Coupled Effects of High Temperature and Steel Fiber Content on Energy Absorption Properties of Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Uniaxial Compression Experiment

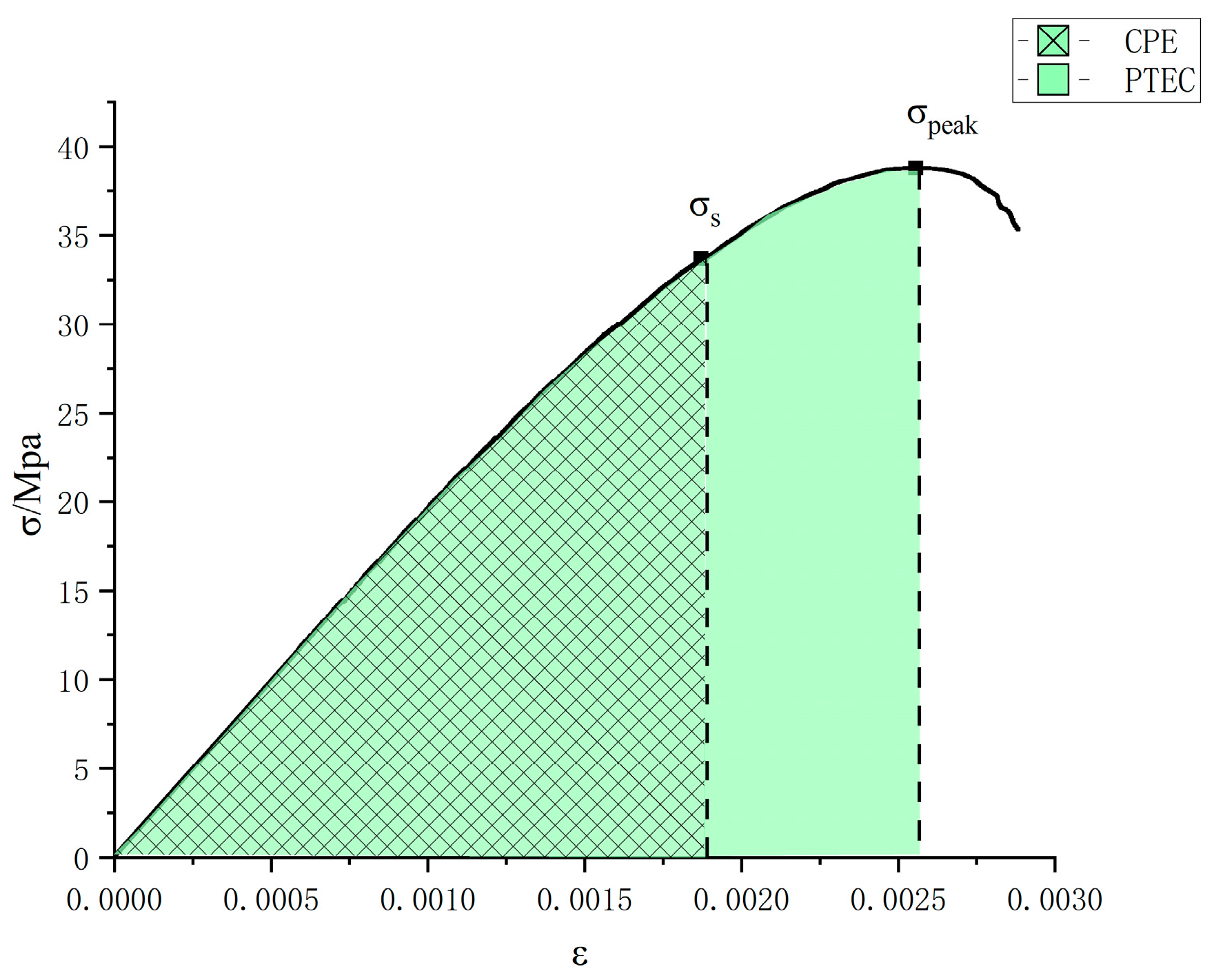

2.2. Energy Absorption and Toughness Index

3. Analysis of Results

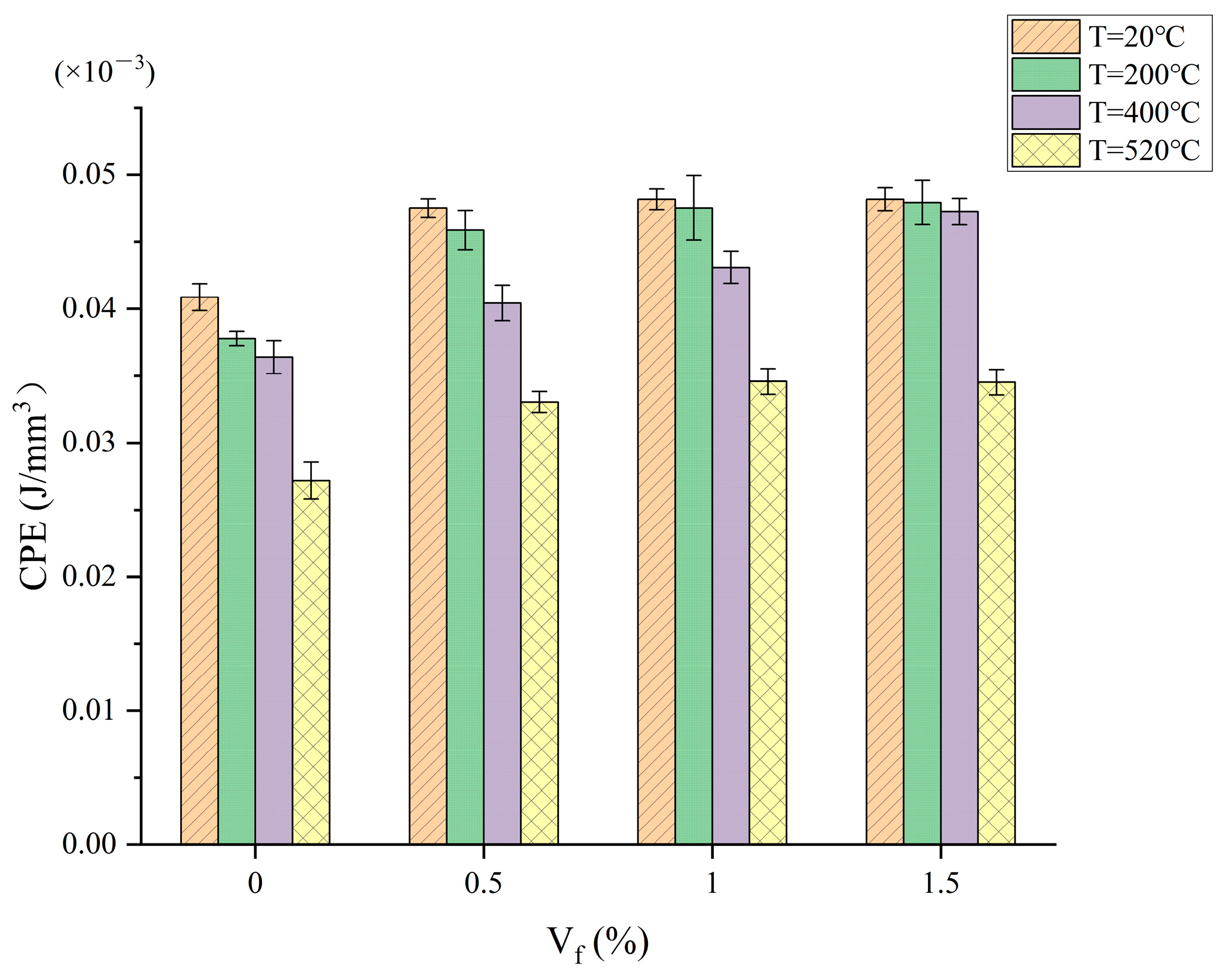

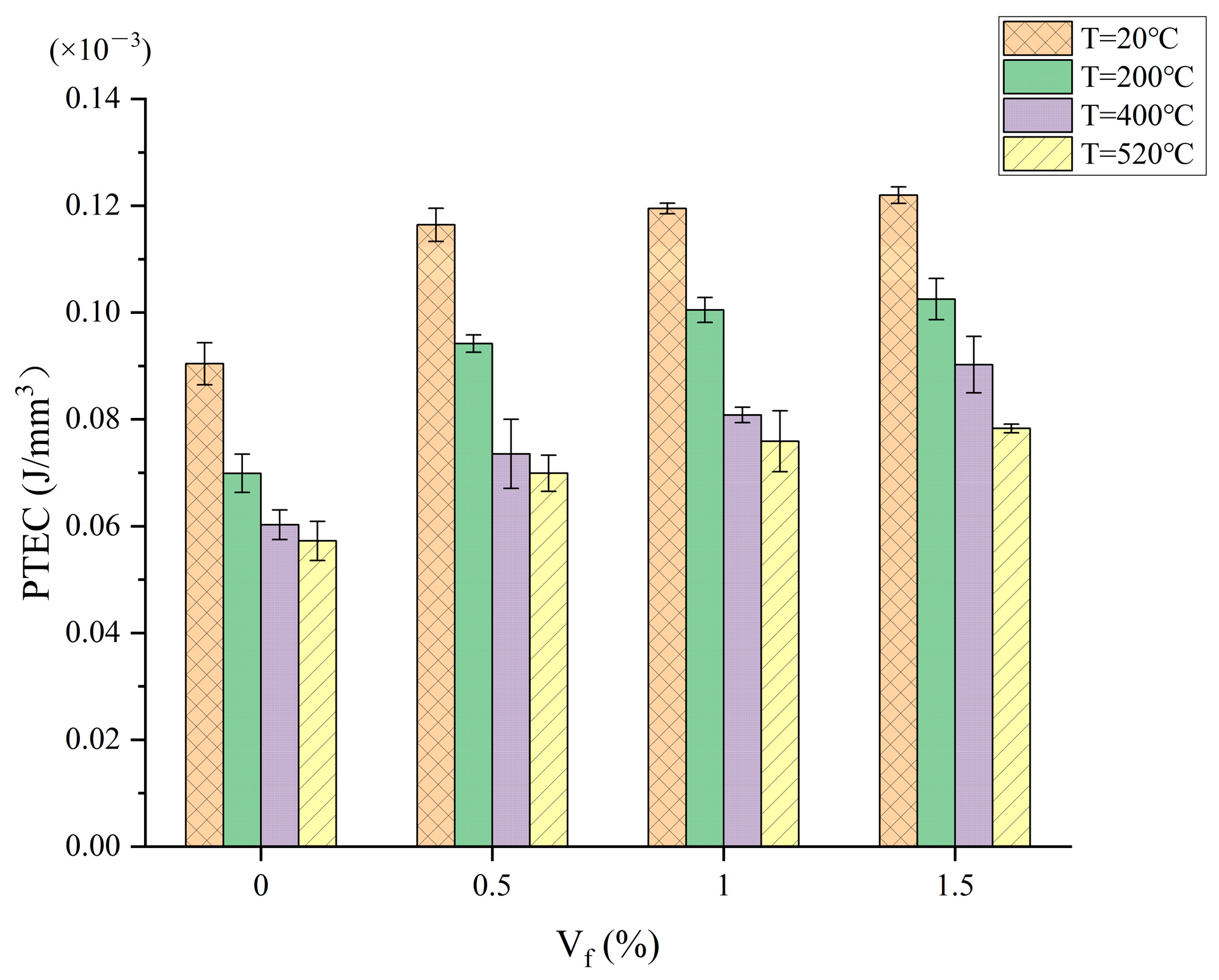

3.1. Reinforcing Effect of Steel Fibers on Energy Absorption Capacity

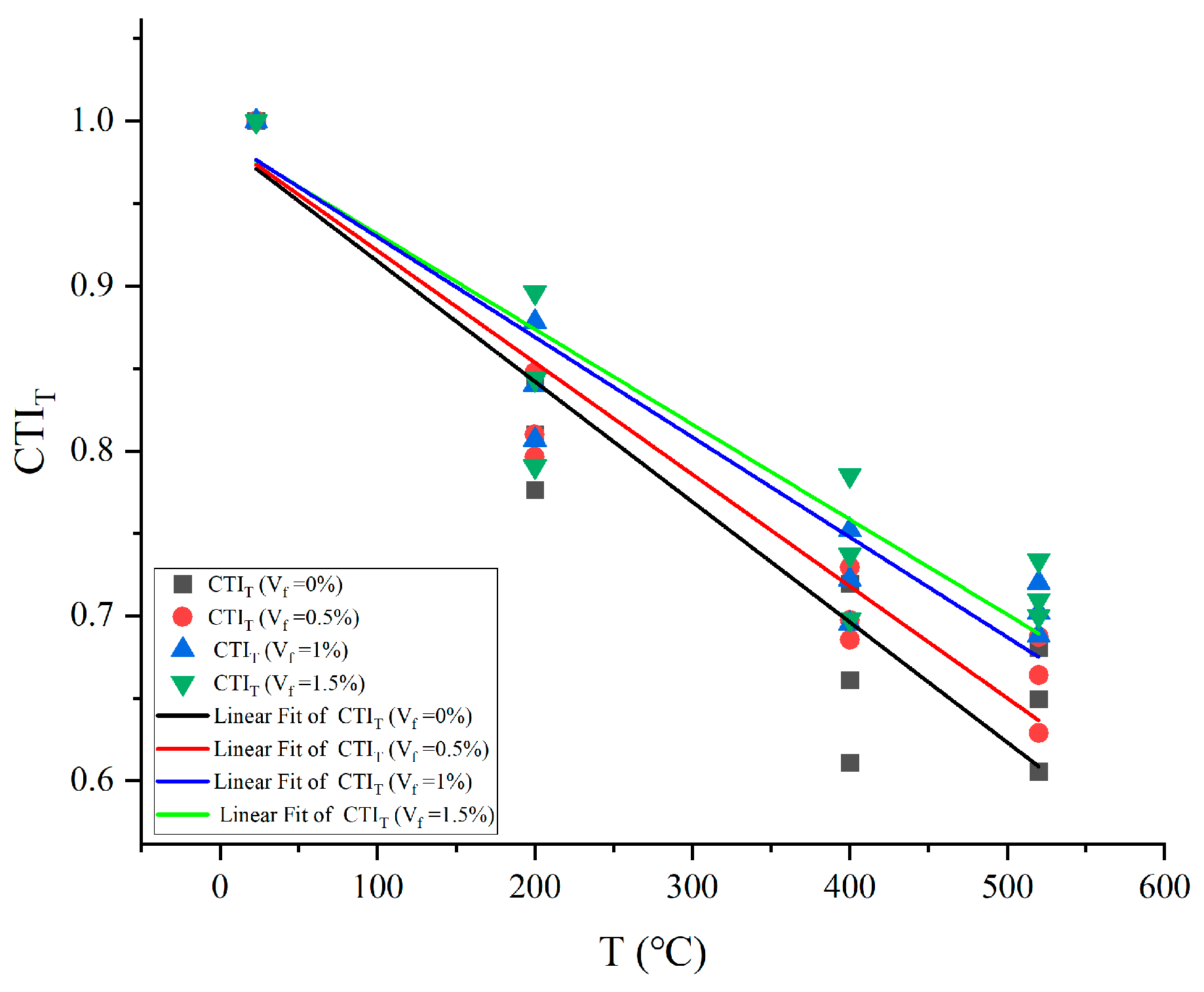

3.2. Weakening Effect of Temperature on Energy Absorption Capacity

