Highly Stable, Bending-Tolerant, and Sustainable Flexible Heater through a Scalable Papermaking Procedure

Abstract

:1. Introduction

2. Experimental Part

2.1. Materials

2.2. Preparation of the Composite Paper through a Papermaking Procedure

2.3. Preparation of the Flexible Heater

2.4. Characterization

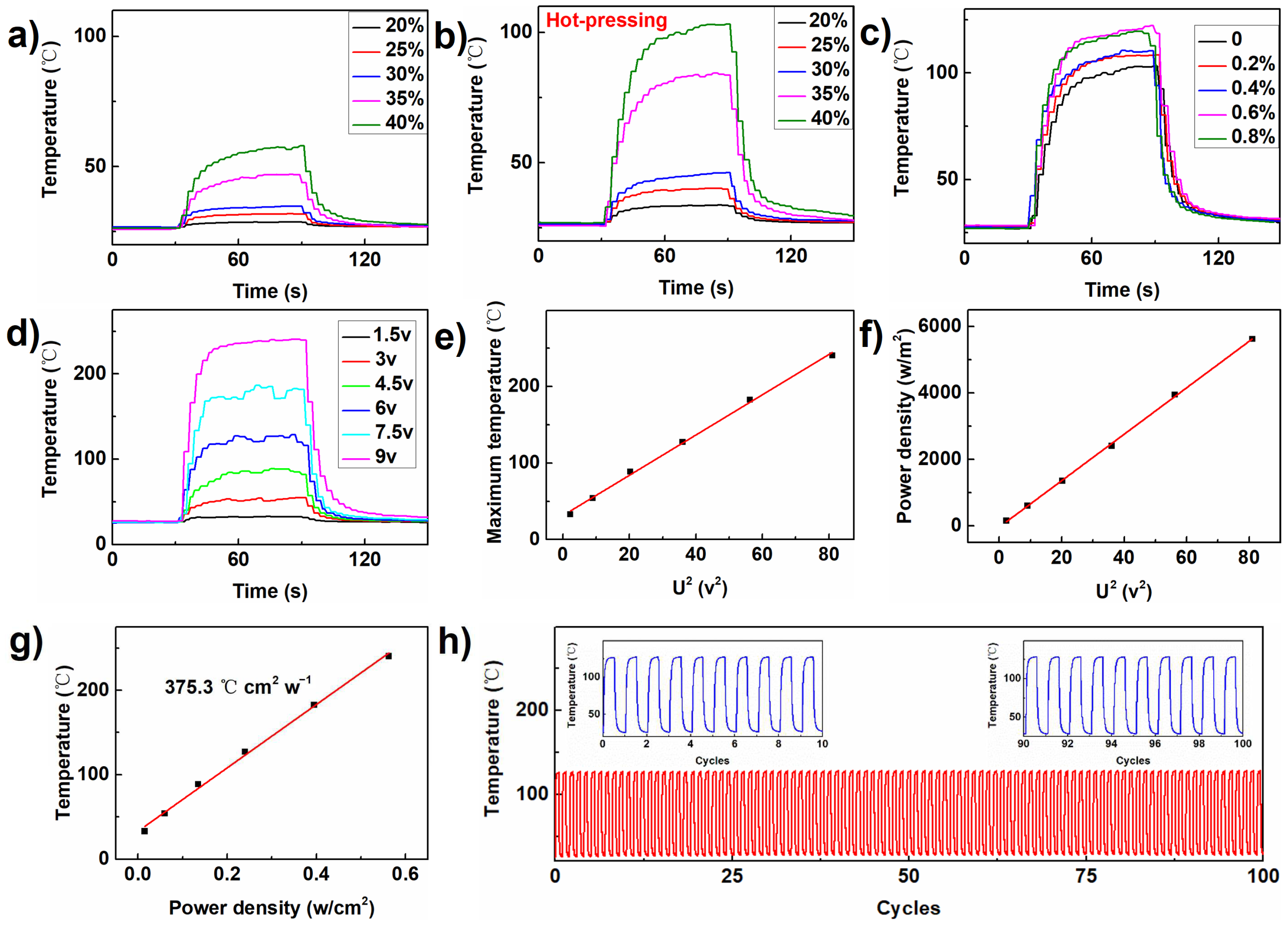

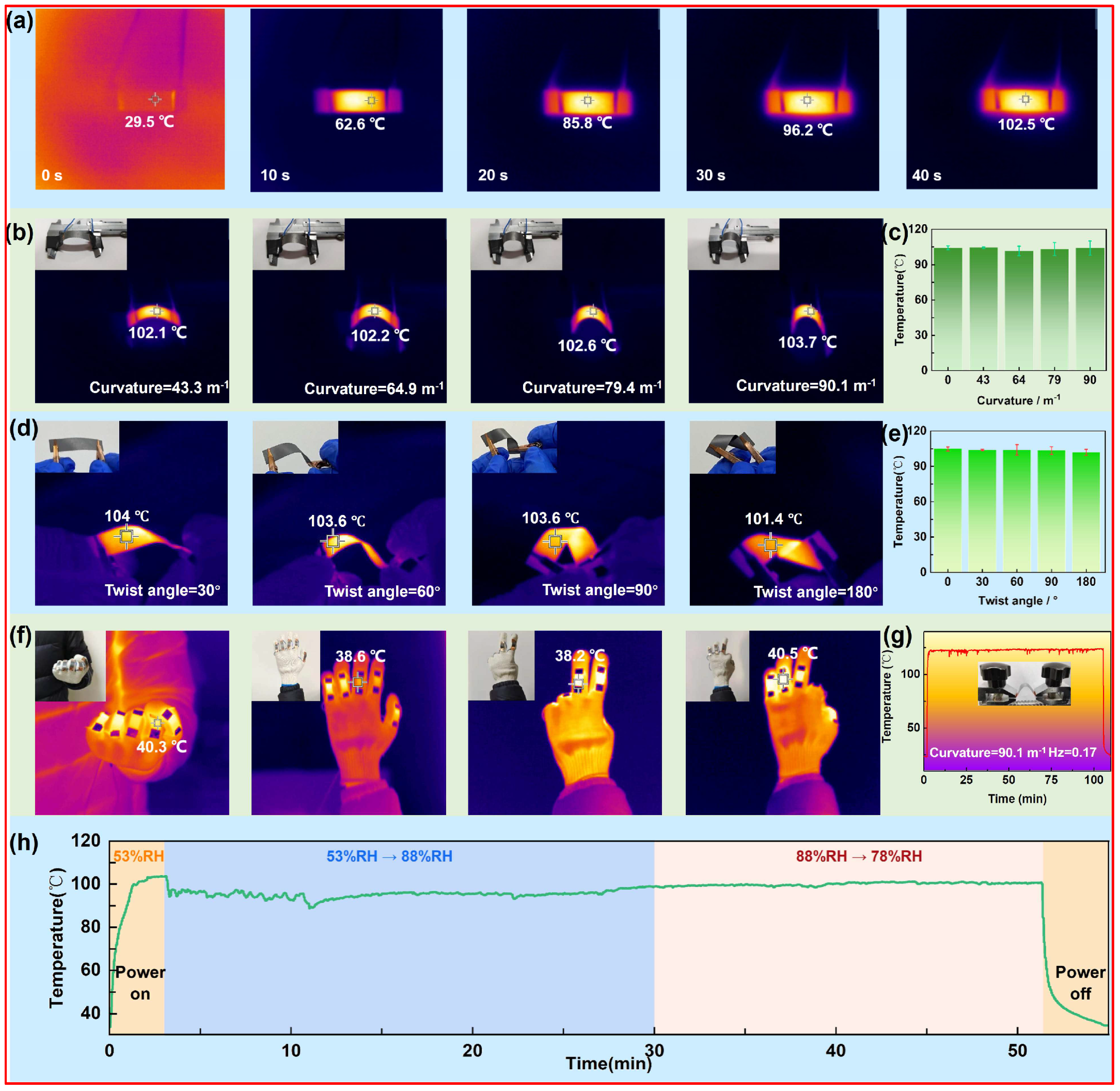

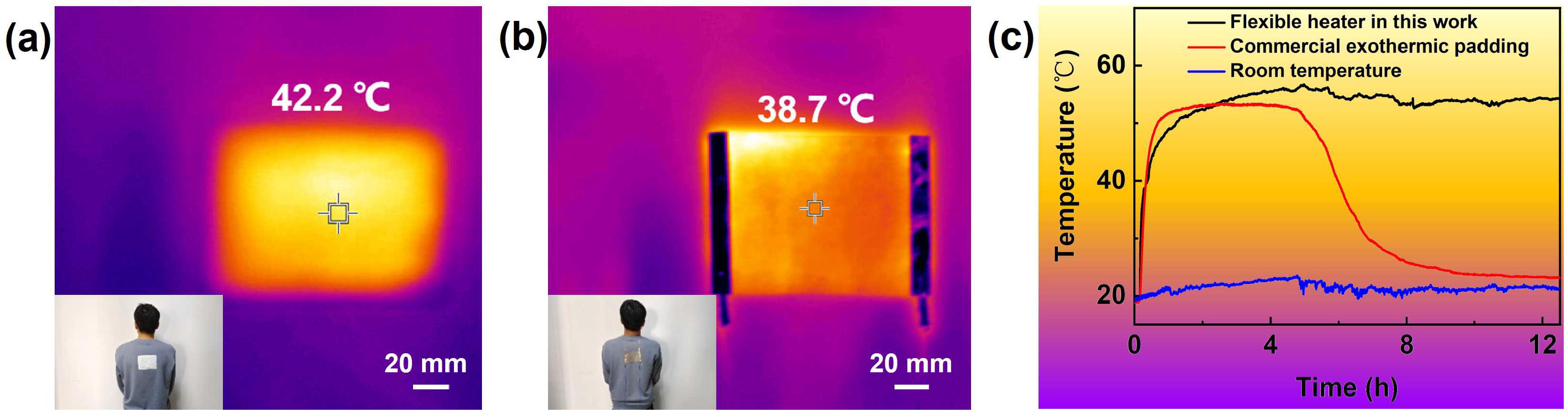

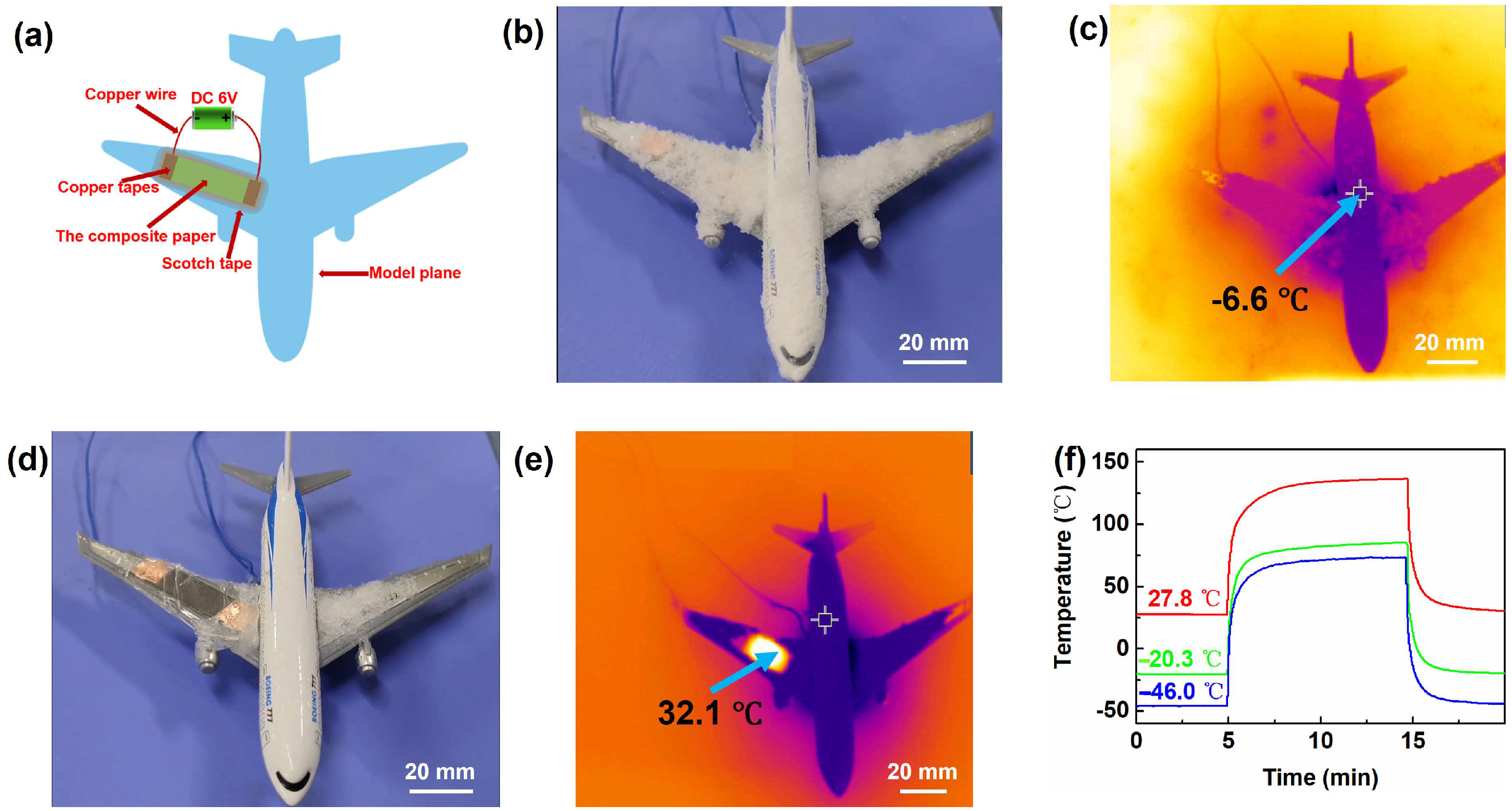

