Enhancement of Abnormal Grain Growth by Surface Quenching Treatment to Eliminate Cu–Cu Bonding Interfaces Using (111)-Oriented Nanotwinned Copper

Abstract

:1. Introduction

2. Experimental

2.1. Preparation of Nanotwinned Cu Film

2.2. Sample Pretreatment and Surface Quenching Treatment

2.3. Bonding Process

2.4. Material Characterizations

3. Results and Discussion

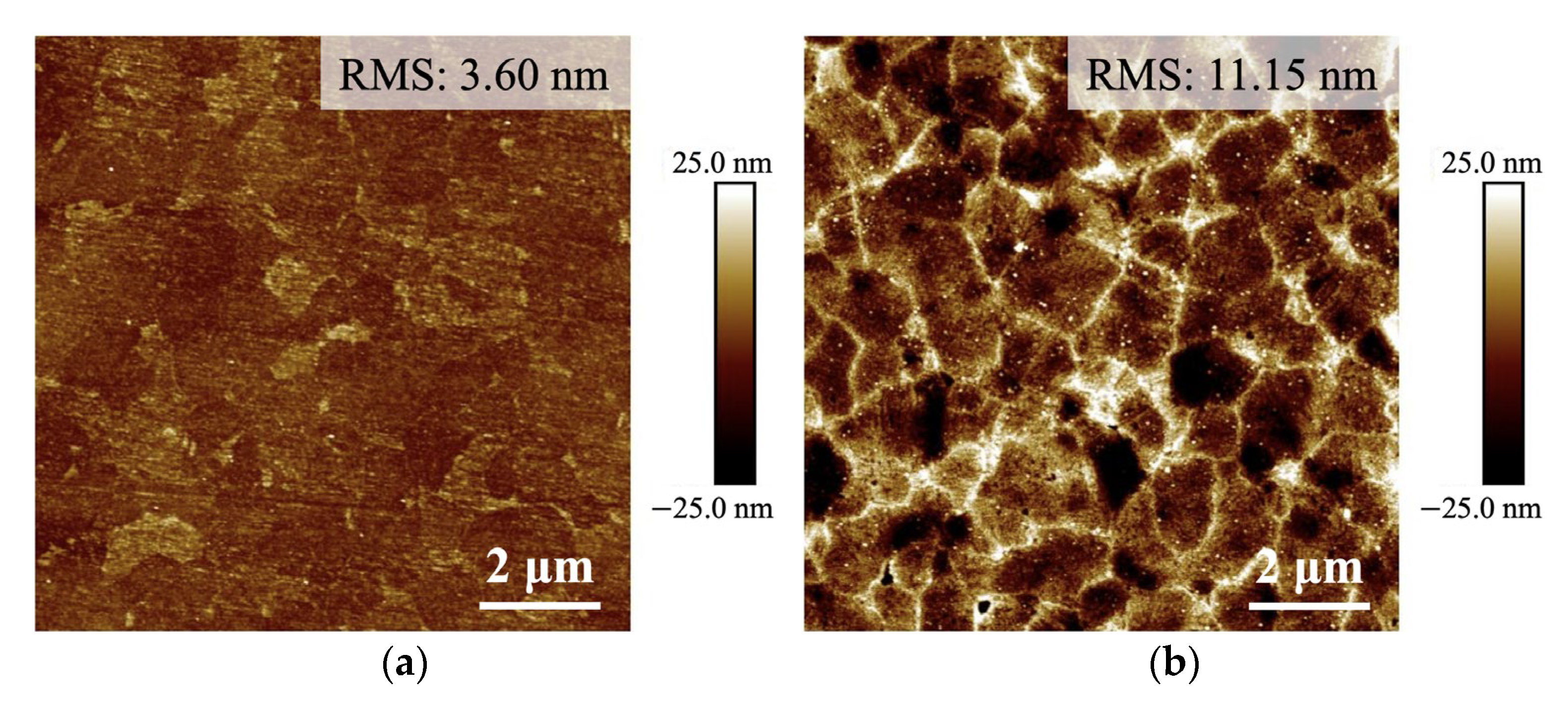

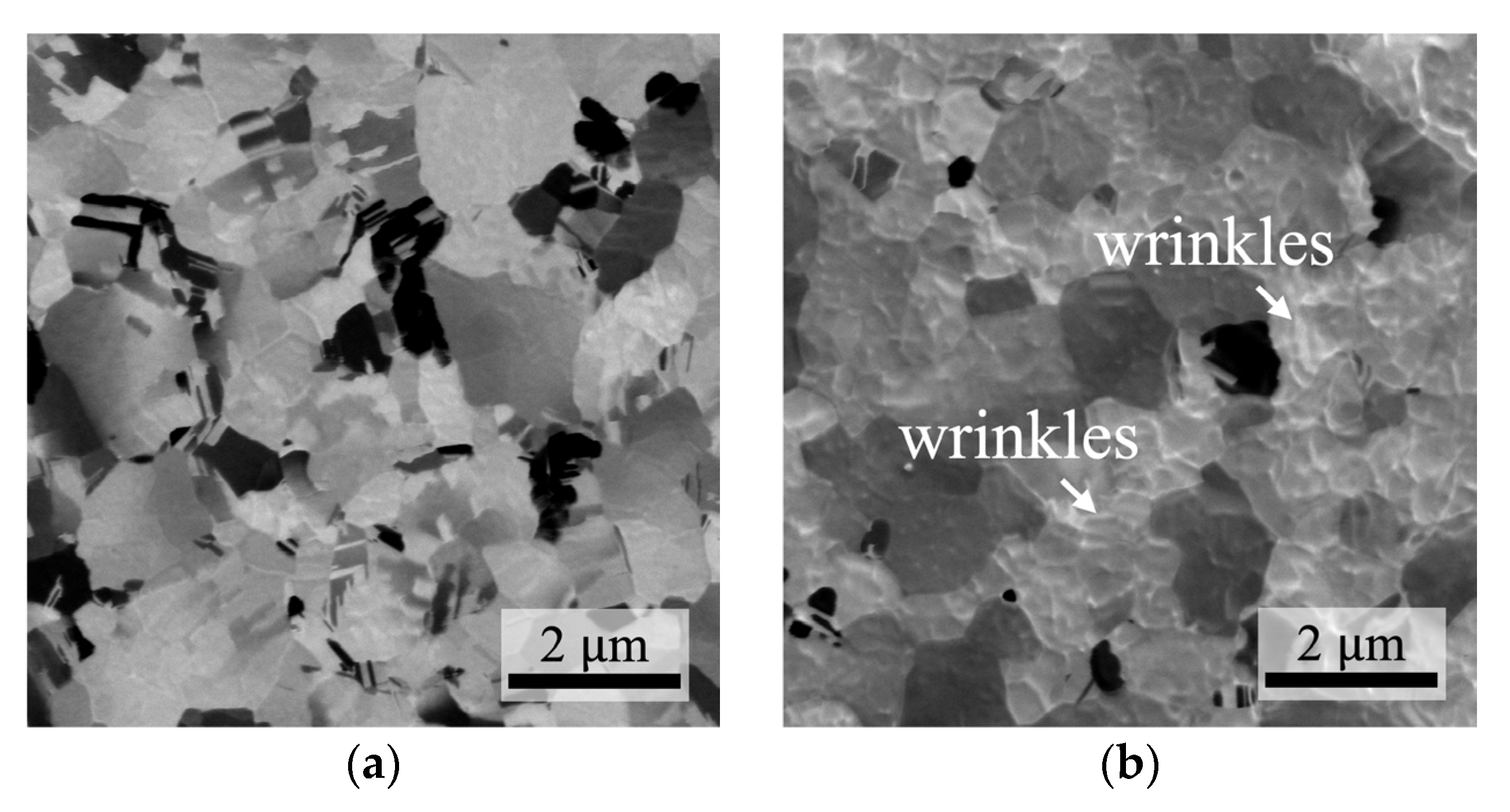

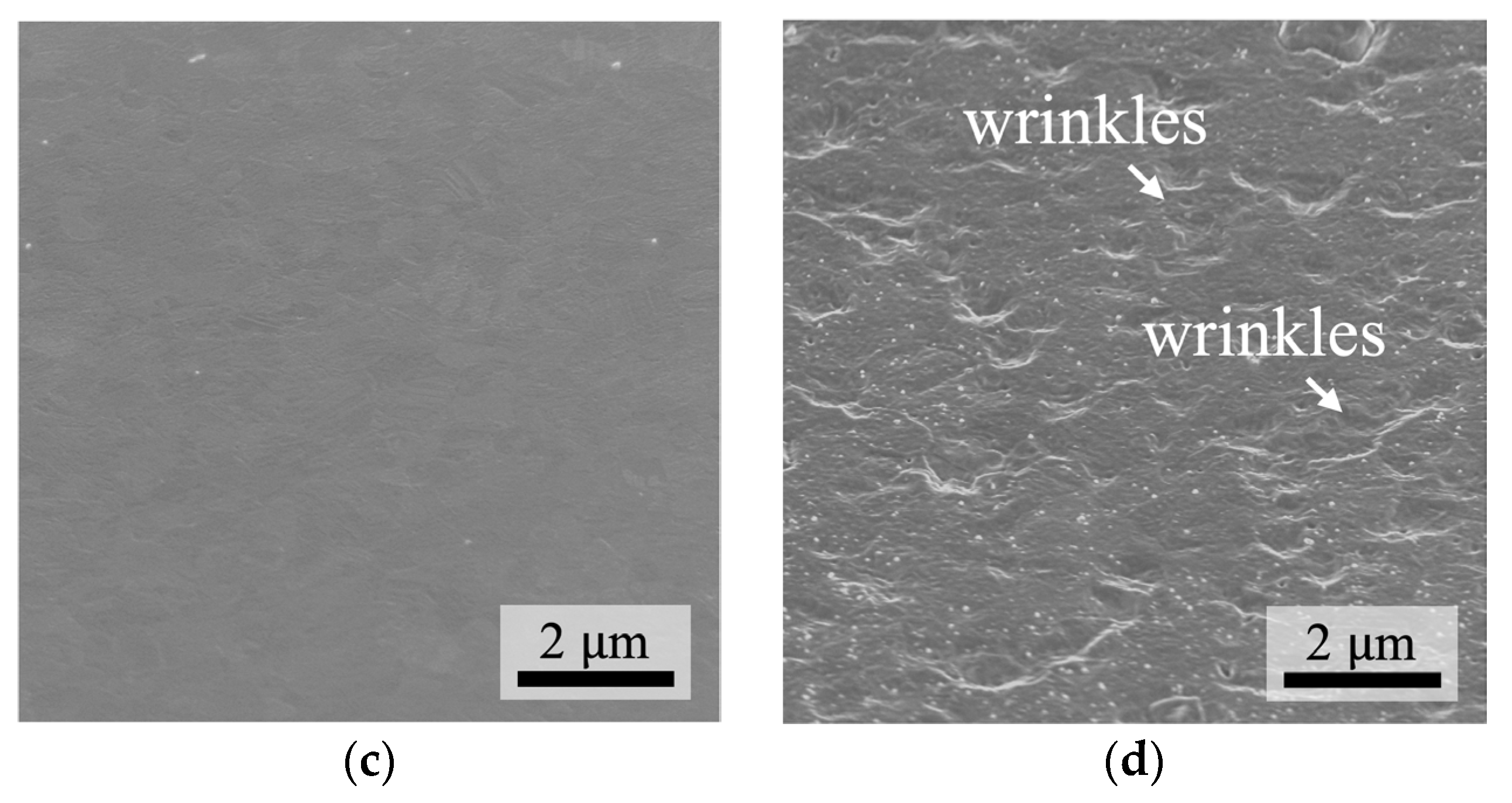

3.1. Surface Roughness and Morphology of NtCu Films

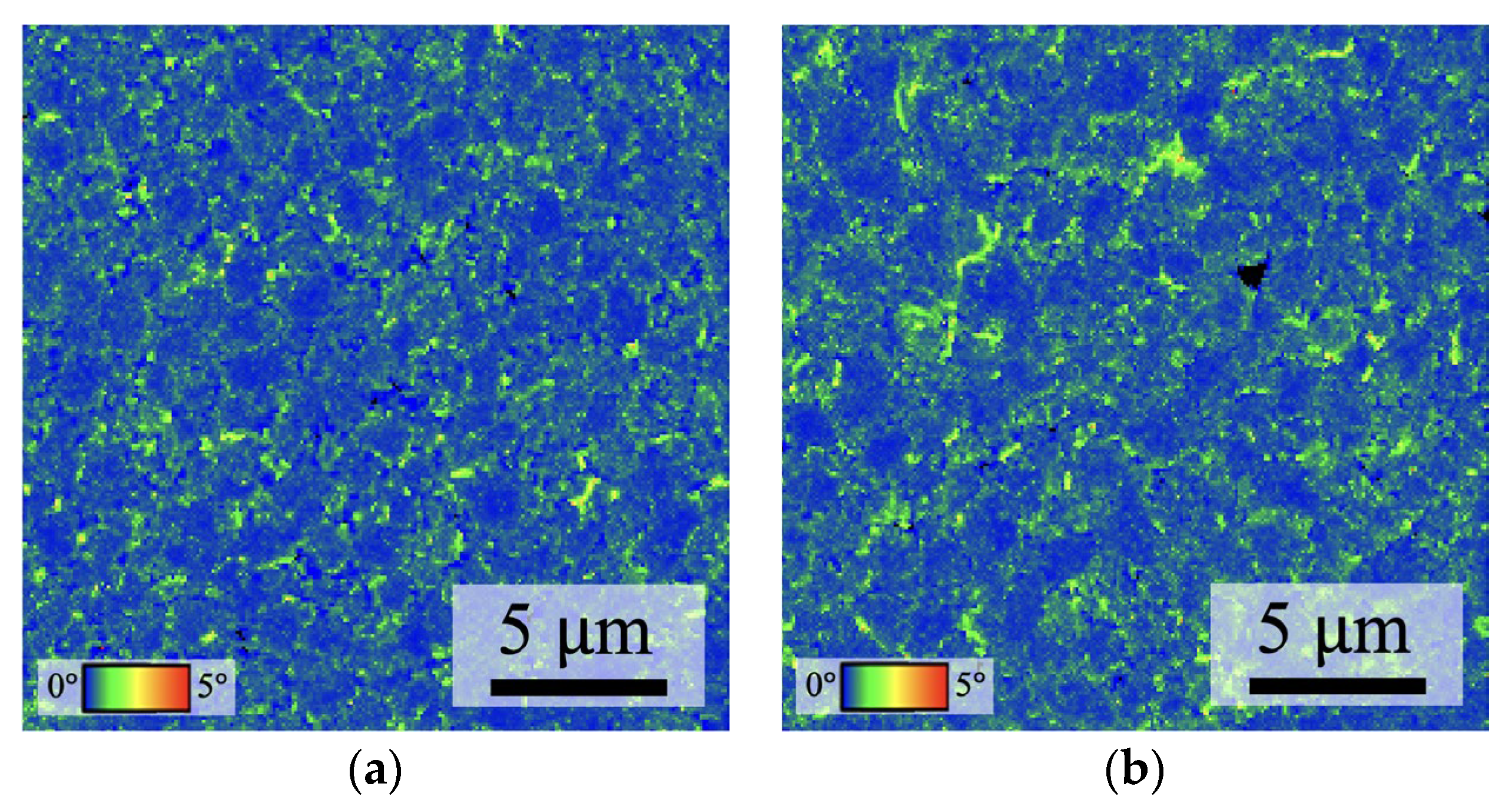

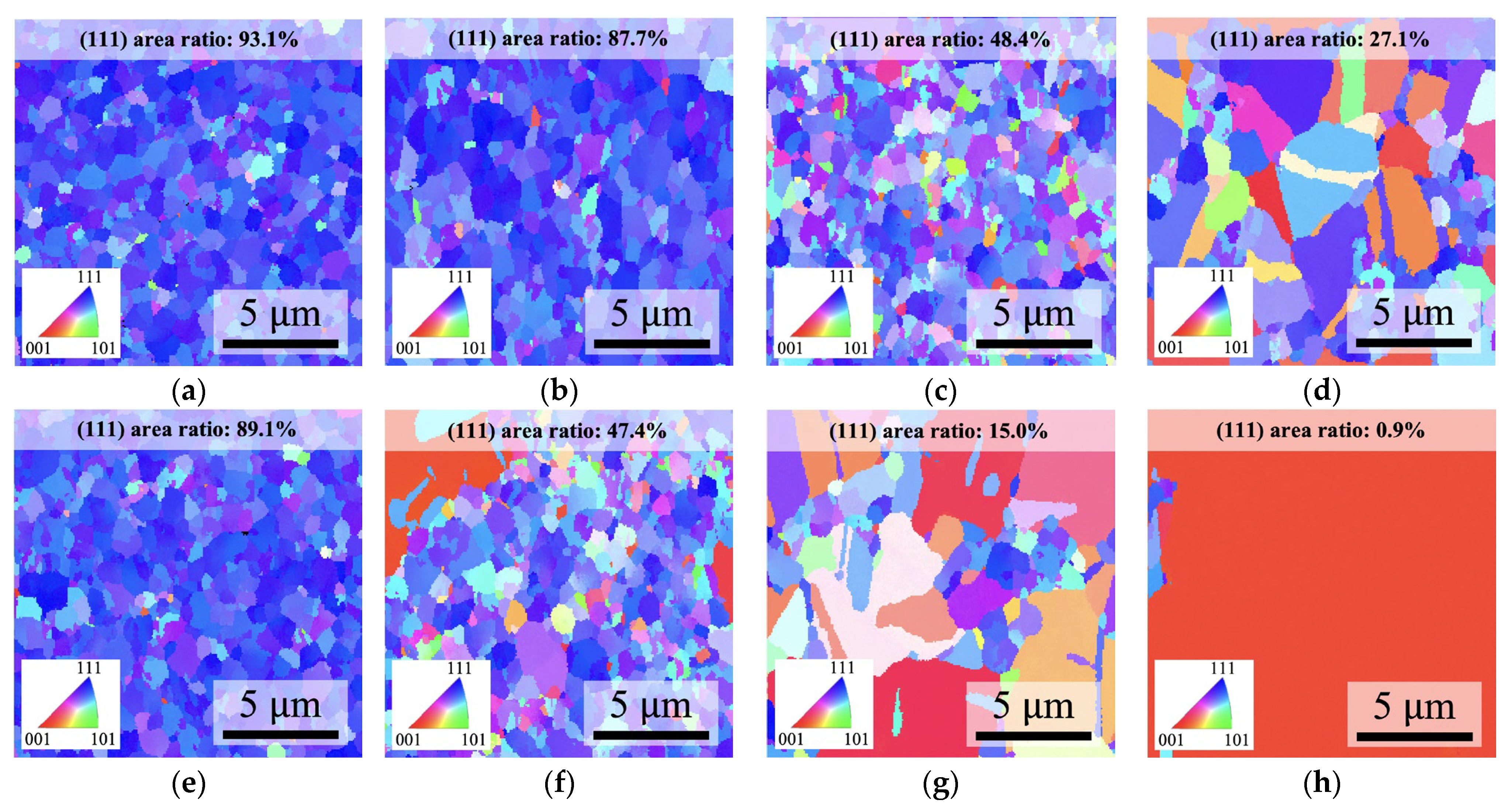

