From Facile One-Pot Synthesis of Semi-Degradable Amphiphilic Miktoarm Polymers to Unique Degradation Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

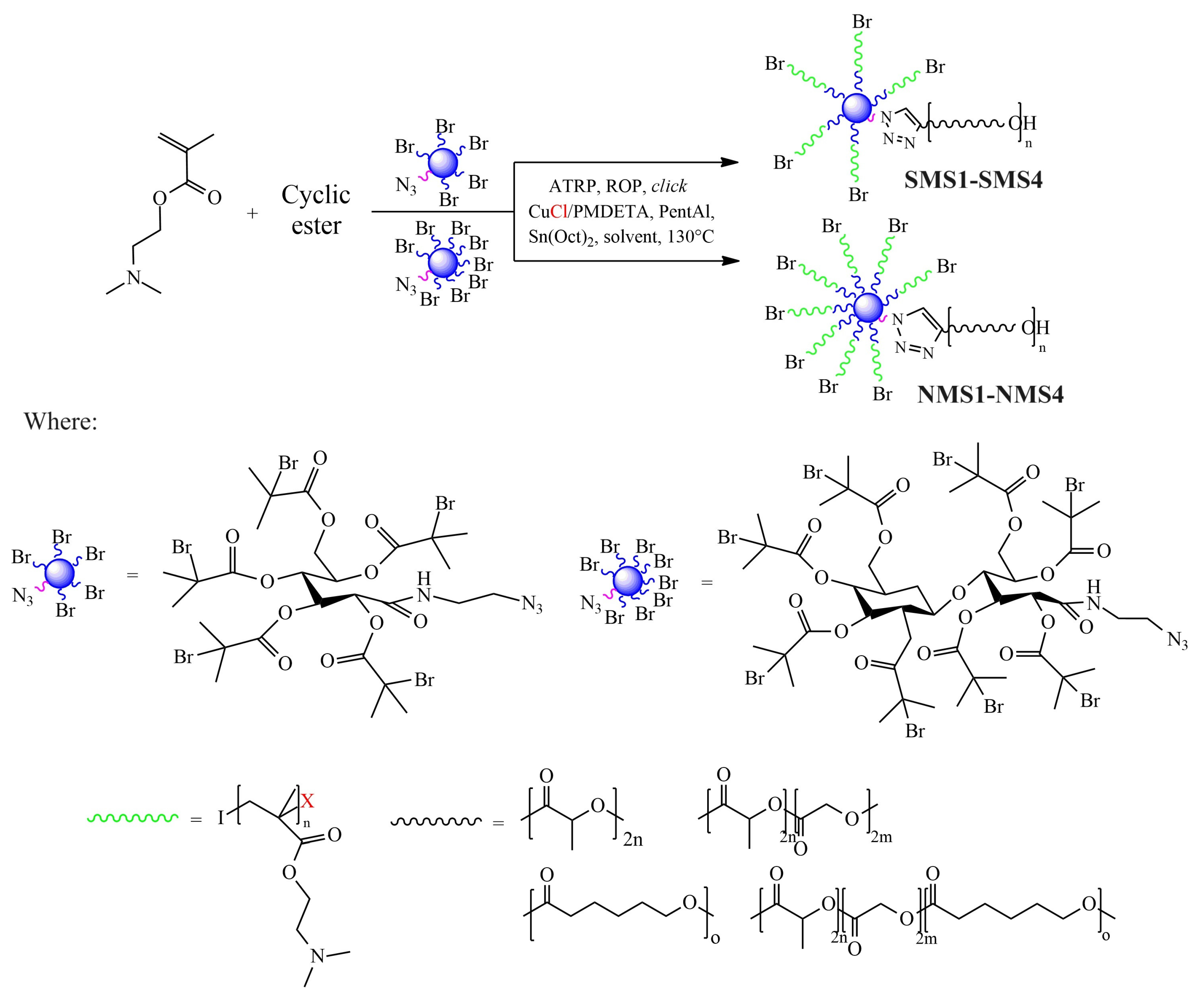

