An Analysis of Changes in the Harmfulness of the Bottle Packaging Process Depending on the Type of Heat-Shrinkable Film

Abstract

:1. Introduction

2. Materials and Methods

- Goal and the Scope definition,

- Life cycle investment analysis,

- Life cycle impact assessment,

- Life cycle interpretation.

3. Results and Discussion

3.1. Testing of Film Properties

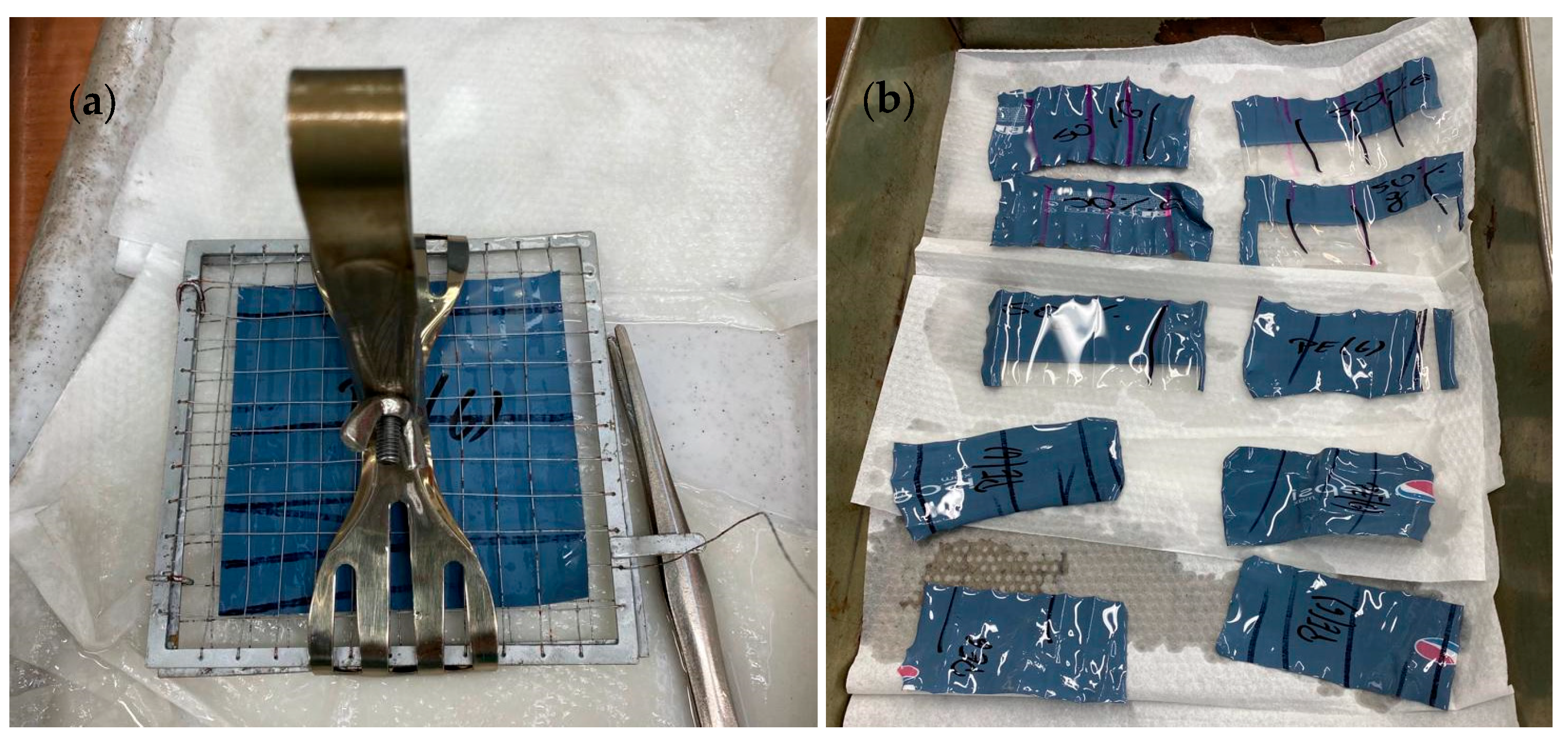