3.2. Influence of Strain Energy on Abnormal Grain Growth in NtCu Films

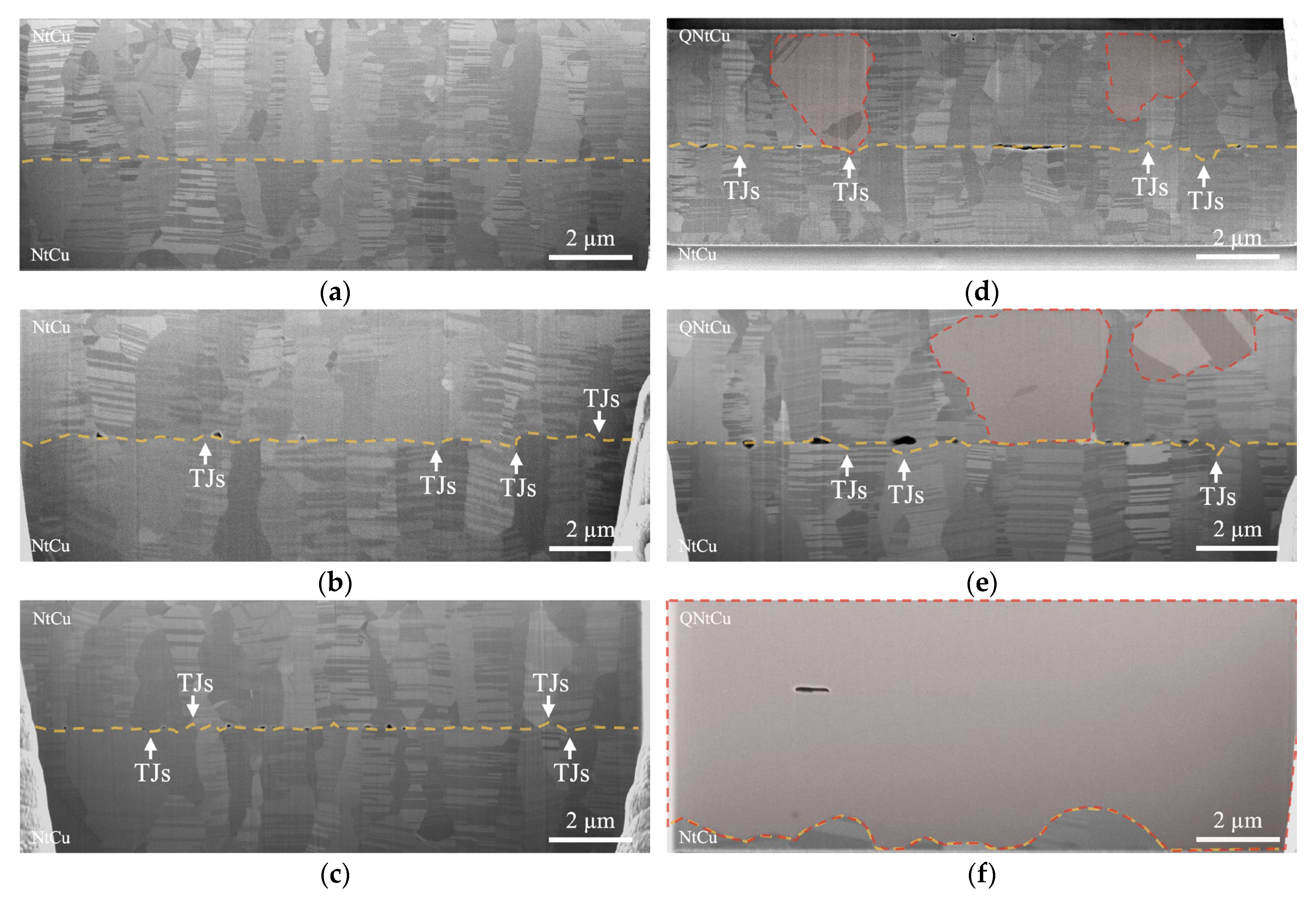

3.3. Influence of Strain Energy on Abnormal Grain Growth at the Bonding Interface

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shen, W.-W.; Chen, K.-N. Three-dimensional integrated circuit (3D IC) key technology: Through-silicon via (TSV). Nanoscale Res. Lett. 2017, 12, 56. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Park, S. Three-dimensional and 2.5 dimensional interconnection technology: State of the art. J. Electron. Packag. 2014, 136, 014001. [Google Scholar] [CrossRef]