2.2. One-Pot Synthesis of Amphiphilic Miktoarm Star-Shaped Polymers

2.3. Characterization of Miktoarm Star-Shaped Polymers

2.4. Hydrolytic Degradation

3. Results and Discussion

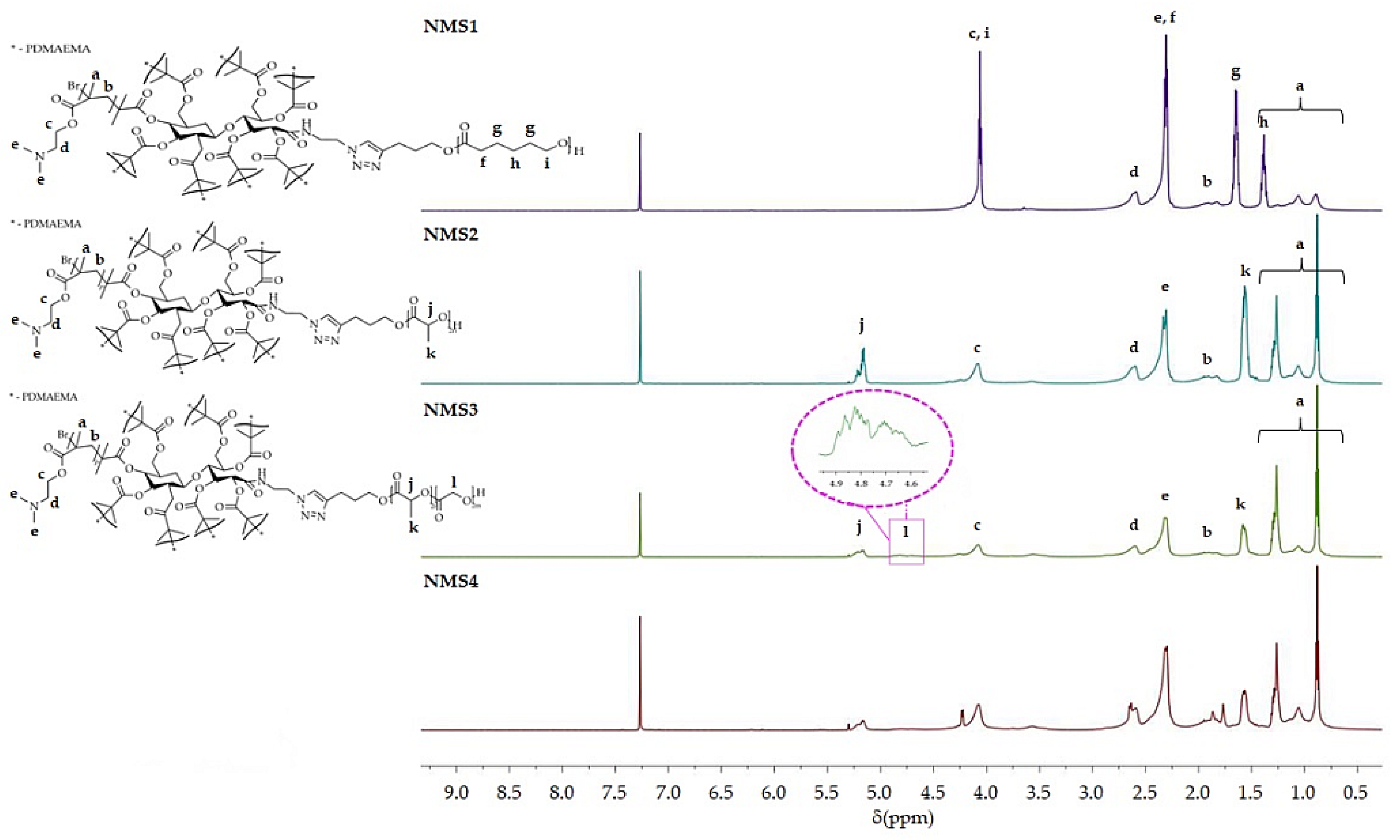

3.1. One-Pot Synthesis of Miktoarm Stars

3.2. Miktoarm Stars Behavior in Water Solution

3.3. Thermal Stability

3.4. Wettability and Hydrophilicity