3.1.1. Testing the Free Shrinkage of Linear Heat-Shrinkable Film

3.1.2. Determination of Tear Strength (Elmendorf Method)

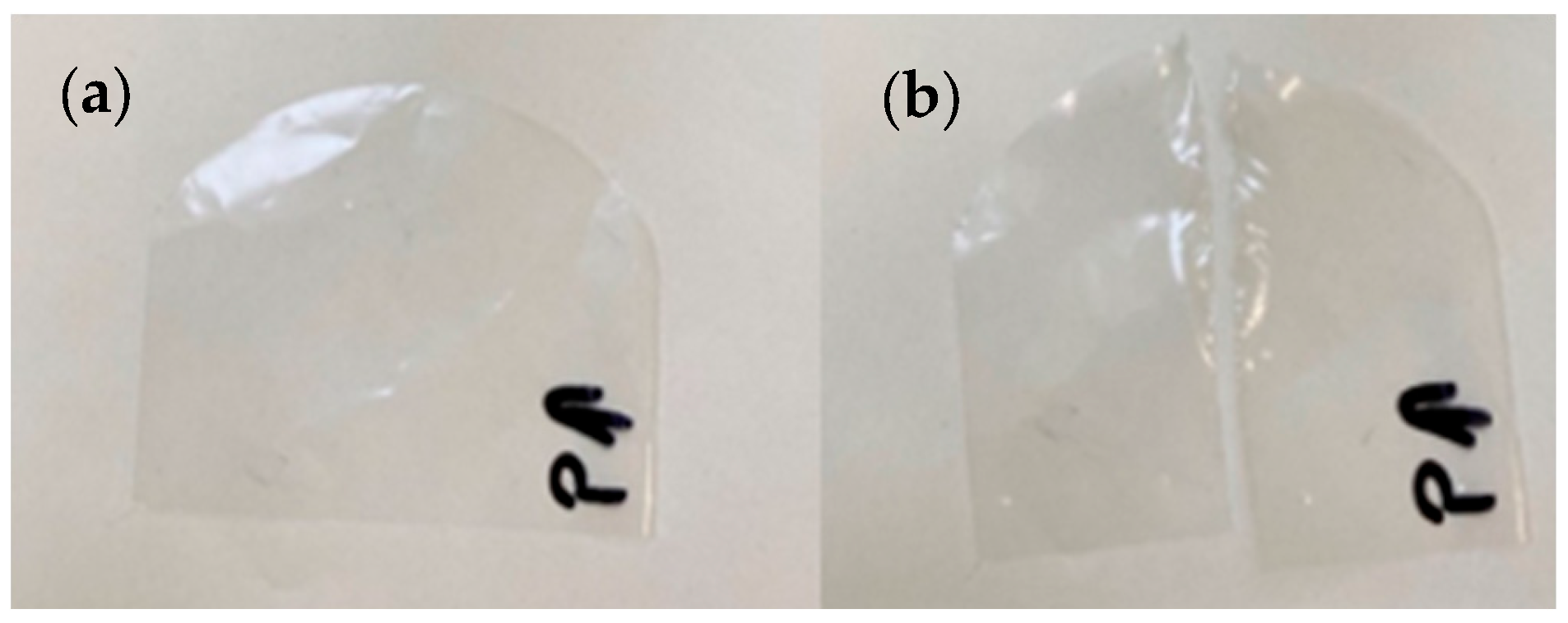

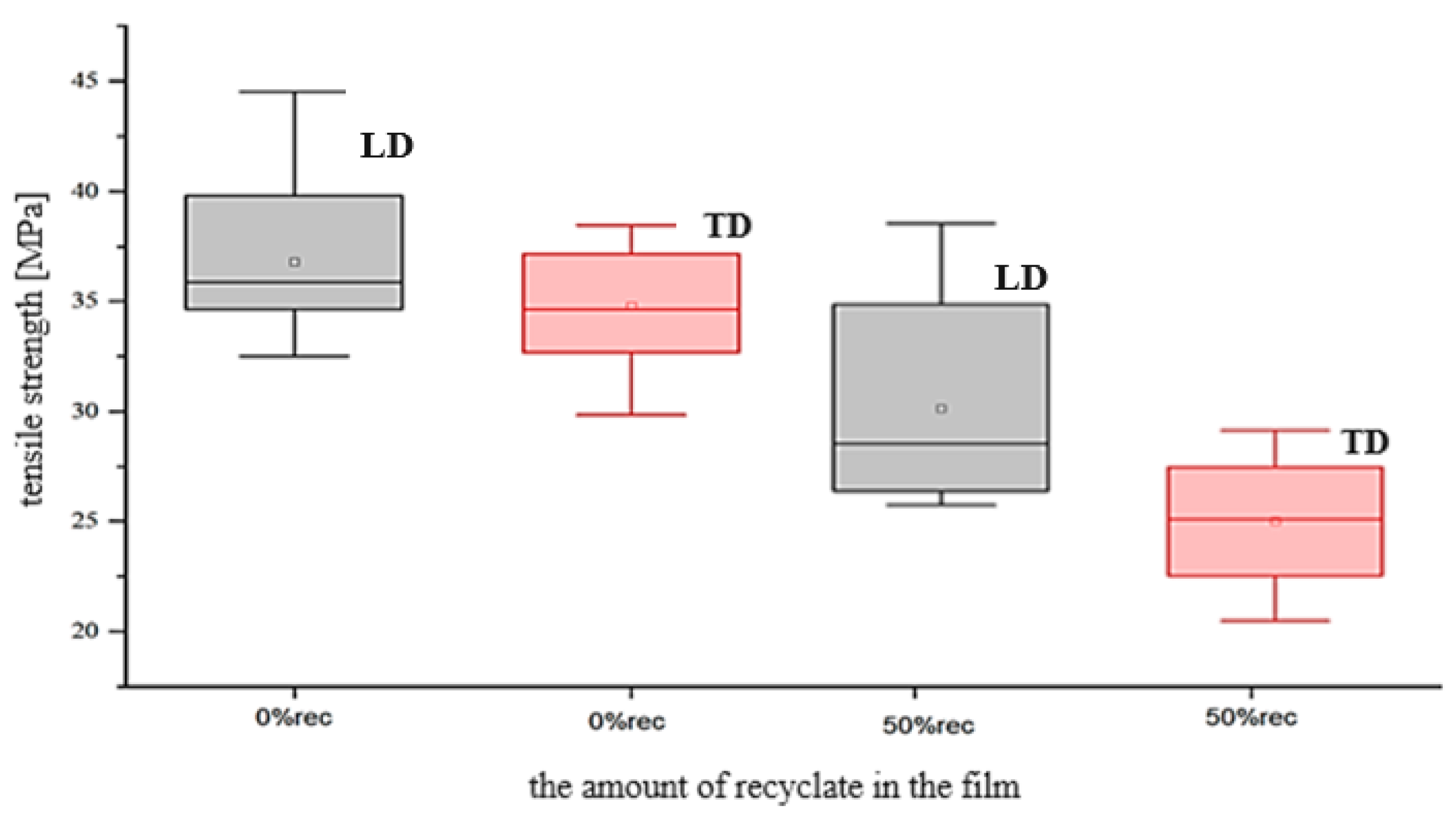

3.1.3. Comparison of Mechanical Properties of Tested Films under Static Tension

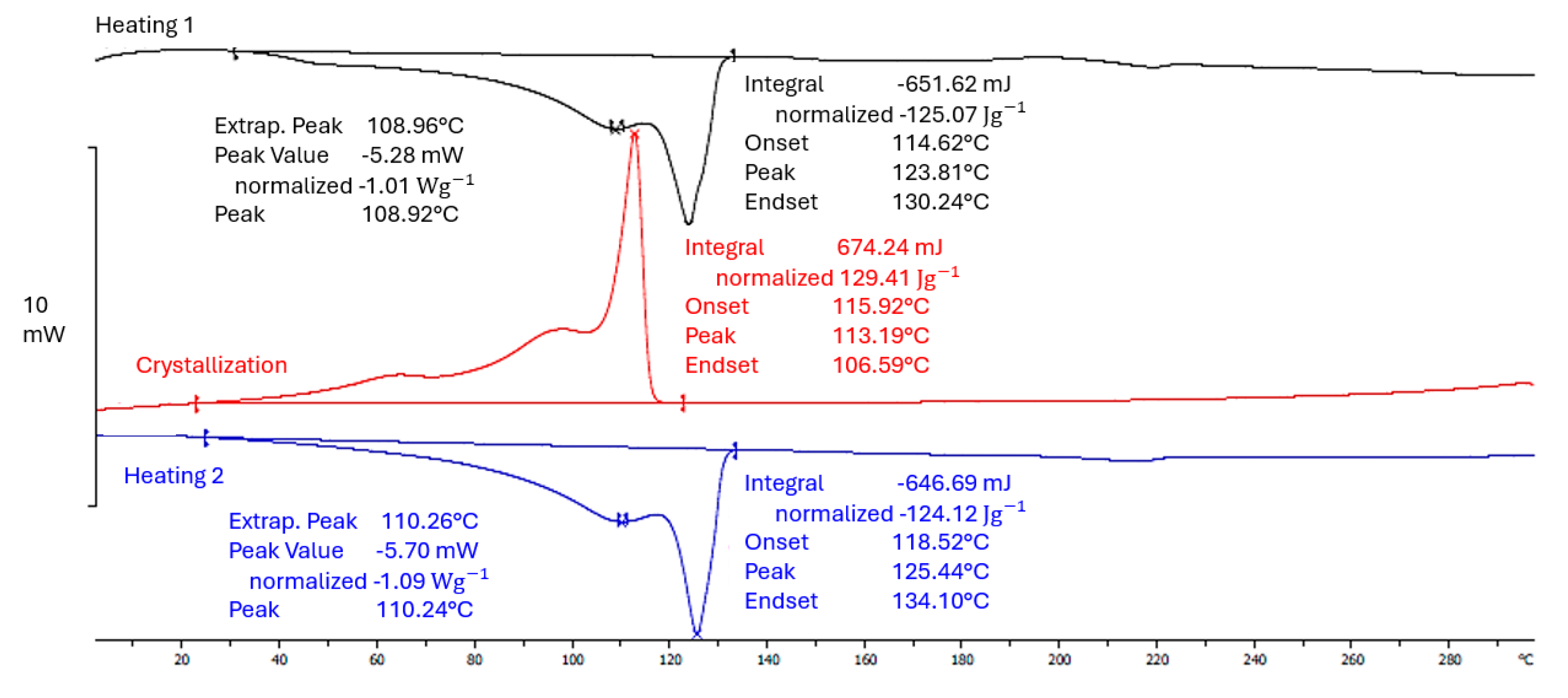

3.1.4. Determination of Thermal Properties

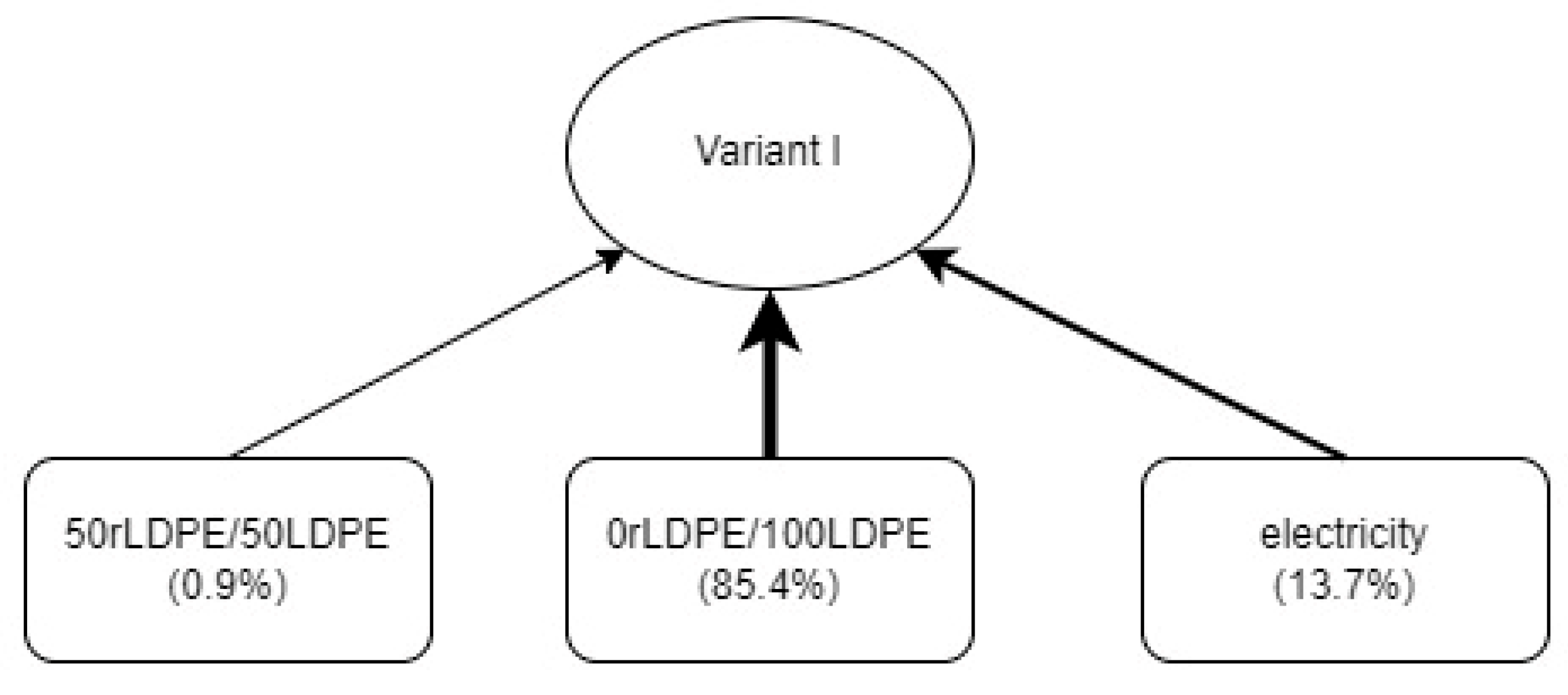

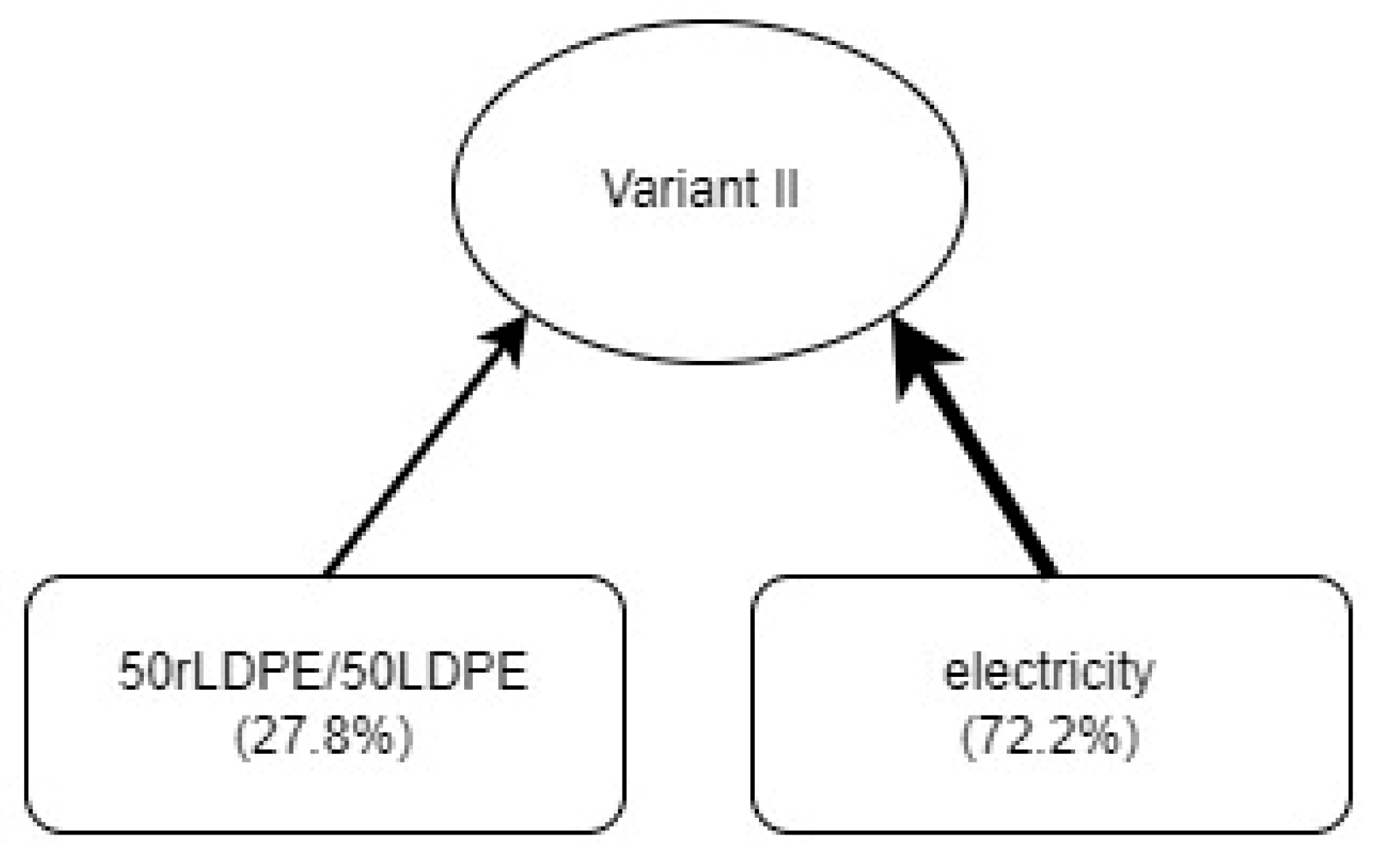