- Koester, S.J.; Young, A.M.; Yu, R.; Purushothaman, S.; Chen, K.-N.; La Tulipe, D.C.; Rana, N.; Shi, L.; Wordeman, M.R.; Sprogis, E.J. Wafer-level 3D integration technology. IBM J. Res. Dev. 2008, 52, 583–597. [Google Scholar] [CrossRef]

- Chen, C.; Yu, D.; Chen, K.-N. Vertical interconnects of microbumps in 3D integration. MRS Bull. 2015, 40, 257–263. [Google Scholar] [CrossRef]

- Tu, K.-N. Solder Joint Technology; Springer: New York, NY, USA, 2007; Volume 117. [Google Scholar]

- Kuo, Y.-H.; Tran, D.-P.; Ong, J.-J.; Tu, K.-N.; Chen, C. Hybrid Cu-to-Cu bonding with nano-twinned Cu and non-conductive paste. J. Mater. Res. Technol. 2022, 18, 859–871. [Google Scholar] [CrossRef]

- Liang, Y.; Chen, C.; Tu, K.-N. Side wall wetting induced void formation due to small solder volume in microbumps of Ni/SnAg/Ni upon reflow. ECS Solid State Lett. 2012, 1, P60. [Google Scholar] [CrossRef]

- Oi, K.; Otake, S.; Shimizu, N.; Watanabe, S.; Kunimoto, Y.; Kurihara, T.; Koyama, T.; Tanaka, M.; Aryasomayajula, L.; Kutlu, Z. Development of new 2.5 D package with novel integrated organic interposer substrate with ultra-fine wiring and high density bumps. In Proceedings of the 2014 IEEE 64th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 27–30 May 2014; pp. 348–353. [Google Scholar]