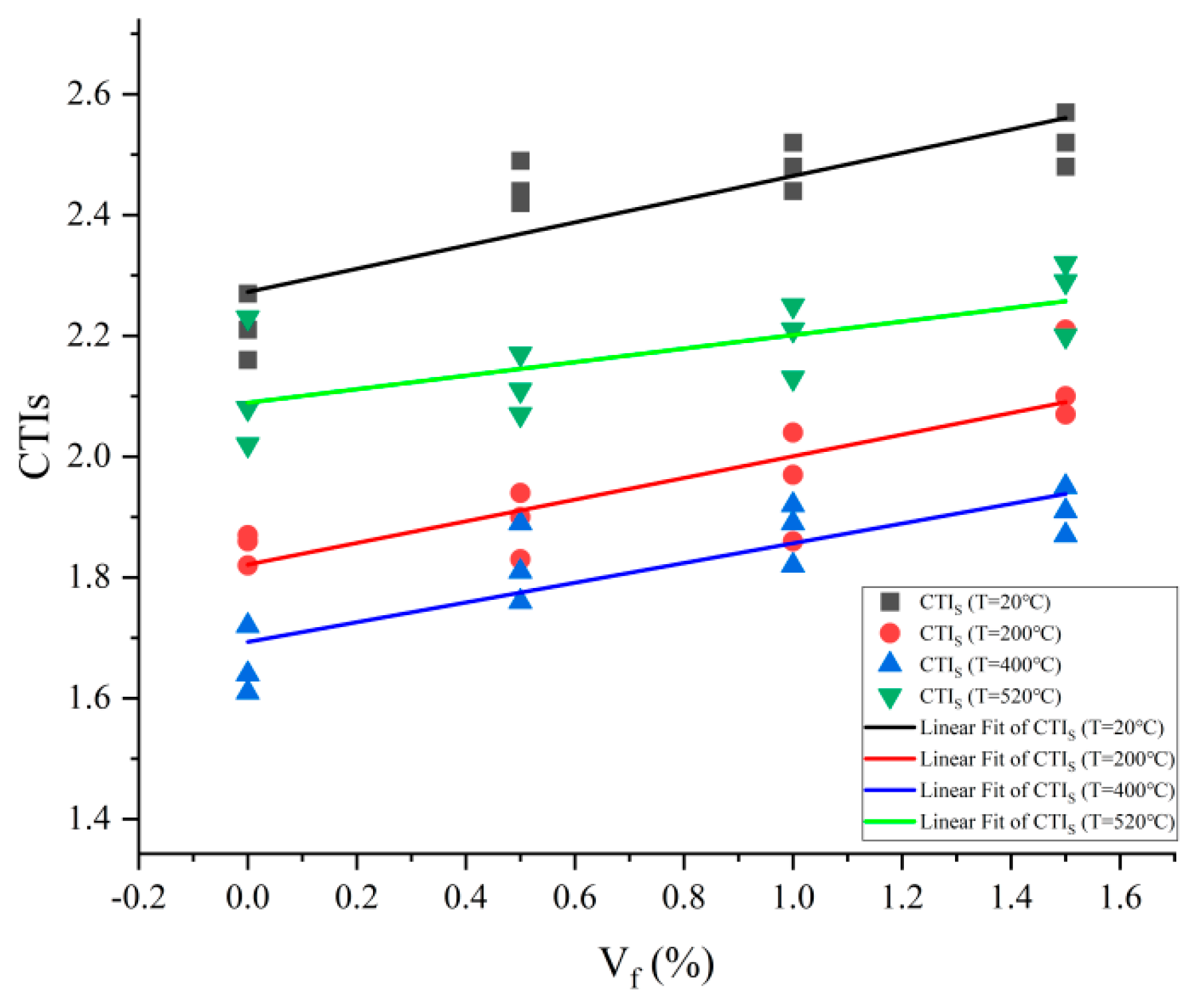

3.3. Coupled Effect of Steel Fiber and Temperature on Energy Absorption Capacity of Concrete

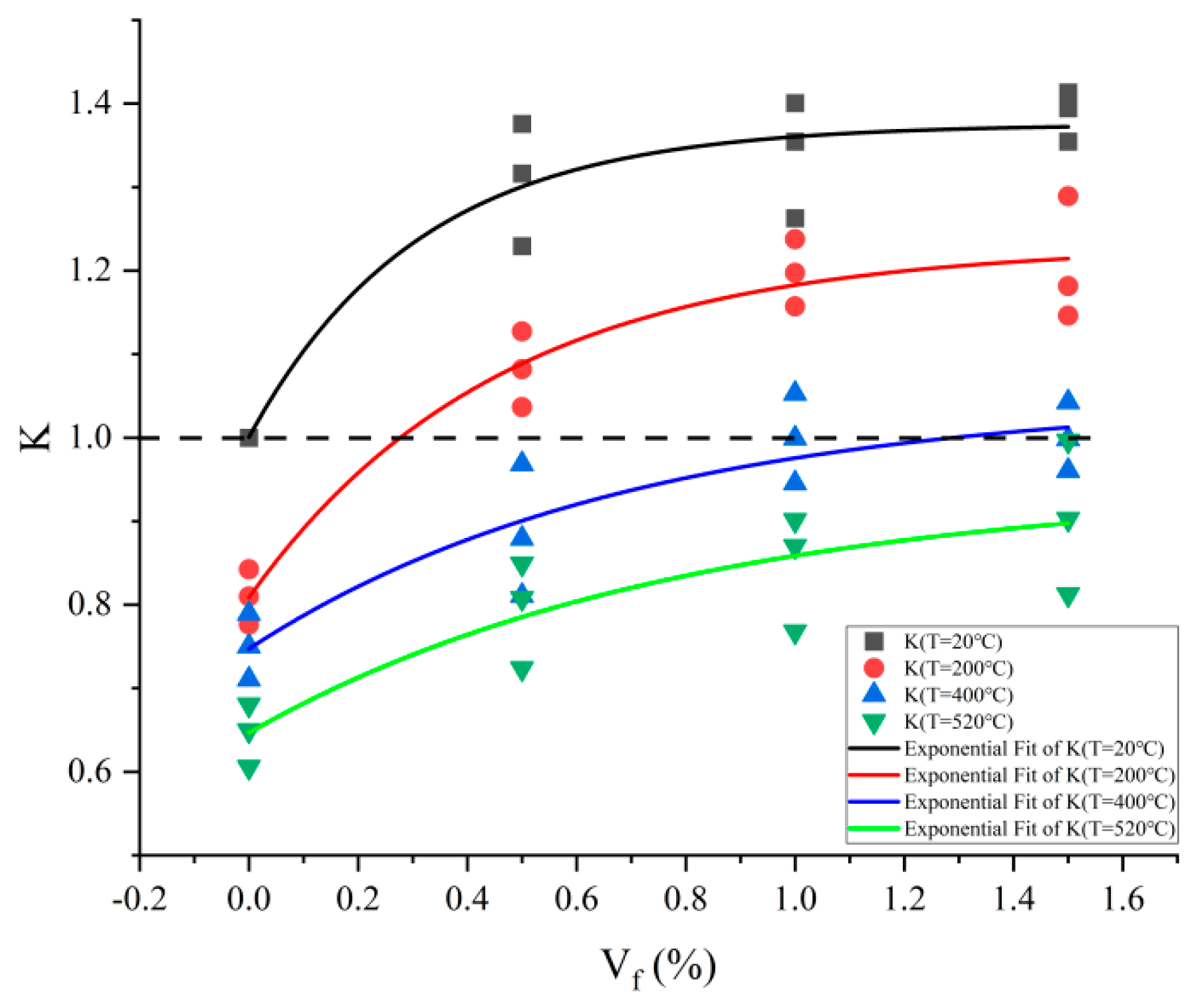

- (1)

- The K-Vf fitting curve has a different intercept on the longitudinal coordinate axis (K-axis), which is the temperature weakening factor KT (the ratio of energy absorbed under high-temperature conditions in plain concrete to that absorbed under normal-temperature conditions in plain concrete, WPT/WP0) of the material’s ability to absorb energy under normal-temperature or high-temperature conditions of plain concrete, that is, K (Vf = 0) = KT. There is a decreasing effect of temperature on the energy-absorbing capability of concrete, as evidenced by the fact that the energy-absorbing capability of plain concrete (Vf = 0) diminishes with rising temperatures. At a normal temperature (T = 20 °C), K > 1 was always present at different steel fiber contents, confirming that steel fibers have a reinforcing influence on the ability to absorb energy.