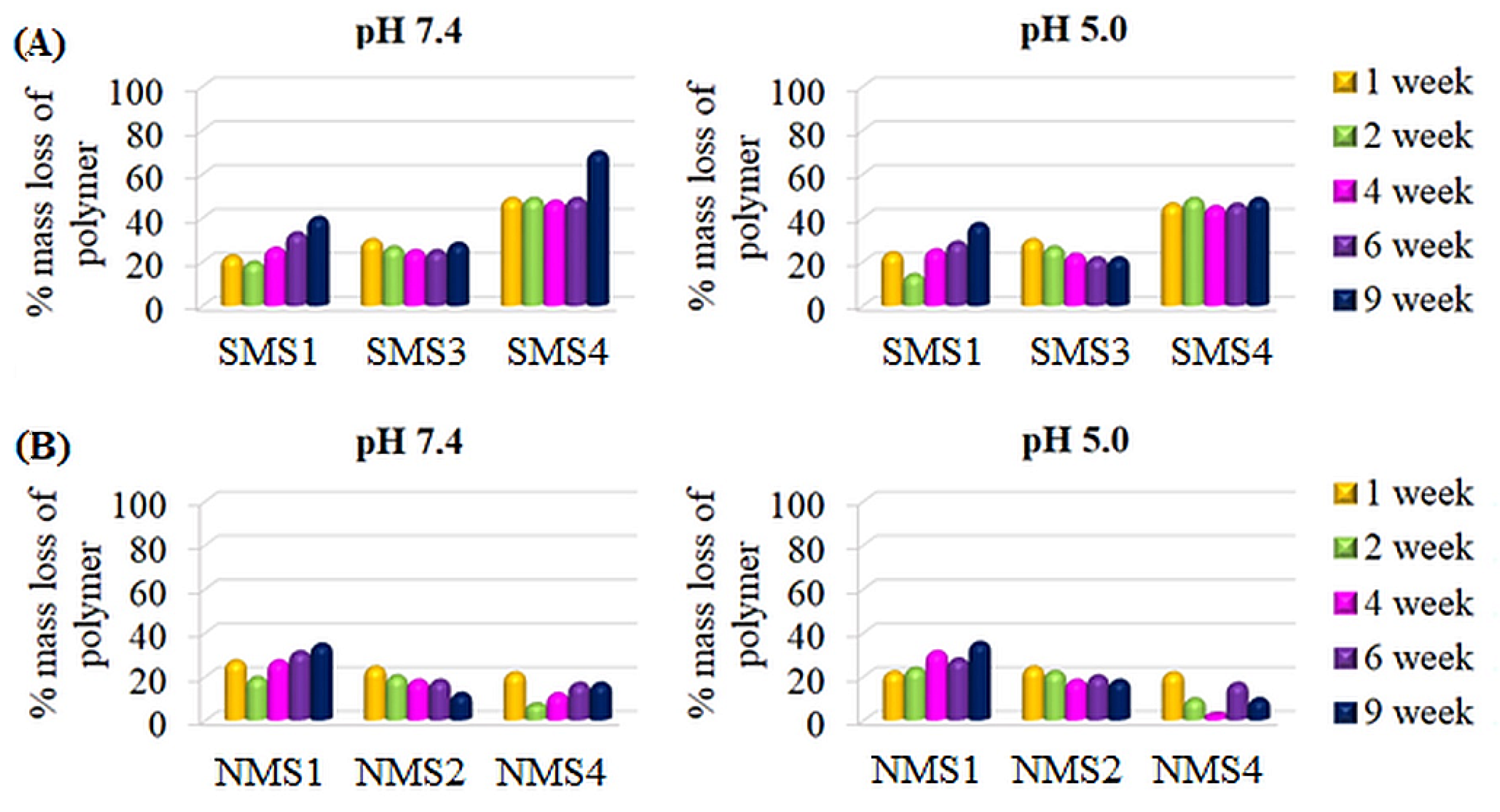

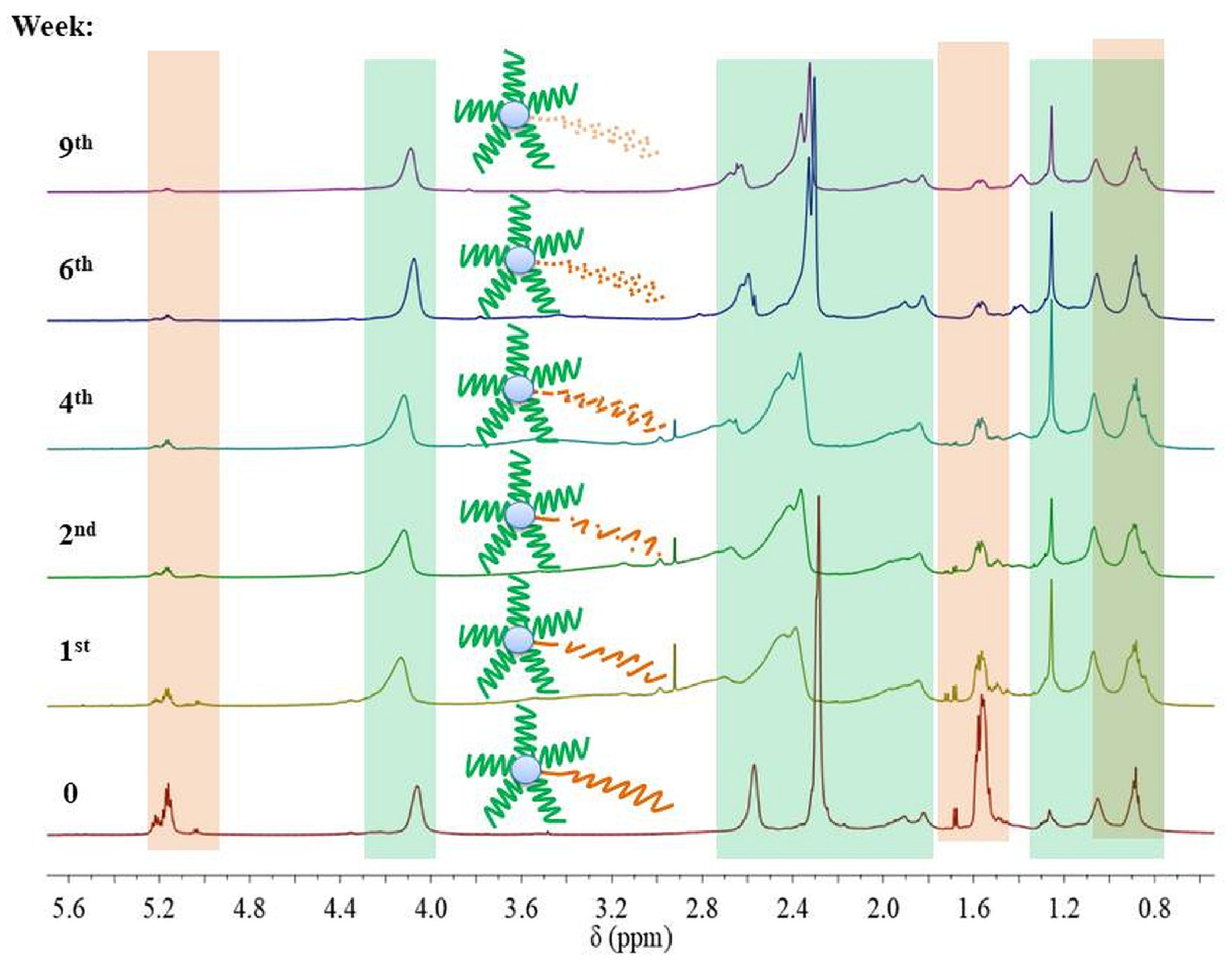

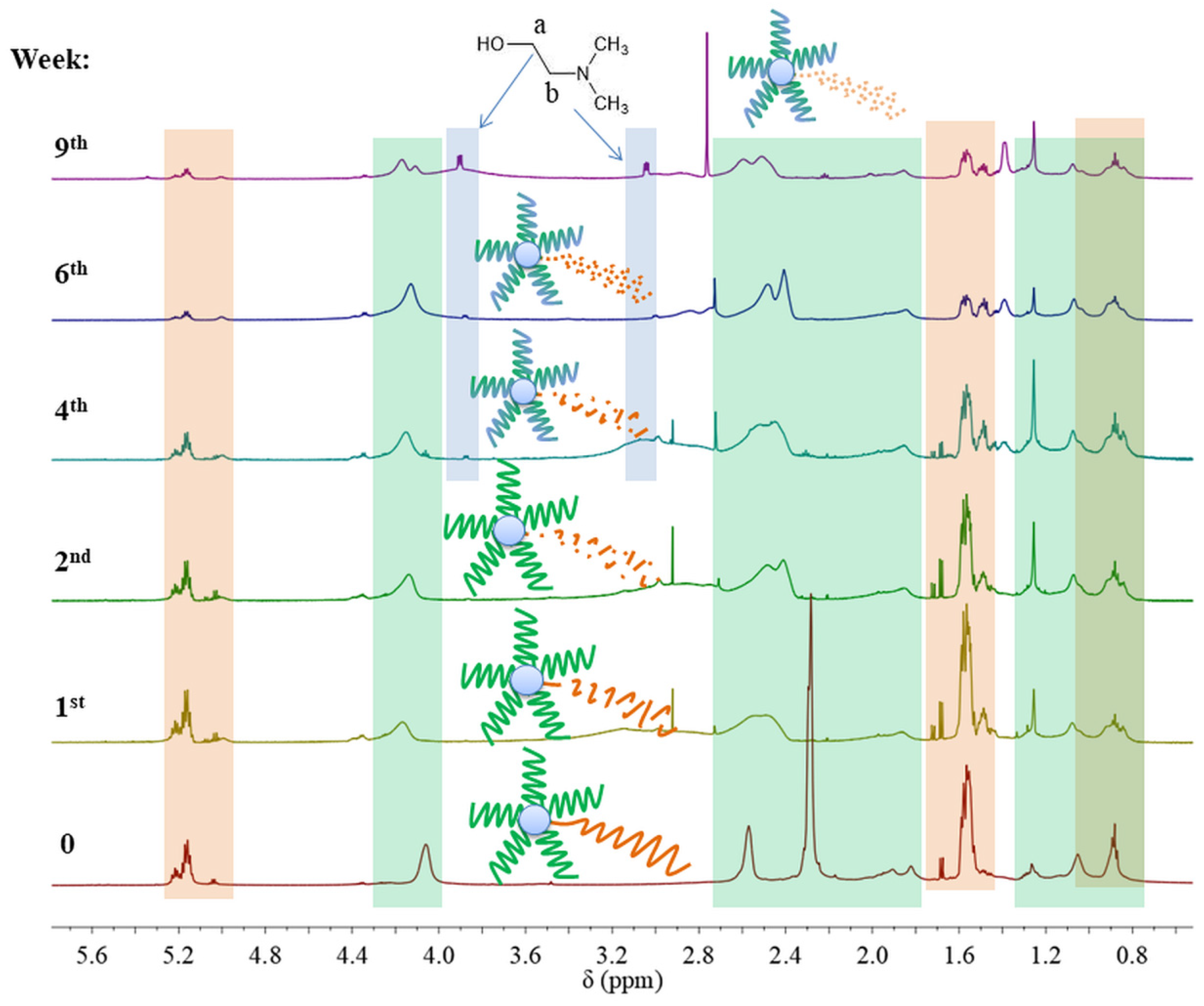

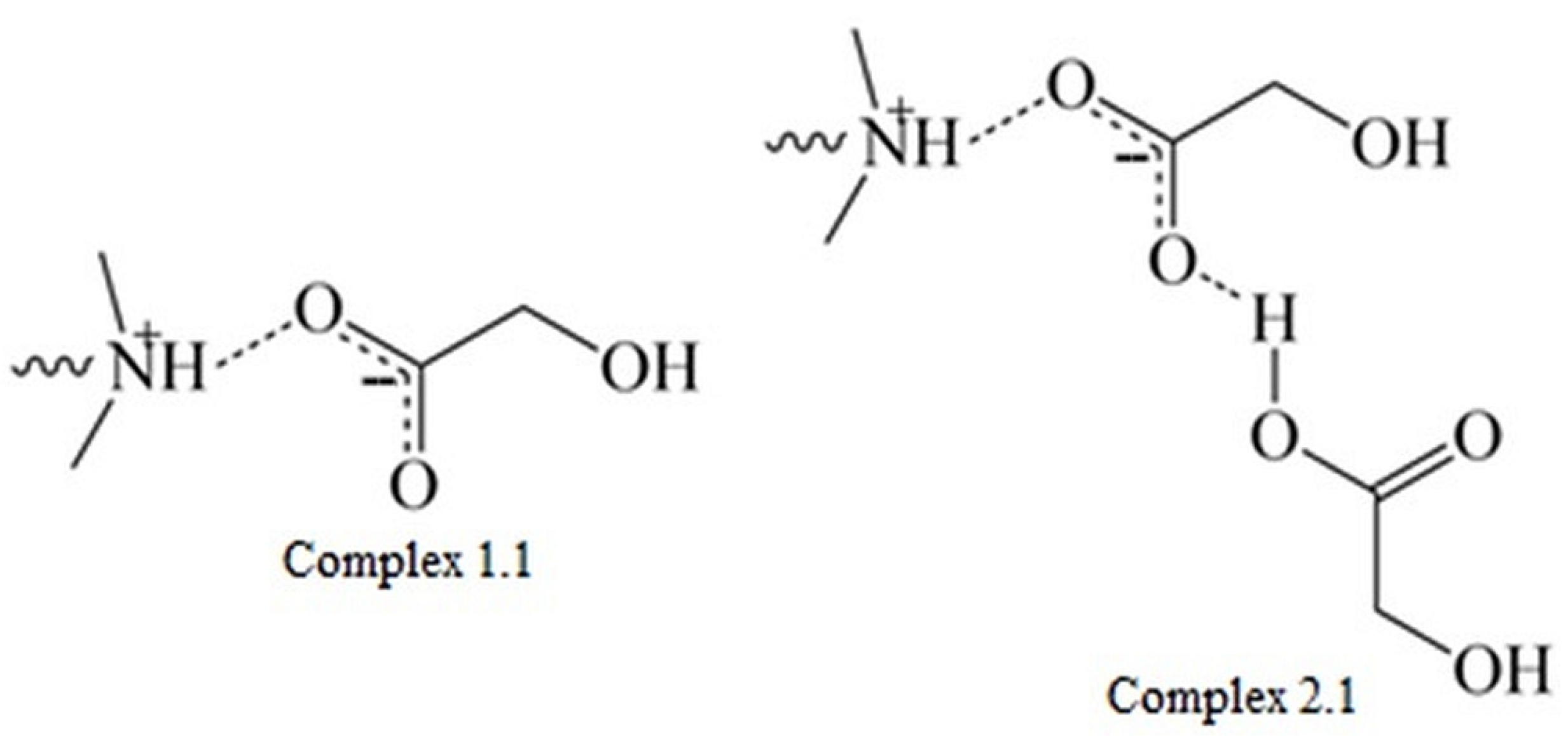

3.5. Hydrolytic Degradation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Robinson, R. LXIII.-A synthesis of tropinone. J. Chem. Soc. Trans. 1917, 111, 762–768. [Google Scholar] [CrossRef]