- Wang, L.; Fountain, G.; Lee, B.; Gao, G.; Uzoh, C.; McGrath, S.; Enquist, P.; Arkalgud, S.; Mirkarimi, L. Direct Bond Interconnect (DBI®) for fine-pitch bonding in 3D and 2.5 D integrated circuits. In Proceedings of the 2017 Pan Pacific Microelectronics Symposium (Pan Pacific), Kauai, HI, USA, 6–9 February 2017; pp. 1–6. [Google Scholar]

- Mudrick, J.P.; Sierra-Suarez, J.A.; Jordan, M.B.; Friedmann, T.A.; Jarecki, R.; Henry, M.D. Sub-10µm Pitch Hybrid Direct Bond Interconnect Development for Die-to-Die Hybridization. In Proceedings of the 2019 IEEE 69th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 28–31 May 2019; pp. 648–654. [Google Scholar]

- Kim, S.-W.; Fodor, F.; Heylen, N.; Iacovo, S.; De Vos, J.; Miller, A.; Beyer, G.; Beyne, E. Novel Cu/SiCN surface topography control for 1 μm pitch hybrid wafer-to-wafer bonding. In Proceedings of the 2020 IEEE 70th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 3–30 June 2020; pp. 216–222. [Google Scholar]

- Lhostis, S.; Farcy, A.; Deloffre, E.; Lorut, F.; Mermoz, S.; Henrion, Y.; Berthier, L.; Bailly, F.; Scevola, D.; Guyader, F. Reliable 300 mm wafer level hybrid bonding for 3D stacked CMOS image sensors. In Proceedings of the 2016 IEEE 66th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 31 May–3 June 2016; pp. 869–876. [Google Scholar]

