Precipitates’ Effect on Grain Deformation Behavior and Mechanical Properties of S31254 Super Austenitic Stainless Steel

Abstract

:1. Introduction

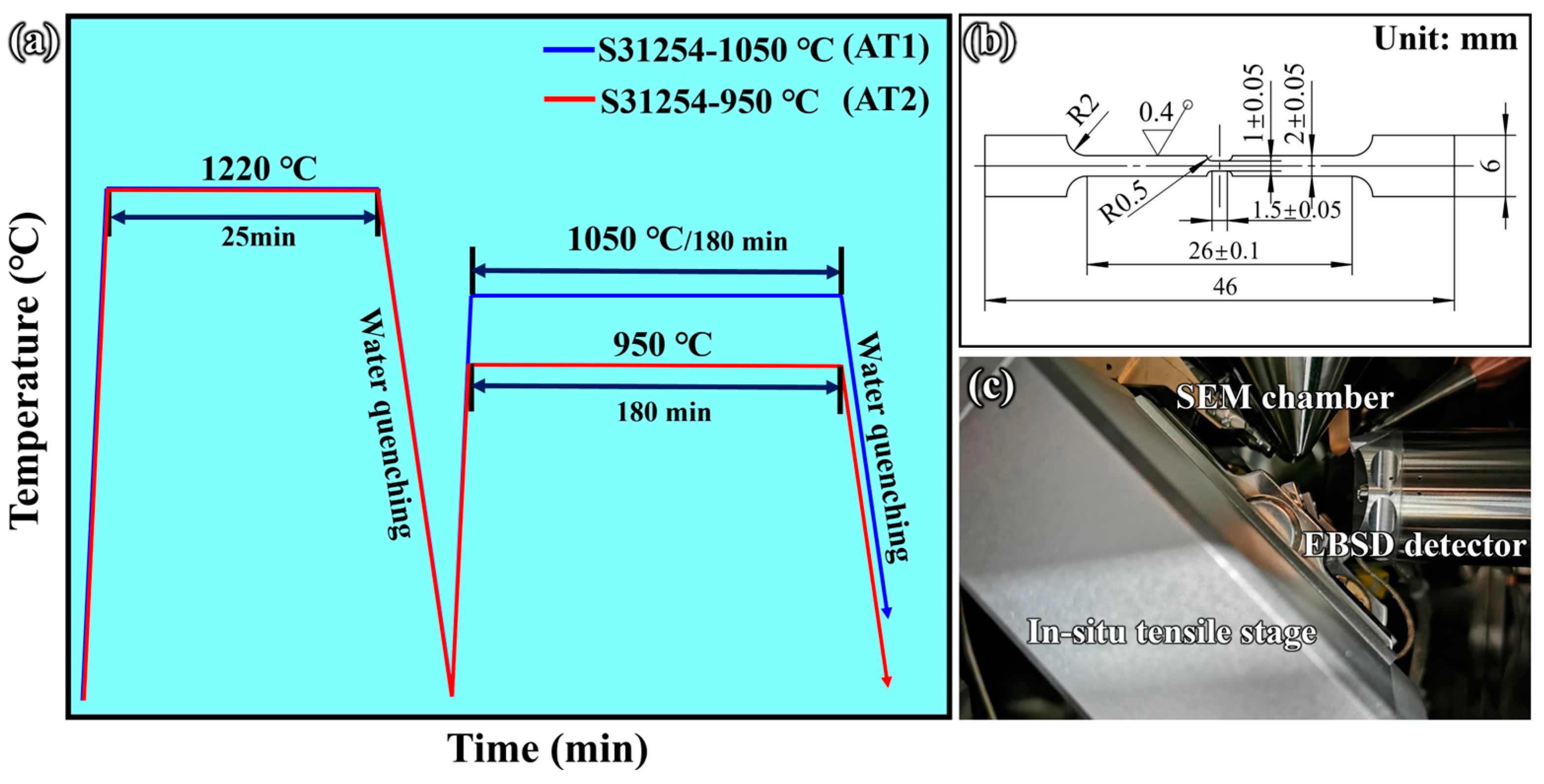

2. Materials and Methods

2.1. Materials Preparation

2.2. Microstructure Characterization

3. Results

3.1. Microstructure Characterization

3.2. Mechanical Behavior of the S31254

3.3. Microstructure Evolution during Tensile Deformation

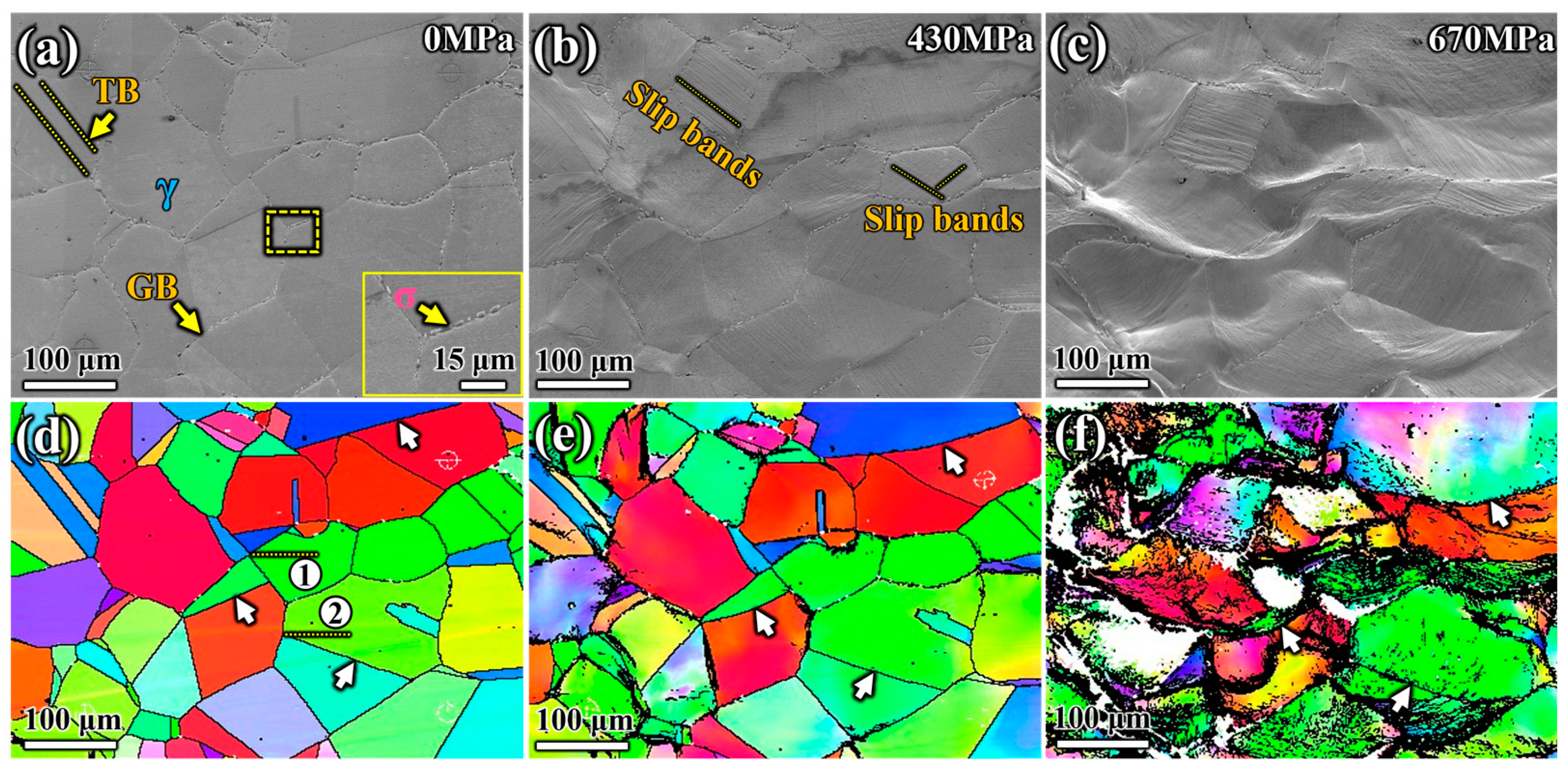

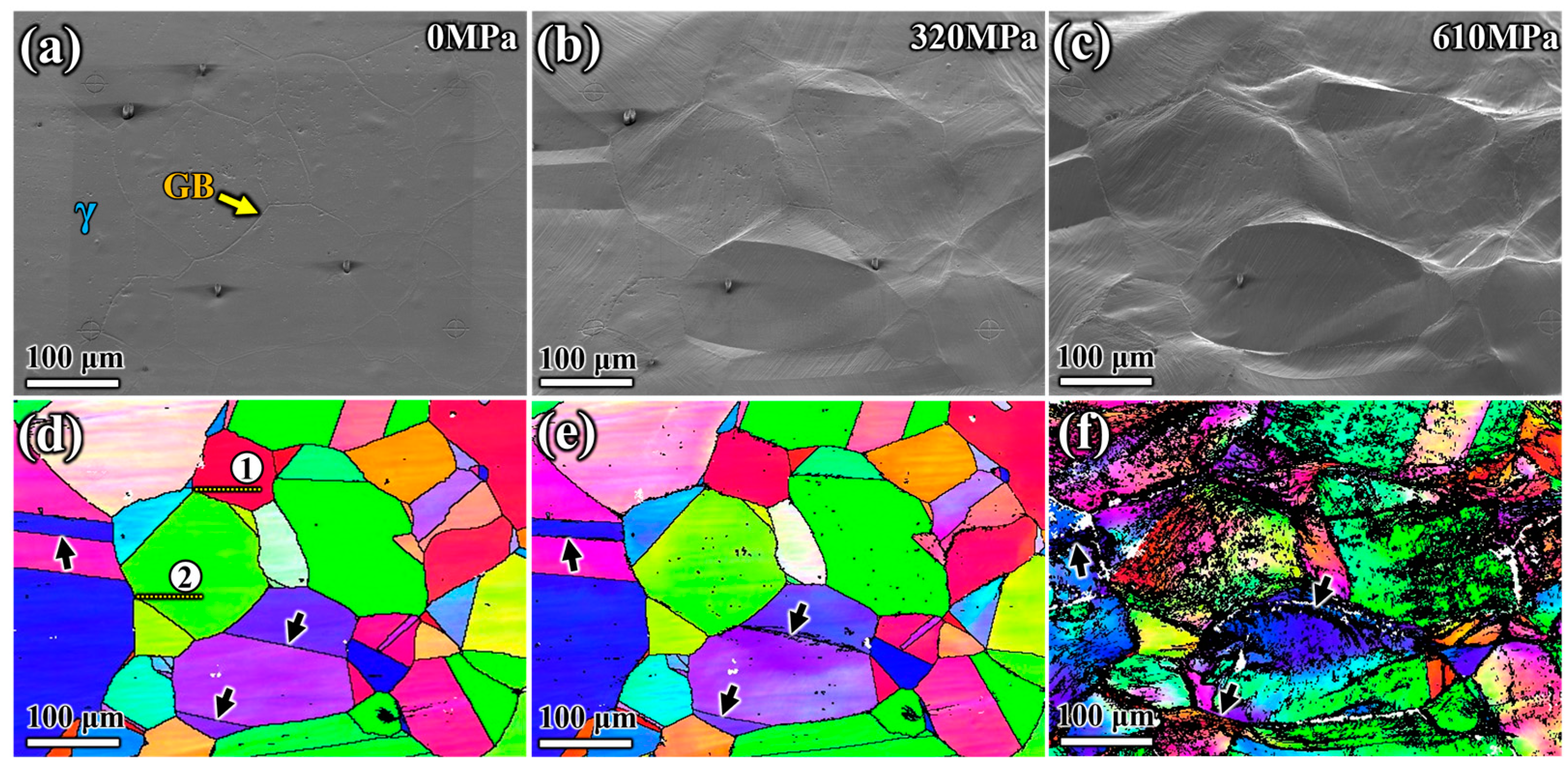

4. Discussion

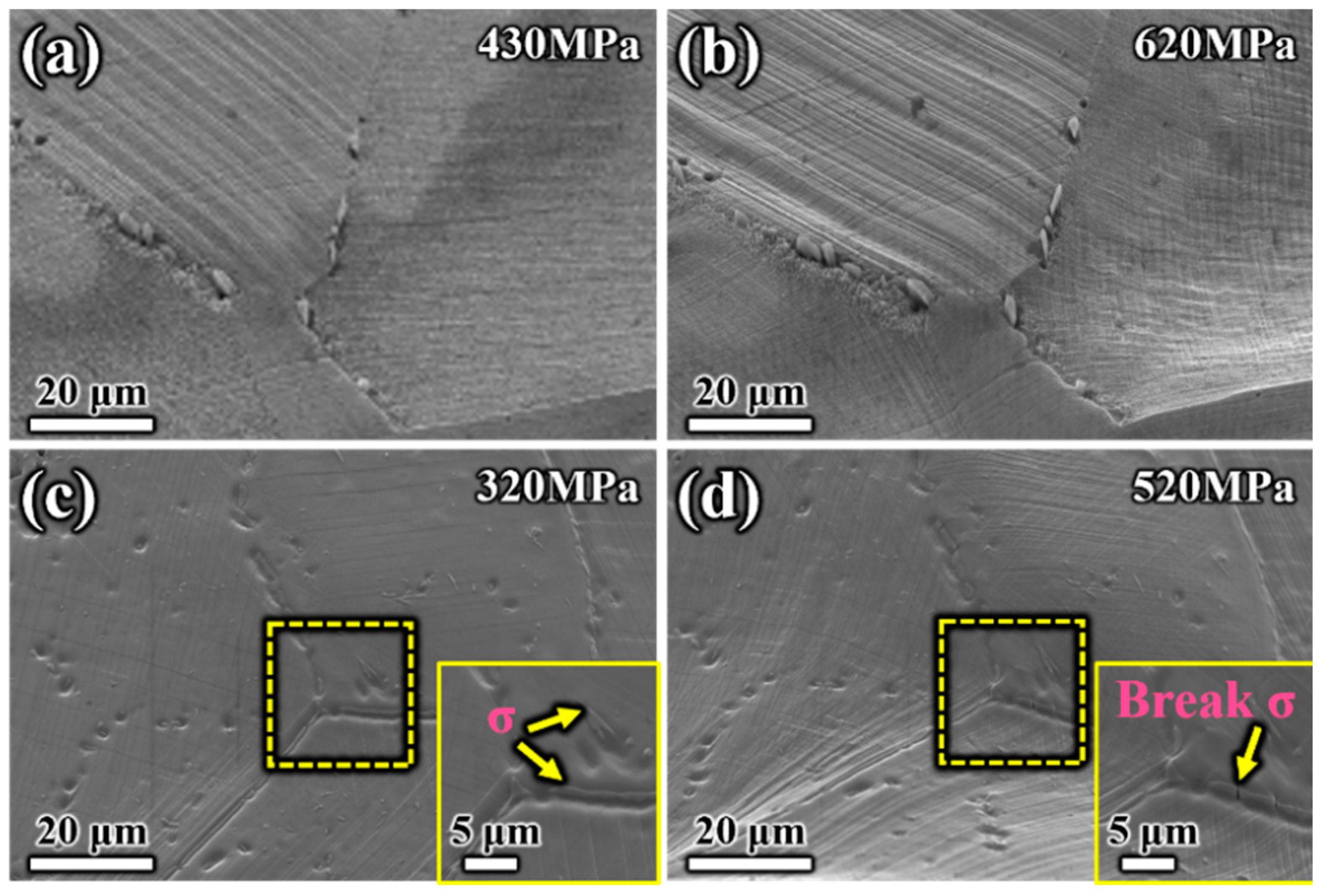

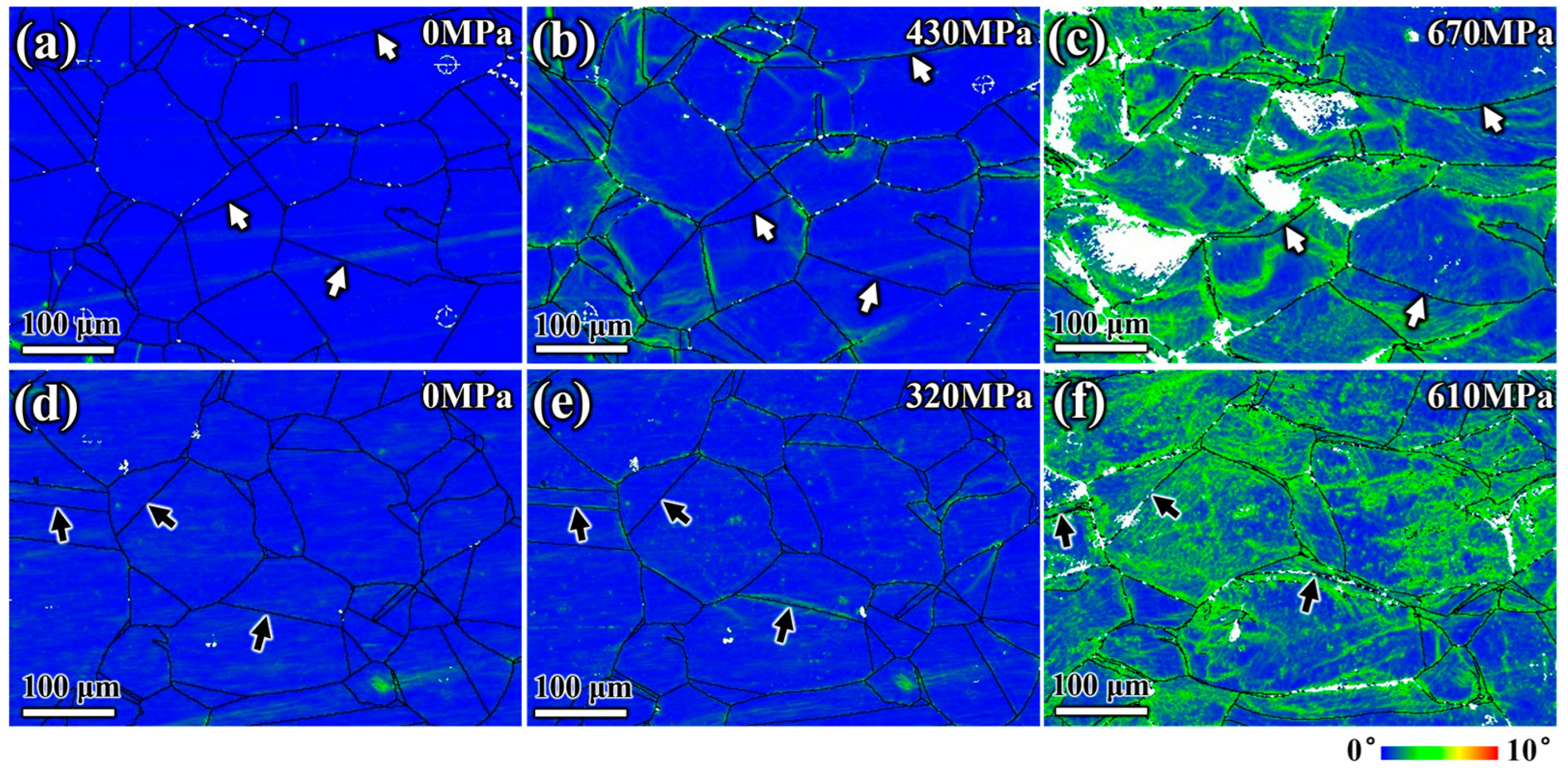

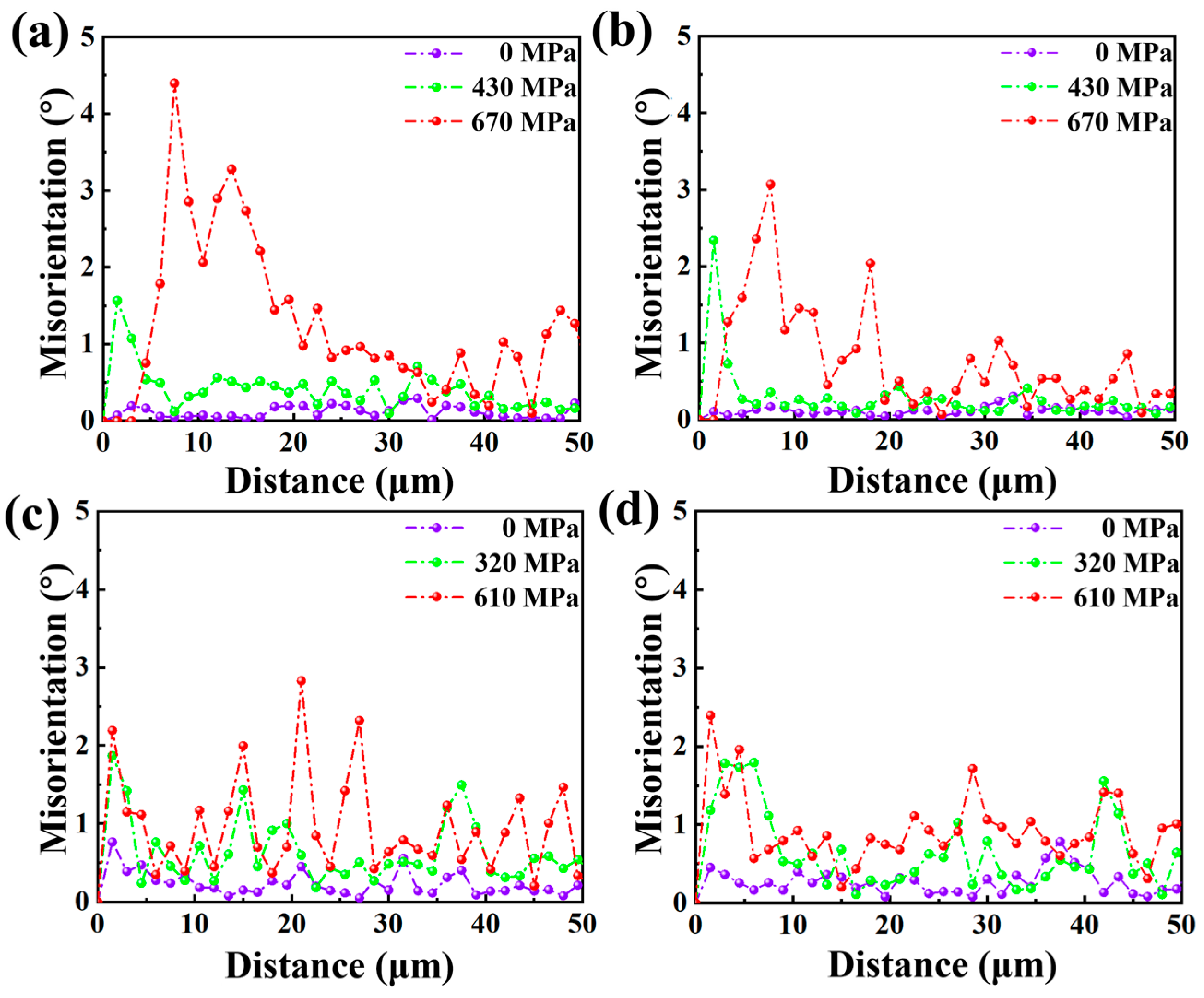

4.1. Influence of Precipitates’ Distribution on Local Deformation Behavior

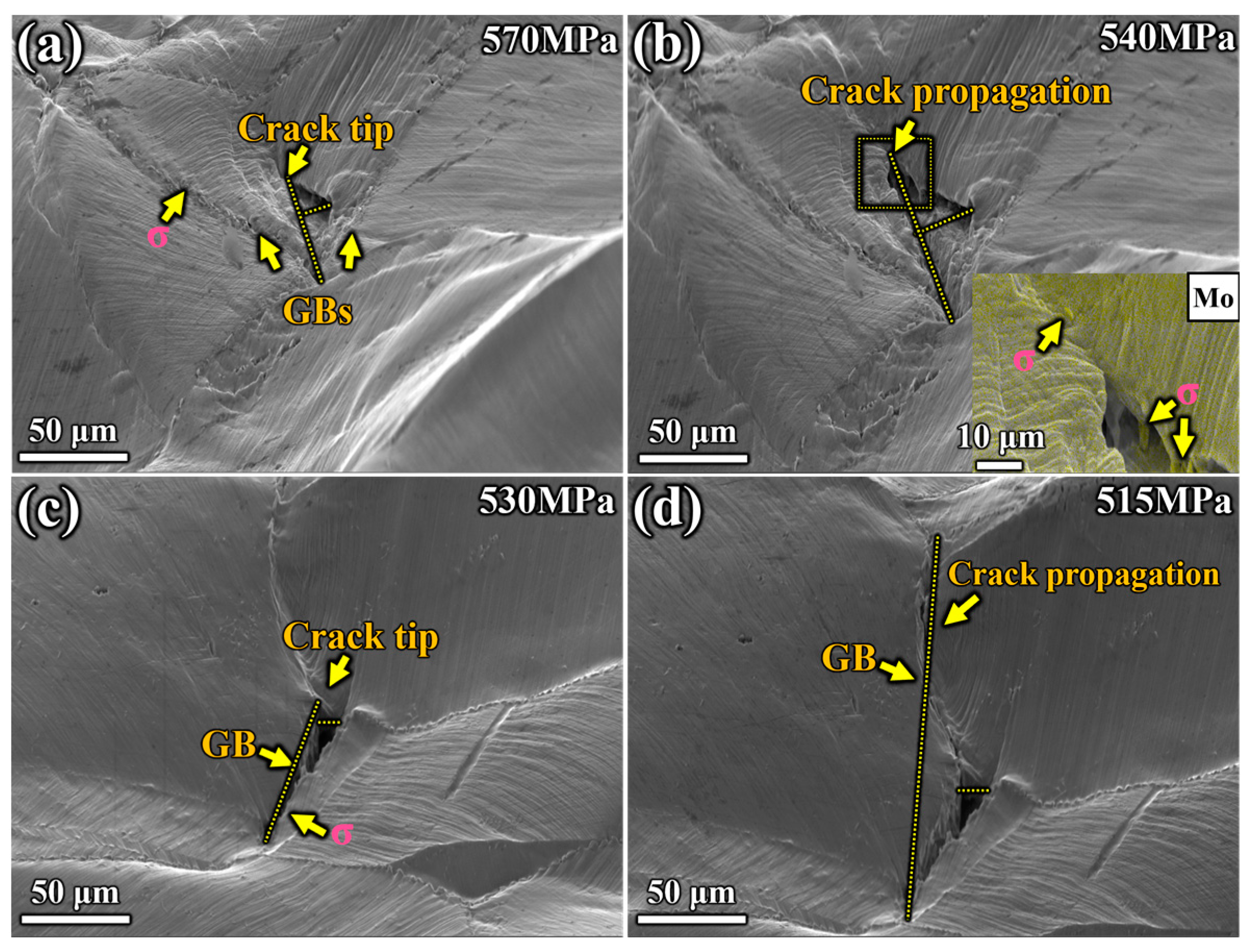

