Enhancing Ablation Resistance of TaB2-Based Ultra-High Temperature Ceramics by Mixing Fine TaC Particles and Dispersed Multi-Walled Carbon Nanotubes

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Powder Processing

2.3. Spark Plasma Sintering (UHTCs Preparation)

2.4. Characterization

3. Results and Discussion

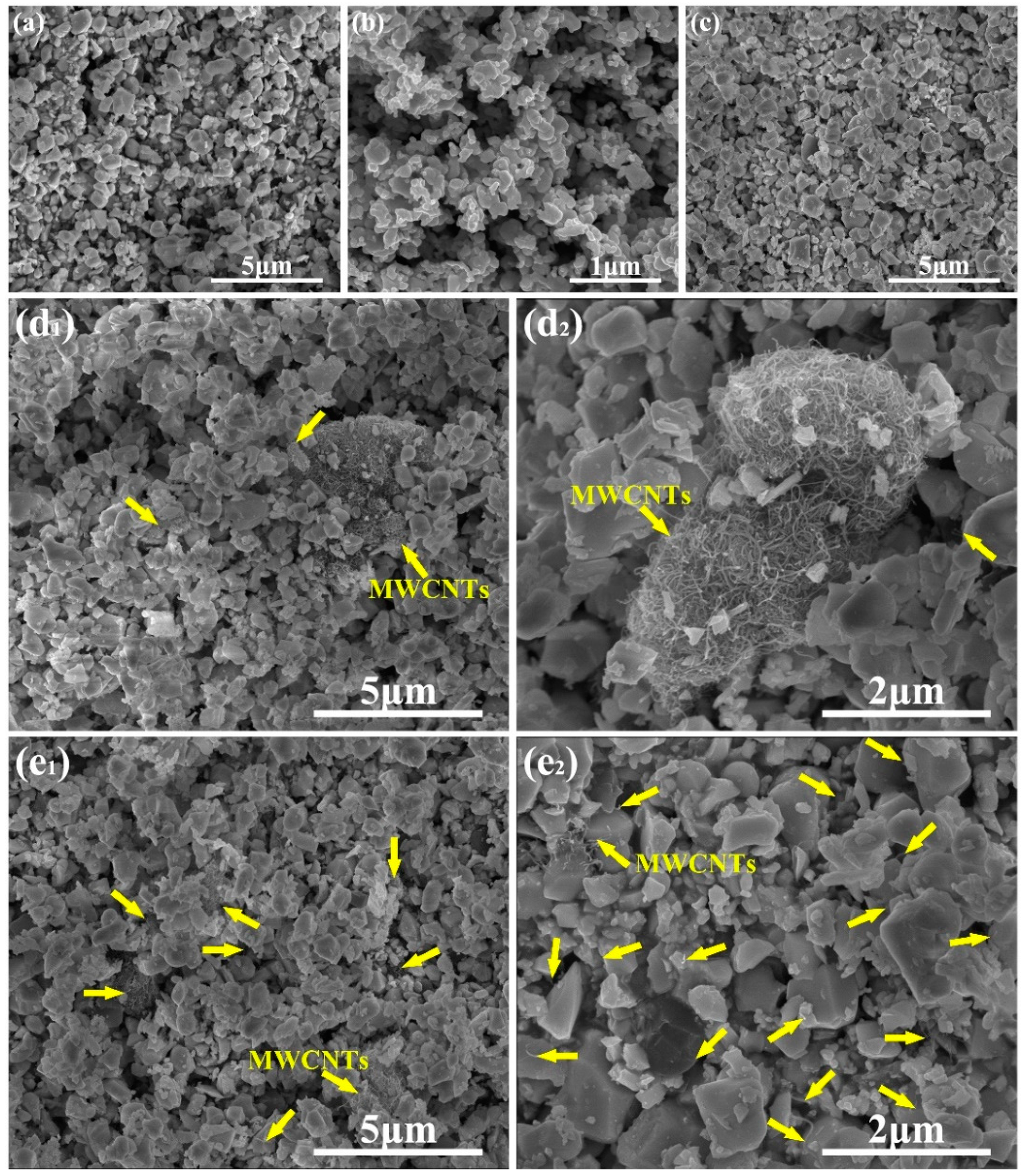

3.1. Raw Material Microstructure

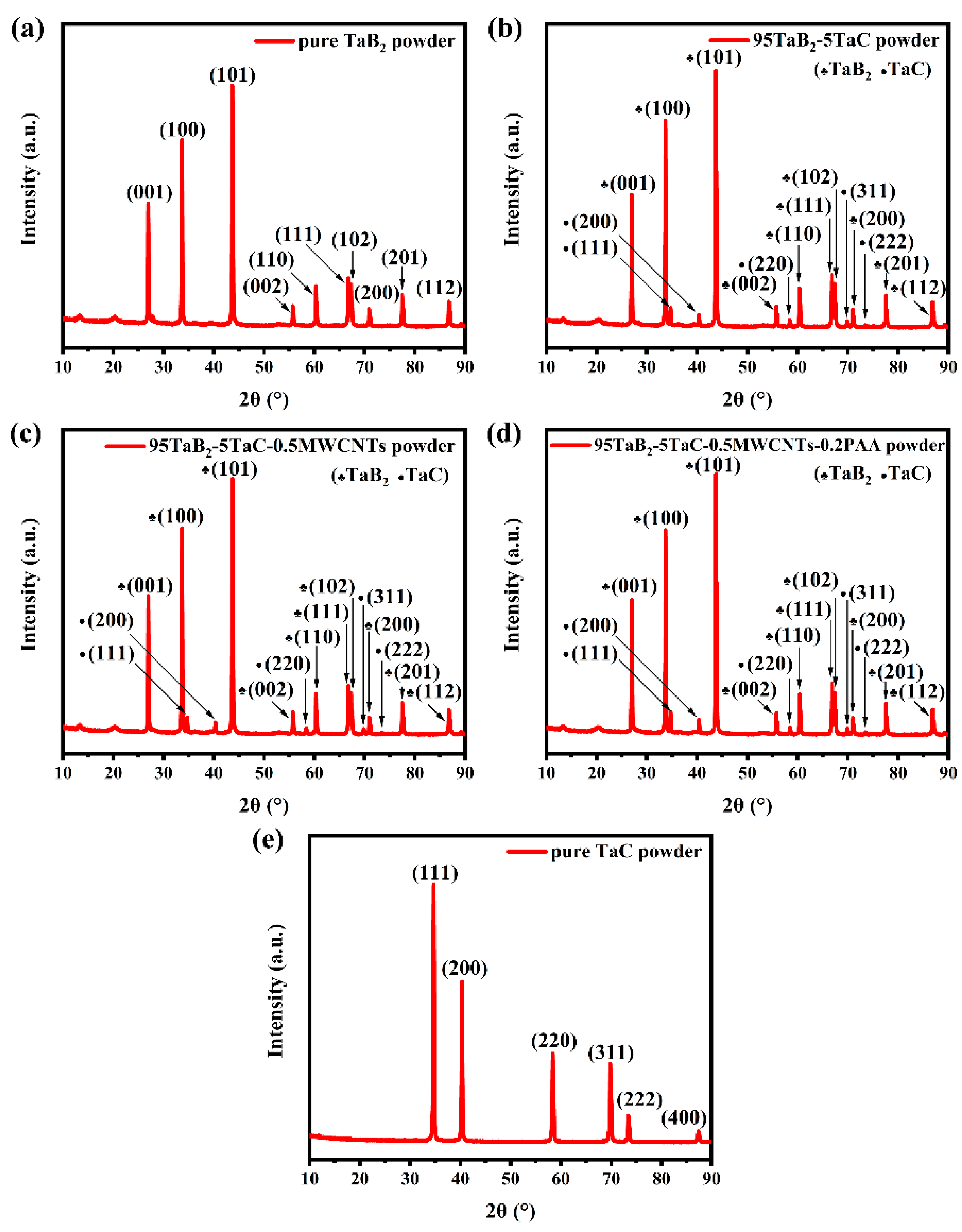

3.2. XRD Characterization for Raw Material

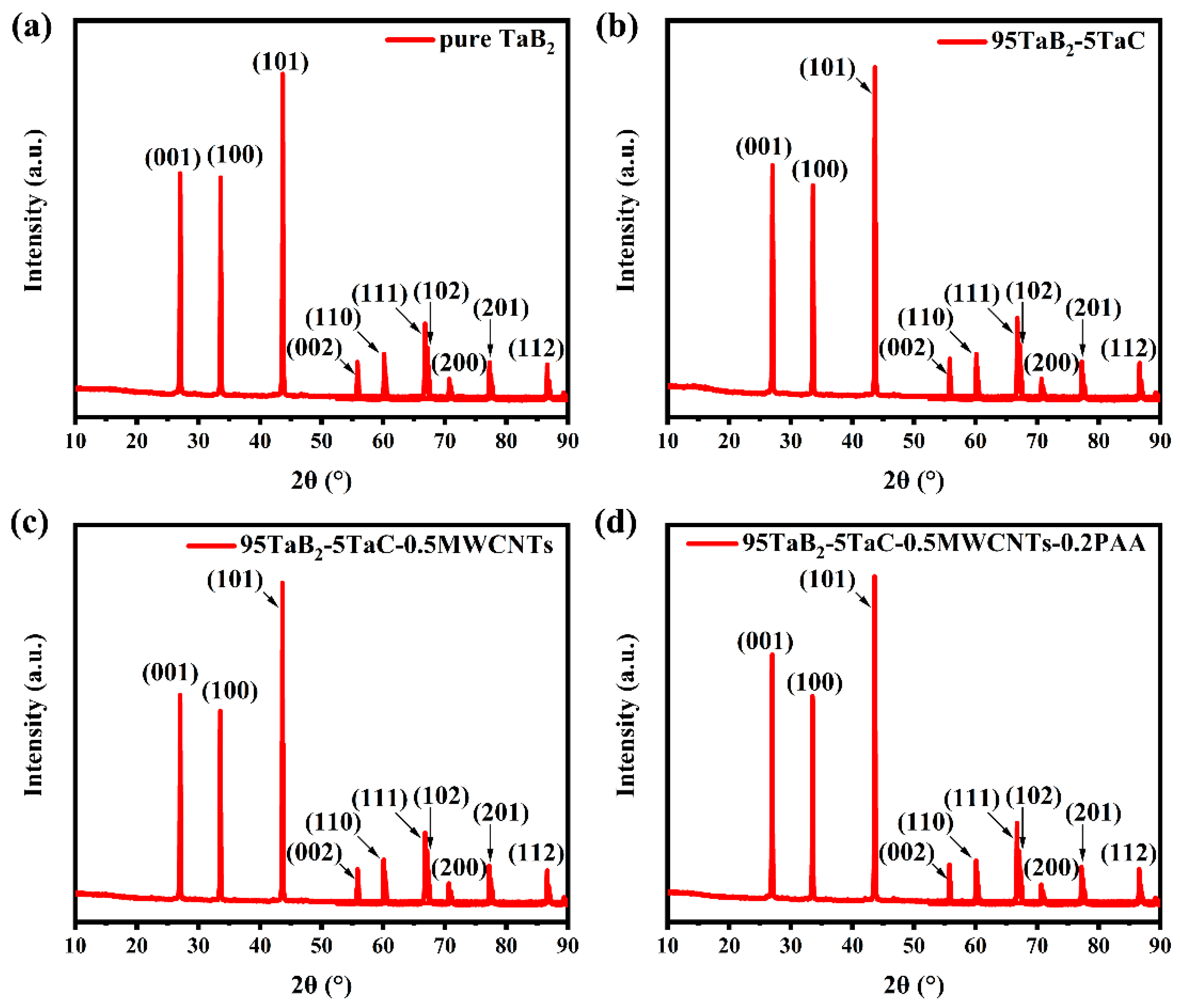