- Tu, K.-N. Recent advances on electromigration in very-large-scale-integration of interconnects. J. Appl. Phys. 2003, 94, 5451–5473. [Google Scholar] [CrossRef]

- Lim, D.; Wei, J.; Leong, K.; Tan, C. Cu passivation for enhanced low temperature (≤300 °C) bonding in 3D integration. Microelectron. Eng. 2013, 106, 144–148. [Google Scholar] [CrossRef]

- Jung, M.; Mitra, J.; Pan, D.Z.; Lim, S.K. TSV stress-aware full-chip mechanical reliability analysis and optimization for 3D IC. Commun. ACM 2014, 57, 107–115. [Google Scholar] [CrossRef]

- Chu, Y.-C.; Chen, C. Anisotropic grain growth to eliminate bonding interfaces in direct copper-to-copper joints using< 111>-oriented nanotwinned copper films. Thin Solid Film. 2018, 667, 55–58. [Google Scholar] [CrossRef]

- Yang, S.-C.; Chen, C. High Temperature Storage of Cu-Cu Joints Fabricated by Highly (111)-oriented Nanotwinned Cu. In Proceedings of the 2023 IEEE 73rd Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 30 May–2 June 2023; pp. 2075–2078. [Google Scholar]

- Ong, J.-J.; Tran, D.-P.; Lin, Y.-Y.; Shen, F.-C.; Yang, S.-C.; Lee, K.-P.; Shen, G.-Y.; Yu, M.-H.; Hsu, P.-N.; Tsou, N.-T. Single-crystal-like Cu joints with high strength and resistance to fatigue failures. Mater. Sci. Eng. A 2022, 857, 144051. [Google Scholar] [CrossRef]

- Lu, T.-F.; Wang, P.-W.; Cheng, Y.-F.; Yen, Y.-T.; Wu, Y.S. Enhanced Nanotwinned Copper Bonding through Epoxy-Induced Copper Surface Modification. Nanomaterials 2024, 14, 771. [Google Scholar] [CrossRef]

- Lu, T.-F.; Yen, Y.-T.; Wang, P.-W.; Cheng, Y.-F.; Chen, C.-H.; Wu, Y.S. Enhanced Copper Bonding Interfaces by Quenching to Form Wrinkled Surfaces. Nanomaterials 2024, 14, 861. [Google Scholar] [CrossRef]

- Liu, T.-C.; Liu, C.-M.; Hsiao, H.-Y.; Lu, J.-L.; Huang, Y.-S.; Chen, C. Fabrication and characterization of (111)-oriented and nanotwinned Cu by DC electrodeposition. Cryst. Growth Des. 2012, 12, 5012–5016. [Google Scholar] [CrossRef]

- Tseng, I.-H.; Hsu, Y.-T.; Leu, J.; Tu, K.-N.; Chen, C. Effect of thermal stress on anisotropic grain growth in nano-twinned and un-twinned copper films. Acta Mater. 2021, 206, 116637. [Google Scholar] [CrossRef]

- Lin, P.-F.; Tran, D.-P.; Liu, H.-C.; Li, Y.-Y.; Chen, C. Interfacial characterization of low-temperature Cu-to-Cu direct bonding with chemical mechanical planarized nanotwinned Cu films. Materials 2022, 15, 937. [Google Scholar] [CrossRef]

- Chung, J.Y.; Nolte, A.J.; Stafford, C.M. Surface wrinkling: A versatile platform for measuring thin-film properties. Adv. Mater. 2011, 23, 349–368. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.; Low, T.; Perebeinos, V.; Bol, A.A.; Zhu, Y.; Yan, H.; Tersoff, J.; Avouris, P. Structure and electronic transport in graphene wrinkles. Nano Lett. 2012, 12, 3431–3436. [Google Scholar] [CrossRef]

- Deng, B.; Pang, Z.; Chen, S.; Li, X.; Meng, C.; Li, J.; Liu, M.; Wu, J.; Qi, Y.; Dang, W. Wrinkle-free single-crystal graphene wafer grown on strain-engineered substrates. ACS Nano 2017, 11, 12337–12345. [Google Scholar] [CrossRef]

- Liu, N.; Pan, Z.; Fu, L.; Zhang, C.; Dai, B.; Liu, Z. The origin of wrinkles on transferred graphene. Nano Res. 2011, 4, 996–1004. [Google Scholar] [CrossRef]

- Qin, E.; Lu, L.; Tao, N.; Lu, K. Enhanced fracture toughness of bulk nanocrystalline Cu with embedded nanoscale twins. Scr. Mater. 2009, 60, 539–542. [Google Scholar] [CrossRef]