- Lundberg, P.; Hawker, C.J.; Hult, A.; Malkoch, M. Click Assisted One-Pot Multi-Step Reactions in Polymer Science: Accelerated Synthetic Protocols. Macromol. Rapid Commun. 2008, 29, 998–1015. [Google Scholar] [CrossRef]

- Medley, J.W.; Movassaghi, M. Robinson’s landmark synthesis of tropinone. Chem. Commun. 2013, 49, 10775–10777. [Google Scholar] [CrossRef]

- Hayashi, Y. Pot economy and one-pot synthesis. Chem. Sci. 2016, 7, 866–880. [Google Scholar] [CrossRef] [PubMed]

- Corma, A.; Navas, J.; Sabater, M.J. Advances in One-Pot Synthesis through Borrowing Hydrogen Catalysis. Chem. Rev. 2018, 118, 1410–1459. [Google Scholar] [CrossRef]

- Ugi, I. Recent progress in the chemistry of multicomponent reactions. Pure Appl. Chem. 2001, 73, 187–191. [Google Scholar] [CrossRef]

- Heck, S.; Dömling, A. A versatile multi-component one-pot thiazole synthesis. Synlett 2000, 2000, 424–426. [Google Scholar] [CrossRef]

- Tietze, L.F.; Rackelmann, N. Domino reactions in the synthesis of heterocyclic natural products and analogs. Pure Appl. Chem. 2004, 76, 1967–1983. [Google Scholar] [CrossRef]

- Konieczny, M.T.; Konieczny, W.; Wolniewicz, S.; Wierzba, K.; Suda, Y. New domino reaction. One pot synthesis of 4, 7-dihydroxythioaurone derivatives from benzaldehydes and 4-acetyl-2-oxo-benz [1, 3] oxathiole. Tetrahedron 2005, 61, 8648–8655. [Google Scholar] [CrossRef]

- Evans, P.A.; Robinson, J.E. Regio- and Diastereoselective Tandem Rhodium-Catalyzed Allylic Alkylation/Pauson-Khand Annulation Reactions. J. Am. Chem. Soc. 2001, 123, 4609–4610. [Google Scholar] [CrossRef]

- Gao, C.; Zheng, X. Facile synthesis and self-assembly of multihetero-arm hyperbranched polymer brushes. Soft Matter 2009, 5, 4788–4796. [Google Scholar] [CrossRef]

- Shahrokhinia, A.; Biswas, P.; Reuther, J.F. Orthogonal synthesis and modification of polymer materials. J. Polym. Sci. 2021, 59, 1748–1786. [Google Scholar] [CrossRef]

- Xia, X.; Gao, T.; Li, F.; Suzuki, R.; Isono, T.; Satoh, T. Multidimensional Control of Repeating Unit/Sequence/Topology for One-Step Synthesis of Block Polymers from Monomer Mixtures. J. Am. Chem. Soc. 2022, 144, 17905–17915. [Google Scholar] [CrossRef] [PubMed]

- Braunecker, W.A.; Matyjaszewski, K. Controlled/living radical polymerization: Features, developments, and perspectives. Prog. Polym. Sci. 2007, 32, 93–146. [Google Scholar] [CrossRef]

- Hawker, C.J.; Bosman, A.W.; Harth, E.; Copolymers, D.R. New Polymer Synthesis by Nitroxide Mediated Living Radical Polymerizations. Chem. Rev. 2001, 101, 3661–3688. [Google Scholar] [CrossRef] [PubMed]

- Rizzardo, E.; Chiefari, J.; Mayadunne, R.; Moad, G.; Thang, S. Tailored Polymer Architectures by Reversible Addition-Fragmentation Chain Transfer. Macromol. Symp. 2001, 174, 209–212. [Google Scholar] [CrossRef]

- Mespouille, L.; Vachaudez, M.; Suriano, F.; Gerbaux, P.; Flammang, R.; Dubois, P.; Coulembier, O.; Dege, P. One-Pot Synthesis of Well-Defined Amphiphilic and Adaptative Block Copolymers via Versatile Combination of “Click” Chemistry and ATRP. Macromol. Rapid Commun. 2007, 28, 2151–2158. [Google Scholar] [CrossRef]

- Huang, X.; Xiao, Y.; Lang, M. Synthesis of star-shaped PCL-based copolymers via one-pot ATRP and their self-assembly behavior in aqueous solution. Macromol. Res. 2012, 20, 597–604. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, C.; Liu, S. One-Pot Synthesis of ABC Miktoarm Star Terpolymers by Coupling ATRP, ROP, and Click Chemistry Techniques. J. Polym. Sci. Part A Polym. Chem. 2009, 47, 3066–3077. [Google Scholar]

