Polymers: From Waste to Potential Reuse

A special issue of Materials (ISSN 1996-1944). This special issue belongs to the section "Polymeric Materials".

Deadline for manuscript submissions: 20 August 2024 | Viewed by 3130

Special Issue Editor

Interests: materials; polymers; coating; biomaterials

Special Issues, Collections and Topics in MDPI journals

Special Issue Information

Dear Colleagues,

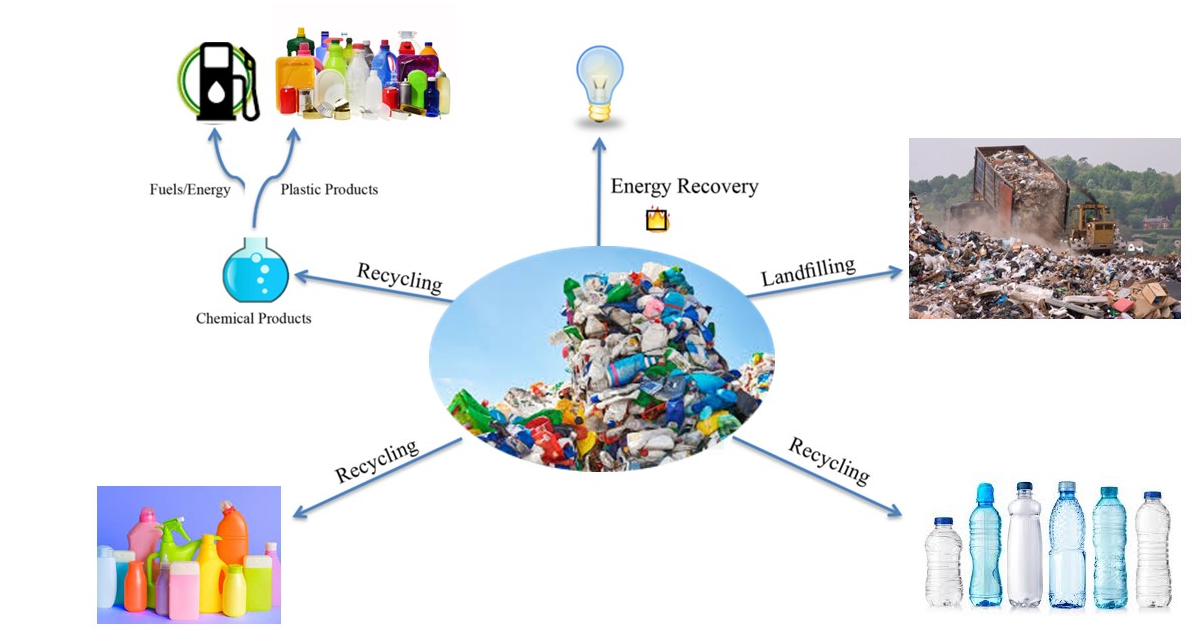

In recent years, environmental pollution is a problem affecting our ability to solve the impacts of polymer solid waste that are evident in the ever-increasing levels of global plastic pollution, both on land and in the oceans. Plastics have become widely used materials in everyday life due to their special properties such as their durability, easy processing, lightweight nature, and low cost of production. However, because of their stable and nonbiodegradable nature, postconsumer plastics become an issue to the environment. Growing amounts of waste are generated, as plastic products are commonly used only once before disposal. The alternatives of practical techniques for solid waste management are redesign, reprocessing, and recycling. Recycling techniques should be constantly developed. The recycling of plastic waste helps to conserve natural resources due to polymeric materials being made from oil and gas. There are four main recycling methods: reuse, mechanical recycling, chemical recycling, and energy recovery.

This Special Issue focuses on recent advances in recycling waste methods, redesign, and processing, in particular polymer recovery from waste to reuse.

It is our pleasure to invite you to contribute original full research papers, short communications, and state-of-the-art reviews to this Special Issue.

Dr. Lucia Sansone

Guest Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Materials is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- polymers

- waste

- recovery

- environment pollution

- recycling

- mechanical recycling

- chemical recycling

- energy recovery