- Pan, Q.; Zhou, H.; Lu, Q.; Gao, H.; Lu, L. History-independent cyclic response of nanotwinned metals. Nature 2017, 551, 214–217. [Google Scholar] [CrossRef]

- Cheng, H.-Y.; Tran, D.-P.; Tu, K.; Chen, C. Effect of deposition temperature on mechanical properties of nanotwinned Cu fabricated by rotary electroplating. Mater. Sci. Eng. A 2021, 811, 141065. [Google Scholar] [CrossRef]

- Kamaya, M. Measurement of local plastic strain distribution of stainless steel by electron backscatter diffraction. Mater. Charact. 2009, 60, 125–132. [Google Scholar] [CrossRef]

- Grabulov, A.; Petrov, R.; Zandbergen, H. EBSD investigation of the crack initiation and TEM/FIB analyses of the microstructural changes around the cracks formed under Rolling Contact Fatigue (RCF). Int. J. Fatigue 2010, 32, 576–583. [Google Scholar] [CrossRef]

- Demir, E.; Raabe, D. Mechanical and microstructural single-crystal Bauschinger effects: Observation of reversible plasticity in copper during bending. Acta Mater. 2010, 58, 6055–6063. [Google Scholar] [CrossRef]

- Thompson, C.V.; Carel, R. Stress and grain growth in thin films. J. Mech. Phys. Solids 1996, 44, 657–673. [Google Scholar] [CrossRef]

- Tseng, C.-H.; Tseng, I.-H.; Huang, Y.-P.; Hsu, Y.-T.; Leu, J.; Tu, K.-N.; Chen, C. Kinetic study of grain growth in highly (111)-preferred nanotwinned copper films. Mater. Charact. 2020, 168, 110545. [Google Scholar] [CrossRef]

- Wu, Y.S.; Lai, T.-Y.; Li, M.; Lu, T.-F.; Wang, Y.H.; Tseng, T.Y. Bonding mechanisms of roughened nanotwinned-Cu surface at temperature as low as 120 °C. ECS J. Solid State Sci. Technol. 2020, 9, 124005. [Google Scholar] [CrossRef]

- Lai, T.-Y.; Li, M.; Tseng, T.Y.; Lin, T.-C.; Lu, T.-F.; Wu, Y.S. Evolution Kinetics of Voids in Electroplated Cu-Cu Wafer Bonding. ECS J. Solid State Sci. Technol. 2021, 10, 064009. [Google Scholar] [CrossRef]

- Juang, J.-Y.; Lu, C.-L.; Chen, K.-J.; Chen, C.-C.A.; Hsu, P.-N.; Chen, C.; Tu, K.-N. Copper-to-copper direct bonding on highly (111)-oriented nanotwinned copper in no-vacuum ambient. Sci. Rep. 2018, 8, 13910. [Google Scholar] [CrossRef] [PubMed]

- Gottstein, G.; Shvindlerman, L.; Zhao, B. Thermodynamics and kinetics of grain boundary triple junctions in metals: Recent developments. Scr. Mater. 2010, 62, 914–917. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, T.-F.; Yen, Y.-T.; Cheng, Y.-F.; Wang, P.-W.; Wu, Y.S. Enhancement of Abnormal Grain Growth by Surface Quenching Treatment to Eliminate Cu–Cu Bonding Interfaces Using (111)-Oriented Nanotwinned Copper. Materials 2024, 17, 3245. https://doi.org/10.3390/ma17133245

Lu T-F, Yen Y-T, Cheng Y-F, Wang P-W, Wu YS. Enhancement of Abnormal Grain Growth by Surface Quenching Treatment to Eliminate Cu–Cu Bonding Interfaces Using (111)-Oriented Nanotwinned Copper. Materials. 2024; 17(13):3245. https://doi.org/10.3390/ma17133245

Chicago/Turabian StyleLu, Tsan-Feng, Yu-Ting Yen, Yuan-Fu Cheng, Pei-Wen Wang, and YewChung Sermon Wu. 2024. "Enhancement of Abnormal Grain Growth by Surface Quenching Treatment to Eliminate Cu–Cu Bonding Interfaces Using (111)-Oriented Nanotwinned Copper" Materials 17, no. 13: 3245. https://doi.org/10.3390/ma17133245

APA StyleLu, T.-F., Yen, Y.-T., Cheng, Y.-F., Wang, P.-W., & Wu, Y. S. (2024). Enhancement of Abnormal Grain Growth by Surface Quenching Treatment to Eliminate Cu–Cu Bonding Interfaces Using (111)-Oriented Nanotwinned Copper. Materials, 17(13), 3245. https://doi.org/10.3390/ma17133245