3.3. UHTCs’ XRD Characterization

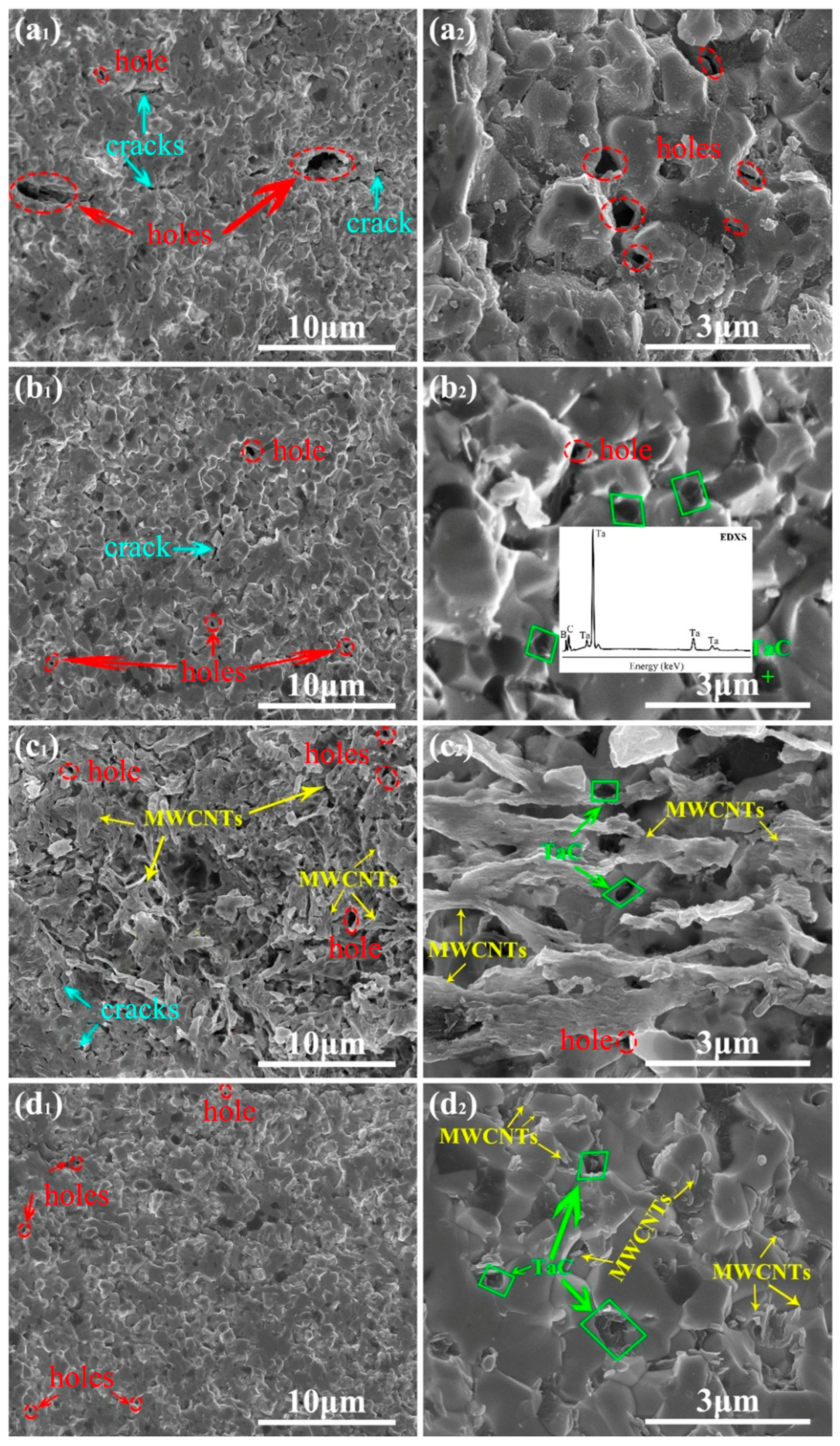

3.4. UHTCs’ Cross-Sectional Microstructure

3.5. UHTCs’ Physical Properties

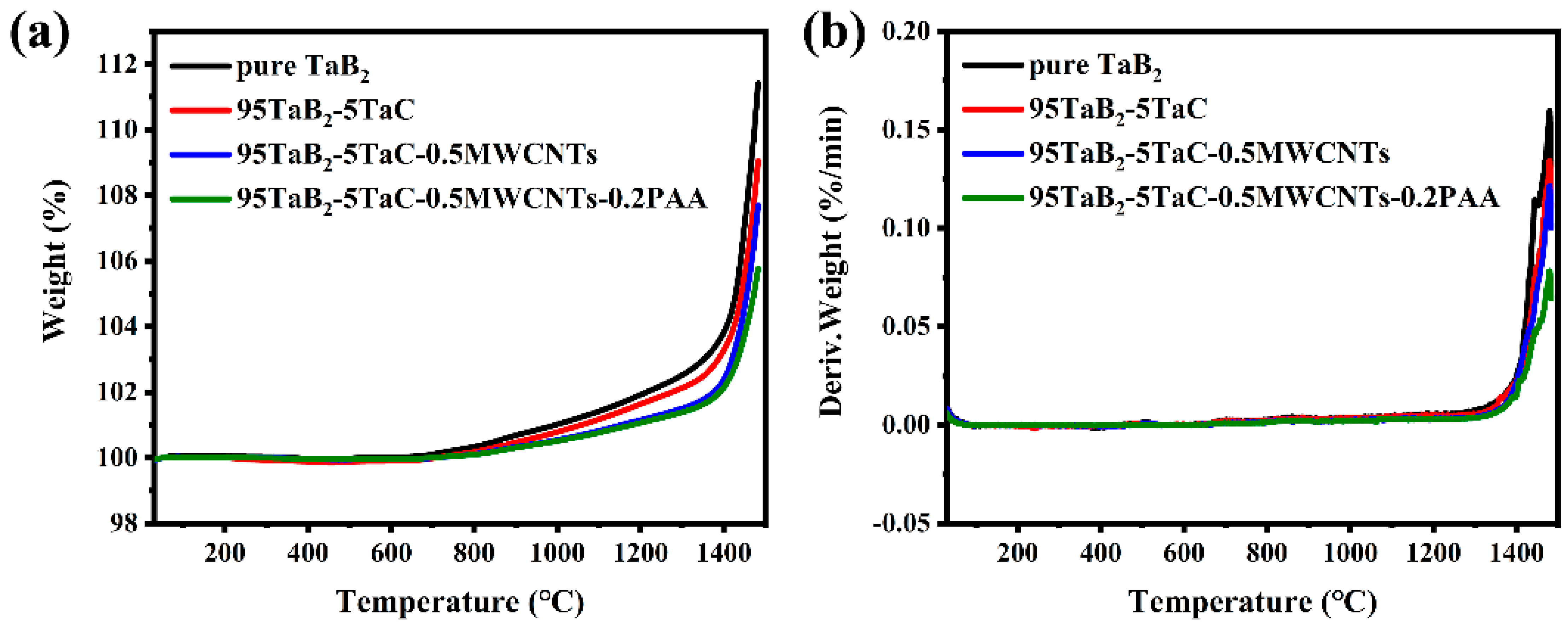

3.6. UHTCs’ TGA Characterization