- (2)

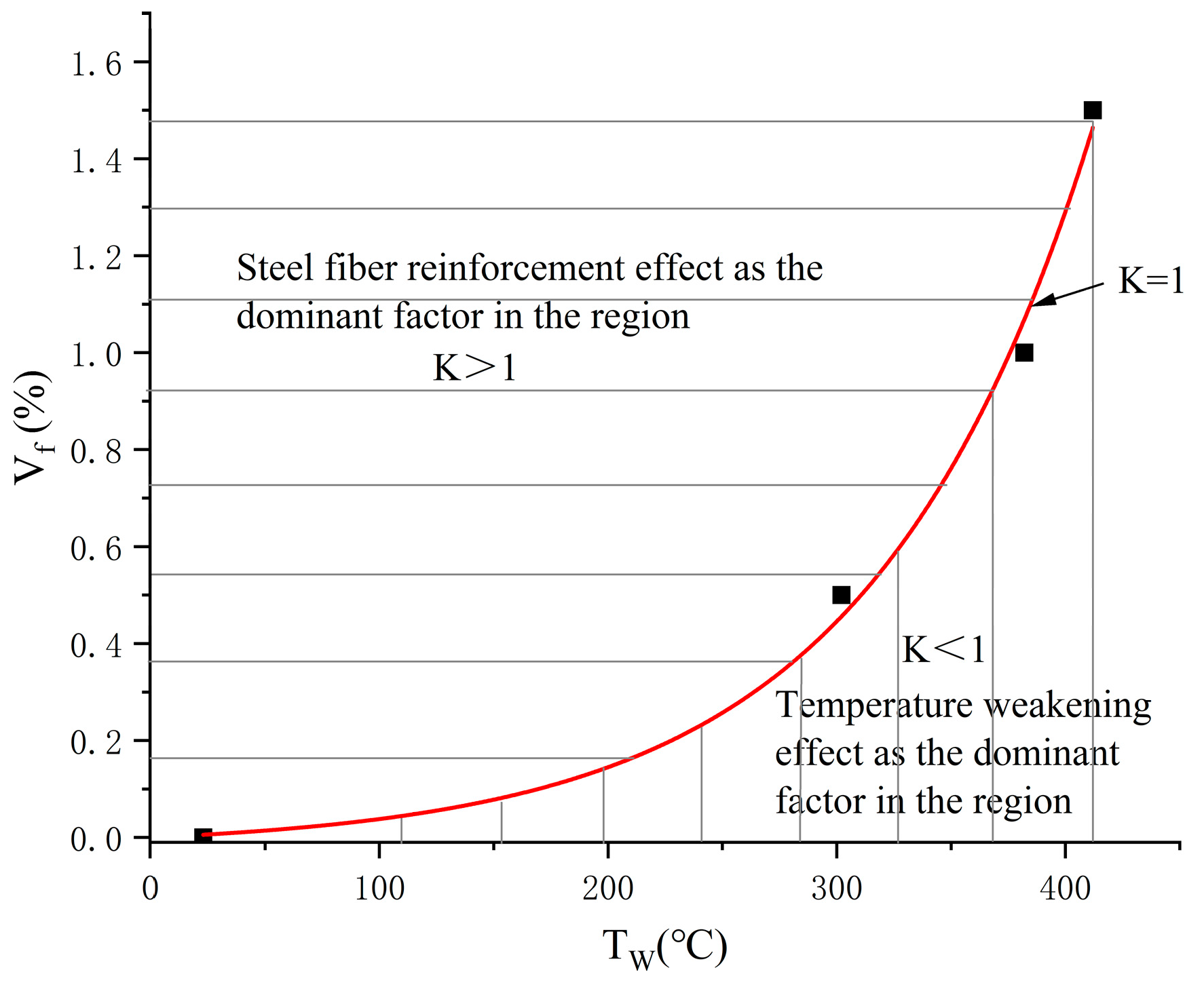

- Under the joint condition of steel fiber and temperature, when K = 1, the energy absorption capability of concrete is weakened by temperature in an amount equivalent to that of concrete that has been reinforced by steel fiber. Under this condition, the amount of energy that steel fiber concrete absorbs at elevated temperatures WST is equal to the energy absorbed by plain concrete at normal temperature WP0, that is, WST = WP0. When T = 200 °C and steel fiber percentage Vf < 0.28%, K < 1, indicating that the steel fiber reinforcing effect and the temperature weakening effect compete with each other as a result of the dominant temperature weakening effect on the energy absorption capability of concrete. If steel fiber content Vf > 0.28%, K > 1, indicating that the steel fiber reinforcing effect and the temperature weakening effect compete with each other as a result of the dominant steel fiber reinforcing effect on the energy absorption capability of concrete. When T = 400 °C, if the steel fiber content Vf < 1.33%, K < 1, indicating that the temperature weakening effect dominates the energy-absorbing capacity of concrete. If steel fiber content Vf > 1.33%, K > 1, indicating that the steel fiber reinforcing effect dominates the energy absorption capacity of concrete. When T = 520 °C, K < 1 is consistently found at varying steel fiber concentrations. The K values of concrete in high-temperature conditions are all less than the K values at a normal temperature.

- (3)