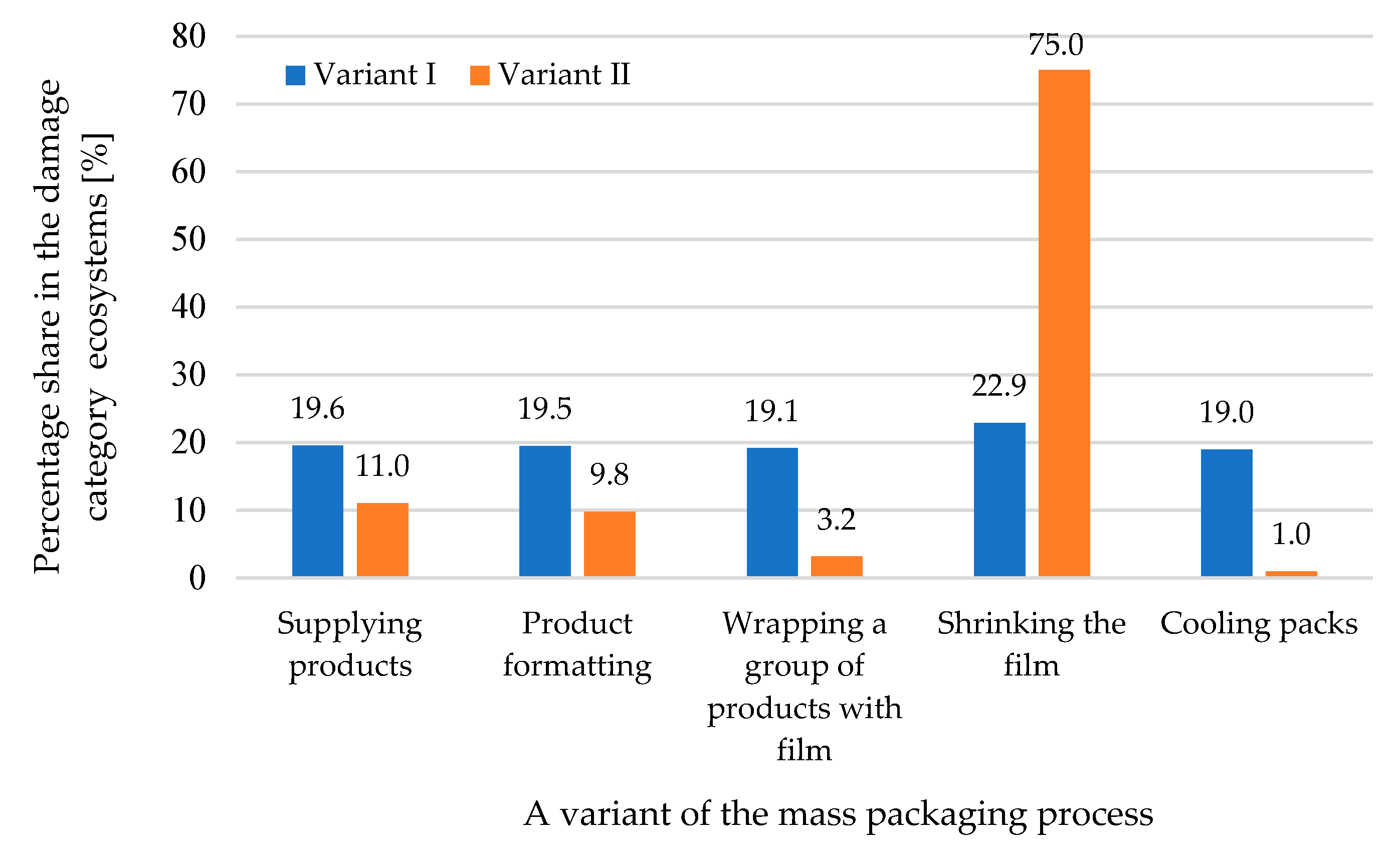

3.2. A Comparison of the Environmental Impact of the Tested Variants of the Mass Packaging Process

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pehnt, M. Dynamic Life Cycle Assessment (LCA) of Renewable Energy Technologies. Renew. Energy 2006, 31, 55–71. [Google Scholar] [CrossRef]

- Kuzia, A. System Pakowania w Folie Kurczliwe; Scientific and Technical Publishing House: Warsaw, Poland, 1978. [Google Scholar]

- Ragattieri, A.; Santarelii, G. The Important Role of Packaging in Operations Management. In Operations Management; Intechopen: London, UK, 2013; pp. 183–219. [Google Scholar]

- Koliński, A. Przegląd metod i technik oceny efektywności procesu produkcyjnego. Logistyka 2011, 5, 1083–1091. [Google Scholar]

- Wojciechowska, N. Odnawialne źródła energii jako katalizator wprowadzenia modelu gospodarki obiegu zamkniętego. Zesz. Stud. Nasze Stud. 2021, 11, 104–117. [Google Scholar]

- Ankiel, M.; Wojciechowska, P.; Wiszumirska, K. Innowacje Opakowaniowe na Rynku Produktów Konsumpcyjnych; Wydawnictwo Uniwersytetu Ekonomicznego w Poznaniu: Poznań, Poland, 2021; pp. 51–64. [Google Scholar]

- Yao, Z.; Seong, H.; Jang, Y. Environmental toxicity and decomposition of polyethylene. Ecotoxicol. Environ. Saf. 2022, 242, 113933. [Google Scholar] [CrossRef] [PubMed]