3.7. Linear Ablation Rate and Mass Ablation Rate

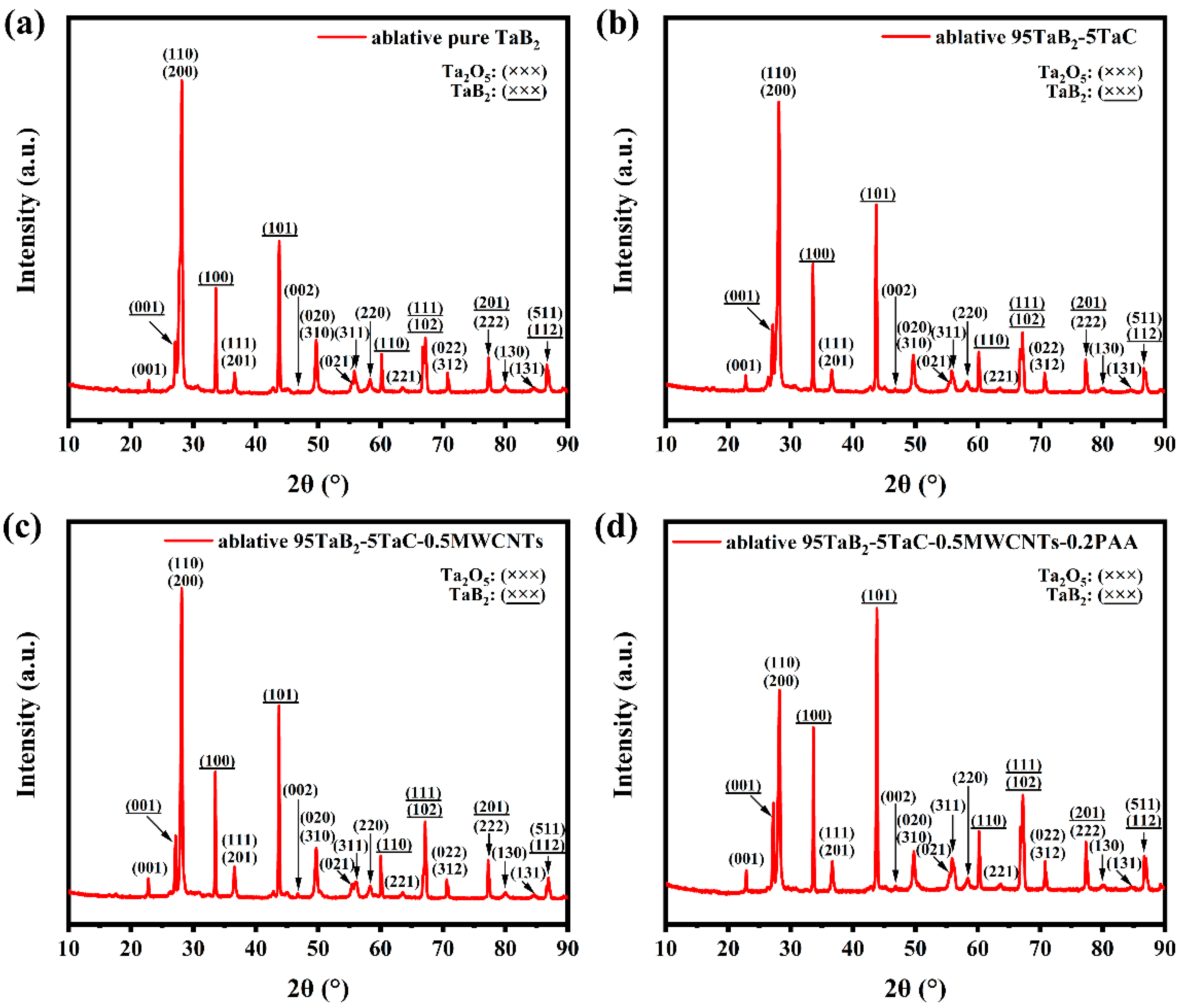

3.8. XRD Characterization for Ablative UHTCs

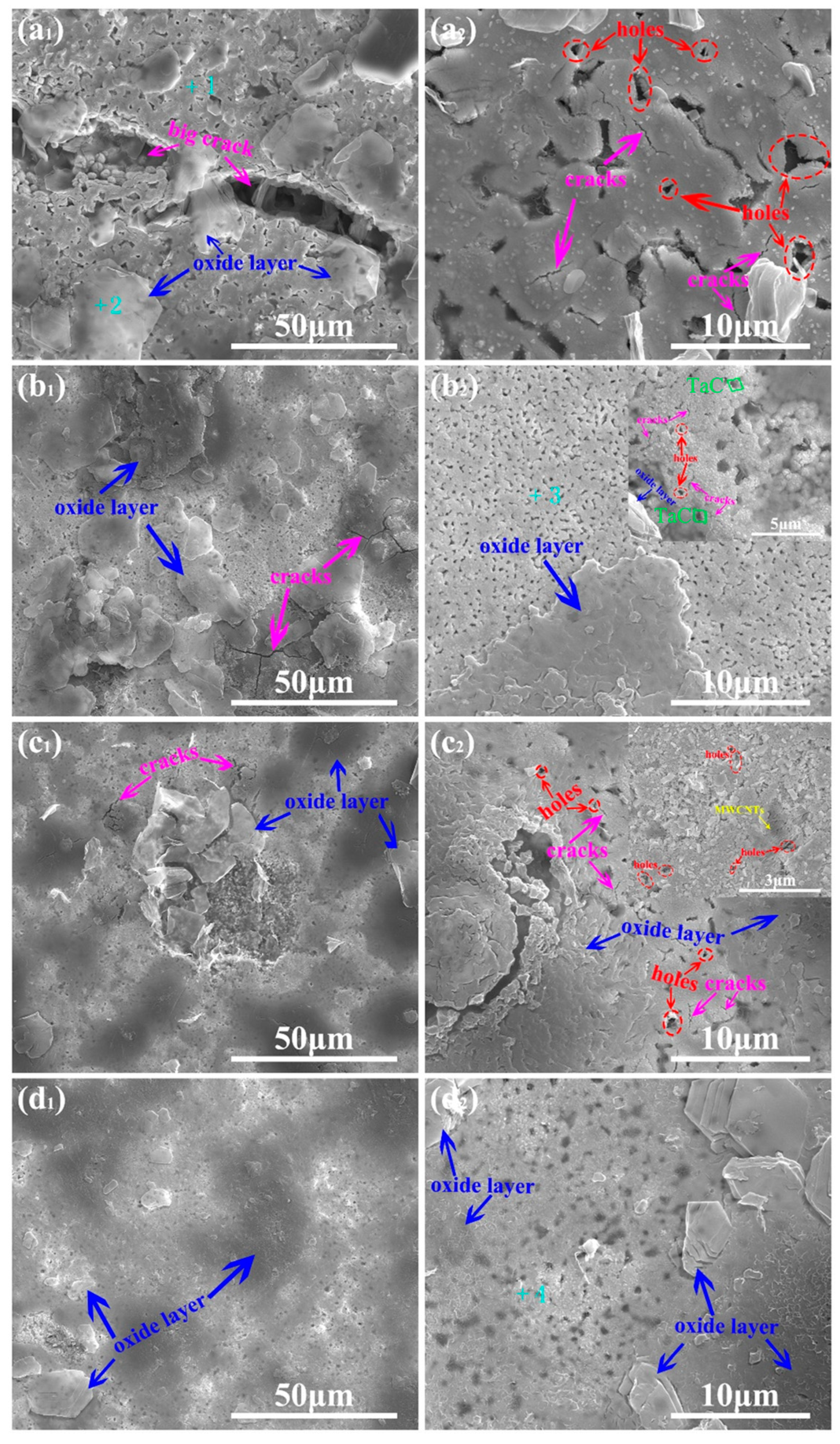

3.9. Ablative UHTCs’ Surface Microstructure

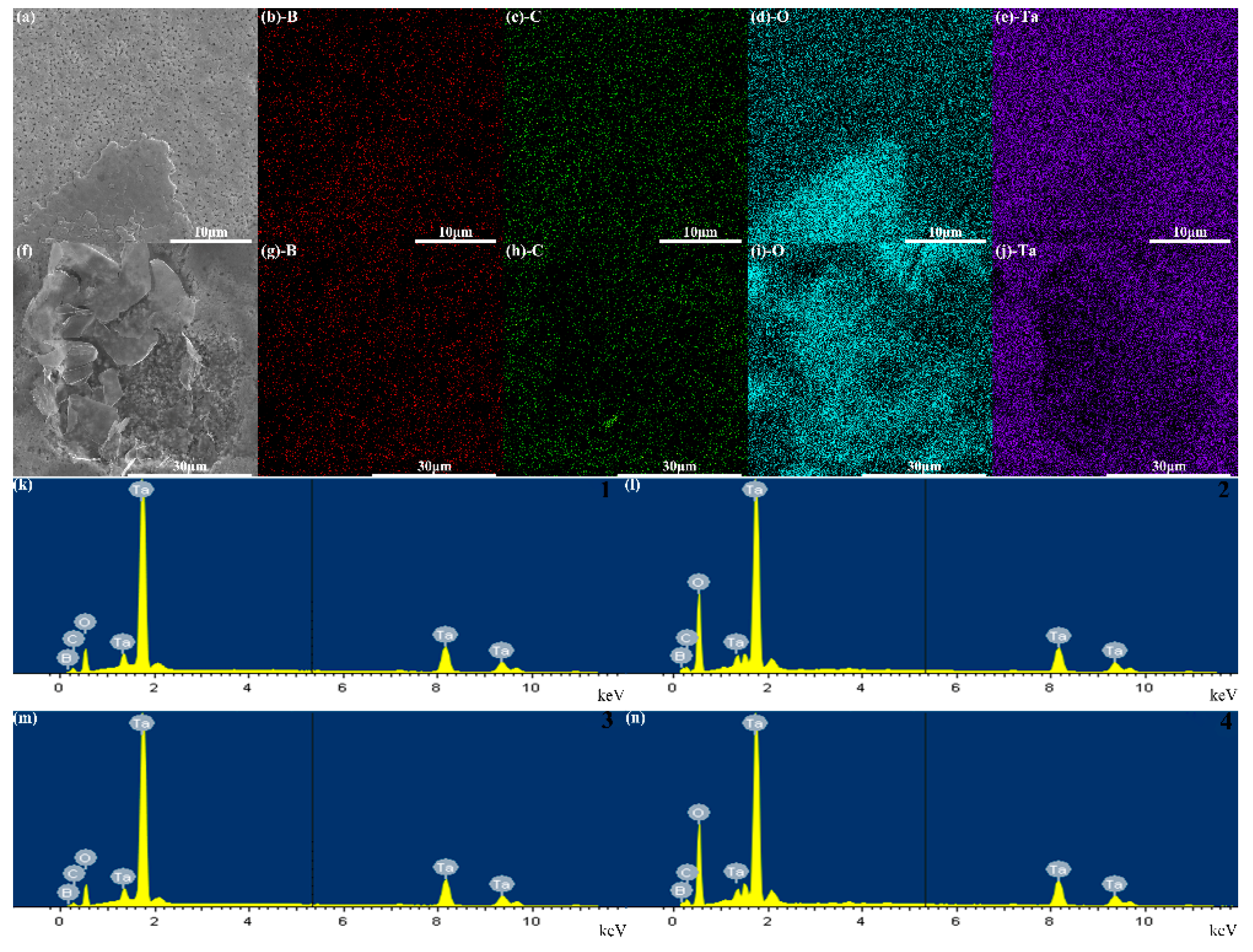