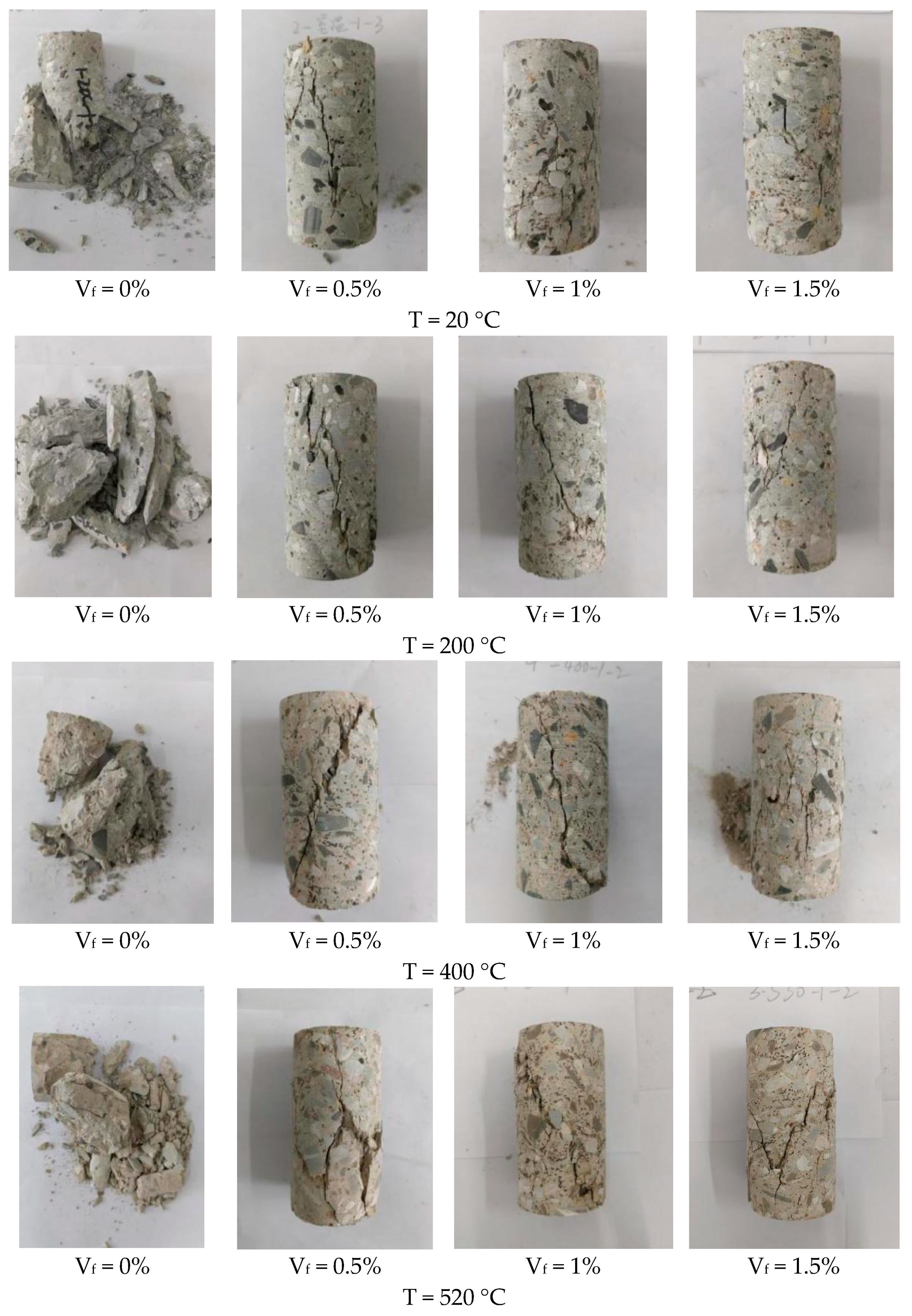

- At different temperatures, the joint factor K shows a rising pattern as the amount of steel fiber increases, and the K-Vf fitting curve gradually flattens out and the slope gradually decreases, suggesting a progressive weakening of the steel fibers’ strengthening function. However, under high-temperature circumstances, the energy absorption capability of steel fiber concrete specimens was still higher than that of plain concrete. The main reason for this is the steady reinforcing effect of the steel fibers when mixed in the mortar. This reinforcing effect is due to the indiscriminately distributed steel fibers enhancing the bond between the concrete matrix and the coarse aggregate, effectively hindering the formation of cracks, allowing for uniform pressure transfer and dispersion.

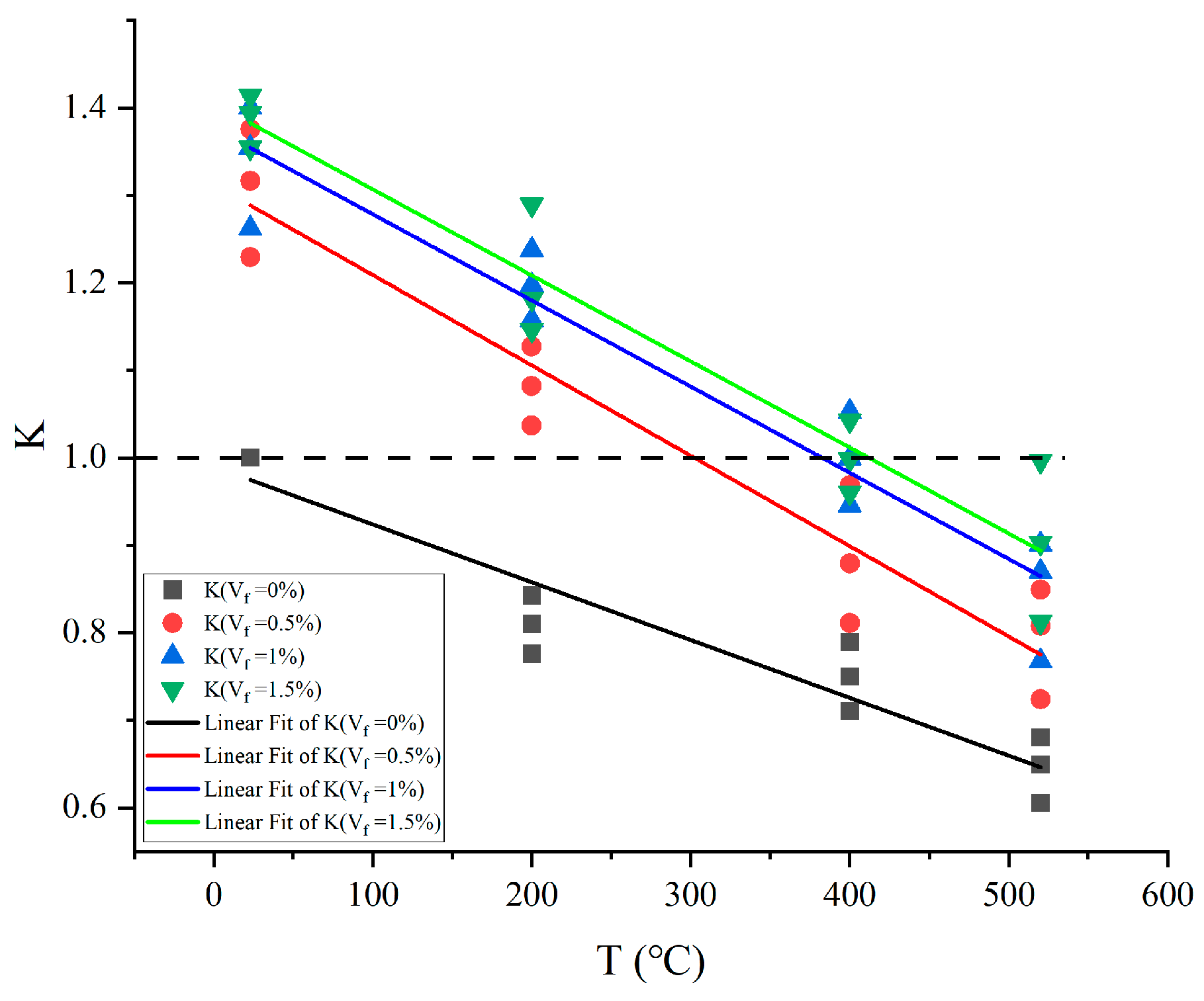

- (1)

- At T = 20 °C, the steel fiber reinforcing factor KS is the joint factor K of temperature and steel fiber (the proportion of energy absorbed by plain concrete at a normal temperature divided by that of steel fiber concrete at the same temperature, WSO/WPO) for concrete at ambient conditions, that is, KS = K (T = 20 °C), and KS is a function of steel fiber content only. Under both ambient and elevated temperature conditions, the energy-absorbing capability of concrete rises as the quantity of steel fibers rises. Moreover, steel fiber concrete has a consistently better energy-absorbing capacity than plain concrete, illustrating the steel fibers’ reinforcing effect. At steel fiber content Vf = 0, K < 1 is always present at different temperatures, confirming that temperature has a weakening influence on the ability to absorb energy.

- (2)

- When the steel fibers and temperature are combined, the trend of the joint factor K of steel fiber concrete with temperature is the same as that of plain concrete, and K decreases linearly with the increase in temperature. When Vf = 0.5%, if temperature T < 302 °C, K > 1, indicating that the temperature weakening effect and the steel fiber reinforcement effect compete with each other as a result of the steel fiber reinforcing impact on concrete’s energy absorption capability, which is dominant. If temperature T > 302 °C, K < 1, indicating that the temperature weakening effect and the steel fiber reinforcement effect compete with each other as a result of the temperature weakening impact on concrete’s energy absorption capability, which is dominant. When Vf = 1%, if temperature T < 382 °C, K > 1, indicating that the steel fiber reinforcing effect dominates the energy absorption capability of concrete. If temperature T > 382 °C, K < 1, indicating that the temperature weakening effect dominates the energy absorption capacity of concrete. When Vf = 1.5%, if temperature T < 412 °C, K > 1, indicating that the steel fiber reinforcement effect dominates the energy absorption capability of concrete. If temperature T > 412 °C, K < 1, indicating that the temperature weakening effect dominates the energy absorption ability of concrete. Despite the fact that steel fiber concrete specimens’ ability to absorb energy declines with warmth, at both normal and high temperatures, the energy-absorbing capability of steel fiber concrete is greater than that of plain concrete, and the steel fibers’ impact on the energy-absorbing capacity shows a reinforcing effect.