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Q.; Tian, B.; Liang, J.; Wu, W. Recent advances in printed flexible heaters for portable and wearable thermal management. Mater. Horiz. 2021, 8, 1634–1656. [Google Scholar] [CrossRef] [PubMed]

- Yuan, S.; Fan, Z.; Wang, G.; Chai, Z.; Wang, T.; Zhao, D.; Busnaina, A.A.; Lu, X. Fabrication of Flexible and Transparent Metal Mesh Electrodes Using Surface Energy-Directed Assembly Process for Touch Screen Panels and Heaters. Adv. Sci. 2023, 10, 2304990. [Google Scholar] [CrossRef] [PubMed]

- Jia, X.; Zhao, L.; Yang, P.; An, W.; Wang, Z.; Yu, S. Flexible Transparent Conductive Films of Ag/Cr2O3 Core-Shell Nanowires as Electrodes for Electroluminescent Devices and Heaters. ACS Appl. Nano Mater. 2023, 6, 16024–16033. [Google Scholar] [CrossRef]

- Xu, D.; Ouyang, Z.; Dong, Y.; Yu, H.-Y.; Zheng, S.; Li, S.; Tam, K.C. Robust, Breathable and Flexible Smart Textiles as Multifunctional Sensor and Heater for Personal Health Management. Adv. Fiber Mater. 2023, 5, 282–295. [Google Scholar] [CrossRef]

- Zhang, Y.; Ren, H.; Chen, H.; Chen, Q.; Jin, L.; Peng, W.; Xin, S.; Bai, Y. Cotton Fabrics Decorated with Conductive Graphene Nanosheet Inks for Flexible Wearable Heaters and Strain Sensors. ACS Appl. Nano Mater. 2021, 4, 9709–9720. [Google Scholar] [CrossRef]

- Weerathunga, H.; Do, T.T.; Pham, H.D.; Jones, R.; MacLeod, J.; Kim, T.; Dubal, D. Washable and Flexible All Carbon Electrothermal Joule Heater for Electric Vehicles. Adv. Mater. Technol. 2023, 8, 2201538. [Google Scholar] [CrossRef]