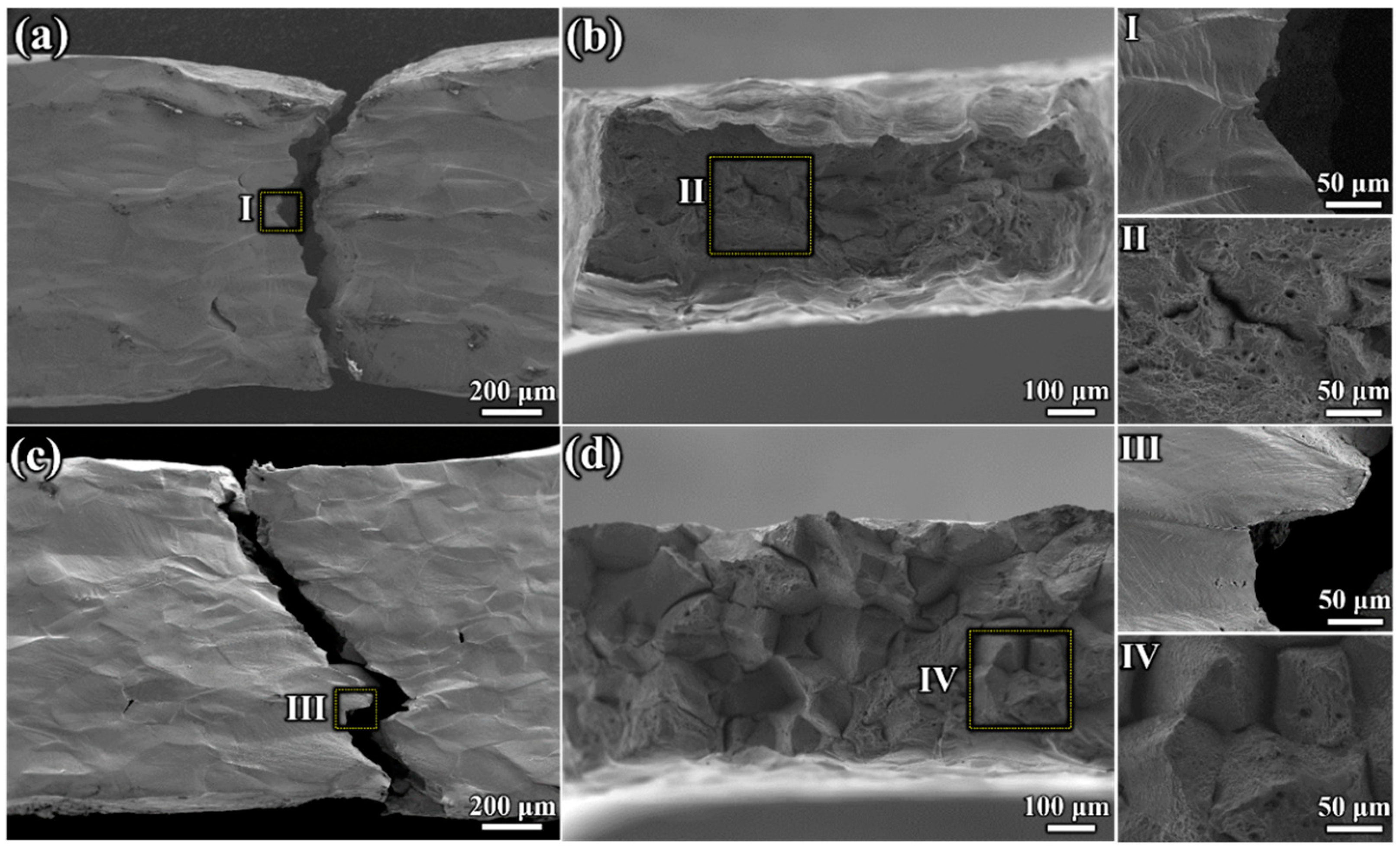

4.2. Influence of Precipitates’ Distribution on Crack Nucleation and Propagation Behavior

5. Conclusions

- No apparent precipitates were observed inside the grains in the specimen aged at 1050 °C, while precipitates at GBs were distributed discontinuously. In the specimen aged at 950 °C, many acicular precipitates were inside the grains, and the precipitates exhibited an elongated strip distribution at GBs. Despite the different precipitate distributions, they were all identified as σ phase.

- The slip lines are fine and dense, with some grains exhibiting evident multi-system slip traces during plastic deformation due to intermittent precipitates. Moreover, the grains can coordinate rotational deformation to release