- (3)

- At different steel fiber contents, it is known from the intersection of the K-T fitting curve of concrete energy absorption capacity and DIF = 1 that the higher the steel fiber percentage, the further the junction point shifts rearward, which corresponds to a higher temperature. We describe the temperature corresponding to the intersection of the K-T fitting curves with DIF = 1 for different steel fiber contents as characteristic temperature TW. Table 4 illustrates the relationship between steel fiber percentage and characteristic temperature.

3.4. Destruction Patterns

4. Mechanism Analysis

5. Conclusions

- (1)

- The incorporated steel fibers have a crack-blocking and toughening effect, which significantly improves the energy-absorbing capacity of the concrete, which increases as the content of steel fibers in the concrete increases. Additionally, steel fiber concrete has better energy absorption properties than plain concrete, demonstrating that the concrete’s steel fiber composition amplifies its ability to absorb energy. High-temperature action causes damage to the cement matrix and aggregate of concrete, water evaporates, porosity increases, and microcracks gradually arise and expand. As the temperature rose, the energy-absorbing capability of concrete with varying steel fiber contents all declined, which reflected the weakening effect of temperature on the energy-absorbing capacity of concrete.

- (2)

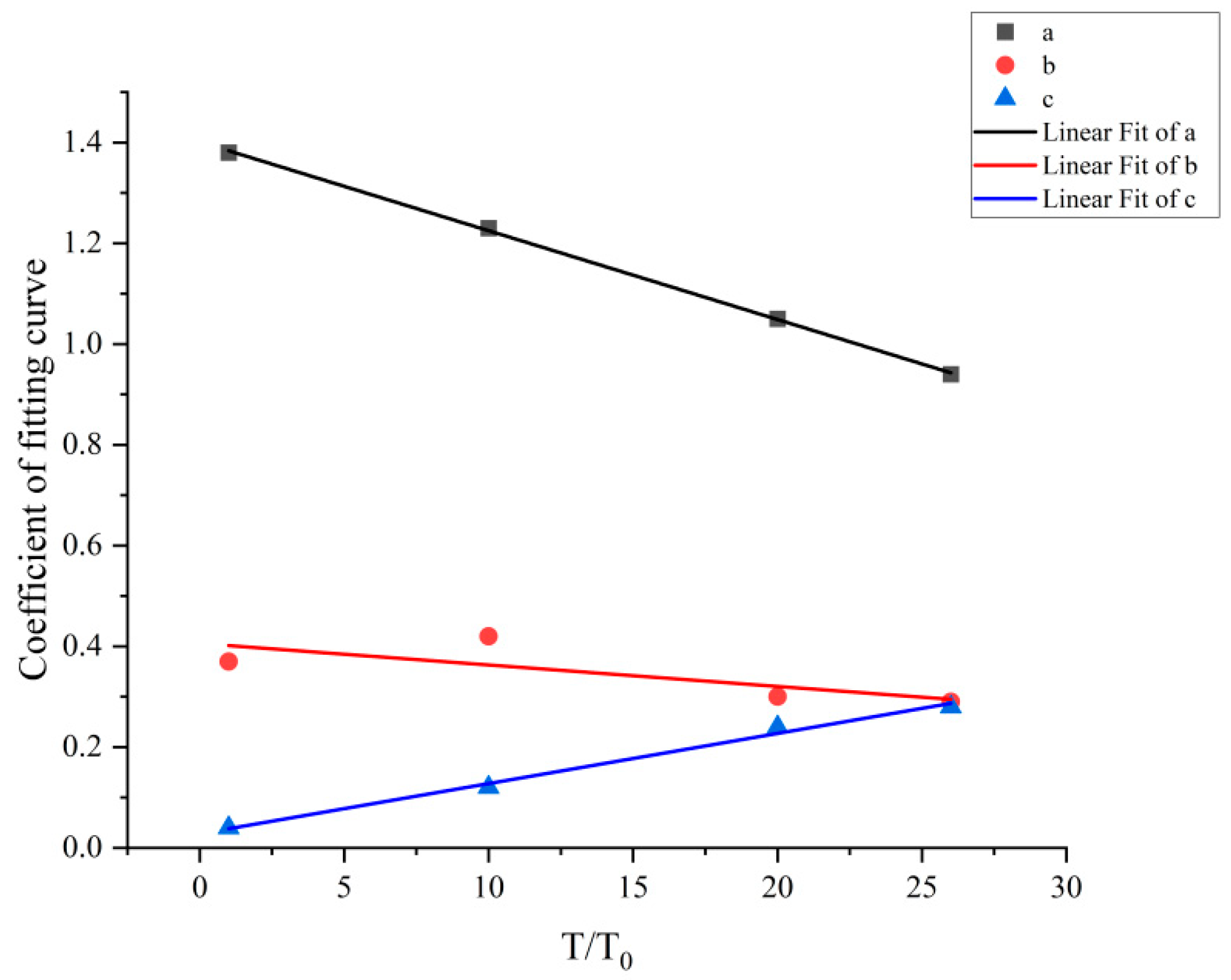

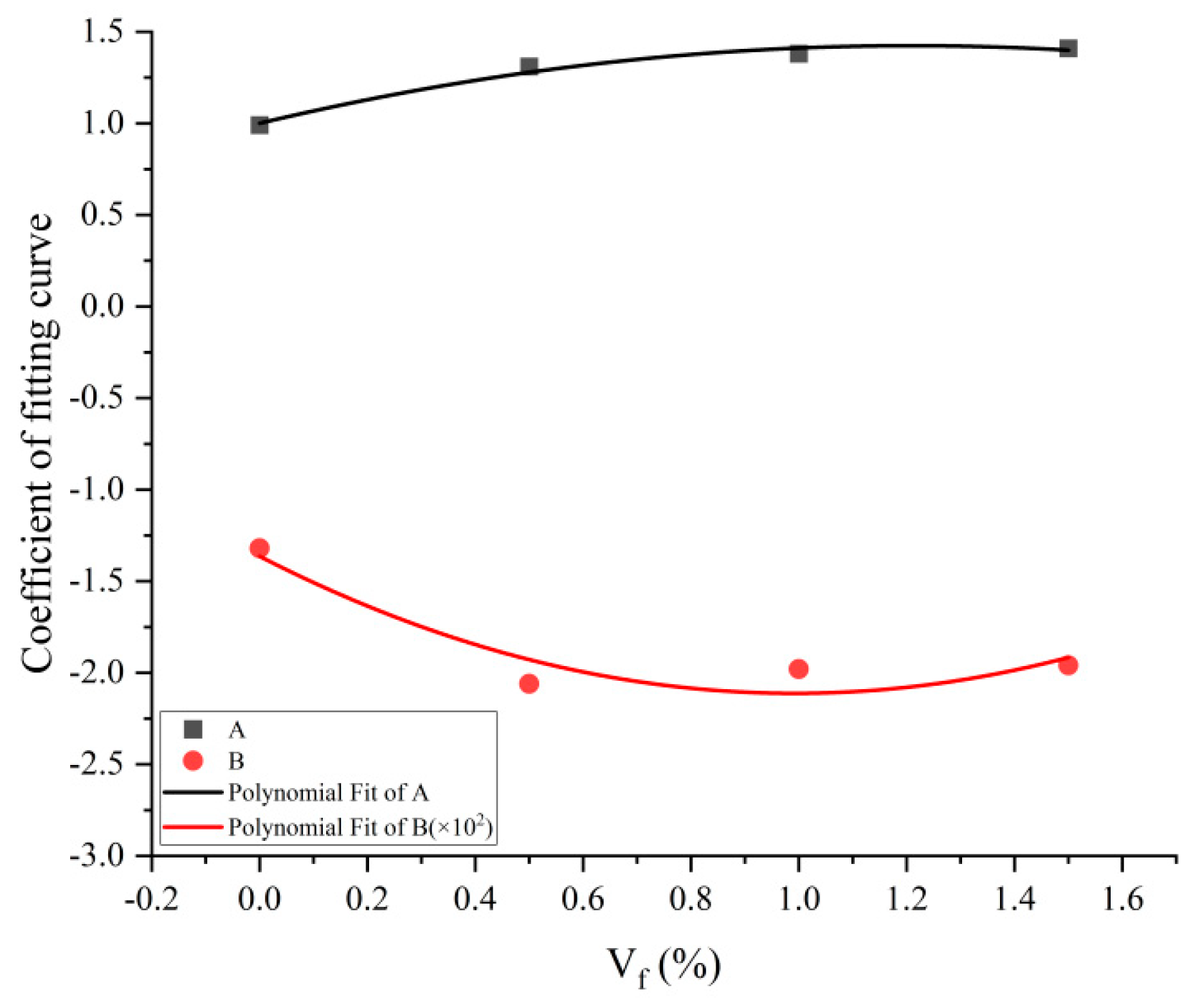

- Under the joint condition of steel fiber and temperature, the expression of joint factor K with temperature T is , where a(T), b(T), and c(T) pertain to the temperature function, which is only related to the magnitude of the temperature. At Vf = 0, the joint factor K of steel fiber and temperature is the temperature weakening factor KT (the ratio of energy absorbed under high temperature conditions of plain concrete to the amount of energy absorbed under normal temperature conditions of plain concrete, WPT/WP0) of the energy-absorbing capacity of the material under normal or high temperature conditions, that is, K (Vf = 0) = KT.

- (3)

- Under the joint condition of steel fiber and temperature, the expression for joint factor K and steel fiber content Vf is , where A(Vf) and B(Vf) are functions of the steel fiber percentage, the magnitude of which is related only to the steel fiber content. At T = 20 °C, the joint factor K of steel fiber and temperature equals the steel fiber reinforcement factor KS (the ratio of energy absorbed by steel fiber concrete at a normal temperature to that absorbed by plain concrete at a normal temperature, WS0/WP0) for steel fiber concrete at a normal temperature, that is, KS = K (T = 20 °C).

- (4)

- On the condition of steel fiber temperature coupling, the dominant regions of influence of the reinforcing effect of steel fiber and the weakening effect of temperature on the energy absorption capacity of concrete are given, and the intrinsic relational equation between steel fiber and temperature, when the steel fiber–temperature effect is comparable, is established as .

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alshaikh, I.M.; Bakar, B.A.; Alwesabi, E.A.; Akil, H.M. Progressive collapse of reinforced rubberised concrete: Experimental study. Constr. Build. Mater. 2019, 226, 307–316. [Google Scholar] [CrossRef]

- Mu, B.; Li, Z.; Peng, J. Short fiber-reinforced cementitious extruded plates with high percentage of slag and different fibers. Cem. Concr. Res. 2000, 30, 1277–1282. [Google Scholar] [CrossRef]