- Wagner, K.; Kell, A.J.; Martinez-Rubi, Y.; Paquet, C.; Lessard, B.H. Engineering Silver Microgrids with a Boron Nitride Nanotube Interlayer for Highly Conductive and Flexible Transparent Heaters. Adv. Mater. Technol. 2022, 7, 2200037. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, L.; Cheng, H.; Wang, B.; Feng, X.; Mao, Z.; Sui, X. Mechanically flexible, waterproof, breathable cellulose/polypyrrole/polyurethane composite aerogels as wearable heaters for personal thermal management. Chem. Eng. J. 2020, 402, 126222. [Google Scholar] [CrossRef]

- Zhang, D.; Li, S.; Gao, S.; Fu, S.; Liu, K.; He, D.; Liu, H.; Zhang, X.; Hu, W. NIR-II Organic Photothermal Cocrystals with Strong Charge Transfer Interaction for Flexible Wearable Heaters. Chin. J. Chem. 2024, 42, 1563–1570. [Google Scholar] [CrossRef]

- Yoshikawa, R.; Tenjimbayashi, M.; Matsubayashi, T.; Manabe, K.; Magagnin, L.; Monna, Y.; Shiratori, S. Designing a Flexible and Transparent Ultrarapid Electrothermogenic Film Based on Thermal Loss Suppression Effect: A Self-Fused Cu/Ni Composite Junctionless Nanonetwork for Effective Deicing Heater. ACS Appl. Nano Mater. 2018, 1, 860–868. [Google Scholar] [CrossRef]

- Chen, Y.; Long, J.; Xie, B.; Kuang, Y.; Chen, X.; Hou, M.; Gao, J.; Liu, H.; He, Y.; Wong, C.-P. One-Step Ultraviolet Laser-Induced Fluorine-Doped Graphene Achieving Superhydrophobic Properties and Its Application in Deicing. ACS Appl. Mater. Interfaces 2022, 14, 4647–4655. [Google Scholar] [CrossRef]

- Zheng, B.; Wang, H.; Wu, X.; Yang, K.; Yu, Y.; Cui, H.; Gao, F.; Qian, K.; Yao, H.; Li, J.; et al. Flexible nanocomposite electrothermal films based on carbon nanotubes and waterborne polyurethane with high reliability, stretchability and low-temperature performance for wind turbine blade deicing. Compos. Part A-Appl. Sci. Manuf. 2022, 158, 106979. [Google Scholar] [CrossRef]

- Zhang, H.; Cao, Y.; Zhen, Q.; Xu, Q.-G.; Song, W.-M.; Qian, X.-M. Large-Scale Preparation of Micro-Nanofibrous and Fluffy Propylene-Based Elastomer/Polyurethane@Graphene Nanoplatelet Membranes with Breathable and Flexible Characteristics for Wearable Stretchy Heaters. ACS Appl. Mater. Interfaces 2022, 14, 48161–48170. [Google Scholar] [CrossRef]

- Deokar, G.; Reguig, A.; Tripathi, M.; Buttner, U.; Fina, A.; Dalton, A.B.; Costa, P.M.F.J. Flexible, Air-Stable, High-Performance Heaters Based on Nanoscale-Thick Graphite Films. ACS Appl. Mater. Interfaces 2022, 14, 17899–17910. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Wang, T.; Liu, X.-L.; Bao, Z.-L.; Qian, P.-F.; Liu, K.; Shi, Y.; Ming, X.; Geng, H.-Z. Highly stable phosphotungstic acid/Au dual doped carbon nanotube transparent conductive films for transparent flexible heaters. Carbon 2023, 207, 219–229. [Google Scholar] [CrossRef]

- Kwon, G.; Ko, Y.; Lee, K.; Jeon, Y.; Lee, S.; Lee, C.; You, J. Flexible and transparent cellulose-based electrothermal composites for high-performance heaters. Cellulose 2024, 31, 335–347. [Google Scholar] [CrossRef]