the stress concentration at GBs caused by external loading. Due to the elongated strip distribution of the σ phase, the atomic spacing between the slip lines becomes larger, and the pinning effect of precipitates on GBs results in more significant deformation both at GBs and inside the grains. The plastic deformation in the 1050 °C specimen is more uniform than that of the 950 °C specimen, with smaller local deformation and stress inside the grains.

- During the tensile process of the 1050 °C specimen, a crack initiates inside the austenite grain due to the development of continuous slip bands, and stress concentration, and the accumulation of slip dislocations under high-stress conditions. In the specimen aged at 950 °C, the crack is located at the GBs, where precipitates are continuously distributed, and it propagates along GBs with continuous precipitates’ distribution under external loading. The microcracks in the front of the main crack tip are always adjacent to the σ phase.

- The continuous distribution of precipitates at GBs is primarily related to the segregation of Mo atoms. The greater the segregation of Mo atoms, the lower the charge density between Fe atoms, weakening the interfacial bonding ability of the grain boundaries, leading to the embrittlement of GBs.

- The intermittent distribution of granular precipitates along the GBs is the critical factor leading to a high average hardness, uniform hardness distribution, and superior strength and plasticity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Heino, S.; Karlsson, B. Cyclic Deformation and Fatigue Behaviour of 7Mo–0.5N Superaustenitic Stainless Steel—Stress–Strain Relations and Fatigue Life. Acta Mater. 2001, 49, 339–351. [Google Scholar] [CrossRef]

- Zhang, S.; Jiang, Z.; Li, H.; Zhang, B.; Fan, S.; Li, Z.; Feng, H.; Zhu, H. Precipitation Behavior and Phase Transformation Mechanism of Super Austenitic Stainless Steel S32654 during Isothermal Aging. Mater. Charact. 2018, 137, 244–255. [Google Scholar] [CrossRef]

- Zhang, S.; Jiang, Z.; Li, H.; Feng, H.; Zhang, B. Detection of Susceptibility to Intergranular Corrosion of Aged Super Austenitic Stainless Steel S32654 by a Modified Electrochemical Potentiokinetic Reactivation Method. J. Alloys Compd. 2017, 695, 3083–3093. [Google Scholar] [CrossRef]

- Li, S.; Ma, J.; Wang, J.; Fan, G.; Li, H.; Jiang, Z.; Han, P.; Liang, W. Impact of Boron Addition on the Hot Deformation Behavior and Microstructure Evolution of S31254. Mater. Lett. 2022, 315, 131971. [Google Scholar] [CrossRef]

- Zhang, S.; Li, H.; Jiang, Z.; Zhang, B.; Li, Z.; Wu, J.; Feng, H.; Zhu, H.; Duan, F. Chloride- and Sulphate-Induced Hot Corrosion Mechanism of Super Austenitic Stainless Steel S31254 under Dry Gas Environment. Corros. Sci. 2020, 163, 108295. [Google Scholar] [CrossRef]

- Dou, Y.; Han, S.; Wang, L.; Wang, X.; Cui, Z. Characterization of the Passive Properties of 254SMO Stainless Steel in Simulated Desulfurized Flue Gas Condensates by Electrochemical Analysis, XPS and ToF-SIMS. Corros. Sci. 2020, 165, 108405. [Google Scholar] [CrossRef]