- Yehia, S.; Douba, A.; Abdullahi, O.; Farrag, S. Mechanical and durability evaluation of fiber-reinforced self-compacting concrete. Constr. Build. Mater. 2016, 121, 120–133. [Google Scholar] [CrossRef]

- Khan, A.A.; Khan, M.A.; Domada, R.V.V.; Huang, X.; Usmani, A.; Bakhtiyari, S.; Ashtiani, M.J.; Garivani, S.; Aghakouchak, A.A. Fire modelling framework for investigating tall building fire: A case study of the Plasco Building. Case Stud. Therm. Eng. 2023, 45, 103018. [Google Scholar] [CrossRef]

- Xie, Q.; Xiao, J.; Gardoni, P.; Hu, K. Probabilistic analysis of building fire severity based on fire load density models. Fire Technol. 2019, 55, 1349–1375. [Google Scholar] [CrossRef]

- Ma, Q.; Guo, R.; Zhao, Z.; Lin, Z.; He, K. Mechanical properties of concrete at high temperature—A review. Constr. Build. Mater. 2015, 93, 371–383. [Google Scholar] [CrossRef]

- Ergün, A.; Kürklü, G.; Serhat, B.M.; Mansour, M.Y. The effect of cement dosage on mechanical properties of concrete exposed to high temperatures. Fire Saf. J. 2013, 55, 160–167. [Google Scholar] [CrossRef]

- Hanif, A.; Parthasarathy, P.; Lu, Z.; Sun, M.; Li, Z. Fiber-reinforced cementitious composites incorporating glass cenospheres—Mechanical properties and microstructure. Constr. Build. Mater. 2017, 154, 529–538. [Google Scholar] [CrossRef]

- Gao, D.; Lv, M.; Yang, L.; Tang, J. Flexural properties of high ductility cementitious composites with totally recycled fine aggregate. J. Mater. Res. Technol. 2021, 14, 1319–1332. [Google Scholar] [CrossRef]

- Bajaber, M.A.; Hakeem, I.Y. UHPC evolution, development, and utilization in construction: A review. J. Mater. Res. Technol. 2021, 10, 1058–1074. [Google Scholar] [CrossRef]

- Pyo, S.; Koh, T.; Tafesse, M.; Kim, H.K. Chloride-induced corrosion of steel fiber near the surface of ultra-high performance concrete and its effect on flexural behavior with various thickness. Constr. Build. Mater. 2019, 224, 206–213. [Google Scholar] [CrossRef]

- Smarzewski, P. Study of toughness and macro/micro-crack development of fibre-reinforced ultra-high performance concrete after exposure to elevated temperature. Materials 2019, 12, 1210. [Google Scholar] [CrossRef] [PubMed]

- Al-Majidi, M.H.; Lampropoulos, A.; Cundy, A.B. Steel fibre reinforced geopolymer concrete (SFRGC) with improved microstructure and enhanced fibre-matrix interfacial properties. Constr. Build. Mater. 2017, 139, 286–307. [Google Scholar] [CrossRef]

- Ríos, J.D.; Leiva, C.; Ariza, M.P.; Seitl, S.; Cifuentes, H. Analysis of the tensile fracture properties of ultra-high-strength fiber-reinforced concrete with different types of steel fibers by X-ray tomography. Mater. Des. 2019, 165, 107582. [Google Scholar] [CrossRef]

- Guo, J.J.; Wang, K.; Qi, C.G. Determining the mineral admixture and fiber on mechanics and fracture properties of concrete under sulfate attack. J. Mar. Sci. Eng. 2021, 9, 251. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, X.; Wu, Z.; Yu, H.; Fang, Q. Fracture properties of steel fiber reinforced concrete: Size effect study via mesoscale modelling approach. Eng. Fract. Mech. 2022, 260, 108193. [Google Scholar] [CrossRef]

- Lian, H.; Sun, X.; Yu, Z.; Yang, T.; Zhang, J.; Li, G.; Guan, Z.; Diao, M. Research on the fracture mechanical performance of basalt fiber nano-CaCO3 concrete based on DIC technology. Constr. Build. Mater. 2022, 329, 127193. [Google Scholar] [CrossRef]

- Song, P.S.; Hwang, S. Mechanical properties of high-strength steel fiber-reinforced concrete. Constr. Build. Mater. 2004, 18, 669–673. [Google Scholar] [CrossRef]

- Zhang, Y.; Si, Z.; Huang, L.; Yang, C.; Du, X. Experimental study on the properties of internal cured concrete reinforced with steel fibre. Constr. Build. Mater. 2023, 393, 132046. [Google Scholar] [CrossRef]