- Feng, H.; Lu, X.; Wang, W.; Kang, N.G.; Mays, J.W. Block copolymers: Synthesis, self-assembly, and applications. Polymers 2017, 9, 494. [Google Scholar] [CrossRef]

- Davis, K.; Matyjaszewski, K. Advances in Polymer Science; Springer: Berlin/Heidelberg, Germany; Springer: New York, NY, USA, 2002; Volume 159. [Google Scholar]

- Ren, J.M.; McKenzie, T.G.; Fu, Q.; Wong, E.H.H.; Xu, J.; An, Z.; Shanmugam, S.; Davis, T.P.; Boyer, C.; Qiao, G.G. Star Polymers. Chem. Rev. 2016, 116, 6743–6836. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Blankenship, J.R.; Levi, A.E.; Fu, Q.; Hudson, Z.M.; Bates, C.M. Miktoarm Star Polymers: Synthesis and Applications. Chem. Mater. 2022, 34, 6188–6209. [Google Scholar] [CrossRef]

- Kupczak, M.; Mielańczyk, A.; Neugebauer, D. The Influence of Polymer Composition on the Hydrolytic and Enzymatic Degradation of Polyesters and Their Block Copolymers with PDMAEMA. Materials 2021, 14, 3636. [Google Scholar] [CrossRef] [PubMed]

- Kupczak, M.; Mielańczyk, A.; Neugebauer, D. PDMAEMA/polyester miktopolymers: Synthesis via in-out approach, physicochemical characterization and enzymatic degradation. Materials 2021, 14, 1277. [Google Scholar] [CrossRef] [PubMed]

- Mielańczyk, A.; Kupczak, M.; Klymenko, O.; Mielańczyk, Ł.; Arabasz, S.; Madej, K.; Neugebauer, D. The structure-self-assembly relationship in PDMAEMA/polyester miktoarm stars. Polym. Chem. 2022, 13, 4763–4775. [Google Scholar] [CrossRef]

- Mielańczyk, A.; Kupczak, M.; Burek, M.; Mielańczyk, Ł.; Klymenko, O.; Wandzik, I.; Neugebauer, D. Functional (mikto)stars and star-comb copolymers from D-gluconolactone derivative: An efficient route for tuning the architecture and responsiveness to stimuli. Polymer 2018, 146, 331–343. [Google Scholar] [CrossRef]

- Goc, K.; Mielańczyk, A.; Kupczak, M.; Milewska, M.; Babilas, D.; Milewski, A.; Neugebauer, D. Towards green synthesis of stimuli-responsive star-shaped copolymers with lactobionic or D-gluconic amide in the core. Manuscr. Prep. 2023. (under peer review). [Google Scholar]

- Van Ravensteijn, B.G.P.; Bou Zerdan, R.; Helgeson, M.E.; Hawker, C.J. Minimizing Star-Star Coupling in Cu(0)-Mediated Controlled Radical Polymerizations. Macromolecules 2019, 52, 601–609. [Google Scholar] [CrossRef]

- Netopilík, M.; Podzimek, S. Retention Mechanism of Branched Macromolecules in Size Exclusion Chromatography. ACS Omega 2020, 5, 14254–14260. [Google Scholar] [CrossRef]

- Kunz, W.; Henle, J.; Ninham, B.W. ‘Zur Lehre von der Wirkung der Salze’ (about the science of the effect of salts): Franz Hofmeister’ s historical papers. Curr. Opin. Colloid Interface Sci. 2004, 9, 19–37. [Google Scholar] [CrossRef]

- Stawski, D.; Nowak, A. Thermal properties of poly(N,N-dimethylaminoethyl methacrylate). PLoS ONE 2019, 14, e0217441. [Google Scholar] [CrossRef]

- Persenaire, O.; Alexandre, M.; Degée, P.; Dubois, P. Mechanisms and kinetics of thermal degradation of poly(ε-caprolactone). Biomacromolecules 2001, 2, 288–294. [Google Scholar] [CrossRef] [PubMed]

- Xiang, S.; Feng, L.; Bian, X.; Li, G.; Chen, X. Evaluation of PLA content in PLA/PBAT blends using TGA. Polym. Test. 2020, 81, 106211. [Google Scholar] [CrossRef]

- Palacios, J.; Albano, C.; González, G.; Castillo, R.V.; Karam, A.; Covis, M. Characterization and thermal degradation of poly(d,l-lactide-co-glycolide) composites with nanofillers. Polym. Eng. Sci. 2013, 53, 1414–1429. [Google Scholar] [CrossRef]