- Harding, K.G.; Dennis, J.S.; Blottnitz, H.; Harrison, S.T.L. Environmental analysis of plastic production processes: Comparing petroleum-based polypropylene and polyethylene with biologically based poly-β-hydroxybutyric acid using life cycle analysis. J. Biotechnol. 2007, 130, 57–66. [Google Scholar] [CrossRef] [PubMed]

- Brock, A.; Williams, I. Life cycle assessment and beverage packaging. Detritus 2020, 13, 47–61. [Google Scholar] [CrossRef]

- Martín-Lara, M.A.; Moreno, J.A.; Garcia-Garcia, G.; Arjandas, S.; Calero, M. Life cycle assessment of mechanical recycling of post-consumer polyethylene flexible films based on a real case in Spain. J. Clean. Prod. 2022, 365, 132625. [Google Scholar] [CrossRef]

- Tan, Q.; Yang, L.; Wei, F.; Chen, Y.; Li, J. Comparative life cycle assessment of polyethylene agricultural mulching film and alternative options including different end-of-life routes. Renew. Sustain. Energy Rev. 2023, 178, 113239. [Google Scholar] [CrossRef]

- Romero-Hernández, O.; Romero-Hernández, S.; Muñoz, D.; Detta-Silveira, E.; Palacios-Brun, A.; Laguna, A. Environmental implications and market analysis of soft drink packaging systems in Mexico. A waste management approach. Int. J. Life Cycle Assess. 2009, 14, 107–113. [Google Scholar] [CrossRef]

- Kang, D.H.; Auras, R.; Singh, J. Life cycle assessment of non-alcoholic single-serve polyethylene terephthalate beverage bottles in the state of California. Resour. Conserv. Recycl. 2017, 116, 45–52. [Google Scholar] [CrossRef]

- Ferrara, C.; Migliaro, V.; Ventura, F.; De Feo, G. An economic and environmental analysis of wine packaging systems in Italy: A life cycle (LC) approach. Sci. Total Environ. 2023, 857, 159323. [Google Scholar] [CrossRef] [PubMed]

- Boutros, M.; Saba, S.; Manneh, R. Life cycle assessment of two packaging materials for carbonated beverages (polyethylene terephthalate vs. glass): Case study for the Lebanese context and importance of the end-of-life scenarios. J. Clean. Prod. 2021, 314, 128289. [Google Scholar] [CrossRef]

- Saraiva, A.B.; Pacheco, E.B.; Gomes, G.M.; Visconte, L.L.; Bernardo, C.A.; Simoes, C.L.; Soares, A.G. Comparative lifecycle assessment of mango packaging made from a polyethylene/natural fiber-composite and from cardboard material. J. Clean. Prod. 2016, 139, 1168–1180. [Google Scholar] [CrossRef]

- Lin, H.; Black, M.J.; Walsh, L.; Giordano, F.S.; Borrion, A. Life cycle assessment of baby leaf spinach: Reduction of waste through interventions in growing treatments and packaging. J. Clean. Prod. 2024, 449, 141723. [Google Scholar] [CrossRef]

- Civancik-Uslu, D.; Puig, R.; Voigt, S.; Walter, D.; Fullana-i-Palmer, P. Improving the production chain with LCA and eco-design: Application to cosmetic packaging. Resour. Conserv. Recycl. 2019, 151, 104475. [Google Scholar] [CrossRef]

- Abbasi, T.; Jaafarzadeh Haghighi Fard, N.; Madadizadeh, F.; Eslami, H.; Ebrahimi, A.A. Environmental Impact Assessment of Low-Density Polyethylene and Polyethylene Terephthalate Containers Using a Life Cycle Assessment Technique. J. Polym. Environ. 2023, 31, 3493–3508. [Google Scholar] [CrossRef]

- Dong, H.; Yang, G.; Zhang, Y.; Yang, Y.; Wang, D.; Zhou, C. Recycling, disposal, or biodegradable-alternative of polyethylene plastic film for agricultural mulching? A life cycle analysis of their environmental impacts. J. Clean. Prod. 2022, 380, 134950. [Google Scholar] [CrossRef]

- Horodytska, O.; Kiritsis, D.; Fullana, A. Upcycling of printed plastic films: LCA analysis and effects on the circular economy. J. Clean. Prod. 2020, 268, 122138. [Google Scholar] [CrossRef]

- Choi, B.; Yoo, S.; Park, S.I. Carbon footprint of packaging films made from LDPE, PLA, and PLA/PBAT blends in South Korea. Sustainability 2018, 10, 2369. [Google Scholar] [CrossRef]

- Salwa, H.N.; Sapuan, S.M.; Mastura, M.T.; Zuhri, M.Y.M.; Ilyas, R.A. Life Cycle Assessment of Bio-Based Packaging Products. In Bio-Based Packaging: Material, Environmental and Economic Aspects; Wiley: Hoboken, NJ, USA, 2021; pp. 381–411. [Google Scholar]

- Bala, A.; Arfelis, S.; Oliver-Ortega, H.; Méndez, J.A. Life cycle assessment of PE and PP multi film compared with PLA and PLA reinforced with nanoclays film. J. Clean. Prod. 2022, 380, 134891. [Google Scholar] [CrossRef]

- Tunçok-Çeşme, B.; Yıldız-Geyhan, E.; Çiftçioğlu, G.A. Environmental Life Cycle Assessment of Two Types of Flexible Plastic Packaging under a Sustainable Circular Economy Approach. Sustainability 2024, 16, 3149. [Google Scholar] [CrossRef]

- Drabczyk, M.; Kruczek, B. Wpływ dodatku materiału nieprzetwarzalnego na wytrzymałość na rozciąganie folii LDPE, Problemy Nauk Stosowanych. Probl. Nauk. Stosowanych. 2016, 4, 73–78. [Google Scholar]

- Rojek, M.; Szymiczek, M. Ocena wpływu dodatku regranulatu na własności opakowaniowej folii pęcherzykowej. Przetwórstwo Tworzyw. 2014, 20, 82–87. [Google Scholar]

- PN-EN ISO 527-1:2020-01; Tworzywa Sztuczne—Oznaczanie Właściwości Mechanicznych Przy Statycznym Rozciąganiu—Część 1: Zasady Ogólne. Polski Komitet Normalizacyjny: Warsaw, Poland, 2020.