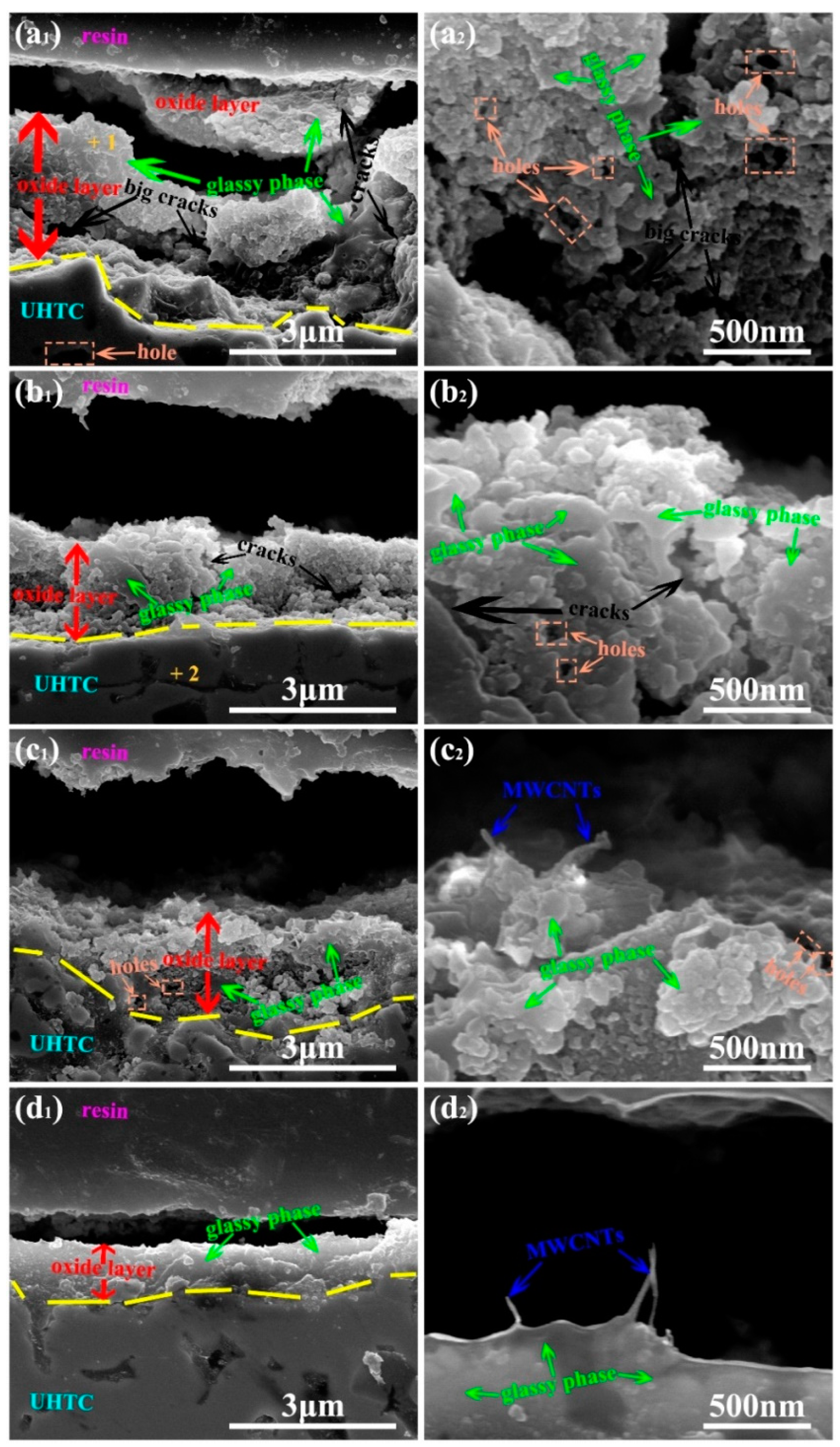

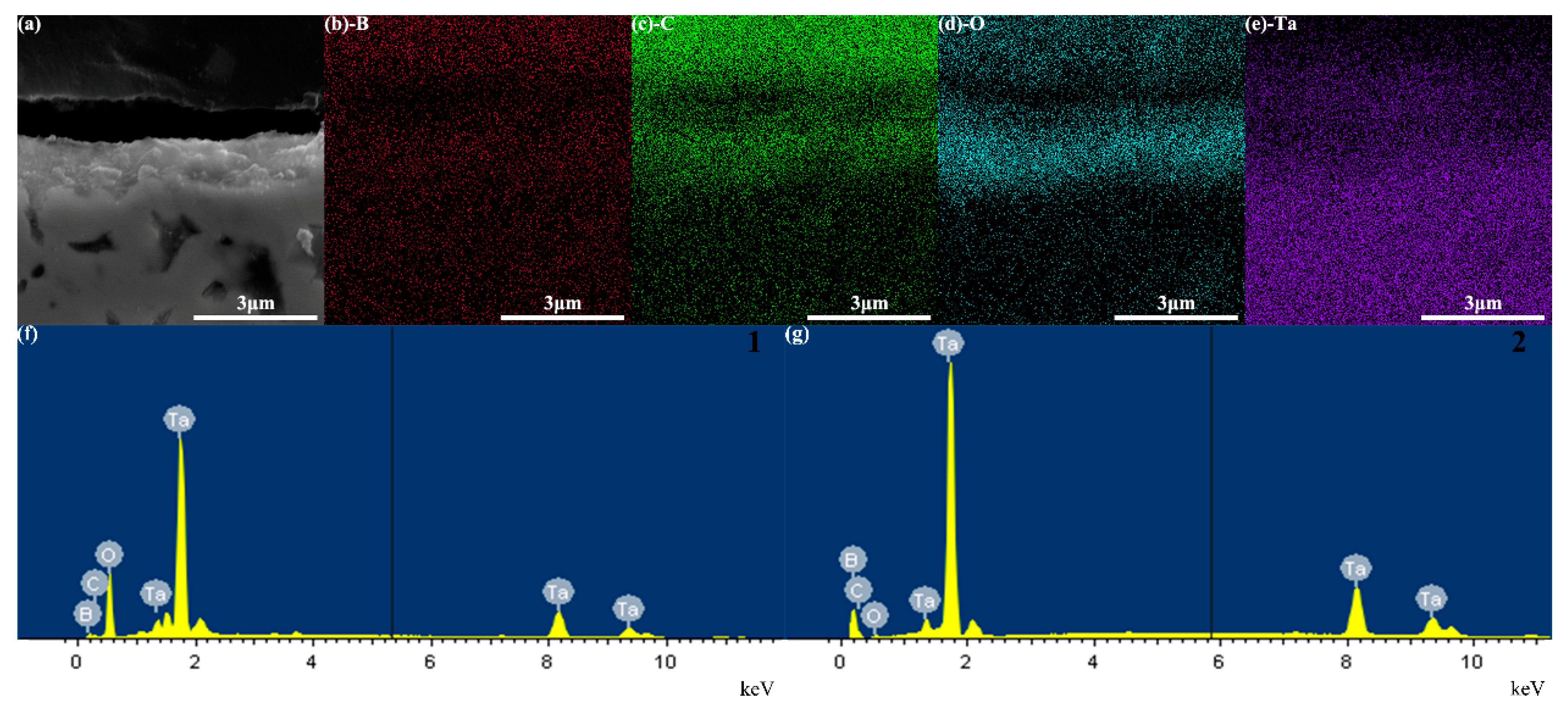

3.10. Ablative UHTCs’ Vertical Cross-Sectional Microstructure

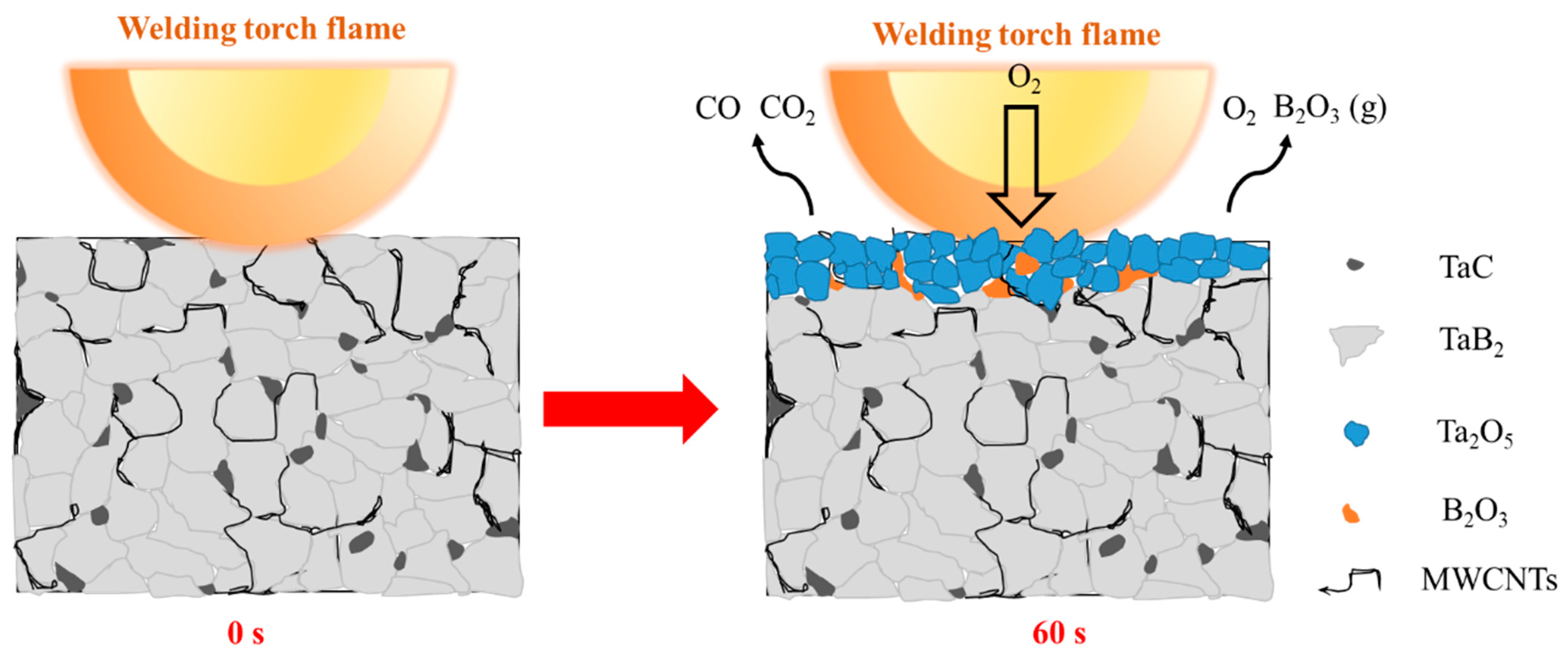

3.11. Ablation Mechanism of TaC and MWCNTs Reinforced TaB2-Based UHTCs

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Z.; Liang, H.; Chen, H.; Ding, L.; Song, M.; Wang, J. Physical properties of high-temperature sintered Tab2 under high pressure. Ceram. Int. 2021, 47, 9061–9067. [Google Scholar] [CrossRef]