- Dedduwakumara, H.T.; Barner-Kowollik, C.; Dubal, D.; Boase, N.R.B. The Macromolecular Design of Poly(styrene-isoprene-styrene) (SIS) Copolymers Defines their Performance in Flexible Electrothermal Composite Heaters. ACS Appl. Mater. Interfaces 2024. online ahead of print. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.; Li, S.; Guo, H.; Huang, C.; Bian, Y.; Gong, Y.; Huang, J.; Zeng, Q. Multi-scale GO/CNT/AlN nanocomposites for high-performance flexible electrothermal film heaters. J. Mater. Chem. C 2023, 11, 9925–9936. [Google Scholar] [CrossRef]

- Meng, X.; Chen, T.; Li, Y.; Liu, S.; Pan, H.; Ma, Y.; Chen, Z.; Zhang, Y.; Zhu, S. Assembly of carbon nanodots in graphene-based composite for flexible electro-thermal heater with ultrahigh efficiency. Nano Res. 2019, 12, 2498–2508. [Google Scholar] [CrossRef]

- Zhang, N.; Huang, C.; Wan, S.; Kang, L.; Hu, M.; Zhang, Y.; Wu, X.; Zhang, J. A Novel Flexible Silver Heater Fabricated by a Solution-Based Polyimide Metalization and Inkjet-Printed Carbon Masking Technique. ACS Appl. Electron. Mater. 2019, 1, 928–935. [Google Scholar] [CrossRef]

- Li, L.; Hong, S.K.; Jo, Y.; Tian, M.; Woo, C.Y.; Kim, S.H.; Kim, J.-M.; Lee, H.W. Transparent, Flexible Heater Based on Hybrid 2D Platform of Graphene and Dry-Spun Carbon Nanotubes. ACS Appl. Mater. Interfaces 2019, 11, 16223–16232. [Google Scholar] [CrossRef] [PubMed]

- Hong, W.; Sun, B.; Li, Z.; Fu, Z.; Zhang, J.; Jiang, M.; Zhang, Y.; Li, Y.; Zhang, Y.; Qian, K. Biodegradable, Flexible Transparent Ordered Ag NWs Micromesh Conductor for Electrical Heater and Electromagnetic Interference Shielding Applications. ACS Appl. Electron. Mater. 2022, 4, 5446–5455. [Google Scholar] [CrossRef]

- Xu, R.; Sun, B.; Han, X.; Hong, W.; Xu, J.; Zhu, H.; Fu, Z.; Xu, Y.; Sun, X.; Qian, K. High-Performance Flexible Transparent Electrical Heater Based on a Robust Ordered Ag Nanowire Micromesh Conductor. ACS Appl. Electron. Mater. 2022, 4, 1776–1783. [Google Scholar] [CrossRef]

- Cetin, O.; Cakir, O.; Koylan, S.; Doganay, D.; Khan, Y.; Unalan, H.E. All-Solution Processed, Highly Stable MXene/Cu Nanowire Networks for Flexible Transparent Thin-Film Heaters. ACS Appl. Nano Mater. 2023, 6, 22446–22458. [Google Scholar] [CrossRef]

- Zhang, Y.-S.; Wang, T.; Bao, Z.-L.; Qian, P.-F.; Liu, X.-C.; Geng, W.-H.; Zhang, D.; Wang, S.-W.; Zhu, Q.; Geng, H.-Z. MXene and AgNW based flexible transparent conductive films with sandwich structure for high-performance EMI shielding and electrical heaters. J. Colloid Interface Sci. 2024, 665, 376–388. [Google Scholar] [CrossRef]

- Huang, Y.; Tao, L.-Q.; Yu, J.; Zheng, K.; Wang, G.; Chen, X. Improved Performance of Flexible Graphene Heater Based on Repeated Laser Writing. IEEE Electron Device Lett. 2020, 41, 501–504. [Google Scholar] [CrossRef]

- Sun, B.; Xu, R.; Han, X.; Xu, J.; Hong, W.; Xu, Y.; Fu, Z.; Zhu, H.; Sun, X.; Wang, J.; et al. Ultra-high temperature tolerant flexible transparent electrode with embedded silver nanowires bundle micromesh for electrical heater. NPJ Flex. Electron. 2022, 6, 48. [Google Scholar] [CrossRef]