- PN-EN ISO 527-3:2019-01; Tworzywa Sztuczne—Oznaczanie Właściwości Przy Rozciąganiu—Część 3: Warunki Badań Folii i Płyt. Polski Komitet Normalizacyjny: Warsaw, Poland, 2019.

- ASTM D2732; Standard Test Method for Unrestrained Linear Thermal Shrinkage of Plastic Film and Sheeting. ASTM International: West Conshohocken, PA, USA, 2020.

- PN-EN ISO 6383-2:2005; Tworzywa Sztuczne—Folie i Płyty—Oznaczanie Wytrzymałości na Rozdzieranie—Część 2: Metoda Elmendorfa. Tworzywa Sztuczne: Żary, Poland, 2005.

- Pauer, E.; Tacker, M.; Gabriel, V.; Krauter, V. Sustainability of flexible multilayer packaging: Environmental impacts and recyclability of packaging for bacon in block. Clean. Environ. Syst. 2020, 1, 100001. [Google Scholar] [CrossRef]

- Sazdovski, A.; Bala, A.; Palmer, P. Linking LCA literature with circular economy value creation: A review on beverage packaging. Sci. Total Environ. 2021, 771, 145322. [Google Scholar] [CrossRef]

- Bałdowska-Witos, P.; Kruszelnicka, W.; Kasner, R.; Piotrowska, K.; Tomporowski, A.; Rudnicki, J.; Opielak, M.; Flizikowski, J. Assessment of the Environmental Impact of a Car Tire throughout Its Lifecycle Using the LCA Method. Materials 2019, 12, 4177. [Google Scholar] [CrossRef] [PubMed]

- Idzikowski, A.; Walichnowska, P. The management of the technological process of a product on the example a shrink film in the aspect life cycle assessment. Syst. Saf. Hum.—Tech. Facil.—Environ. 2022, 4, 1–9. [Google Scholar] [CrossRef]

- Janicka, J.; Koźmińska, R. Tekstylia w materiałach kompozytowych. Tech. Wyr. Włókiennicze 2009, 17, 20–28. [Google Scholar]

- Walichnowska, P.; Idzikowski, A. Assessment and Analysis of the Environmental Impact of the Thermo-Shrinkable Packaging Process on the Way the Packaging Machine is Powered Based on LCA. Manag. Syst. Prod. Eng. 2023, 31, 355–360. [Google Scholar] [CrossRef]

- Leda, P.; Idzikowski, A.; Piasecka, I.; Bałdowska-Witos, P.; Cierlicki, T.; Zawada, M. Management of Environmental Life Cycle Impact Assessment of a Photovoltaic Power Plant on the Atmosphere, Water, and Soil Environment. Energies 2023, 16, 4230. [Google Scholar] [CrossRef]

- Pieragostini, C.; Mussati, M.C.; Pío Aguirre, P. On process optimization considering LCA methodology. J. Environ. Manag. 2012, 96, 43–54. [Google Scholar] [CrossRef]

- Kloziński, A.; Jakubowska, P. Folie wytwarzane z dodatkiem recyklatów—Przetwórstwo, właściwości. Inż. Apar. Chem. 2010, 49, 61–62. [Google Scholar]

- Kloziński, A.; Jakubowska, P. Właściwości mechaniczne folii poużytkowych stosowanych w rolnictwie. Inż. Apar. Chem. 2012, 51, 231–232. [Google Scholar]

- Bembenek, M.; Kowalski, Ł.; Kosoń-Schab, A. Research on the Influence of Processing Parameters on the Specific Tensile Strength of FDM Additive Manufactured PET-G and PLA Materials. Polymers 2022, 14, 2446. [Google Scholar] [CrossRef] [PubMed]

- Kowalska, D. Różnicowa kalorymetria skaningowa DSC, ciśnieniowa różnicowa kalorymetria skaningowa PDSC, StepScan DSC, temperaturowo modulowana DSC szybka i superszybka DSC w badaniu żywności. Apar. Badaw. Dydakt. 2017, 22, 128–133. [Google Scholar]

- ISO 11357-3:2018; International Organization for Standardization. Plastics—Differential Scanning Calorimetry (DSC)—Part 3: Determination of Temperature and Enthalpy of Melting and Crystallization. ISO: Geneva, Switzerland, 2018.

- ISO 14001:2005; The Polish Committee for Standardization. Environmental Management Systems—Requirements and Guidelines for Use. PN-EN: Warsaw, Poland, 2005.