- Jang, S.J.; Yun, H.D. Combined effects of steel fiber and coarse aggregate size on the compressive and flexural toughness of high-strength concrete. Compos. Struct. 2018, 185, 203–211. [Google Scholar] [CrossRef]

- Sun, X.; Zhao, K.; Li, Y.; Huang, R.; Ye, Z.; Zhang, Y.; Ma, J. A study of strain-rate effect and fiber reinforcement effect on dynamic behavior of steel fiber-reinforced concrete. Constr. Build. Mater. 2018, 158, 657–669. [Google Scholar] [CrossRef]

- Li, Y.; Li, Y. Experimental study on performance of rubber particle and steel fiber composite toughening concrete. Constr. Build. Mater. 2017, 146, 267–275. [Google Scholar] [CrossRef]

- Yang, S.; Zhao, R.; Ma, B.; Si, R.; Zeng, X. Mechanical and fracture properties of fly ash-based geopolymer concrete with different fibers. J. Build. Eng. 2023, 63, 105281. [Google Scholar] [CrossRef]

- Li, P.; Liu, J.; Duan, S.; Huang, R. Variation pattern of the compressive strength of concrete under combined heat and moisture conditions. Materials 2023, 16, 1548. [Google Scholar] [CrossRef] [PubMed]

- Han, C.G.; Hwang, Y.S.; Yang, S.H.; Gowripalan, N. Performance of spalling resistance of high performance concrete with polypropylene fiber contents and lateral confinement. Cem. Concr. Res. 2005, 35, 1747–1753. [Google Scholar] [CrossRef]

- Kalifa, P.; Chene, G.; Galle, C. High-temperature behaviour of HPC with polypropylene fibres: From spalling to microstructure. Cem. Concr. Res. 2001, 31, 1487–1499. [Google Scholar] [CrossRef]

- Khaliq, W.; Kodur, V. High Temperature Mechanical Properties of High-Strength Fly Ash Concrete with and without Fibers. ACI Mater. J. 2012, 109, 665. [Google Scholar]

- Serrano, R.; Cobo, A.; Prieto, M.I.; de las Nieves González, M. Analysis of fire resistance of concrete with polypropylene or steel fibers. Constr. Build. Mater. 2016, 122, 302–309. [Google Scholar] [CrossRef]

- Lau, A.; Anson, M. Effect of high temperatures on high performance steel fibre reinforced concrete. Cem. Concr. Res. 2006, 36, 1698–1707. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Pomchiengpin, W.; Songpiriyakij, S. Post-crack (or post-peak) flexural response and toughness of fiber reinforced concrete after exposure to high temperature. Constr. Build. Mater. 2010, 24, 1967–1974. [Google Scholar] [CrossRef]

- ASTM C1018; Standard Test Method for Flexural Toughness and First-Crack Strength of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading). ASTM Standards: West Conshohocken, PA, USA, 1997; pp. 1–8.

- Poon, C.S.; Shui, Z.H.; Lam, L. Compressive behavior of fiber reinforced high-performance concrete subjected to elevated temperatures. Cem. Concr. Res. 2004, 34, 2215–2222. [Google Scholar] [CrossRef]

- Maksudov, F.; Daraei, A.; Sesha, A.; Marx, K.A.; Guthold, M.; Barsegov, V. Strength, deformability and toughness of uncrosslinked fibrin fibers from theoretical reconstruction of stress-strain curves. Acta Biomater. 2021, 136, 327–342. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.; Fan, L.; Zhang, Z.; Yuan, J.; He, H.; Yu, J.; Hu, Z.; Xu, W.; Lin, W.; Yu, K.; et al. Research on axial compressive performance of ceramic concrete reinforced with HTPP fibers. Case Stud. Constr. Mater. 2024, 21, e03412. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, X.; Jiang, H.; Su, X.; Zhang, X.; Zou, M. Study on the mechanical properties and energy absorbing capability of polyurethane microcellular elastomers under different compressive strain rates. Polymers 2023, 15, 778. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Liu, Y.; Wang, W.; Wang, K.; Zhang, Y.; Hou, J. Effect of basalt fiber on uniaxial compression-related constitutive relation and compressive toughness of recycled aggregate concrete. Materials 2023, 16, 1849. [Google Scholar] [CrossRef] [PubMed]

- Wu, K.; Shao, Z.; Qin, S. A solution for squeezing deformation control in tunnels using foamed concrete: A review. Constr. Build. Mater. 2020, 257, 119539. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Ali, M. Effect of basalt fibers on mechanical properties of calcium carbonate whisker-steel fiber reinforced concrete. Constr. Build. Mater. 2018, 192, 742–753. [Google Scholar] [CrossRef]

- Cao, S.; Xue, G.; Yilmaz, E.; Yin, Z.; Yang, F. Utilizing concrete pillars as an environmental mining practice in underground mines. J. Clean. Prod. 2021, 278, 123433. [Google Scholar] [CrossRef]

- Xargay, H.; Folino, P.; Sambataro, L.; Etse, G. Temperature effects on failure behavior of self-compacting high strength plain and fiber reinforced concrete. Constr. Build. Mater. 2018, 165, 723–734. [Google Scholar] [CrossRef]

- Ahmad, S.H.; Arockiasamy, M.; Balaguru, P.N.; Ball, C.G.; Ball, H.P., Jr.; Batson, G.B.; Bentur, A.; Craig, R.J.; Criswell, M.E.; Daniel, J.I.; et al. Measurement of Properties of Fiber Reinforced Concrete; American Concrete Institute: Farmington Hills, MI, USA, 1988. [Google Scholar]

| Steel Fiber Volume Fraction (%) | Cement (kg/m3) | Sand (kg/m3) | Aggregate (kg/m3) | Water (kg/m3) | Superplasticizer (kg/m3) | Steel Fiber (kg/m3) |

|---|---|---|---|---|---|---|

| 0 | 425 | 600 | 1132 | 184 | 8 | 0 |

| 0.5% | 425 | 600 | 1132 | 184 | 8 | 39 |

| 1% | 425 | 600 | 1132 | 184 | 8 | 78 |

| 1.5% | 425 | 600 | 1132 | 184 | 8 | 117 |

| T/°C | a | b | c |

|---|---|---|---|

| 20 | 1.38 | 0.37 | 0.04 |

| 200 | 1.23 | 0.42 | 0.12 |

| 400 | 1.05 | 0.30 | 0.24 |

| 520 | 0.94 | 0.29 | 0.28 |

| Vf/% | A | B × 102 |

|---|---|---|

| 0 | 0.99 | −1.32 |

| 0.5 | 1.31 | −2.06 |

| 1 | 1.38 | −1.98 |

| 1.5 | 1.41 | −1.96 |

| TW/°C | Vf/% |

|---|---|

| 20 | 0 |

| 302 | 0.5 |

| 382 | 1 |

| 412 | 1.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Feng, J.; Gu, J.; Duan, S. Coupled Effects of High Temperature and Steel Fiber Content on Energy Absorption Properties of Concrete. Materials 2024, 17, 3440. https://doi.org/10.3390/ma17143440

Li P, Feng J, Gu J, Duan S. Coupled Effects of High Temperature and Steel Fiber Content on Energy Absorption Properties of Concrete. Materials. 2024; 17(14):3440. https://doi.org/10.3390/ma17143440

Chicago/Turabian StyleLi, Ping, Jie Feng, Jiming Gu, and Shiwei Duan. 2024. "Coupled Effects of High Temperature and Steel Fiber Content on Energy Absorption Properties of Concrete" Materials 17, no. 14: 3440. https://doi.org/10.3390/ma17143440

APA StyleLi, P., Feng, J., Gu, J., & Duan, S. (2024). Coupled Effects of High Temperature and Steel Fiber Content on Energy Absorption Properties of Concrete. Materials, 17(14), 3440. https://doi.org/10.3390/ma17143440