- Wagner, K.; Zou, S.; Martinez-Rubi, Y.; Kell, A.J.; Paquet, C.; Lessard, B.H. Towards sustainable transparent flexible heaters: Integration of a BNNT interlayer using green solvent substitution. Flex. Print. Electron. 2023, 8, 025005. [Google Scholar] [CrossRef]

- Huang, Z.; Xu, J.; Zhang, Q.; Liu, G.; Wu, T.; Lin, T.; He, P. Low-temperature polyol synthesis of millimeter-scale-length silver nanowires enabled by high concentration of Fe3+ for flexible transparent heaters. Mater. Today Chem. 2023, 30, 101569. [Google Scholar] [CrossRef]

- Liu, H.; Xiang, H.; Ma, Y.; Li, Z.; Meng, Q.; Jiang, H.; Wu, H.; Li, P.; Zhou, H.; Huang, W. Flexible, Degradable, and Cost-Effective Strain Sensor Fabricated by a Scalable Papermaking Procedure. ACS Sustain. Chem. Eng. 2018, 6, 15749–15755. [Google Scholar] [CrossRef]

- Ichiura, H.; Kitaoka, T.; Tanaka, H. Removal of indoor pollutants under UV irradiation by a composite TiO2-zeolite sheet prepared using a papermaking technique. Chemosphere 2003, 50, 79–83. [Google Scholar] [CrossRef] [PubMed]

- Ait Benhamou, A.; Boukind, S.; Khalili, H.; Moubarik, A.; El Achaby, M.; Kassab, Z.; Sehaqui, H. Strong and Flame-Resistant Nanocellulose Sheets Derived from Agrowastes via a Papermaking-Assisted Process. ACS Appl. Polym. Mater. 2024, 6, 2763–2776. [Google Scholar] [CrossRef]

- Guadagno, L.; Vertuccio, L.; Foglia, F.; Raimondo, M.; Barra, G.; Sorrentino, A.; Pantani, R.; Calabrese, E. Flexible eco-friendly multilayer film heaters. Compos. Part B-Eng. 2021, 224, 109208. [Google Scholar] [CrossRef]

- Ji, S.; He, W.; Wang, K.; Ran, Y.; Ye, C. Thermal Response of Transparent Silver Nanowire/PEDOT:PSS Film Heaters. Small 2014, 10, 4951–4960. [Google Scholar] [CrossRef]

- Winkless, L. De-icing aircraft with a carbon nanotube web. Mater. Today 2018, 21, 581. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Xiang, H.; Wang, W.; Tao, X.; Bai, Z.; Li, Z.; Wu, H.; Yuan, S.; Zhou, H.; Liu, H. Highly Stable, Bending-Tolerant, and Sustainable Flexible Heater through a Scalable Papermaking Procedure. Materials 2024, 17, 3507. https://doi.org/10.3390/ma17143507

Liu J, Xiang H, Wang W, Tao X, Bai Z, Li Z, Wu H, Yuan S, Zhou H, Liu H. Highly Stable, Bending-Tolerant, and Sustainable Flexible Heater through a Scalable Papermaking Procedure. Materials. 2024; 17(14):3507. https://doi.org/10.3390/ma17143507

Chicago/Turabian StyleLiu, Jiajie, Huacui Xiang, Wei Wang, Xiujuan Tao, Zhou Bai, Zhijian Li, Haiwei Wu, Suochao Yuan, Hongwei Zhou, and Hanbin Liu. 2024. "Highly Stable, Bending-Tolerant, and Sustainable Flexible Heater through a Scalable Papermaking Procedure" Materials 17, no. 14: 3507. https://doi.org/10.3390/ma17143507

APA StyleLiu, J., Xiang, H., Wang, W., Tao, X., Bai, Z., Li, Z., Wu, H., Yuan, S., Zhou, H., & Liu, H. (2024). Highly Stable, Bending-Tolerant, and Sustainable Flexible Heater through a Scalable Papermaking Procedure. Materials, 17(14), 3507. https://doi.org/10.3390/ma17143507