- Ghanem, A.F.; Yassin, M.A.; Cosquer, R.; Gouanvé, F.; Espuche, E.; Abdel Rehim, M.H. Polycaprolactone composite films infused with hyperbranched polyester/reduced graphene oxide: Influence on biodegradability, gas/water transport and antimicrobial properties for sustainable packaging. RSC Adv. 2024, 14, 5740–5753. [Google Scholar] [CrossRef] [PubMed]

- Laput, O.; Vasenina, I.; Salvadori, M.C.; Savkin, K.; Zuza, D.; Kurzina, I. Low-temperature plasma treatment of polylactic acid and PLA/HA composite material. J. Mater. Sci. 2019, 54, 11726–11738. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, Y.; Luo, R.; Chen, S.; Li, X.; Yuan, S.; Wang, J.; Huang, N. In vitro hemocompatibility and cytocompatibility of dexamethasone-eluting PLGA stent coatings. Appl. Surf. Sci. 2015, 328, 154–162. [Google Scholar] [CrossRef]

- Tamadat, J.A.; King, C.J. Extraction of carboxylic acids with amine extractants. 2. Chemical interactions and interpretation of data. Ind. Eng. Chem. Res 1990, 29, 1327–1333. [Google Scholar] [CrossRef]

- Procházka, J.; Heyberger, A.; Bízek, V.; Koušová, M.; Volaufová, E. Amine Extraction of Hydroxycarboxylic Acids. 2. Comparison of Equilibria for Lactic, Malic, and Citric Acids. Ind. Eng. Chem. Res. 1994, 33, 1565–1573. [Google Scholar] [CrossRef]

| No | DPDMAEMA (x [%]) | DPε-CL (x [%]) | DPLA (x [%]) | DPGA (x [%]) | FDMAEMA | Mn, theo [g/mol] | Mn, SEC [g/mol] | Đ | TCP, H2O [°C] | TCP, PBS [°C] | CAC [mg/mL] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SMS1 | 94 (94) | 99 (99) | - | - | 0.49 | 26,100 | 14,200 | 1.50 | n. d. | n. d. | n. d. |

| SMS2 | 88 (88) | - | 162 (81) | - | 0.35 | 25,500 | 4800 | 1.27 | 58.4 | 63.6 | 0.040 |

| SMS3 | 83 (83) | - | 129 (86) | 50 (100) | 0.32 | 25,200 | 6000 | 1.35 | - | 87.8 | 0.008 |

| SMS4 | 88 (88) | 34 (67) | 72 (90) | 19 (95) | 0.41 | 24,000 | 8000 | 1.23 | - | 75.5 | 0.060 |

| NMS1 | 95 (95) | 99 (99) | - | - | 0.49 | 26,200 | 11,900 | 1.39 | n. d. | n. d. | n. d. |

| NMS2 | 86 (86) | - | 192 (96) | - | 0.31 | 27,400 | 5000 | 1.48 | 66.7 | 76.6 | 0.019 |

| NMS3 | 92 (92) | - | 141 (94) | 50 (99) | 0.33 | 27,500 | 3000 | 1.36 | - | >90.0 | 0.042 |

| NMS4 | 89 (89) | 33 (66) | 74 (92) | 19 (97) | 0.41 | 24,200 | 9900/2600 a | 1.55 b | - | >90.0 | 0.045 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kupczak, M.; Mielańczyk, A.; Fronczyk, T.; Drejka, P.; Ledwon, P.; Neugebauer, D. From Facile One-Pot Synthesis of Semi-Degradable Amphiphilic Miktoarm Polymers to Unique Degradation Properties. Materials 2024, 17, 2684. https://doi.org/10.3390/ma17112684

Kupczak M, Mielańczyk A, Fronczyk T, Drejka P, Ledwon P, Neugebauer D. From Facile One-Pot Synthesis of Semi-Degradable Amphiphilic Miktoarm Polymers to Unique Degradation Properties. Materials. 2024; 17(11):2684. https://doi.org/10.3390/ma17112684

Chicago/Turabian StyleKupczak, Maria, Anna Mielańczyk, Tomasz Fronczyk, Patryk Drejka, Przemyslaw Ledwon, and Dorota Neugebauer. 2024. "From Facile One-Pot Synthesis of Semi-Degradable Amphiphilic Miktoarm Polymers to Unique Degradation Properties" Materials 17, no. 11: 2684. https://doi.org/10.3390/ma17112684

APA StyleKupczak, M., Mielańczyk, A., Fronczyk, T., Drejka, P., Ledwon, P., & Neugebauer, D. (2024). From Facile One-Pot Synthesis of Semi-Degradable Amphiphilic Miktoarm Polymers to Unique Degradation Properties. Materials, 17(11), 2684. https://doi.org/10.3390/ma17112684