- Savino, R.; Criscuolo, L.; Di Martino, G.D.; Mungiguerra, S. Aero-thermo-chemical characterization of ultra-high-temperature ceramics for aerospace applications. J. Eur. Ceram. Soc. 2018, 38, 2937–2953. [Google Scholar] [CrossRef]

- Young, C.; Zhang, C.; Loganathan, A.; Nautiyal, P.; Boesl, B.; Agarwal, A. Densification and oxidation behavior of spark plasma sintered hafnium diboride-hafnium carbide composite. Ceram. Int. 2020, 46, 14625–14631. [Google Scholar] [CrossRef]

- Lin, J.; Huang, Y.; Zhang, H.; Jin, H. Characterization of hot-pressed short ZrO2 fiber toughened ZrB2-based ultra-high temperature ceramics. Mater. Charact. 2014, 95, 272–277. [Google Scholar] [CrossRef]

- Neuman, E.W.; Hilmas, G.E.; Fahrenholtz, W.G. Pressureless sintering of zirconium diboride with carbon and boron carbide nanopowder. Ceram. Int. 2022, 48, 13071–13079. [Google Scholar] [CrossRef]

- Xu, H.; Ji, W.; Guo, W.; Li, Y.; Zou, J.; Wang, W.; Fu, Z. Enhanced mechanical properties and oxidation resistance of zirconium diboride ceramics via grain-refining and dislocation regulation. Adv. Sci. 2022, 9, 2104532. [Google Scholar]

- Mattia, D.; Desmaison-Brut, M.; Dimovski, S.; Gogotsi, Y.; Desmaison, J. Oxidation behaviour of an aluminium nitride–hafnium diboride ceramic composite. J. Eur. Ceram. Soc. 2005, 25, 1789–1796. [Google Scholar] [CrossRef]

- Monticelli, C.; Bellosi, A.; Zucchi, F.; Dal Colle, M. Corrosion behaviour of hafnium diboride in aqueous solutions. Electrochim. Acta 2007, 52, 6943–6955. [Google Scholar] [CrossRef]

- Hassan, R.; Sarvesha, R.; Balani, K. Heterogeneous solid solutioning in carbon nanotube reinforced HfB2-ZrB2-SiC ultra high temperature ceramic composites. Mater. Charact. 2023, 201, 112941. [Google Scholar]

- Ren, X.; Wang, W.; Shang, T.; Mo, H.; Feng, P.; Guo, L.; Li, Z. Dynamic oxidation protective ultrahigh temperature ceramic TaB2-20%wt SiC composite coating for carbon material. Compos. B Eng. 2019, 161, 220–227. [Google Scholar]

- Hassan, R.; Balani, K. Densification mechanism of spark plasma sintered ZrB2 and ZrB2-SiC ceramic composites. Mater. Charact. 2021, 179, 111320. [Google Scholar] [CrossRef]

- Meng, X.; Yan, J.; Ou, B.; He, Q.; Zhang, Y.; Fang, S. Effect of Tac On microstructure and mechanical properties of 316L stainless steel by selective laser melting. Mater. Charact. 2023, 202, 112990. [Google Scholar] [CrossRef]

- Licheri, R.; Musa, C.; Orrù, R.; Cao, G.; Sciti, D.; Silvestroni, L. Bulk monolithic zirconium and tantalum diborides by reactive and non-reactive spark plasma sintering. J. Alloys Compd. 2016, 663, 351–359. [Google Scholar] [CrossRef]

- Zhang, C.; Gupta, A.; Seal, S.; Boesl, B.; Agarwal, A. Solid solution synthesis of tantalum carbide-hafnium carbide by spark plasma sintering. J. Am. Ceram. Soc. 2017, 100, 1853–1862. [Google Scholar] [CrossRef]

- Lu, J.; Hao, K.; Liu, L.; Li, H.; Li, K.; Qu, J.; Yan, X. Ablation resistance of Sic–Hfc–Zrc multiphase modified carbon/carbon composites. Corros. Sci. 2016, 103, 1–9. [Google Scholar] [CrossRef]

- Lu, Z.; Liu, L.; Geng, G.; Laptev, A.M.; Hou, Z.; Wang, Y. Effect of boron addition on microstructure, mechanical properties and oxidation resistance of tac ceramics. Ceram. Int. 2019, 45, 6712–6717. [Google Scholar] [CrossRef]

- Geng, G.; Liu, L.; Wang, Y.; Hai, W.; Sun, W.; Chen, Y.; Wu, L. Microstructure and mechanical properties of tac ceramics with 1-7.5 Mol% Si as sintering aid. J. Am. Ceram. Soc. 2017, 100, 2461–2470. [Google Scholar] [CrossRef]

- Kaplan Akarsu, M.; Akin, I.; Sahin, F.; Goller, G. Comparative study of reactive and nonreactive spark plasma sintering routes for the production of TaB2-Tac Composites. Int. J. Appl. Ceram. Technol. 2022, 19, 332–343. [Google Scholar] [CrossRef]

- Liu, L.; Geng, G.; Jiang, Y.; Wang, Y.; Hai, W.; Sun, W.; Chen, Y.; Wu, L. Microstructure and mechanical properties of tantalum carbide ceramics: Effects of Si3N4 as Sintering Aid. Ceram. Int. 2017, 43, 5136–5144. [Google Scholar] [CrossRef]

- Yuan, Y.; Liu, J.; Zhang, G. Effect of Hfc and Sic On microstructure and mechanical properties of HfB2 -Based Ceramics. Ceram. Int. 2016, 42, 7861–7867. [Google Scholar] [CrossRef]

- Qian, Y.; Wang, Y.; Chen, L.; Zhou, Y. Microstructure, Mechanical Properties and Thermal Conductivity of (Ti0.5Nb0.5)C–SiC Composites. Ceram. Int. 2022, 48, 6745–6749. [Google Scholar] [CrossRef]

- Zhang, X.; Hilmas, G.E.; Fahrenholtz, W.G. Densification, mechanical properties, and oxidation resistance of TaC-TaB2 Ceramics. J. Am. Ceram. Soc. 2008, 91, 4129–4132. [Google Scholar] [CrossRef]