- Zhang, S.; Li, H.; Jiang, Z.; Li, Z.; Wu, J.; Zhang, B.; Duan, F.; Feng, H.; Zhu, H. Influence of N on Precipitation Behavior, Associated Corrosion and Mechanical Properties of Super Austenitic Stainless Steel S32654. J. Mater. Sci. Technol. 2020, 42, 143–155. [Google Scholar] [CrossRef]

- Han, Y.; Wu, H.; Zhang, W.; Zou, D.; Liu, G.; Qiao, G. Constitutive Equation and Dynamic Recrystallization Behavior of As-Cast 254SMO Super-Austenitic Stainless Steel. Mater. Des. 2015, 69, 230–240. [Google Scholar] [CrossRef]

- Babu, K.A.; Mandal, S.; Athreya, C.N.; Shakthipriya, B.; Sarma, V.S. Hot Deformation Characteristics and Processing Map of a Phosphorous Modified Super Austenitic Stainless Steel. Mater. Des. 2017, 115, 262–275. [Google Scholar] [CrossRef]

- Zhang, S.; Li, H.; Jiang, Z.; Zhang, B.; Li, Z.; Wu, J.; Fan, S.; Feng, H.; Zhu, H. Effects of Cr and Mo on Precipitation Behavior and Associated Intergranular Corrosion Susceptibility of Superaustenitic Stainless Steel S32654. Mater. Charact. 2019, 152, 141–150. [Google Scholar] [CrossRef]

- Anburaj, J.; Nazirudeen, S.S.M.; Narayanan, R.; Anandavel, B.; Chandrasekar, A. Ageing of Forged Superaustenitic Stainless Steel: Precipitate Phases and Mechanical Properties. Mater. Sci. Eng. A 2012, 535, 99–107. [Google Scholar] [CrossRef]

- Ebrahimi, G.R.; Keshmiri, H.; Momeni, A.; Mazinani, M. Dynamic Recrystallization Behavior of a Superaustenitic Stainless Steel Containing 16%Cr and 25%Ni. Mater. Sci. Eng. A 2011, 528, 7488–7493. [Google Scholar] [CrossRef]

- Pu, E.; Zheng, W.; Xiang, J.; Song, Z.; Feng, H.; Zhu, Y. Hot Working Characteristic of Superaustenitic Stainless Steel 254SMO. Acta Metall. Sin. (Engl. Lett.) 2014, 27, 313–323. [Google Scholar] [CrossRef]

- Liu, G.; Han, Y.; Shi, Z.; Sun, J.; Zou, D.; Qiao, G. Hot Deformation and Optimization of Process Parameters of an As-Cast 6Mo Superaustenitic Stainless Steel: A Study with Processing Map. Mater. Des. 2014, 53, 662–672. [Google Scholar] [CrossRef]

- Yu, J.; Zhang, S.; Li, H.; Jiang, Z.; Feng, H.; Xu, P.; Han, P. Influence Mechanism of Boron Segregation on the Microstructure Evolution and Hot Ductility of Super Austenitic Stainless Steel S32654. J. Mater. Sci. Technol. 2022, 112, 184–194. [Google Scholar] [CrossRef]

- Koutsoukis, T.; Papadopoulou, E.G.; Zormalia, S.; Kokkonidis, P.; Fourlaris, G. Precipitation Sequences in Cold Deformed Superaustenitic Stainless Steels. Mater. Sci. Technol. 2010, 26, 1041–1048. [Google Scholar] [CrossRef]

- Li, J.; Liang, W.; Wu, M.; Zhang, S.; Zhang, W. Microstructure Evolution in the Segregation Area of S31254 Stainless Steel Plate. Mater. Today Proc. 2015, 2, S319–S324. [Google Scholar] [CrossRef]

- Zhang, S.; Yu, J.; Li, H.; Jiang, Z.; Geng, Y.; Feng, H.; Zhang, B.; Zhu, H. Refinement Mechanism of Cerium Addition on Solidification Structure and Sigma Phase of Super Austenitic Stainless Steel S32654. J. Mater. Sci. Technol. 2022, 102, 105–114. [Google Scholar] [CrossRef]

- Yu, J.; Zhang, S.; Li, H.; Jiang, Z.; Feng, H.; Zhang, B.; Zhu, H.; Dai, Y. Influence Mechanism of Cerium Addition on Precipitation Behaviour of Super Austenitic Stainless Steel S32654. J. Mater. Res. Technol. 2023, 24, 7108–7120. [Google Scholar] [CrossRef]

- Pu, E.; Zheng, W.; Xiang, J.; Song, Z.; Li, J. Hot Deformation Characteristic and Processing Map of Superaustenitic Stainless Steel S32654. Mater. Sci. Eng. A 2014, 598, 174–182. [Google Scholar] [CrossRef]

- Adams, K.D.; DuPont, J.N.; Marder, A.R. The Influence of Centerline Sigma (σ) Phase on the Through-Thickness Toughness and Tensile Properties of Alloy AL-6XN. J. Mater. Eng. Perform. 2007, 16, 123–130. [Google Scholar] [CrossRef]

- Fonda, R.W.; Lauridsen, E.M.; Ludwig, W.; Tafforeau, P.; Spanos, G. Two-Dimensional and Three-Dimensional Analyses of Sigma Precipitates and Porosity in a Superaustenitic Stainless Steel. Met. Mater. Trans. A 2007, 38, 2721–2726. [Google Scholar] [CrossRef]

- Hao, Y.; Liu, W.; Li, J.; Nie, B.; Zhang, W.; Liu, Z. Microstructural Bandings Evolution Behavior and Their Effects on Microstructure and Mechanical Property of Super-Austenitic Stainless Steel. Mater. Sci. Eng. A 2018, 736, 258–268. [Google Scholar] [CrossRef]

- Gao, J.; Ma, J.; Yang, S.; Guo, Z.; Ma, J.; Li, H.; Jiang, Z.; Han, P. Grain Boundary Co-Segregation of B and Ce Hindering the Precipitates of S31254 Super Austenitic Stainless Steel. J. Mater. Res. Technol. 2023, 24, 2653–2667. [Google Scholar] [CrossRef]