- Qin, Y.; Cucurachi, S.; Suh, S. Perceived Uncertainties of Characterization in LCA: A Survey. Int. J. Life Cycle Assess. 2020, 25, 1846–1858. [Google Scholar] [CrossRef]

- Ram, A.; Sharma, P. A study on Life Cycle Assessment. Int. J. Eng. Adv. Technol. 2017, 6, 197–201. [Google Scholar]

- Wikström, F.; Williams, H.; Vergheseb, K.; Clunec, S. The influence of packaging attributes on consumer behaviour in food-packaging life cycle assessment studies—A neglected topic. J. Clean. Prod. 2014, 73, 100–108. [Google Scholar] [CrossRef]

- Williams, H.; Wikström, F. Environmental impact of packaging and food losses in a life cycle perspective: A comparative analysis of five food items. J. Clean. Prod. 2011, 19, 43–48. [Google Scholar] [CrossRef]

- Górzyński, J. Podstawy Analizy Środowiskowej Wyrobów i Obiektu; Wydawnictwo WNT: Warsaw, Poland, 2007; p. 62. [Google Scholar]

- Zhao, S.; You, F. Comparative Life-Cycle Assessment of Li-Ion Batteries through Process-Based and Integrated Hybrid Approaches. ACS Sustain. Chem. Eng. 2019, 7, 5082–5094. [Google Scholar] [CrossRef]

| Type of Film | Longitudinal Direction (LD) | Transverse Direction (TD) | ||

|---|---|---|---|---|

| Mean (%) | Standard Deviation (%) | Mean (%) | Standard Deviation (%) | |

| 0rLDPE/100LDPE (0.046 mm) | 66.8 | 0.8 | 23.6 | 1.7 |

| 50rLDPE/50LDPE white (0.045 mm) | 75.4 | 1.1 | 25.4 | 1.9 |

| Type of Film | Longitudinal Direction (LD), N | Transverse Direction (TD), N |

|---|---|---|

| 0rLDPE/100LDPE (0.046 mm) | 0.7 | 10.8 |

| 50rLDPE/50LDPE white (0.045 mm) | 2.1 | 5.2 |

| Film Properties | 0rLDPE/100LDPE (0.046 mm) | 50rLDPE/50LDPE White (0.045 mm) | |||

|---|---|---|---|---|---|

| LD | TD | LD | TD | ||

| Tensile strength (MPa) | 1 | 38.63 | 35.53 | 32.86 | 25.56 |

| 2 | 2.78 | 2.38 | 1.66 | 0.81 | |

| 3 | 7.20 | 6.78 | 5.05 | 3.19 | |

| Stress at break (MPa) | 1 | 37.62 | 35.10 | 32.49 | 25.47 |

| 2 | 3.78 | 3.23 | 1.91 | 0.99 | |

| 3 | 10.04 | 9.19 | 5.87 | 3.90 | |

| Yield strength (MPa) | 1 | - | 22.70 | - | 13.39 |

| 2 | - | 0.64 | - | 0.28 | |

| 3 | - | 2.83 | - | 2.12 | |

| Elongation at maximum tensile stress (%) | 1 | 654.84 | 952.62 | 408.8 | 735.61 |

| 2 | 43.09 | 28.67 | 28.36 | 26.89 | |

| 3 | 6.58 | 3.01 | 6.94 | 3.66 | |

| Elongation at break (%) | 1 | 655.06 | 953.3 | 411.5 | 736.5 |

| 2 | 43.01 | 27.98 | 281.4 | 26.17 | |

| 3 | 6.57 | 2.93 | 6.84 | 3.55 | |

| Elongation at yield point (%) | 1 | 9.51 | 7.77 | - | 9.88 |

| 2 | 0.26 | 0.51 | - | 0.43 | |

| 3 | 2.70 | 6.53 | - | 4.38 | |

| Sample thickness (mm) | 1 | 0.046 | 0.043 | 0.044 | 0.043 |

| 2 | 0.002 | 0.002 | 0.001 | 0.0001 | |

| 3 | 4.64 | 3.83 | 3.37 | 1.62 | |

| Parameter | Variant I | Variant II |

|---|---|---|

| Electrical energy, kWh | 46.10 | 67.81 |

| Film, kg | 35.35 | 37.57 |

| Energy consumption (kWh) | ||

| Supplying products | 5.07 | 7.46 |

| Product formatting | 4.52 | 6.64 |

| Wrapping a group of products with film | 1.48 | 2.17 |

| Shrinking the film | 34.58 | 50.85 |

| Cooling packs | 0.46 | 0.68 |

| Consumption of the material (kg) | ||

| Film 0rLDPE/100LDPE | 31.52 | 0 |

| Film 50rLDPE/50LDPE | 3.83 | 31.57 |

| Damage Category | Unit | Analyzed Process Variant | Value |

|---|---|---|---|

| Human health | DALY | I | 1.77 × 10−4 |

| II | 5.97 × 10−5 | ||

| Ecosystems | species.yr | I | 7.54 × 10−7 |

| II | 2.39 × 10−7 | ||

| Resources | $ | I | 9.77 |

| II | 1.24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Walichnowska, P.; Kruszelnicka, W.; Mazurkiewicz, A.; Kłos, Z.; Rudawska, A.; Bembenek, M. An Analysis of Changes in the Harmfulness of the Bottle Packaging Process Depending on the Type of Heat-Shrinkable Film. Materials 2024, 17, 4115. https://doi.org/10.3390/ma17164115

Walichnowska P, Kruszelnicka W, Mazurkiewicz A, Kłos Z, Rudawska A, Bembenek M. An Analysis of Changes in the Harmfulness of the Bottle Packaging Process Depending on the Type of Heat-Shrinkable Film. Materials. 2024; 17(16):4115. https://doi.org/10.3390/ma17164115

Chicago/Turabian StyleWalichnowska, Patrycja, Weronika Kruszelnicka, Adam Mazurkiewicz, Zbigniew Kłos, Anna Rudawska, and Michał Bembenek. 2024. "An Analysis of Changes in the Harmfulness of the Bottle Packaging Process Depending on the Type of Heat-Shrinkable Film" Materials 17, no. 16: 4115. https://doi.org/10.3390/ma17164115