- Li, S.; Wei, C.; Cheng, J.; Zhang, L.; Gao, P.; Wang, P.; Zhou, L.; Wen, G. Crack tolerant tac–sic ceramics prepared by spark plasma sintering. Ceram. Int. 2020, 46, 25230–25235. [Google Scholar] [CrossRef]

- Nieto, A.; Lahiri, D.; Agarwal, A. Graphene nanoplatelets reinforced tantalum carbide consolidated by spark plasma sintering. Mater. Sci. Eng. A 2013, 582, 338–346. [Google Scholar] [CrossRef]

- Nisar, A.; Ariharan, S.; Venkateswaran, T.; Sreenivas, N.; Balani, K. Oxidation studies on tac based ultra-high temperature ceramic composites under plasma arc jet exposure. Corros. Sci. 2016, 109, 50–61. [Google Scholar] [CrossRef]

- Paul, A.; Venugopal, S.; Binner, J.G.P.; Vaidhyanathan, B.; Heaton, A.C.J.; Brown, P.M. Uhtc–carbon fibre composites: Preparation, oxyacetylene torch testing and characterisation. J. Eur. Ceram. Soc. 2013, 33, 423–432. [Google Scholar] [CrossRef]

- Wei, Y.; Yang, Y.; Liu, M.; Li, Q.; Huang, Z. Oxidation mechanism and kinetics of SiBCN/HfC ceramic composites at high temperatures. J. Mater. Res. Technol. 2020, 9, 2289–2298. [Google Scholar] [CrossRef]

- Mallik, M.; Ray, K.K.; Mitra, R. Oxidation behavior of hot pressed ZrB2–SiC and HfB2–SiC composites. J. Eur. Ceram. Soc. 2011, 31, 199–215. [Google Scholar] [CrossRef]

- Yu, L.; Jia, P.; Song, Y.; Zhao, B.; Pan, Y.; Wang, J.; Cui, H.; Feng, R.; Li, H.; Cui, X.; et al. Effect of carbon nanotubes on the microstructure and properties of plasma electrolytic oxidized ceramic coatings on high silicon aluminum alloy. J. Mater. Res. Technol. 2022, 18, 3541–3552. [Google Scholar] [CrossRef]

- Pellegrini, C.; Balat-Pichelin, M.; Rapaud, O.; Bêche, E. Oxidation resistance of Zr- And Hf-diboride composites containing SiC in air plasma up to 2600 K for aerospace applications. Ceram. Int. 2022, 48, 2177–2190. [Google Scholar] [CrossRef]

- Zhou, L.; Zhang, J.; Hu, D.; Fu, Q.; Zhu, J.; Song, J.; Ding, W.; Hou, J.; Tong, M. Investigation on the oxidation and ablation behaviors of HfB2-SiC-Si/SiC-Si coatings for carbon/carbon composites. Corros. Sci. 2021, 190, 109638. [Google Scholar] [CrossRef]

- Tong, K.; Zhang, M.; Su, Z.; Wu, X.; Zeng, C.; Xie, X.; Fang, C.; Yang, C.; Huang, Q.; Huang, D. Ablation behavior of (Zr,Ta)B2-SiC coating on carbon/carbon composites at 2300 °C. Corros. Sci. 2021, 188, 109545. [Google Scholar] [CrossRef]

| Samples | Average Grain Size | Relative Density | Elastics Modulus | Nano Hardness |

|---|---|---|---|---|

| μm | % | GPa | GPa | |

| Pure TaB2 | 1.5 ± 0.12 | 89.2% ± 0.8% | 356.3 ± 13.3 | 17.7 ± 1.4 |

| 95TaB2-5TaC | 1.3 ± 0.2 | 95.9% ± 0.5% | 372.1 ± 10.7 | 19.4 ± 1.2 |

| 95TaB2-5TaC-0.5MWCNTs | 1.4 ± 0.2 | 94.3% ± 0.7% | 368.1 ± 11.5 | 18.9 ± 1.4 |

| 95TaB2-5TaC-0.5MWCNTs-0.2PAA | 1.3 ± 0.1 | 98.6% ± 0.4% | 386.3 ± 9.6 | 21.7 ± 1.0 |

| Samples | Rl (μm/s) | Rm (mg/(s·cm2)) |

|---|---|---|

| Pure TaB2 | −8.3 × 10−2 ± 2.7 × 10−2 | −2.0 × 10−3 ± 0.3 × 10−3 |

| 95TaB2-5TaC | −5.0 × 10−2 ± 2.0 × 10−2 | −1.7 × 10−3 ± 0.2 × 10−3 |

| 95TaB2-5TaC-0.5MWCNTs | −5.0 × 10−2 ± 2.1 × 10−2 | −1.8 × 10−3 ± 0.3 × 10−3 |

| 95TaB2-5TaC-0.5MWCNTs-0.2PAA | −3.3 × 10−2 ± 1.1 × 10−2 | −1.3 × 10−3 ± 0.2 × 10−3 |

| Reactions | △G (kJ/mol) | Keq | pO2 (atm) |

|---|---|---|---|

| 1 | −400.7 | 6.4 × 1011 | 1.6 × 10−12 |

| 2 | −476.2 | 1.1 × 1014 | 9.4 × 10−15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bo, G.; Tian, X.; Li, H.; Ye, L.; Xu, X.; Gu, Z.; Yan, J.; Su, X.; Yan, Y. Enhancing Ablation Resistance of TaB2-Based Ultra-High Temperature Ceramics by Mixing Fine TaC Particles and Dispersed Multi-Walled Carbon Nanotubes. Materials 2024, 17, 3394. https://doi.org/10.3390/ma17143394

Bo G, Tian X, Li H, Ye L, Xu X, Gu Z, Yan J, Su X, Yan Y. Enhancing Ablation Resistance of TaB2-Based Ultra-High Temperature Ceramics by Mixing Fine TaC Particles and Dispersed Multi-Walled Carbon Nanotubes. Materials. 2024; 17(14):3394. https://doi.org/10.3390/ma17143394

Chicago/Turabian StyleBo, Guangxu, Xiaoke Tian, Huanhuan Li, Luona Ye, Xiaoling Xu, Zhaorui Gu, Jinyong Yan, Xingjian Su, and Yunjun Yan. 2024. "Enhancing Ablation Resistance of TaB2-Based Ultra-High Temperature Ceramics by Mixing Fine TaC Particles and Dispersed Multi-Walled Carbon Nanotubes" Materials 17, no. 14: 3394. https://doi.org/10.3390/ma17143394

APA StyleBo, G., Tian, X., Li, H., Ye, L., Xu, X., Gu, Z., Yan, J., Su, X., & Yan, Y. (2024). Enhancing Ablation Resistance of TaB2-Based Ultra-High Temperature Ceramics by Mixing Fine TaC Particles and Dispersed Multi-Walled Carbon Nanotubes. Materials, 17(14), 3394. https://doi.org/10.3390/ma17143394