- Gao, W.; Lu, J.; Zhou, J.; Liu, L.; Wang, J.; Zhang, Y.; Zhang, Z. Effect of Grain Size on Deformation and Fracture of Inconel718: An in-Situ SEM-EBSD-DIC Investigation. Mater. Sci. Eng. A 2022, 861, 144361. [Google Scholar] [CrossRef]

- Bibhanshu, N.; Gussev, M.N.; Massey, C.P.; Field, K.G. Investigation of Deformation Mechanisms in an Advanced FeCrAl Alloy Using In-Situ SEM-EBSD Testing. Mater. Sci. Eng. A 2022, 832, 142373. [Google Scholar] [CrossRef]

- Jing, W.; Yongqing, Z.; Qinyang, Z.; Chao, L.; Wei, Z.; Weidong, Z. In-Situ Study on Tensile Deformation and Fracture Mechanisms of Metastable β Titanium Alloy with Equiaxed Microstructure. Materials 2022, 15, 1325. [Google Scholar] [CrossRef] [PubMed]

- Heard, R.; Siviour, C.R.; Dragnevski, K. Investigating Iron Alloy Phase Changes Using High Temperature In Situ SEM Techniques. Materials 2022, 15, 3921. [Google Scholar] [CrossRef]

- Ning, J.; Gao, B.; Zhou, J.; Chen, L.; Tang, G.; Li, S. In-Situ Study on the Tensile Deformation and Fracture Mechanism of a Bimodal-Structured Mg-Gd-Y Alloy. Materials 2023, 16, 5978. [Google Scholar] [CrossRef]

- Ma, J.; Lu, J.; Tang, L.; Wang, J.; Sang, L.; Zhang, Y.; Zhang, Z. A Novel Instrument for Investigating the Dynamic Microstructure Evolution of High Temperature Service Materials up to 1150 °C in Scanning Electron Microscope. Rev. Sci. Instrum. 2020, 91, 043704. [Google Scholar] [CrossRef]

- Koutsoukis, T.; Redjaïmia, A.; Fourlaris, G. Phase Transformations and Mechanical Properties in Heat Treated Superaustenitic Stainless Steels. Mater. Sci. Eng. A 2013, 561, 477–485. [Google Scholar] [CrossRef]

- Lee, T.-H.; Kim, S.-J. Phase Identification in an Isothermally Aged Austenitic 22Cr-21Ni-6Mo-N Stainless Steel. Scr. Mater. 1998, 39, 951–956. [Google Scholar] [CrossRef]

- Hariharan, K.; Dubey, P.; Jain, J. Time Dependent Ductility Improvement of Stainless Steel SS 316 Using Stress Relaxation. Mater. Sci. Eng. A 2016, 673, 250–256. [Google Scholar] [CrossRef]

- Gussev, M.N.; Leonard, K.J. In Situ SEM-EBSD Analysis of Plastic Deformation Mechanisms in Neutron-Irradiated Austenitic Steel. J. Nucl. Mater. 2019, 517, 45–56. [Google Scholar] [CrossRef]

- Liu, L.; Huang, W.; Ruan, M.; Chen, Z. Effects of Temperatures on Microstructure Evolution and Deformation Behavior of Fe–32Ni by in-Situ EBSD. Mater. Sci. Eng. A 2023, 875, 145097. [Google Scholar] [CrossRef]

- Chen, J.; Lu, J.; Cai, W.; Zhang, Y.; Wang, Y.; Jiang, W.; Rizwan, M.; Zhang, Z. In-Situ Study of Adjacent Grains Slip Transfer of Inconel 718 during Tensile Process at High Temperature. Int. J. Plast. 2023, 163, 103554. [Google Scholar] [CrossRef]

- Liu, Q.; Hansen, N. Geometrically Necessary Boundaries and Incidental Dislocation Boundaries Formed during Cold Deformation. Scr. Metall. Mater. 1995, 32, 1289–1295. [Google Scholar] [CrossRef]

- Hsieh, C.-C.; Wu, W. Overview of Intermetallic Sigma (σ) Phase Precipitation in Stainless Steels. ISRN Metall. 2012, 2012, 732471. [Google Scholar] [CrossRef]

| Alloy | C | Cr | Ni | Mo | Si | Mn | P | S | Cu | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| S31254 | 0.018 | 19.84 | 18.07 | 6.61 | 0.17 | 1.82 | 0.007 | 0.027 | 1.52 | 0.199 | Bal. |

| Alloy | Fe | Cr | Ni | Mo | |

|---|---|---|---|---|---|

| S31254-AT1 | 1 | 37.5 | 22.7 | 9.4 | 13.5 |

| S31254-AT2 | 2 | 43.5 | 20.1 | 14.1 | 14.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, J.; Tan, H.; Dong, N.; Gao, J.; Wang, P.; Wang, Z.; Han, P. In Situ Study of Precipitates’ Effect on Grain Deformation Behavior and Mechanical Properties of S31254 Super Austenitic Stainless Steel. Materials 2024, 17, 2676. https://doi.org/10.3390/ma17112676

Ma J, Tan H, Dong N, Gao J, Wang P, Wang Z, Han P. In Situ Study of Precipitates’ Effect on Grain Deformation Behavior and Mechanical Properties of S31254 Super Austenitic Stainless Steel. Materials. 2024; 17(11):2676. https://doi.org/10.3390/ma17112676

Chicago/Turabian StyleMa, Jinyao, Huanyu Tan, Nan Dong, Jiemin Gao, Puli Wang, Zhihua Wang, and Peide Han. 2024. "In Situ Study of Precipitates’ Effect on Grain Deformation Behavior and Mechanical Properties of S31254 Super Austenitic Stainless Steel" Materials 17, no. 11: 2676. https://doi.org/10.3390/ma17112676